Sun shading curtain and flexible thin object clamping mechanism applied to sun shading curtain

A technology for sunshade curtains and sunshade fabrics, applied in the field of sunshade curtains, can solve the problems of high equipment investment and increased manufacturing costs, and achieve the effects of improved work efficiency, reasonable structure, and reliable clamping and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

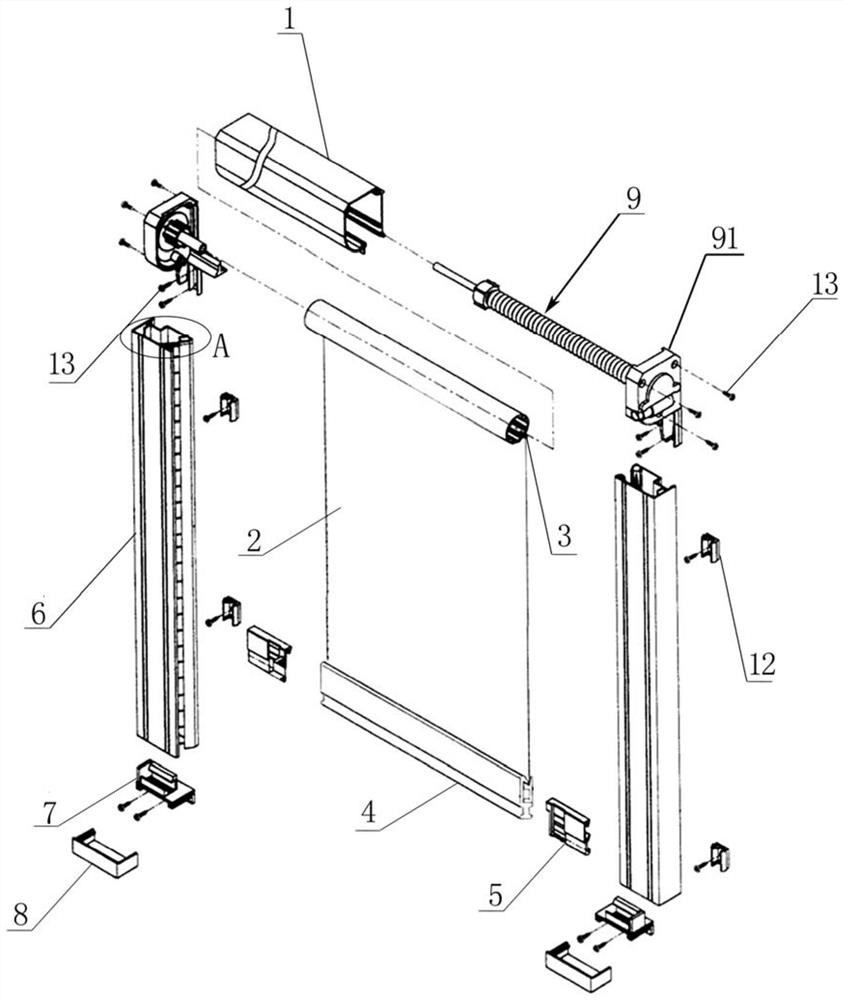

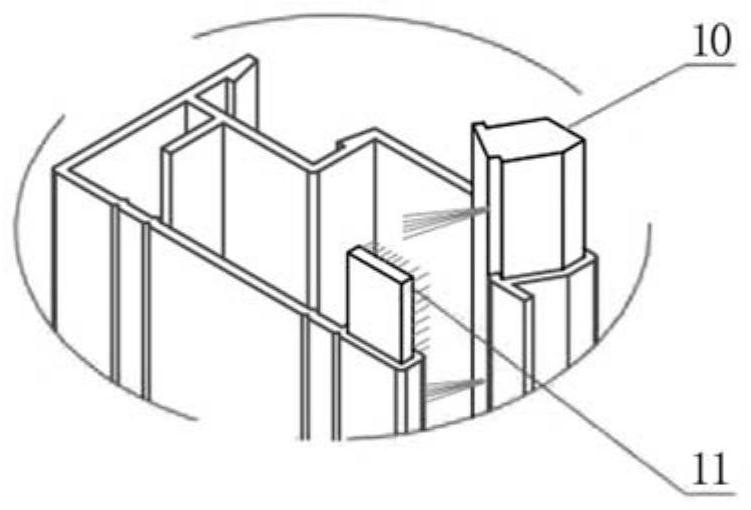

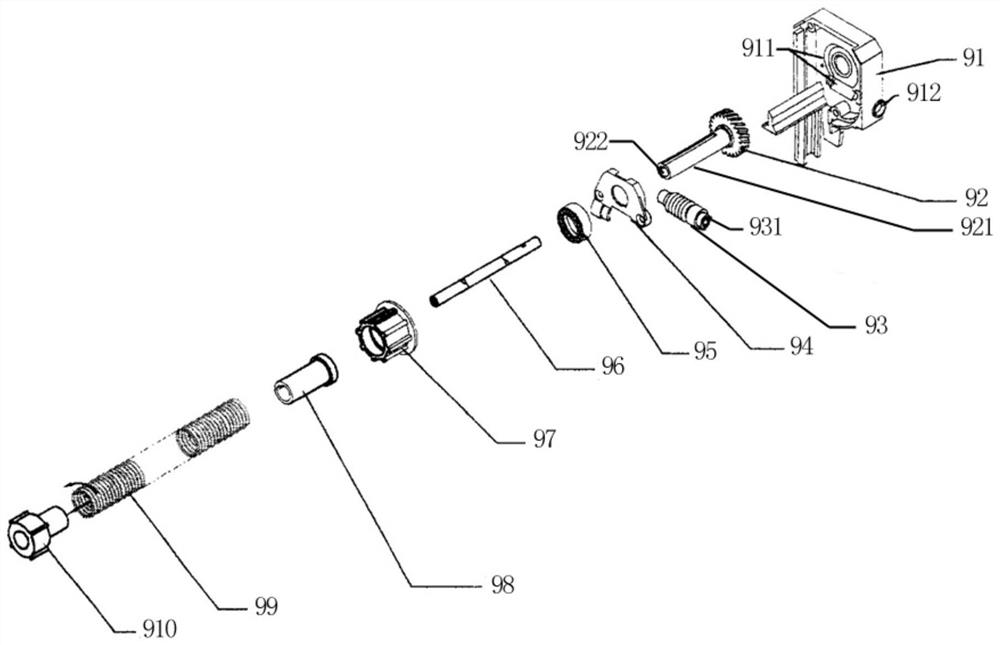

[0029] according to Figure 1-Figure 3 The shown sunshade comprises an outer cover 1 and a sunshade 2. End caps 91 are provided at both ends of the outer cover 1. The top of the sunshade 2 is connected to a reel 3 and is arranged in the outer cover 1 together. The sunshade 2 2 The bottom end is provided with a tension beam 4, and the two ends of the tension beam 4 are provided with a tension beam head 5. The tension beam head 5 is arranged in the channel 6 and can slide up and down along the channel 6. The end of the outer cover 1 Cover 91 is fixed on the upper eaves of the window frame by cross-recessed countersunk head self-tapping screws 13, channel 6 is fixed on both sides of the window frame by straight inner locks 12, and straight inner locks 12 are fixed on the window frame by cross-recessed countersunk head self-tapping screws 13. On both sides of the window frame, a preload adjustment device assembly 9 is installed on one side of the outer cover 1. The preload adjustm...

Embodiment 2

[0035] according to Figure 4 The shown clamping mechanism for a flexible thin object is applied to the sunshade curtain described in Embodiment 1, and the flexible thin object is a sunshade cloth 2, and the mechanism includes a bottom plate 41 and a cover plate 42 on both sides of the sunshade cloth 2, and the bottom plate The inner side of 41 is provided with a unilateral dovetail groove 43, one bottom angle of the unilateral dovetail groove 43 is a dovetail-shaped inner acute angle, and the other bottom angle is a right angle, and a raised line 44 for positioning is provided on the side of the right angle ; The inside of the cover plate 42 is provided with a single-sided dovetail-shaped protrusion 45 , a right-angled protrusion 46 and a groove line 47 that match the dovetail-shaped inner acute angle, right angle and raised line 44 of the bottom plate 41 .

[0036] The outer corners 48 of the right-angled sides of the right-angled protrusions 46 of the cover plate 42 describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com