Patents

Literature

43 results about "Micro technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

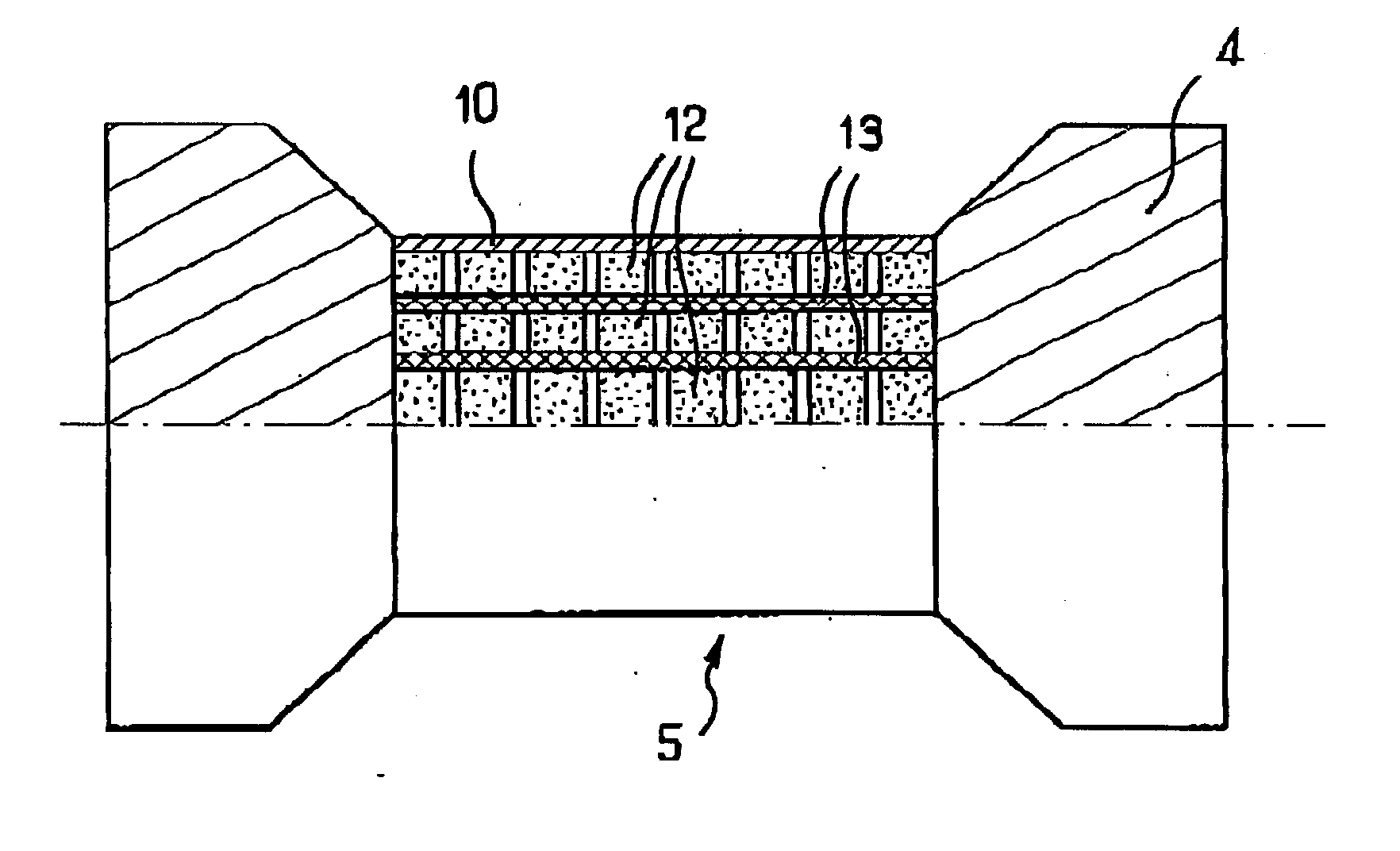

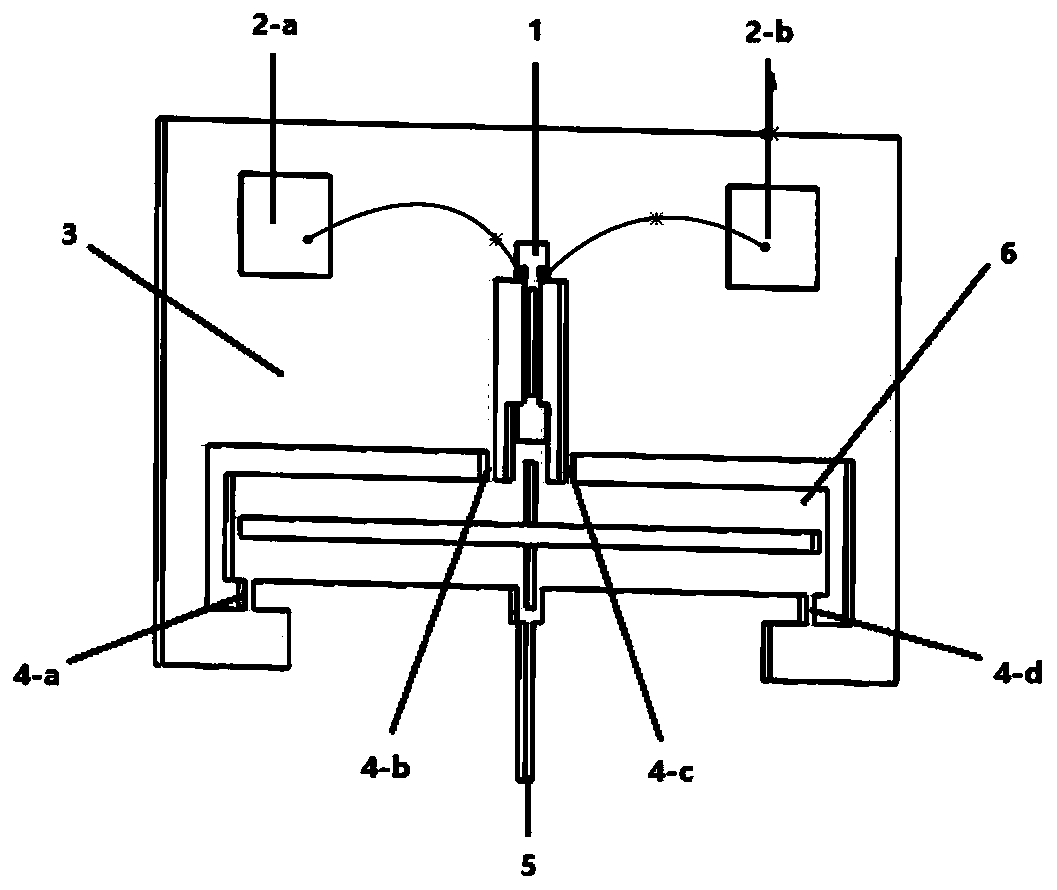

Device and method for separation

InactiveUS20040069717A1Raise the possibilityHigh particle separationOther blood circulation devicesHaemofiltrationElectricityEngineering

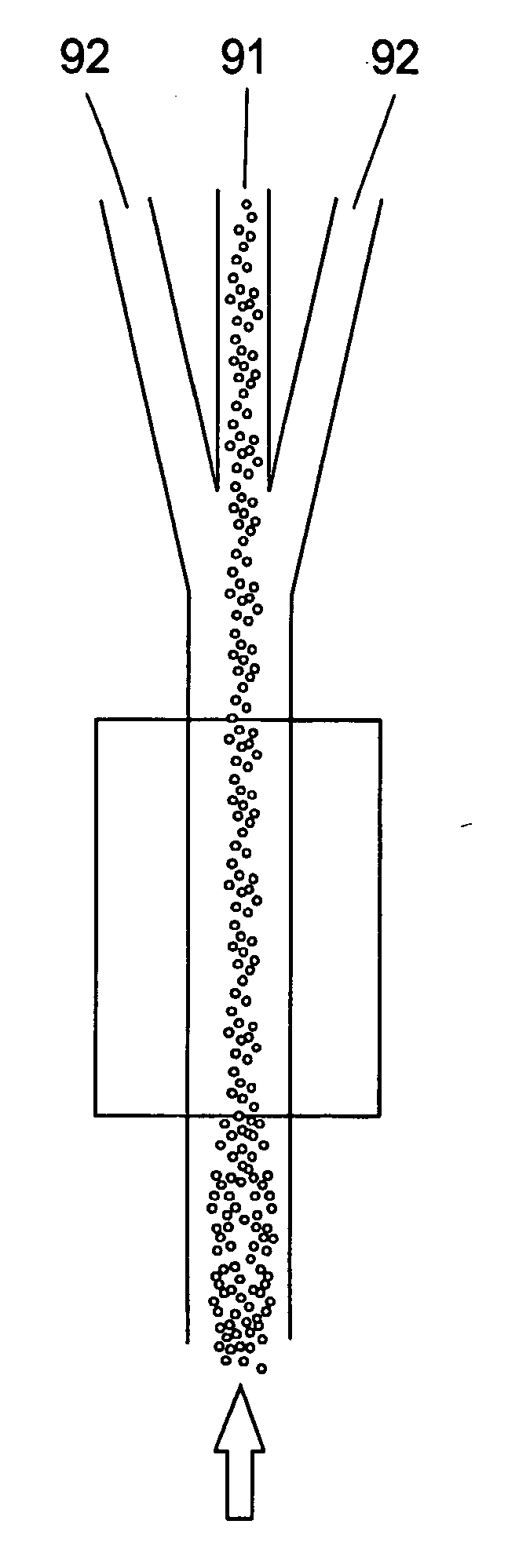

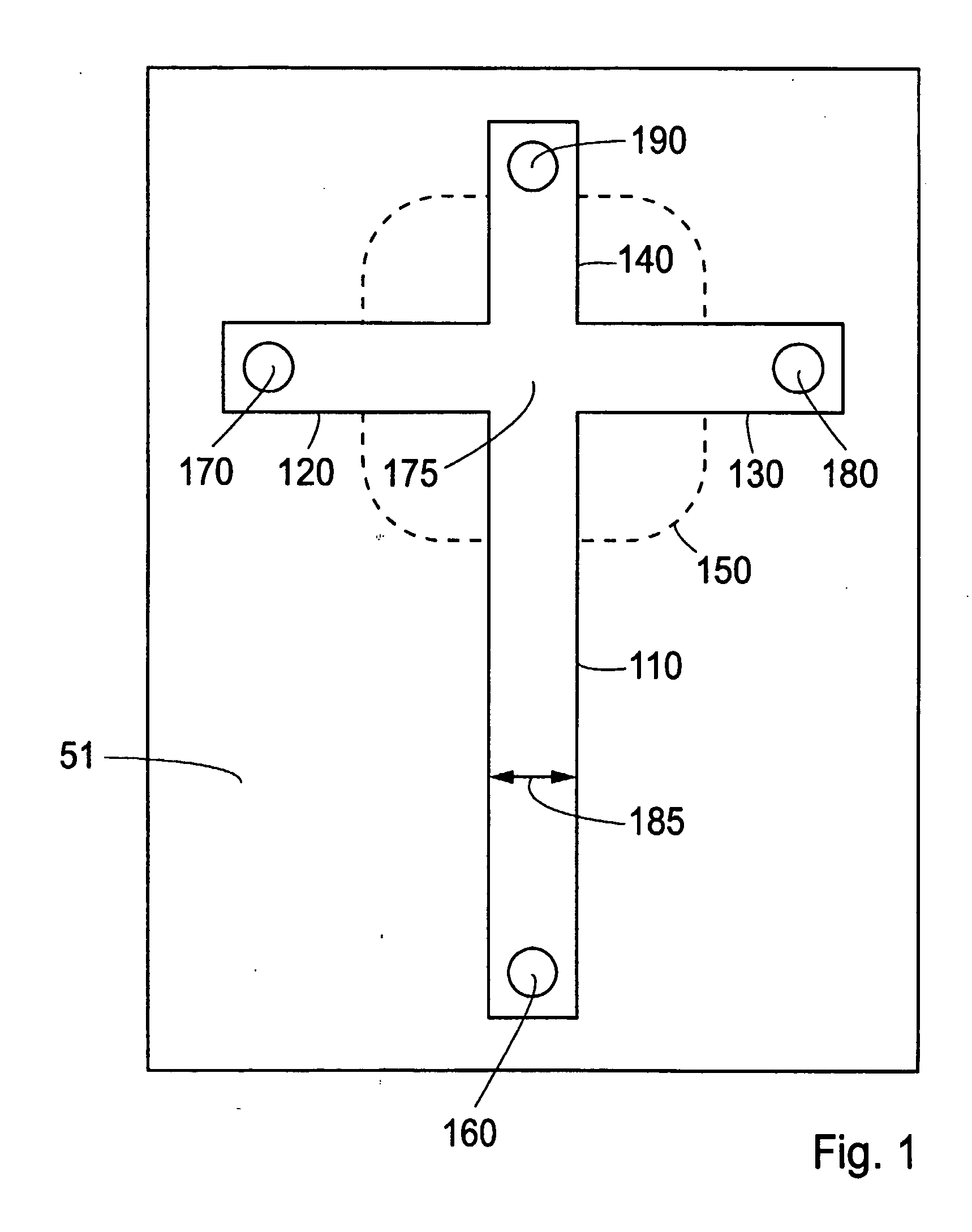

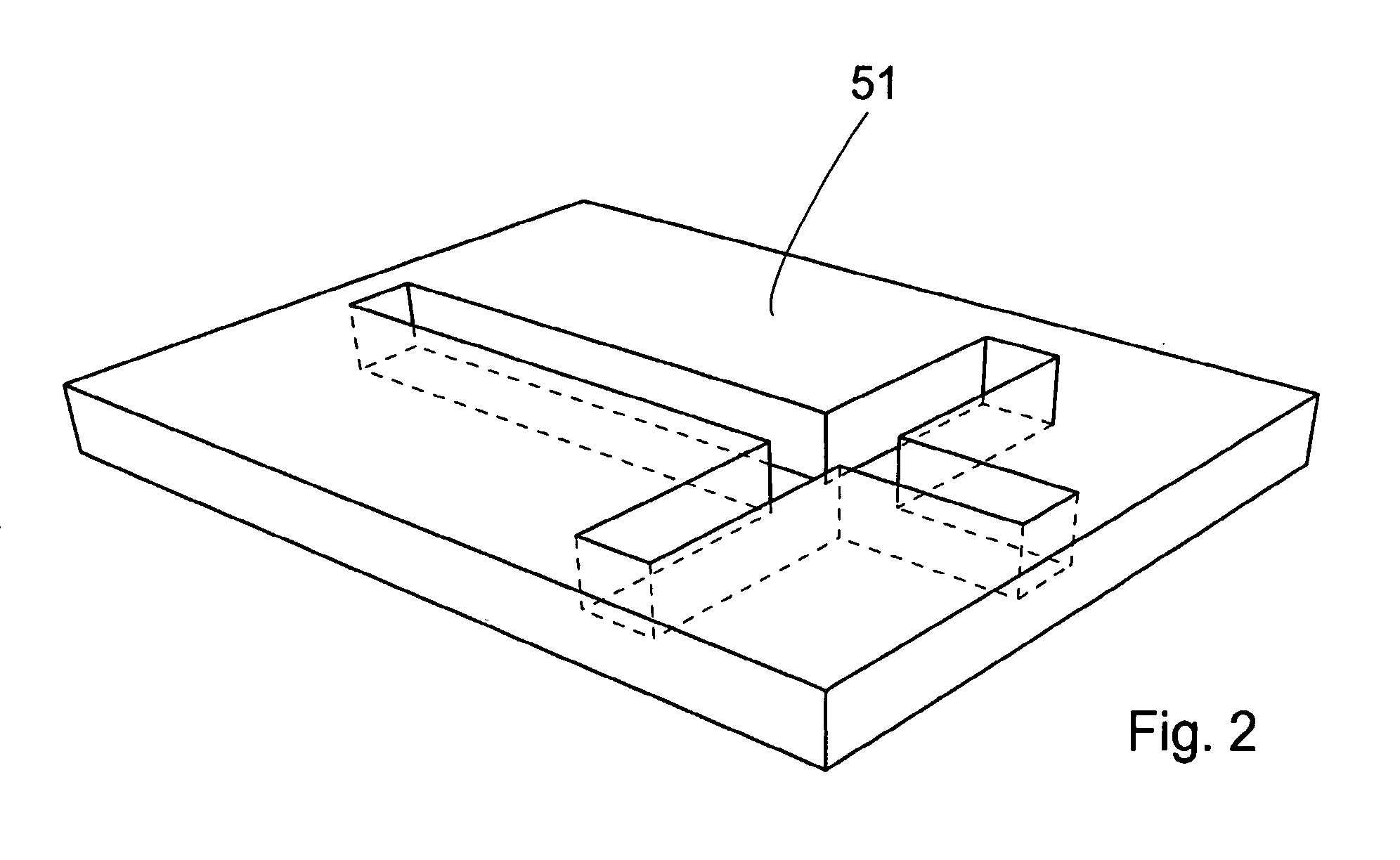

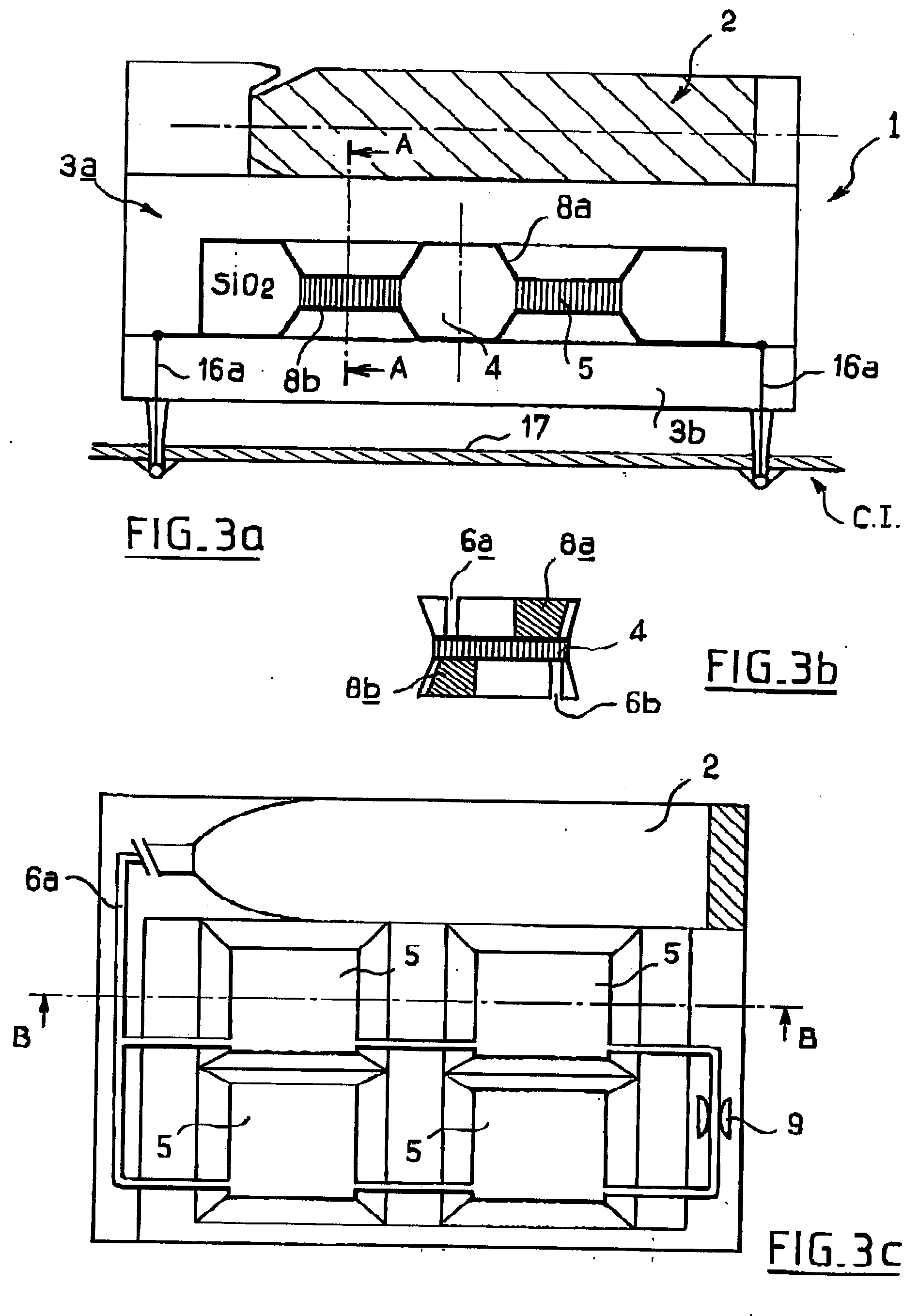

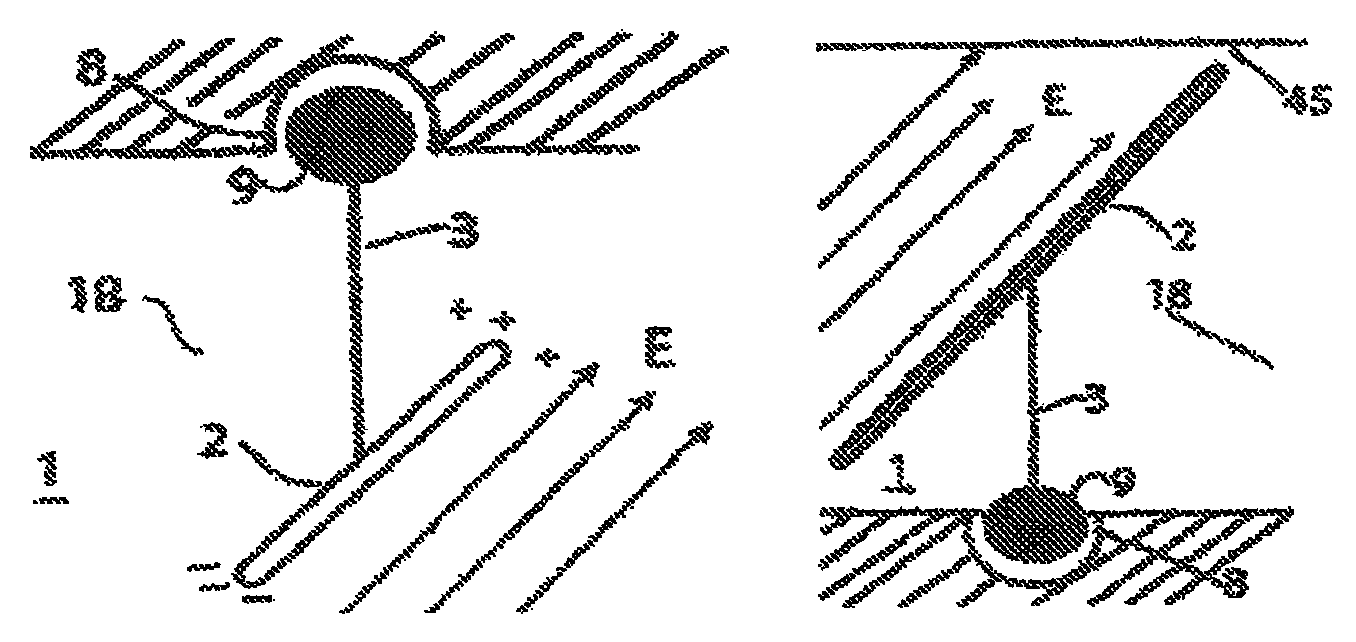

The present invention provides a device and a method for separating particles from fluids using ultrasound, laminar flow, and stationary wave effects comprisinga micro-technology channel system with an integrated branching point or branching fork, and a single ultrasound source. One of the characteristics of the invention is that the single ultrasound source, which generates the standing waves, excites the complete structure including the channel system. No special reflectors or the like are needed. Extremely thin dividers can separate the flow, thereby enhancing the effectiveness of the device. The device could be manufactured in silicon and the ultrasound energy could preferably be delivered by a piezoelectric element.

