Laser cell microoperation control method and device for metal particle

A technology of metal particles and control devices, which is applied in the laser micro field to achieve the effect of rapid prototyping and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

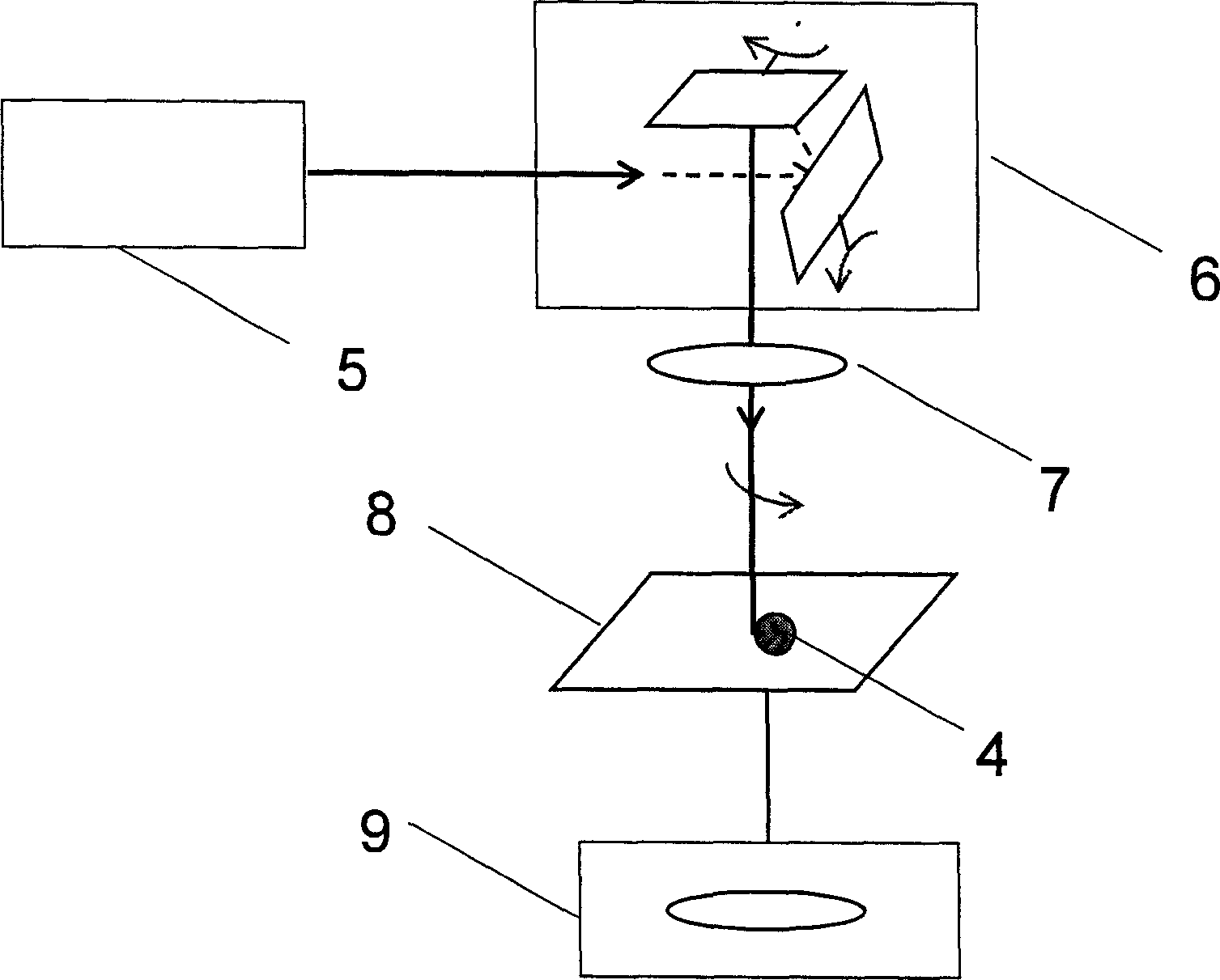

[0024] figure 2 It is a schematic diagram of the composition of the laser optical tweezers manipulation device of the present invention. The control device designed according to the method of the present invention includes: a laser 5 , a two-dimensional scanning galvanometer system 6 , a focusing mirror 7 , a two-dimensional motion platform 8 , and a microscopic observation system 9 .

[0025] Among them, the function of the laser 5 is to emit the laser light source, the function of the focusing mirror 7 is to converge the laser beam, the function of the two-dimensional scanning galvanometer system 6 is to control the scanning direction of the laser beam, and the function of the two-dimensional motion platform 8 is to place Metal particles and control the direction of movement of the metal particles, the role of the microscopic observation system 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com