Method for preparing organic acid and calcium sulfate whisker from organic acid calcium salt by hydrochloric acid method

A calcium sulfate whisker and calcium organic acid technology, which is applied in carboxylate preparation, organic chemistry, chemical instruments and methods, etc., can solve the problems of a large amount of waste, low utilization value, and environmental pollution, and achieve low cost and simple method , the effect of high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

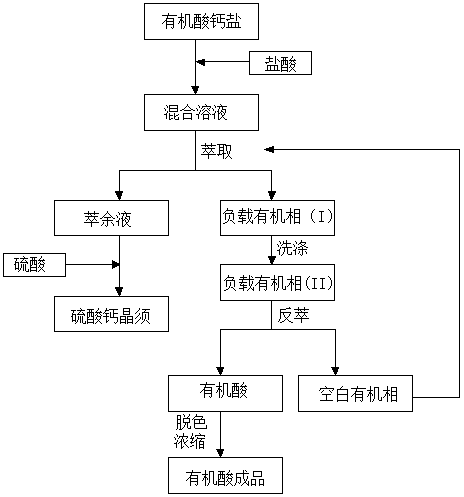

[0021] As shown in the figure, a method for preparing organic acid and calcium sulfate whiskers from organic acid calcium salt by hydrochloric acid is characterized in that the preparation method is as follows: (1): the raw materials are organic acid calcium salt and hydrochloric acid, and the organic Calcium acid salt is mixed with hydrochloric acid to undergo a metathesis reaction, and the resulting mixed solution mainly contains organic acid, calcium salt of organic acid, calcium chloride and hydrochloric acid; (2): The mixed solution is solvent extracted with organic solvent to obtain raffinate and load organic Phase (I), the loaded organic phase (I) is washed to obtain a loaded organic phase (II), and the loaded organic phase (II) is back extracted to obtain an organic acid washing liquid and a blank organic phase; (3): the organic acid obtained in step (2) The washing liquid is decolorized, concentrated or crystallized to obtain an organic acid product; the raffinate obtai...

Embodiment 1

[0024] Take calcium citrate and hydrochloric acid for metathesis reaction. When the ratio of calcium ion concentration to hydrogen ion concentration is 1:6 and the temperature is 60℃, calcium chloride and citric acid are generated. The solution produced by the reaction is extracted by organic solvent to obtain calcium ions. The raffinate and the loaded organic phase (I) containing citric acid, the loaded organic phase (I) is washed to obtain the loaded organic phase (II), the loaded organic phase (II) is back extracted to obtain citric acid and the blank organic phase, the blank organic The phase can be reused in the extraction process. Citric acid is decolorized and concentrated to obtain citric acid products. The raffinate containing calcium ions is added with sulfuric acid or sulfate to react, wherein the concentration of free calcium ions and sulfate in the synthesis system is maintained within the range of 1.0mol / L; the reaction temperature is 80 ℃, and the reaction time is...

Embodiment 2

[0026] Take calcium monohydrogen citrate and hydrochloric acid for metathesis reaction. When the ratio of calcium ion concentration to hydrogen ion concentration is 1:2 and the temperature is 60℃, calcium chloride and citric acid are generated. The solution produced by the reaction is extracted by organic solvent to obtain The raffinate of calcium ions and the loaded organic phase (I) containing citric acid, the loaded organic phase (I) is washed to obtain the loaded organic phase (II), and the loaded organic phase (II) is stripped to obtain citric acid and a blank organic phase. The blank organic phase can be reused in the extraction process. The citric acid is decolorized and concentrated to obtain the citric acid product. The raffinate containing calcium ions is added with sulfuric acid or sulfate to react to maintain the concentration of free calcium ions and sulfate in the synthesis system. The range is 0.03 mol / L, the reaction temperature is optimized to 60 ℃, and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com