Patents

Literature

45results about How to "Increase the number of poles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

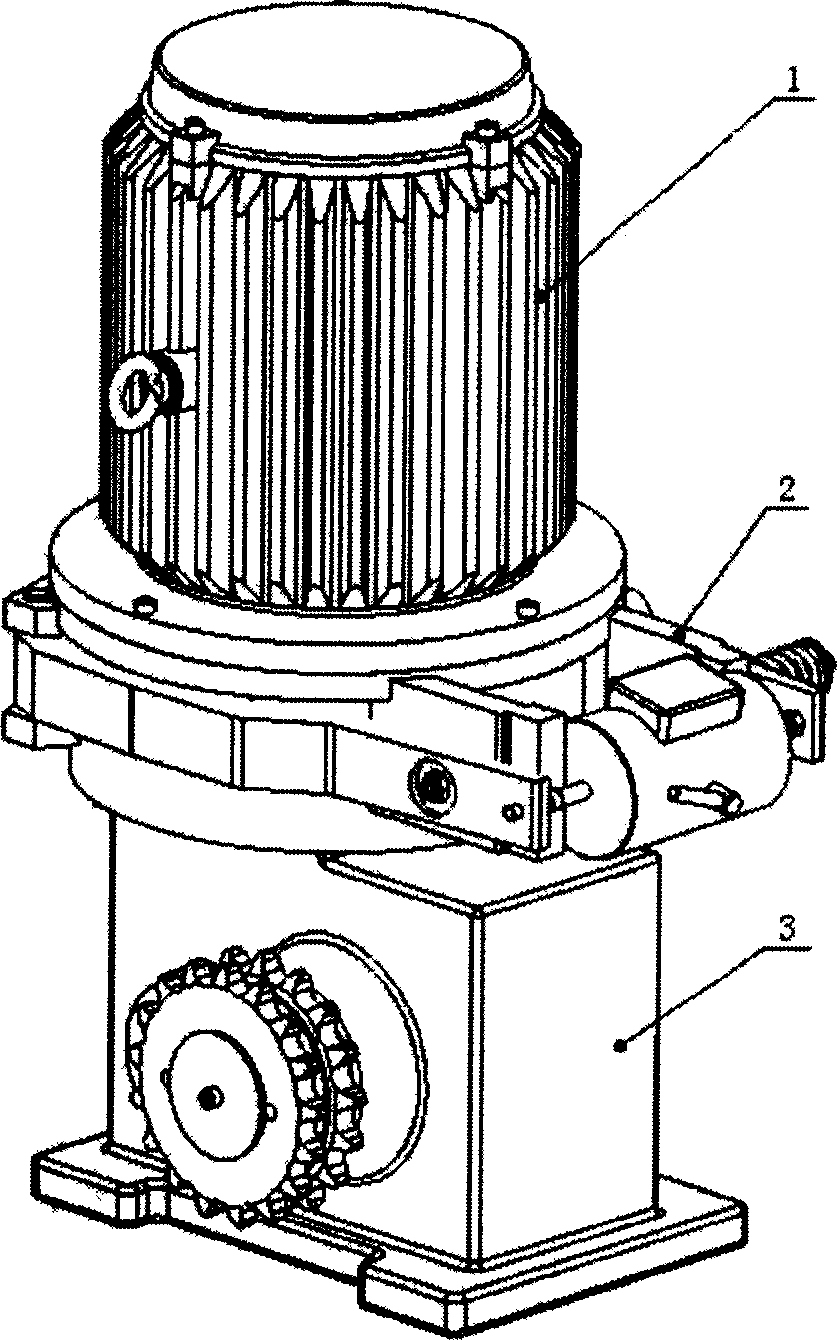

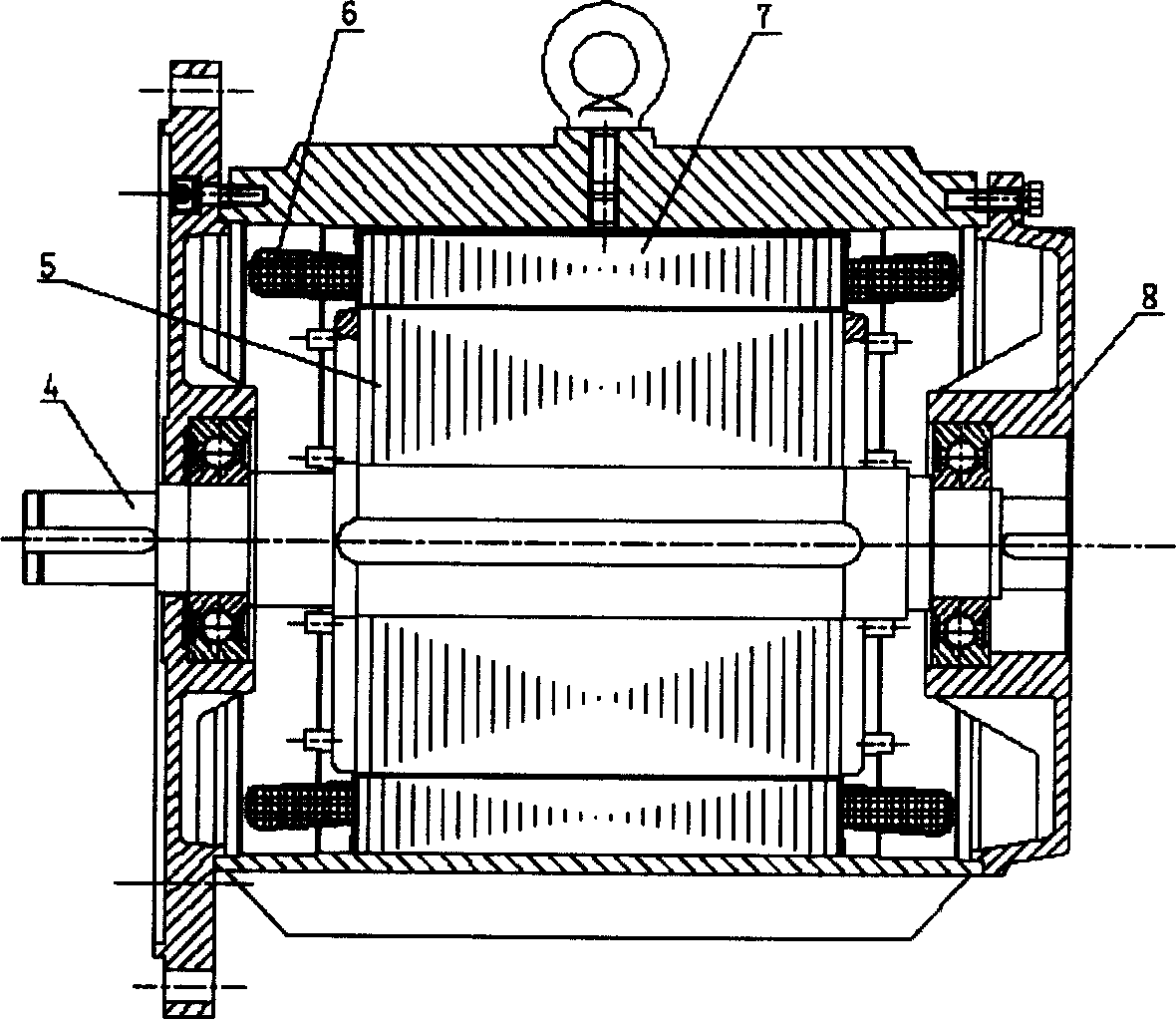

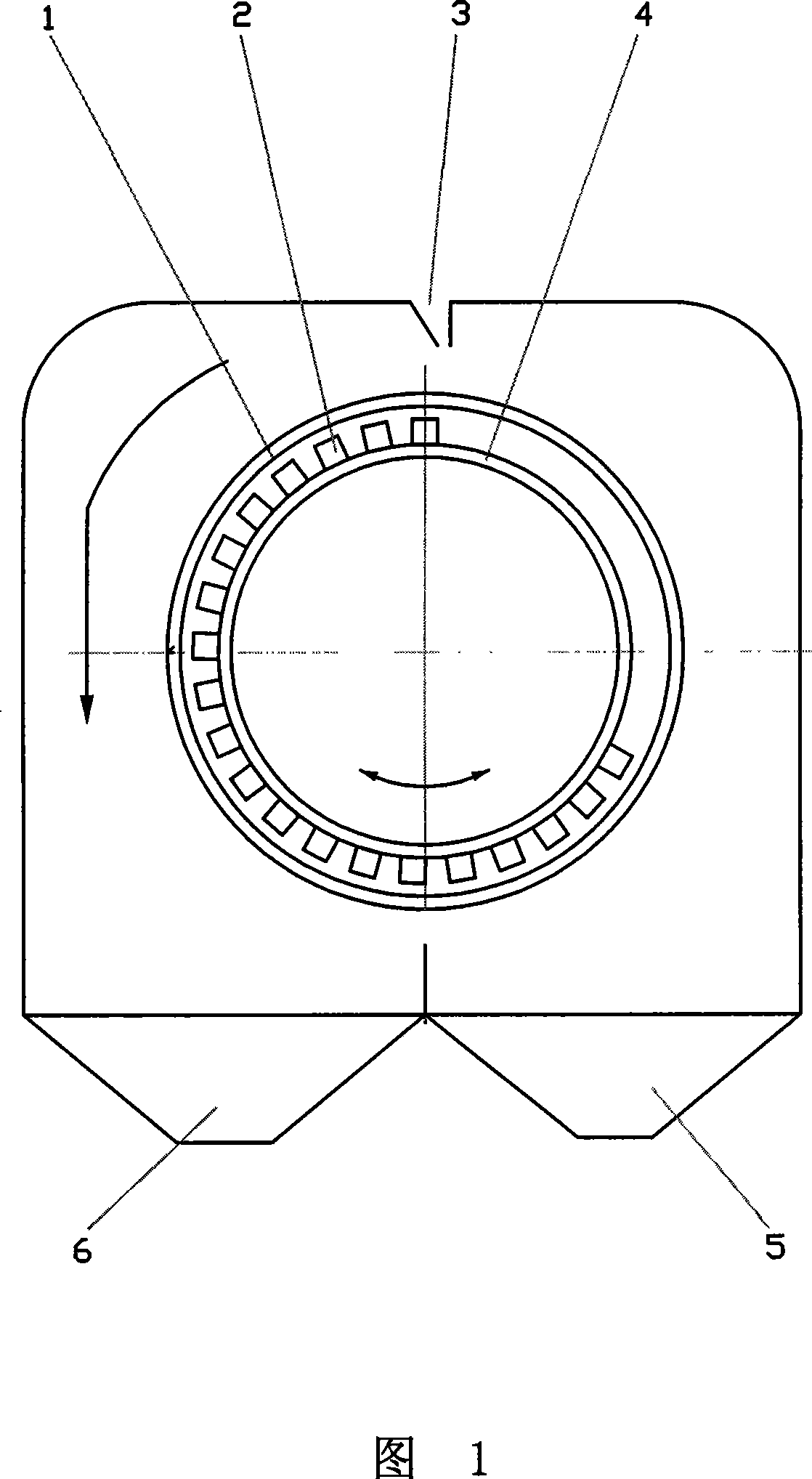

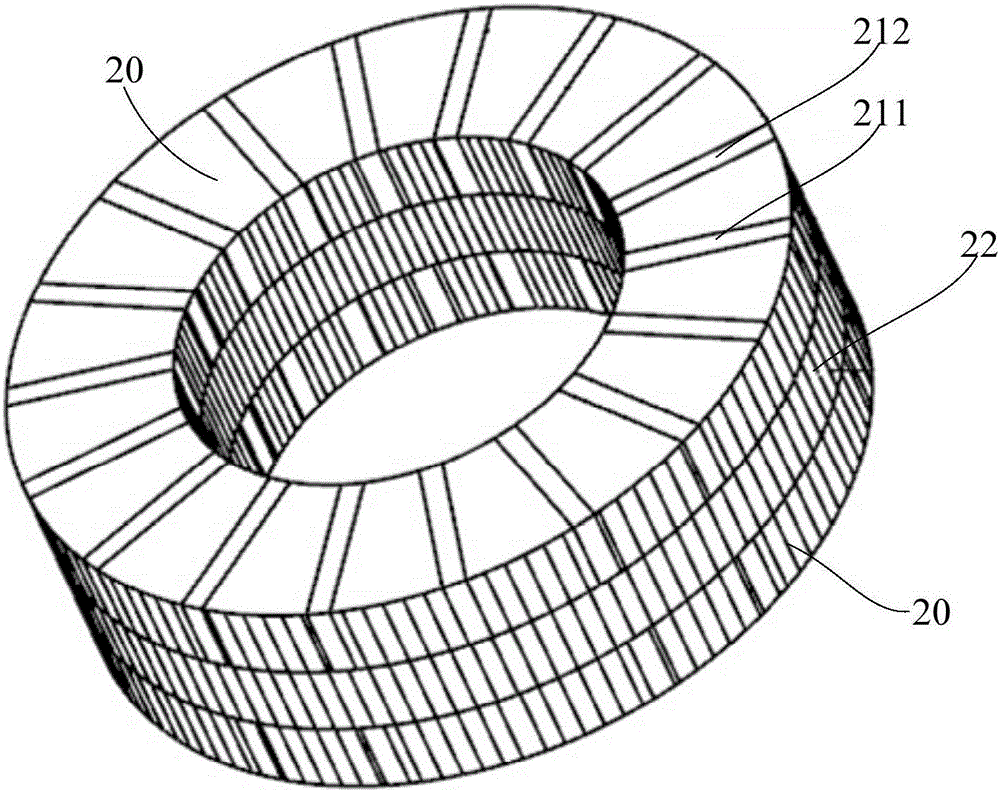

Electrical powered tail rotor of a helicopter

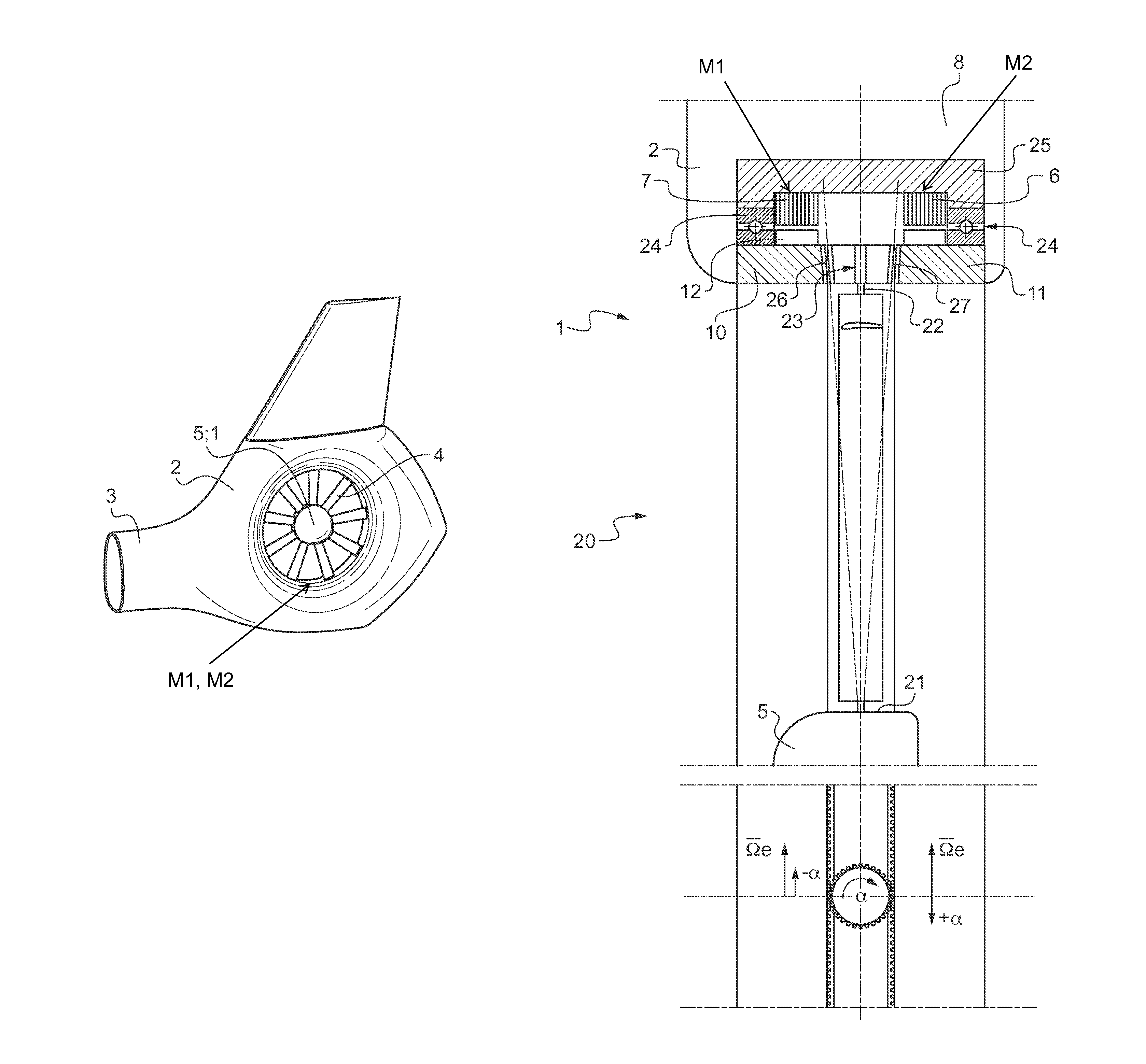

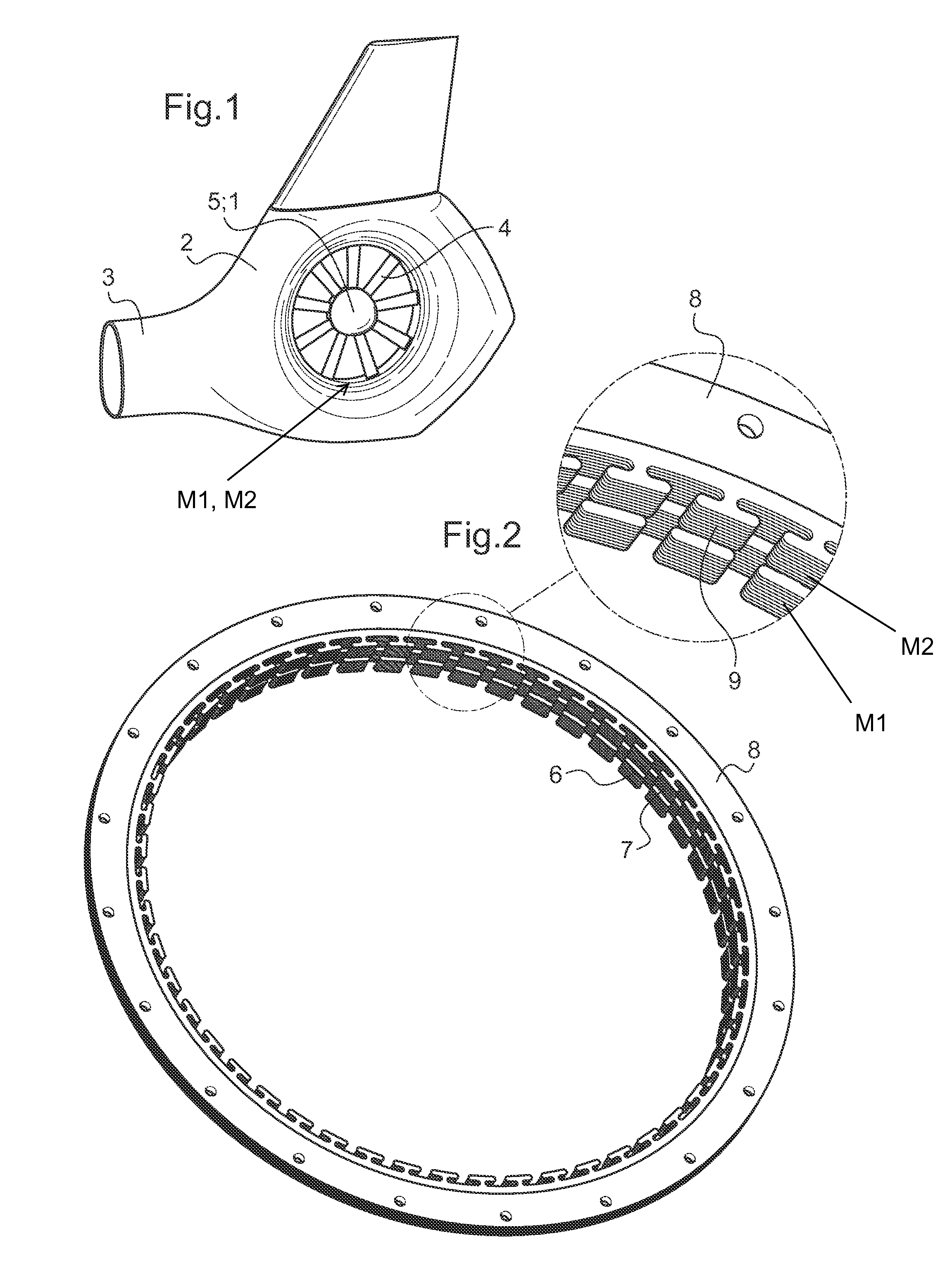

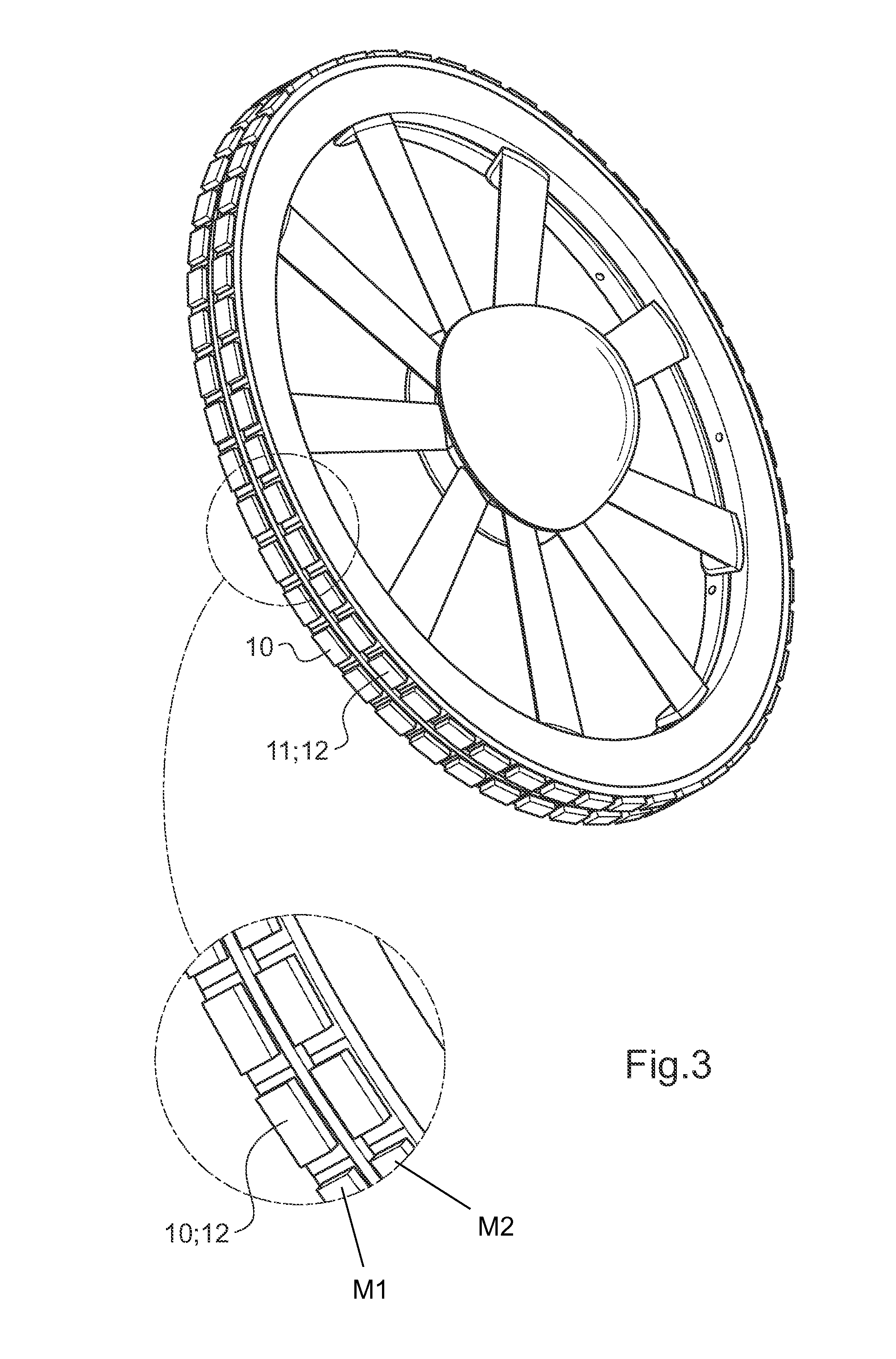

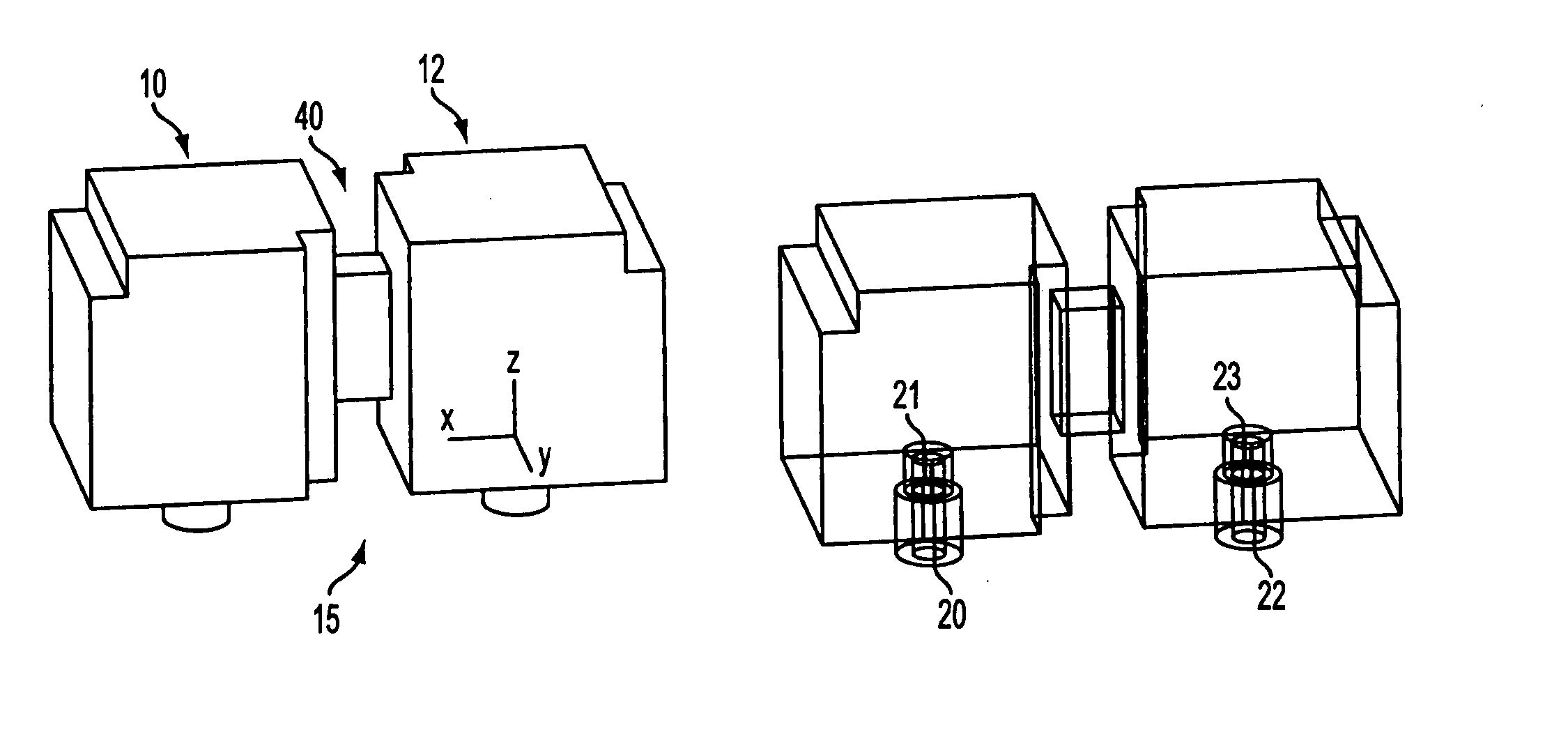

ActiveUS9174728B2Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

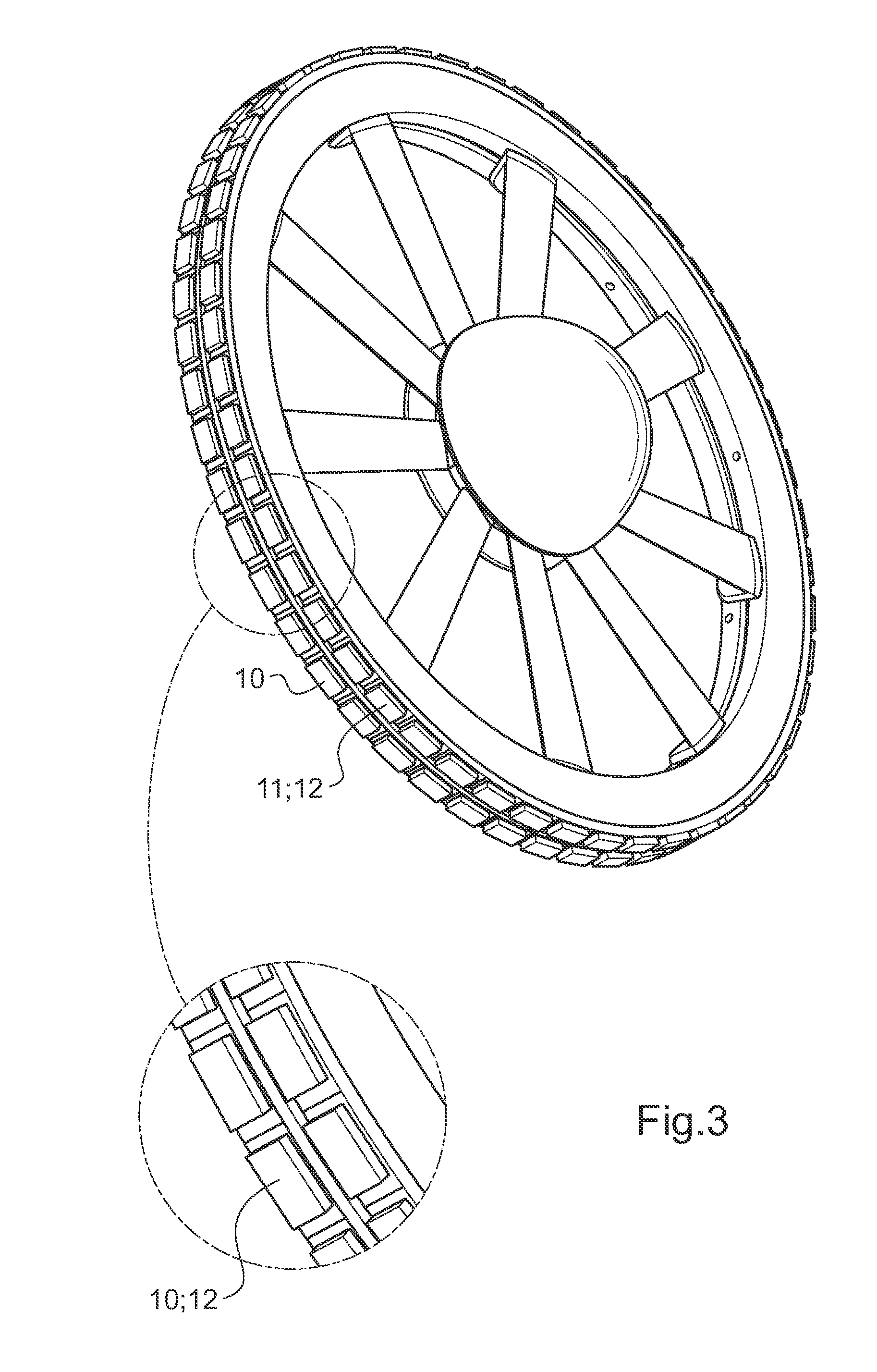

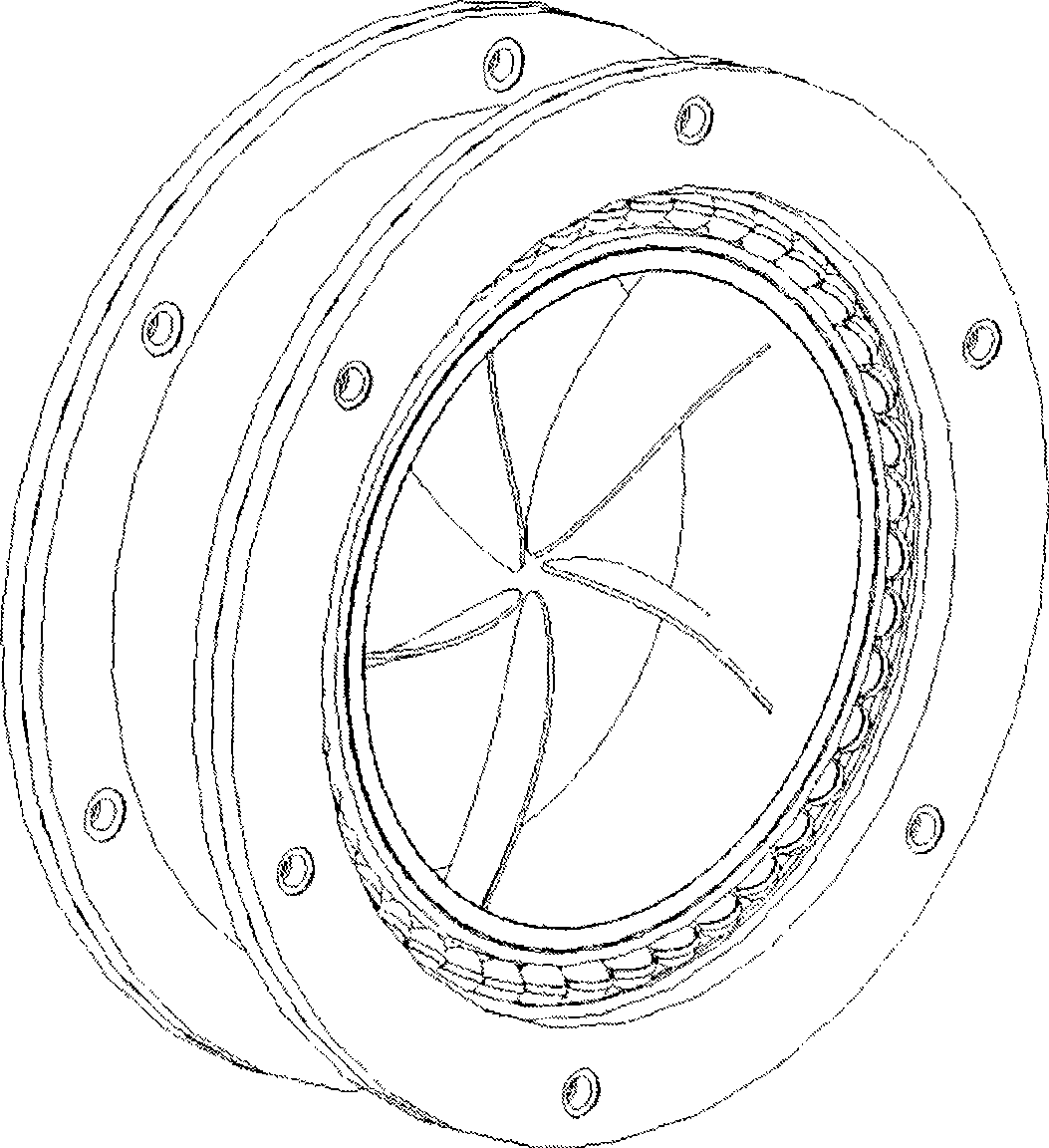

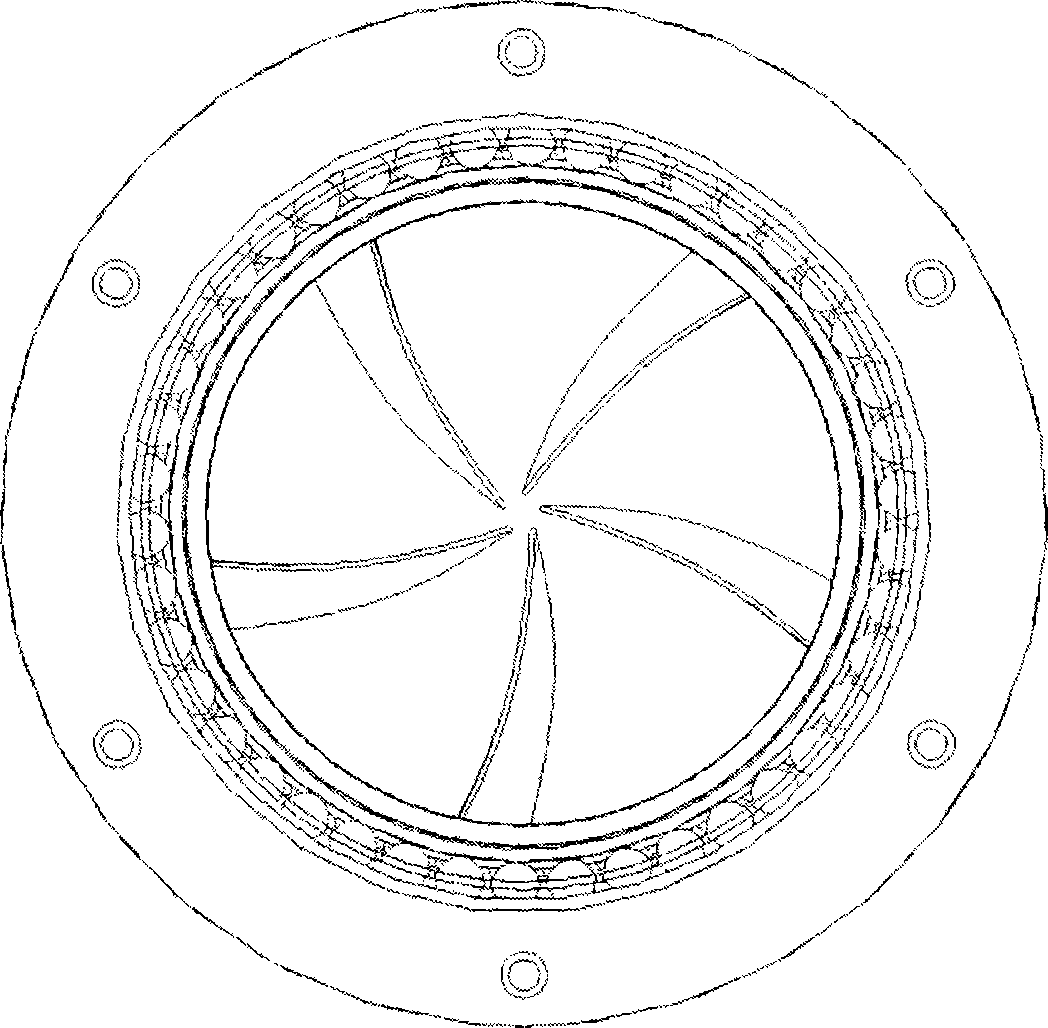

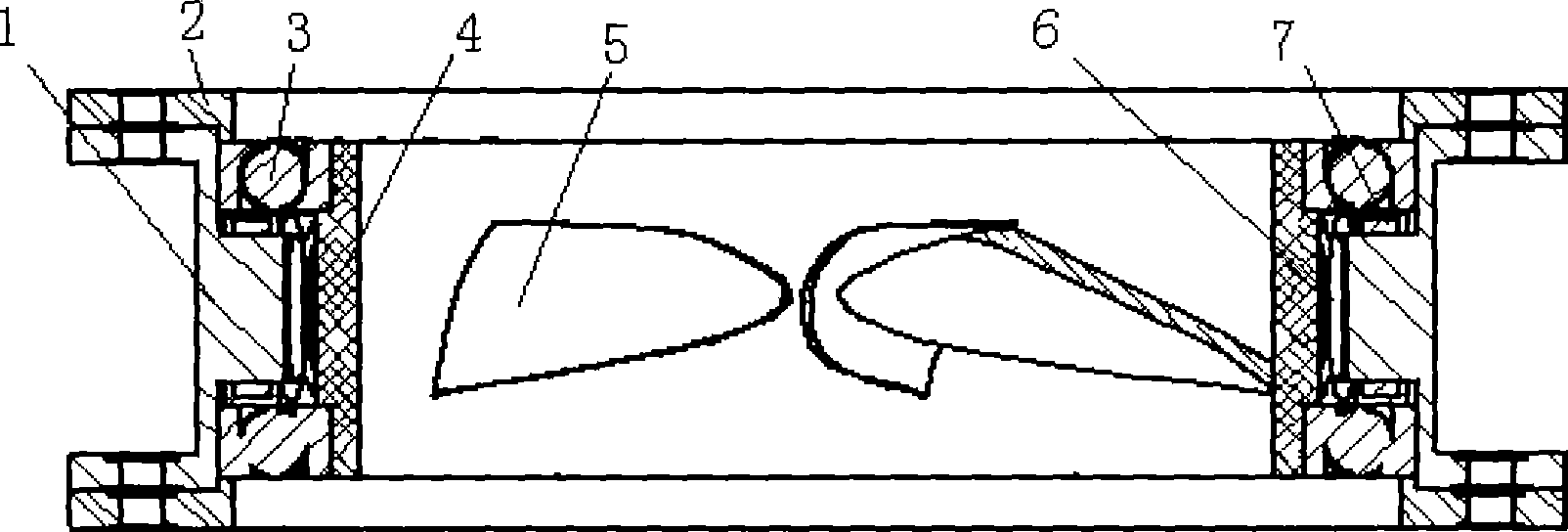

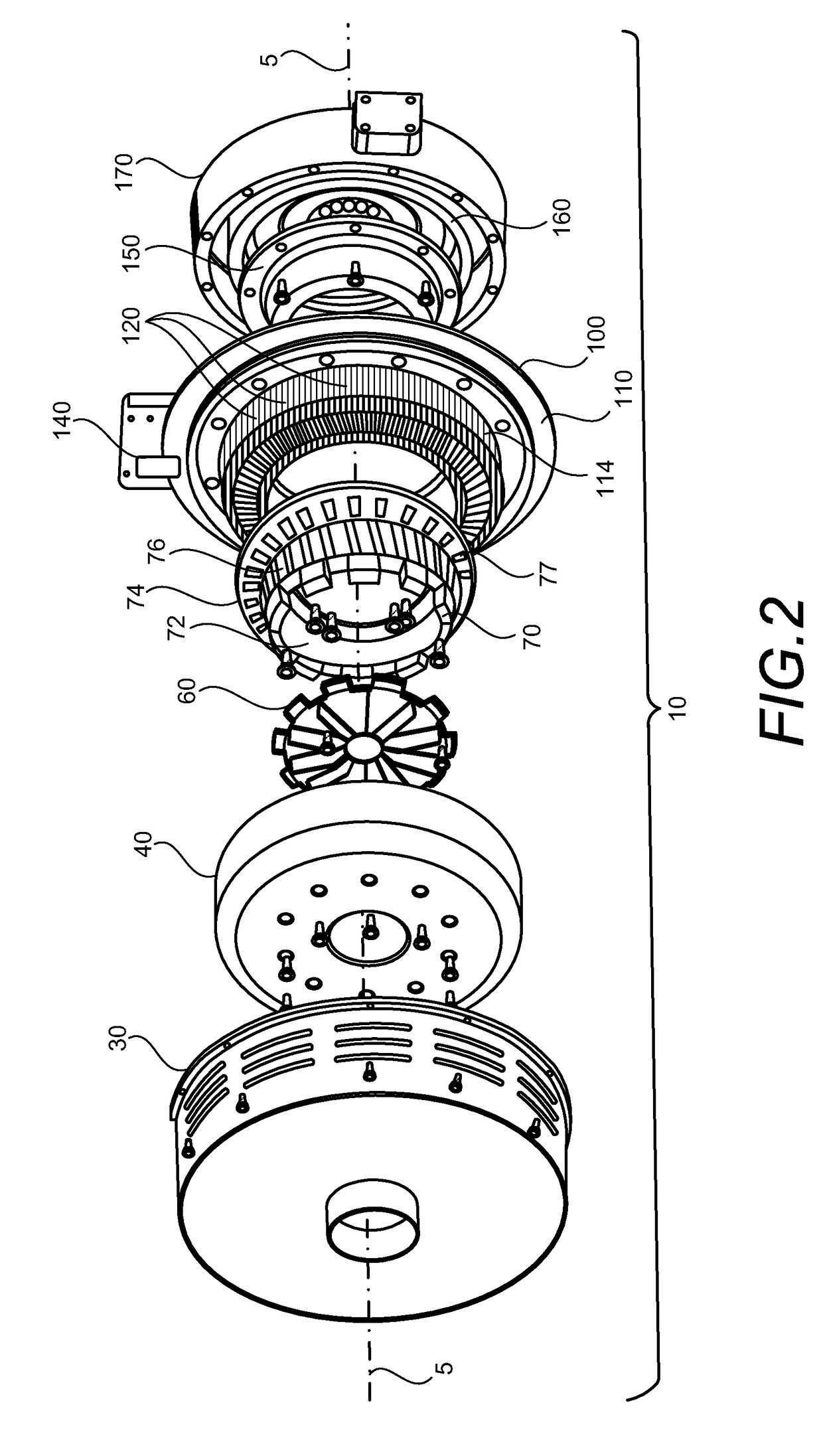