Owner:ERYSAVE

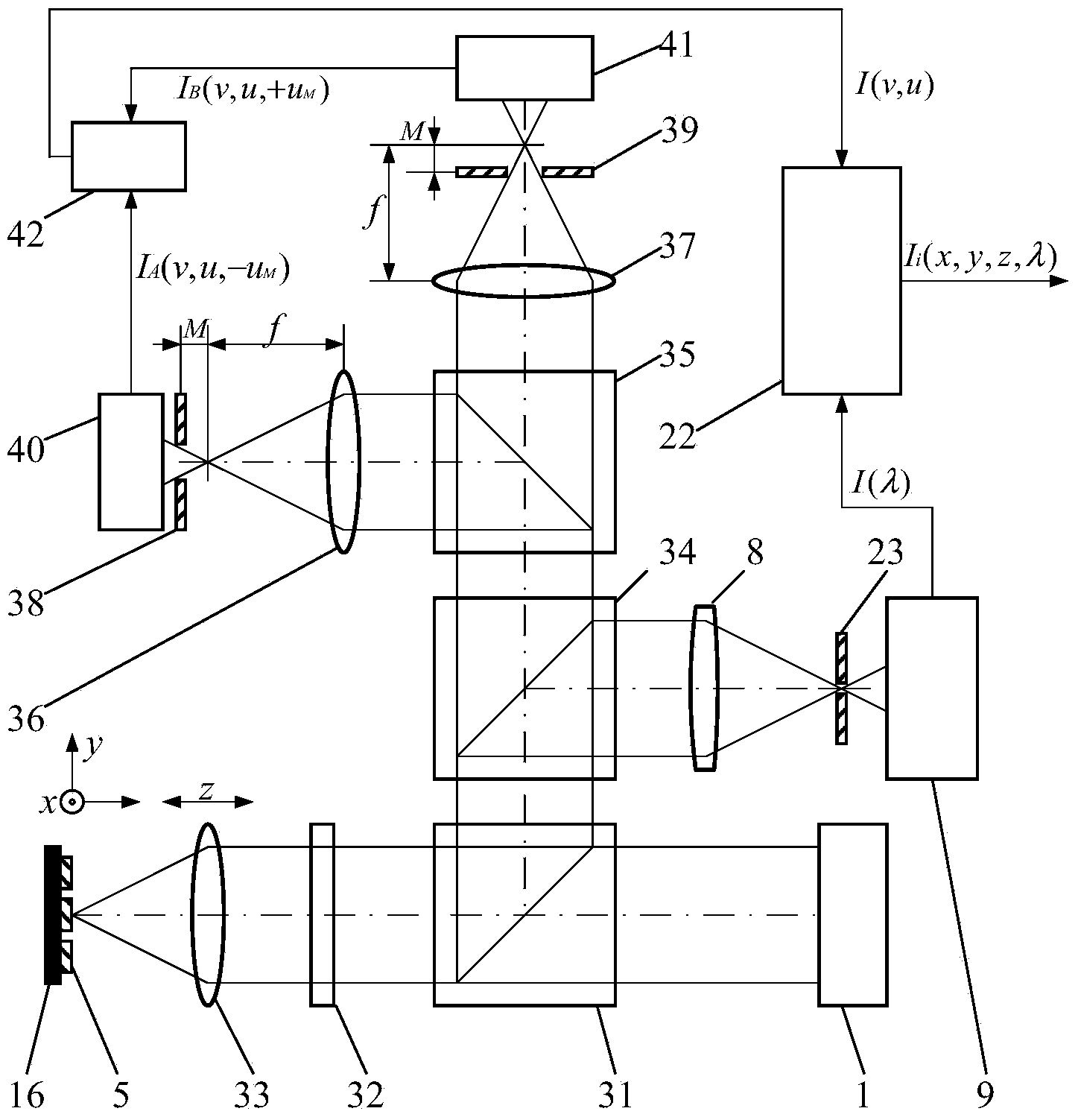

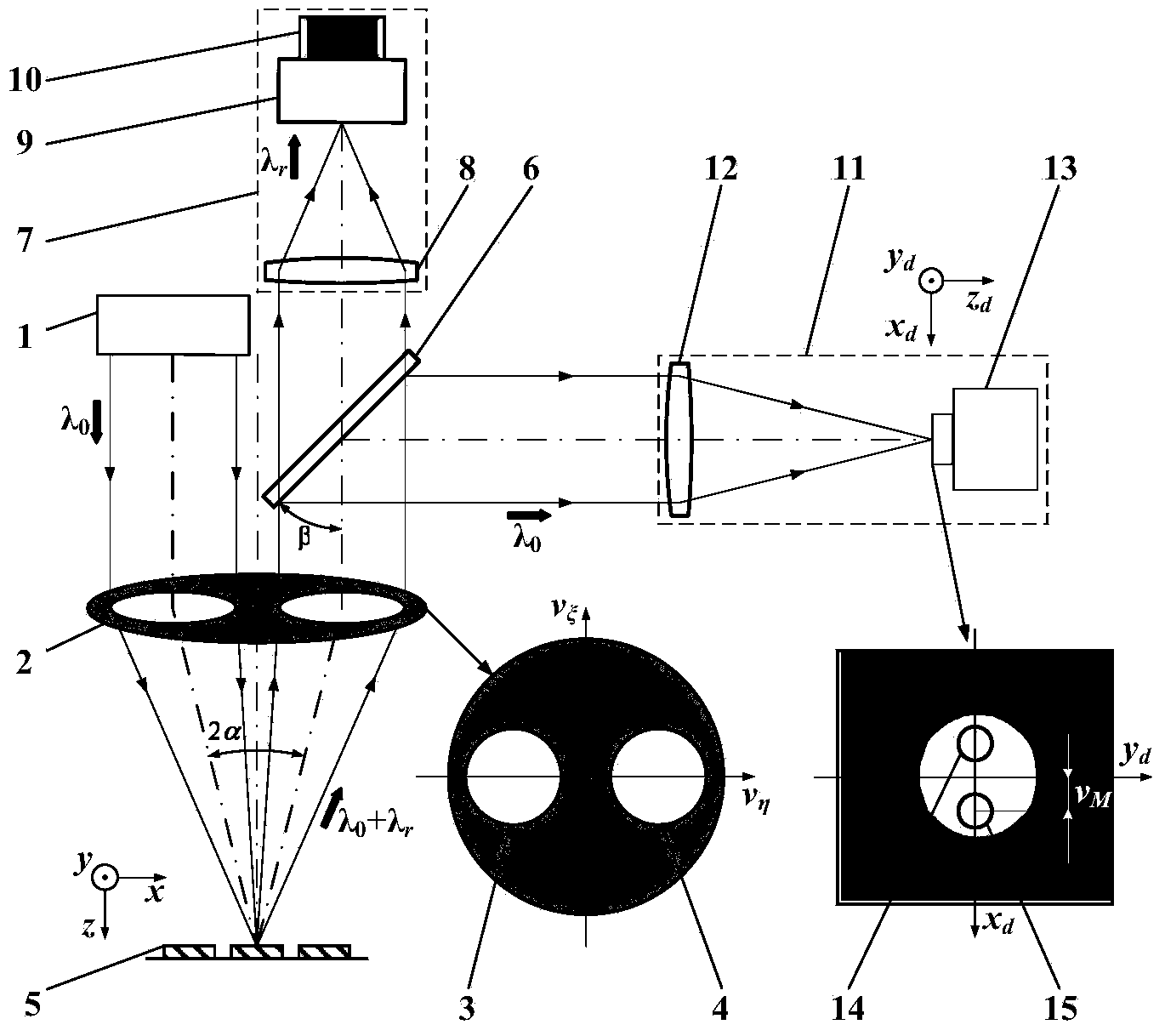

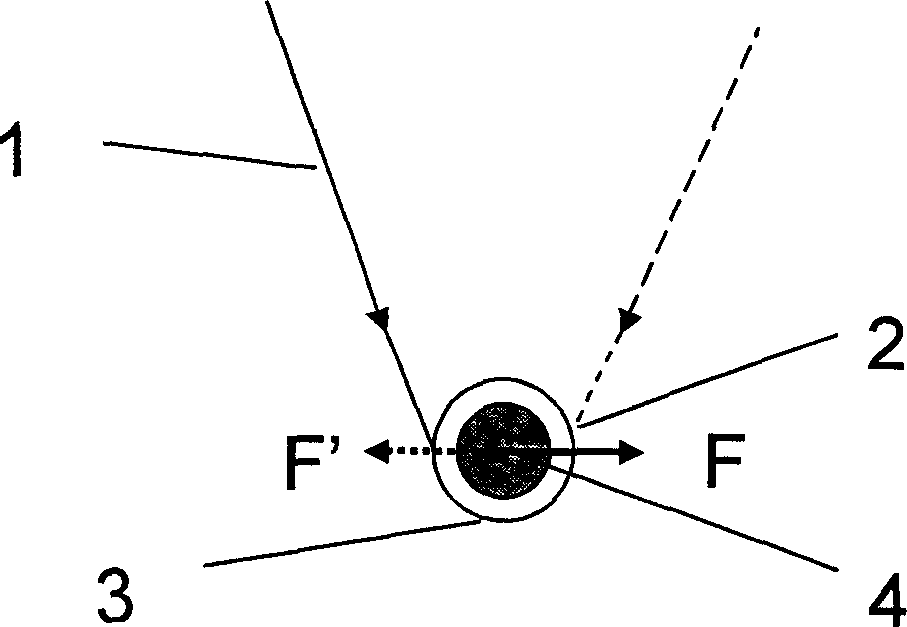

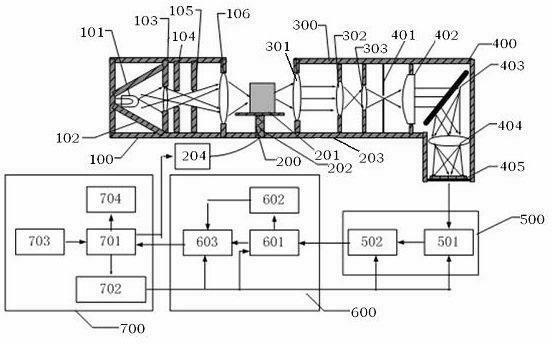

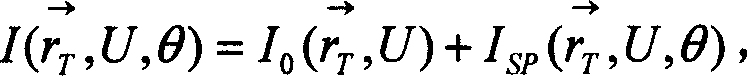

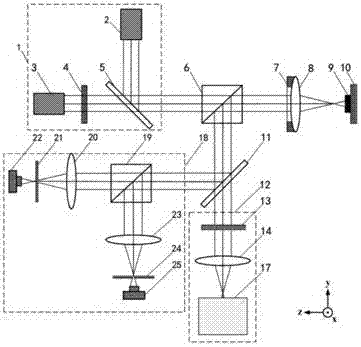

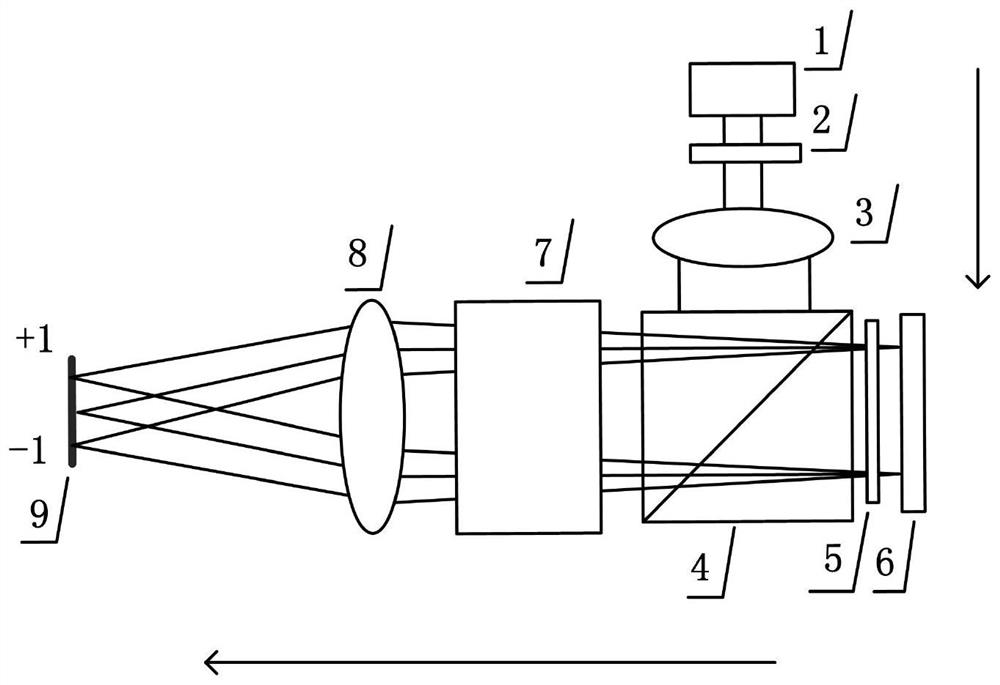

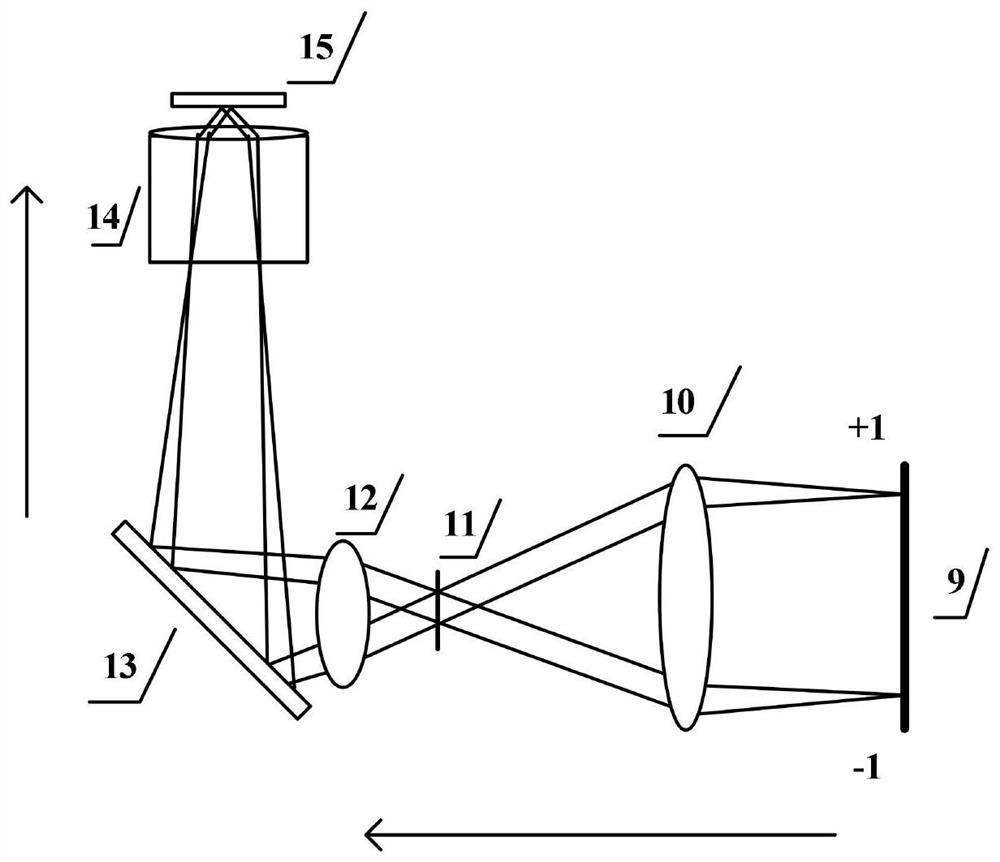

Split pupil laser differential confocal Raman spectrum test method and device

ActiveCN103969239AImproving the ability of micro-region spectral detectionSimple structureRadiation pyrometryRaman scatteringOphthalmologyMicrocell

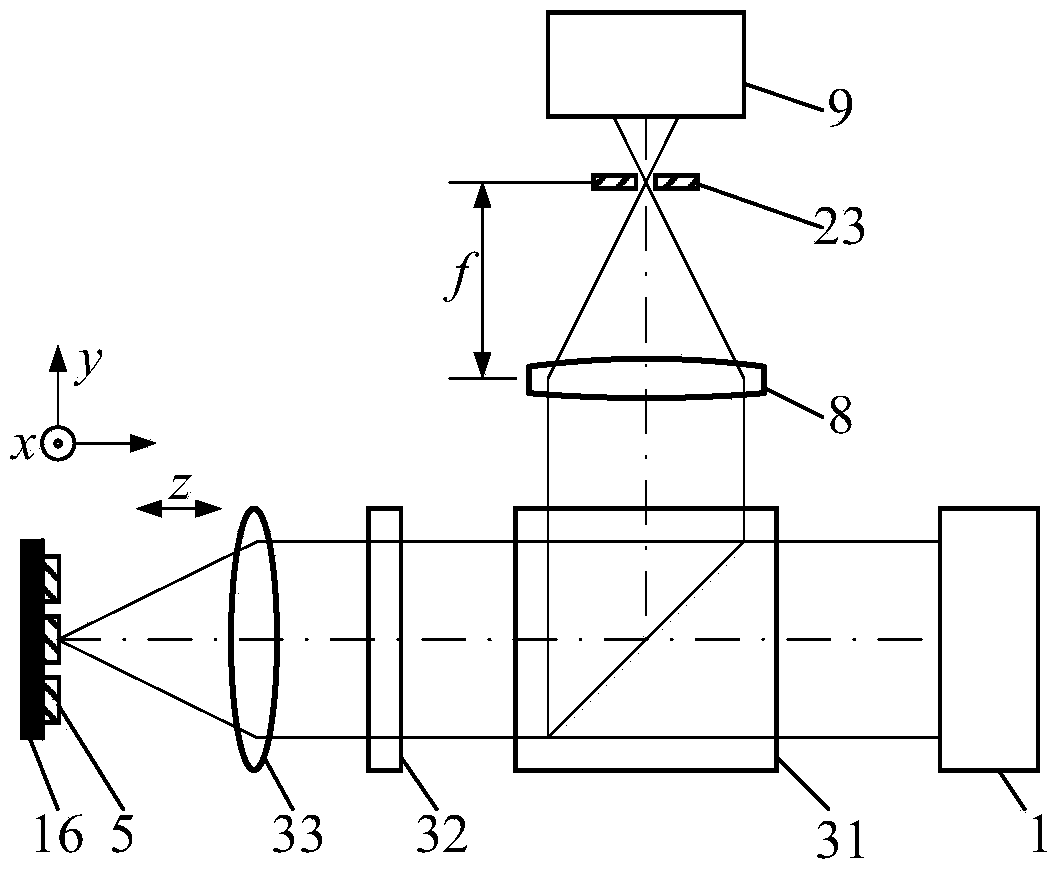

The invention belongs to the technical field of microscopicspectral imaging detection, and relates to a split pupil laser differential confocal Raman spectrum test method and device. According to the test method and device, a split pupil laser differential confocal microtechnique and a laser Raman spectrum detection technique are organically combined, precise imaging of three-dimensional geometrical positions is realized through segmentation focal spot differential detection, the optical path structure of a traditional differential confocal microscopic system is simplified, advantages of an original laser differential confocal system and a split pupil confocal system are inherited, and multi-mode switching and processing of split pupil laser differential confocal microscopic detection, laser confocal Raman spectrum detection and laser differential confocal Raman spectrum detection can be realized only through softwareswitching processing. The test method and device provide a new technological approach for detection ofnanoscale microcell three-dimensional geometrical positions and spectrum, can be applied to fields of biomedicine, industrial precision detection and the like, and has the broad application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

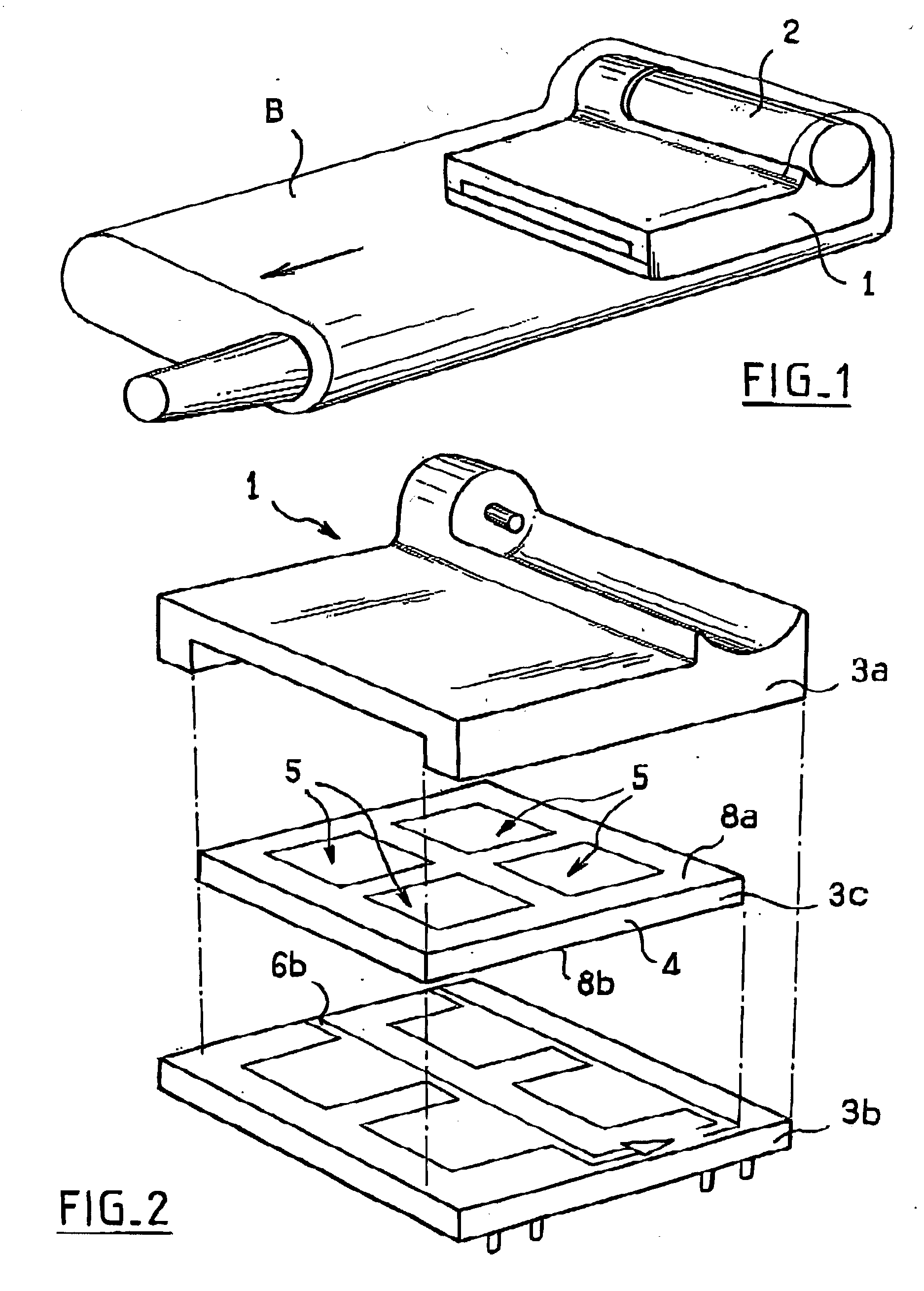

Microfuel cells for use particularly in portable electronic devices and telecommunications devices

InactiveUS20040197613A1MiniaturisationControl DimensionsFinal product manufactureFuel cell auxillariesState of artProton

The invention relates to a miniature fuel cell powered by a hydrocarbon fuel making heavy use of micro-technologies in making and assembling the sub-assemblies of the cell. Relative to the prior art, the main innovation consists in using a semiconductor oxidised and made porous in predetermined areas, to receive an electrolytic polymer allowing the composition of the proton exchange membrane necessary for the fuel cell to operate.

