Nanoneedle array as well as preparation method and application thereof

A nano-needle and array technology, applied in the field of nano-needle array and its preparation, can solve the problems of difficult adjustment of nano-pillar size parameters, limited size of nano-needle array, small preparation area, etc., and achieves large aspect ratio, stable related parameters, Good controllability of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

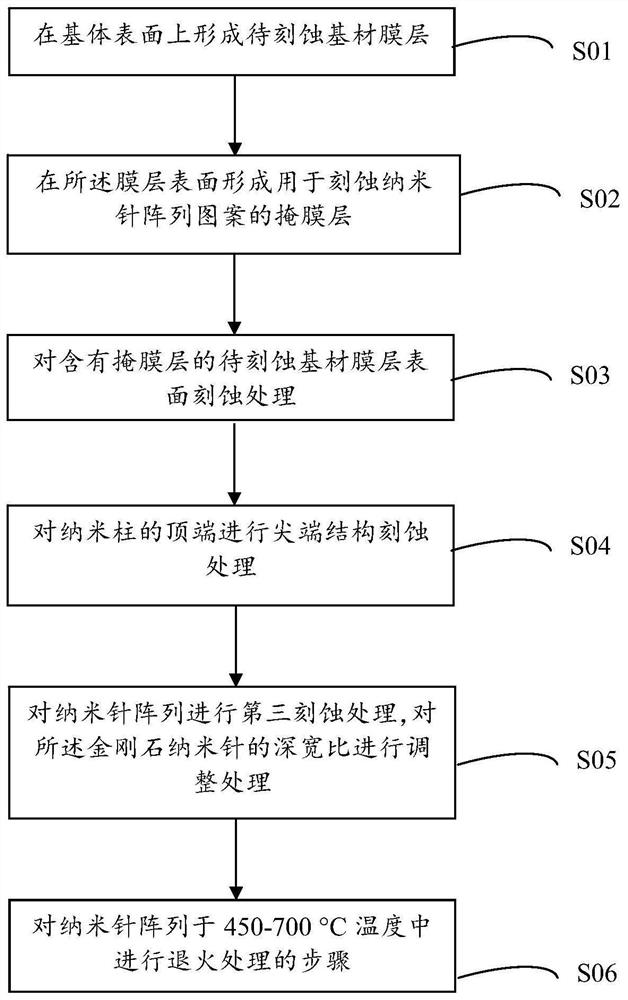

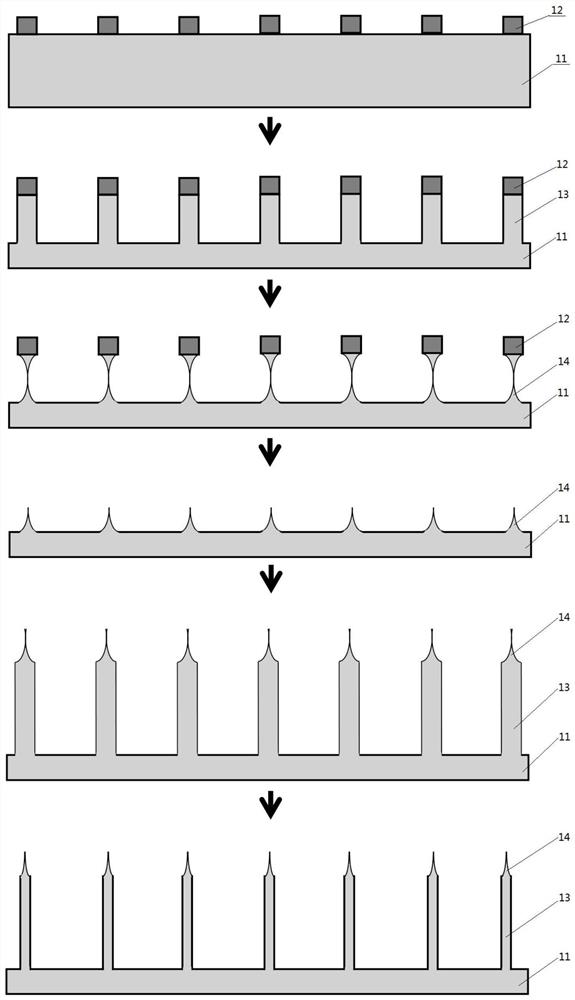

[0040] On the one hand, the embodiment of the present invention provides a method for preparing a nanoneedle array. The process flow of the preparation method of the nanoneedle array is as follows: figure 1 and figure 2 As shown, it includes the following steps:

[0041] S01: forming a substrate film layer 11 to be etched on the surface of the substrate 01;

