Method for producing silver nanowires

A silver nanowire, manufacturing method technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of increased manufacturing cost, large solution processing capacity, etc. The effect of reducing the total

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

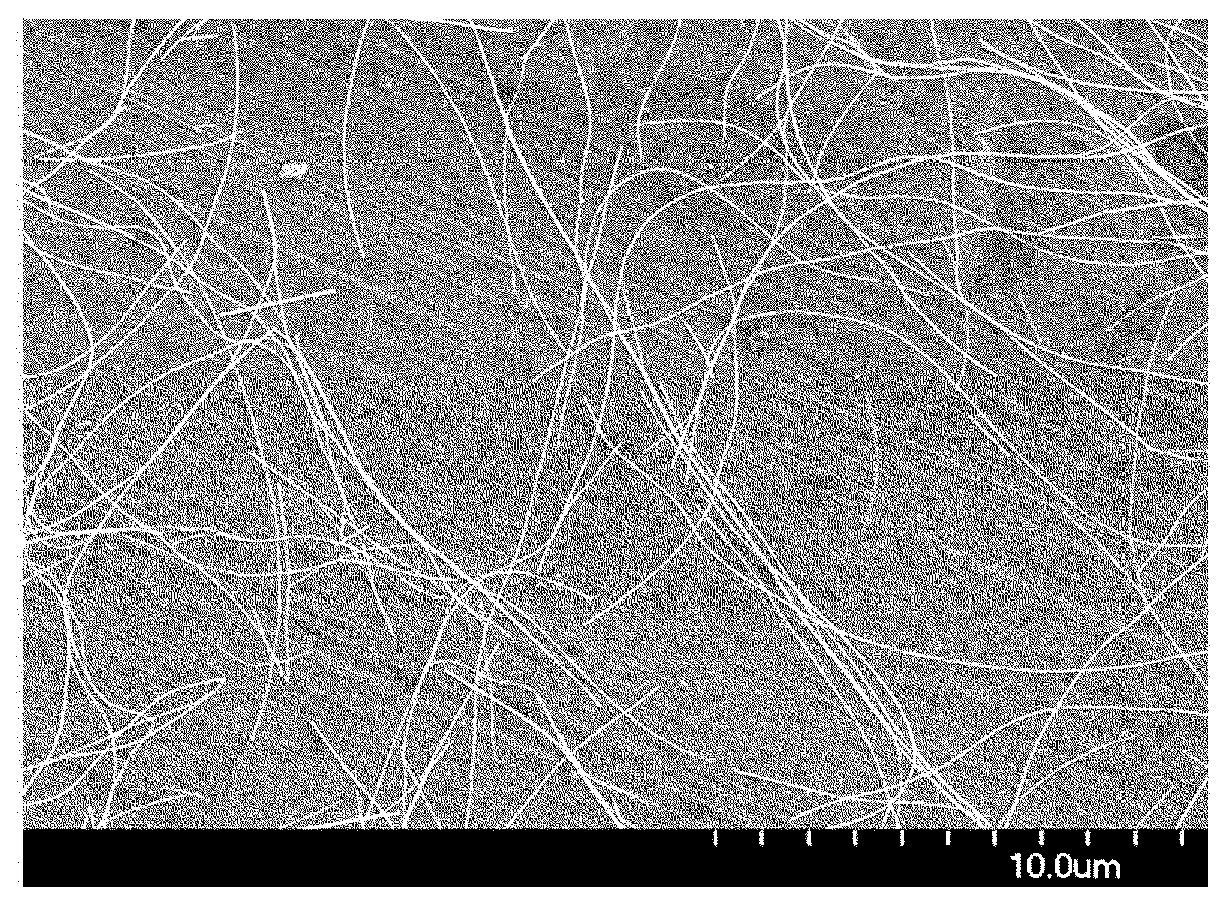

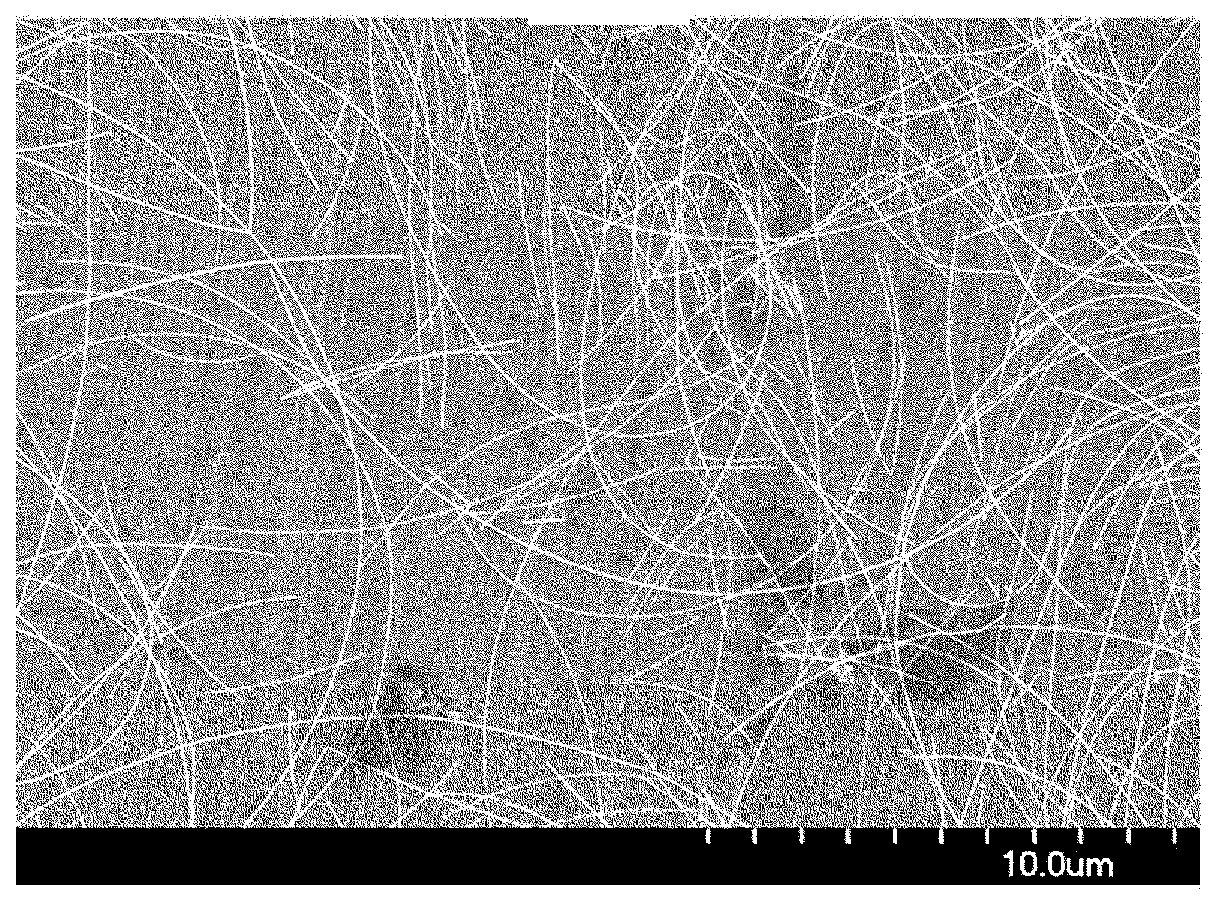

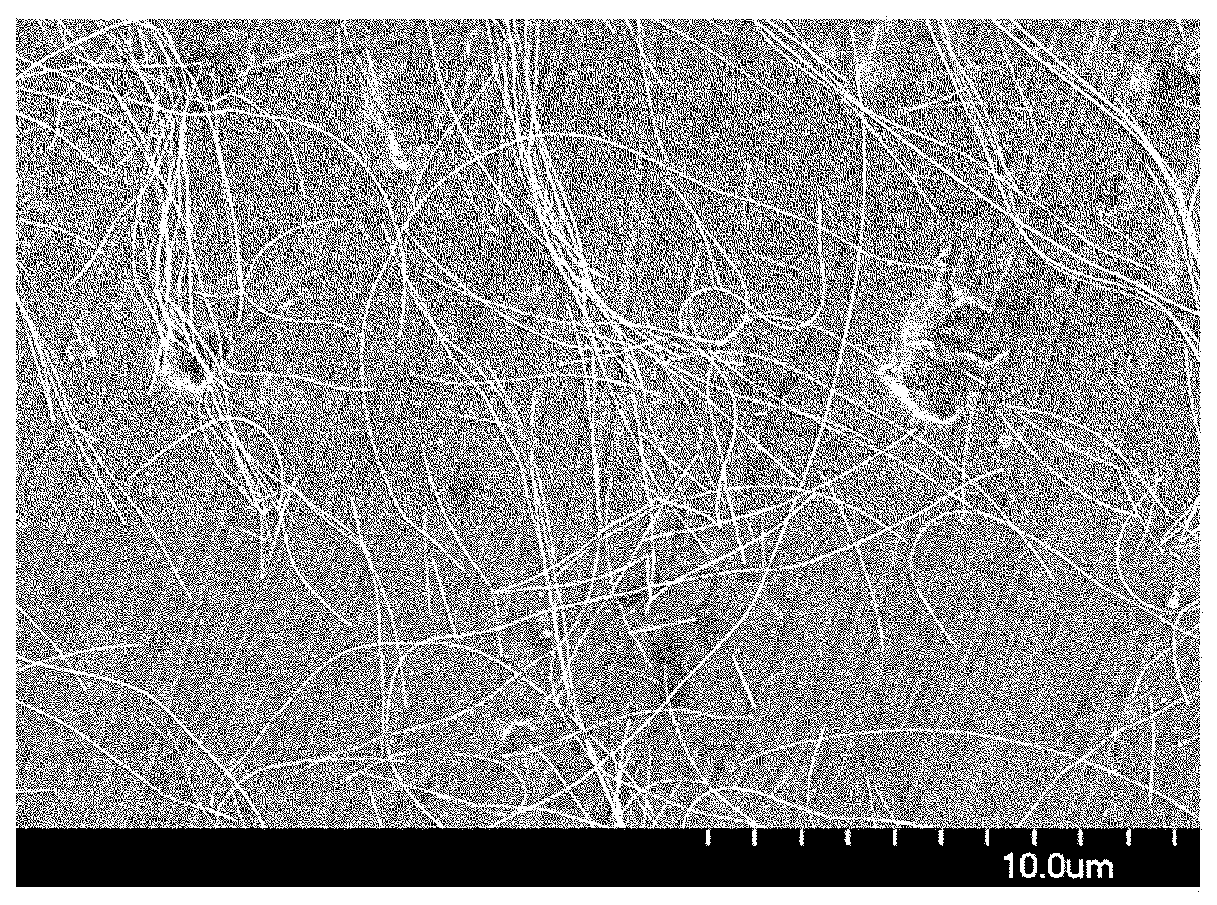

Image

Examples

preparation example Construction

[0070] [Preparation of silver-containing solution]

[0071] The higher the silver concentration of solution B (silver-containing solution) added to solution A, the more the total amount of solution B can be reduced. As a result of various investigations, by setting the silver concentration to 3.5 mol / L or more, the total amount of the silver-containing solution can be significantly reduced compared to conventional methods. It is more effective to set the silver concentration to 3.9 mol / L or more. When further reducing the total amount of the silver-containing solution significantly, the silver concentration is preferably 5.0 mol / L or more, more effectively 10.0 mol / L or more.