Owner:SAGEM SA +1

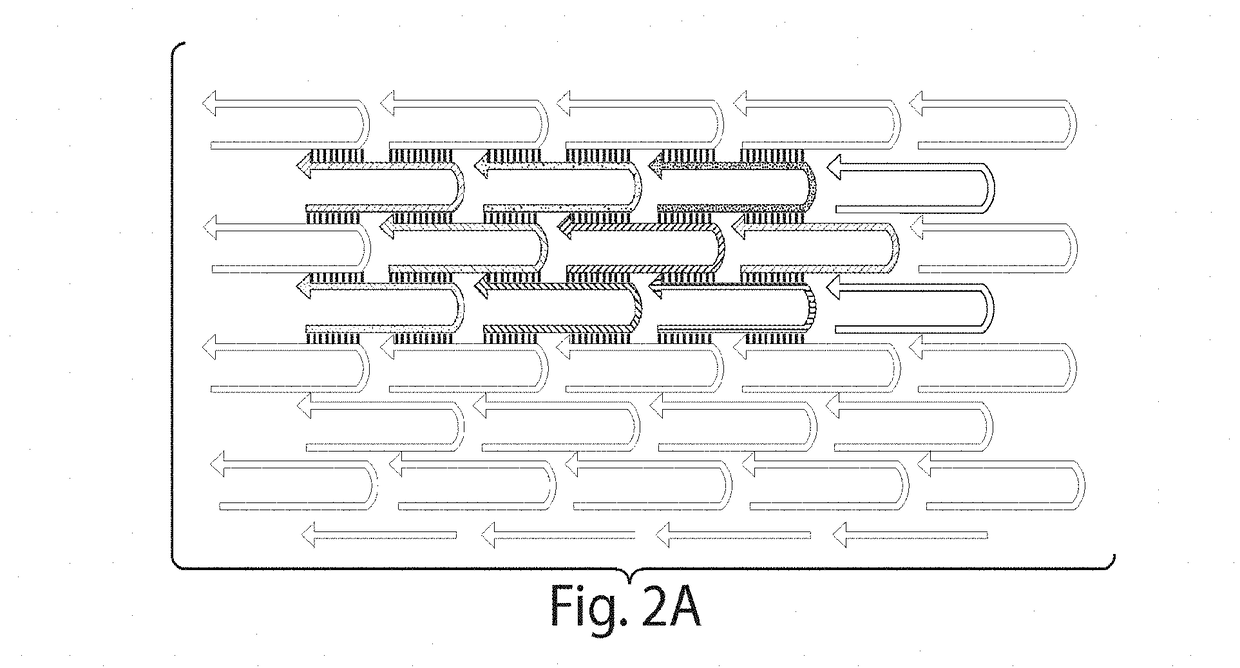

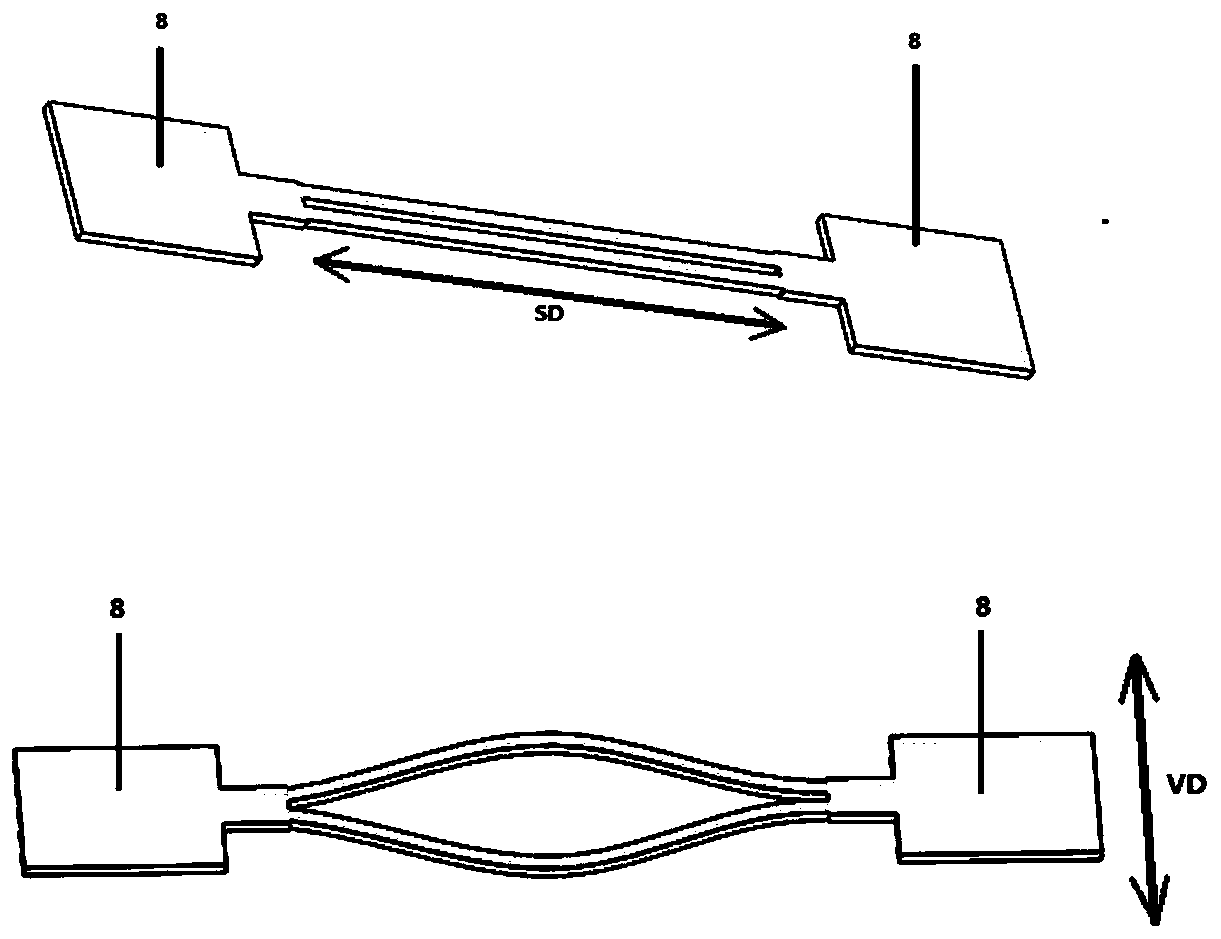

Tracking and focusing adjustable fresnel lens array solar concentrator

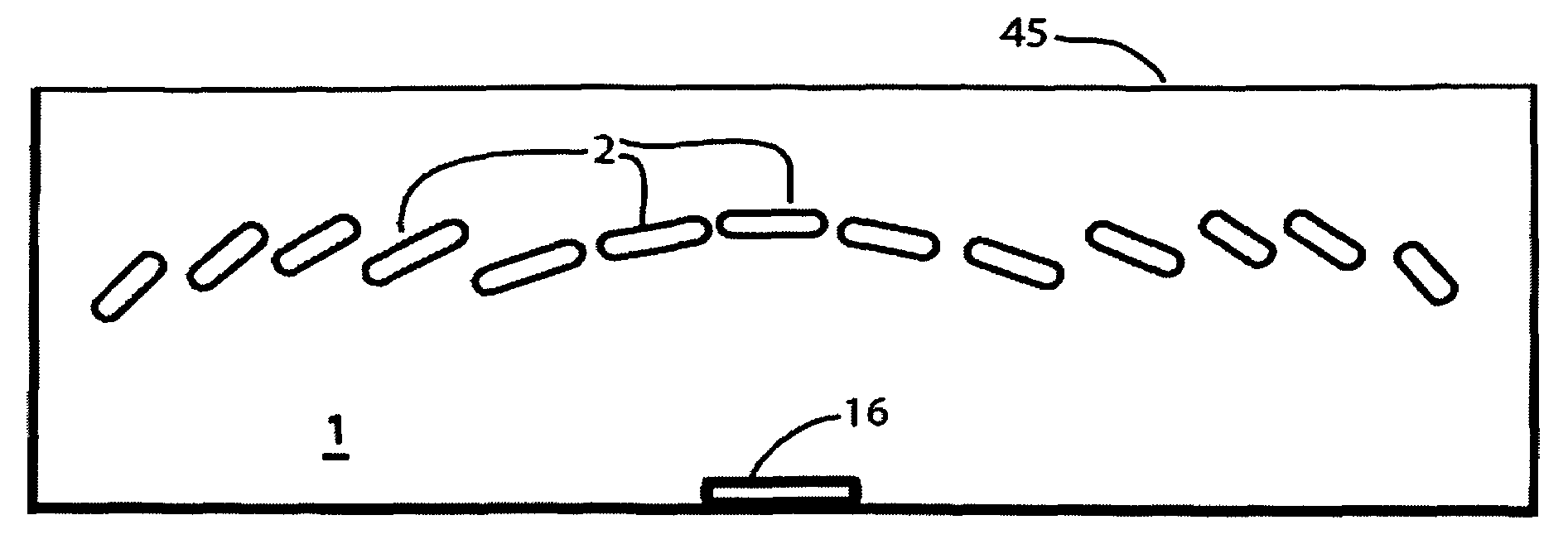

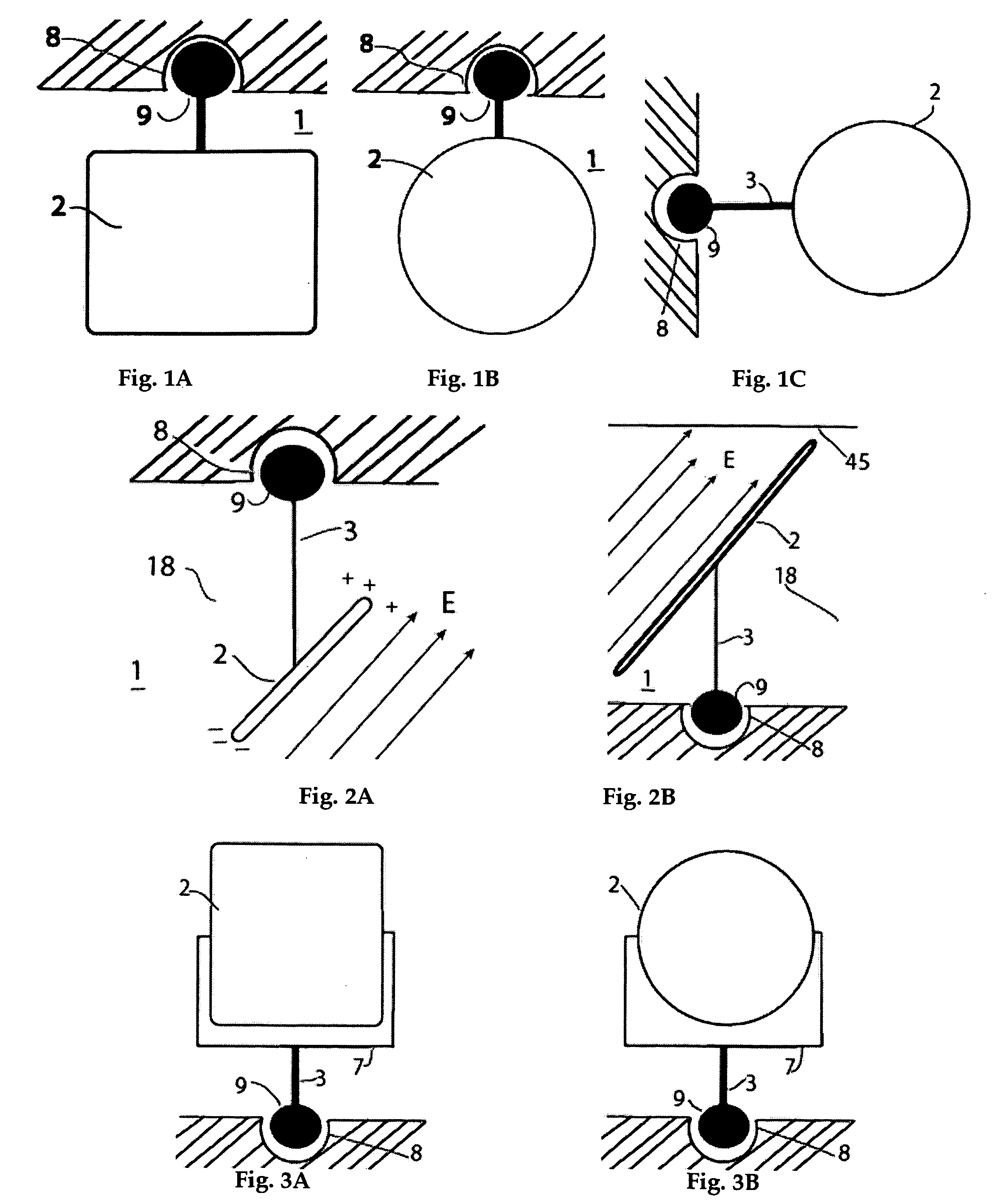

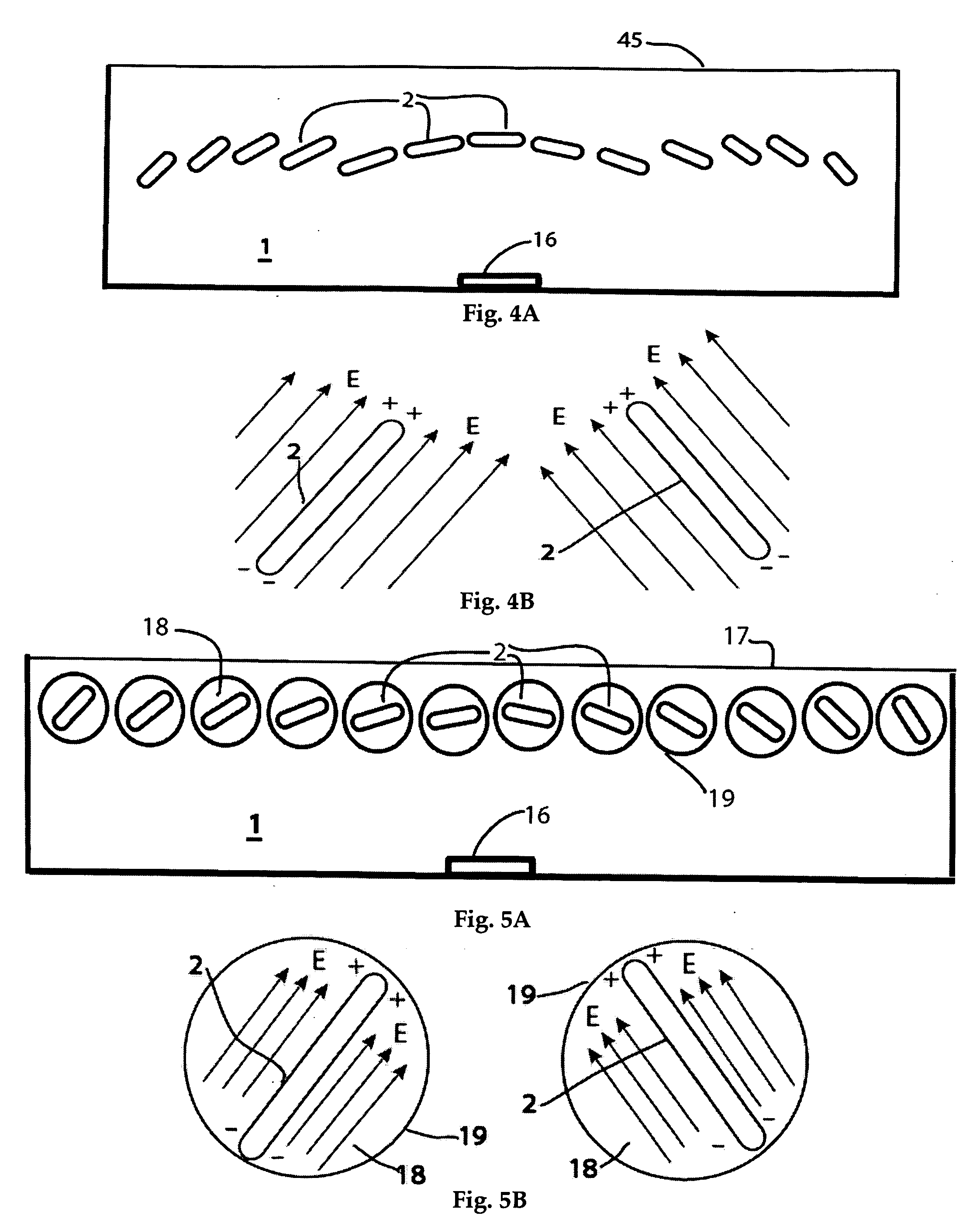

InactiveUS20090188545A1Easy to manufactureEliminate needSolar heating energySolar heat devicesLow voltageDynamic motion

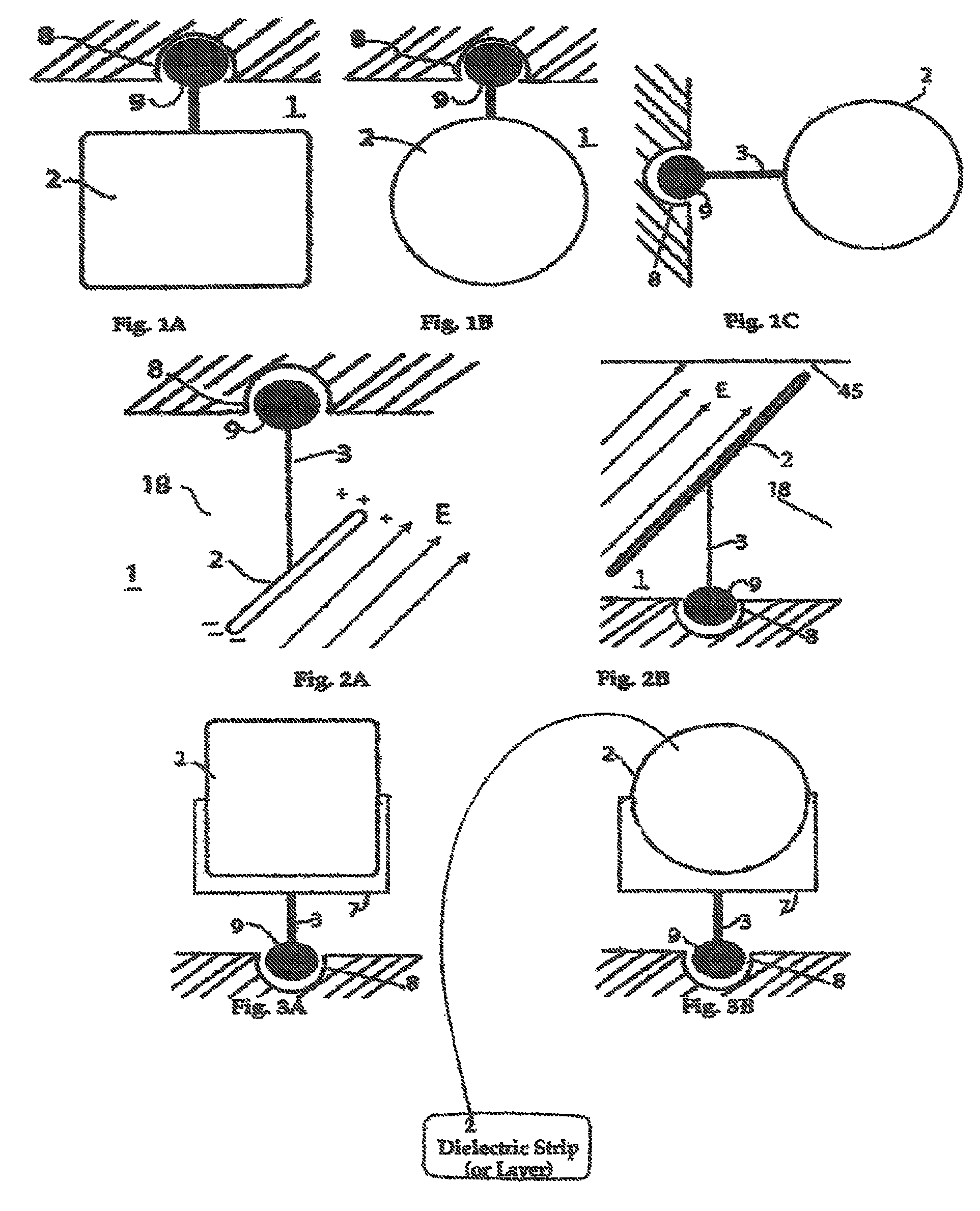

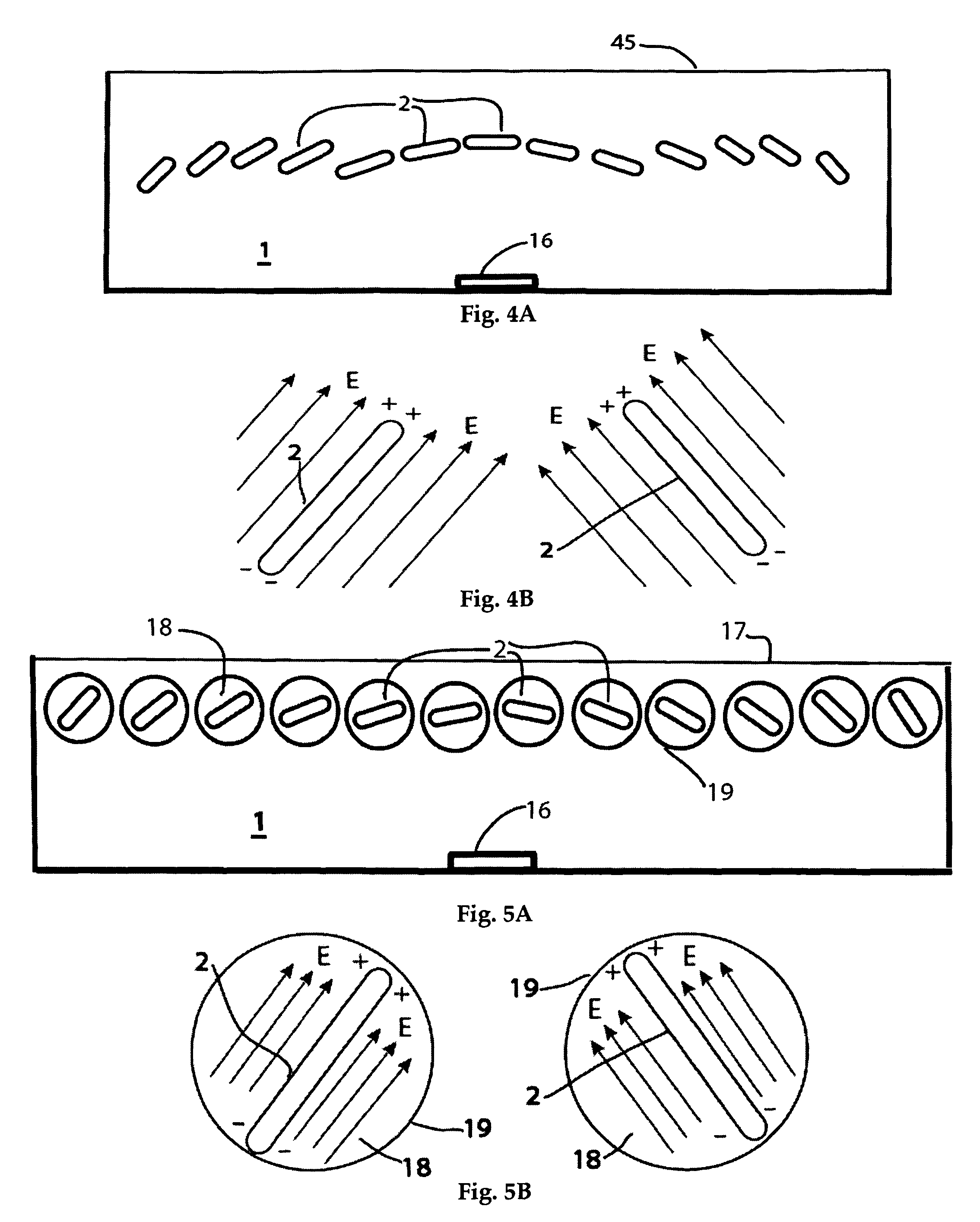

This invention deals with novel method and apparatus for positioning and motion control of the elements (lenses) of a Fresnel lens solar concentrator tracking array by induced and / or permanent dipole coupling to an electronic grid to produce angular deflection, and rotational motion. Thus forces and torques are produced without the use of internal moving parts. Control can be achieved without recourse to magnetic fields, by means of high electric fields which may be attained at relatively low voltages. At low voltages, the instant invention exceeds the capability of conventional systems. It can perform dynamic motion control with independent amplitude and frequency modulation. It is ideally suited for maximization of solar energy focused by the array onto a receiver. Since there are no mechanical likages, the instant invention is the most adapted for fabrication from the mini- to the micro-technology realm. Furthermore it provides less costly and greater ease of manufacture from the mini-to the micro-realm.

Owner:RABINOWITZ MARIO

Tracking and focusing adjustable fresnel lens array solar concentrator

InactiveUS7960641B2Diminish the electric fieldEnhance the dipole fieldSolar heating energySolar heat devicesLow voltageDynamic motion

This invention deals with novel method and apparatus for positioning and motion control of the elements (lenses) of a Fresnel lens solar concentrator tracking array by induced and / or permanent dipole coupling to an electronic grid to produce angular deflection, and rotational motion. Thus forces and torques are produced without the use of internal moving parts. Control can be achieved without recourse to magnetic fields, by means of high electric fields which may be attained at relatively low voltages. At low voltages, the instant invention exceeds the capability of conventional systems. It can perform dynamic motion control with independent amplitude and frequency modulation. It is ideally suited for maximization of solar energy focused by the array onto a receiver. Since there are no mechanical likages, the instant invention is the most adapted for fabrication from the mini- to the micro-technology realm. Furthermore it provides less costly and greater ease of manufacture from the mini-to the micro-realm.

Owner:RABINOWITZ MARIO

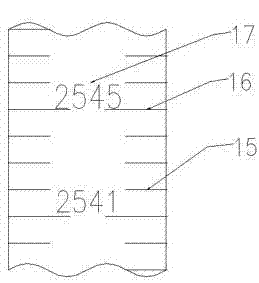

A ship draft and river water level measurement system with special shrinking amplitude and water gauge

ActiveCN102295062ASignificant technological progressLess investmentVessel stability improvementMovement controllersA wave amplitudeLive action

The invention discloses a system for measuring ship draft and river water level based on special micro wave amplitude and a water gauge, belonging to the measurement field of the ship draft and the river water level and solving the technical problem that a measurement field video image comprising high-precision ship draft or river water level data can be displayed in real time by just using one miniature video picture. In the system, a technology of displaying the average height of irregular wave surfaces, a special micro technology of wave amplitude and ship water gauge maker or river water gauge, a video image monitoring system technology, an automatic tracking and shooting target technology of miniature camera equipment and the like are mainly adopted. The system has the advantages that visual, real, objective, just, clear and high-precision measurement data and measuring field live action which can be put on records is provided in real time by the video image and can be transmitted outside. The system has low cost, is simple and practical, is convenient to operate, carry and maintain and is energy-saving and environmentally-friendly, and the automatic measurement of the ship draft and the water levels of the river and the like is easily achieved.

