Device for particle free handling of substrates

A substrate, particle technology, applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as limiting effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

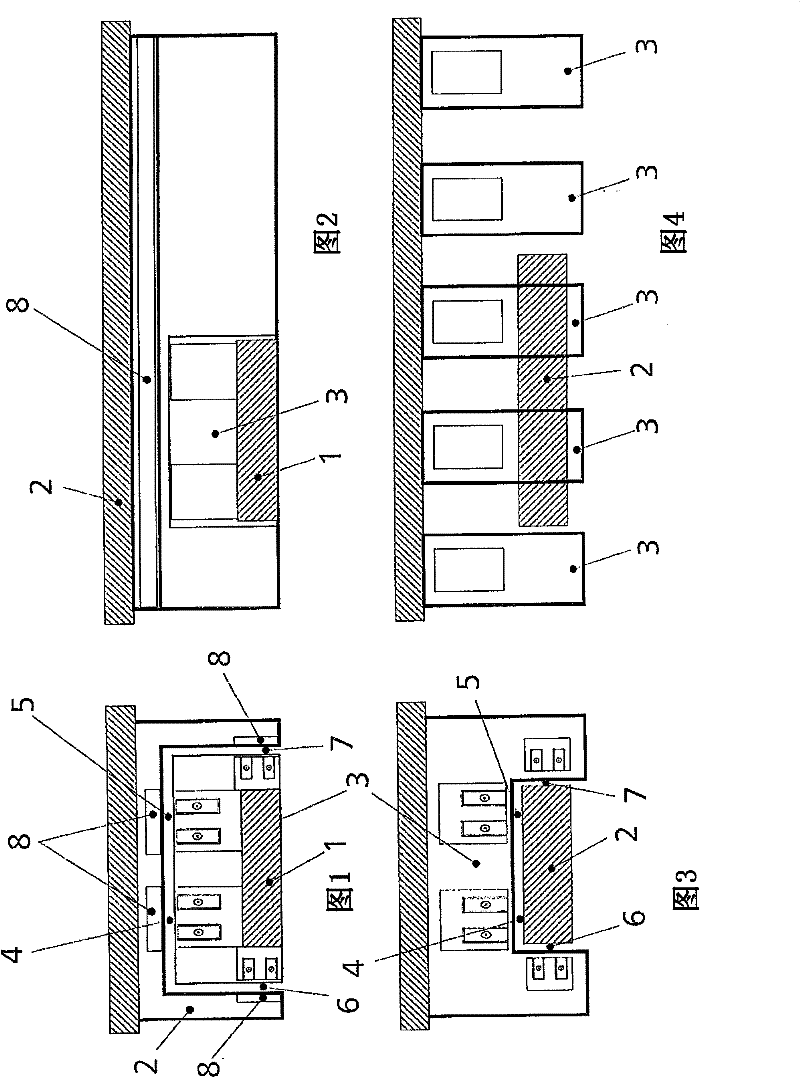

[0043] figure 1 A device for the particle-free handling of substrates (not shown) or other objects to be conveyed in a container 1 according to the invention is shown, showing a cross-sectional view transverse to the drive direction. The device consists of a fixed passive part 2 and an active part 3 that can move by magnetic force along a planned track. Since the active part is moving, it needs to be supplied with energy for the magnetic bearings 4, 5 which keep the active part floating below the passive part. The energy supply is realized by means of an electromagnetic coupling device 6 , wherein the electromagnetic coupling device 6 also supplies energy to a drive motor 7 designed as a linear induction motor. The passive part 2 is only provided with permanent magnets 8 .

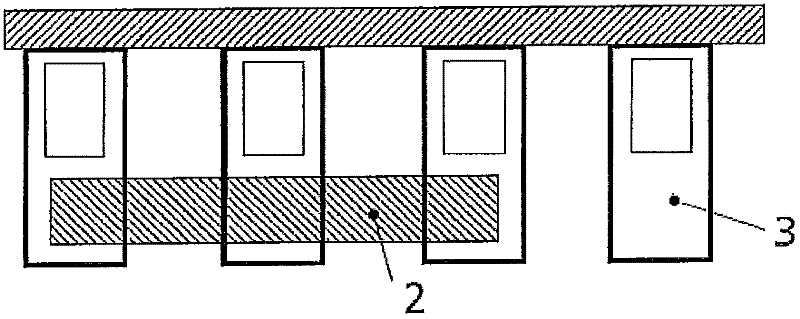

[0044] figure 2 The active part 3 is shown during driving along the passive part 2 .

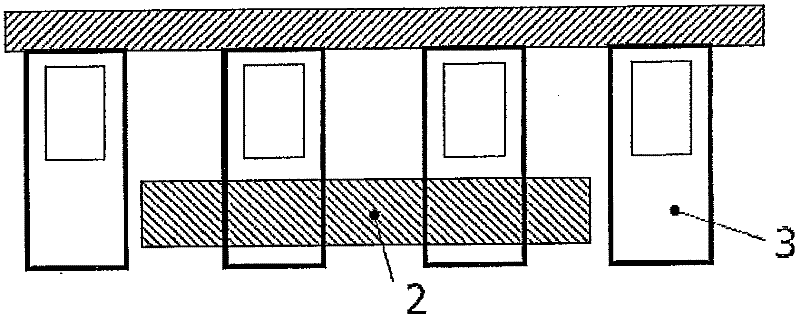

[0045] exist image 3 A stationary active part 3 with a passive part 2 being moved is shown in . The items with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com