Martensite heat-resistant steel and grain display method thereof

A display method and technology of heat-strength steel, applied in the fields of machinery, aerospace, metallurgy, metal material micro, chemical industry, aviation, energy, etc., can solve the problem of non-appearance of grain boundaries, and achieve the solution of non-corrosion, convenient structure inspection, good mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with a typical embodiment.

[0022] In this embodiment, a 1-ton vacuum induction furnace is used for smelting, and 6 furnaces are smelted successively, and each steel ingot weighs about 1 ton.

[0023] Table 1 Chemical composition (wt %) of the embodiment of the present invention

[0024]

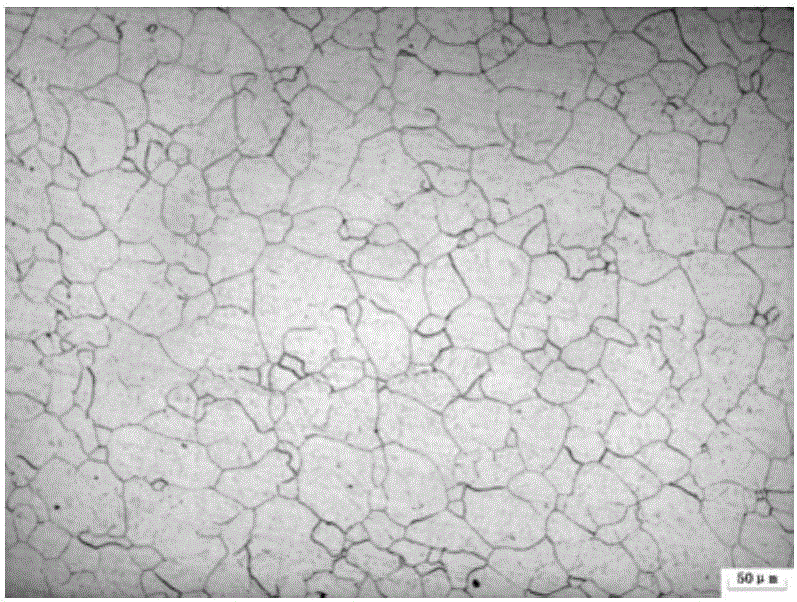

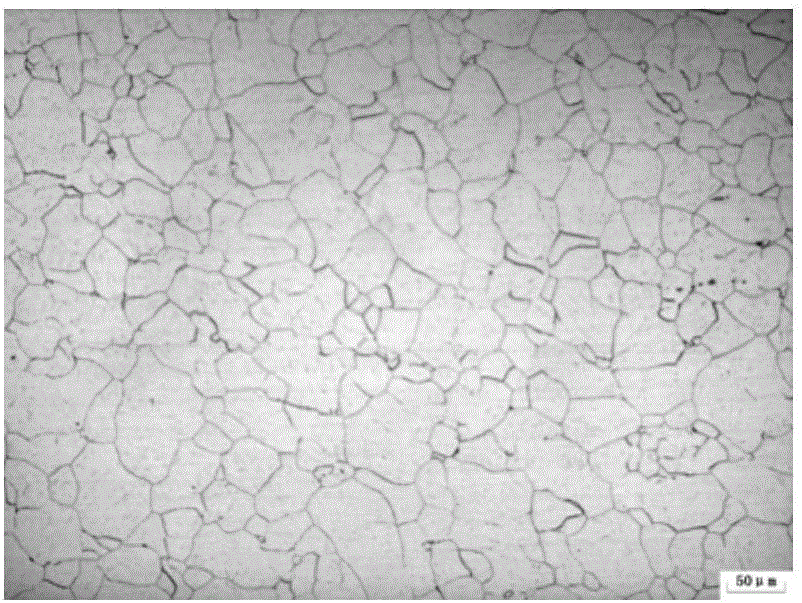

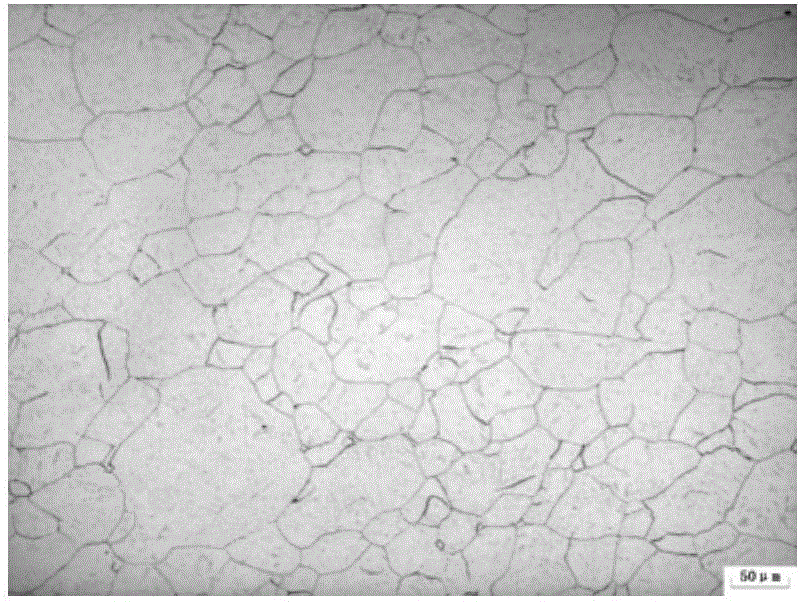

[0025]The specific composition of the smelted 6-heat martensitic heat-strength steel is shown in Table 1. After quenching the parts made of 6 heats of steel, cut cylindrical samples of Ф15mm×15mm from the workpiece respectively. Put the sample into a heat treatment furnace, heat it at 700-720°C for 30-40 minutes, and then put it in water to cool. The temperature and time of reheating the samples of these 6 heats of steel are shown in Table 2. Then these 6 samples were polished on metallographic sandpaper of 200 mesh, 500 mesh, 800 mesh and 1000 mesh respectively, polished on a metallographic polishing machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com