Owner:郭顺福

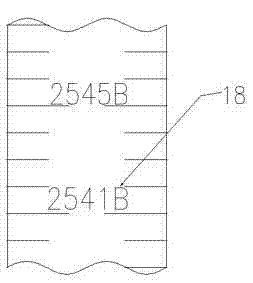

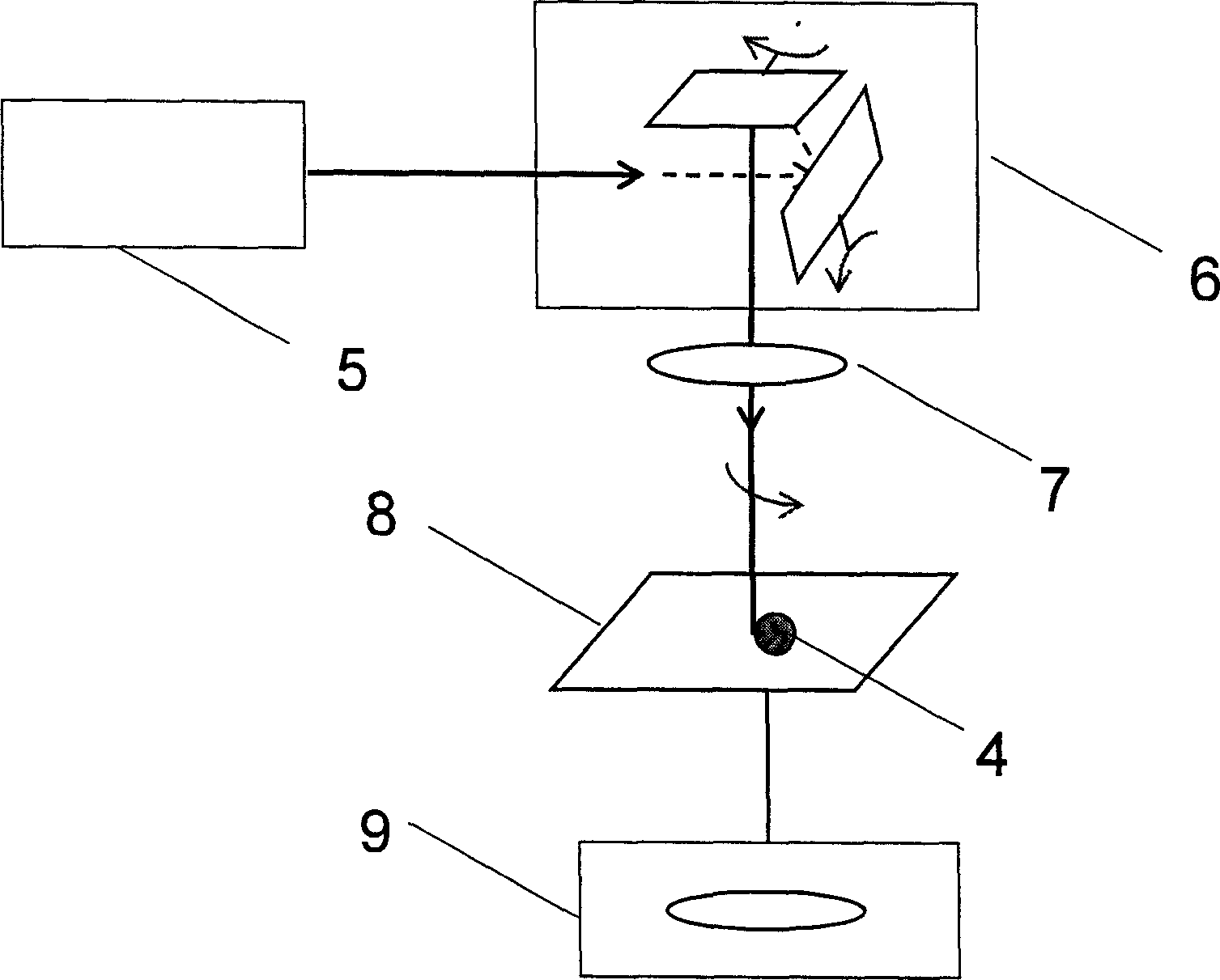

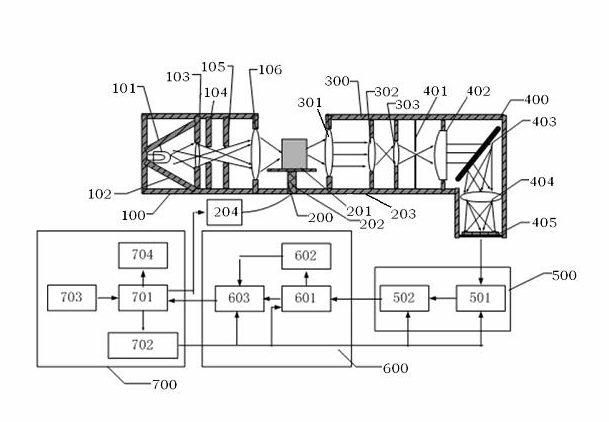

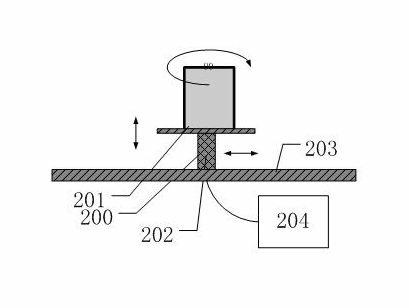

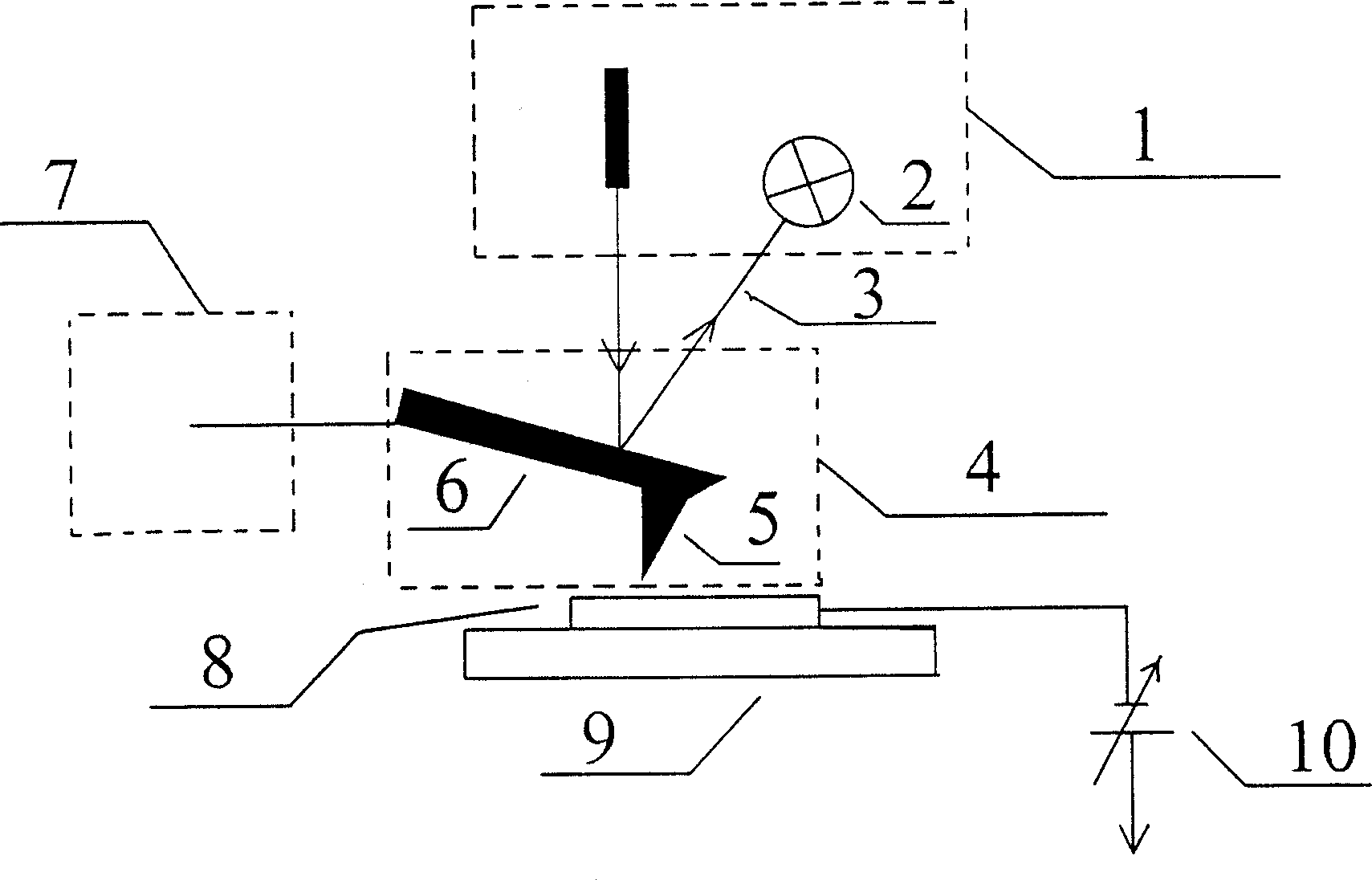

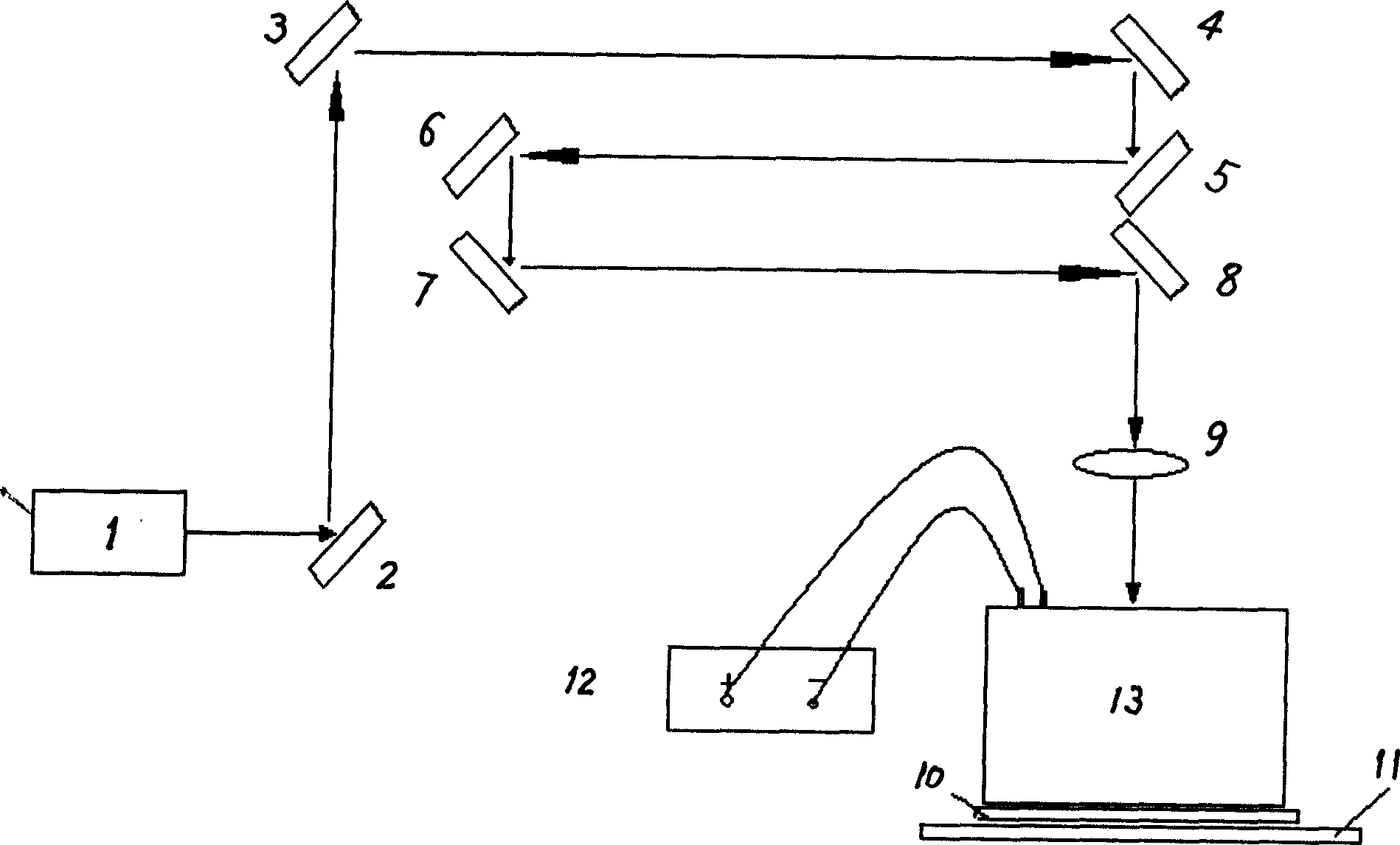

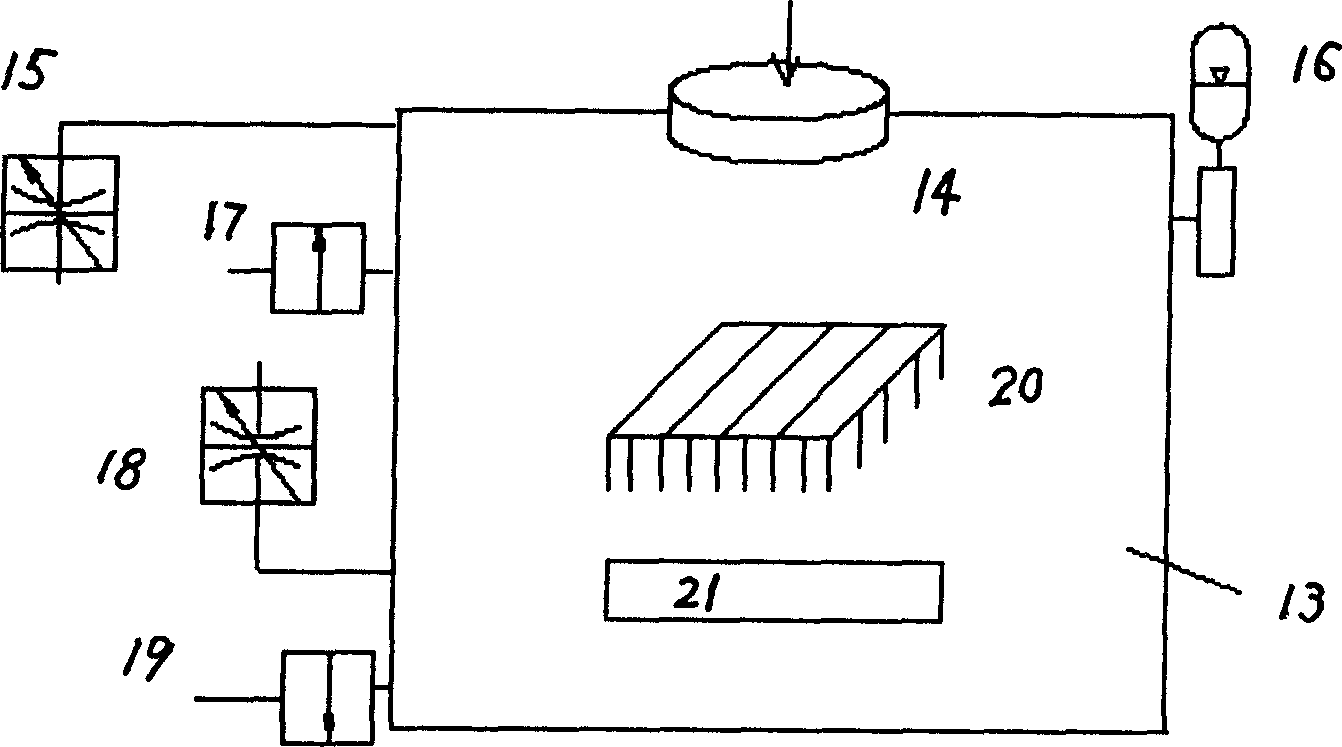

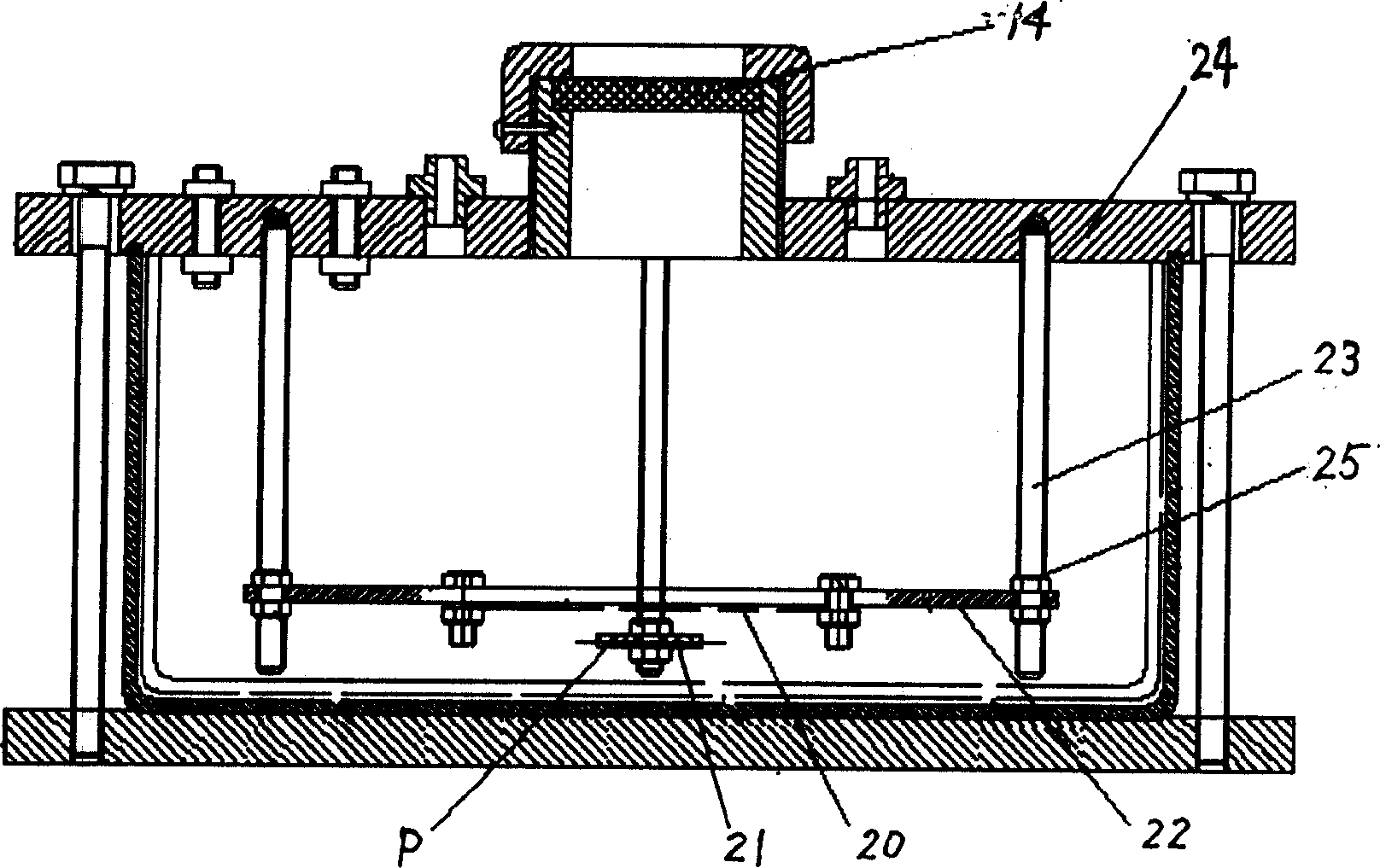

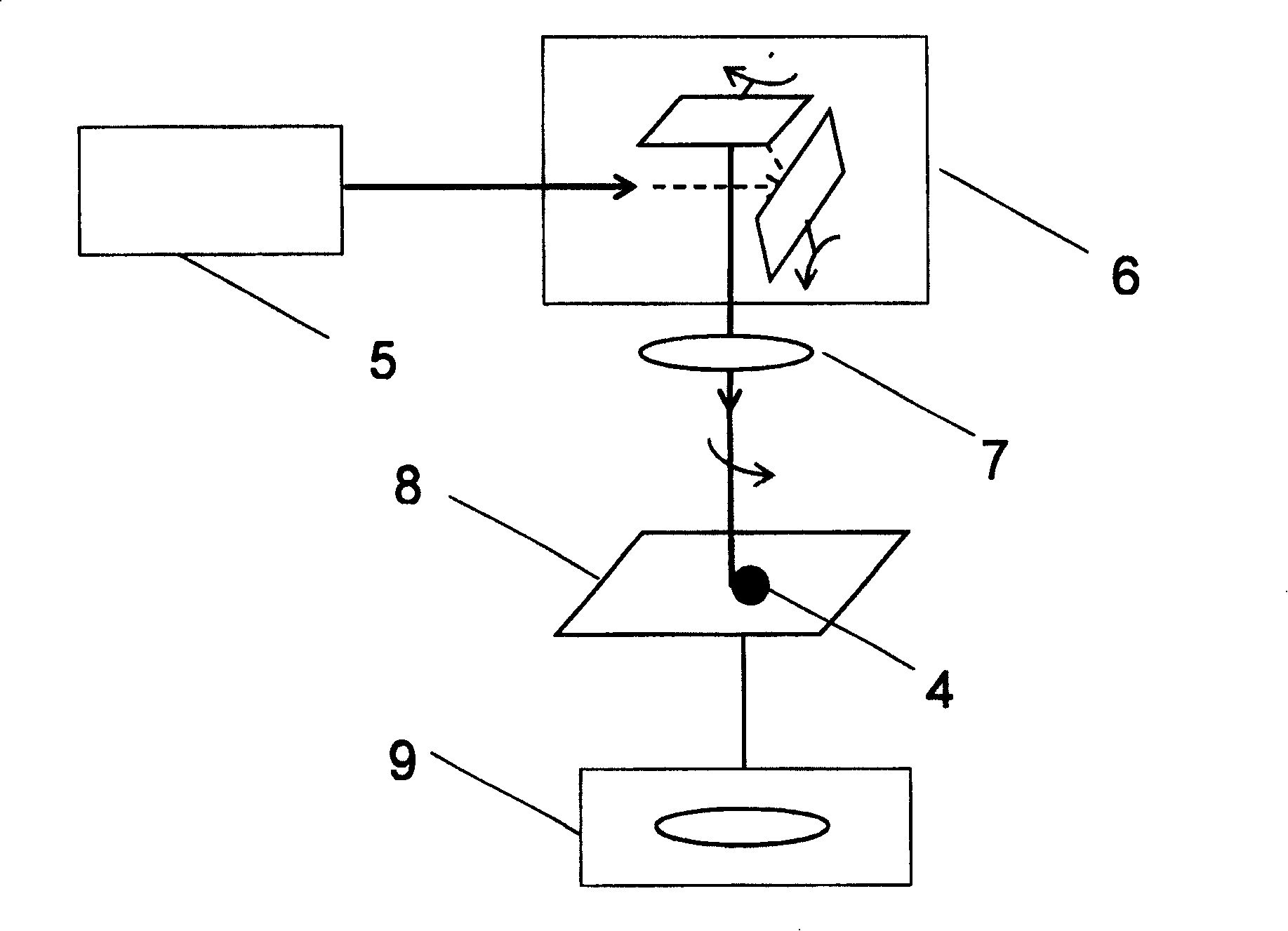

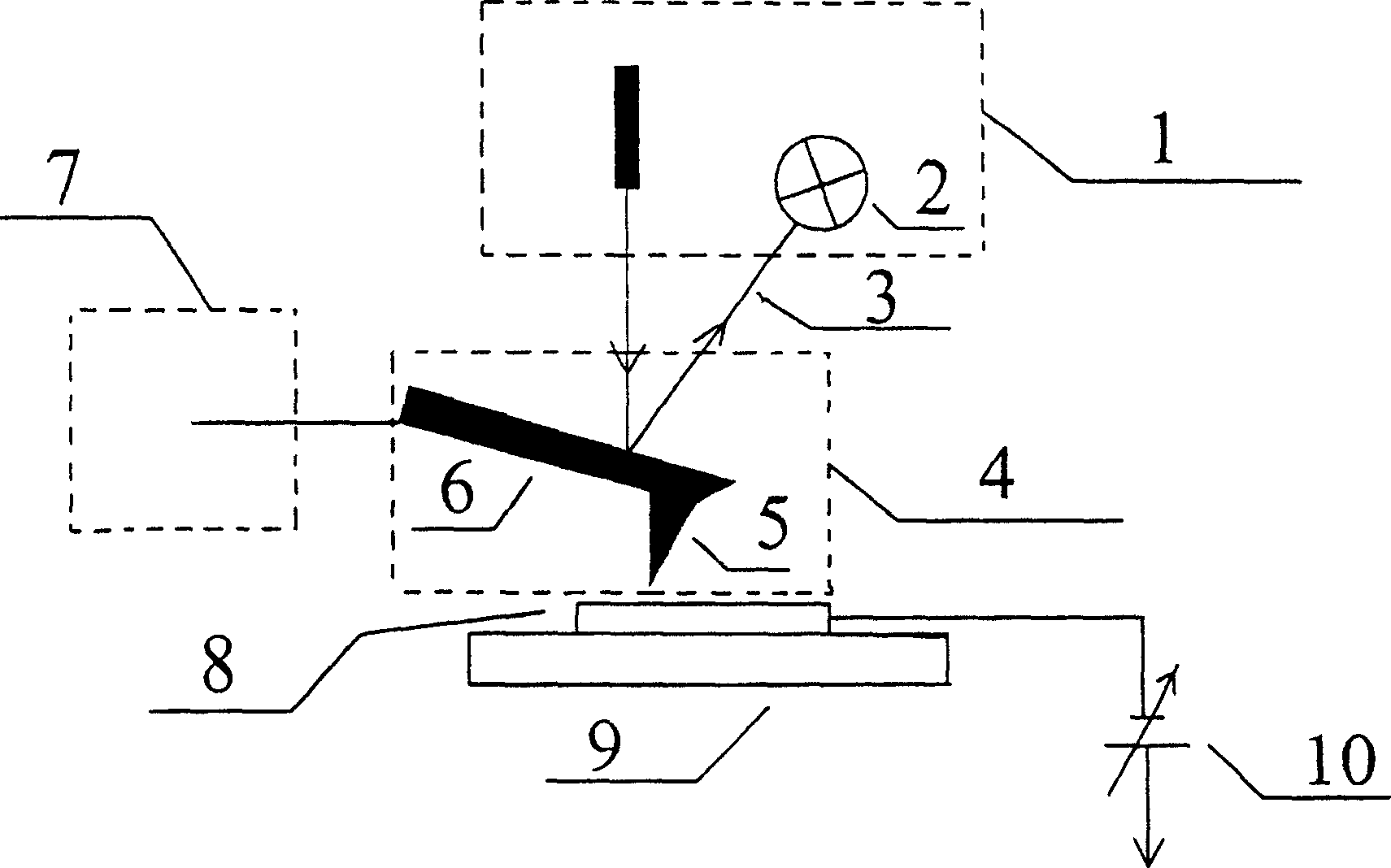

Laser cell microoperation control method and device for metal particle

InactiveCN1830752ADirect manipulationRapid prototypingTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLight beamOptoelectronics

A method for manipulating the laser tweezers of metallic micro-particles features that a 2D scanning polarizer system is used to control the circular scanning of laser beam around metallic micro-particles, and the action force of laser beam to each metallic micro-particle points to the curvature center of scanning trace, so gathering the metallic micro-particles in the center. Its apparatus is composed of laser device, focusing lens, 2D moving platform, microscopic observing system, and 2D scanning polarizer system.

Owner:BEIJING UNIV OF TECH

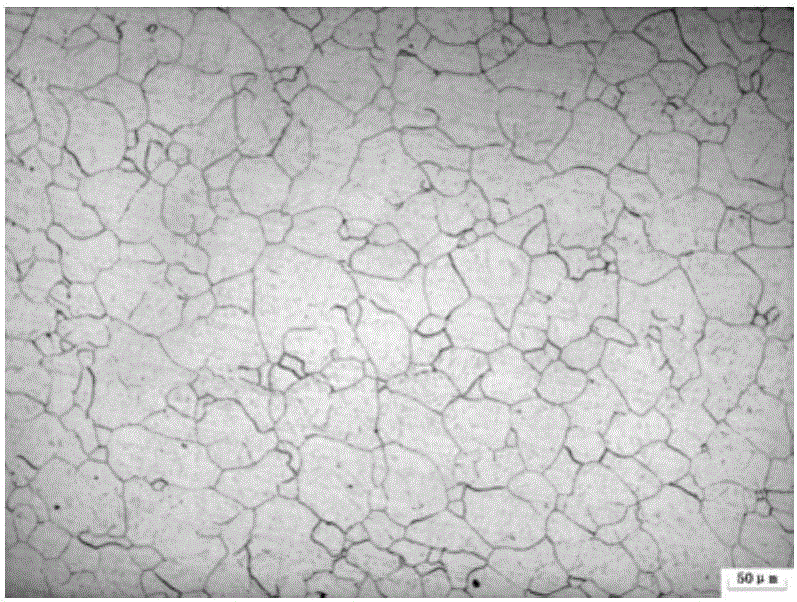

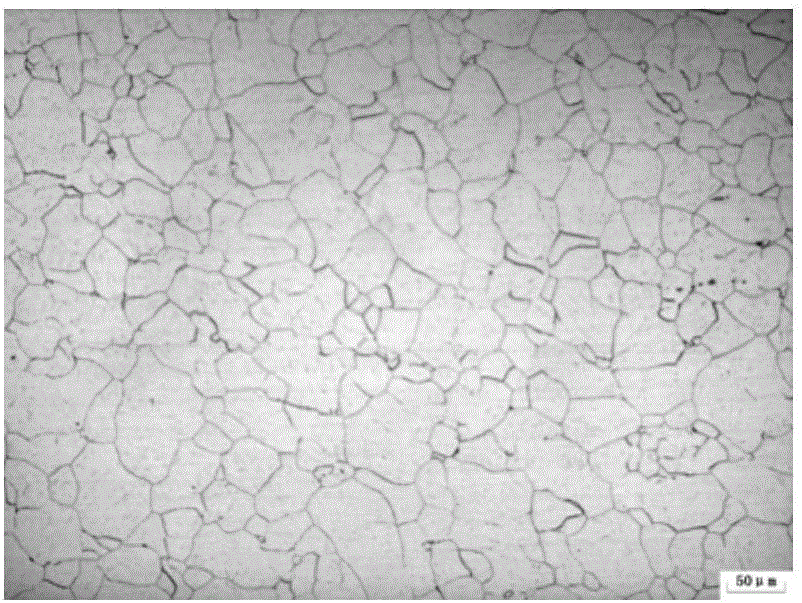

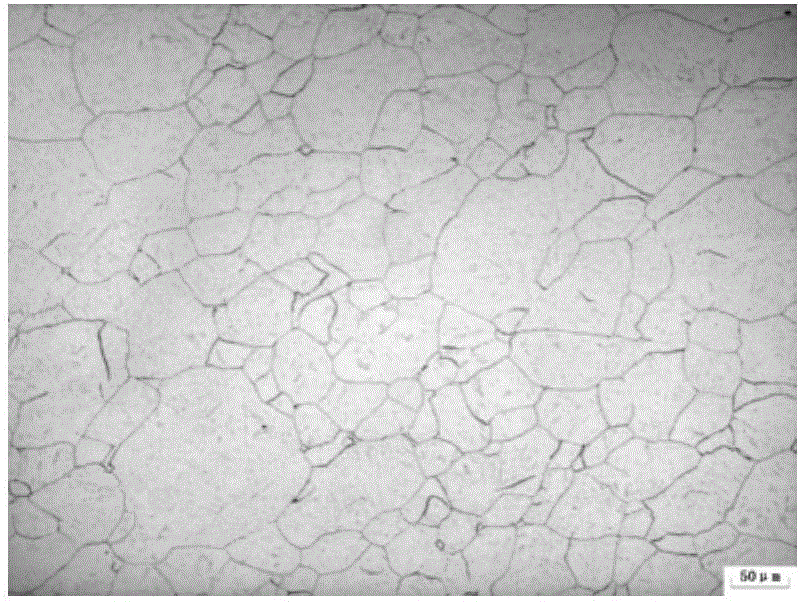

Martensite heat-resistant steel and grain display method thereof

ActiveCN106756606AGood mechanical propertiesSolve the problem of not easy to corrodePreparing sample for investigationParticle size analysisChemical compositionMetallic materials

The invention relates to martensite heat-resistant steel and a grain display method thereof and belongs to the field of metal material micro-technology. The steel comprises the chemical components, by weight, of 0.05%-0.15% of C, 0.7% or the less of Si, 0.8% or the less of Mn, 0.020% or the less of P, 0.020% or the less of S, 13.0%-15.0% of Cr, 4.0%-4.5% of Ni, 2.0%-2.5% of Mo, 3.0%-4.0% of W, 0.15%-0.35% of Nb, 0.30%-0.35% of N and the balance Fe and inevitable impurities. A cylindrical specimen with phi being 15 mm x15 mm is cut on a quenched workpiece. The specimen is put into a heat treating furnace at the temperature of 700-720 DEG C to be heated for 30-40 minutes, and then put into water to be cooled. A grain size specimen is polished on metallographical sand paper with the meshes being 200, 500, 800 and 1000 separately and buffed on a metallographical buffing machine. The surface of the specimen is observed, after the surface of the specimen is free from scratches visible to naked eyes and defects, corrosion is conducted. The martensite heat-resistant steel and the grain display method thereof have the advantages that the problem that when the grain size of the martensite heat-resistant steel is detected, grain boundaries do not occur can be solved, corrosion liquid does not needed to be heated at the time of corrosion, the operation is easy and the method is easy to master.

