Preparation method of carbon nano-tube array and its application in preparing antenna array

A technology of carbon nanotubes and manufacturing methods, which is applied in the field of dipole antenna devices, can solve the problems of low efficiency, high price, unsuitability for large-scale research and application of nano-optoelectronic integrated devices, etc., and achieves simple preparation process, uniform diameter, improved Effect of Optical Signal Receiving Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Catalyst preparation

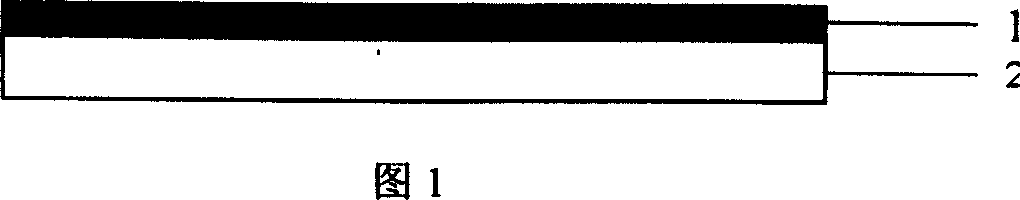

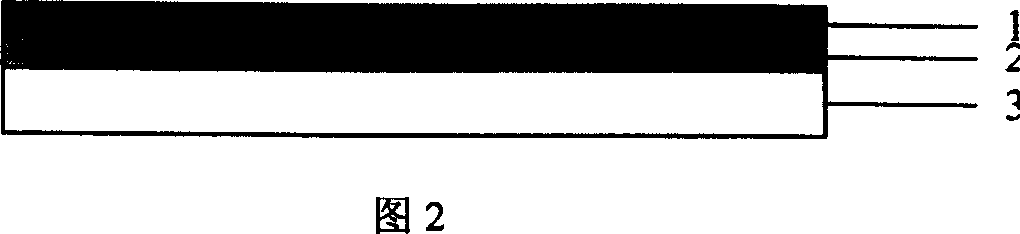

[0062] The substrate used to grow carbon nanotubes can be any solid material that can withstand the growth temperature (generally 300 ℃ ~ 500 ℃), including metals (or alloys), semiconductors (such as silicon), oxides (such as SiO 2 , ITO, ZnO, etc.) and polymer molecular materials (such as Polyimide), the above ITO refers to indium tin oxide: indium tin oxide. As shown in Figure 2, if a conductive substrate 2 such as metal or semiconductor is used, a layer of transition metal catalyst film 1 (such as iron, cobalt, nickel and their alloys) can be deposited directly on the surface of the substrate. The deposition method can be electrical Chemical deposition, thermal (or electron beam) evaporation deposition, sputtering deposition, and any other common metal thin film preparation methods in scientific research and industry. As shown in FIG. 2, if an insulating substrate 3 (such as glass, etc.) is used, a conductive layer 2 (such as chromium, t...

