Active coating welding wire for carbon dioxide gas arc welding and preparation method thereof

A technology of gas shielded welding and active coating, which is applied to welding equipment, welding equipment, arc welding equipment, etc., and can solve the problems of low viscosity and non-stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

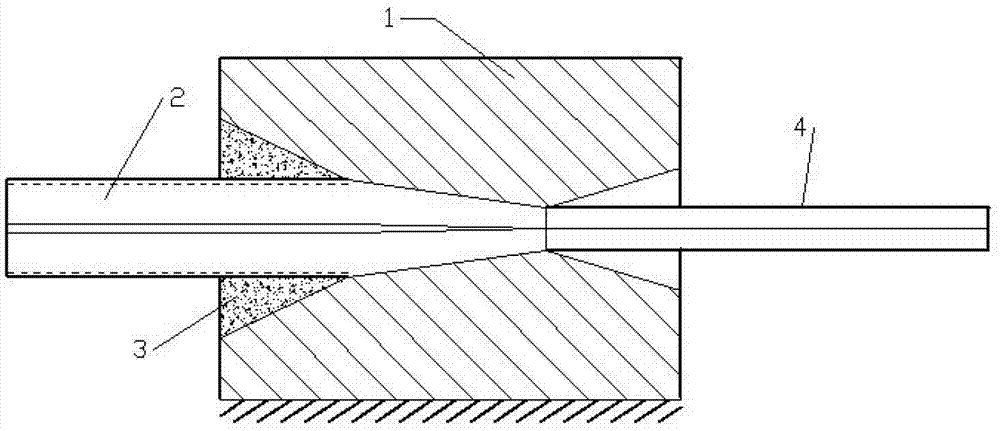

[0021] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. Since the commonly used carbon dioxide gas shielded welding wire is generally Φ1.2-1.6mm in diameter, the present invention uses a drawing process to pull it to Φ1.2-1.6mm, but the present invention is not limited thereto. A commercially available Φ5.5mm H08 carbon steel wire rod is used.

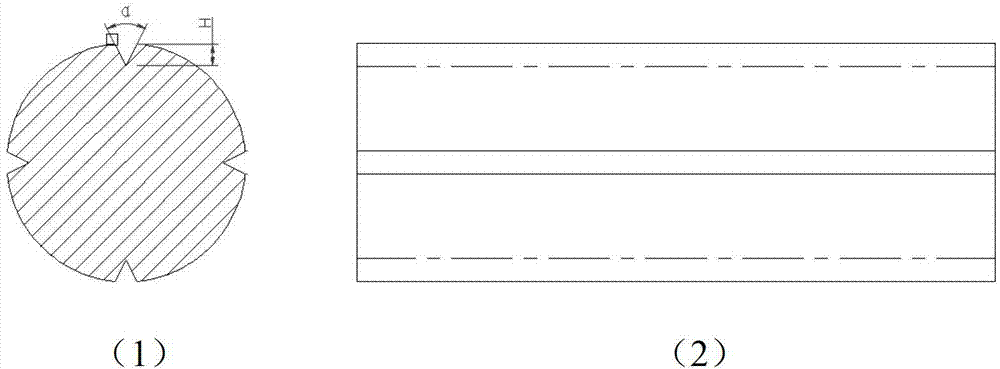

[0022] The Φ5.5mm H08 wire rod is peeled off and rusted, and at the two ends of the horizontal diameter direction and the vertical diameter direction of the cross section of the welding wire, a continuous V-shaped groove is processed along the length direction on the circumferential surface of the welding wire by a scoring knife. Where α is the opening angle of the V-shaped notch 60°, and H is the depth of the V-shaped notch 0.8mm.

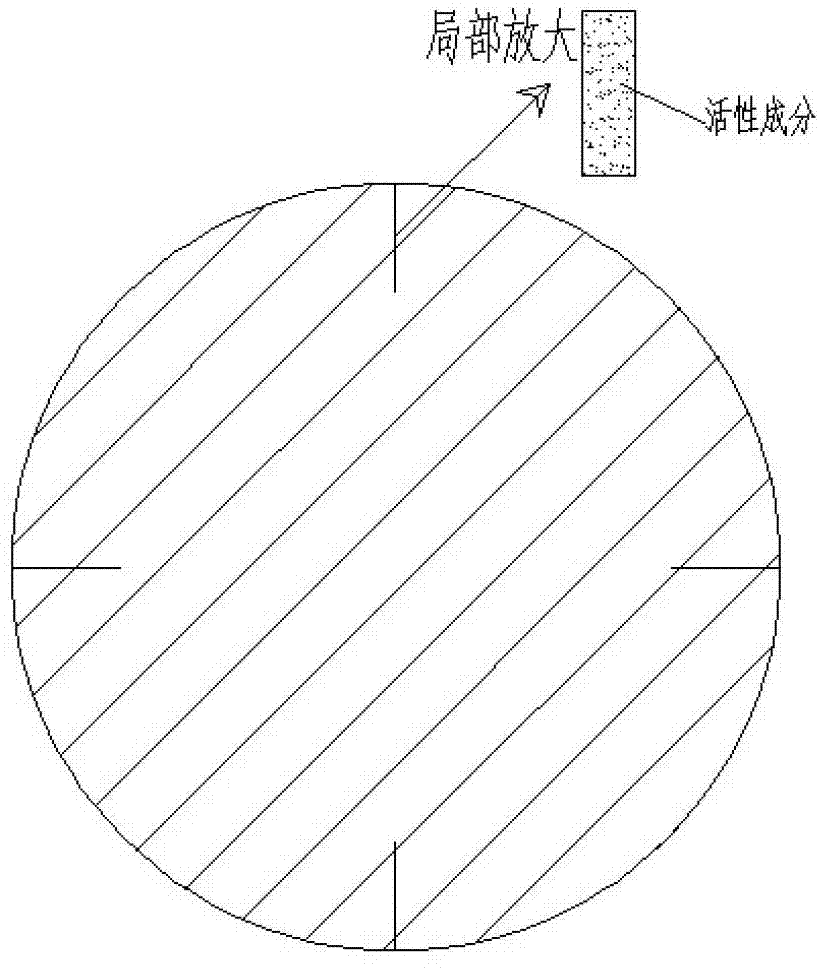

[0023] On the surface of the above-mentioned metal wire, the surface of the above-mentioned metal wire is uniformly coated with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com