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

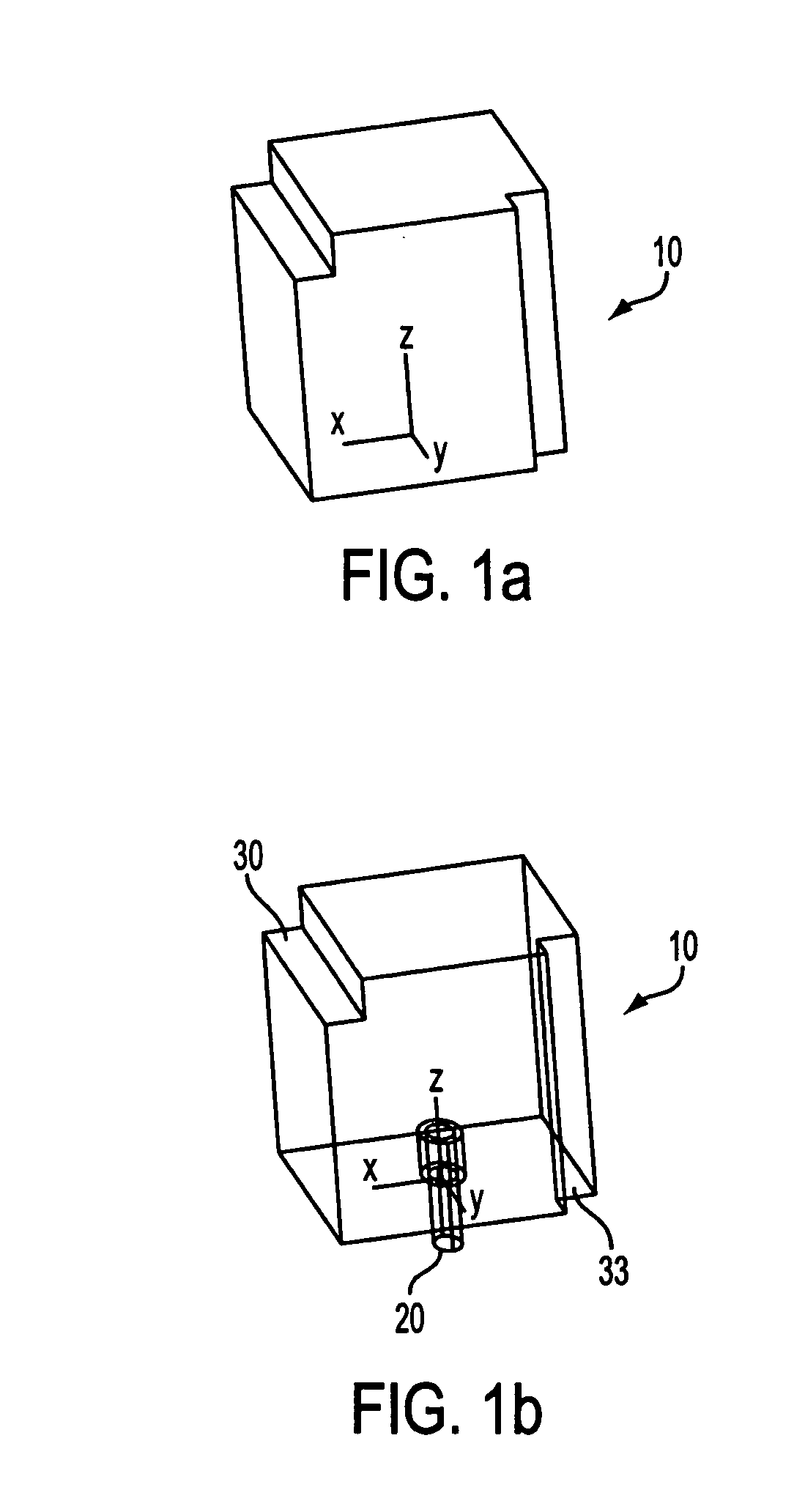

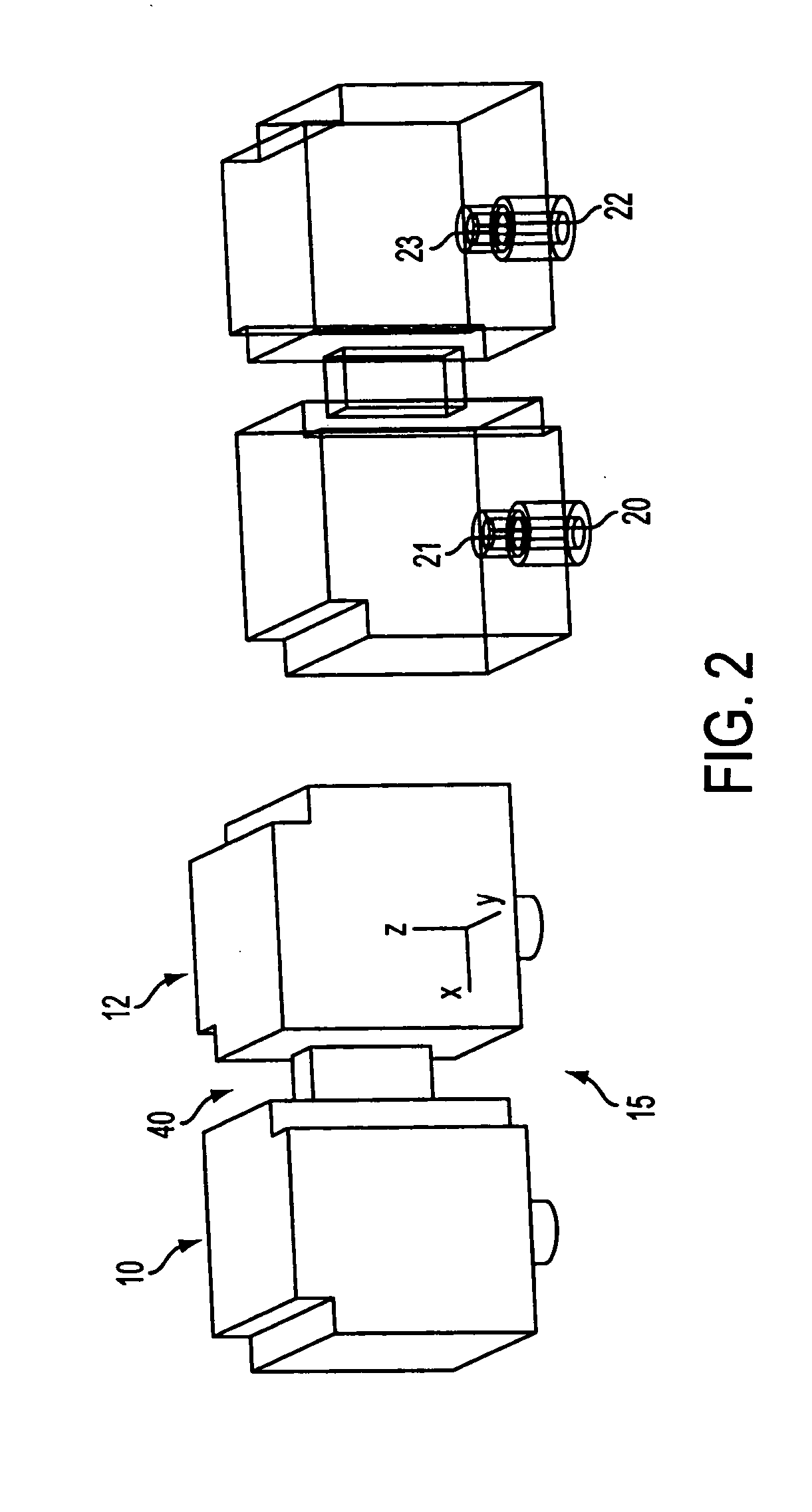

Hybrid triple-mode ceramic/metallic coaxial filter assembly

ActiveUS20050128031A1Increase the number ofIncrease the number of polesWaveguidesWaveguide type devicesHybrid filterReduced size

A hybrid filter assembly is provided having a first ceramic triple-mode mono-block resonator, a second ceramic triple-mode mono-block resonator and at least one metallic resonator coupled to at least one of the first and second mono-block resonators. Each triple-mode mono-block resonator supports three resonant modes and each metallic resonator supports an additional mode, thereby providing a hybrid filter assembly of reduced size having more than six poles.

