Draw Forming Method and Device

a technology of drawing and forming method, applied in the field of drawing forming method and device, can solve the problem of marked non-uniform forming dimensions, and achieve the effect of reducing non-uniformity, reducing non-uniformity, and extremely small deflection in the central section of the blank material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

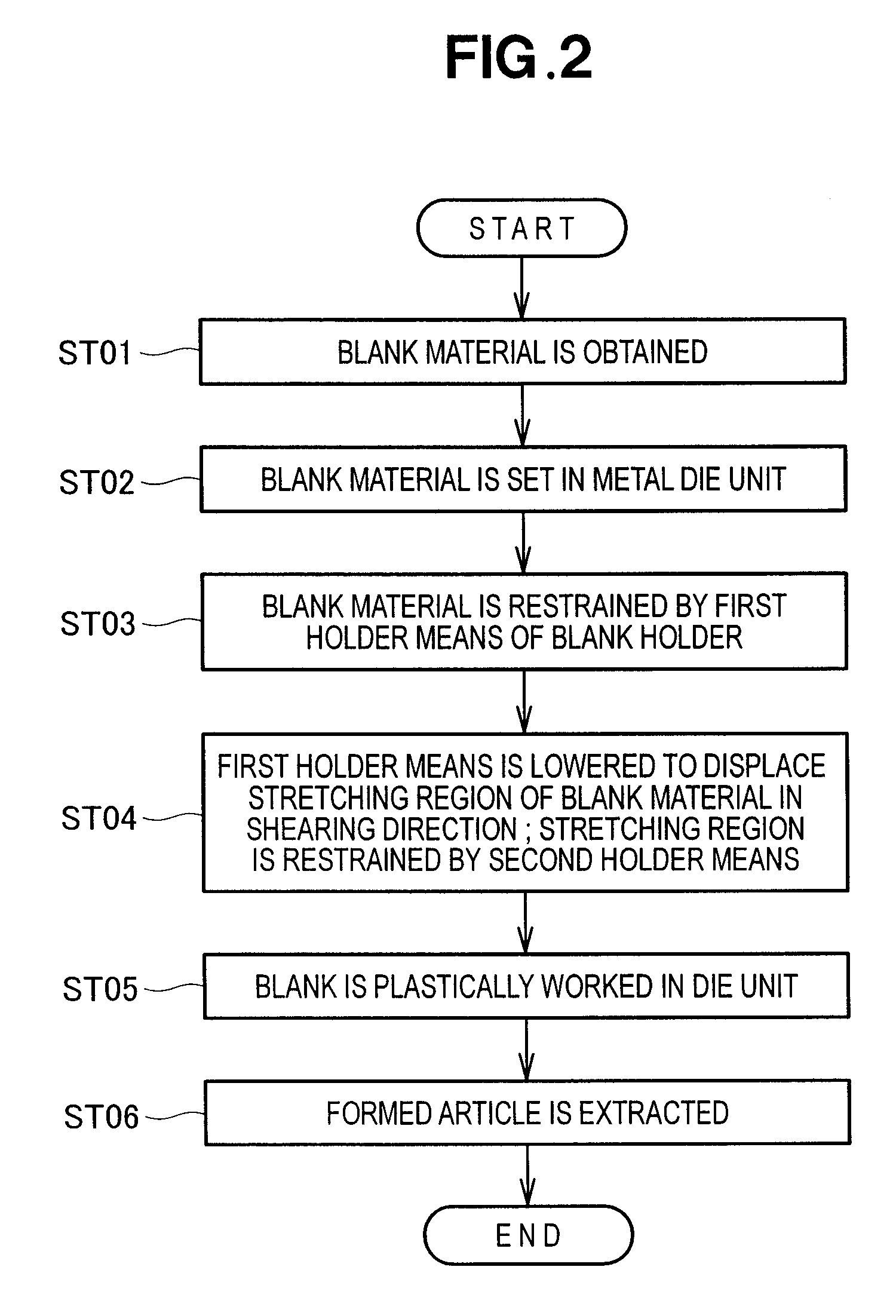

first embodiment

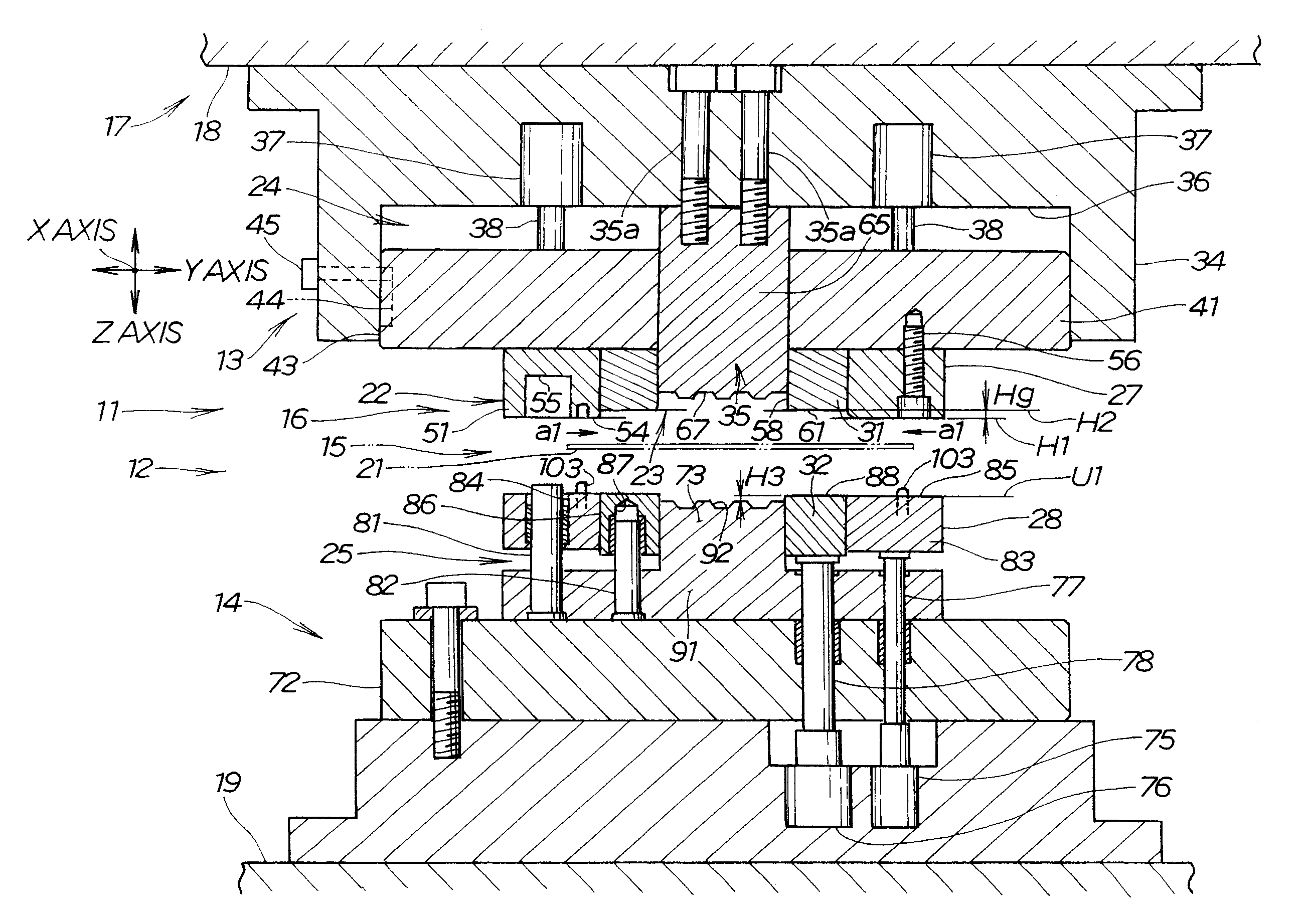

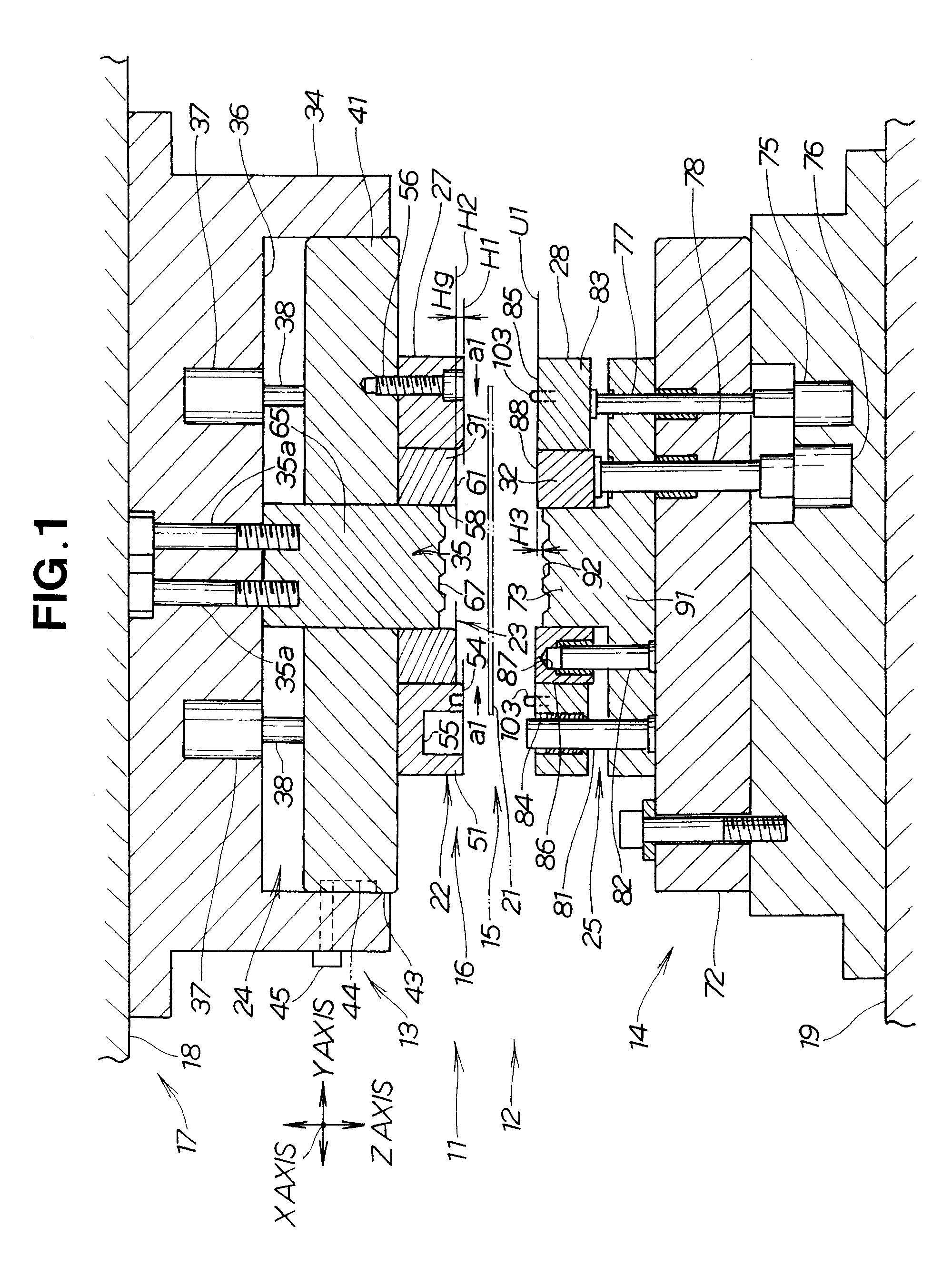

[0030]A draw forming device 11 of the first embodiment shown in FIG. 1 is composed of a metal die unit 12 comprising an upper metal die unit 13 and a lower metal die unit 14, and a blank holder 16 provided to the metal die unit 12 to apply pressure to the blank material 15. The upper metal die unit 13 is mounted on a ram 18 of a press 17. The lower metal die unit 14 is mounted on a bed 19 of the press 17. The draw forming device 11 performs draw forming.

