Connection method for thick plate TiNi alloy and titanium alloy dissimilar materials

A technology of dissimilar materials and connection methods, applied in welding equipment, metal processing equipment, electron beam welding equipment, etc., can solve the problems of severe joint embrittlement and poor comprehensive mechanical properties of joints, and achieve grain refinement and joint structure uniformity. The effect of reducing and preventing joint cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

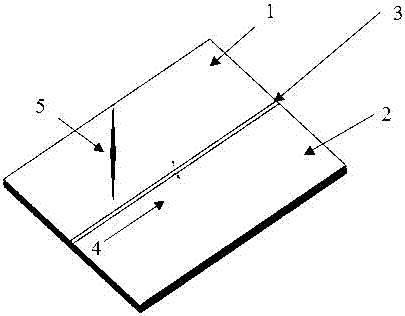

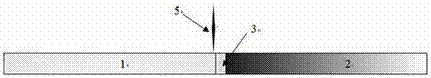

[0025] The invention provides a method for connecting thick-plate TiNi alloys and titanium alloy dissimilar materials, such as Figure 1-3 It is the main process diagram; the experiment uses TiNi shape memory alloy (titanium-nickel atomic ratio is 50.4:49.6) and TC4 titanium alloy, the size of TC4 is 100×70×3mm, the size of TiNi alloy is 100×70×3.05mm, and the filling metal is pure 99.9% niobium sheet with a thickness of 0.4mm. If the thickness is too thin, Nb will melt and lose its physical barrier effect, making the dissimilar materials to be welded contact with each other to form brittle intermetallic compounds. If it is too thick, it will be difficult to make the TiNi alloy side fully metallurgical with Nb. The reaction leads to a decrease in the strength of the joint, such as figure 1 ; The working distance of the vacuum chamber is 290CM, the welding speed is 600 mm / min, the electron beam current is 18mA, and the workpiece is preheated for 4 times with a 3mA electron beam...

Embodiment 2

[0027] The invention provides a method for connecting thick-plate TiNi alloys and titanium alloy dissimilar materials, such as Figure 1-2 , 4 is the main process diagram; the test uses TiNi shape memory alloy (titanium-nickel atomic ratio is 50.4:49.6) and TC4 titanium alloy, the size of TC4 is 100×70×3mm, the size of TiNi alloy is 100×70×3.05mm, the filler metal It is a niobium sheet with a purity of 99.9% and a thickness of 0.6mm. If the thickness is too thin, Nb will melt and lose its physical barrier effect, causing the dissimilar materials to be welded to contact each other to form brittle intermetallic compounds. If it is too thick, it will be difficult to make the TiNi alloy side contact with the Nb Full metallurgical reaction leads to reduction of joint strength, such as figure 1 ; The working distance of the vacuum chamber is 290CM, the welding speed is 600 mm / min, the scanning waveform is circular, the scanning frequency is 500 Hz, the scanning amplitude is 0.25 mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com