Owner:RADIO FREQUENCY SYST

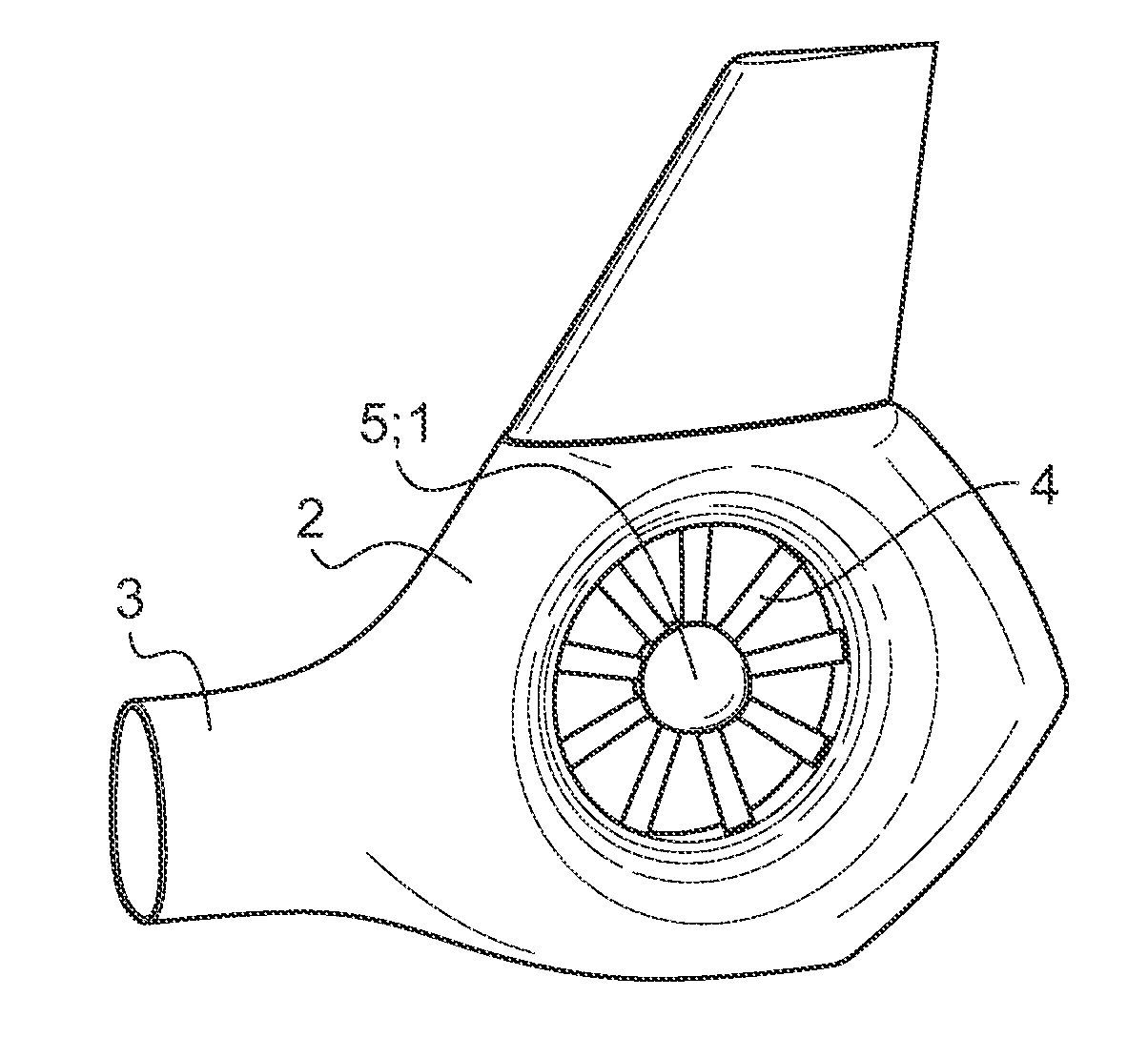

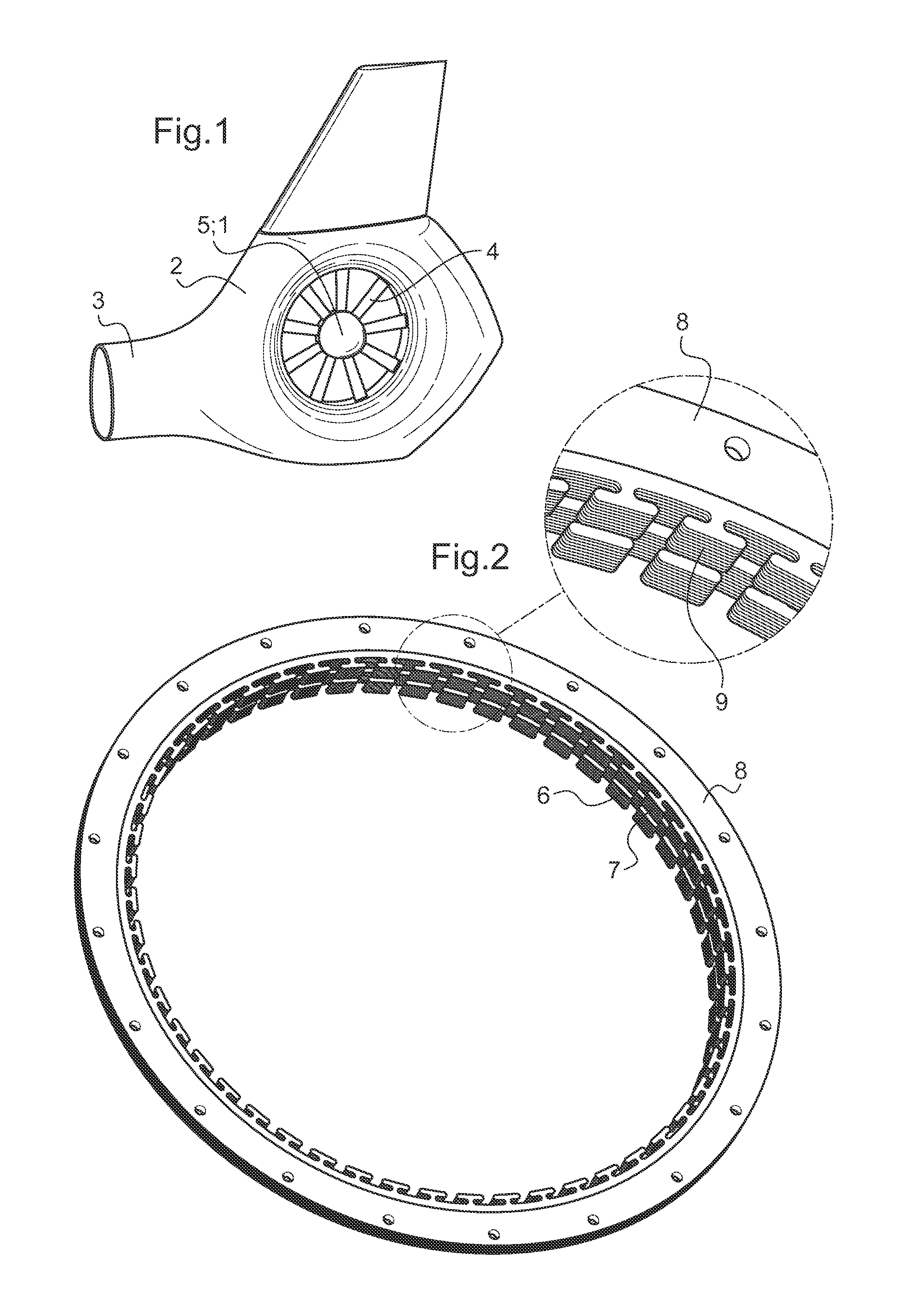

Electrical powered tail rotor of a helicopter

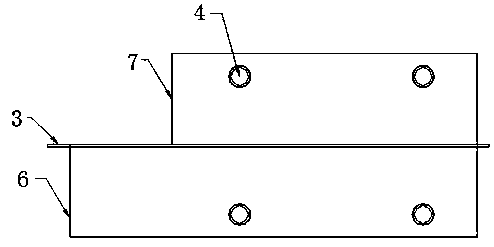

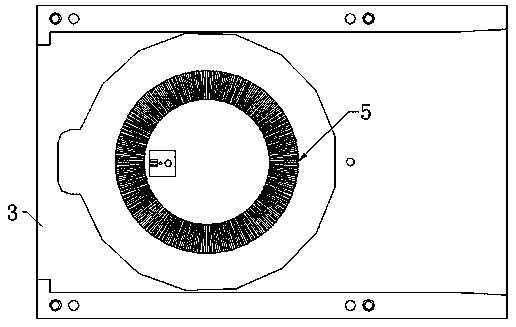

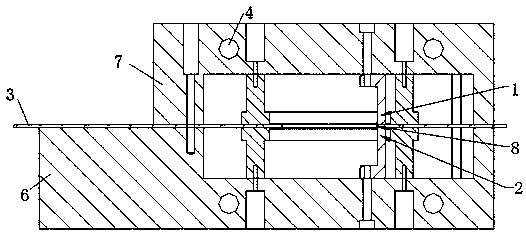

ActiveUS20130170985A1Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

Brushless motor

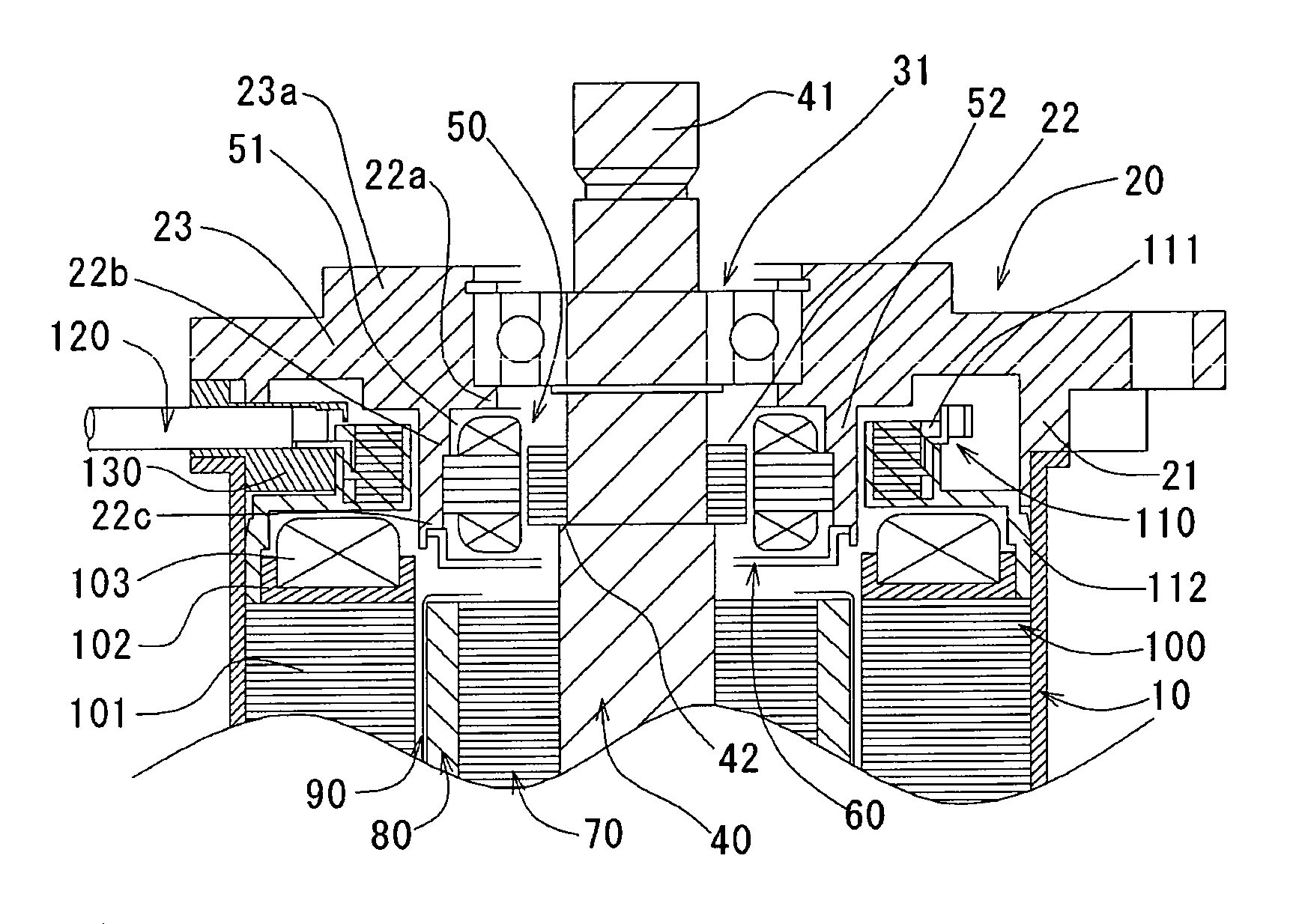

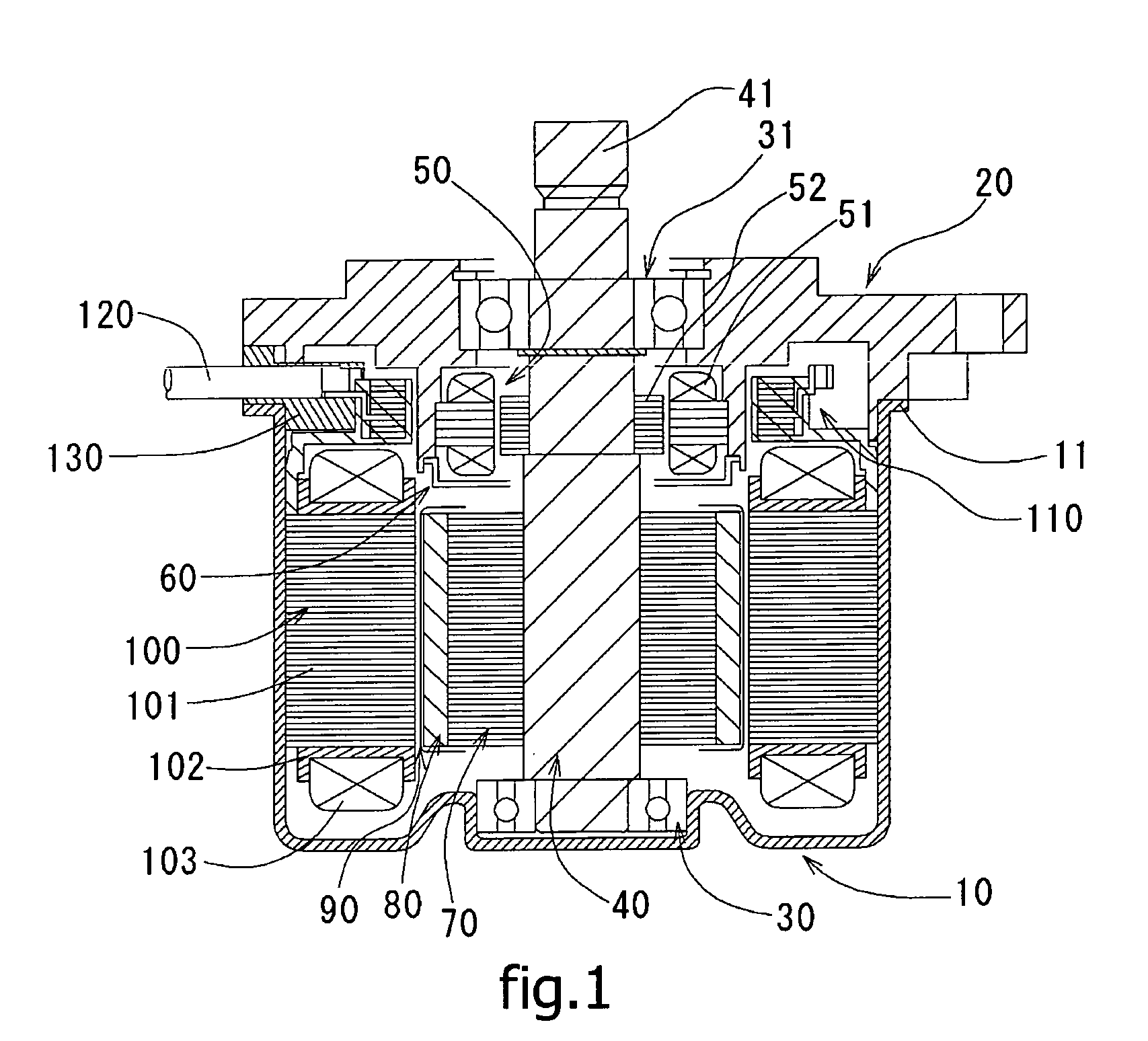

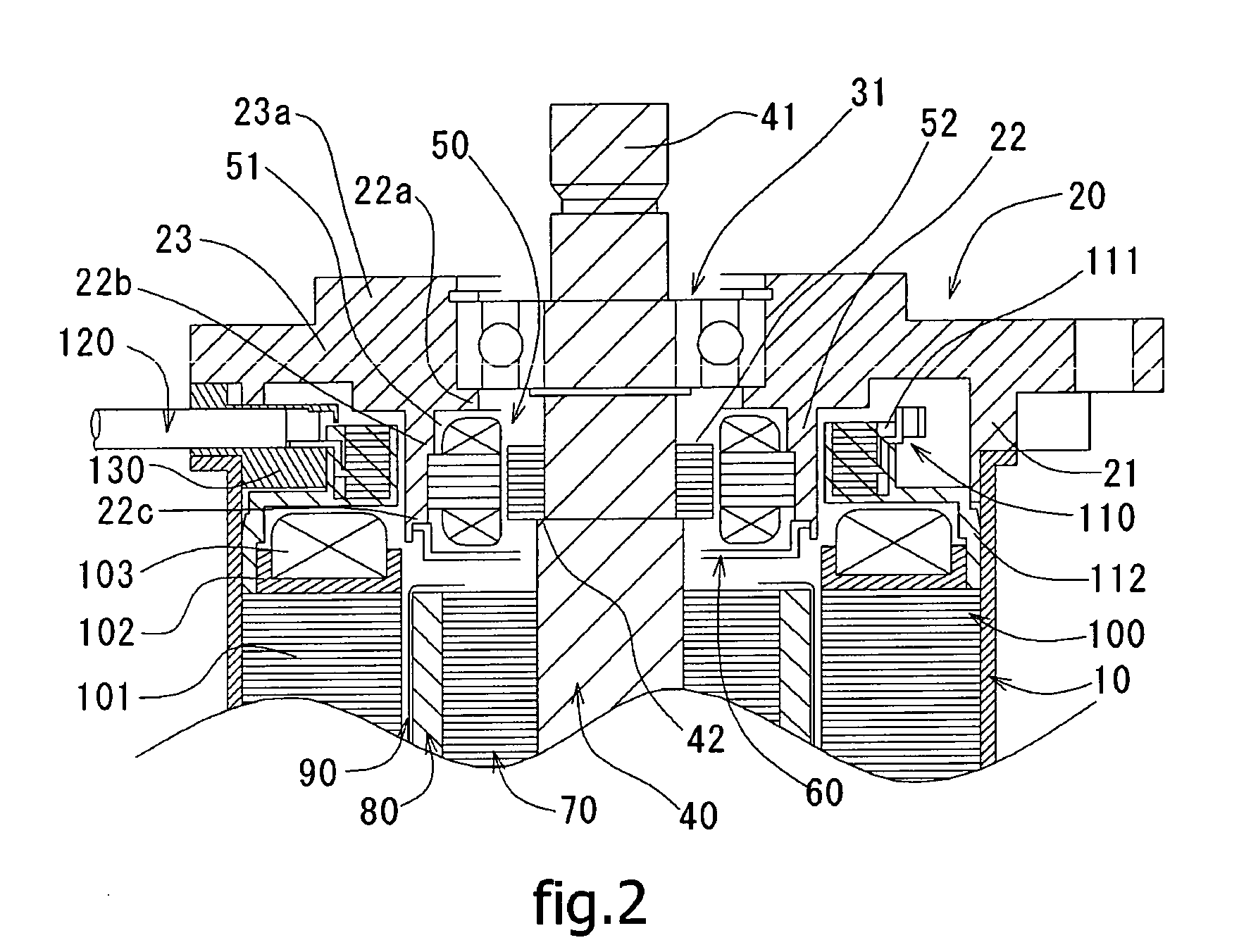

ActiveUS7453175B2Improve the efficiency of position adjustmentImprove efficiencySynchronous generatorsAsynchronous induction motorsBrushless motorsEngineering

A second bracket part for holding a resolver stator of a resolver as position detecting means is inserted in an opening hole in a first bracket part. An expanded part formed in the second bracket part and the opening hole in the first bracket hole are connected to each other with a fixing member. A through hole in which the fixing member for the expanded part is inserted has a circular arc shape. By reducing the fixing strength of the fixing member, the second bracket part can be made movable in the circumferential direction.