[0031]The blank holder 16 includes first holder means 22 for restraining the outer peripheral section 21 (restraint region 98 in FIG. 3) of the blank material 15, and second holder means 23 disposed on the inside (in the direction of the arrows a1, a1) of the first holder means 22. An upper cushion mechanism 24 is mounted on the upper metal die unit 13, and a lower cushion mechanism 25 is mounted on the lower metal die unit 14 in order to operate the first and second holder means 22, 23.

[0032]The first holder means 22 is composed of ...

second embodiment

[0087]A draw forming device 211 of the second embodiment shown in FIG. 7 is composed of a metal die unit 212 comprising an upper metal die unit 213 and a lower metal die unit 214, and a blank holder 216 provided to the metal die unit 212 to hold down the blank material 15. The upper metal die unit 213 is mounted on the double-action press 217. The lower metal die unit 214 is mounted on a bed 219.

[0088]The double-action press 217 includes an inner slider 245 for applying pressing force in order to form the blank material 15, and an external slider 246 disposed on the outside of the inner slider 245 to hold down the blank material 15. The external slider 246 is raised and lowered individually by hydraulic pressure, for example.

[0089]The upper metal die unit 213 is composed of an upper base member 234 integrally mounted on the external slider 246 of the double-action press 217, and an upper die 235 disposed inside an open section 247 formed in the center of the upper base member 234.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| tensile force | aaaaa | aaaaa |

| dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com