Owner:CENT IRON & STEEL RES INST

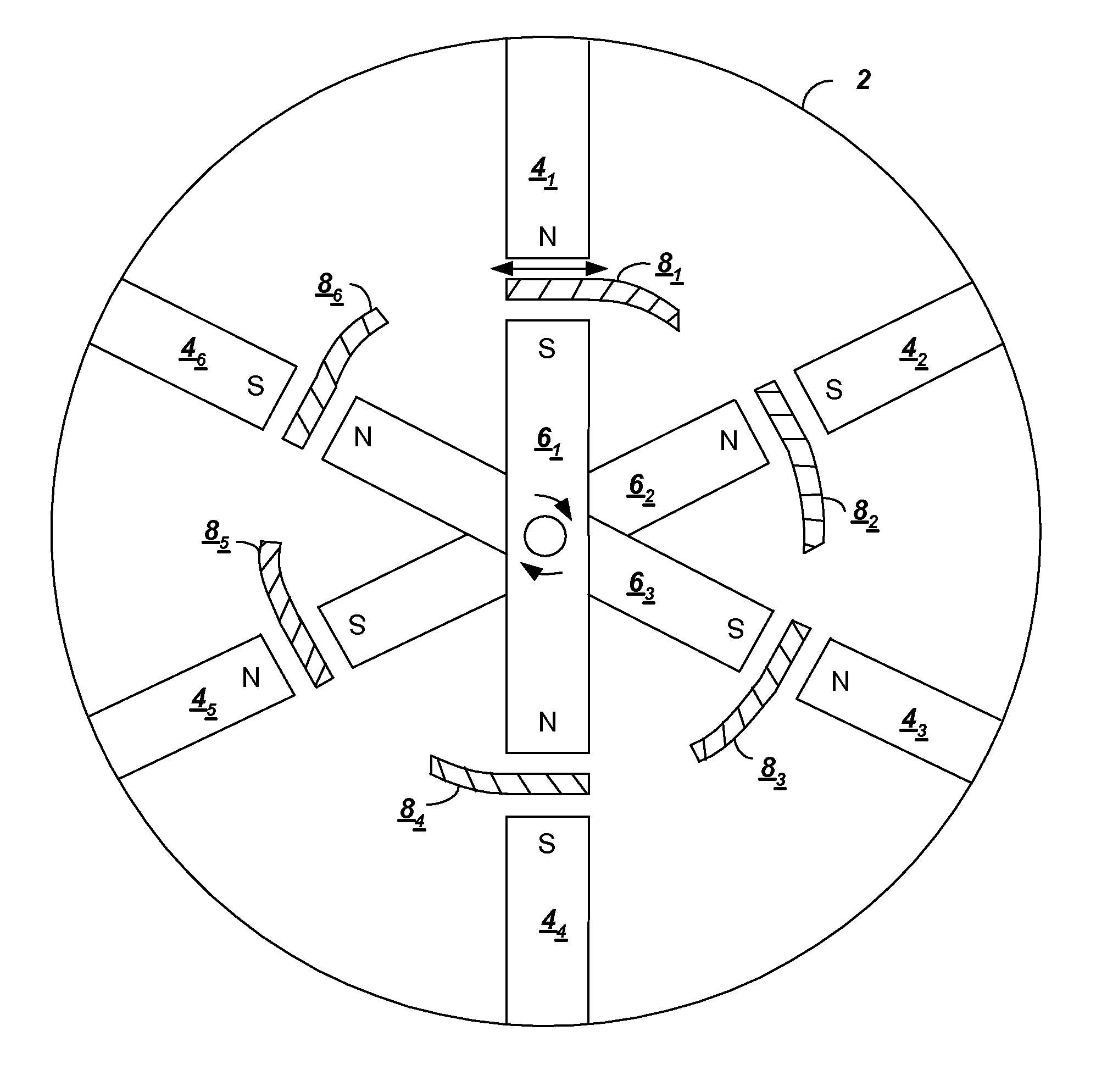

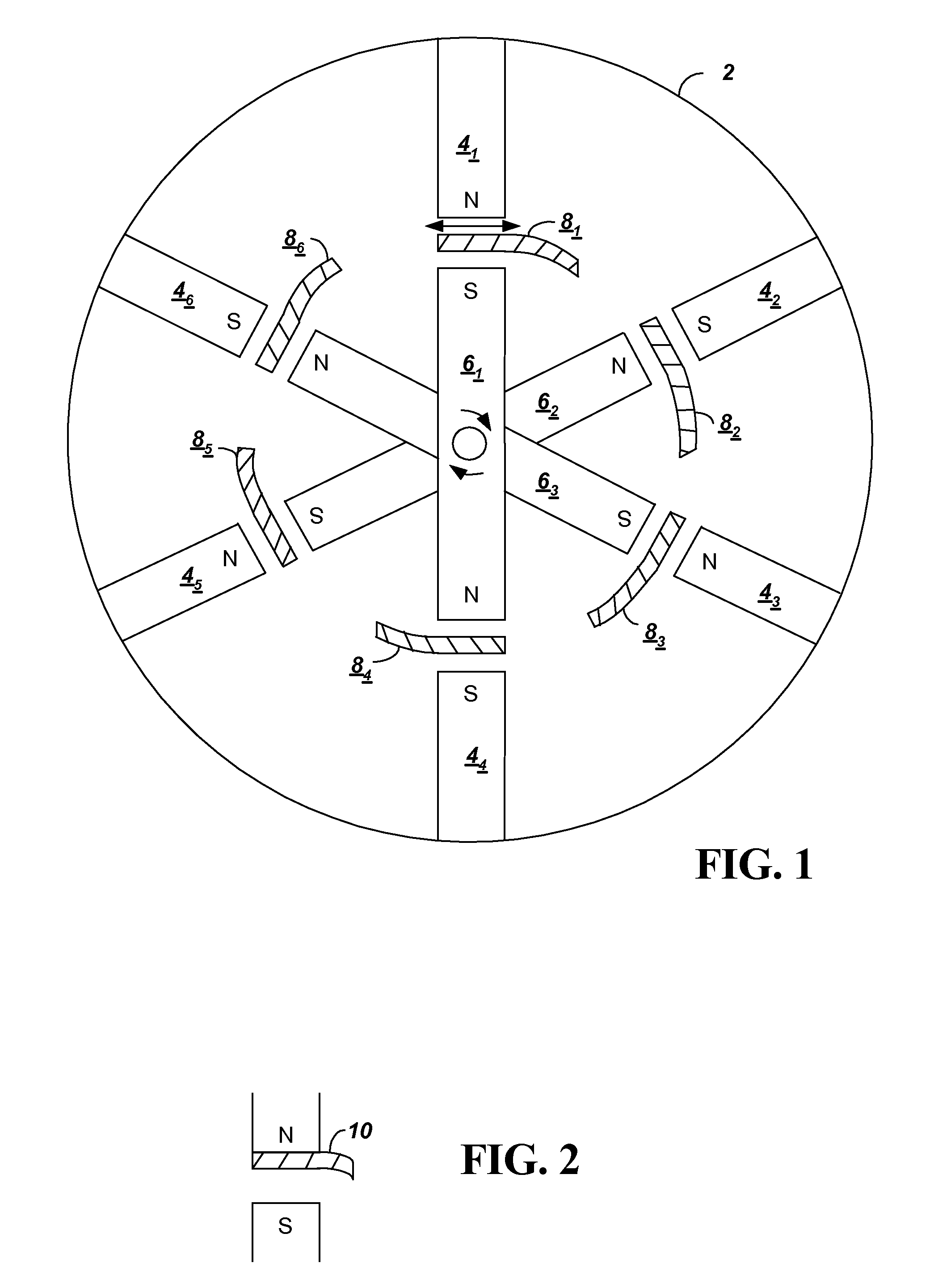

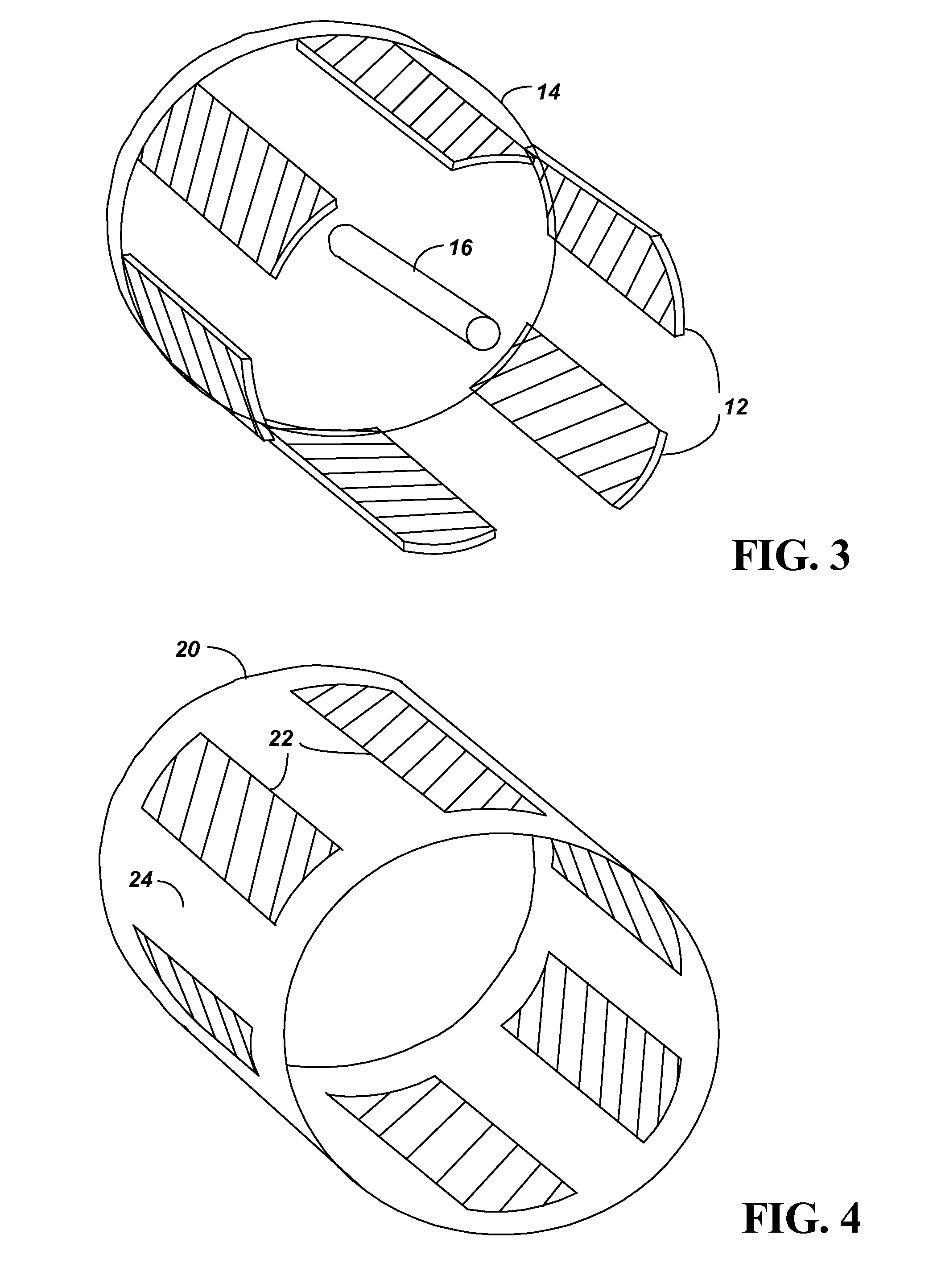

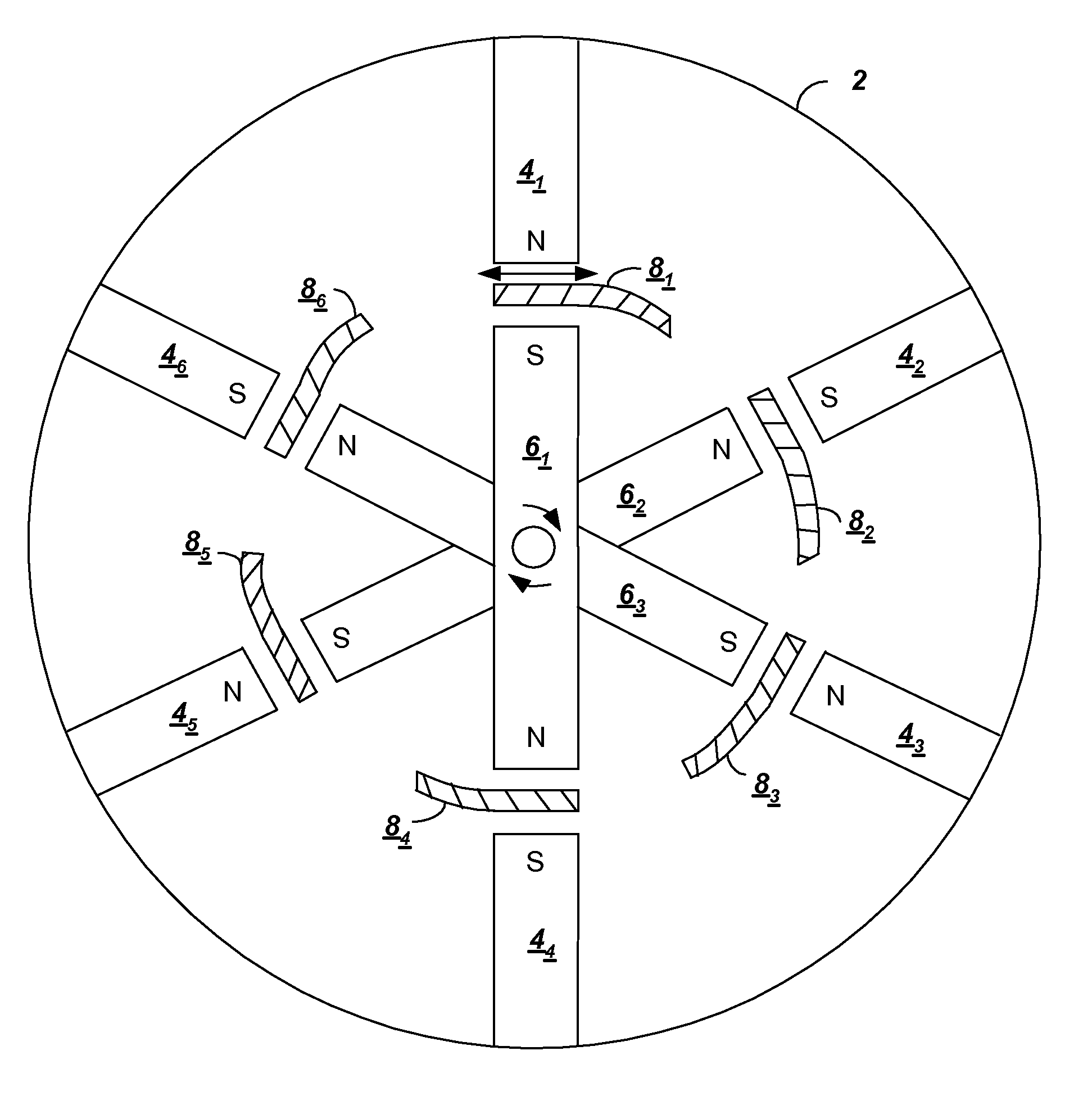

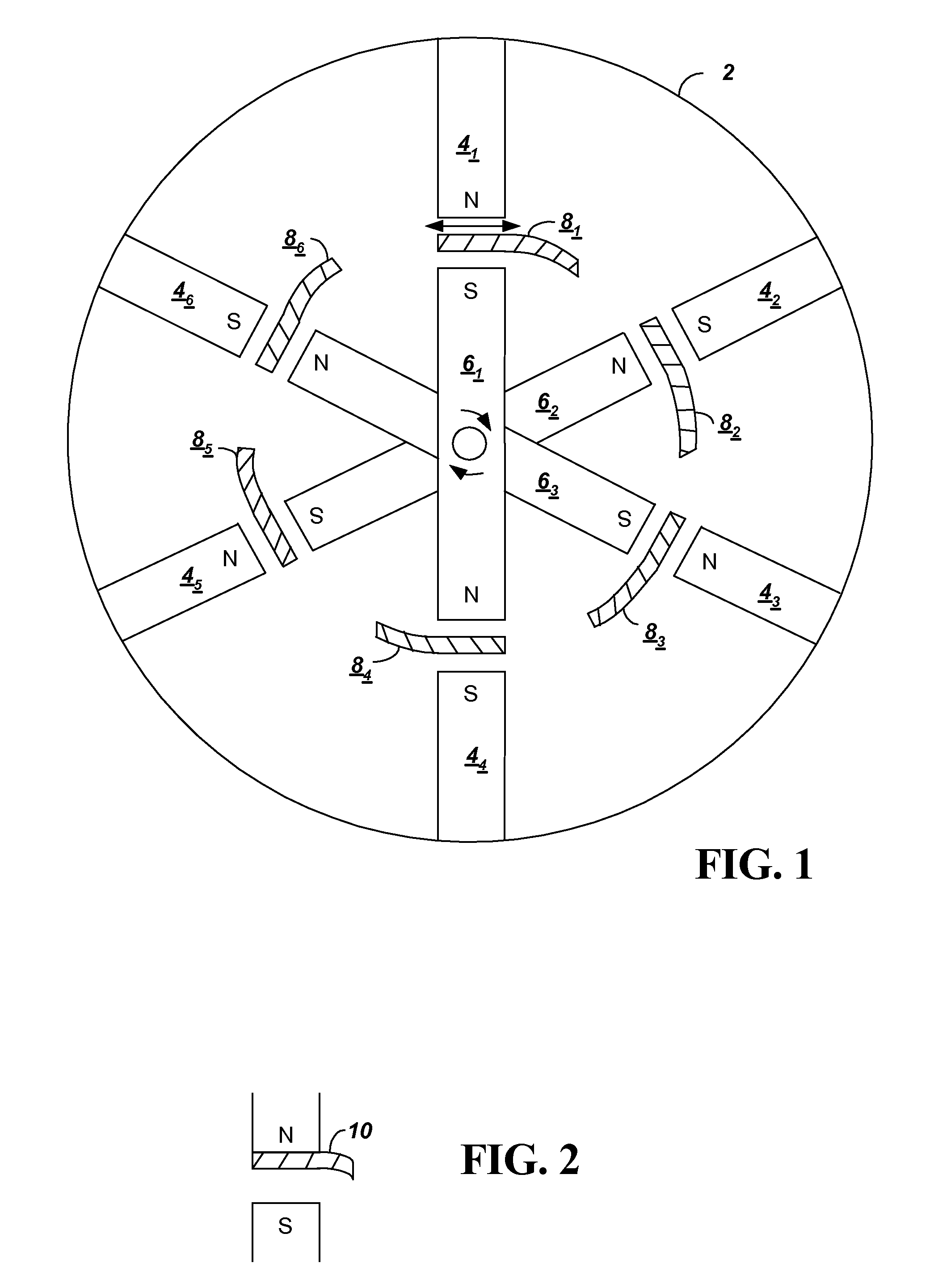

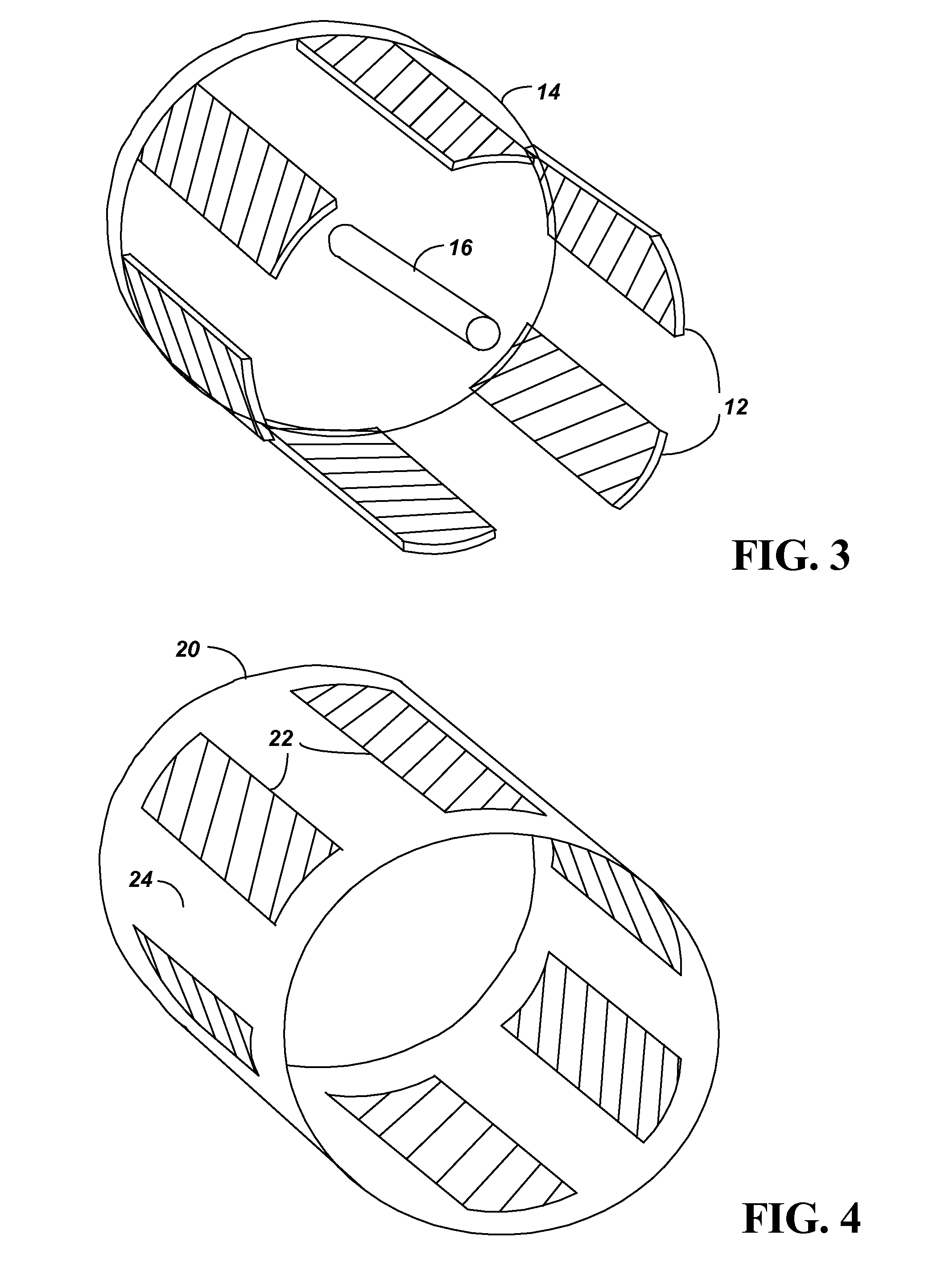

Mass magnifier using magnetic fields and mu-metal to provide an energy storage flywheel for use in conventional, microtechnology, and nanotechnology engines

A mass magnifier is created by combining the properties of permanent magnets or electromagnets with the property of mu-metal to create a novel energy storage device. In a system mu-metal is placed in the magnetic field created by a magnet or electromagnetic in a manner to provide an energy storage device, similar to a fly wheel. The system includes a set of magnets arranged in a circle around a cylinder in a stationary position, effectively forming a stator. Another set of opposing magnets are arranged to form a rotor. When the rotor is rotated, mu-metal material is inserted between the rotor and stator magnets in a manner so that the rotor will remain in motion in a desired rotation direction, even if an opposing force is applied to the rotor axle. The system, thus, forms an energy storage device similar to a fly wheel. The system can also provide energy storage for conventional machines or for smaller micro-technology or nano-technology type devices.

Owner:BRIDGEWAY RES

Microscopical hyperspectral chromatography three-dimensional imaging device

InactiveCN102661919AHas the effectInformativeScattering properties measurementsTransmissivity measurementsEcological environmentBeam splitting

The invention discloses a microscopical hyperspectral chromatography three-dimensional imaging device, which comprises a light source unit, a three-dimensional scanning platform, a front microscopical light path unit, a beam-splitting imaging unit, a signal pretreatment unit, a signal acquisition unit and a control unit. The device integrates a hyperspectral imaging technology, a microtechnique, a fluorescence molecular tomography and a three-dimensional imaging technology. The device can obtain the two-dimensional hyperspectral chromatography images under conditions of multiple wavelengths and angles of an object and can obtain the light spectrum under wavelength corresponding to each pixel; meanwhile, based on a three-dimensional image reconstruction technology, the device can obtain the three-dimensional microscopical hyperspectral image of the object; and combining with the microtechnique, the device can obtain the micro three-dimensional hyperspectral chromatography images of the surface and internal structures of micro objects. Compared with other spectrographs, the device has the advantages of more information, higher precision, more powerful functions and higher stability. The device is suitable for biomedical test, food safety test and ecological environment monitoring.

Owner:JIANGXI SCI & TECH NORMAL UNIV

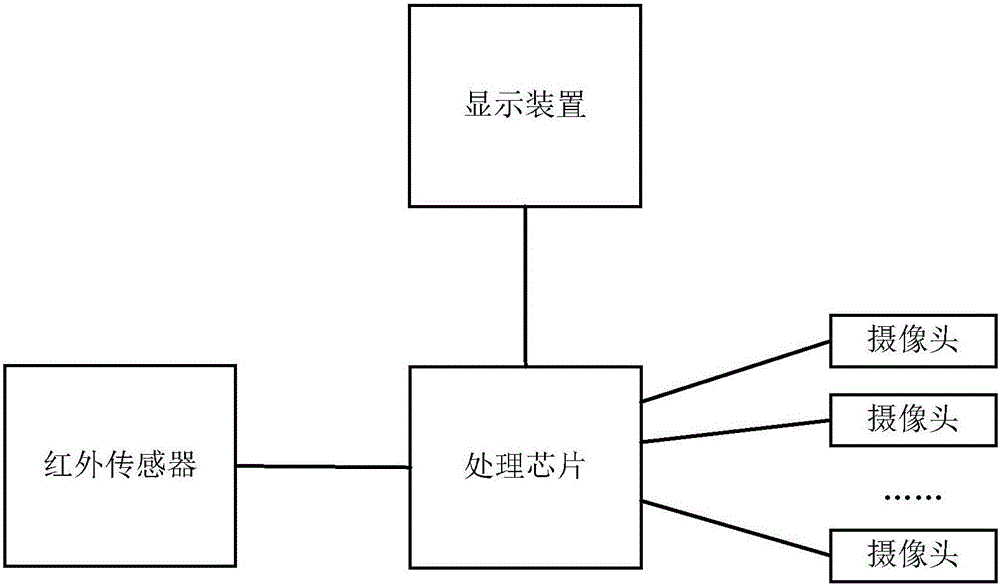

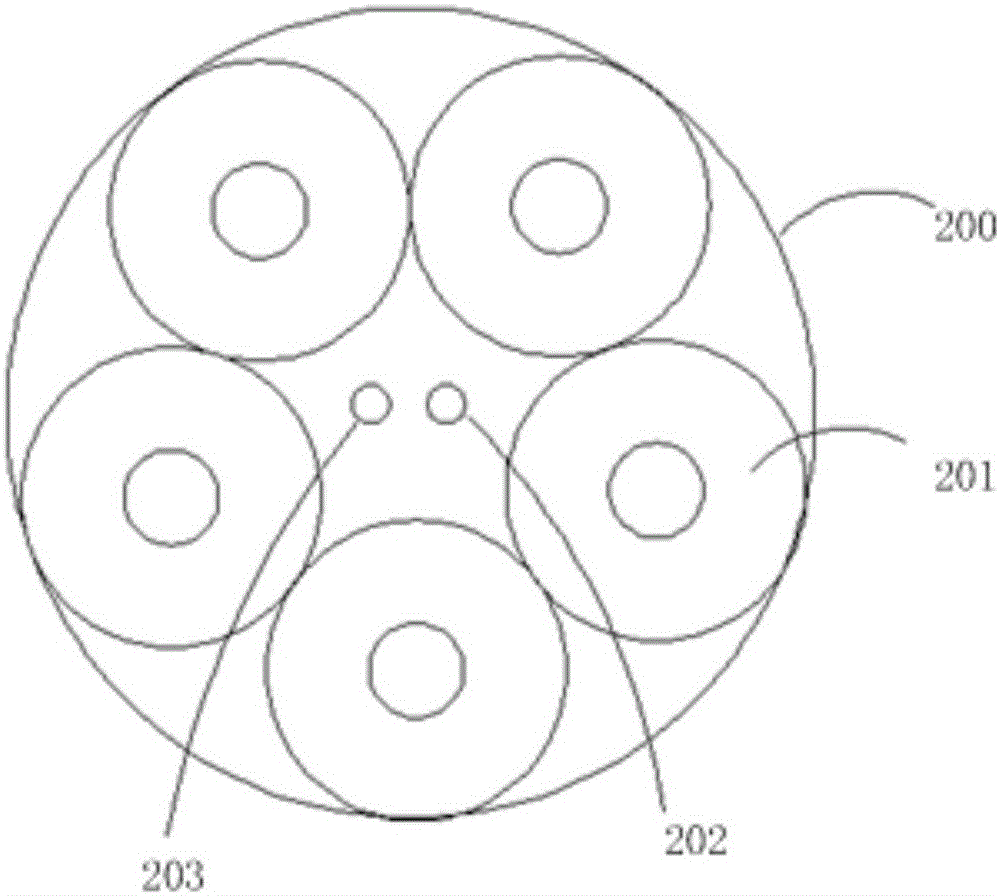

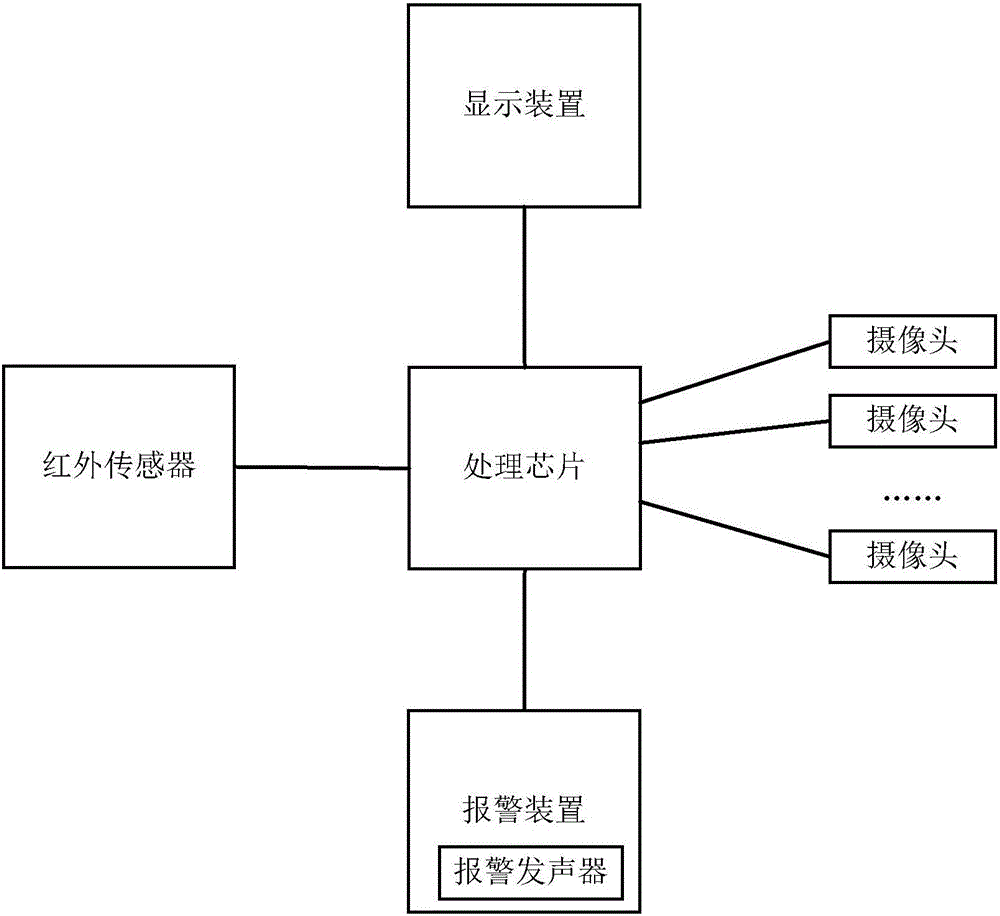

Vehicle bottom region monitoring device and method

InactiveCN105667401AHigh sensitivityEasy to viewAcoustic signal devicesClosed circuit television systemsSmall animalFresnel lens

The invention relates to the technical field of vehicle active safety and discloses a vehicle bottom region monitoring device and method. The vehicle bottom region monitoring device comprises an infrared sensor, a Fresnel lens, N cameras, a processing chip and a display device. The Fresnel lens is located in front of the infrared sensor. The infrared sensor, the cameras and the display device are in communication connection with the processing chip. The processing chip is used for triggering the cameras when the infrared sensor detects that the temperature of a vehicle bottom changes and transmitting vehicle bottom region information collected by the cameras to the display device. N is a natural number. The sensitivity of the monitoring device is improved. Abnormal conditions of a complicated condition region at the vehicle bottom are acquired accurately in time by detecting the micro technology changes of the vehicle bottom region so as to protect small animals hiding under vehicles against injuries.