Owner:NIDEC CORP

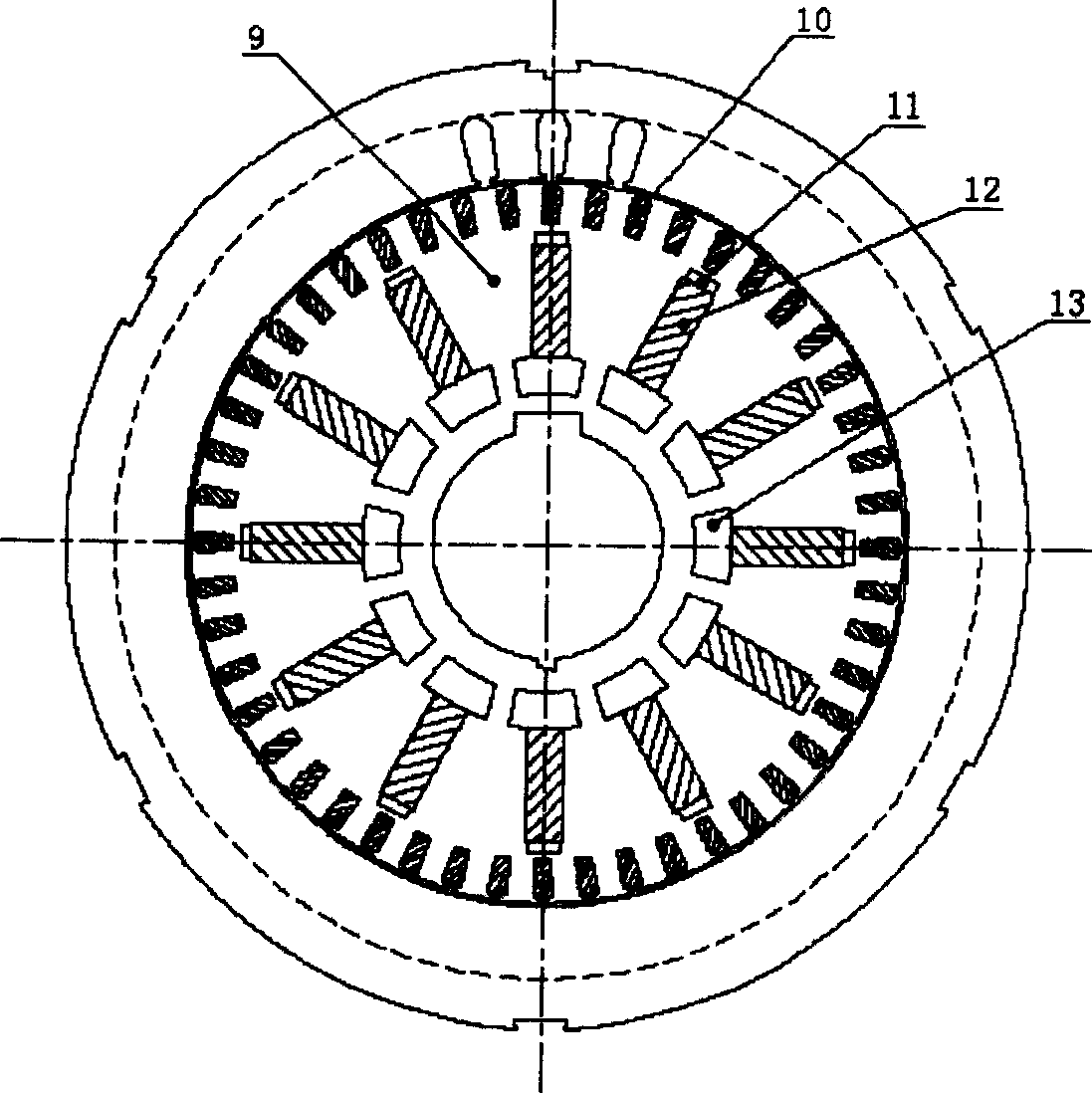

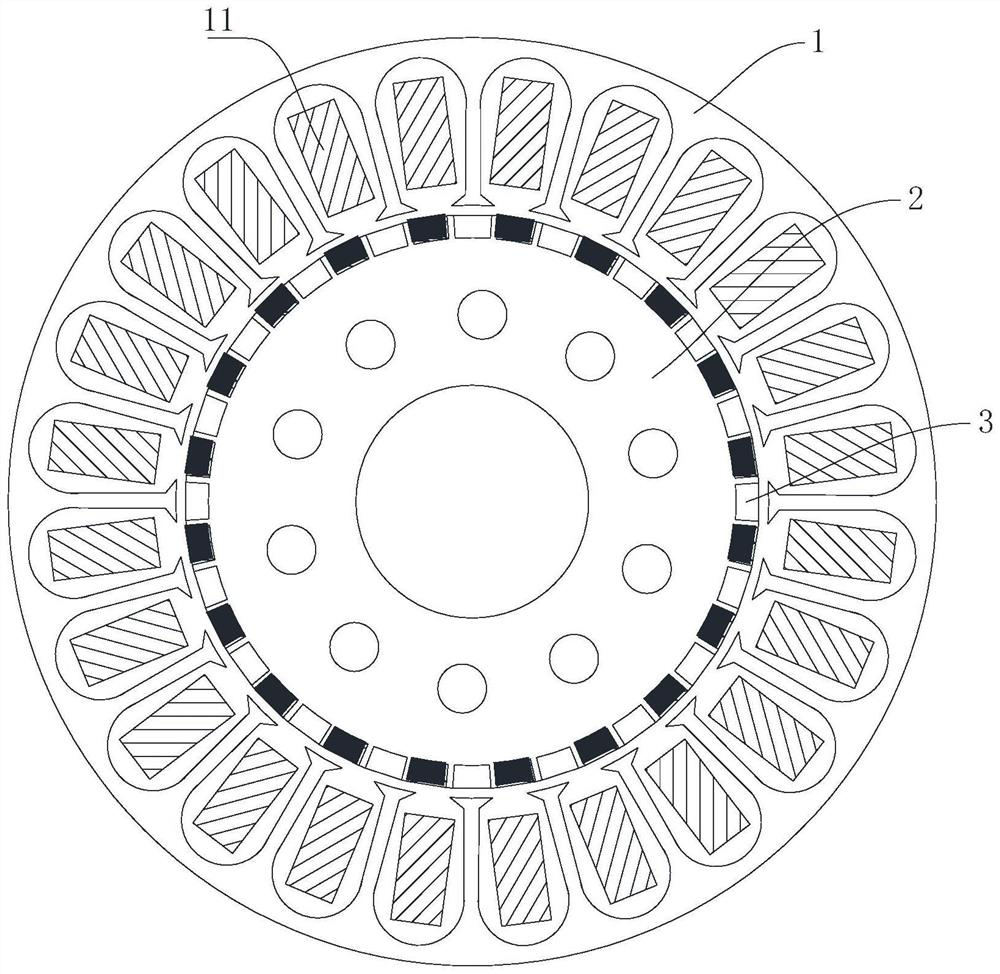

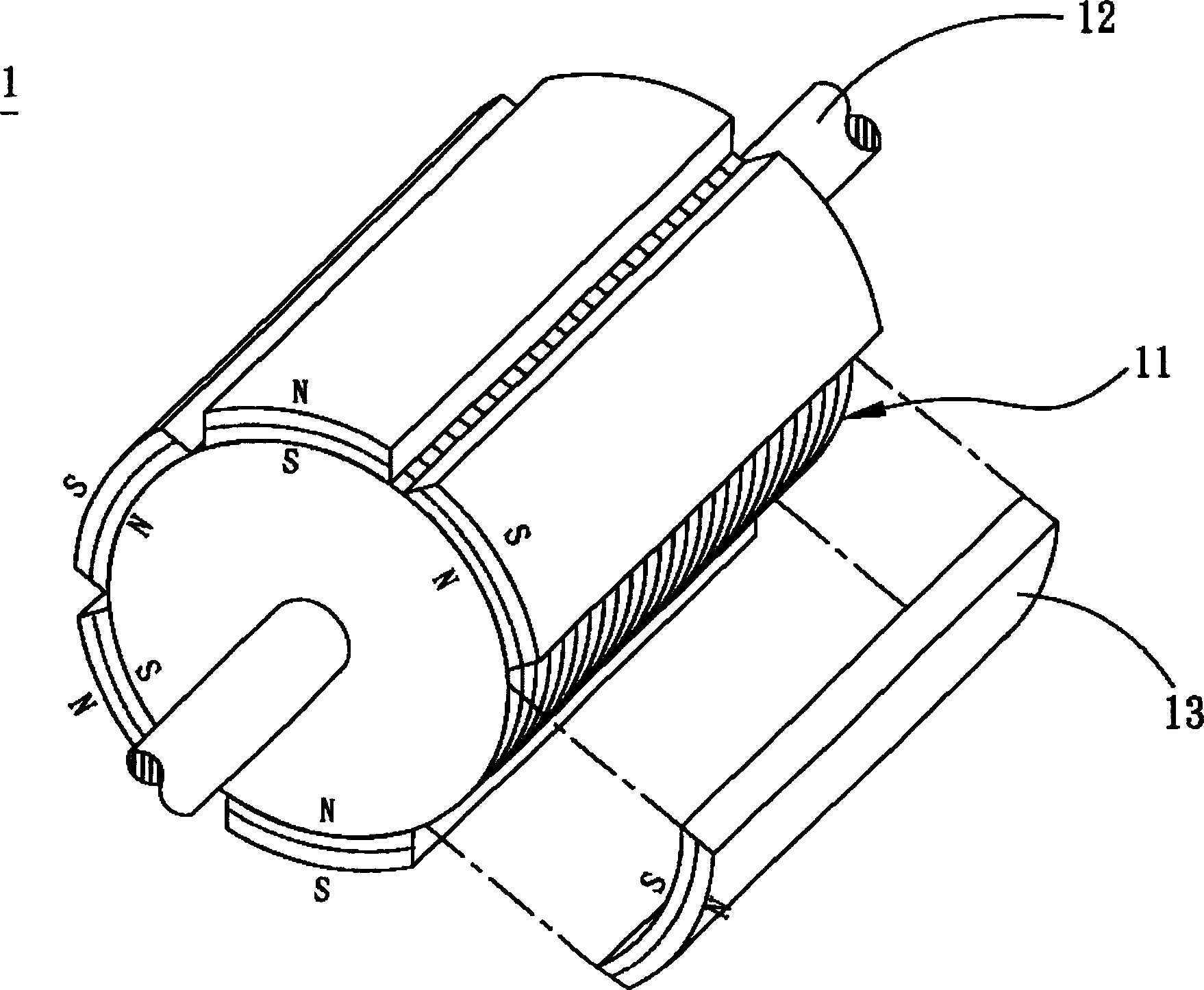

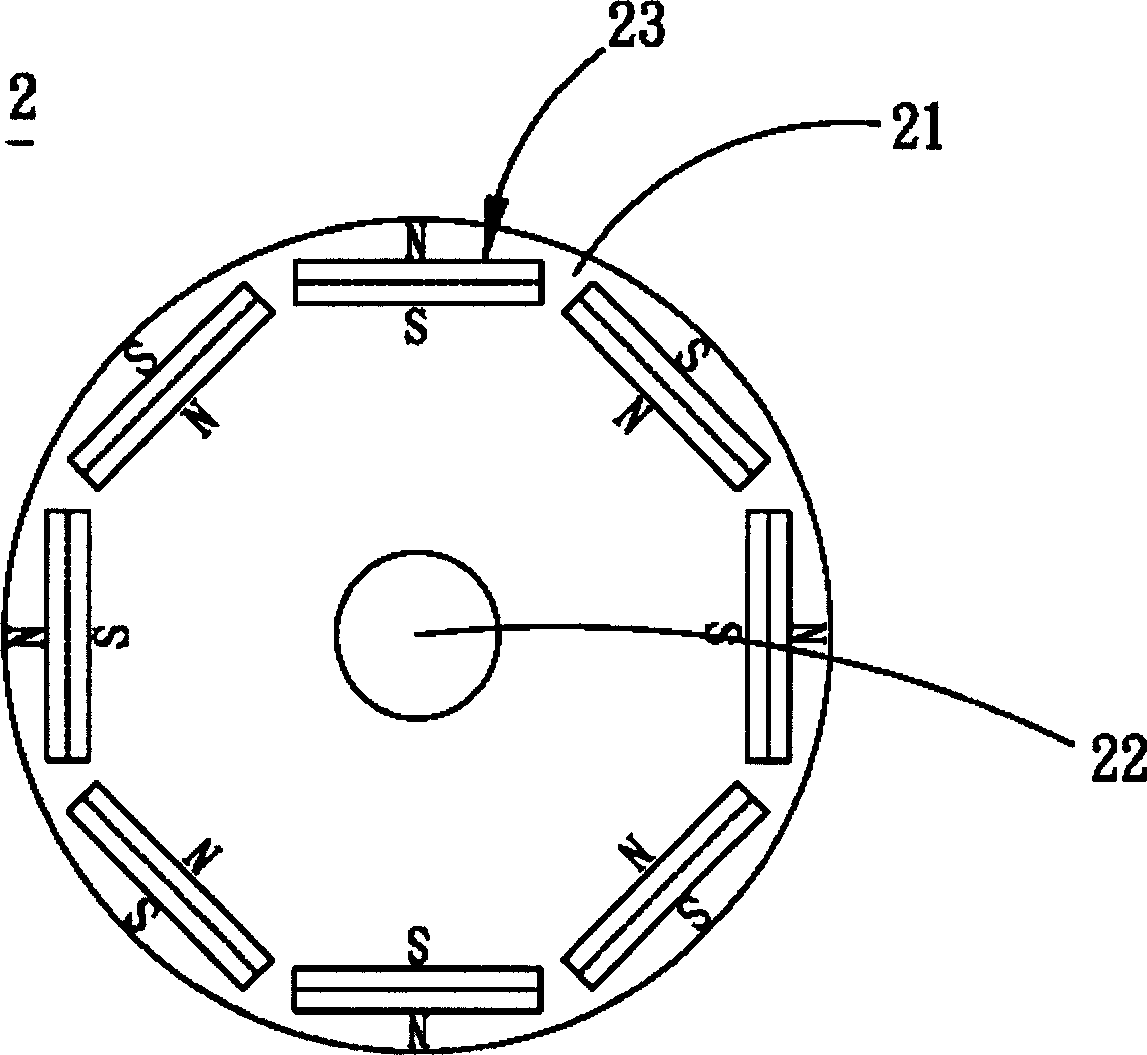

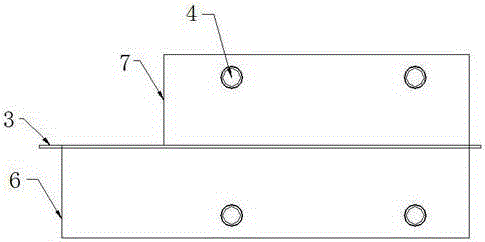

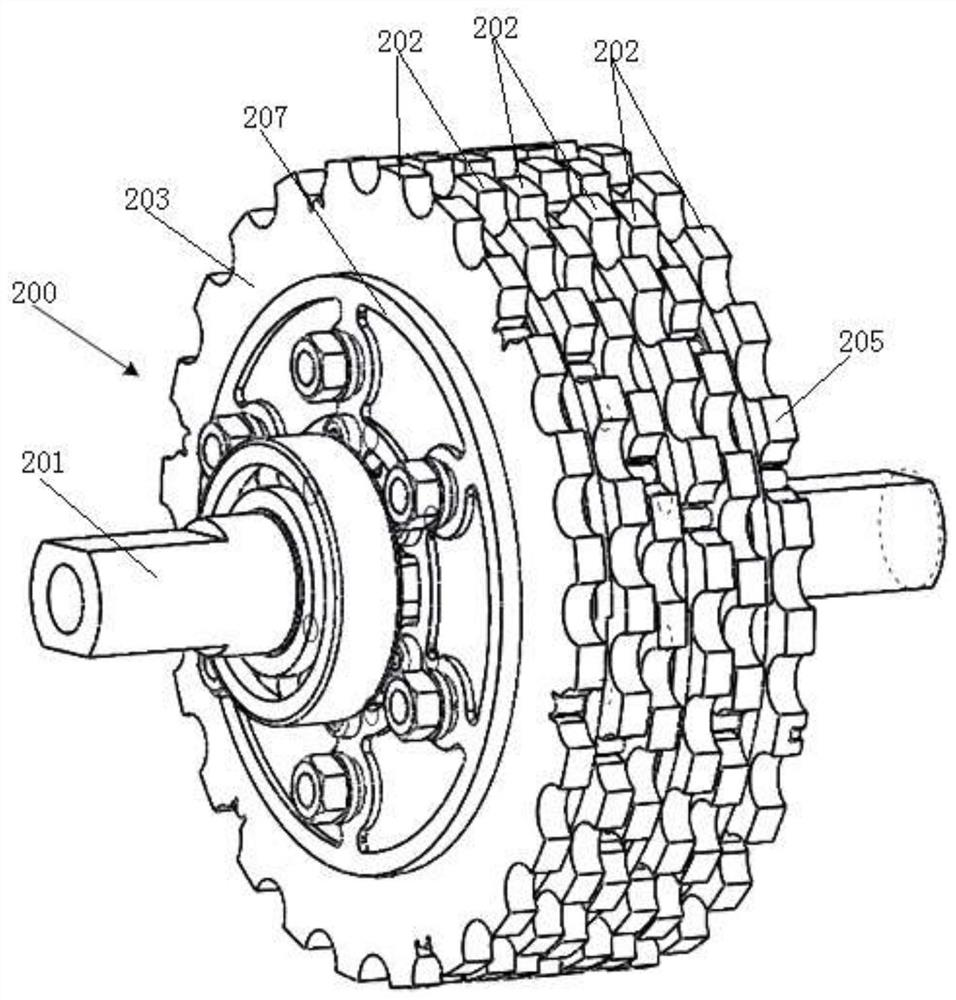

Underwater hollow hub-free propeller

InactiveCN101546939AWork lessIncrease the number of polesRotary propellersMechanical energy handlingUnderwaterPropeller

The invention provides an underwater hollow hub-free propeller, which comprises a motor shell, a stator coil, a stator silicon-steel sheet, a rotor permanent magnet, a rotor, a screw propeller and a ceramic bearing. The stator coil is wound on the stator silicon-steel sheet, the stator coil wound on the stator silicon-steel sheet is arranged at the center of the motor shell, the rotor has a hollow annular structure, split poles of the rotor permanent magnet are fixed on the rotor to form a hollow structural rotor, the screw propeller is fixed inside the hollow rotor, and the screw propeller, the rotor and the rotor permanent magnet form a whole; and the rotor is fixed in the motor shell through the ceramic bearing. When blades rotate, induced resistance and cavity bubble phenomenon are not generated so as to greatly improve the efficiency of the screw propeller. Moreover, because the diameter of a motor is enlarged, the pole number of the motor is increased and the torque of the motor is improved, the underwater hollow hub-free propeller is particularly suitable for working in an environment with large water depth and large density; and because the motor and the screw propeller of the underwater propeller have an integral hollow structure, the underwater hollow hub-free propeller can be easily arranged on a ship hull.

Owner:HARBIN ENG UNIV

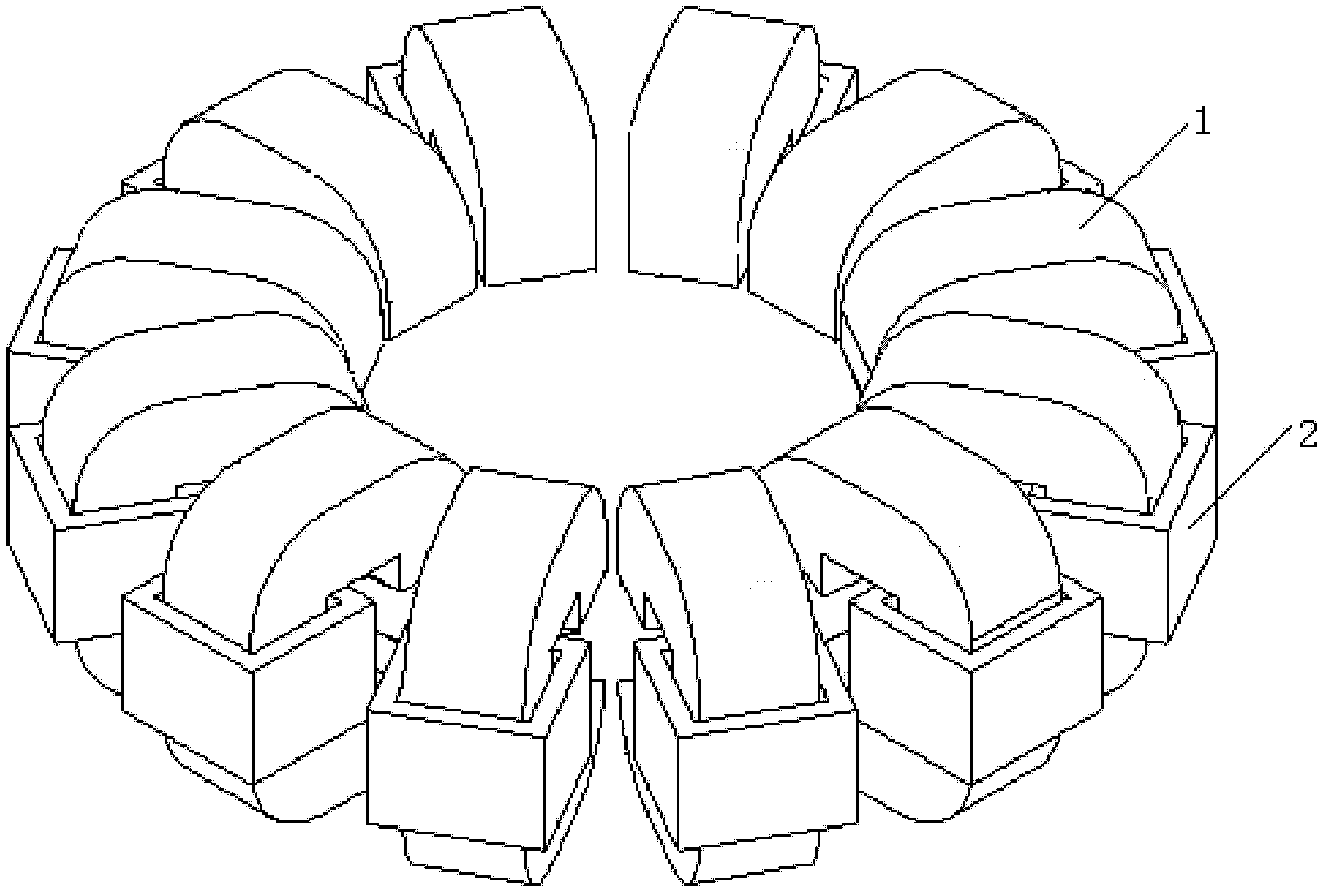

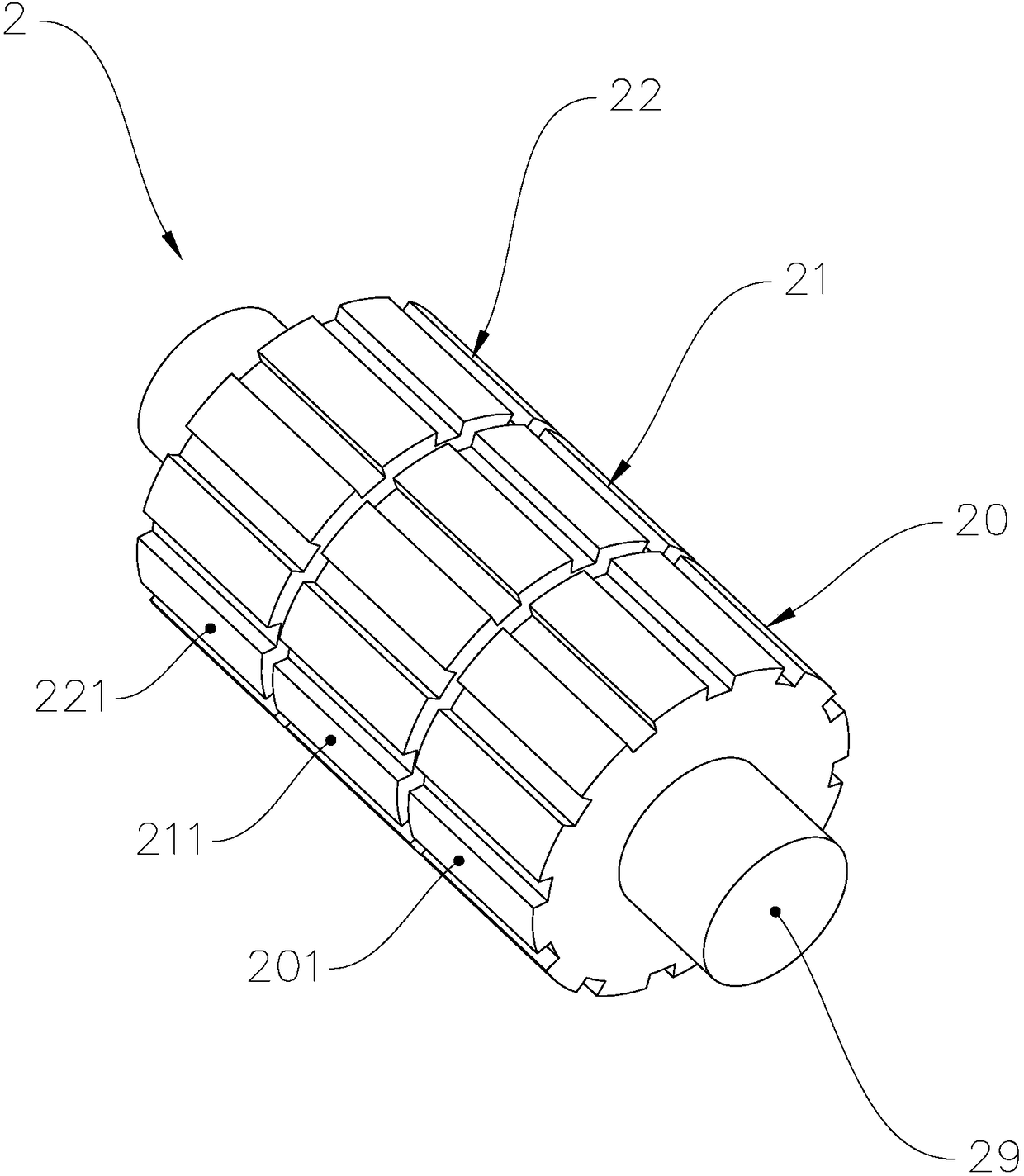

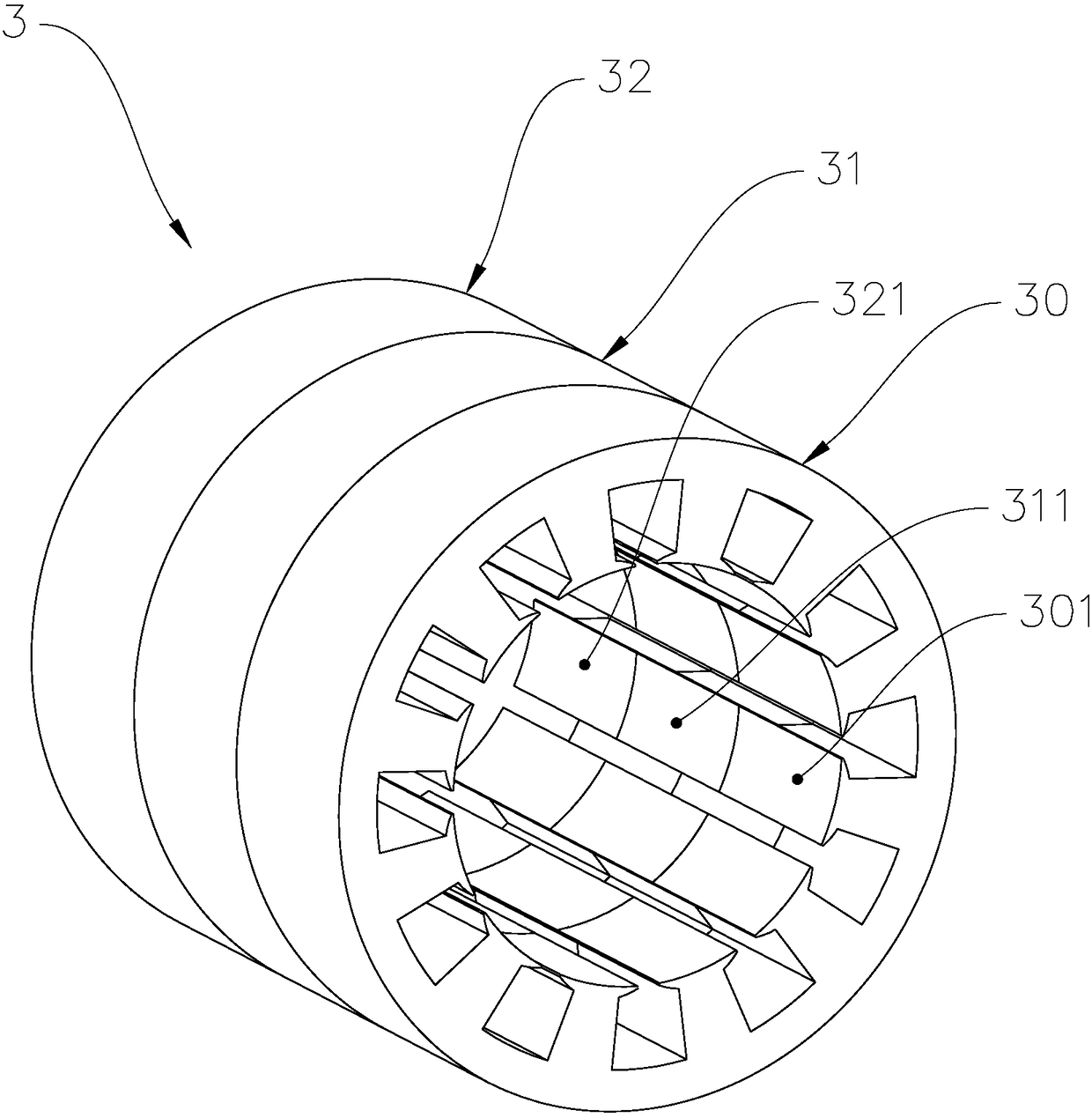

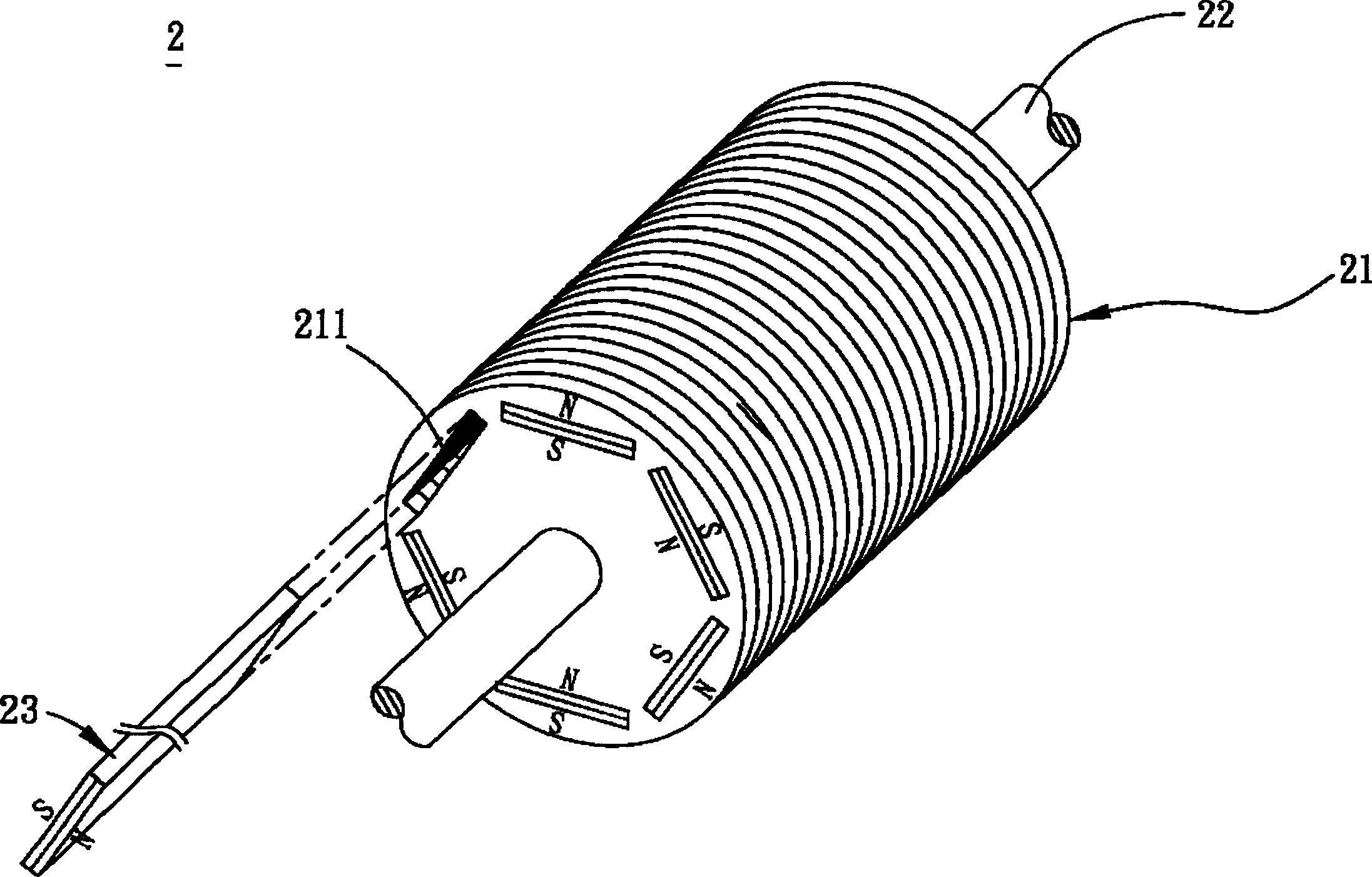

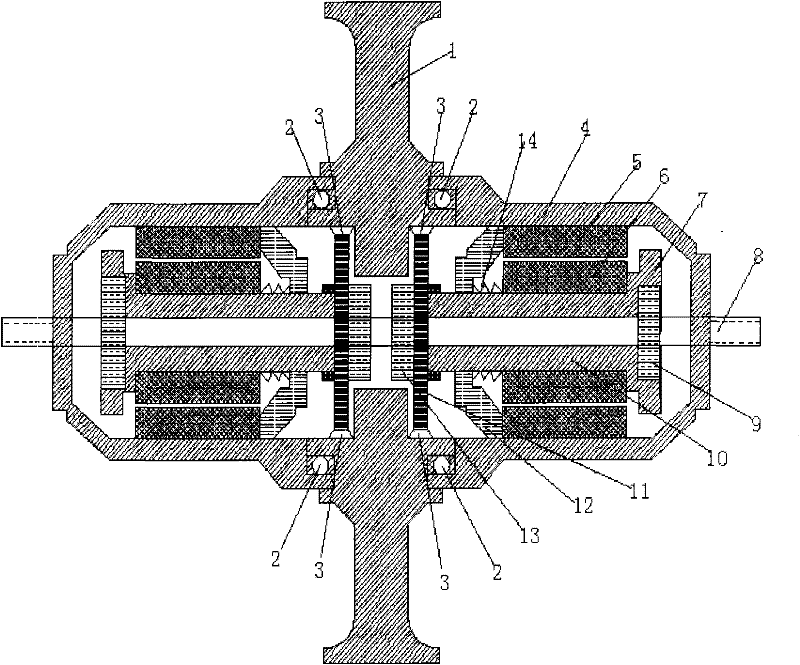

Permanent-magnet axial-magnetic-field brushless motor and assembling method thereof

