Spin polarized channel atomic force microtechnic

A technique of atomic force microscopy and spin polarization, which is applied in the field of ultra-high resolution susceptibility imaging, can solve the problems of untrue magnetic information on the surface of samples, complex winding coil technology, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

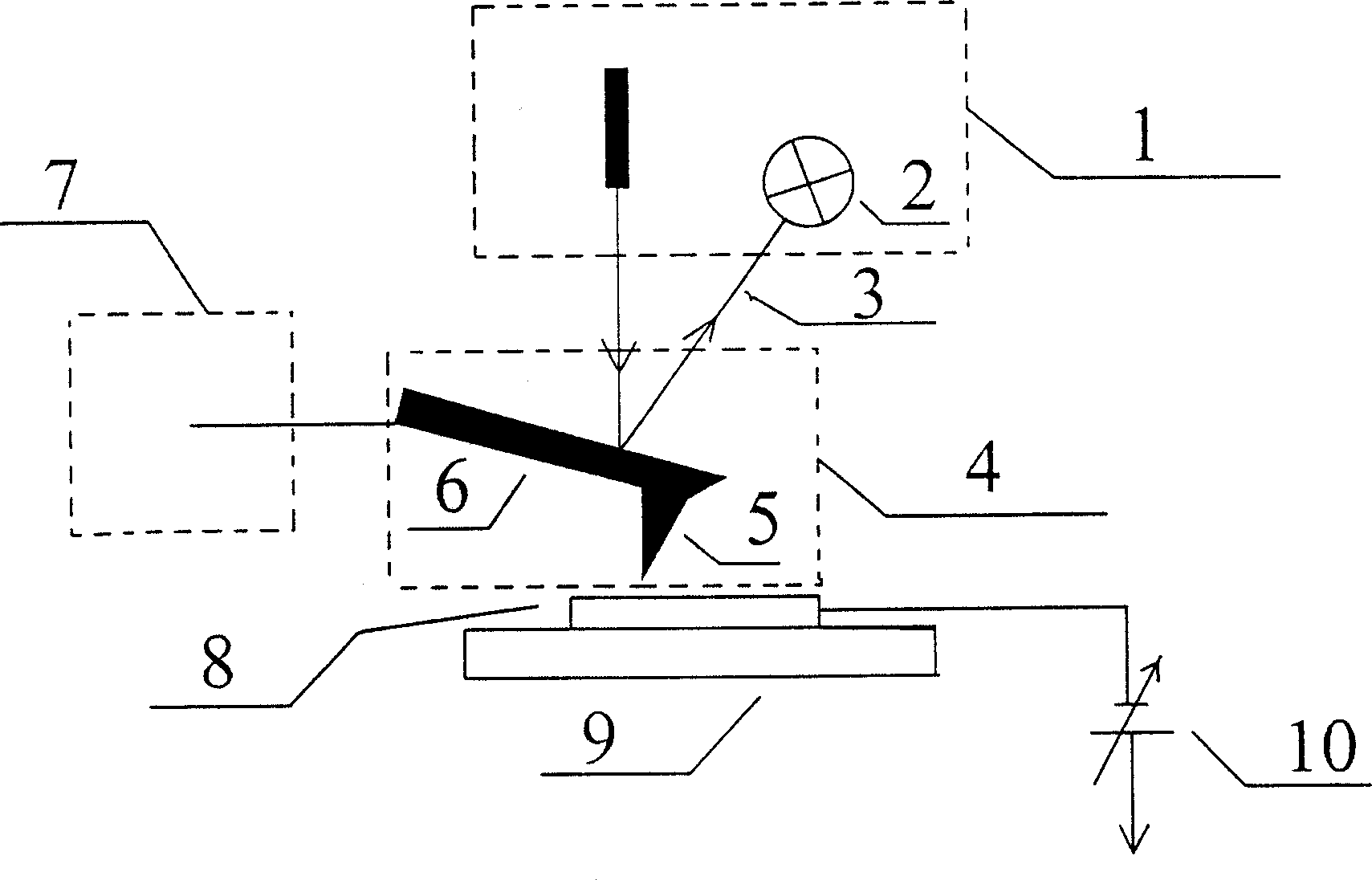

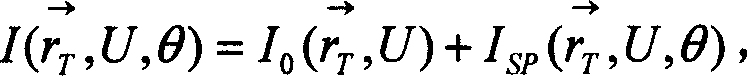

[0027] like figure 1 As shown, a conductive elastic microcantilever 6 with a magnetic tip is used. One end of the cantilever 6 is connected to the control system, and the other end is a magnetic tip 4. The control system 7 is used to control the probe 4 to approach the single crystal cobalt sample 8, the tip atoms and the surface of the sample 8 The atomic force generated between the atoms makes the micro-cantilever 6 bend, the laser 3 shines on the smooth back of the cantilever and then reflects to the detector 2, and the laser feedback system 1 is used to detect the deformation of the micro-probe cantilever 6 and feed back to the control system 7, the control system 7 Control the deformation of the microprobe cantilever 6 to be constant during the scanning process, and the control system 7 records the position coordinates of the probe 4 during the scanning process to obtain the surface morphology of the single crystal cobalt sample 8; at the same time, apply a Constant bias ...

Embodiment 2

[0029] like figure 1 As shown, the control system 7 is used to control the probe 4 to approach the single crystal cobalt sample 8, and the laser feedback system 1 is used to detect the deformation of the microprobe cantilever 6 and feed back to the control system 7. The control system 7 controls the microprobe cantilever during the scanning process. The deformation of 6 is constant, and the control system 7 records the position coordinates of the probe 4 during the scanning process to obtain the surface morphology of the single crystal cobalt sample 8; at the same time, a constant bias voltage (0.2 volts) 10 is applied to the single crystal cobalt sample 8 , apply a small alternating voltage (±20mV)10 on the basis of a constant bias voltage, record the ratio ΔI / ΔU of the tunnel current change to the voltage change when the needle tip scans at different positions on the sample surface, and obtain single crystal cobalt samples at the same time8 Surface susceptibility images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com