Welding agent-core welding wire for titanium and titanium alloy

A technology of flux-cored welding wire and titanium-based alloy, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of easy falling off of active agent coating layer, affecting welding quality and low efficiency, etc. The effect of easy cleaning, good weld formation and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The titanium-based alloy flux-cored welding wire of the present invention will be further described through examples below.

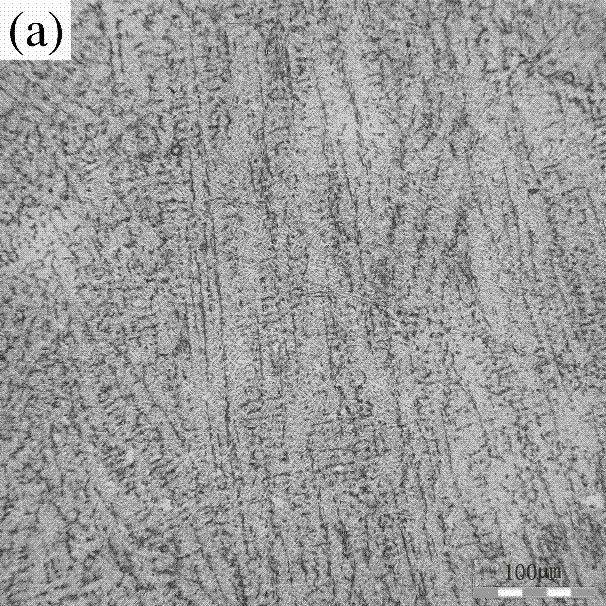

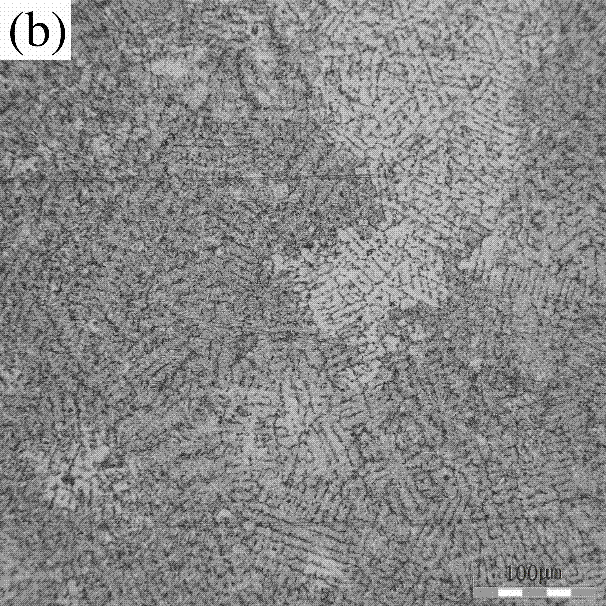

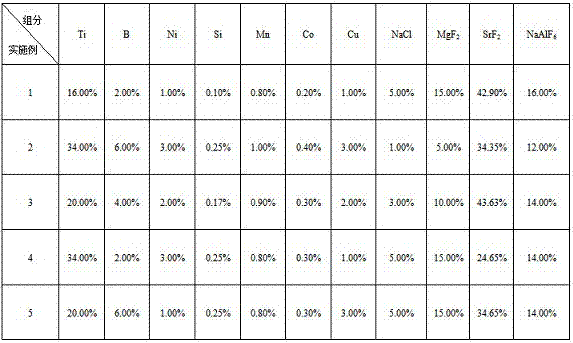

[0014] A titanium-based alloy flux-cored welding wire, including a metal sheath and an inner active flux core, the metal sheath is a titanium strip with a titanium content of not less than 98% by mass and a hydrogen content of not more than 0.015% by mass, and the inner active flux core is composed of Composition of metal powder, B powder, Si powder and active agent, described metal powder includes Ti, Co, Mn, Ni and Cu, described active agent includes chloride, fluoroaluminate, MgF 2 and SrF 2 , the mass percent of each composition of metal powder, B powder, Si powder and active agent: Ti is 16%~34%; Co is 0.2%~0.4%; Mn is 0.8%~1%; Ni is 1%~ 3%; Cu is 1% to 3%; B is 2% to 6%; Si is 0.10% to 0.25%; chloride is 1% to 5%; fluoroaluminate is 12% to 16%; MgF 2 5% to 15%; SrF 2 20% to 60%. The outer metal skin is a titanium tube with a circular cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com