Method and device for depositing a protective layer during an etching procedure

A protective layer and etching technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increasing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

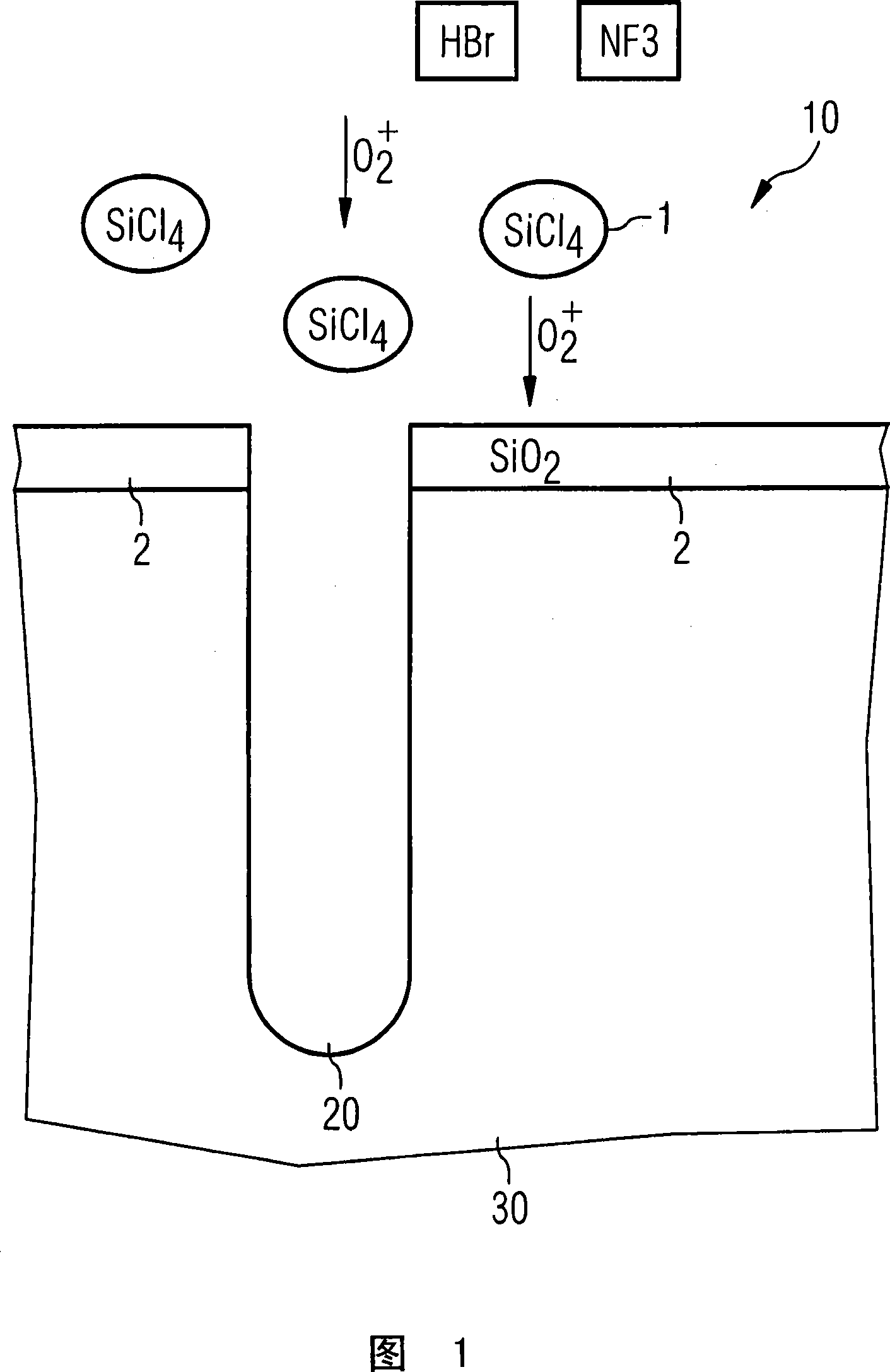

[0015] FIG. 1 schematically shows a trench structure 20 in a material 30 . It is assumed here that the material 30 is a silicon wafer used to manufacture DRAM chips. The silicon wafer has a diameter of 300 mm.

[0016] The trench structure 20 here is a deep trench structure of a memory cell with an aspect ratio of about 55.

[0017] By dry etching step with plasma 10, with HBr, NF 3 The deep trench structure 20 is introduced into the material 30 as an etching medium. Since the etching of the deep trench structure 20 takes a relatively long time, the surfaces of the horizontal layers on the left and right of the deep trench structure 20 in FIG. 1 will be removed through this etching process.

[0018] According to the embodiment of the invention shown here, a precursor 1 is added to the plasma 10 in a targeted manner, which precursor is compatible with the constituents in the plasma 10 (O 2 ) react together, so that the protective layer 2 is formed on the material 30 in a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com