Preparation method and application of silver nanowire with high length-width ratio

A silver nanowire, aspect ratio technology, applied to conductive layers on insulating carriers, metal/alloy conductors, etc., can solve the problems of affecting the photoelectric properties of thin films, low photoelectric properties of transparent conductive films, etc., to improve process stability, High uniformity and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Measure 0.099L of ethylene glycol, 10g of polyvinylpyrrolidone (PVP), and 1ml of silver chloride liquid with a concentration of 0.01mol / L to prepare a mixed solution (the concentration of metal halide in the mixed solution is 0.0001mol / l), Heating to 170° C. is stable to obtain "Solution 1";

[0055] 2. Weigh 0.18g of silver nitrate, add it into "solution 1" (the concentration of silver element is 0.01mol / l), and react for 5 hours to get "solution 2";

[0056] "Solution 2" was centrifugally cleaned with a cleaning agent composed of ethanol and acetone at a volume ratio of 1:3 at a centrifugal speed of 500r / min, and stable dispersed silver nanowires could be obtained after cleaning for 3 times.

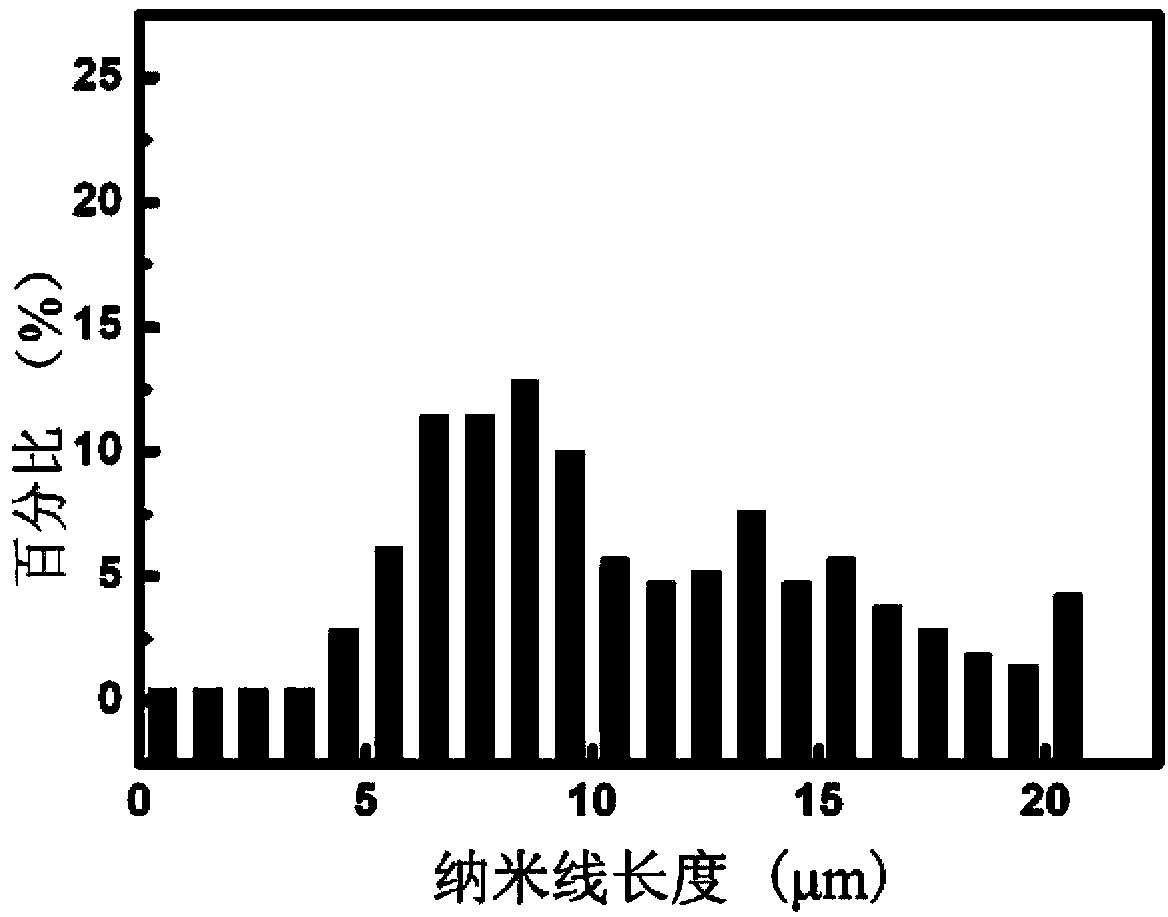

[0057] Comparison of experimental results: Figure 5 This is the optical photo of the silver nanowires synthesized in this example. It can be seen from the photo that the nanowires have good dispersion. Counting its length, the result is as follows Figure 6 shown. From ...

Embodiment 2

[0059] 1. Measure 0.090L ethylene glycol methyl ether, 0.1g polyvinylpyrrolidone (PVP), 10ml sodium chloride solution (molar concentration 0.01mol / L) to prepare a mixed solution (the concentration of metal halide in the mixed solution is 0.001mol / l), heated to 130°C and stabilized to obtain "Solution 1";

[0060] 2. Weigh 3.4g of silver acetate and dissolve it in 0.05L of ethylene glycol to prepare a solution, add it to "solution 1" (the concentration of silver element is 0.2mol / l), and react for 10 hours to obtain "solution 2";

[0061] "Solution 2" was centrifugally cleaned with a cleaning agent composed of ethanol and acetone at a volume ratio of 2:3 at a centrifugal speed of 1000r / min, and stable dispersed silver nanowires could be obtained by cleaning 4 times.

[0062] Experimental results such as Figure 7 , Figure 8 shown. Figure 7 It is an optical photo of silver nanowires. It can be seen from the picture that the nanowires have good dispersion. Counting its len...

Embodiment 3

[0064] 1. Measure 0.099L ethylene glycol, 1g polyvinylpyrrolidone (PVP), 1ml potassium bromide solution (molar concentration 0.03mol / L) to prepare a mixed solution (the concentration of metal halide in the mixed solution is 0.0003mol / l) , heated to 150°C to be stable to obtain "Solution 1";

[0065] 2. Weigh 1.8g of silver nitrate, add it into "solution 1" (the concentration of silver element is 0.1mol / l), react for 7 hours, and get "solution 2";

[0066] "Solution 2" was centrifugally cleaned with a cleaning agent composed of ethanol and acetone at a volume ratio of 1:1 at a centrifugal speed of 2500r / min, and stable dispersed silver nanowires could be obtained by cleaning 5 times.

[0067] Experimental results such as Figure 9 , Figure 10 shown. Figure 9 It is an optical photo of silver nanowires. It can be seen from the picture that the nanowires have good dispersion. Counting its length, the result is as follows Figure 9 shown. From Figure 10 It can be seen tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com