Titanium alloy welding active agent and welding method

A technology of titanium alloy and activator, which is applied in the direction of welding/welding/cutting articles, welding media, welding equipment, etc., can solve the problems that restrict the development of titanium alloy activator welding process, the activator coating layer is easy to fall off, and the activator The slag crust is not easy to clean and other problems, so as to achieve the effect of reducing welding defects, insensitivity to thickness fluctuations, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

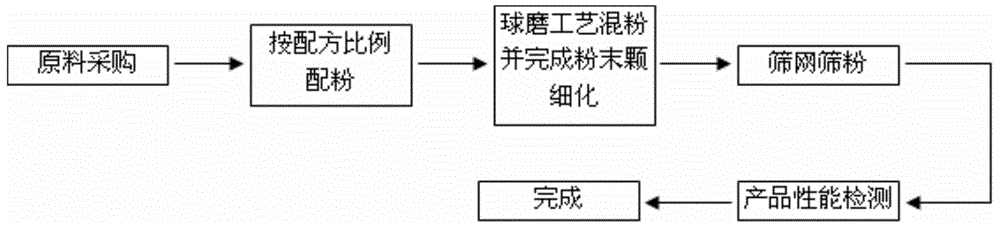

[0027] figure 2 For the preparation process of the titanium alloy coagent of the present invention, firstly, the purchased raw materials are powdered according to the formula ratio given by the present invention, then the powder is mixed with a ball milling process and the powder particles are refined, and then the powder is screened with a sieve. After screening and performance testing, the preparation and performance testing of additives are completed.

[0028] Adopting the titanium alloy welding active auxiliary agent of the present invention to carry out welding comprises the following steps:

[0029] (1) Prepare a titanium alloy welding test piece; the size of the titanium alloy welding test piece is 100mm*200mm*(2.0-4.0)mm.

[0030] (2) Pickling the prepared titanium alloy welding test piece, first degreasing the titanium alloy welding test piece with a degreasing agent, then configuring pickling solution, pickling the titanium alloy welding test piece to be welded, an...

Embodiment 1

[0035] Step 1. Processing TC4 titanium alloy welding test piece, the size of the test plate is 100mm*200mm*3.0mm.

[0036] Step 2, pickling the titanium alloy welding test piece. Use a degreasing agent to degrease the titanium alloy welding test piece. Prepare hydrofluoric acid, nitric acid, and distilled water in a volume ratio of 1:5:6 to form a pickling solution, and pickle the parts to be welded of the titanium alloy welding test piece. Finally, dry the titanium alloy welding test piece with a clean gauze and a hair dryer.

[0037] Step 3: Align the two pickled TC4 titanium alloy welding test pieces along the length direction of 200mm, and perform welding assembly. Apply A-TIG-Ti-01 titanium alloy welding activator on the surface of the welding part (actual composition ratio CaF2: 15%; MgF2: 5%; SrF2: balance), the thickness of the activator coating layer is 0.2-1.0mm.

[0038] Step 4. The titanium alloy test piece is welded by argon tungsten arc welding, and the tip of...

Embodiment 2

[0043] Step 1. Processing TC4 titanium alloy welding test piece, the size of the test plate is 100mm*200mm*3.0mm.

[0044] Step 2, pickling the titanium alloy welding test piece. Use a degreasing agent to degrease the titanium alloy welding test piece. Prepare hydrofluoric acid, nitric acid, and distilled water in a volume ratio of 1:5:6 to form a pickling solution, and pickle the parts to be welded of the titanium alloy welding test piece. Finally, dry the titanium alloy welding test piece with a clean gauze and a hair dryer.

[0045] Step 3: Align the two pickled TC4 titanium alloy welding test pieces along the length direction of 200mm, and perform welding assembly. Apply A-TIG-Ti-01 titanium alloy welding active agent on the surface of the welding part (actual composition ratio CaF2: 25%; MgF2: 15%; SrF2: balance), the thickness of the active agent coating layer is 0.2-1.0mm.

[0046] Step 4. The titanium alloy test piece is welded by argon tungsten arc welding, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com