Stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

A technology of argon tungsten arc welding and activator, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve problems such as the limitation of welding joint penetration, achieve good economic benefits, deep weld penetration, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A stainless steel tungsten argon arc welding activator of the present invention and its preparation method and application, a stainless steel tungsten argon arc welding activator, comprising the following components in weight percentage:

[0044] SiO 2 Powder 35-45%;

[0045] TiO 2 Powder 20-25%;

[0046] Cr 2 o 3 Powder 8-12%;

[0047] MnO powder 5-10%;

[0048] NiO powder 5-10%;

[0049] CuO powder 10-15%.

[0050] Wherein in the present invention, the SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 The average particle diameters of the powder, MnO powder, NiO powder and CuO powder are all 200 μm to 300 μm.

[0051] The stainless steel tungsten argon arc welding activator of the present invention is made of SiO 2 、TiO 2 、Cr 2 o 3 , MnO, NiO and CuO powders are composed of six powders, do not contain precious metals, and its cost is low, less than 130 yuan per kilogram, and it is non-toxic and environmentally friendly. Compared with conventional tungsten argon arc...

Embodiment 1

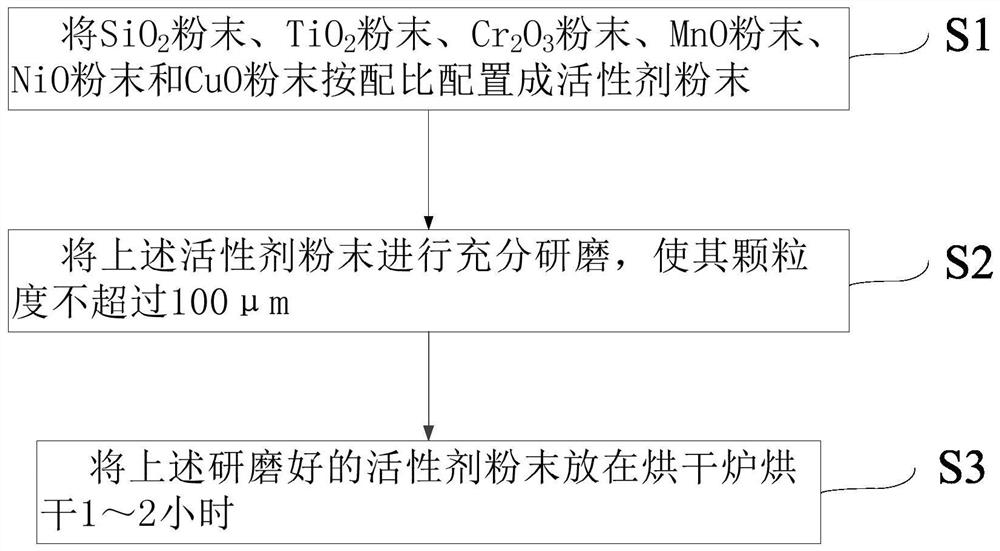

[0064] Prepare stainless steel tungsten argon arc welding activator according to the following steps:

[0065] S1, weighed by mass percentage: 40% SiO 2 Powder, 22%TiO 2 Powder, 10%Cr 2 o 3 Powder, 8% MnO powder, 8% NiO powder and 12% CuO powder, configured as active agent powder; where SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 The average particle diameter of the powder, MnO powder, NiO powder, and CuO powder is all 200 μm.

[0066] S2. Grinding the active agent powder sufficiently so that the particle size does not exceed 100 μm.

[0067] S3, drying the ground activator powder in a drying oven for 1 hour to remove crystal water in the activator powder to obtain a stainless steel tungsten argon arc welding activator.

[0068] The obtained stainless steel tungsten argon arc welding activator is applied according to the following steps:

[0069] (1) Pour the prepared active agent into a beaker, then add an appropriate amount of acetone with a dropper, and keep stirring the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com