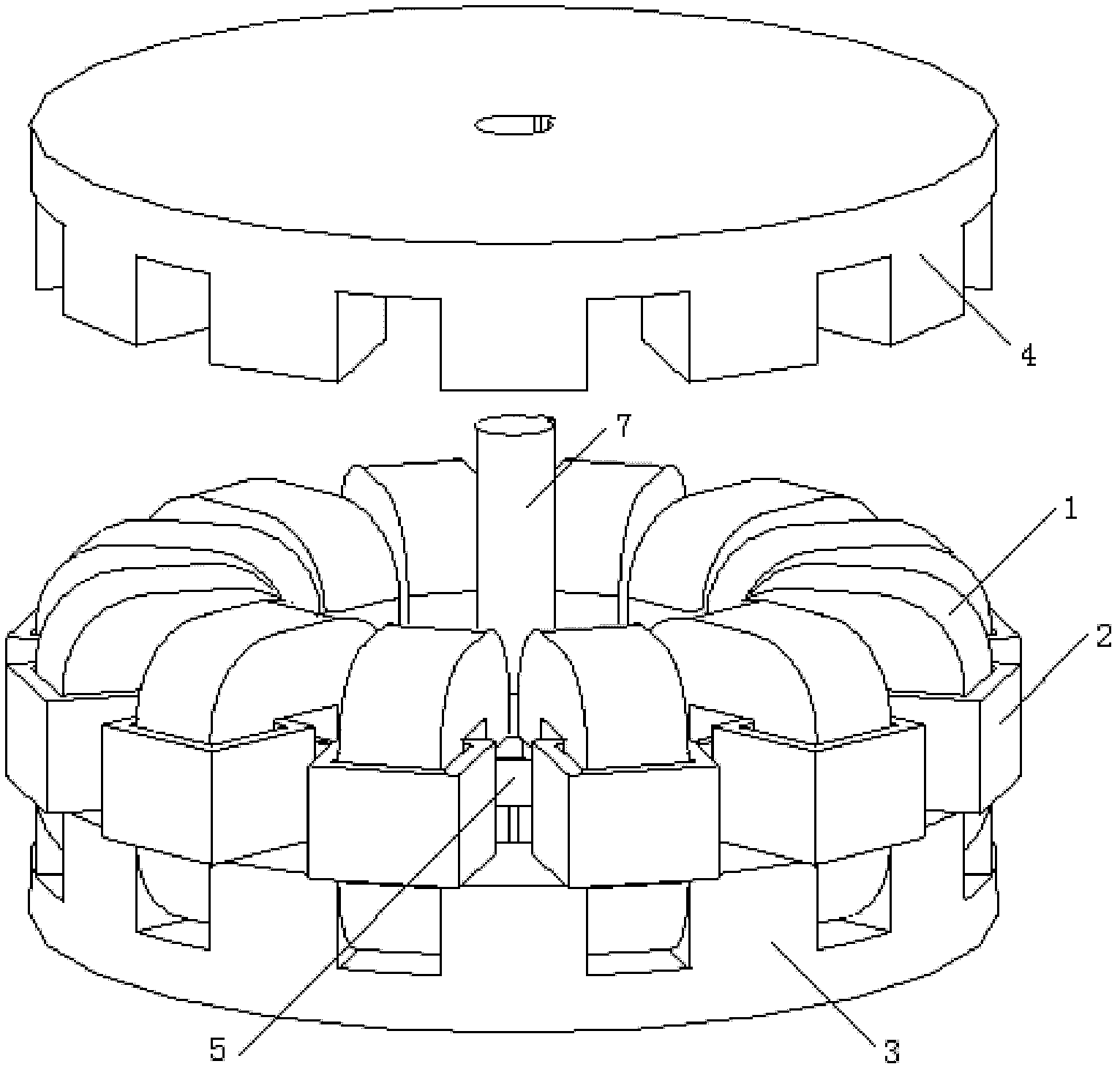

InactiveCN102624183AIncrease the number of polesReduce cogging torque rippleMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsElectric machine

The invention discloses a permanent-magnet axial-magnetic-field brushless motor, which comprises a stator, a rotor, a lower end cap and an upper end cap, wherein the rotor is arranged at the center of the stator. The permanent-magnet axial-magnetic-field brushless motor is characterized in that the stator comprises a plurality of stator C-shaped iron cores and winding coils arranged on the iron cores; the rotor comprises a non-magnet-conductive rotor plate, a plurality of permanent magnets and a rotary shaft, the rotary shaft is arranged at the center of the non-magnet-conductive rotor plate, the permanent magnets are uniformly embedded on the circumference of the non-magnet-conductive rotor plate, the stator C-shaped iron cores are embedded in slots of the upper end cap and the lower end cap and circularly distributed on the circumference of the non-magnet-conductive rotor plate uniformly, and upper magnetic pole surfaces of the stator C-shaped iron cores correspond to the permanent magnets of the non-magnet-conductive rotor plate. The invention further discloses an assembling method of the motor. The permanent-magnet axial-magnetic-field brushless motor and the assembling method thereof have the advantages that electric load and magnetic load are set independently, the stator lamination iron cores are simple in manufacture, and coil magnetic loops formed by the stator windings are independent to each other. Besides, design difficulty of the motor is beneficially reduced, and manufacturing cost of the motor is reduced while performance of the motor is improved.

Owner:SHANDONG UNIV

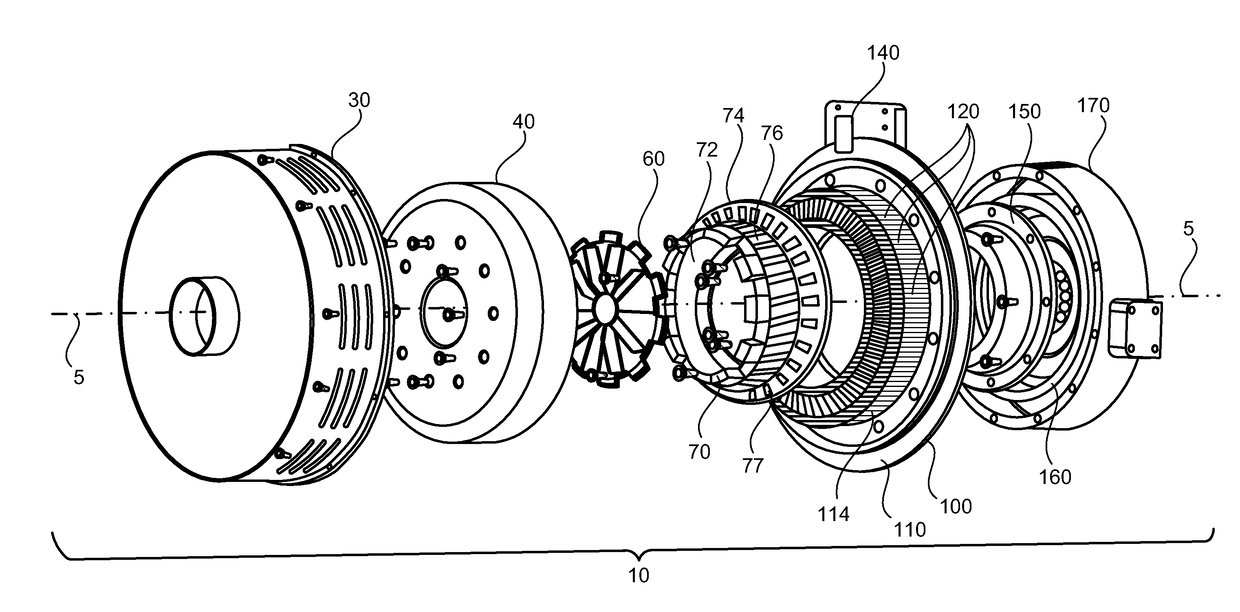

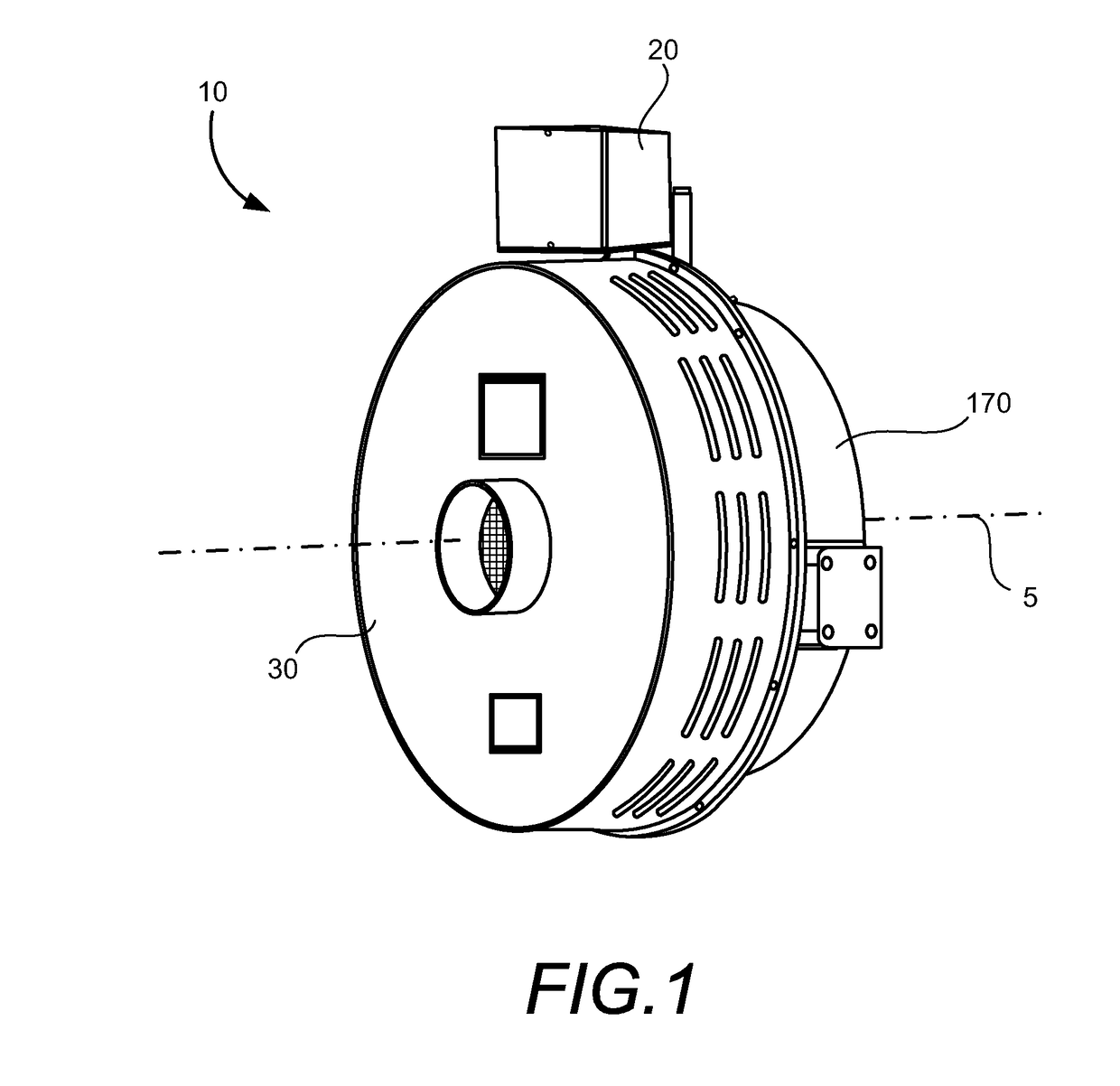

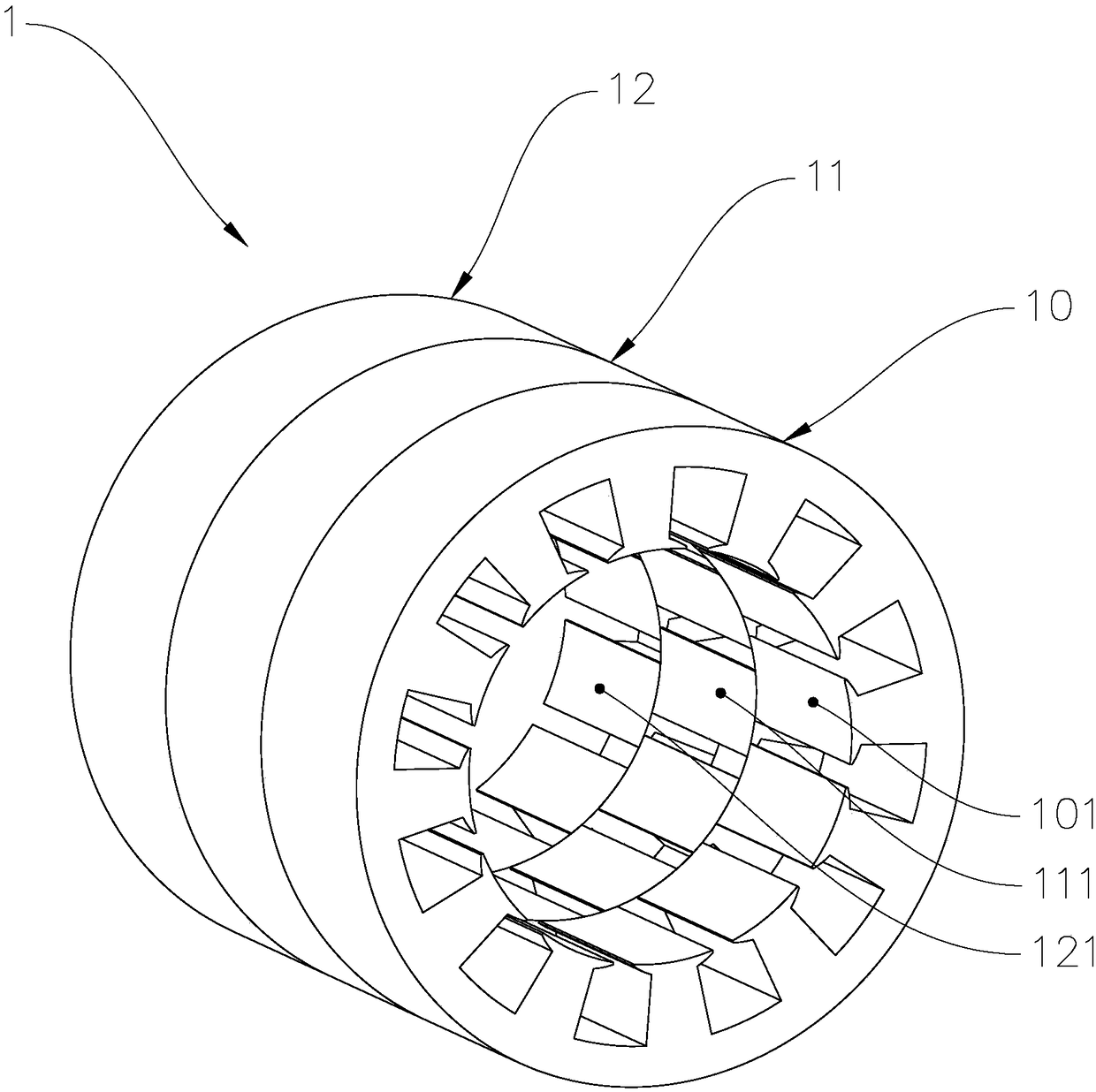

Flux machine

PendingUS20180219464A1Reduce forceIncrease flux densityMagnetic circuitElectric machinesMachineElectric current flow

A flux machine has plural coil assemblies and plural magnet sets arranged in mutual close proximity and circularly about a central axis. Either one of the coil assemblies and the magnet sets are supported by at least one axle which is aligned with the central axis, and either one of the coil assemblies and magnet sets executes rotary motion about the central axis when electrical current is present in the coil assemblies. Magnetic flux of the magnet sets is directed axially and radially while machine rotation is orthogonal to the direction of flux. A plurality of magnets in each magnet set are supported by one or another of a plurality of coaxially aligned axles so that the flux machine may operate as an electrical motor, as an electrical generator, or both at the same time.

Owner:CLEARWATER HLDG

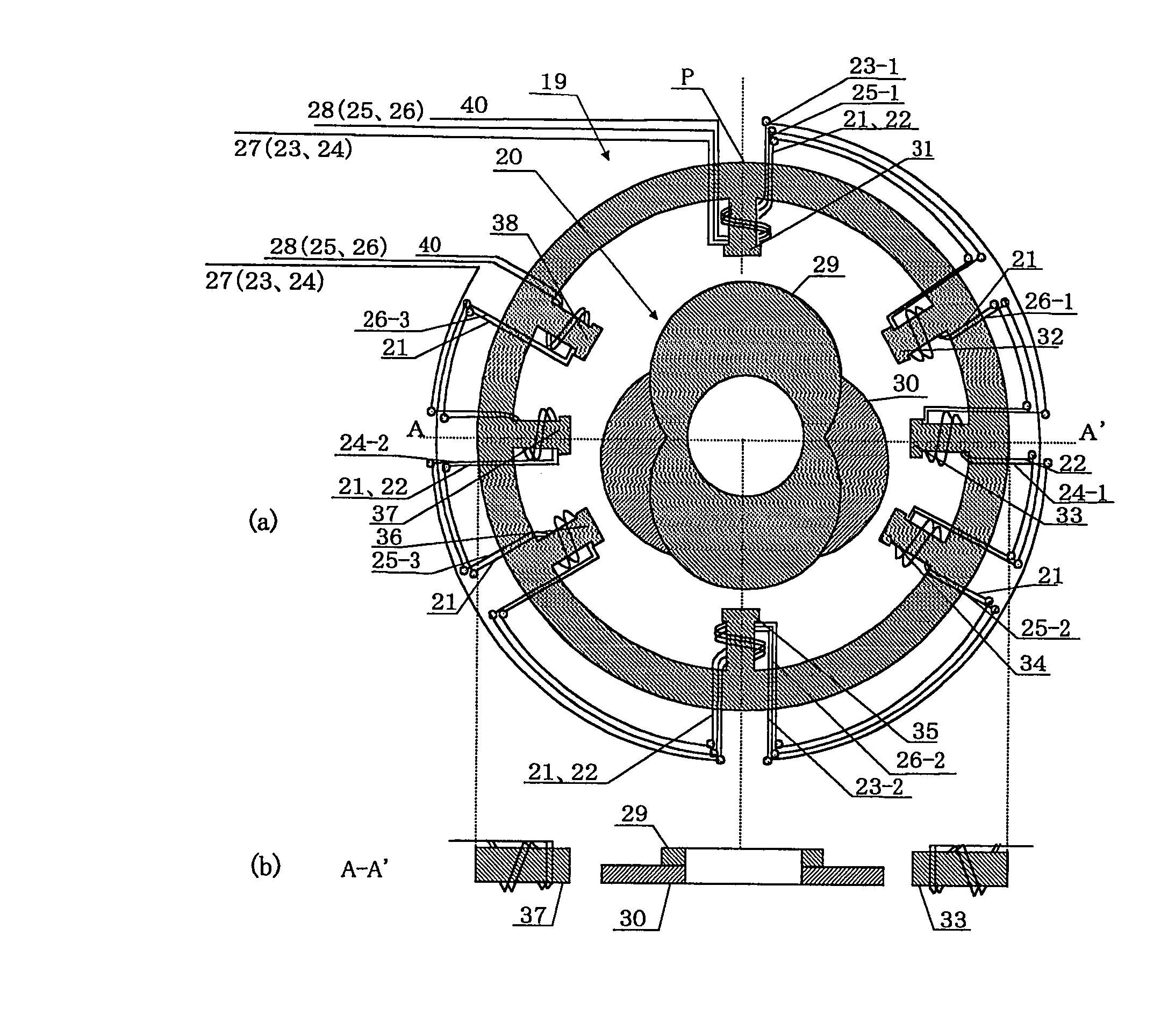

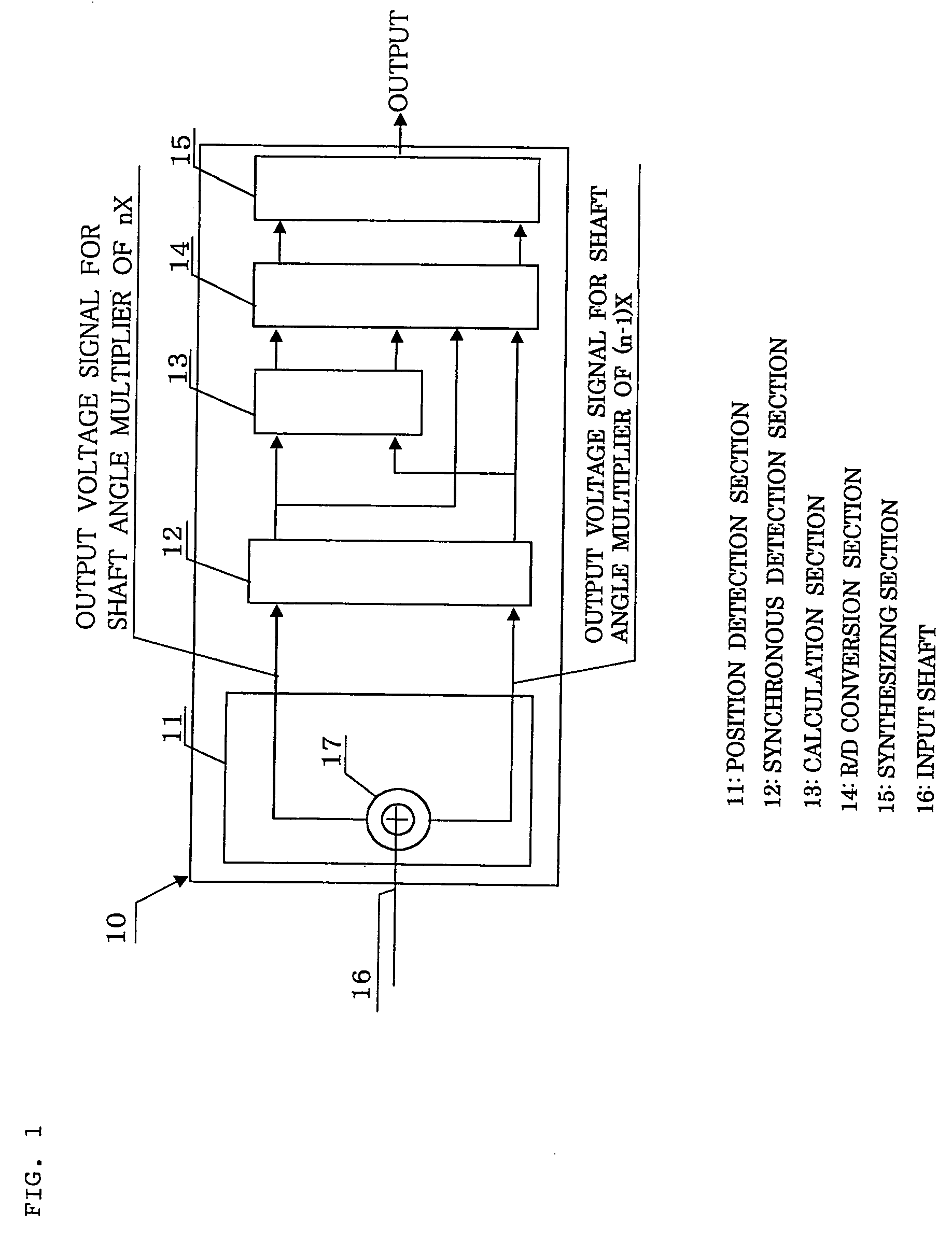

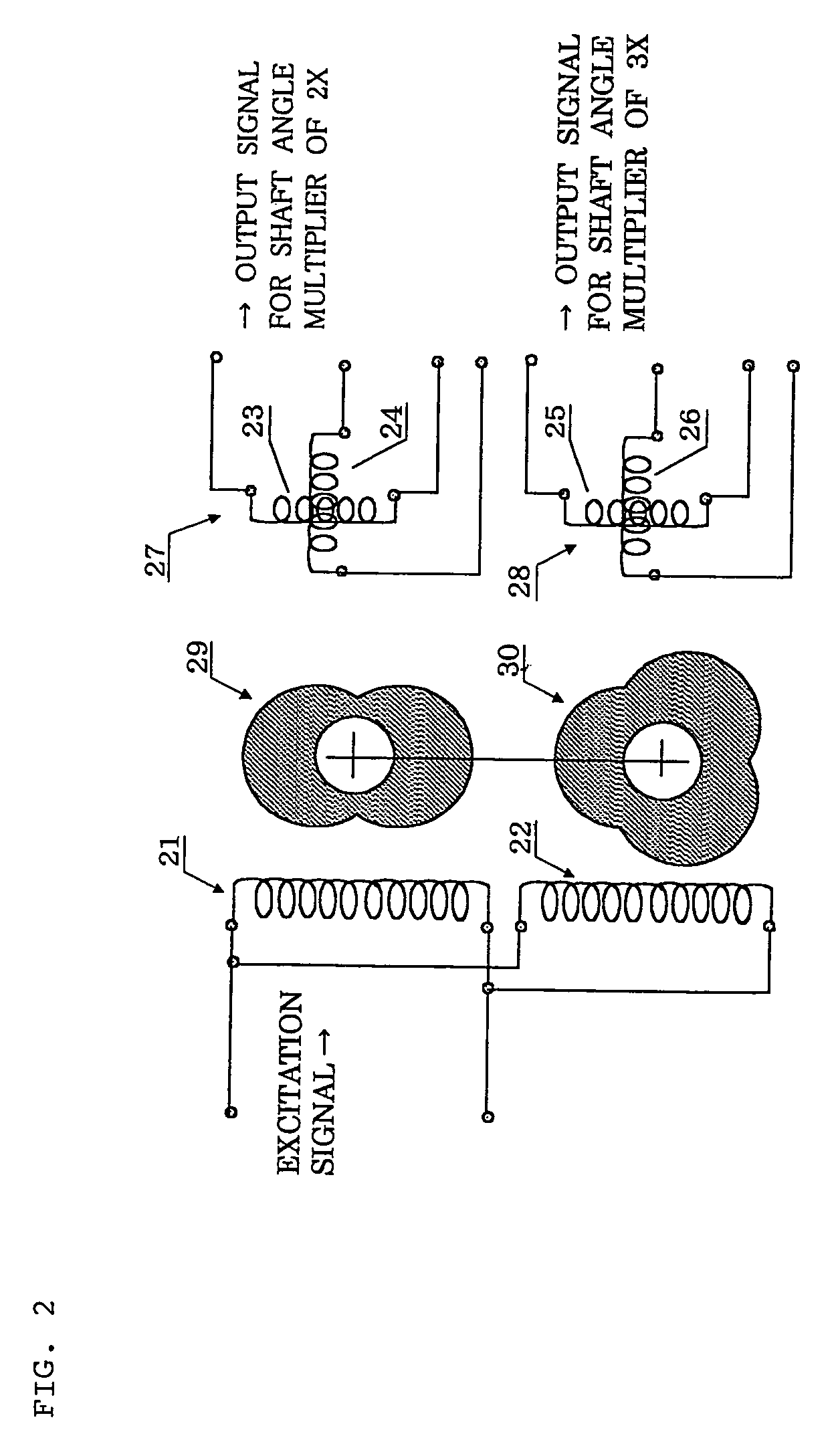

Variable-reluctance resolver and rotational angle sensor using same

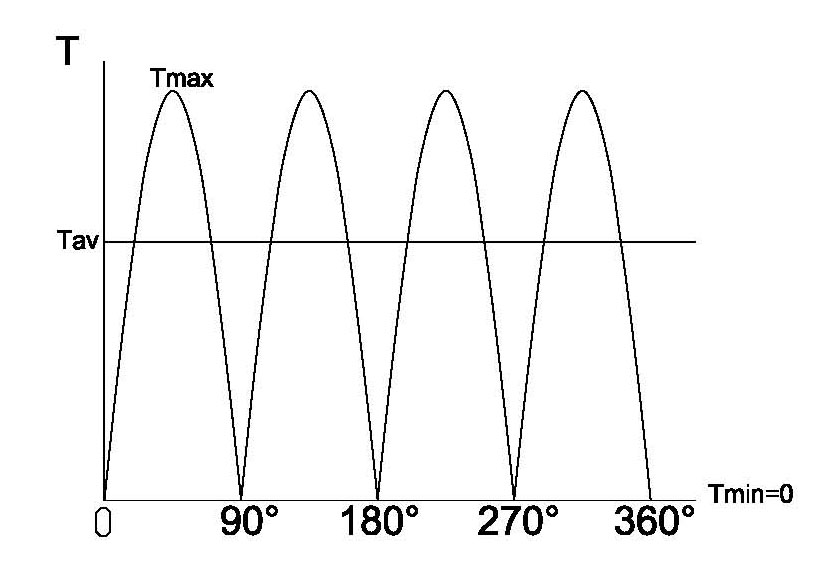

InactiveUS20050212511A1Reduce the impactReduce impactSynchronous generatorsElement comparisonAxis–angle representationPhase difference