Owner:EQUES TECH

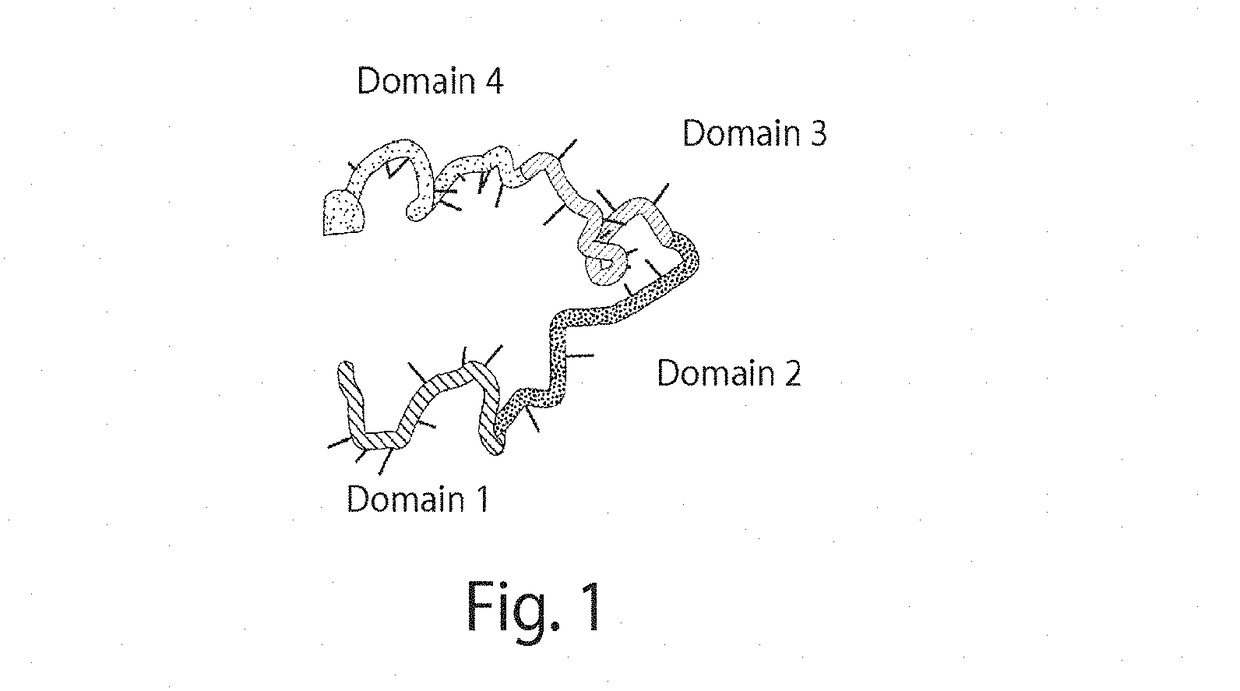

Compositions and methods relating to nucleic acid nano- and micro-technology

ActiveUS9796749B2Sugar derivativesMicrobiological testing/measurementNucleic acid structureSynthesis methods

The invention provides nucleic acid structures of controlled size and shape, comprised of a plurality of oligonucleotides, and methods for their synthesis. The structures are formed, at least in part, by the self-assembly of single stranded oligonucleotides. The location of each oligonucleotide in the resultant structure is known. Accordingly, the structures may be modified with specificity.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Mass magnifier using magnetic fields and mu-metal to provide an energy storage flywheel for use in conventional, microtechnology, and nanotechnology engines

A mass magnifier is created by combining the properties of permanent magnets or electromagnets with the property of mu-metal to create a novel energy storage device. In a system mu-metal is placed in the magnetic field created by a magnet or electromagnetic in a manner to provide an energy storage device, similar to a fly wheel. The system includes a set of magnets arranged in a circle around a cylinder in a stationary position, effectively forming a stator. Another set of opposing magnets are arranged to form a rotor. When the rotor is rotated, mu-metal material is inserted between the rotor and stator magnets in a manner so that the rotor will remain in motion in a desired rotation direction, even if an opposing force is applied to the rotor axle. The system, thus, forms an energy storage device similar to a fly wheel. The system can also provide energy storage for conventional machines or for smaller micro-technology or nano-technology type devices.

Owner:BRIDGEWAY RES

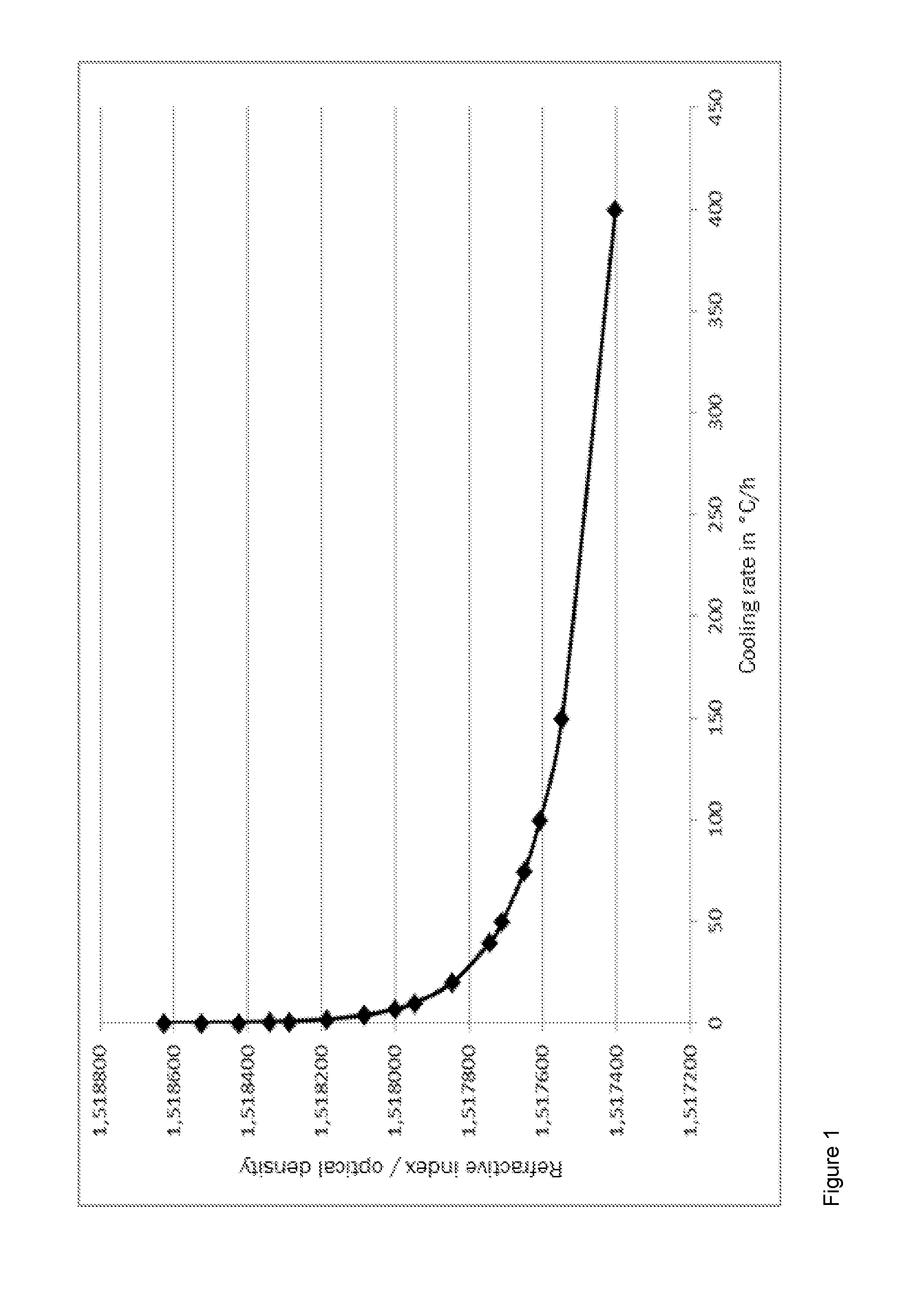

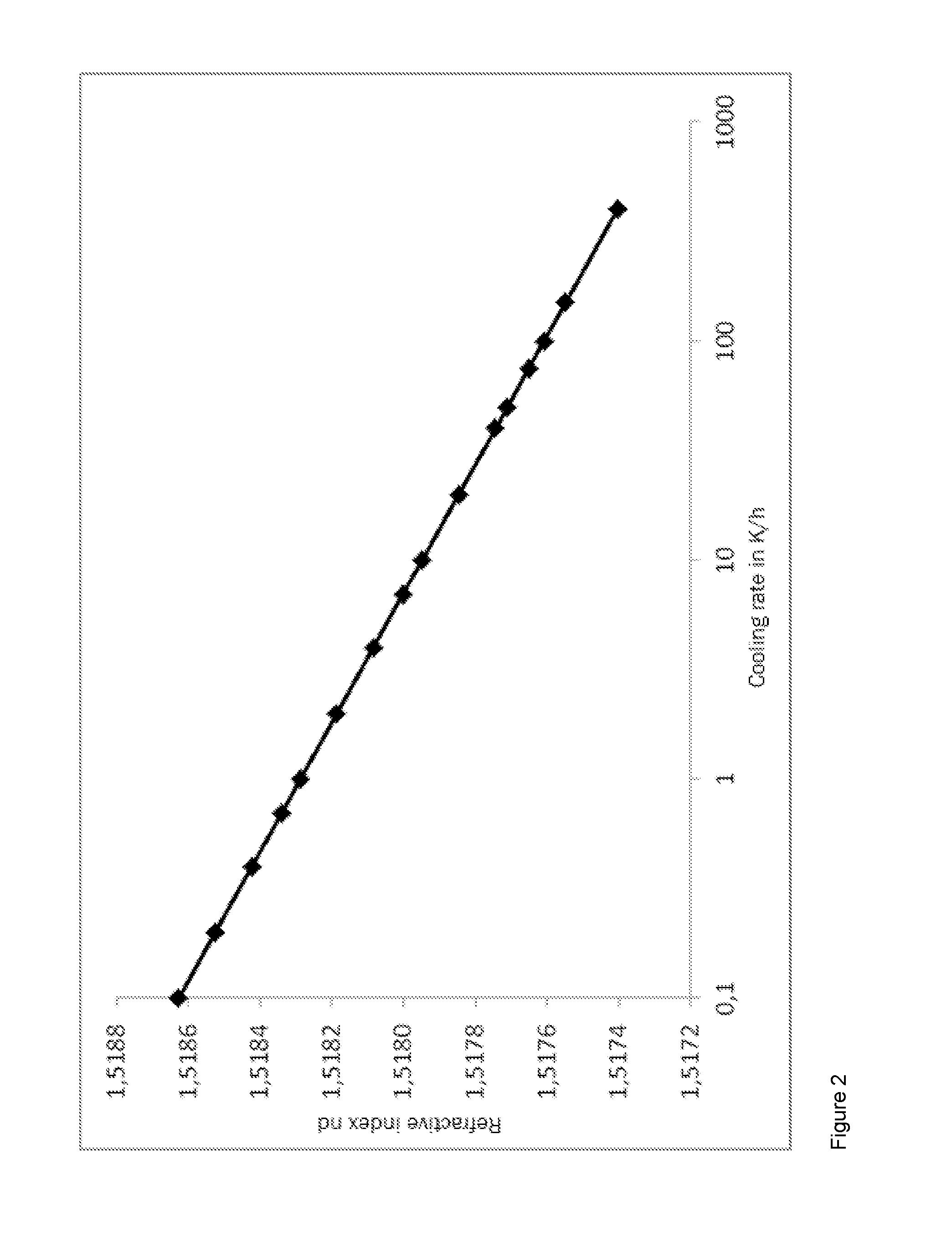

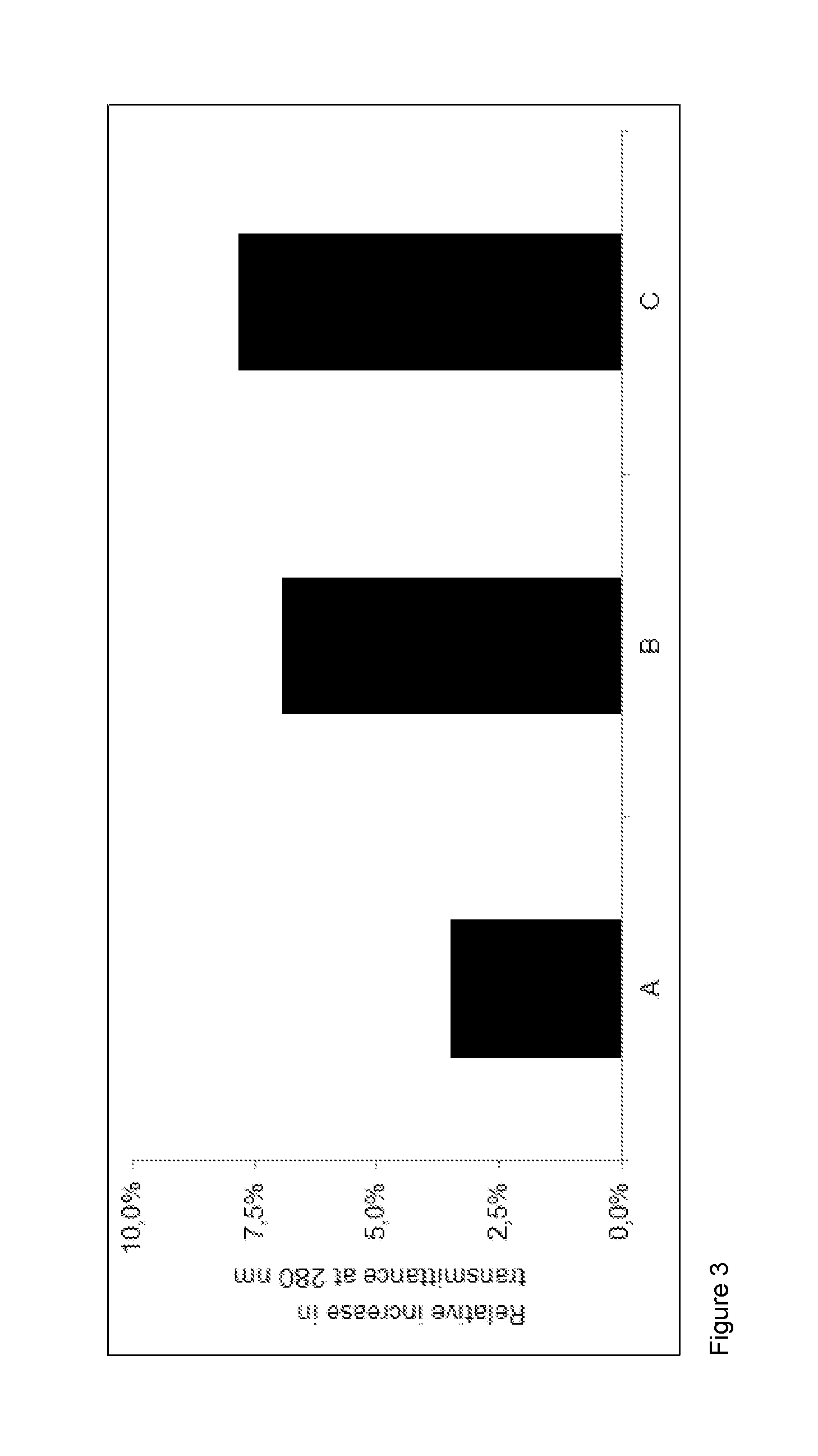

Sensitized, photo-sensitive glass and its production

ActiveUS9914660B2Improve homogeneityGlass transportation apparatusGlass forming apparatusBiotechnologyUltraviolet

Owner:SCHOTT AG

Spin polarized channel atomic force microtechnic

InactiveCN1560594AImprove resolutionHigh resolutionSurface/boundary effectScanning probe microscopyArm surfaceSpin polarized tunneling

The invention is an automatic rotating polarization tunnel atom force micro technology, which belongs to ultrahigh resolution magnetism sensitive imaging technology field. It uses conductive elastic micro suspending arm with magnetic pin, one end of the suspending arm is connected to the control system, another end is the magnetic pin, the control system controls the probe to approach the sample, the pin atom and the sample surface atom generate the atom force to bend the suspending arm, the laser radiates on the suspending arm surface and then reflected to the detector, and it is feed back to the control system, the three-dimension image of the sample surface can be acquired through recording the position coordinate x, y, and z of the probe in scanning process. A constant polarization is added on the sample, measures the current change in the total tunnel, records the plane position coordinate (x, y) and the correspondent total tunnel current value, and acquires the sample magnetism sensitivity information imaging.

Owner:SHANDONG UNIV

Process for fabricating amorphous hydrogenated silicon carbide films provided with through-pores and films thus obtained

The invention relates to a process for fabricating a hydrogenated amorphous silicon carbide film having through-pores, which comprises:a) the formation on a substrate of a film consisting of an amorphous hydrogenated silicon carbide matrix in which silicon oxide through-nanowires are dispersed; and thenb) the selective destruction by a chemical agent of the silicon oxide nanowires present in the film formed at step a).Applications: microelectronics and micro-technology, in all fabrication processes that involve the degradation of a sacrificial material by diffusion of a chemical agent through a film permeable to this agent for the production of air gaps, in particular the fabrication of air-gap interconnects for integrated circuits.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Quasi-molecule laser electrochemical microstructure manufacturing method and equipment

InactiveCN1547079AEliminate damageAspect ratio heightPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrochemical responseShielding gas

The invention belongs to micro manufacturing field, pointing to the deficiency of traditional method, the quasimolecule laser, integrated circuit producing and etching, electric chemical and scanning probe micro technology are integrated together into a new process method. The steps are: (1) produces micro probe array at first; (2) the base is fixed between the plane electrode and the micro probe array, generates the negative voltage, pours in the protection gas; (3) adds in voltage between the two polars after pouring the electrolyte liquid, at the same time, the quasimolecule laser are poured in to control the electrochemical reaction, completes the process. the correspondent device sets an electrochemical reaction room on the laser microprocess machine platform, it includes a laser air moving window, an inlet of protection air, a vacuum pump interface, an electrolyte liquid inlet, a microprobe array, a plane electrode, an assistant electrochemical reaction air inlet and the waste outlet. The invention can acquires microstructure with width-depth ratio 5-50, the character size 1-50 micro meter on the semiconductor base.

Owner:HUAZHONG UNIV OF SCI & TECH

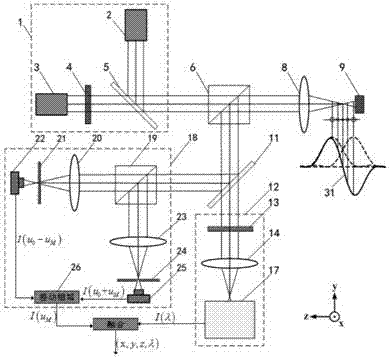

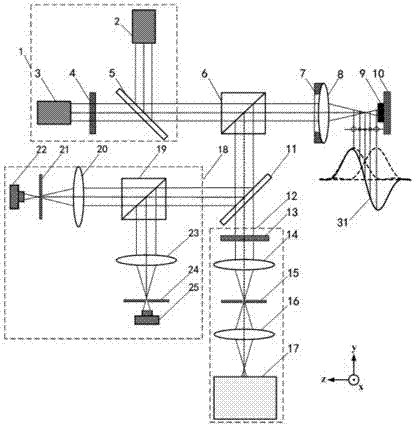

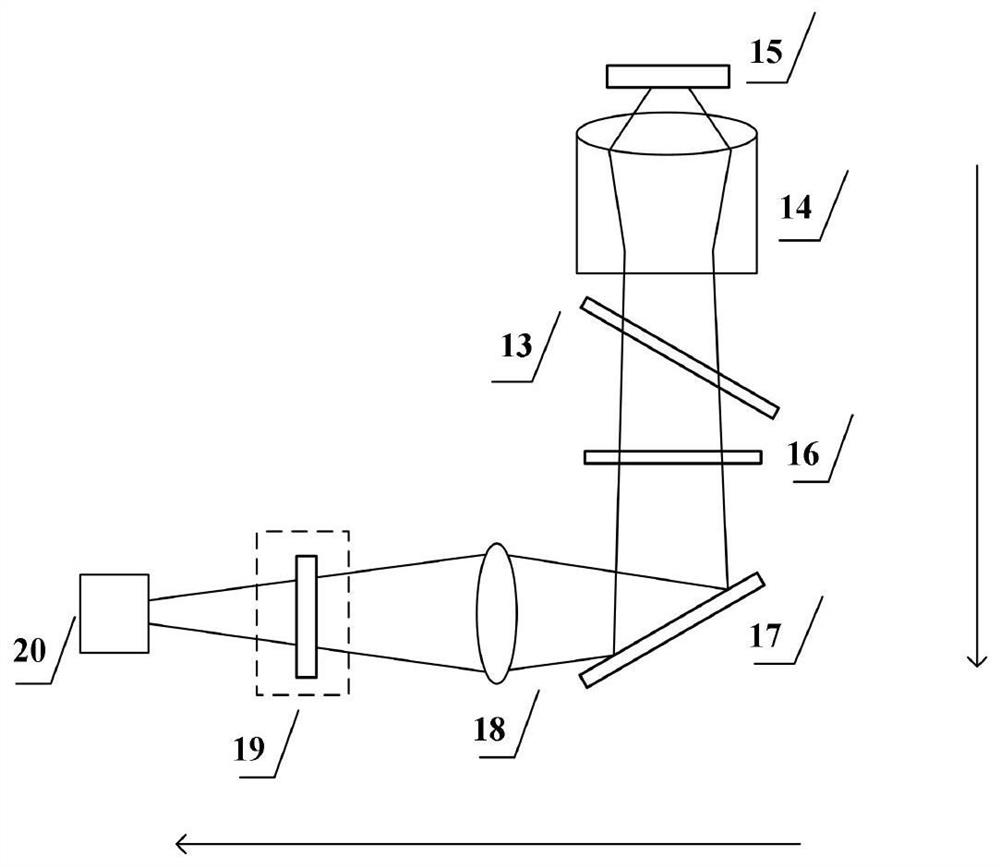

Reflective differential and confocal CARS micro-spectrum testing method and device

PendingCN107037031ARealize image-spectrum integration imagingImplement detectionRaman scatteringHigh spatial resolutionBeam splitting

The invention belongs to the technical field of micro-spectrum imaging detection and relates to a reflective differential and confocal CARS micro-spectrum testing method and device. The core thought of the invention is that dual laser devices serve as light sources to excite Rayleigh light and CARS light having spectral characteristics of a tested sample, a dichroic beam splitting system is utilized to conduct nondestructive separation on the Rayleigh light and the CARS light, geometrical detection and positioning are conducted on the Rayleigh light, and spectral detection is conducted on the CARS light. The characteristic that a differential and confocal curve zero crossing point accurately corresponds to a focal position is utilized to form the method and device capable of achieving high-spatial-resolution spectrum detection of in a sample micro-area. By combining with a CARS microtechnique, the time for exciting Raman scattering light carrying sample information is shorter than that for a traditional Raman effect, and nondestructive sample detection can be rapidly performed. The method and device have the advantages of being accurate in positioning, high in spatial resolution, capable of achieving nondestructive detection, high in spectrum detection detectivity and the like, and a new way is provided for micro-area spectrum detection and geometrical measurement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

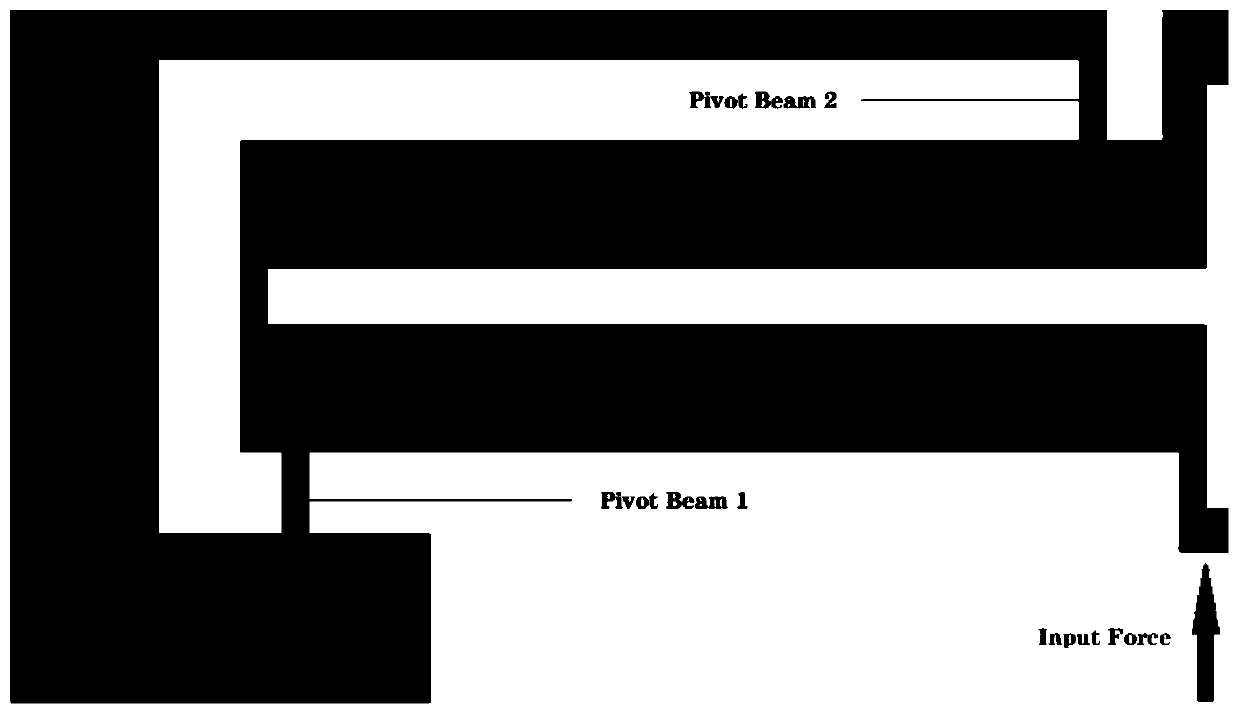

Probe type high-accuracy force sensor based on quartz resonator

InactiveCN110017921AHigh sensitivitySimple structureForce measurement by measuring frquency variationsProbe typeAdhesive

The invention discloses a probe type high-accuracy force sensor based on a quartz resonator. The force sensor comprises a probe, wherein the probe is connected with the input end of a second-order enlargement beam; the second-order enlargement beam is connected with a silicon substrate frame through four supporting point beams; the output end of the second-order enlargement beam is fixedly connected with one end of a quartz tuning fork beam by organic adhesive; the quartz tuning fork beam is positioned in the hollow rectangle of the silicon substrate frame; the other end of the quartz tuning fork beam is fixed on the silicon substrate frame through organic adhesive; the silicon substrate frame is sputtered with a metal electrode; and the metal electrode and the electrode of the quartz tuning fork beam are connected by a gold wire. When a force function is in the presence in a probe sensitivity direction, force amplified by the second-order enlargement beam acts on the quartz tuning fork beam, and the quartz tuning fork beam causes that resonant frequency changes under the function of axial force. The vibrated quartz tuning fork beam is connected into a detection circuit to detect frequency change so as to realize force measurement. Through a way of combining a silicon micro-technology and a quartz processing technology, the force sensor has the advantages of simple structure, frequency output, small volume and high accuracy.

