Split pupil laser differential confocal Raman spectrum test method and device

A spectrum test and differential confocal technology, which is applied in the directions of measuring devices, spectrometry/spectrophotometry/monochromator, Raman scattering, etc., can solve the problem of strict requirements on out-of-focus position and the inability to achieve absolute displacement measurement, Limit the focus tracking accuracy and application range of the confocal Raman system, and achieve the effect of simplifying the optical path structure

Active Publication Date: 2014-08-06

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF4 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing confocal microscopic measurement system has the following disadvantages: when the confocal intensity response hypotenuse is used for measurement, absolute displacement measurement cannot be achieved, and the measurement accuracy is limited by the nonlinearity of the confocal intensity response curve hypotenuse measurement interval, the intensity of the light source Factors such as fluctuations, scattering and reflection characteristics of the measured surface; when using focus tracking measurement, because the focus of the confocal microscopic measurement system corresponds to the apex with the worst confocal intensity response sensitivity, which restricts the further improvement of the focus tracking accuracy of this type of confocal sensor , which in turn limits the focus tracking accuracy and application range of traditional confocal Raman systems

However, because the differential confocal Raman spectroscopy test method uses a dual-path physical pinhole structure, the structure of the differential confocal measurement system is relatively complex, and the requirements for the defocus position are strict, and the installation and adjustment are difficult, which increases the error source: In addition, due to the limitation of the principle of the differential confocal microscope system, it is usually difficult to balance the resolving power, working distance and field of view