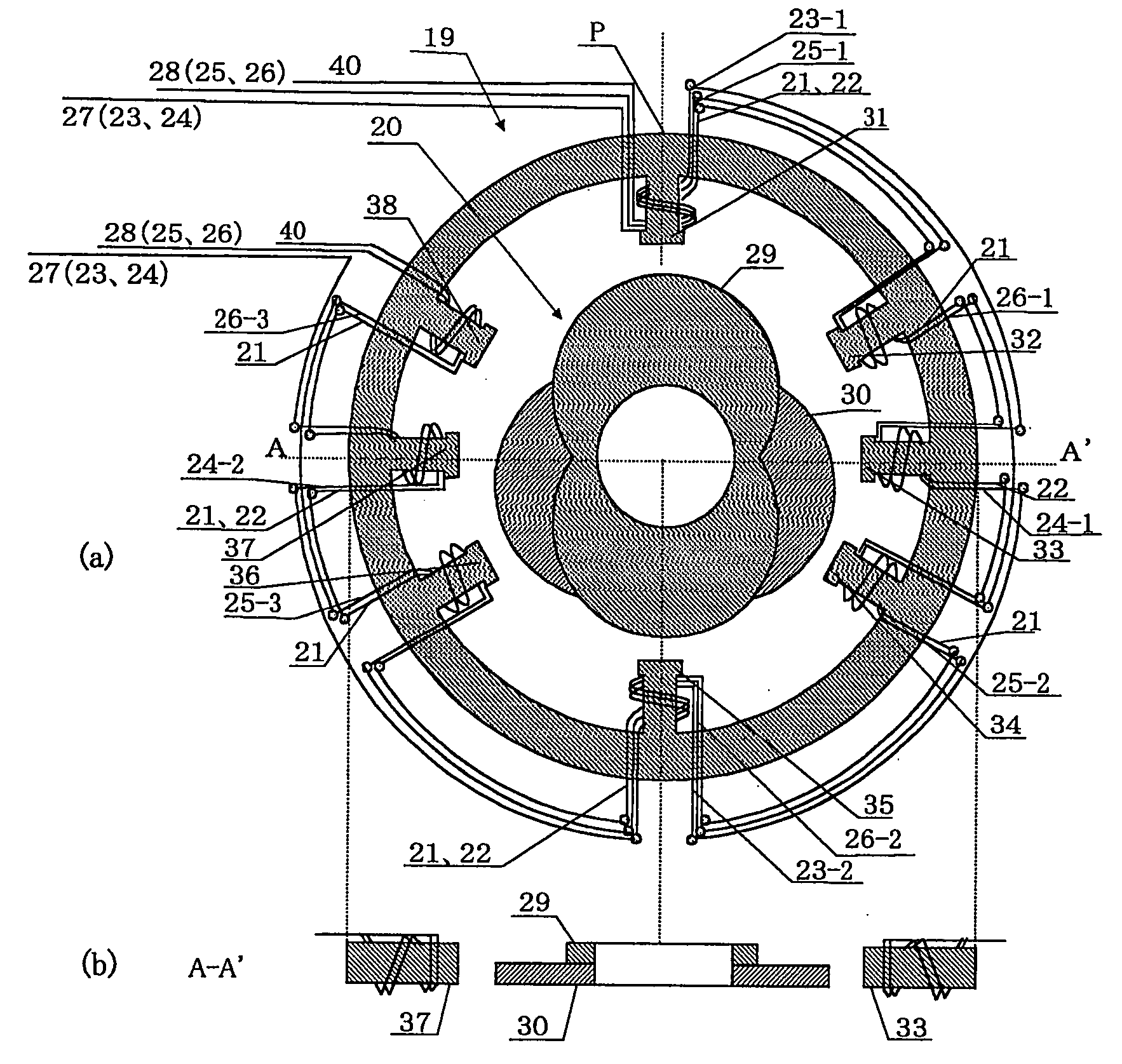

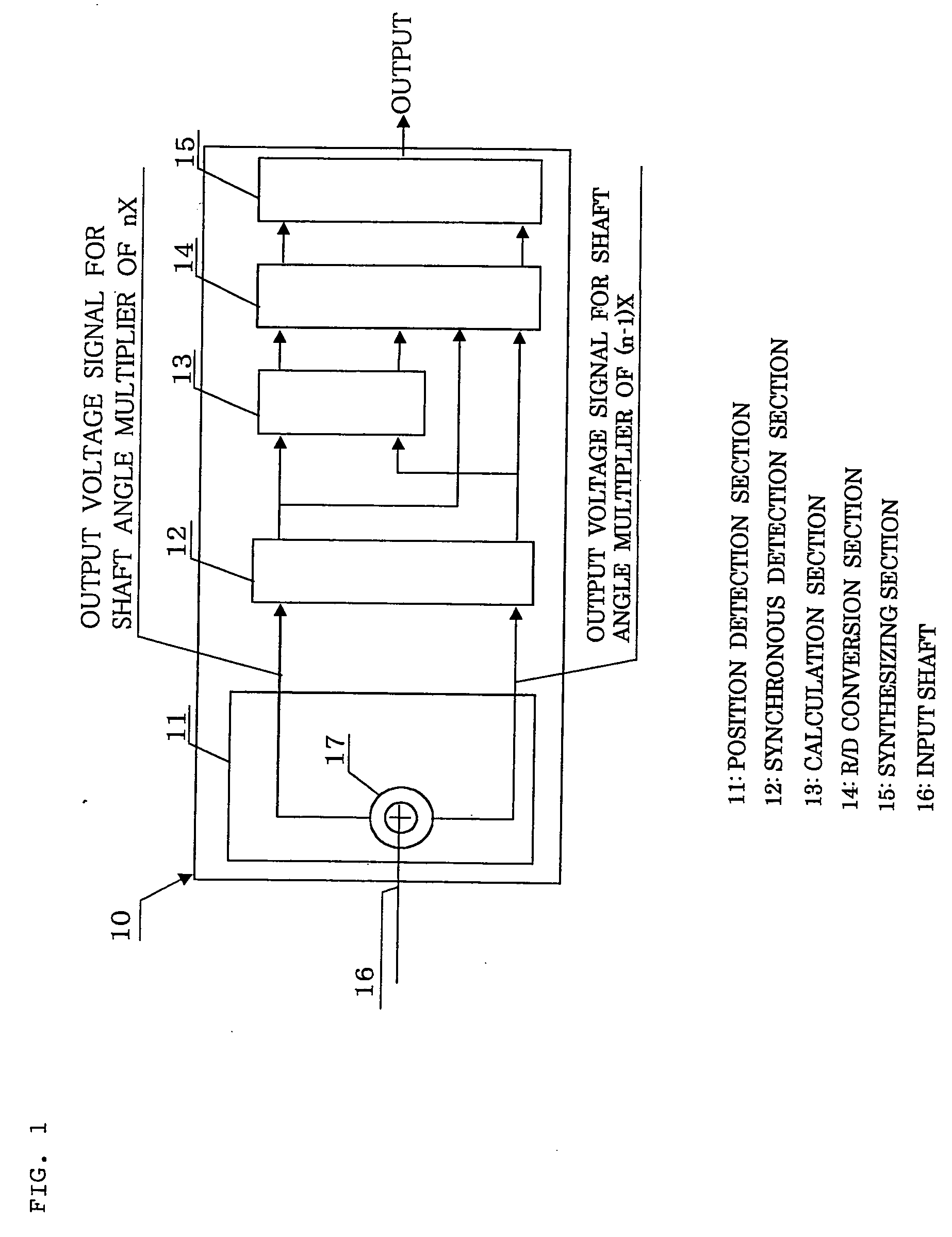

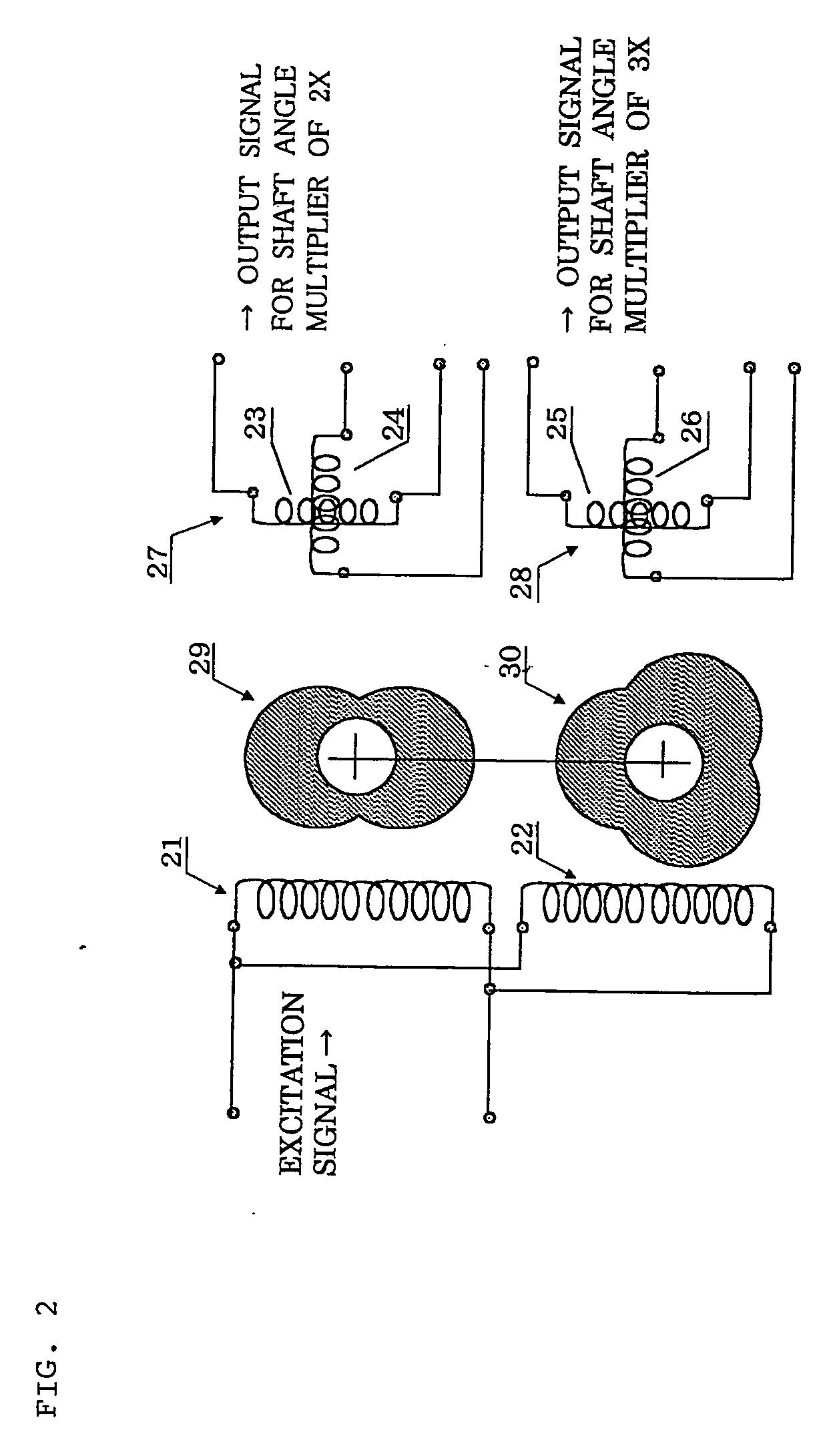

A variable-reluctance resolver includes a rotor and a stator. The rotor includes axially connected first and second rotor portions. The first rotor portion has n salient poles provided about a center axis at uniform angular intervals, where n is an arbitrary integer not less than 3. The second rotor portion has (n-1) salient poles provided about the center axis at uniform angular intervals. The stator has a plurality of magnetic poles provided on an inner circumferential surface thereof. An excitation coil and output coils for shaft angle multipliers of n× and (n-1)× are provided on the magnetic poles in order to output sine and cosine outputs having a phase difference of 90 degrees therebetween. A rotational angle sensor includes the VR resolver and a calculation section for calculating a resolver signal for a shaft angle multiplier of 1× from signals output from the VR resolver.