[0072] According to the research of the inventors, in a solvent using only alcohol, the temperature of the solution containing silver nitrate is raised to about 40° C. and stirred for about 1 hour, thereby obtaining a solution with a silver concentration of 3.5 to 4.5 mol / L. silver solution. In this ...

Embodiment 1

[0092] Except having prepared the solution B as follows, the same experiment as the comparative example 1 was done.

[0093] [Solution B]

[0094] 4.25 g of silver nitrates were added to an alcohol solvent of 6.50 g of propylene glycol, stirred and dissolved at 40° C., and a silver-containing solution (solution B) was obtained. About the obtained solution B, the color of a solution was checked visually. Table 1 shows the concentration of silver nitrate in the solution, the composition of propylene glycol and water, the dissolution conditions (stirring time, temperature), and the color of the solution.

[0095] Table 1 shows the average length, average diameter, and average aspect ratio of the synthesized silver nanowires investigated by the same method as in Comparative Example 1.

Embodiment 2

[0097] Except having prepared the solution B as follows, the same experiment as the comparative example 1 was done.

[0098] [Solution B]

[0099] 4.25 g of silver nitrates were added to a mixed solvent of 6.37 g of propylene glycol and 0.13 g of pure water, stirred and dissolved at 35° C., and a silver-containing solution (solution B) was obtained. About the obtained solution B, the color of a solution was checked visually. Table 1 shows the concentration of silver nitrate in the solution, the composition of propylene glycol and water, the dissolution conditions (stirring time, temperature), and the color of the solution.

[0100] Table 1 shows the average length, average diameter, and average aspect ratio of the synthesized silver nanowires investigated by the same method as in Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com