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

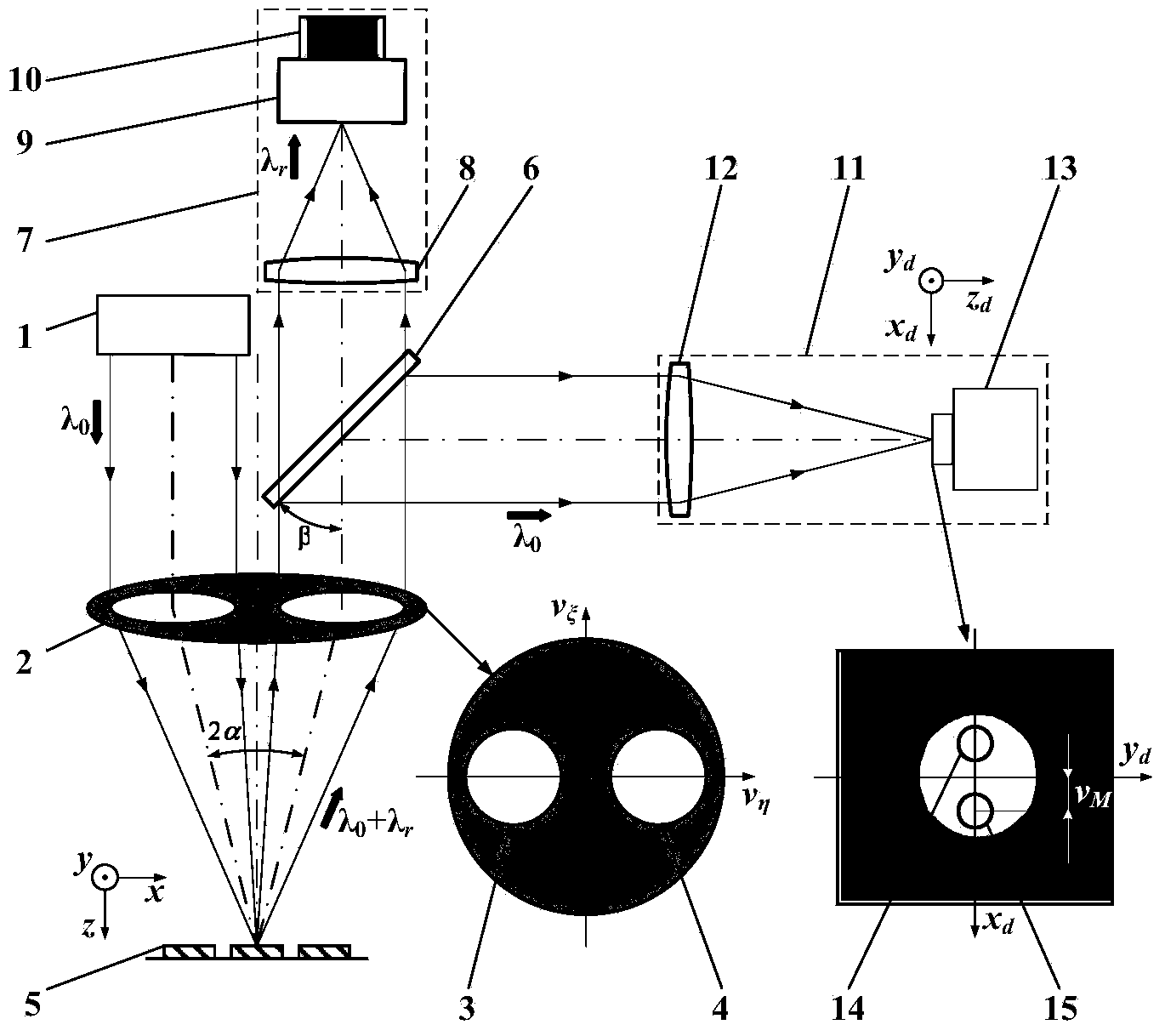

[0073] In this embodiment, the dichroic spectroscopic system 6 is a Notch filter, the spectrum detector 9 is a Raman spectrum detector, the image acquisition system 13 is a CCD, and the image magnification system 28 is a magnifying objective lens.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