Owner:XI AN JIAOTONG UNIV

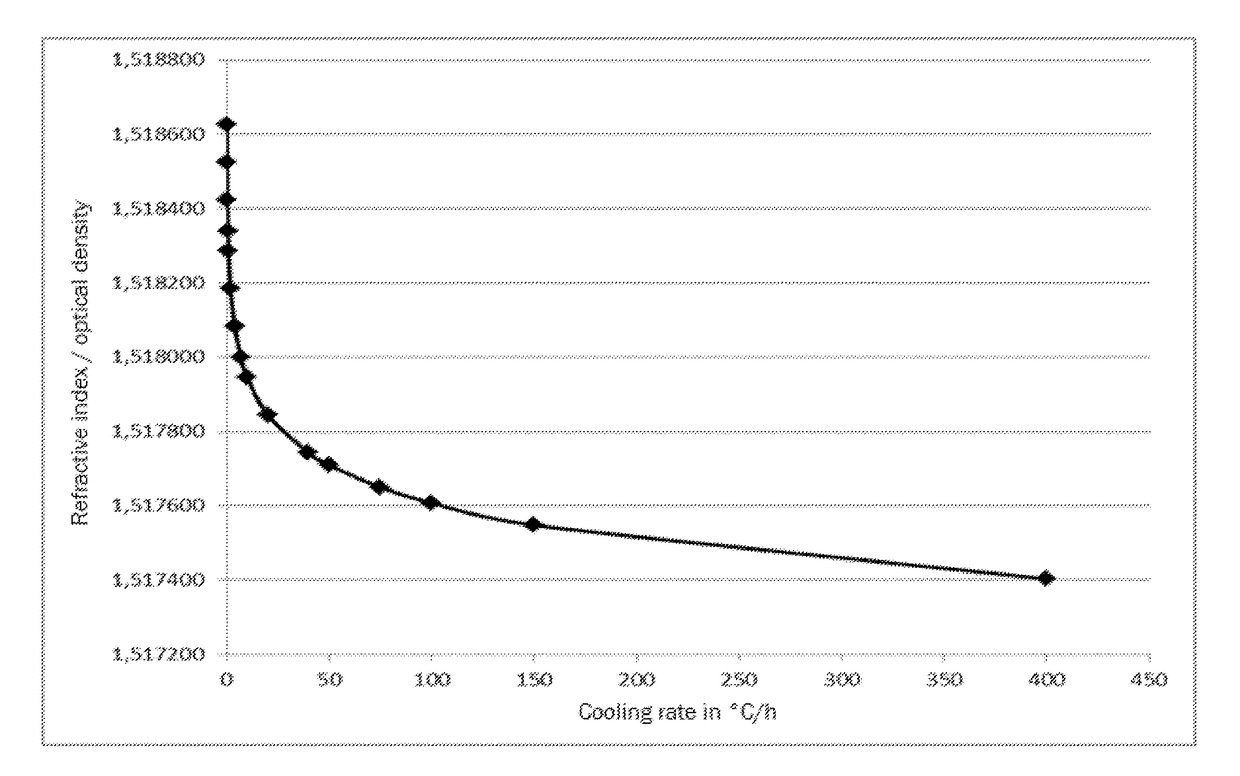

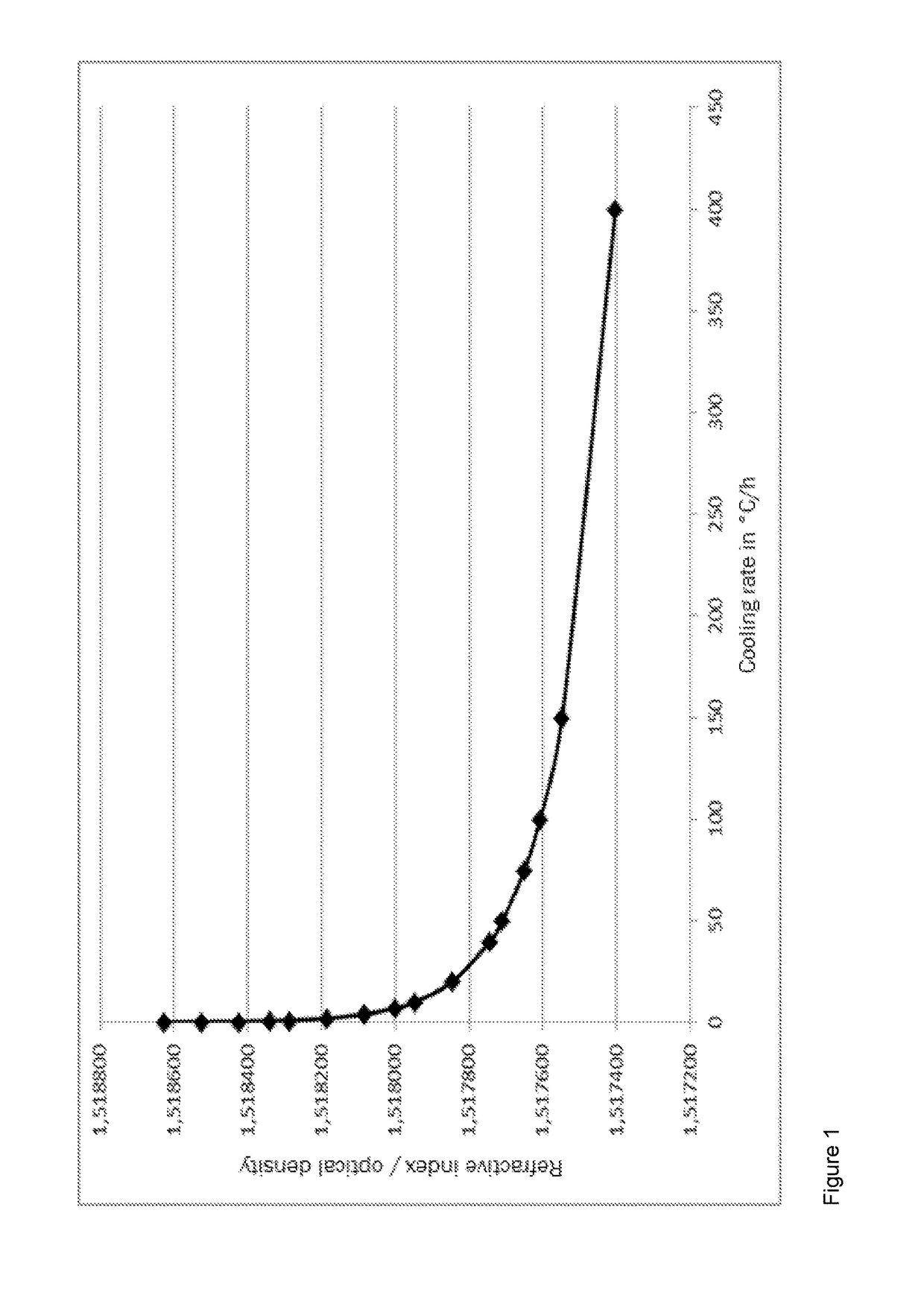

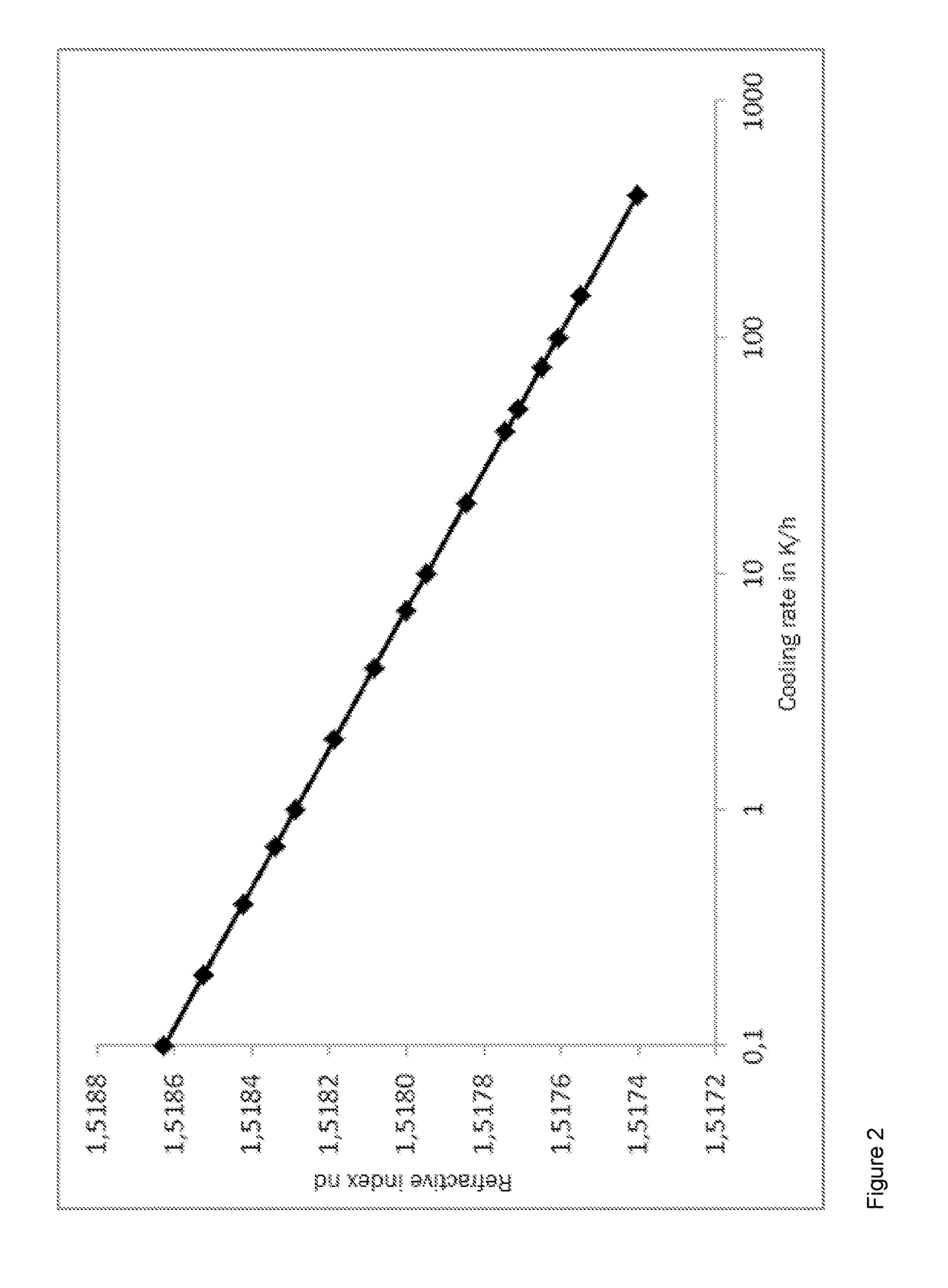

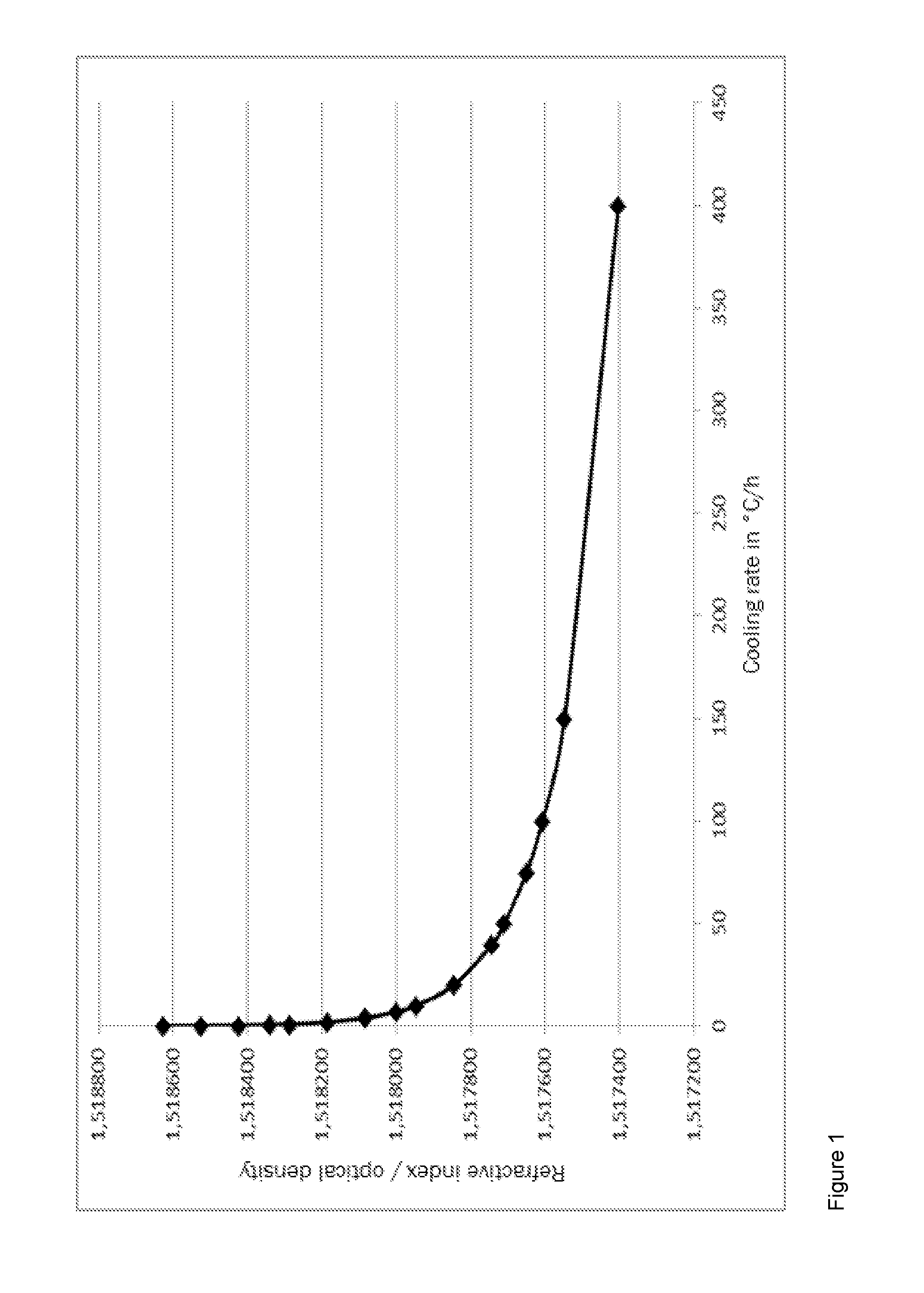

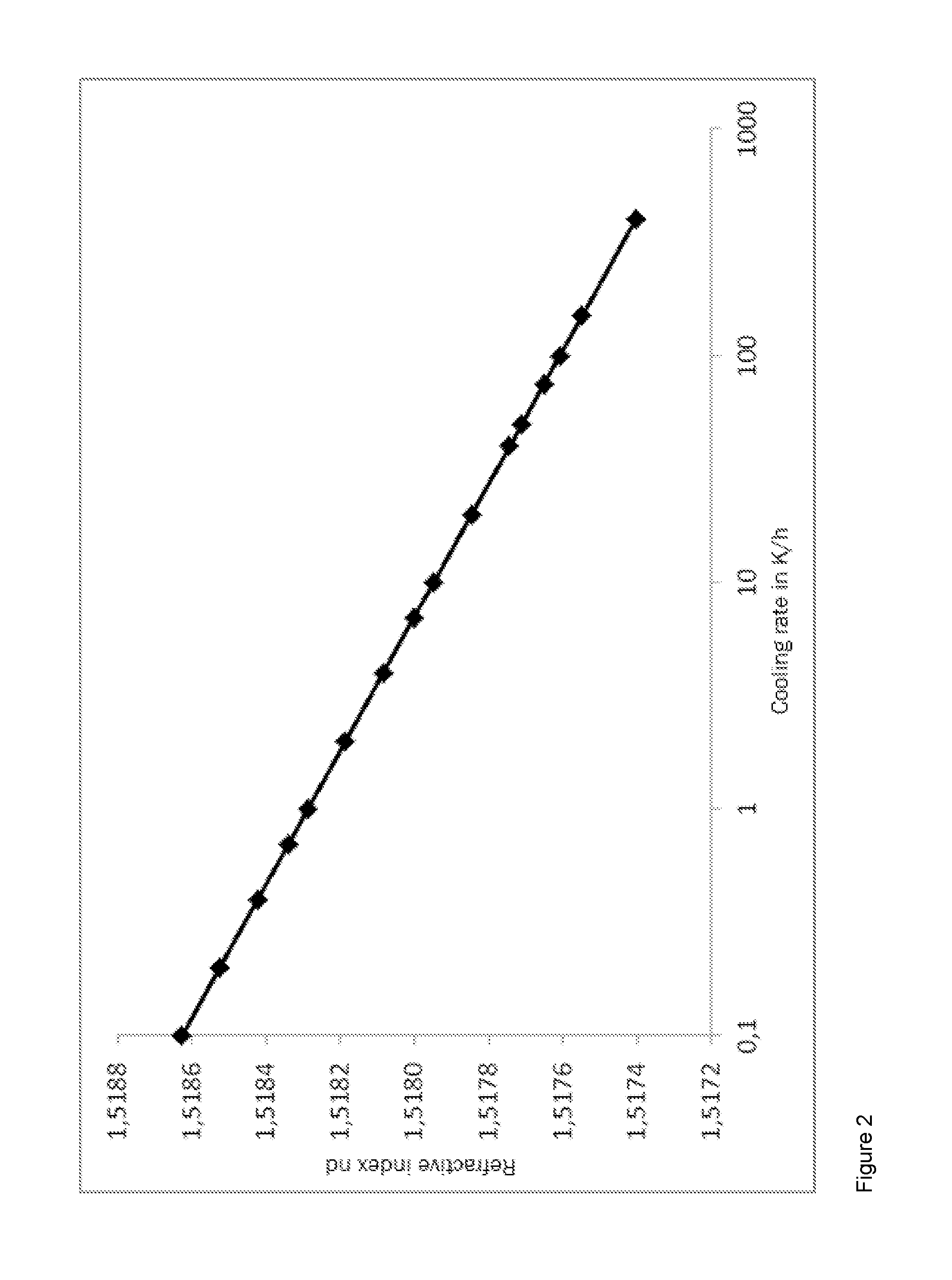

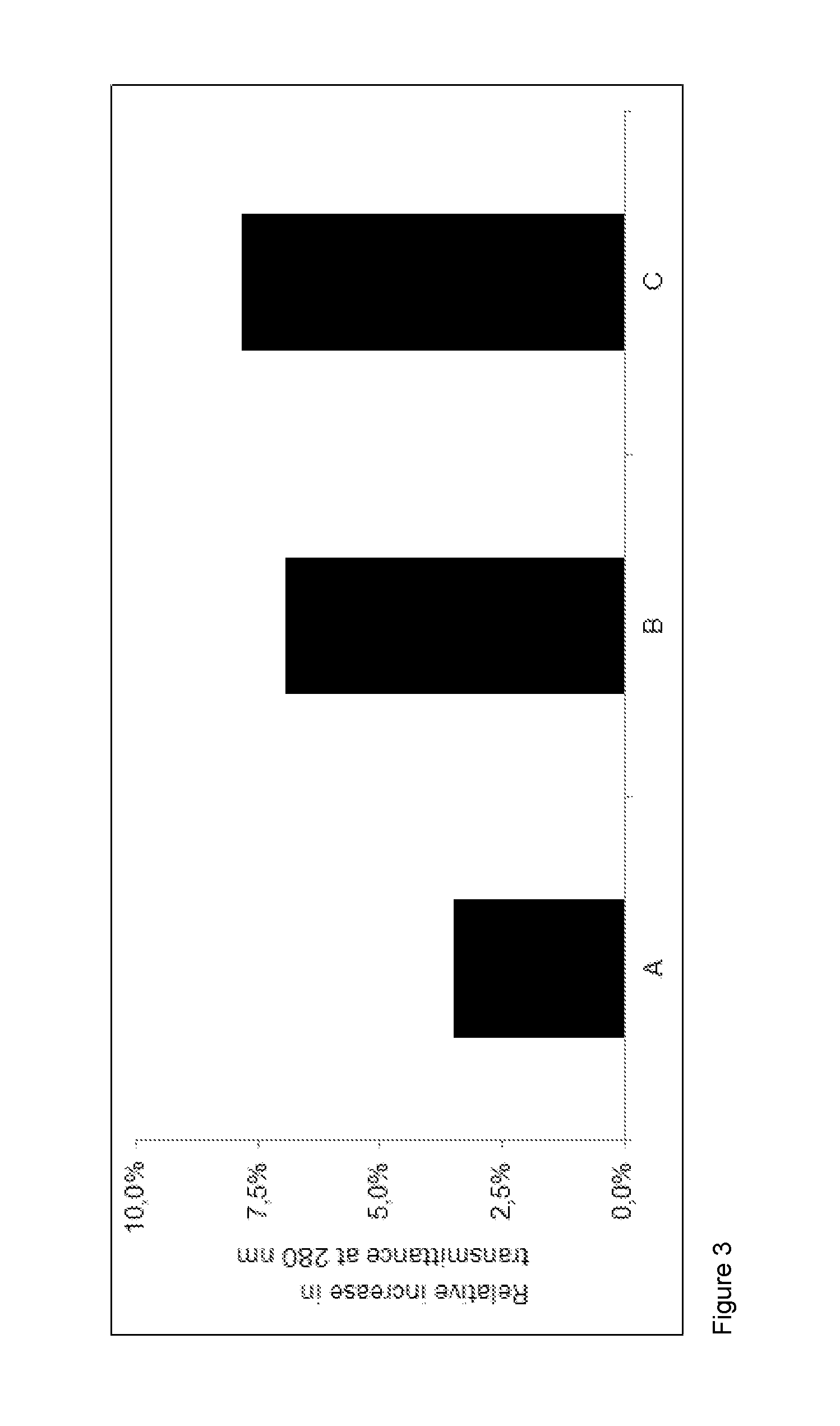

Sensitized, photo-sensitive glass and its production

ActiveUS20160340228A1Improve homogeneityGlass transportation apparatusGlass forming apparatusBiotechnologyUltraviolet

A sensitized, photo-structurable glasses and methods for producing are provided. The glasses includes Si4+, one or more crystal-agonist, one or more crystal-antagonist, and one or more pair of nucleating agents. The glasses are sensitized in that the glass reacts more sensitive to irradiation with UV-light and can be crystallized easier and with higher aspect ratios than a non-sensitized glass with equal composition. Furthermore, the sensitized glasses of this invention have smaller crystal sizes after irradiation and tempering than a non-sensitized glass with equal composition. The invention also relates to a structured glass product. Such product can be obtained by submitting the crystallized glass product to a subsequent etching step. The structured product can be used in components or as component for the application fields micro-technology, micro-reaction-technology, electronic packaging, micro-fluidics, FED spacer, bio-technology, interposer, and / or three-dimensional structured antennae.

Owner:SCHOTT AG

Continuous production of photo-sensitive glass bodies

A method for continuous production of photo-sensitive glass bodies, glass bodies, and structured glass articles are provided. The method comprises steps of a. providing a mixture, b,melting the mixture, c transferring a melted body to a mold, d suppressing the glass in the mold into a glass body, wherein the melted body has temperature higher than 1000 DEG in the mold where the melted body is transferred, wherein the glass bodies include glass having temperature higher than 1000 DEG, the melted body is cooled down in the mold in such mode from 990 DEG to 600 DEG in less than 15 minutes. The glass includes Si4+, at least one crystal-agonist, at least one crystal-antagonist, and at least one pair of nucleating agents. The glass may be used in a method for structuring of glass. The glass bodies may be structured and / or unstructured and used in different applications such as in components or as components in micro-technology, in micro-reaction-technology, in electronic packaging, for micro-fluidic components, in or as FED spacer, for bio-technology (for example titer plates), as interposer, and in or as three-dimensional structure antennae.

Owner:SCHOTT AG +1

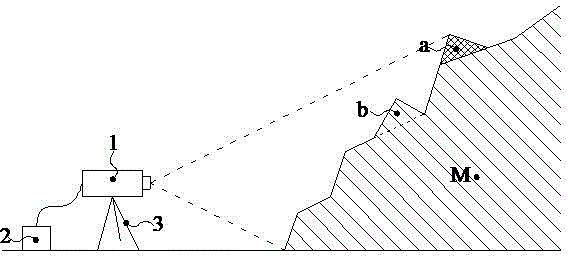

Constant micro technology-based holding rockfall investigation method

InactiveCN104698085AAccurately measure tiny vibrationsSimplify detection stepsAnalysing solids using sonic/ultrasonic/infrasonic wavesBaseline dataVibration measurement

The invention discloses a constant micro technology-based holding rockfall investigation method. The constant micro technology-based holding rockfall investigation method is used for evaluating the stability of a rock body by detecting the constant micro property of the rock body, and comprises the following steps: (1) setting a micro signal detection processing system comprising a scan laser vibration measurement instrument, a data analysis processor, micro data analysis software and an instrument support; (2) acquiring constant micro data of a rock body in a target region by the scan laser vibration measurement instrument, and establishing a corresponding coordinate system; and (3) comparing micro characteristic parameters of a base rock as benchmark data with micro characteristic parameters of other coordinate point, and estimating the fall danger degree of a rock according to the analyzed result, if the constant micro characteristic parameters of a certain coordinate point are greatly different from the benchmark data, showing that the rock corresponding to the position of the point is not actually connected together with the base rock, and the rock is a dangerous rock. According to the method, the constant micro data of a rock body in the target region can be acquired rapidly by the scan laser vibration measurement instrument, and the holding rockfall can be convenient to investigate on a large scale.

Owner:SHANDONG UNIV OF SCI & TECH

Continuous production of photo-sensitive glass bodies

A method for continuous production of photo-sensitive glass bodies, glass bodies, and structured glass articles are provided. The glass bodies include a glass having Si4+, at least one crystal-agonist, at least one crystal-antagonist, and at least one pair of nucleating agents. The glass may be used in a method for structuring of glass. The glass bodies may be structured and / or unstructured and used in different applications such as in components or as components in micro-technology, in micro-reaction-technology, in electronic packaging, for micro-fluidic components, in or as FED spacer, for bio-technology (for example titer plates), as interposer, and in or as three-dimensional structurable antennae.