Owner:MINEBEA CO LTD

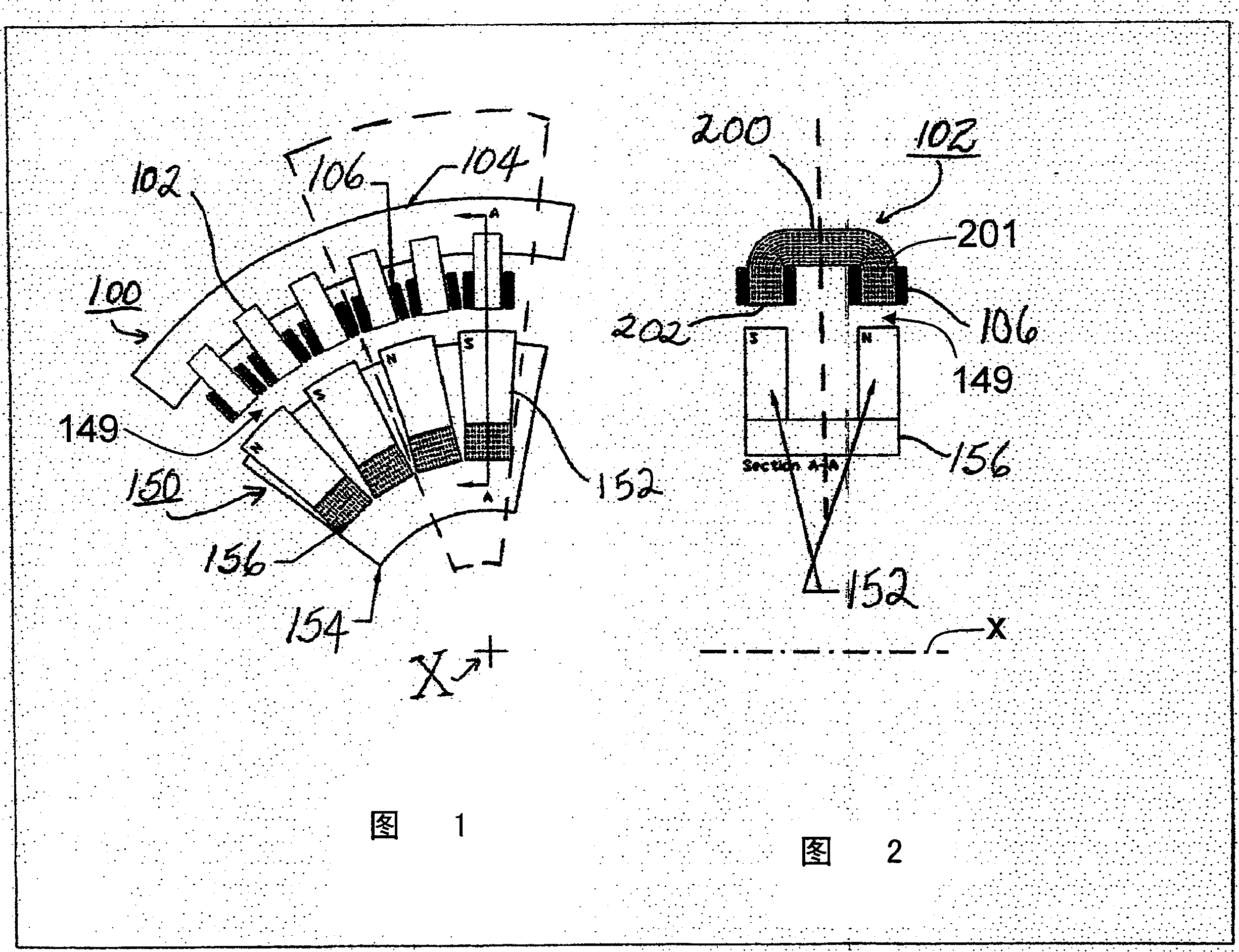

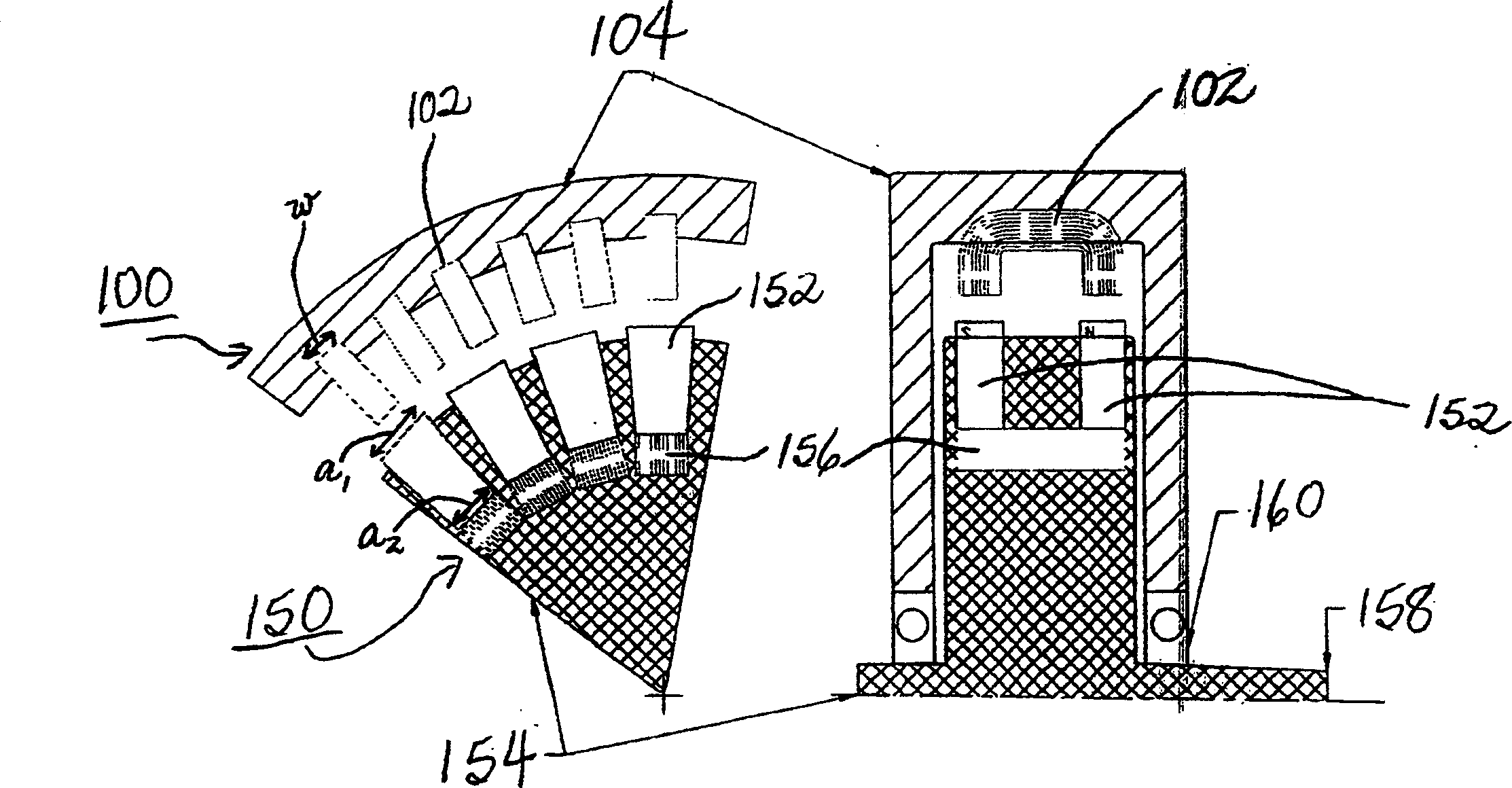

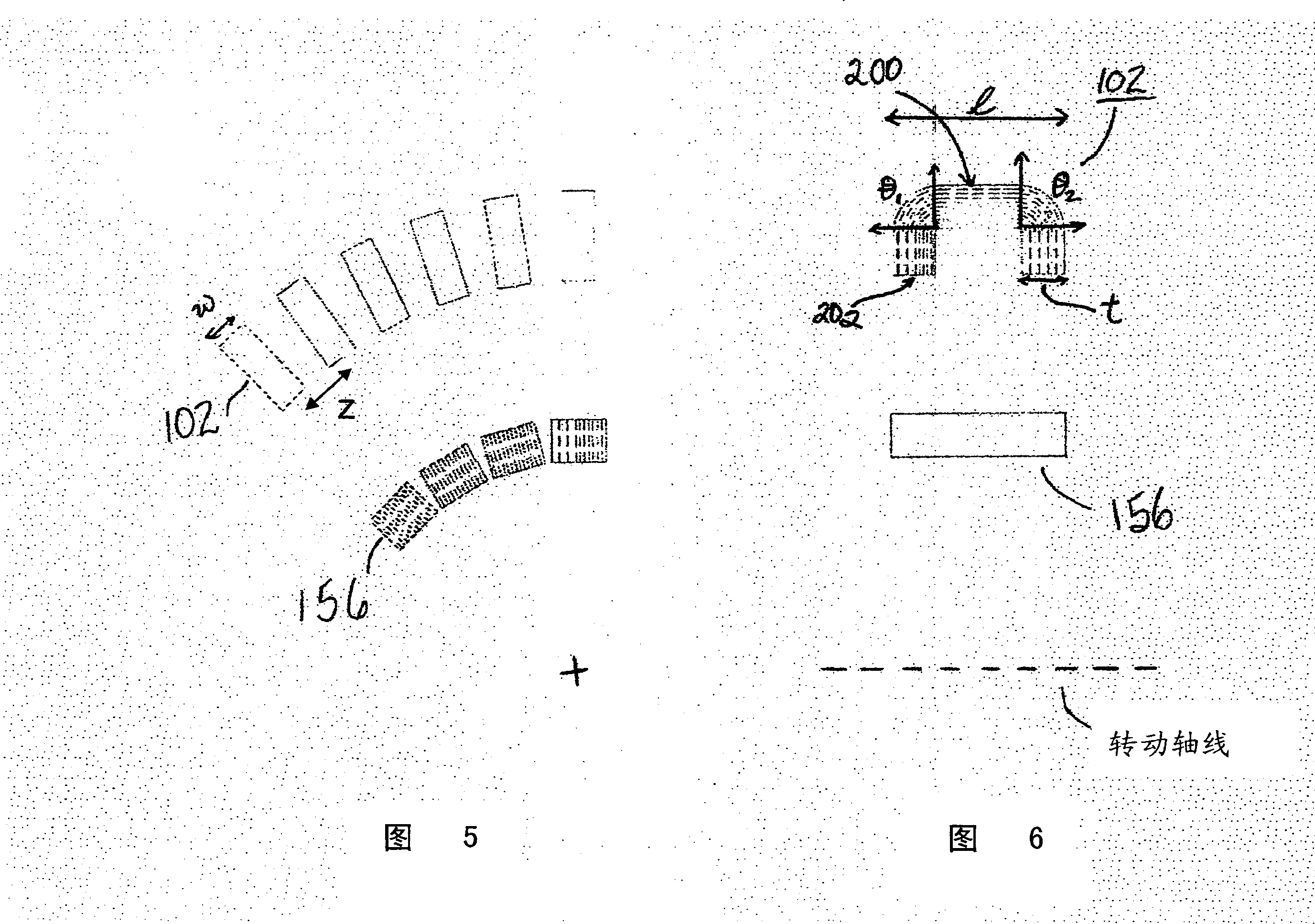

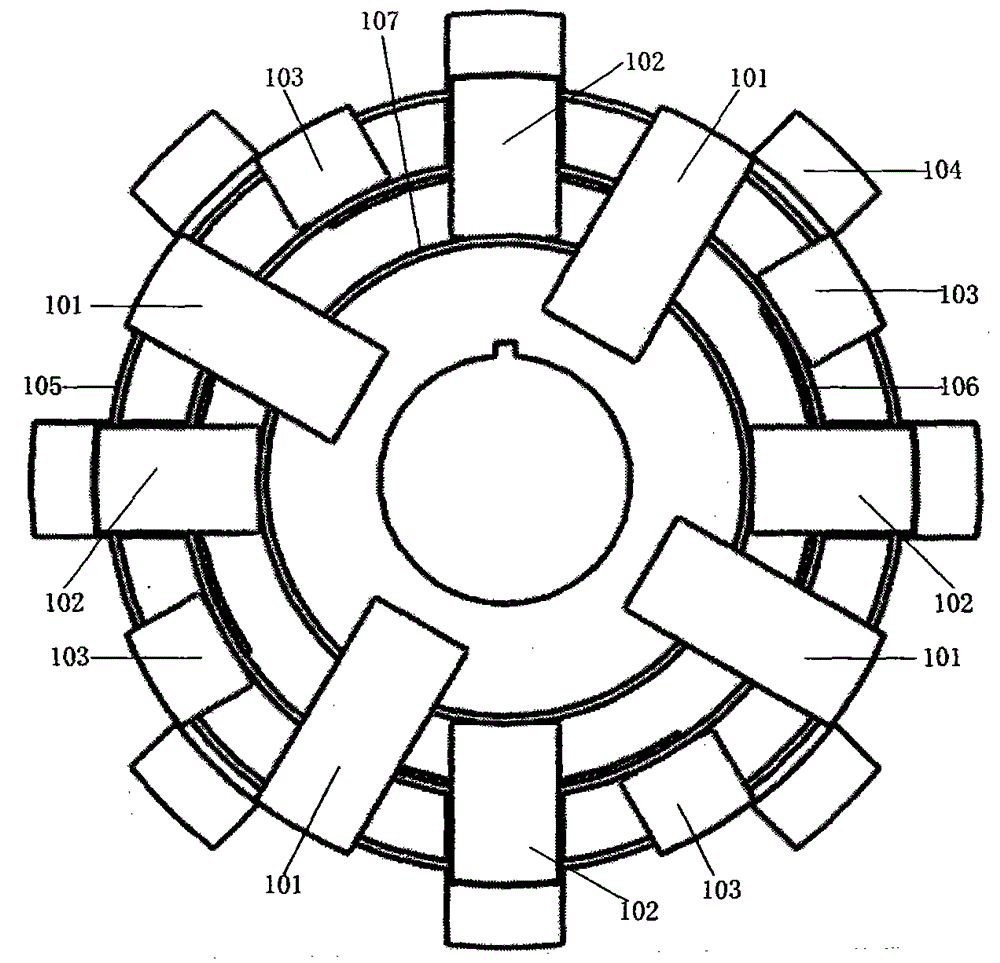

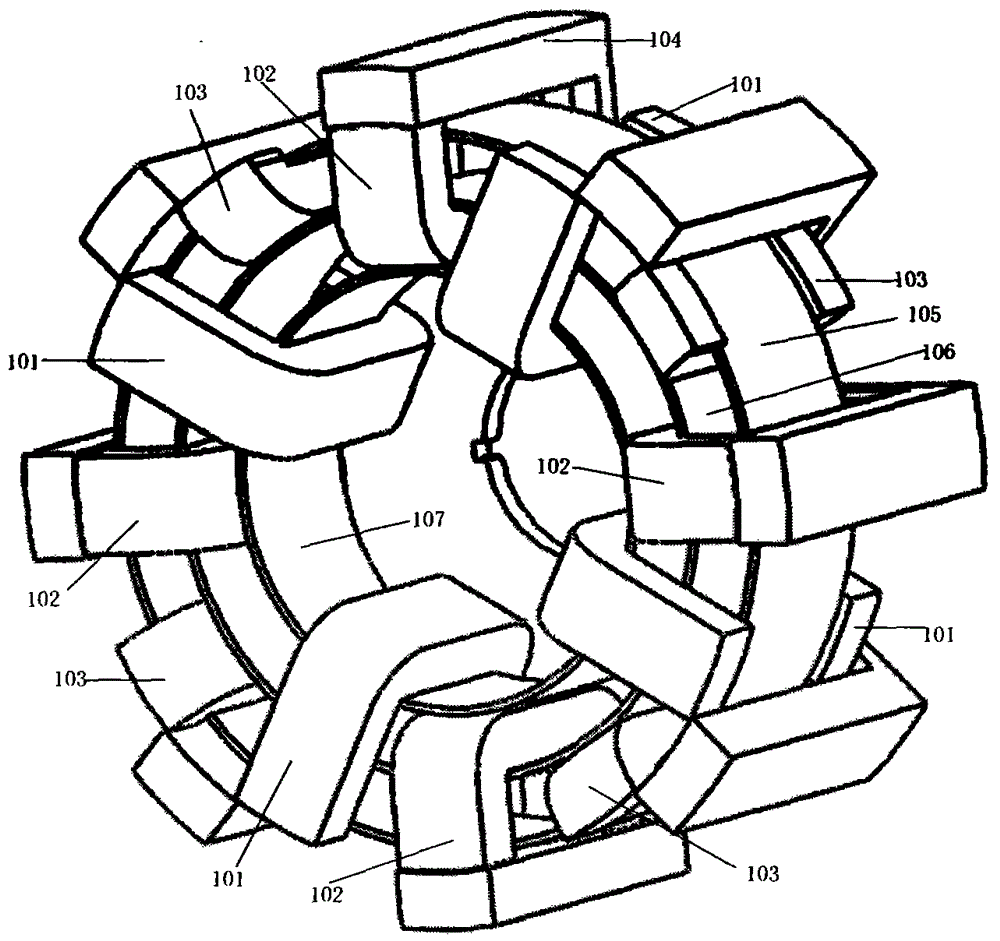

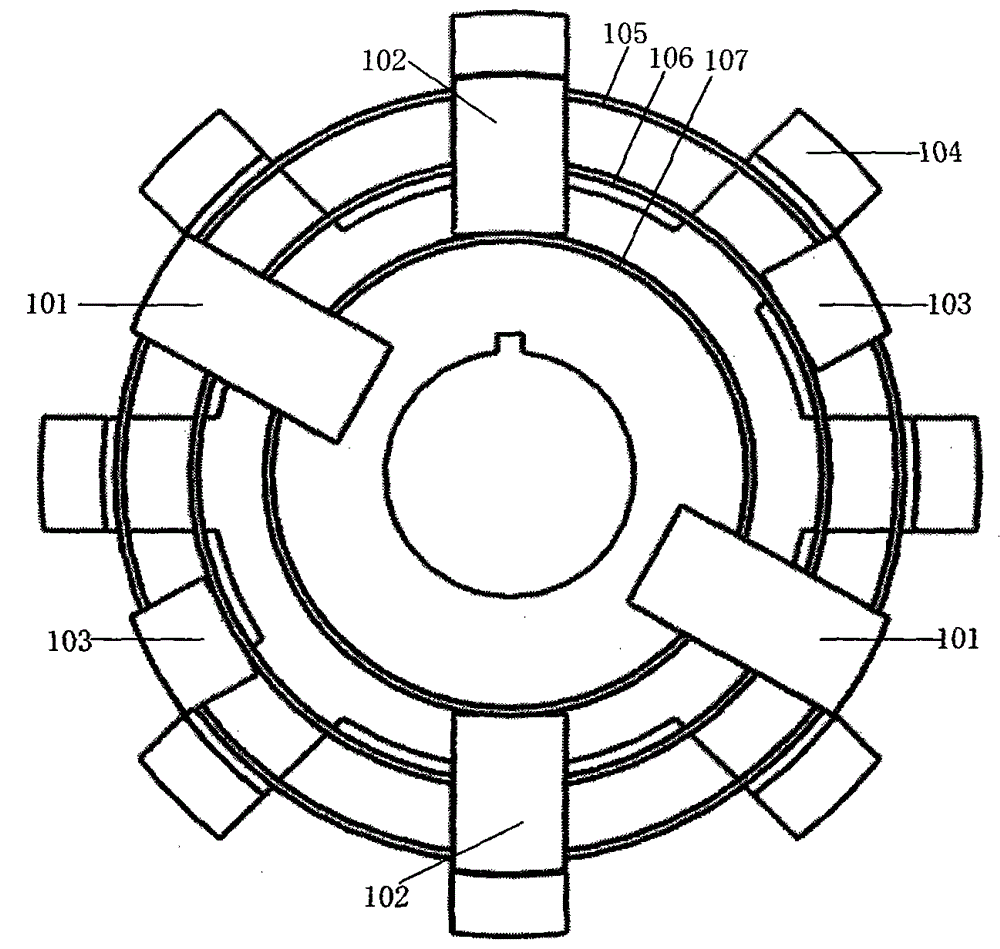

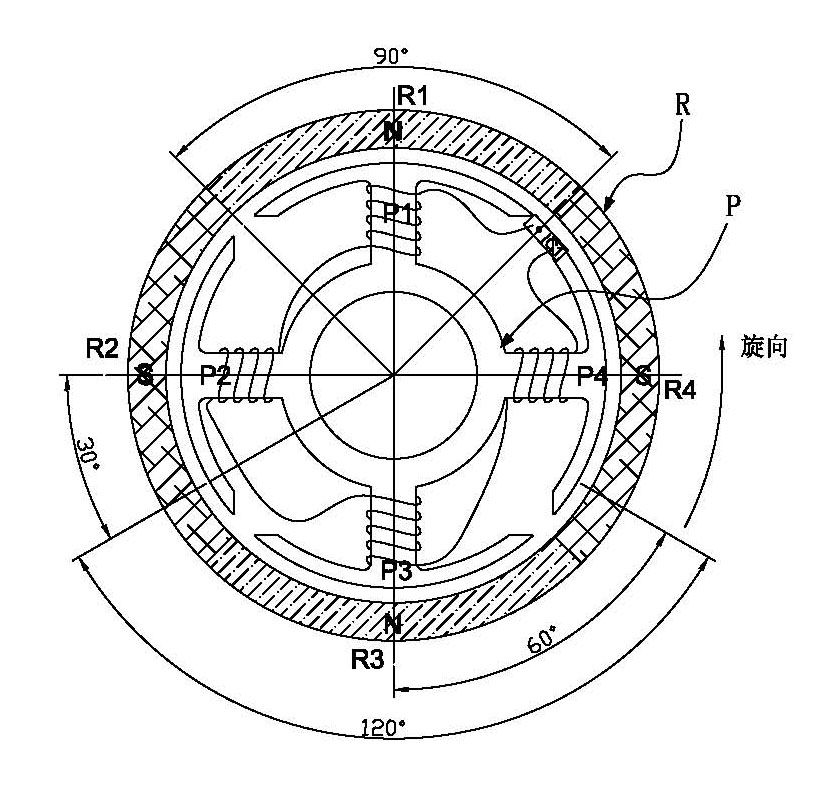

Radial airgap, transverse flux motor

InactiveCN1842954AIncrease the number of polesImproved performance characteristicsSynchronous machines with stationary armatures and rotating magnetsTransverse fluxRotor magnets

A radial gap, transverse flux dynamoelectric machine comprises stator (102) and rotor assemblies (154). The rotor assembly comprises at least two axially spaced, planar rotor layers (152) having equal numbers of magnetic poles of alternating polarity disposed equiangularly about the rotor peripheral circumference. A magnetically permeable member (156) optionally links adjacent rotor magnets. The stator assembly (102) comprises a plurality of amorphous metal stator cores terminating in first and second polefaces. The cores are disposed equiangularly about the peripheral circumference of the stator assembly with their polefaces axially aligned. Respective first and second polefaces are in layers radially adjacent corresponding rotor layers. Stator windings encircle the stator cores. The device is operable at a high commutating frequency and may have a high pole count, providing high efficiency, torque, and power density, along with flexibility of design, ease of manufacture, and efficient use of magnetic materials.

Owner:LIGHT ENGINEERING INC

Variable-reluctance resolver and rotational angle sensor using same

InactiveUS7088025B2Reduce impactInhibition effectSynchronous generatorsElement comparisonPhase differenceMagnetic poles

A variable-reluctance resolver includes a rotor and a stator. The rotor includes axially connected first and second rotor portions. The first rotor portion has n salient poles provided about a center axis at uniform angular intervals, where n is an arbitrary integer not less than 3. The second rotor portion has (n−1) salient poles provided about the center axis at uniform angular intervals. The stator has a plurality of magnetic poles provided on an inner circumferential surface thereof. An excitation coil and output coils for shaft angle multipliers of n× and (n−1)× are provided on the magnetic poles in order to output sine and cosine outputs having a phase difference of 90 degrees therebetween. A rotational angle sensor includes the VR resolver and a calculation section for calculating a resolver signal for a shaft angle multiplier of 1× from signals output from the VR resolver.

Owner:MINEBEA CO LTD

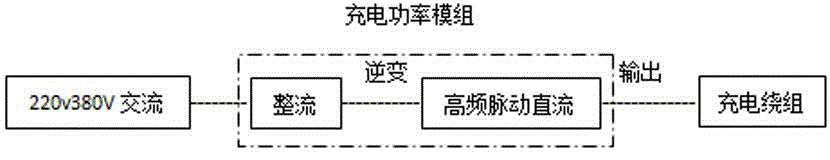

Permanent magnet synchronous electric motor and its automatic staircase or automatic footway

InactiveCN1753286AReduce speedIncrease the number of polesMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorPermanent magnet synchronous motor

This invention relates to a permanent magnetic synchronous motor and its movimg staircase or moving pedestrian crosswalk without inverters and encoders installed. Said magnet synchronous machine has the ability of starting up asynchronously by applying a rotor made of multi-pole built-in magnet steel and having a rotor cage including: a bracing shaft having the rotor, a stator winding, a stator core, end covers at the front and the back and a rotor core, which can drive the staircase and the pedestrian crosswalk to start up smoothly and operate in the state of a synchronous motor showing the high efficiency and power factors either in light, empty or full load.

Owner:西子联合控股有限公司

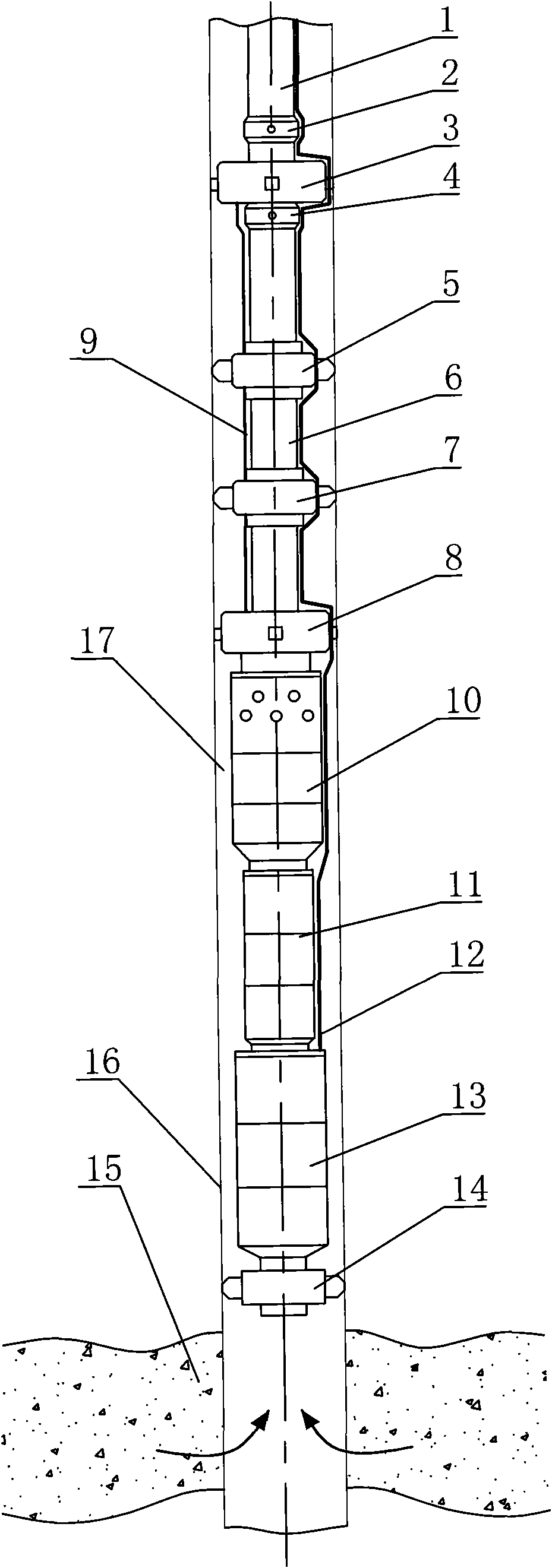

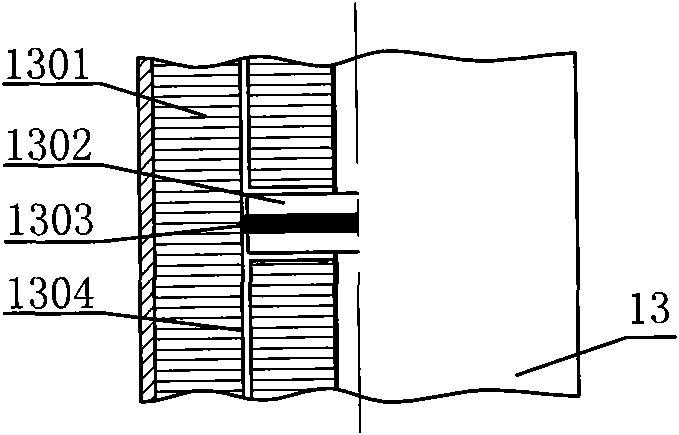

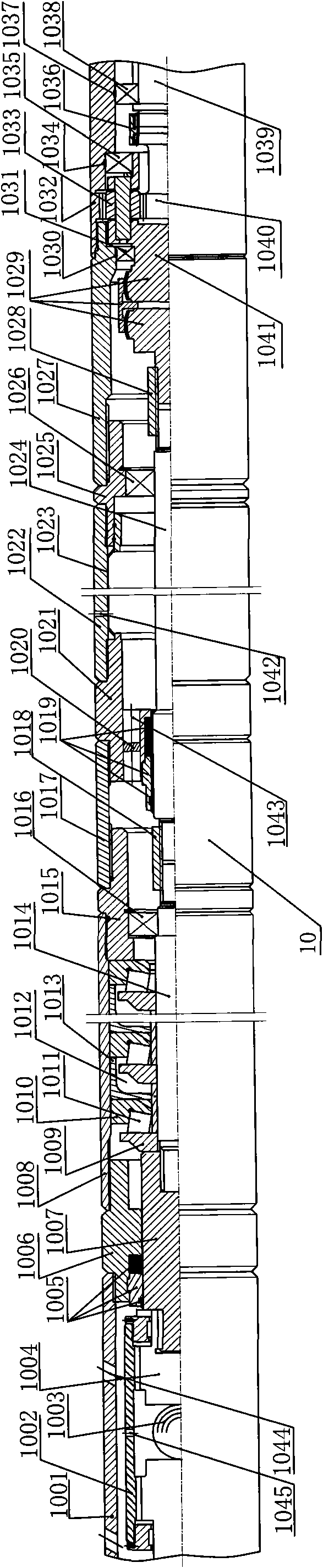

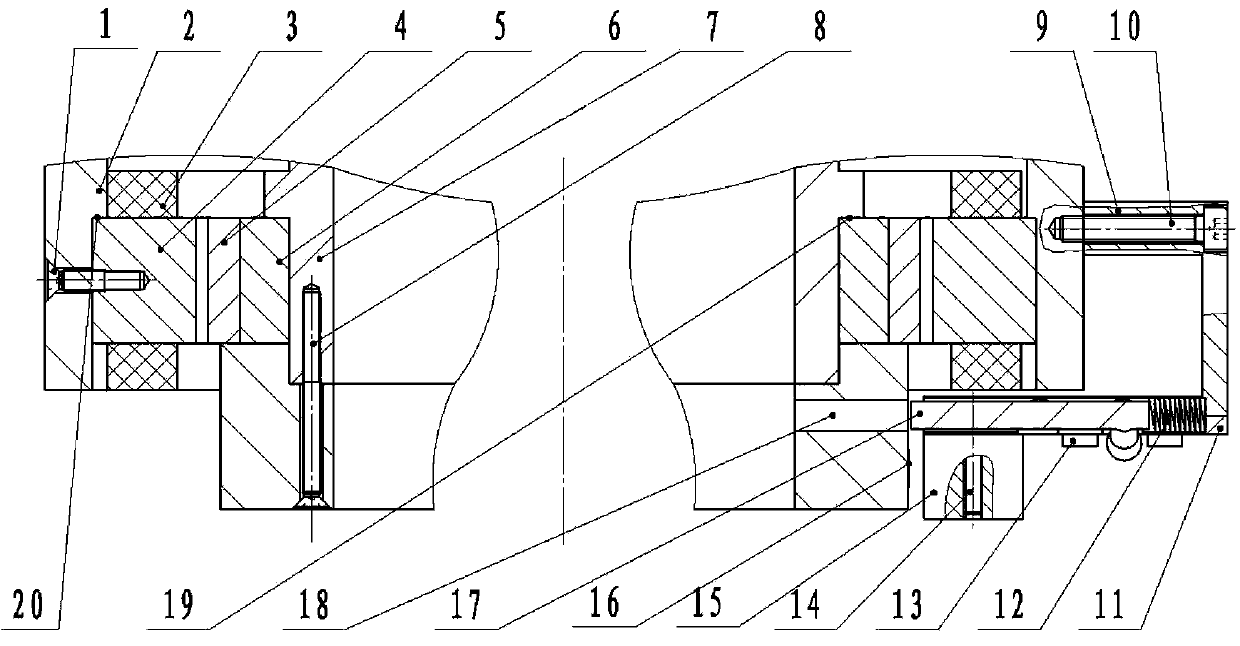

Large-discharge electric submerged screw pump oil extracting equipment

ActiveCN101864932AWith anti-vibration effectAspect ratio heightFluid removalElectric machineCoupling

The invention relates to large-discharge electric submerged screw pump oil extracting equipment. Compared with the traditional electric submerged screw pump oil extracting equipment which belongs to a large-discharge series and also mainly comprises an underground motor, an underground rotating type mechanical drive device, an underground screw pump, and the like, the large-discharge electric submerged screw pump oil extracting equipment has the technical scheme key that the underground screw pump is connected with an underground multistage motor by the underground rotating type mechanical drive device; the screw pump is rigidly fixed on the sleeve pipe wall of an oil well by adopting the underground multistage motor with high torque output and vibration resistance, a drum-gear coupling with high torque output, vibration resistance and an opening type structure, a series combined stopping type bear joint and an underground rotating type mechanical drive device of a compensating type lubricating oil tank through an anchoring device; the problem of oil leakage of an oil pipe of a large-gradient well or a horizontal well is solved by adopting a hydraulic type oil pipe oil drainer; and the large discharge of the electric submerged screw pump is realized by the technical measures, and thus the invention can be used for the oil well with large-discharge (more than 200m<3> / d) on the electric submerged screw pump.

Owner:盘锦三阳石油科技发展有限公司

Permanent magnet brushless direct-current motor with closed windings

InactiveCN102545509AExcellent mechanical propertiesGood regulation characteristicsMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectronic switchConductor Coil

The invention relates to a permanent magnet brushless direct-current motor with closed windings, wherein the windings are in closed connection like the direct-current motor, and permanent magnet excitation and electronic reversing are adopted. An armature winding is placed on a stator, a permanent magnet is placed on a rotor, each coil is connected with a pair of power electronic switches, and the other ends of the power electronic switches are respectively connected with an anode and a cathode of a power source. Current directions of the coils located under an N pole or S pole are identical and keep unchanged by means of electronic reversing, and the running principle of the coils is identical to that of the direct-current motor. As the permanent magnet excitation and the electronic reversing are adopted, the number of poles of the motor can be increased, the number of grooves of each pole of the motor is reduced, and dimensions of a yoke of the motor and ends of the coils are reduced. In addition, as the windings are in closed connection, the number of the grooves does not need to meet symmetric conditions of three phases (or multiple phases). Accordingly, a mechanical characteristic, an adjustment characteristic and a current-torque characteristic of the direct-current motor are kept, furthermore, efficiency and power density are improved, and the design is more flexible.