Embodiment 2

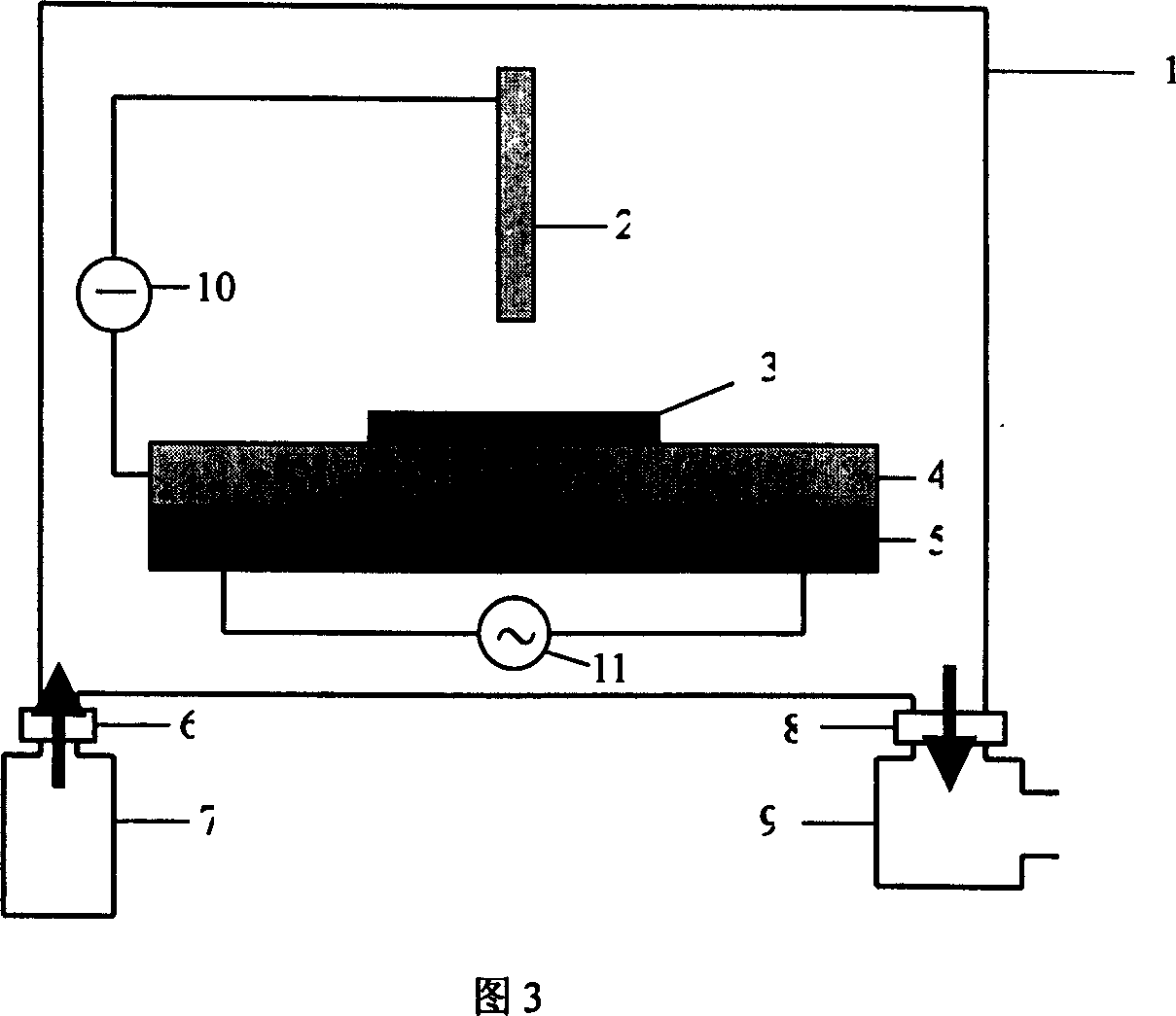

[0063] Embodiment 2: DC plasma chemical vapor deposition system structure

[0064] The growth of vertically aligned carbon nanotubes (fibers) can be accomplished by a direct current plasma chemical vapor deposition system. The basic structure of the system is shown in Figure 3. In the vacuum chamber 1', there are a vertical columnar electrode 2 and a horizontal disk electrode (i.e., a sample stage) 4. The distance between the two electrodes is about 1 to 3 cm, and they are tapped at both ends of the DC power supply 10. The shape of the vertical electrode 2 can also be a disc shape, a needle shape, etc., and its shape and size depend on actual conditions. The sample 3 to be grown is placed above the horizontal electrode (sample stage) 4, and the heater 5 can uniformly heat the electrode below. The heater can be connected to a standard AC power supply 11. Reactive gas (such as NH 3 And C 2 H 2 ) The gas source 7 passes through the flow rate adjusting valve 6 into the cavity. One end...

Embodiment 3

[0065] Example 3: Growth of vertically aligned carbon nanotube (fiber) array

[0066] After the sample is placed in the system, the air pressure in the chamber is pumped to 10 -2 Torr~10 -6 Torr is basically vacuum. Then turn on the heater power and gradually increase the temperature of the sample stage to 400℃~600℃, while passing in 160sccm NH 3 , And keep the system pressure to 1-20 Torr. After the temperature reaches the expected value and stabilizes, turn on the DC power supply and increase the voltage until a certain intensity of plasma is generated between the two electrodes. After a proper pre-etching time (generally no more than a few minutes), pass 20sccm~80sccm C 2 H 2 , To promote the vertical growth of carbon nanotube (fiber) array. The heating and plasma etching process causes the catalyst film to split into nanoparticles, thereby catalyzing the growth of carbon nanotubes (fibers). The length of carbon nanotubes (fibers) can be adjusted by controlling the growth time....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com