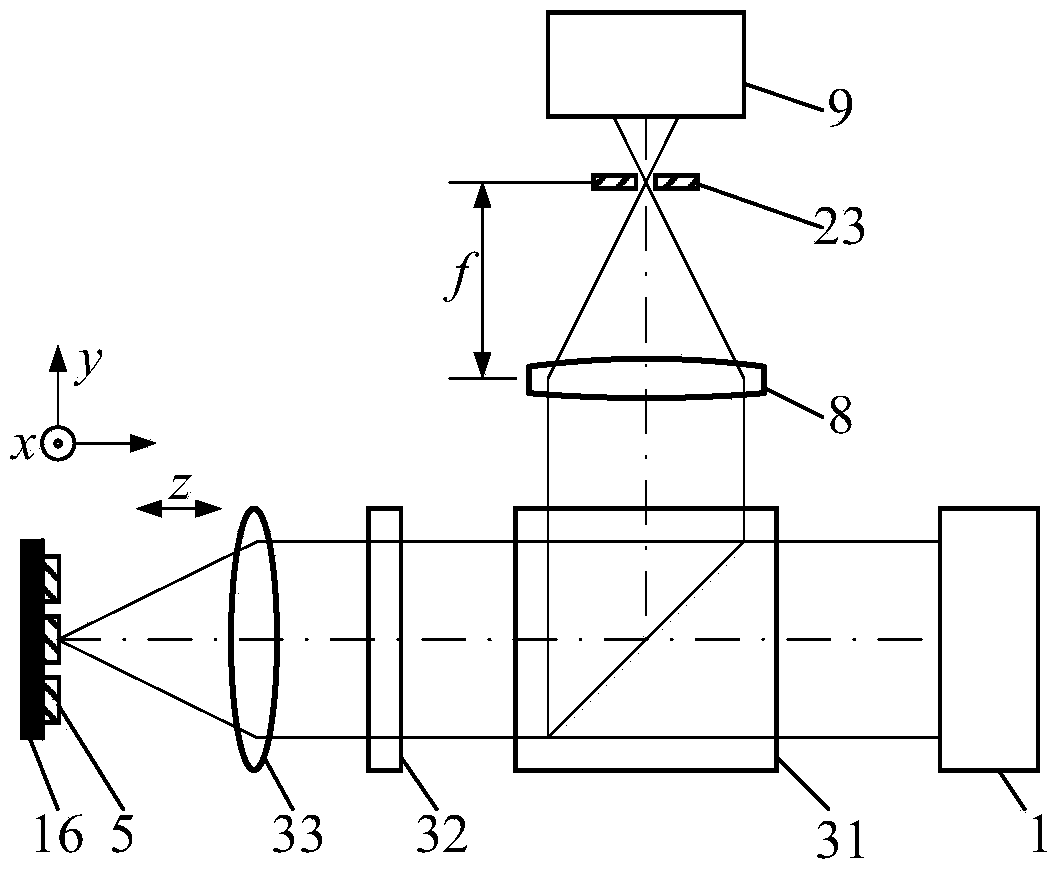

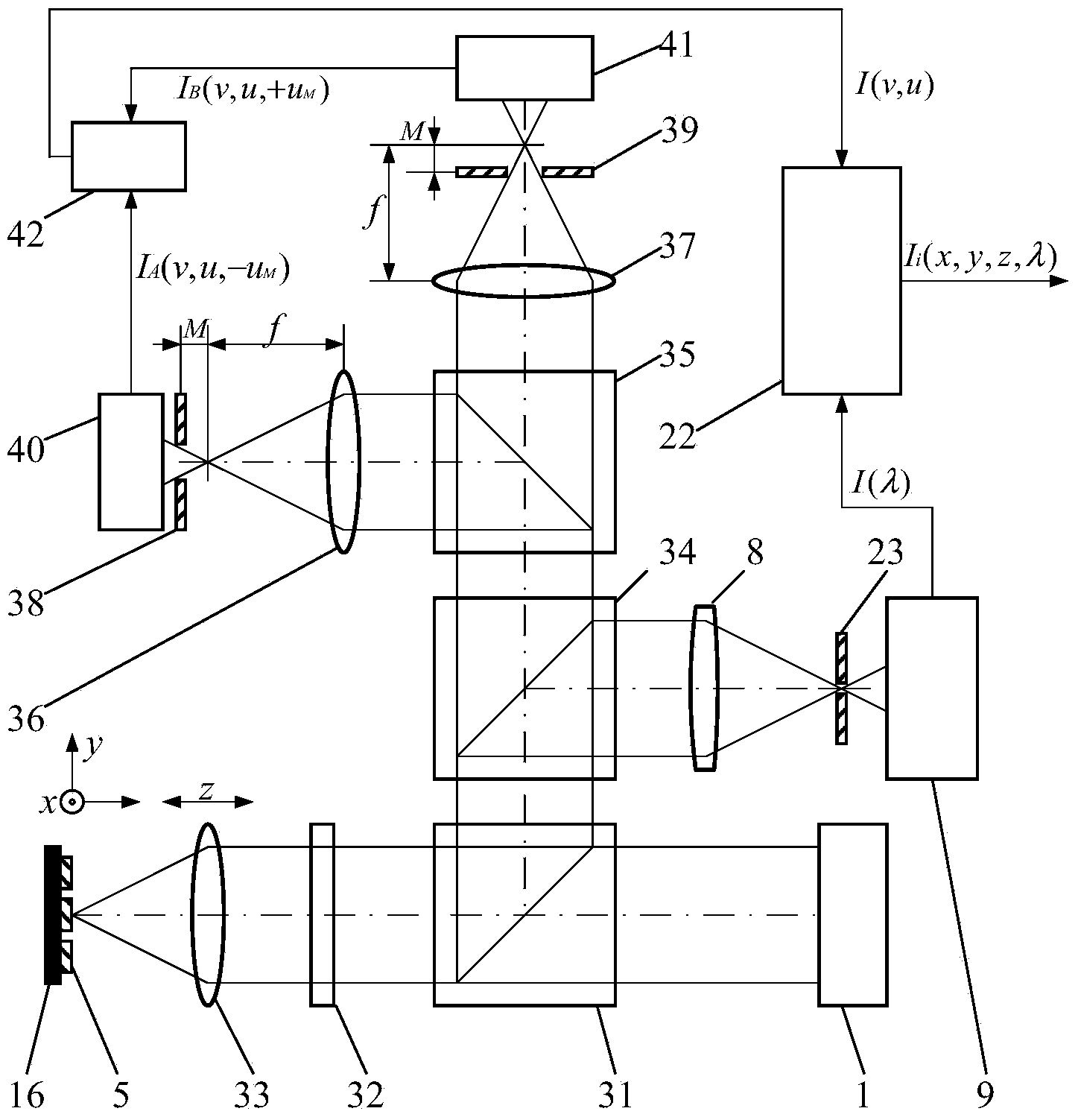

The invention belongs to the technical field of microscopicspectral imaging detection, and relates to a split pupil laser differential confocal Raman spectrum test method and device. According to the test method and device, a split pupil laser differential confocal microtechnique and a laser Raman spectrum detection technique are organically combined, precise imaging of three-dimensional geometrical positions is realized through segmentation focal spot differential detection, the optical path structure of a traditional differential confocal microscopic system is simplified, advantages of an original laser differential confocal system and a split pupil confocal system are inherited, and multi-mode switching and processing of split pupil laser differential confocal microscopic detection, laser confocal Raman spectrum detection and laser differential confocal Raman spectrum detection can be realized only through softwareswitching processing. The test method and device provide a new technological approach for detection ofnanoscale microcell three-dimensional geometrical positions and spectrum, can be applied to fields of biomedicine, industrial precision detection and the like, and has the broad application prospect.

Description

technical field [0001] The invention belongs to the technical field of micro-spectral imaging, combines differential confocal microscopic technology and spectral detection technology, and relates to a high-spatial-resolution spectral imaging and detection method and device of "map-spectrum integration", which can be used for microscopic imaging of various samples. High spatial resolution imaging and detection of Raman spectroscopy in the region. technical background [0002] In 1990, G.J.Puppels and other scholars first invented the confocal Raman spectroscopy microscopy technique when observing the morphology and composition of single cells and chromosomes and successfully used it in experiments. Laser confocal Raman spectroscopy technology causes molecules (or lattices) to vibrate through incident laser light and loses (or gains) part of the energy, causing the frequency of scattered light to change. By analyzing the scattered light, the composition, structure and Relativ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/65G01J3/44

CPCG01J3/44G01N21/65G02B21/0032G02B21/0076

Inventor 赵维谦盛忠邱丽荣邵荣君

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com