Stud welding method based on coating self-protection

A self-protection, stud welding technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of uneven welding pool, arc arc burning, welding joint pores and hot cracks, etc., to achieve good welding. The effect of seam metallographic structure, reducing welding arc offset and improving weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

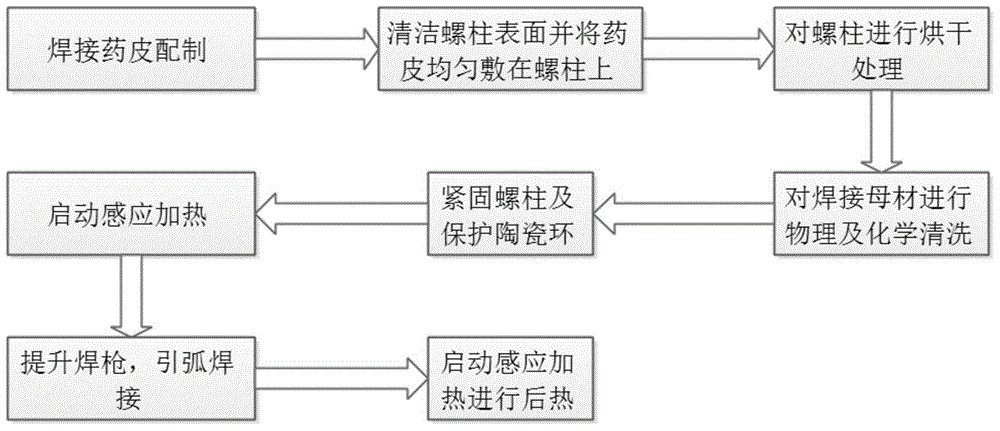

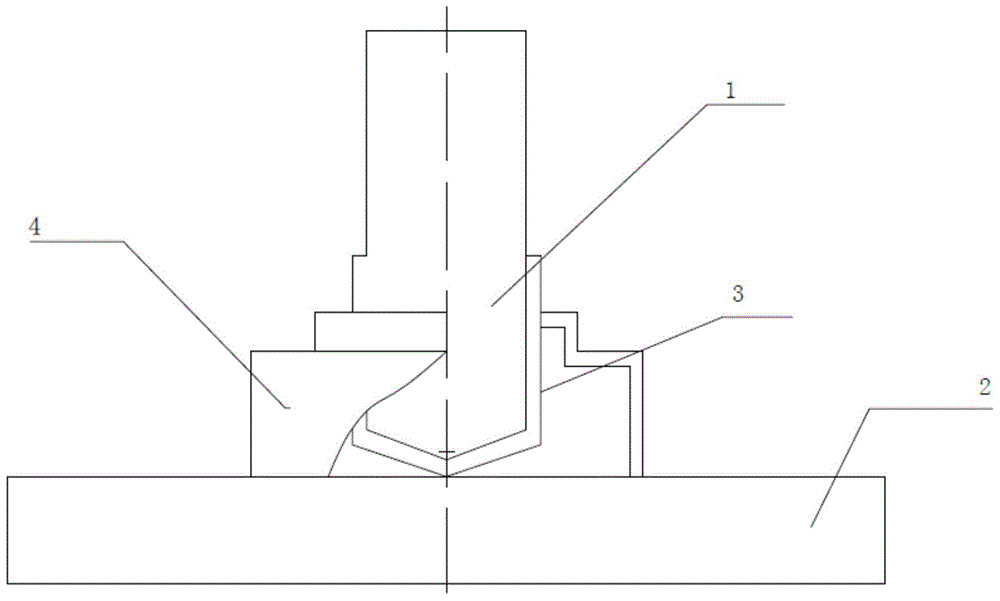

[0020] combine figure 1 and figure 2 , taking a Q235 steel stud 1 with a diameter of 8mm as an example. First prepare protective coating 3 before welding (protective coating 3 composition is; 20% CaO, 10% TiO 2 , 3% fluorite, 8% cryolite, 3% medium carbon ferromanganese powder, 10% Ni powder, 1% V powder, 2% Mo powder, 2% Cr powder, and the rest is Cr 2 o 3 pink. The bonding material is sodium silicate with a modulus of not less than 2.5 and a Baume degree of 45 degrees), and the steel stud 1 welded stud is polished to remove rust, and the steel stud 1 is treated with acetone solution. Cleaning, mixing the ingredients of the coating and the binder, the weight ratio of the binder to the coating is 15-11:100, and then adding the coating mud mixed with the binder into the ceramic mold, The shape of the mold is consistent with that of the steel stud 1, and the diameter of the mold is 10 mm; then, the cleaned steel stud 1 is slowly pressed into the mold. Fix the steel stud 1...

Embodiment 2

[0022] combine figure 1 and figure 2 , taking a Q235 steel stud 1 with a diameter of 16mm as an example. First prepare protective coating 3 before welding (protective coating 3 composition is; content 22% CaO, 13% TiO 2 , 6% fluorite, 6% cryolite, 1% medium carbon ferromanganese powder, 13% Ni powder, 0.6% V powder, 1% Mo powder, 2% Cr powder, and the rest is Cr 2 o 3 pink. The bonding material is sodium silicate with a modulus of not less than 2.5 and a Baume degree of 45 degrees), and the steel stud 1 welded stud is polished to remove rust, and the steel stud 1 is treated with acetone solution. Cleaning, mixing the ingredients of the coating and the binder, the weight ratio of the binder to the coating is 15-11:100, and then adding the coating mud mixed with the binder into the ceramic mold, The shape of the mold is consistent with that of the steel stud 1, and the diameter of the mold is 18 mm; then, the cleaned steel stud 1 is slowly pressed into the mold. Fix the s...

Embodiment 3

[0024] combine figure 1 and figure 2 , taking a Q235 steel stud 1 with a diameter of 27mm as an example. First prepare protective coating 3 before welding (protective coating 3 composition is; content 25% CaO, 15% TiO 2 , 8% fluorite, 8% cryolite, 1% medium carbon ferromanganese powder, 18% Ni powder, 0.6% V powder, 1% Mo powder, 5% Cr powder, and the rest is Cr 2 o 3 pink. The bonding material is sodium silicate with a modulus of not less than 2.5 and a Baume degree of 45 degrees), and the steel stud 1 welded stud is polished to remove rust, and the steel stud 1 is treated with acetone solution. Cleaning, mixing the ingredients of the coating and the binder, the weight ratio of the binder to the coating is 15-11:100, and then adding the coating mud mixed with the binder into the ceramic mold, The shape of the mold is consistent with that of the steel stud 1, and the diameter of the mold is 30mm; then the cleaned steel stud 1 is slowly pressed into the mold. Fix the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com