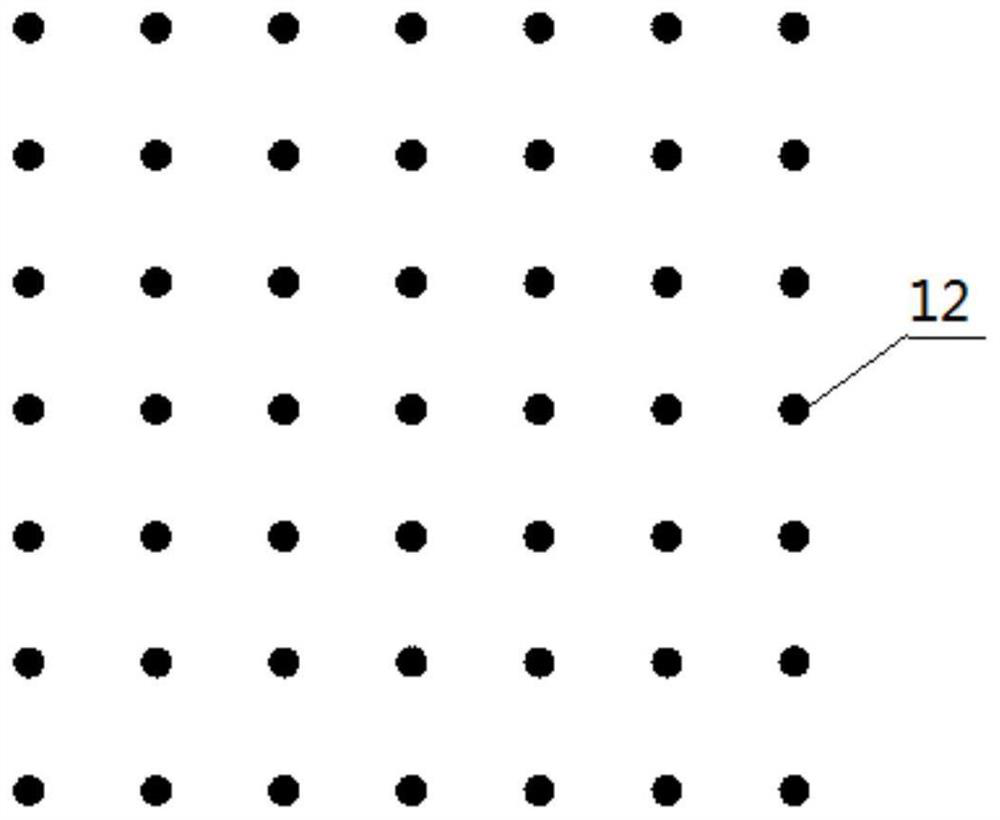

[0042] S02: forming a mask layer 12 for etching nanoneedle array patterns on the surface of the substrate film layer 11 to be etched away from the substrate;

[0043] S03. Etching treatment on the surface of the substrate film layer 11 to be etched containing the mask layer 12: from the direction of the mask layer 12 to the substrate 01, the substrate layer 11 on which the mask layer 12 is formed is etched. Etching the surface of the substrate film layer 11 to perform a first etching treatment to form a nano-column array;

[0044] S04. Carrying out the etching treatment of the tip structure 14 on the top of the nanoc...

Embodiment 1

[0082] This embodiment provides a diamond nanoneedle array and a preparation method thereof. The process flow of the diamond nanoneedle array preparation method is as follows: figure 1 and 2 , which includes the following steps:

[0083] S11. Depositing a diamond film layer 11 on the surface of the substrate by microwave plasma chemical vapor deposition:

[0084] a. Substrate 01 pretreatment: ultrasonically clean the monocrystalline silicon substrate in acetone and alcohol for 10 minutes, and then use H 2 o 2 :NH 3 OH:H 2 O (10:10:50) solution was heated to 80°C, kept for 10 minutes, and deionized water was ultrasonically cleaned for 10 minutes; then the cleaned silicon substrate was placed in a stable nano-diamond powder suspension and ultrasonically treated for 1 hour, and the diamond powder was suspended The average particle size of the liquid is 5nm, it exists in the most dispersed form, the Zeta potential is about +50mV, and the diamond nucleation density exceeds 10...

Embodiment 2

[0097] This embodiment provides a diamond nanoneedle array and a preparation method thereof. The process flow of the diamond nanoneedle array preparation method is as follows: figure 1 and 2 , which includes the following steps:

[0098] S11. Depositing a diamond film layer 11 on the surface of the substrate by microwave plasma chemical vapor deposition:

[0099] a. Substrate 01 pretreatment: carry out with reference to step a in step S11 of embodiment 1;

[0100] b. Depositing a diamond film layer 11 on the substrate: carry out with reference to step b in step S11 of embodiment 1;

[0101] S12. Polishing the diamond film layer 11:

[0102] Carry out with reference to step S12 of embodiment 1;

[0103] S13. Forming the mask layer 12 by electron beam lithography technology:

[0104] In order to promote the adhesion between the electron beam resistance and the substrate, 10nm Ti was evaporated onto the diamond thin film substrate; then, the high-resolution electron beam resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com