Owner:SCHOTT AG

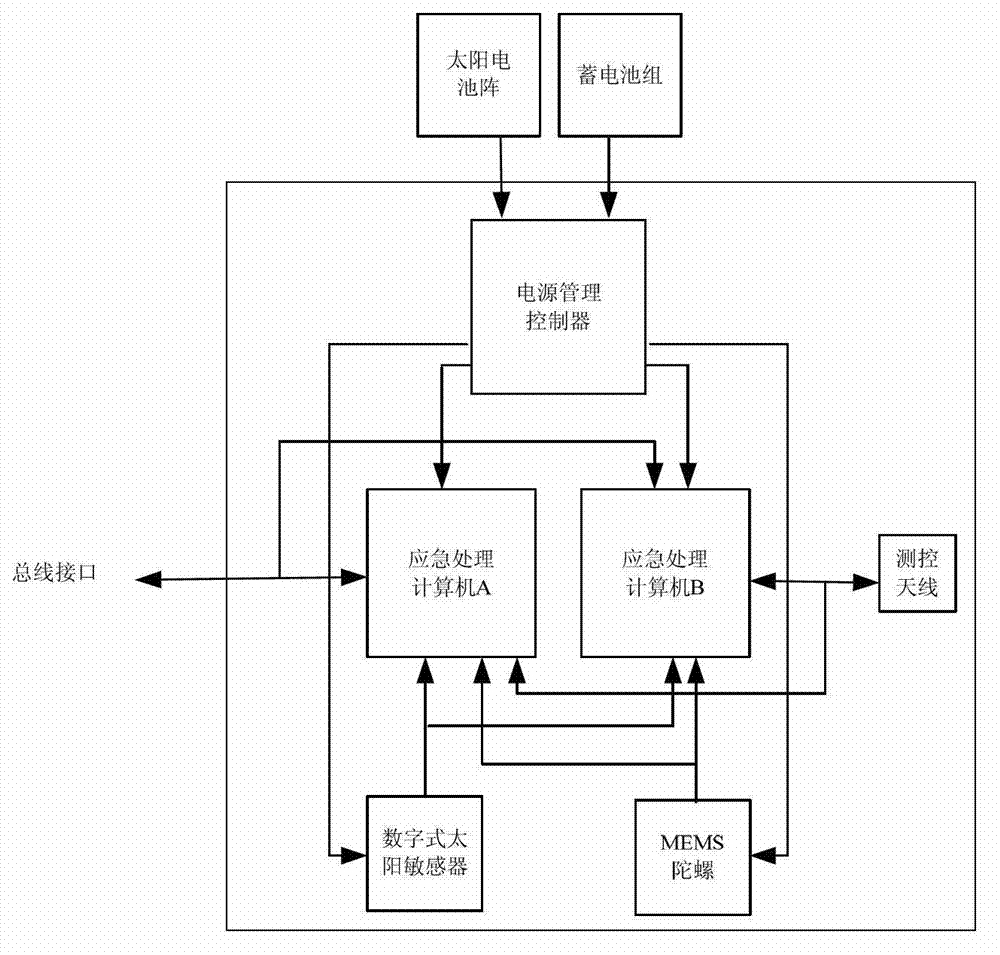

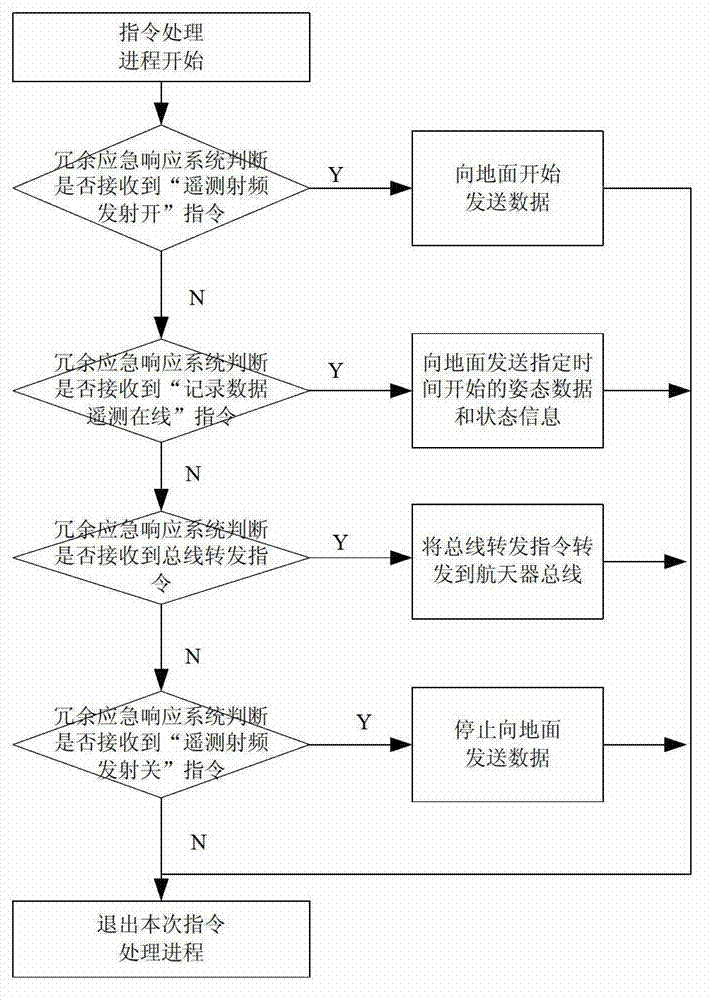

System-level emergency response device of spacecraft

ActiveCN103192998AReduce couplingReduce complexityCosmonautic safety/emergency devicesMicro devicesCoupling

The invention discloses a system-level emergency response device of a spacecraft. Through adoption of a micro technology and micro devices and components, platform design and emergency mechanism design of the spacecraft are coordinated from a top layer of a spacecraft system; main emergency response functions are implemented in an emergency response device; and the platform design only considers the conventional redundancy measures, thereby reducing the coupling degree and the complexity of each spacecraft subsystem due to consideration of emergency design. The emergency response device of the spacecraft achieves an independent power supply function, a spacecraft state monitoring function and a data recording function and is not coupled with an energy subsystem, a measurement and control subsystem, a satellite service subsystem, an attitude and orbit control subsystem and the like of the spacecraft platform; when the subsystems meet emergencies in orbit, the emergency response device of the spacecraft can independently achieve a satellite-ground communication function, a low-precision attitude measurement function and the like, can provide spacecraft state monitoring data and historical spacecraft state data for the ground to eliminate failures; and the emergency response device of the spacecraft is small in volume, low in mass loss (lower than 10kg) and independent and controlled in functions.

Owner:AEROSPACE DONGFANGHONG SATELLITE

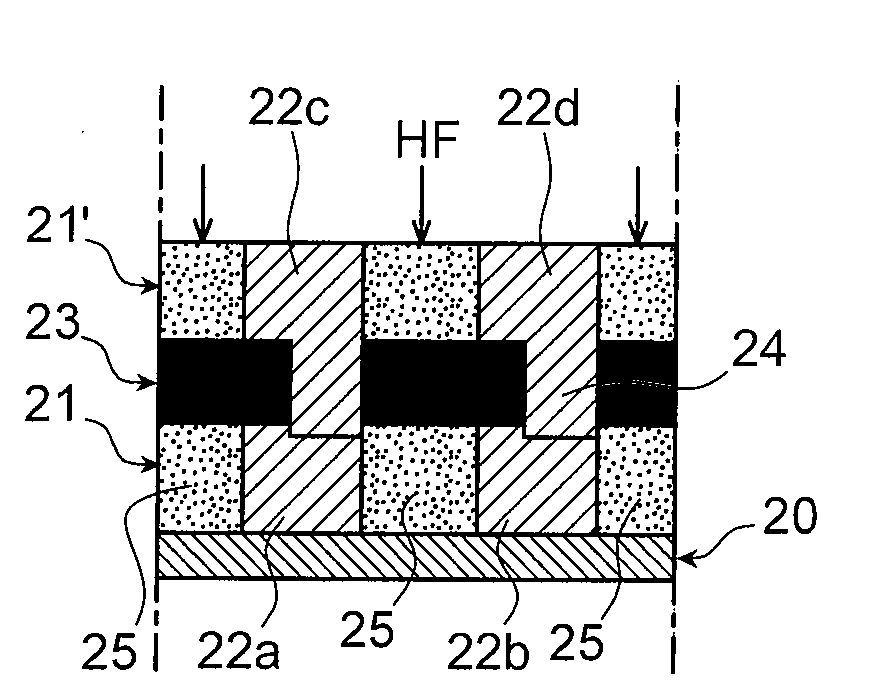

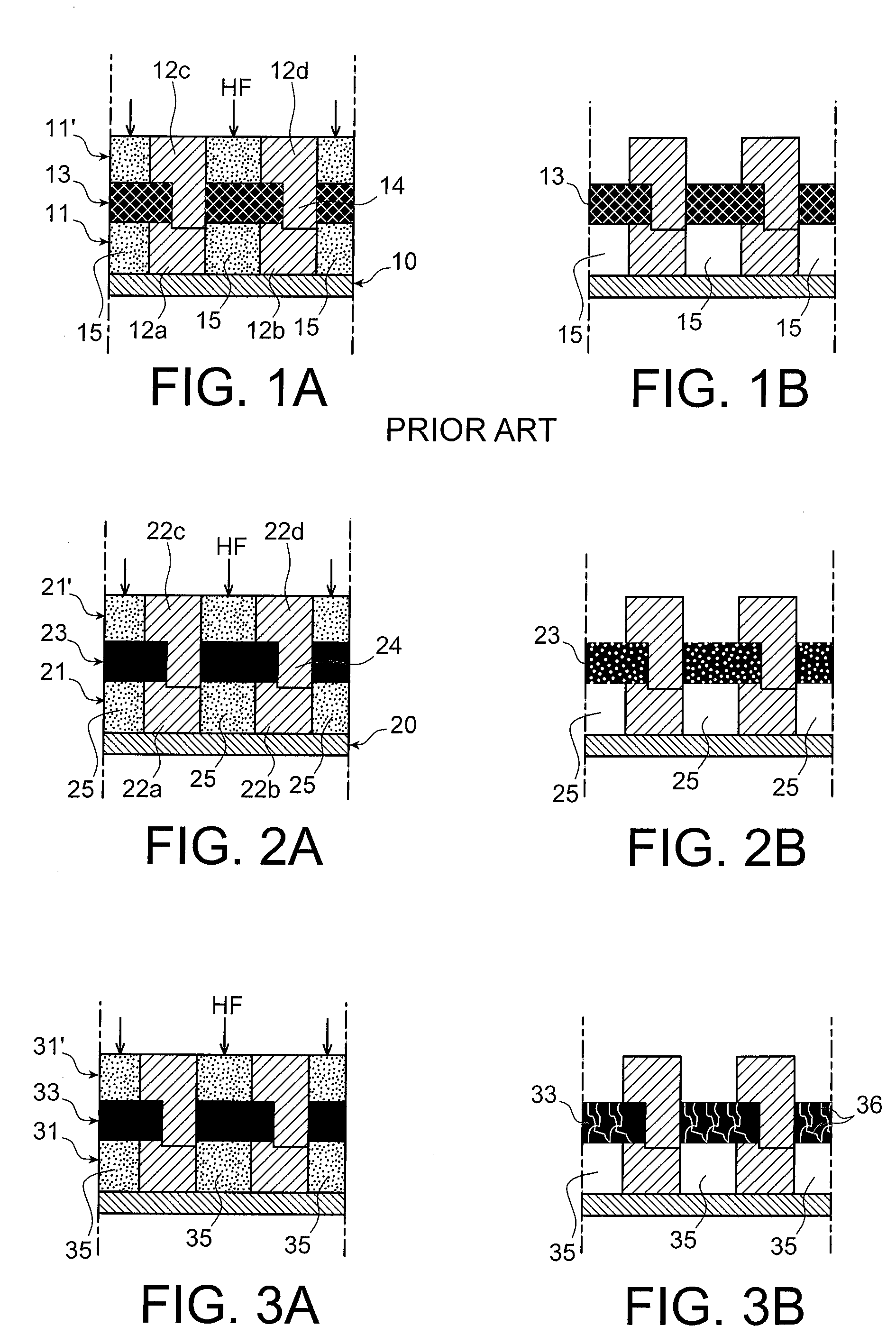

Process for producing air gaps in microstructures

The invention relates to a process for producing at least one air gap in a microstructure, which comprises:a) the supply of a microstructure comprising at least one gap filled with a sacrificial material, this gap being limited over at least part of its surface by an impermeable membrane but which may be rendered permeable by the action of a chemical etchant, this etchant also being capable of degrading the sacrificial material;b) the contacting of the microstructure with said chemical etchant in order to make the membrane permeable and degrade the sacrificial material; andc) the removal of the chemical etchant from the microstructure; and in which the chemical etchant is a fluid containing hydrofluoric acid and / or ammonium fluoride.Applications: Microelectronics and micro-technology.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

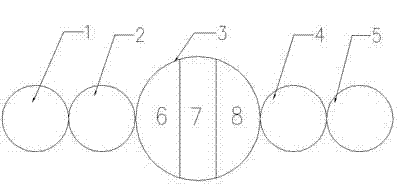

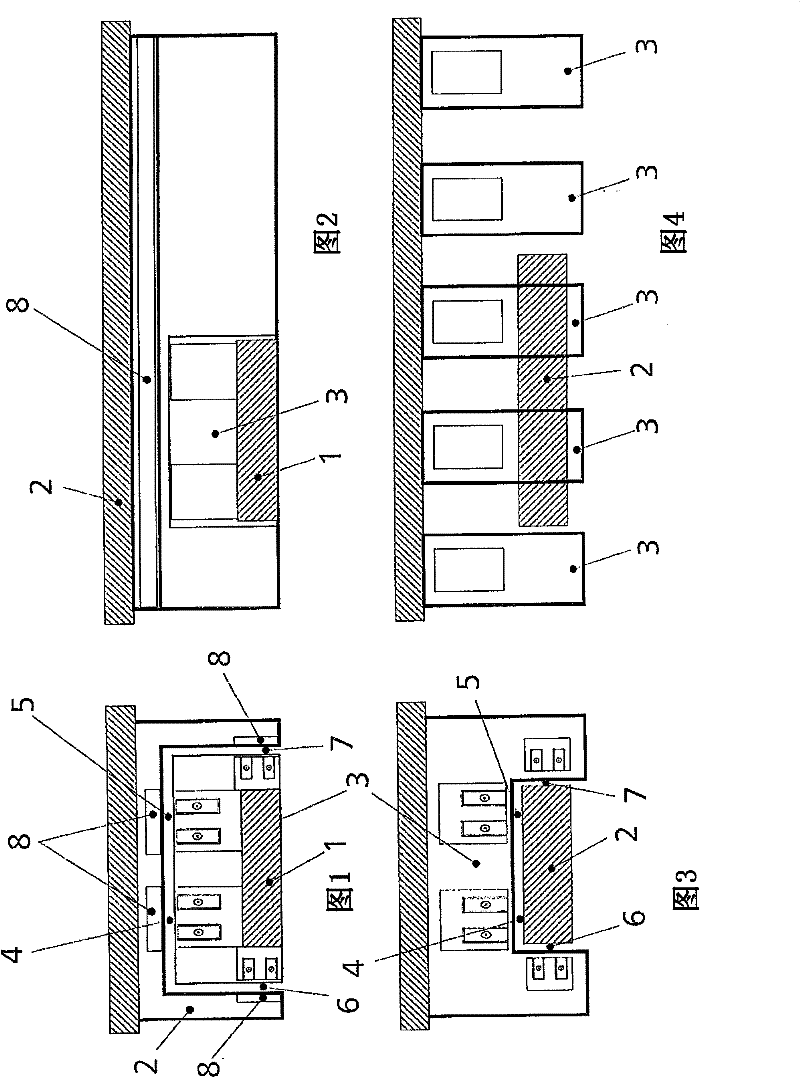

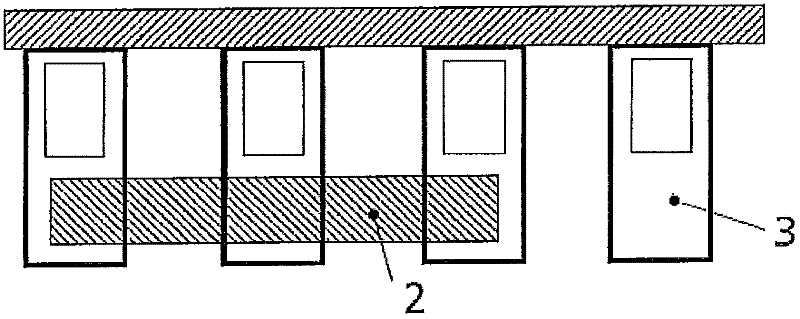

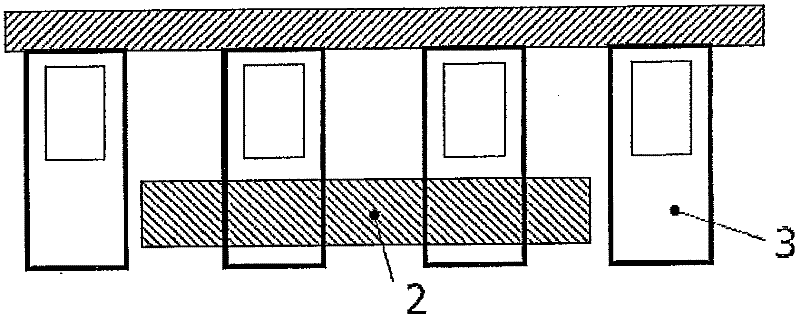

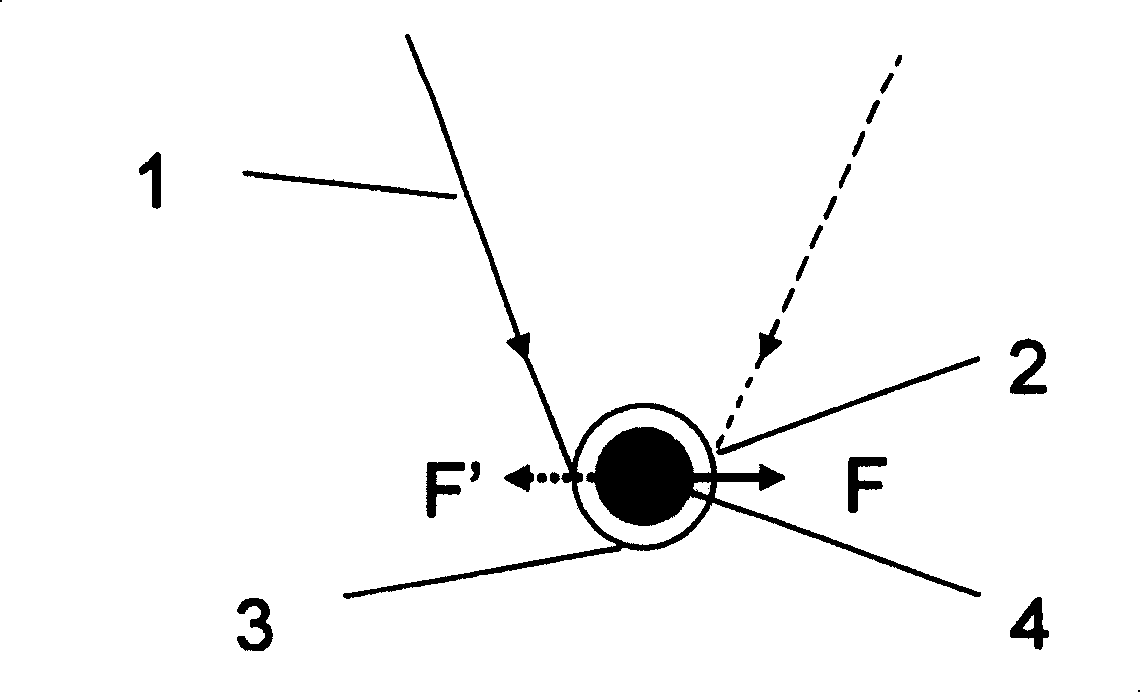

Device for particle free handling of substrates

The invention is concerned with a device for particle free handling of substrates according of micro technology within mini environments under clean room conditions. It is a task of the invention to provide a device for handling of substrates which works friction free and thus particle free. According the invention are designed several degrees of freedom for the device whereby at least the x-, y-, z-axis and a F-direction are supported magnetic and contact free and / or guided, whereby supporting and drive of each of the axis and direction is effected contact less electromagnetic and whereby the transmission of energy for bearing and driving is effected contact less. There is designed at least one active component (3) and at least one passive component (2), whereby the movable active component (3) is guided hanging at the fixed passive component (2) by a magnet bearing (4, 5) and whereby drive motor (7) which rides with the active component (3) is coupled with an energy supply over an electromagnetic coupling.

Owner:SEMILEV

Laser cell microoperation control method and device for metal particle

InactiveCN100406374CDirect manipulationRapid prototypingTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLight beamOptoelectronics

A method for manipulating the laser tweezers of metallic micro-particles features that a 2D scanning polarizer system is used to control the circular scanning of laser beam around metallic micro-particles, and the action force of laser beam to each metallic micro-particle points to the curvature center of scanning trace, so gathering the metallic micro-particles in the center. Its apparatus is composed of laser device, focusing lens, 2D moving platform, microscopic observing system, and 2D scanning polarizer system.

Owner:BEIJING UNIV OF TECH

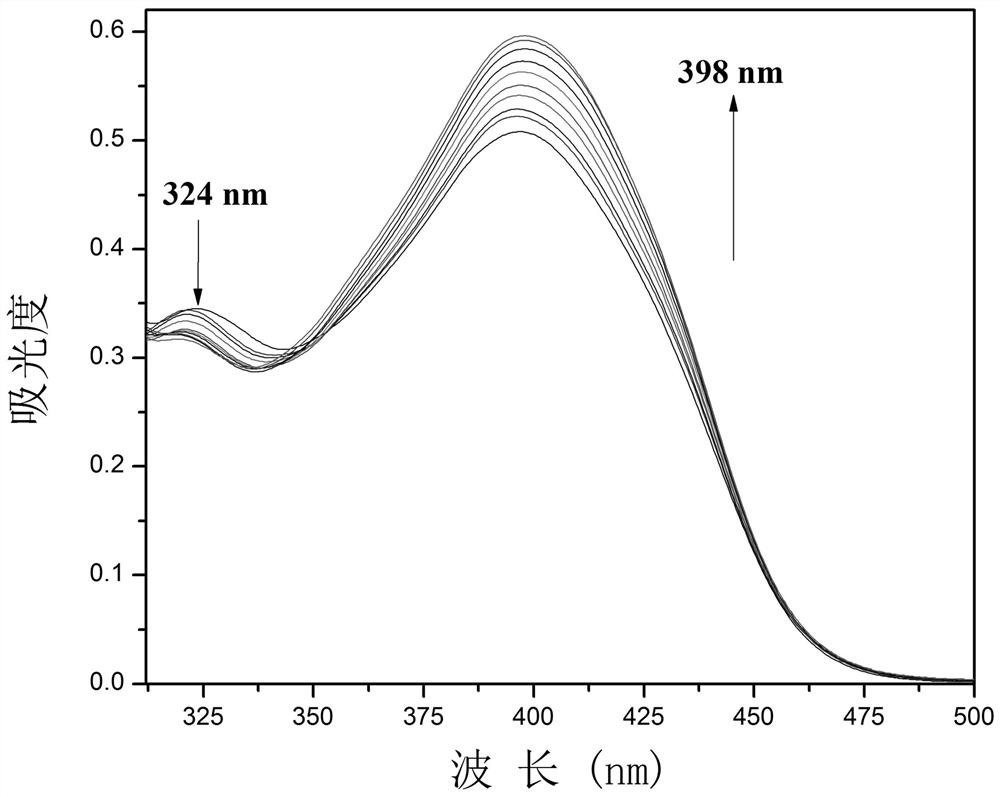

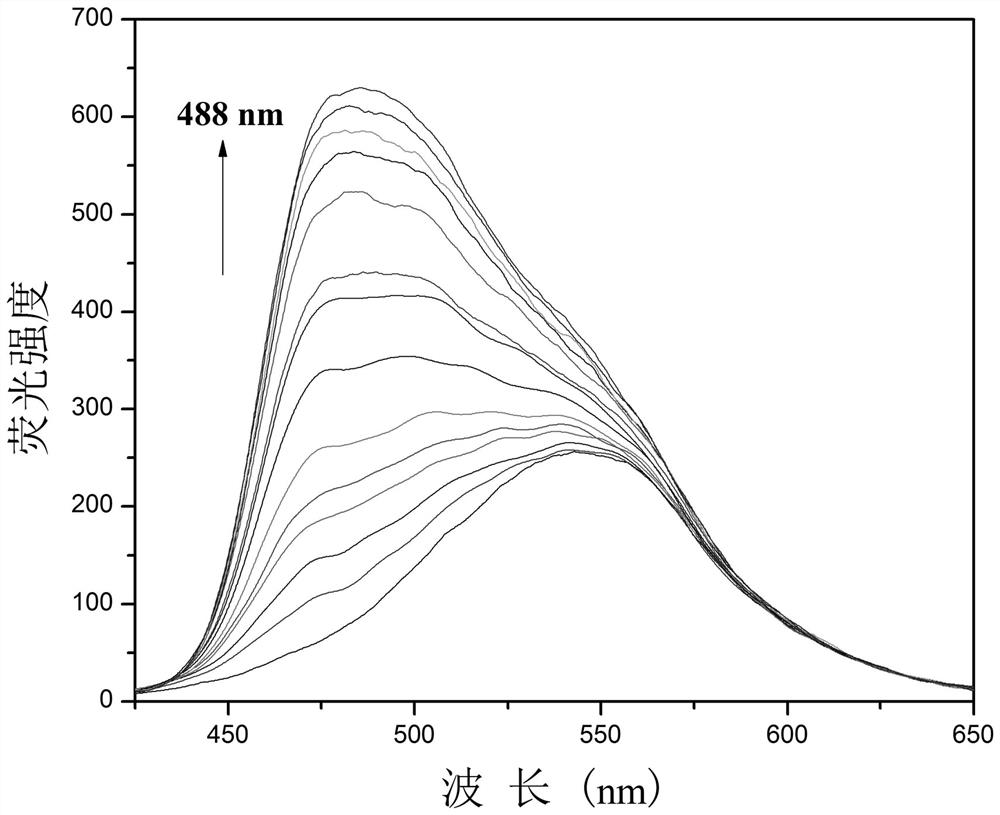

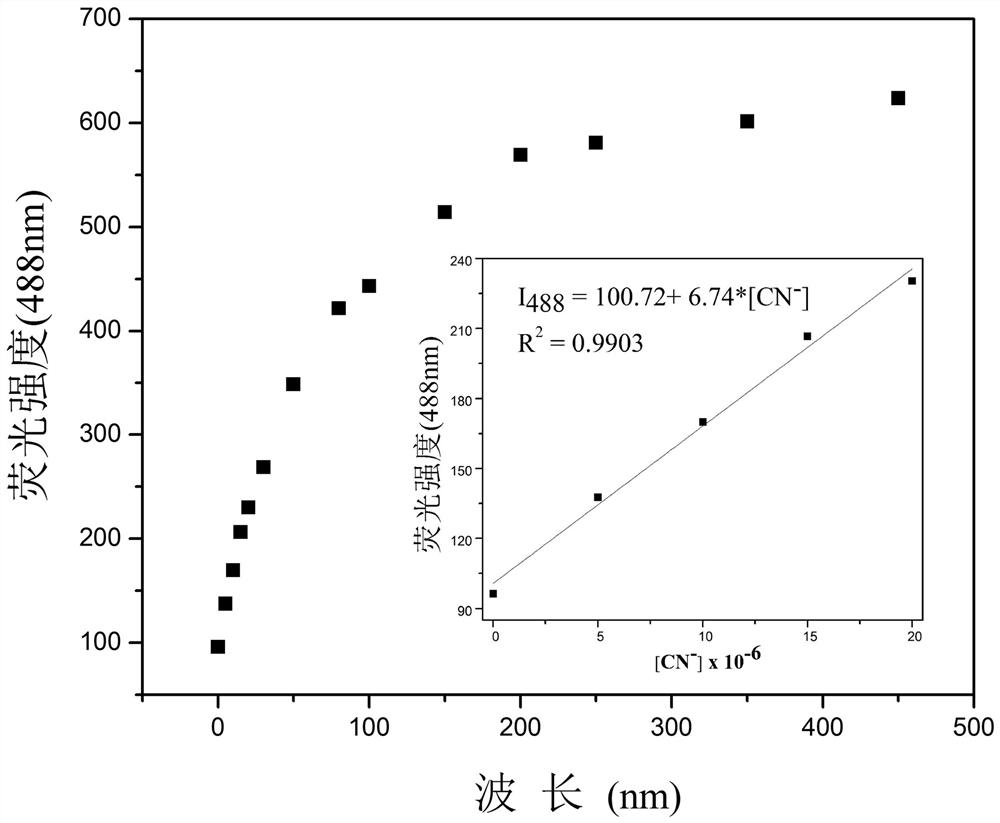

One for detection of cn - Enhanced fluorescent probe and its preparation method and biological application

ActiveCN109232379BThe synthesis steps are simpleLow costOrganic chemistryFluorescence/phosphorescenceFluoProbesFluorescence

Owner:SHANXI UNIV

Raman super-resolution microscopy imaging system and imaging method based on structured light illumination

The invention discloses a Raman super-resolution microimaging system based on structured light illumination and an imaging method and solves the technical problems in the prior art that the structuredlight super-resolution fluorescence microscopy relies on a fluorescent marker and thus has poor specificity, fluorescence bleaching and light injury often happen after long-time observation of the sample, and the Raman super-resolution microimaging technology is implemented based on a near field scanning way and thus has relatively low stability and cannot perform panoramic fast imaging of the sample. The imaging system disclosed by the invention comprises a structured light generation device, a Raman signal excitation device and a one-time Raman imaging device. Through combination of the structured light super-resolution fluorescence microscopy and the Raman super-resolution microimaging technology, the imaging system realizes non-marked, panoramic and fast super-resolution imaging, andcan be applied to the research directions such as cell membranes, artificial phospholipid membranes, artificial nano pores, endocytosis / transfer single molecule and particle system, mechanism of virusentering cells, dynamic process of molecules in living cell, interaction of nano cells and biological effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Spin polarized channel atomic force microtechnic

InactiveCN1272619CImprove resolutionHigh resolutionSurface/boundary effectScanning probe microscopyArm surfaceMicro imaging

The invention is an automatic rotating polarization tunnel atom force micro technology, which belongs to ultrahigh resolution magnetism sensitive imaging technology field. It uses conductive elastic micro suspending arm with magnetic pin, one end of the suspending arm is connected to the control system, another end is the magnetic pin, the control system controls the probe to approach the sample, the pin atom and the sample surface atom generate the atom force to bend the suspending arm, the laser radiates on the suspending arm surface and then reflected to the detector, and it is feed back to the control system, the three-dimension image of the sample surface can be acquired through recording the position coordinate x, y, and z of the probe in scanning process. A constant polarization is added on the sample, measures the current change in the total tunnel, records the plane position coordinate (x, y) and the correspondent total tunnel current value, and acquires the sample magnetism sensitivity information imaging.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com