Owner:江建中 +1

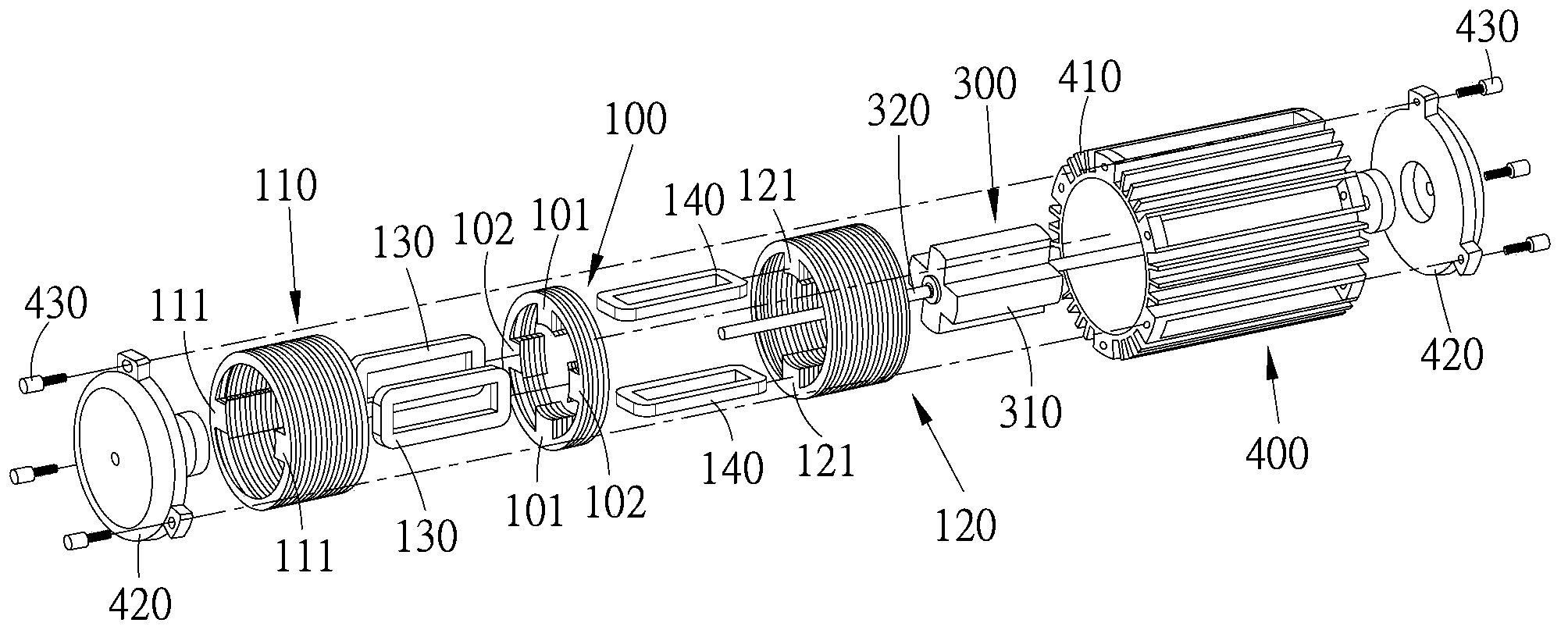

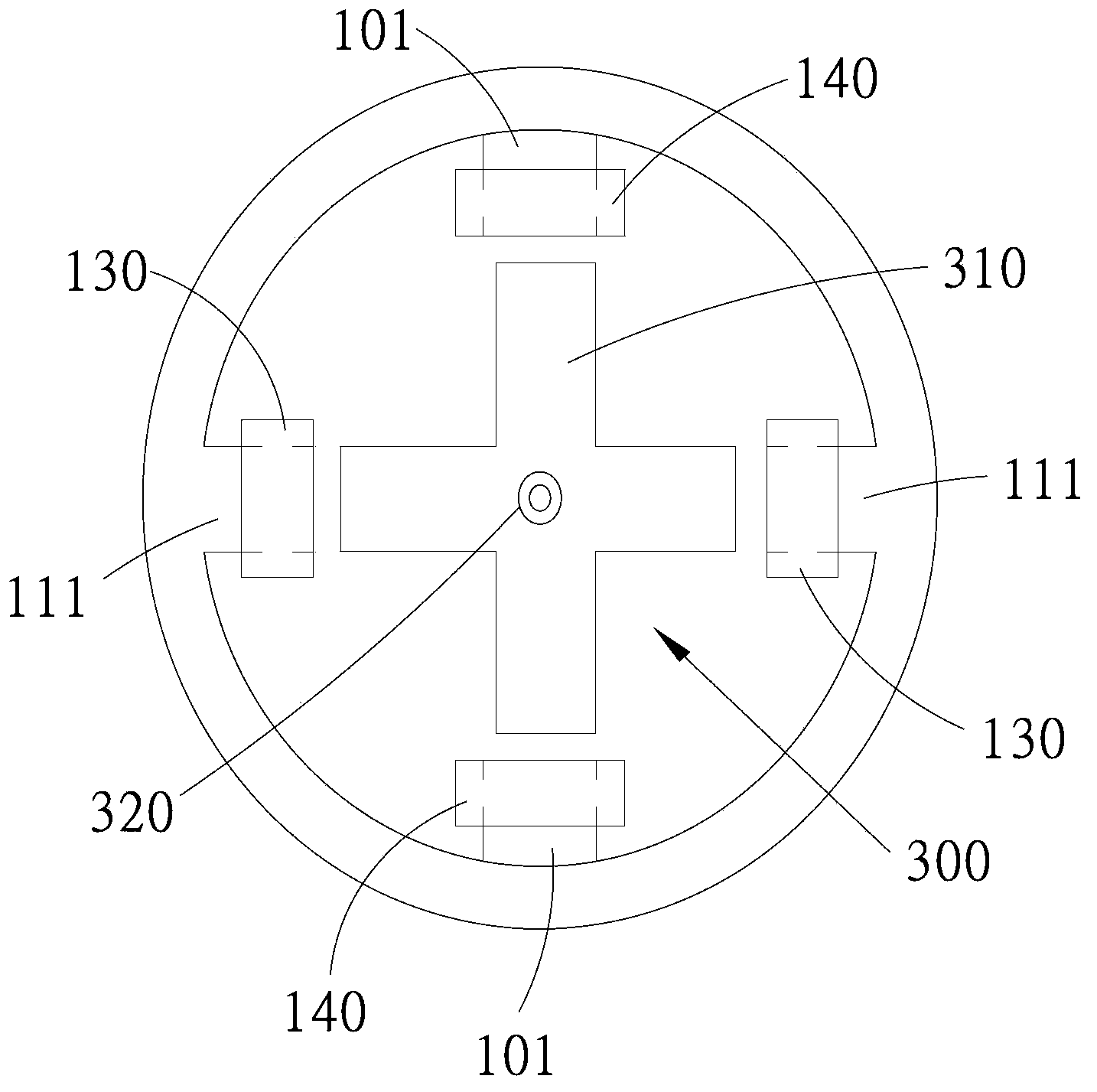

Motor stator, motor, linear motor stator and linear motor

PendingCN108429418ARealize subdivision rotationRealize subdivision rotation, advanceMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedHall element

The invention provides a motor stator, a motor, a linear motor stator and a linear motor. The motor includes n coaxial motor units. The motor unit includes a rotor unit and a stator unit. The numbersof rotor magnetic poles and stator poles are both n. A mechanical deflection angle is arranged between adjacent motor units. The mechanical deflection angle a=360 / (n*m) degrees. The polarities of theadjacent rotor magnetic poles are opposite; a Hall element is arranged between adjacent stator magnetic poles. The linear motor comprises n motor units arranged side by side along the Y-axis direction, wherein the motor unit comprises a rotor unit and a stator unit. The number of the stator magnetic poles is m. The number of the rotor magnetic poles is z. A Hall element is arranged on the stator unit every z-1 stator magnetic poles; the stator magnetic pole has a distance d. The rotor magnetic pole has a distance d. An offset h is arranged between adjacent motor units and the offset h=d / n. Both the motor and the linear motor have the characteristics of direct drive, low speed and large load output.

Owner:ZHUHAI ENPOWER ELECTRIC

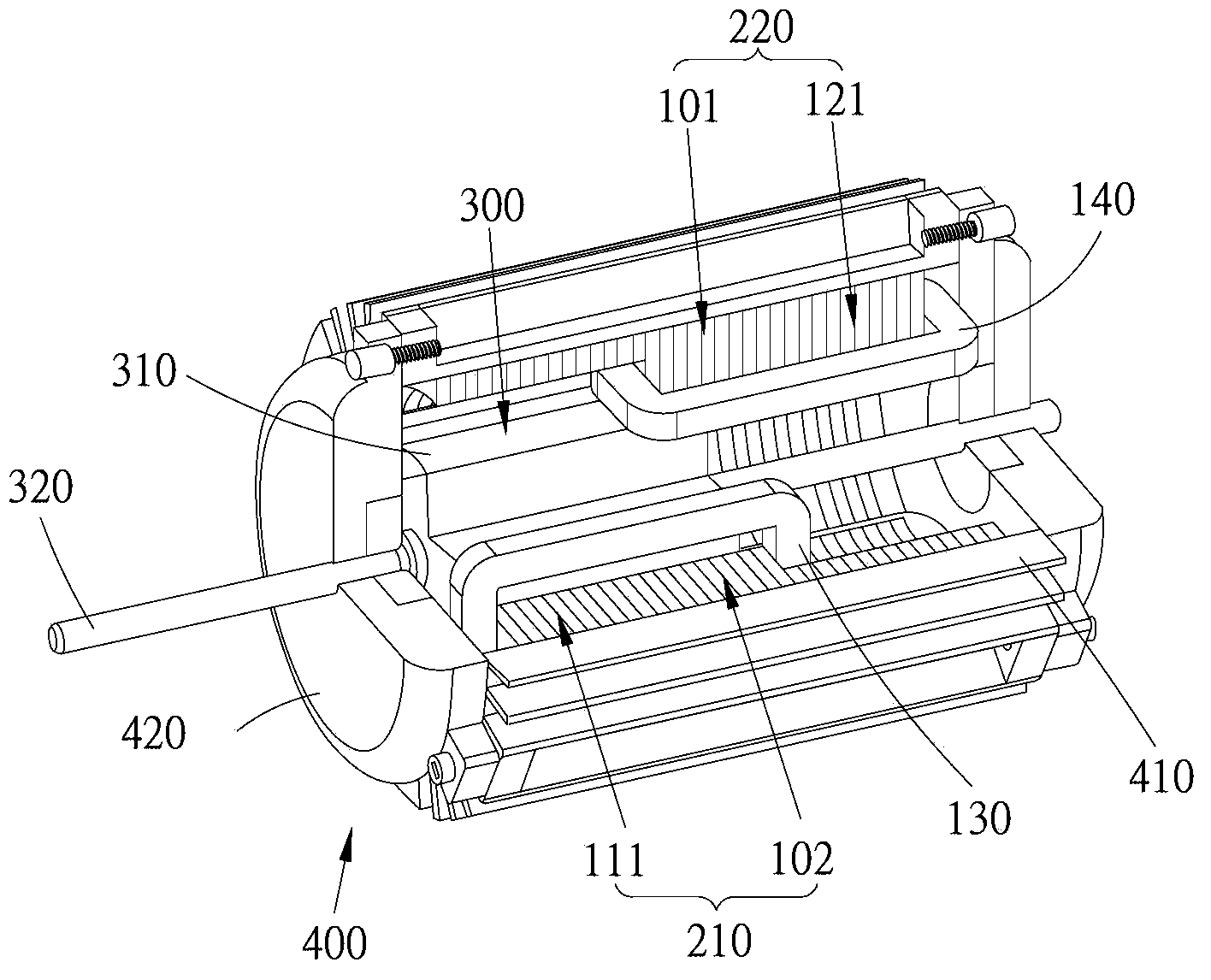

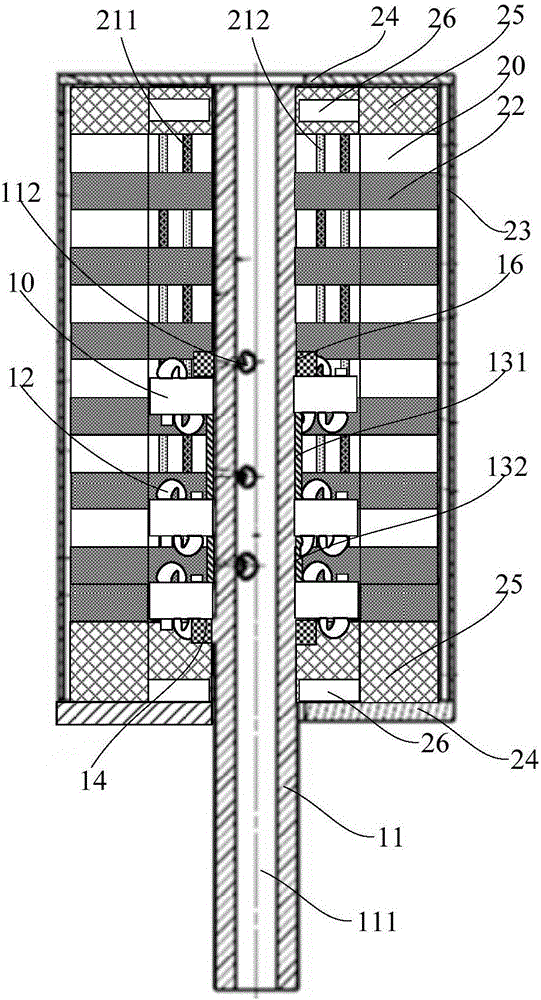

Salient pole type linear motor and reciprocating type double-piston compressor

ActiveCN103633807AIncrease the range of motionEasy to driveMagnetic circuit rotating partsMagnetic circuit stationary partsLinear motionMagnetic poles

The invention discloses a salient pole type linear motor and a reciprocating type double-piston compressor. The salient pole type linear motor at least comprises a housing, a stator, a rotor and multiple coil units, wherein the stator is composed of an intermediate stator core and stator cores at the two sides; the intermediate stator core and stator cores at the two sides are provided with multiple magnetic pole paired inward projections; and the multiple coil units are wound on a magnetic pole back and forth so that when currents are sequentially applied to the front and back coil units, through a magnetic field generated by the coil units wound on the magnetic pole, i.e., through the magnetic pole, the rotor is driven to perform reciprocating linear motion along the axial direction of the stator. The two ends of the salient pole type linear motor are also connected with a compressor with double pistons so that gas in the cylinder of the compressor is compressed or drives a fluid, and thus a reciprocating type double-piston compressor driven by the linear motor is formed.

Owner:林圣梁

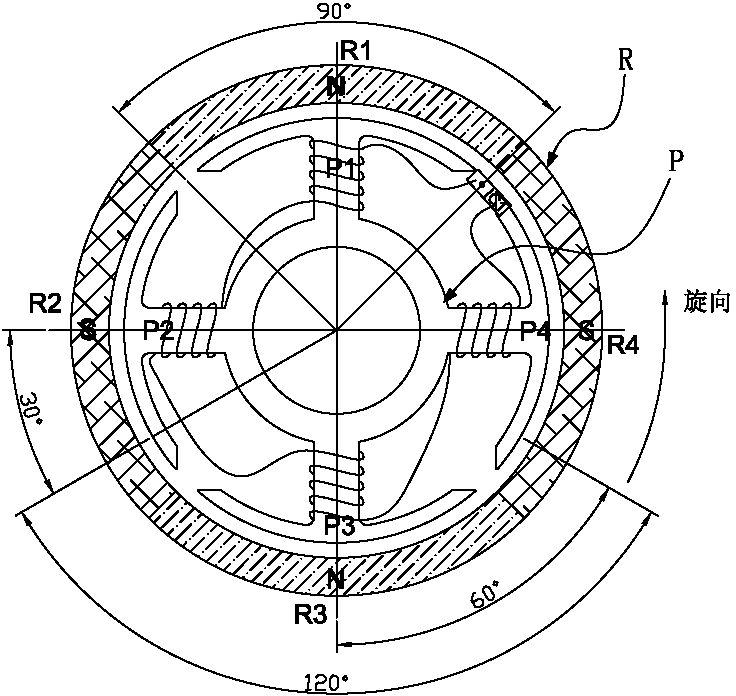

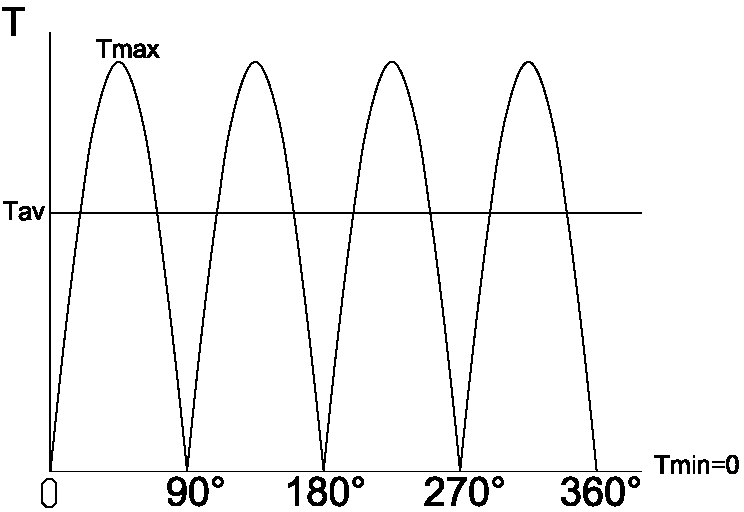

Switch reluctance motor of distributed multiple driving units

InactiveCN104967268ARealize multi-cylinder driveImprove reliabilityTorque ripple controlStructural associationElectrical batteryControl engineering

The invention discloses a switch reluctance motor of distributed multiple driving units. The motor comprises a controller, the switch reluctance motor and a position detector. The motor is characterized in that a stator of the switch reluctance motor comprises two pairs or more than two pairs of reluctance units whose radial directions are opposite; each reluctance unit and the reluctance unit with the opposite radial direction form one driving unit; each driving unit is controlled by different controllers respectively and different battery packs provide power; each reluctance unit is formed by adjacent poles with different phases and a winding. Through adding a pole number of the motor and the number of the driving units, each driving unit can work independently and the plurality of units can work simultaneously so that multi-cylinder driving to an electric car is realized and reliability of a switch reluctance motor speed regulation system is greatly increased. Simultaneously, each driving unit corresponds to the different battery packs so that a bunching effect of the battery is avoided and safety and stability of the battery packs are greatly increased.

Owner:余珊珊

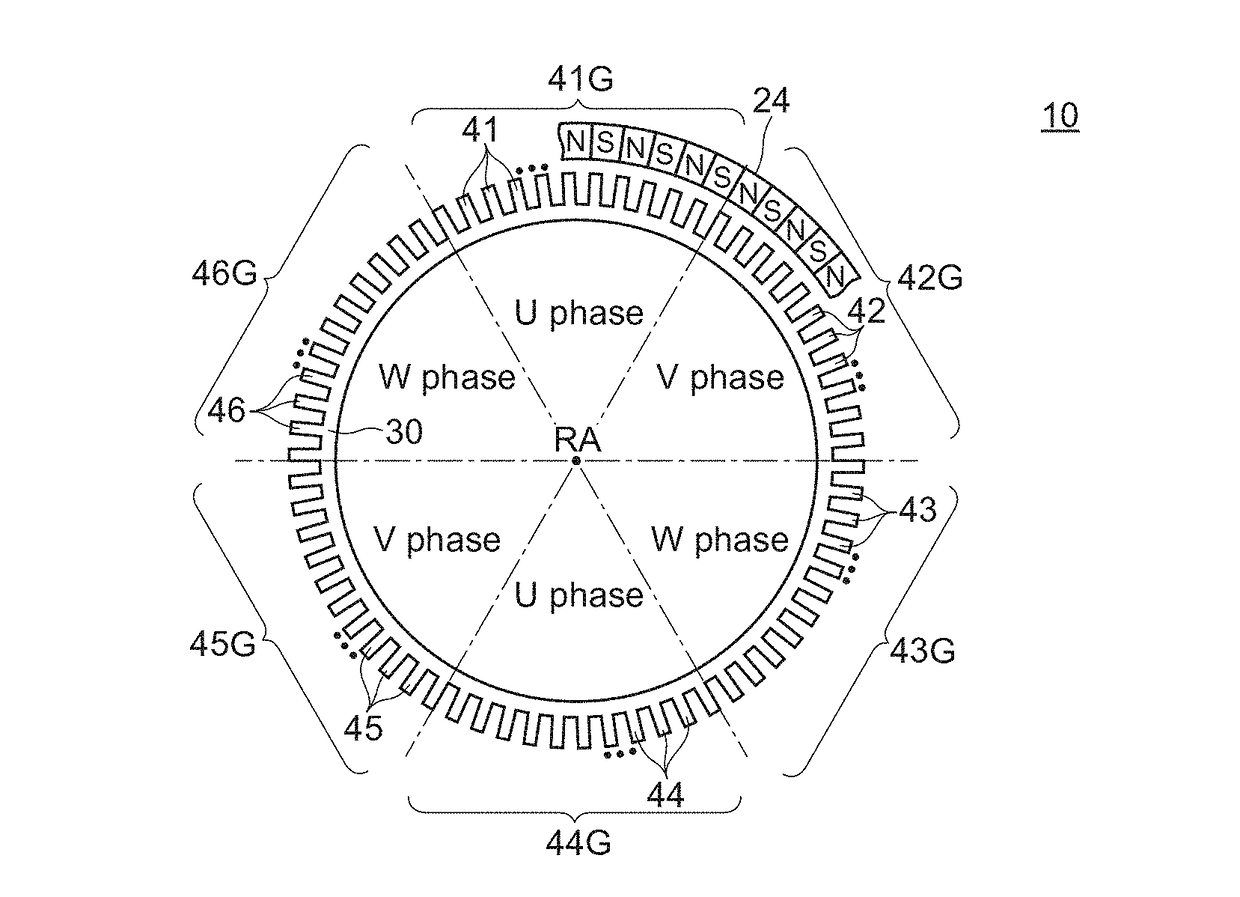

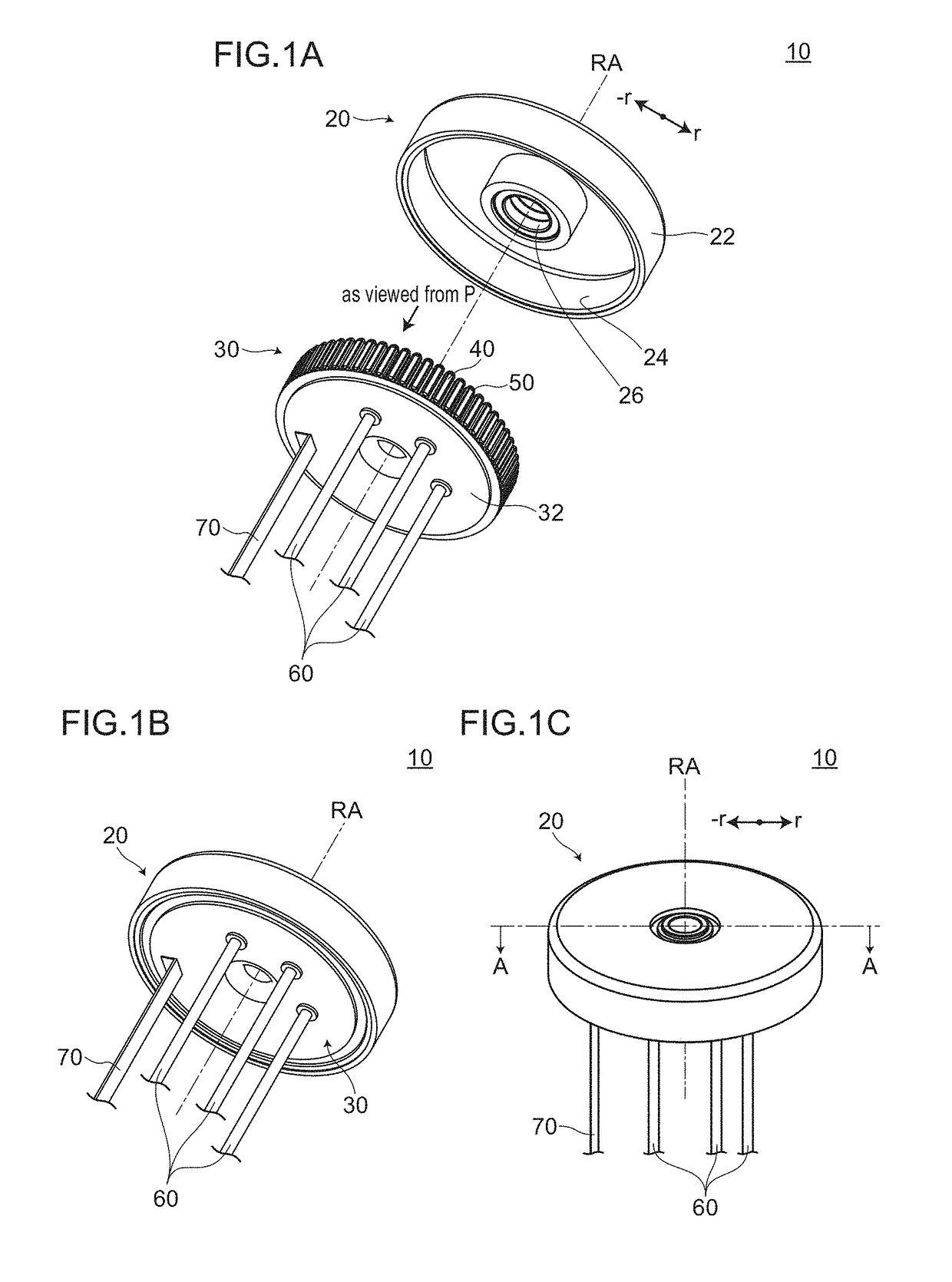

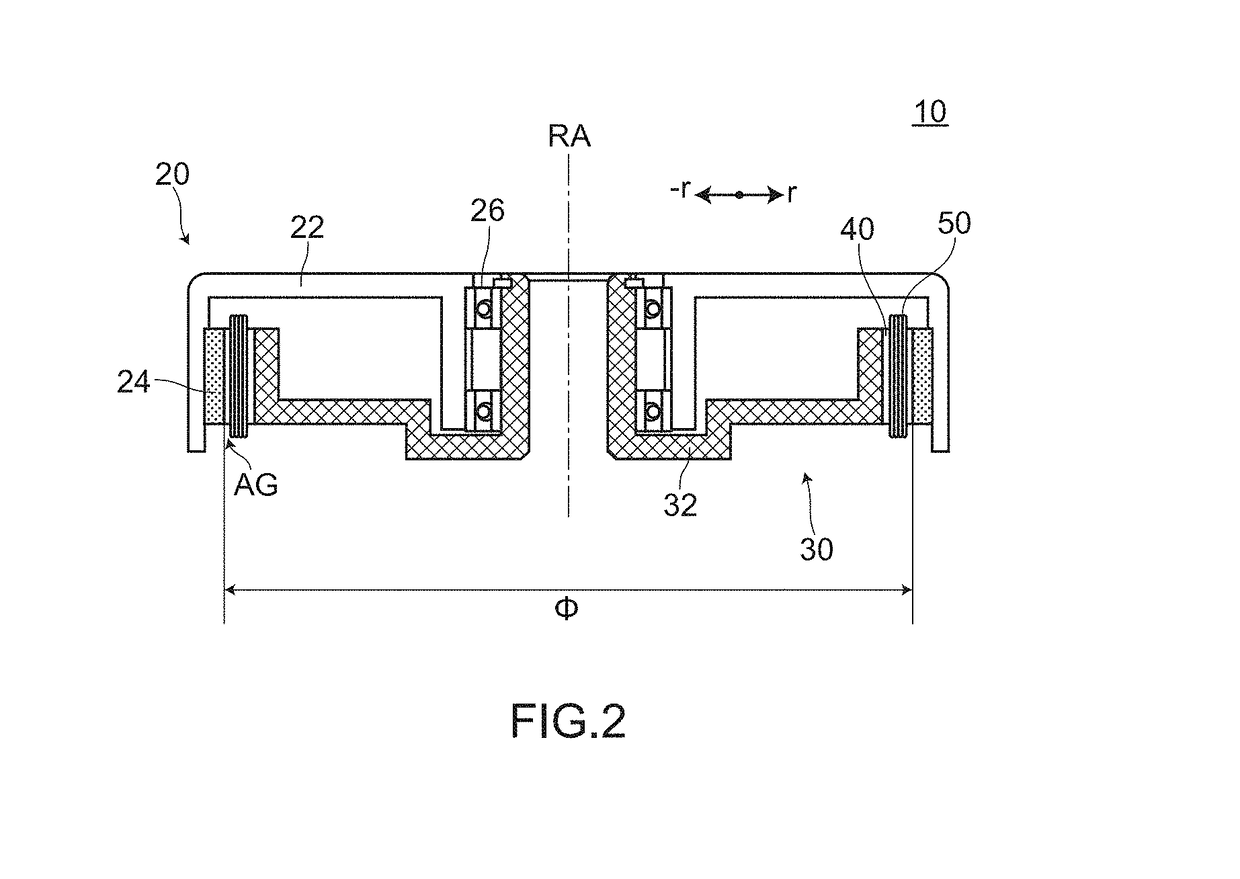

Motor and method of manufacturing motor

ActiveUS20180123410A1Reduce noiseReduce vibrationMagnetic circuit rotating partsManufacturing stator/rotor bodiesWind directionMagnet

A motor includes: a rotor having a permanent magnet and a stator having salient poles with coils. First to sixth salient pole groups each having n salient poles are arranged along a circumferential direction. The salient pole groups to which electric currents of the same phase are supplied are displaced from each other by 180 degrees in mechanical angle. Each salient pole has a straight shape. A coil group on the salient poles of each salient pole group is formed by connecting the n coils in series, winding directions of the coils of adjacent salient poles are opposite to each other, the coils are connected to each other at a distal or a proximal end side of the salient pole by a connecting wire between the adjacent salient poles, and the connecting wires have a reverse relationship with respect to the distal or the proximal end side between adjacent slots.

Owner:TOKYO MOTRONICS CO LTD

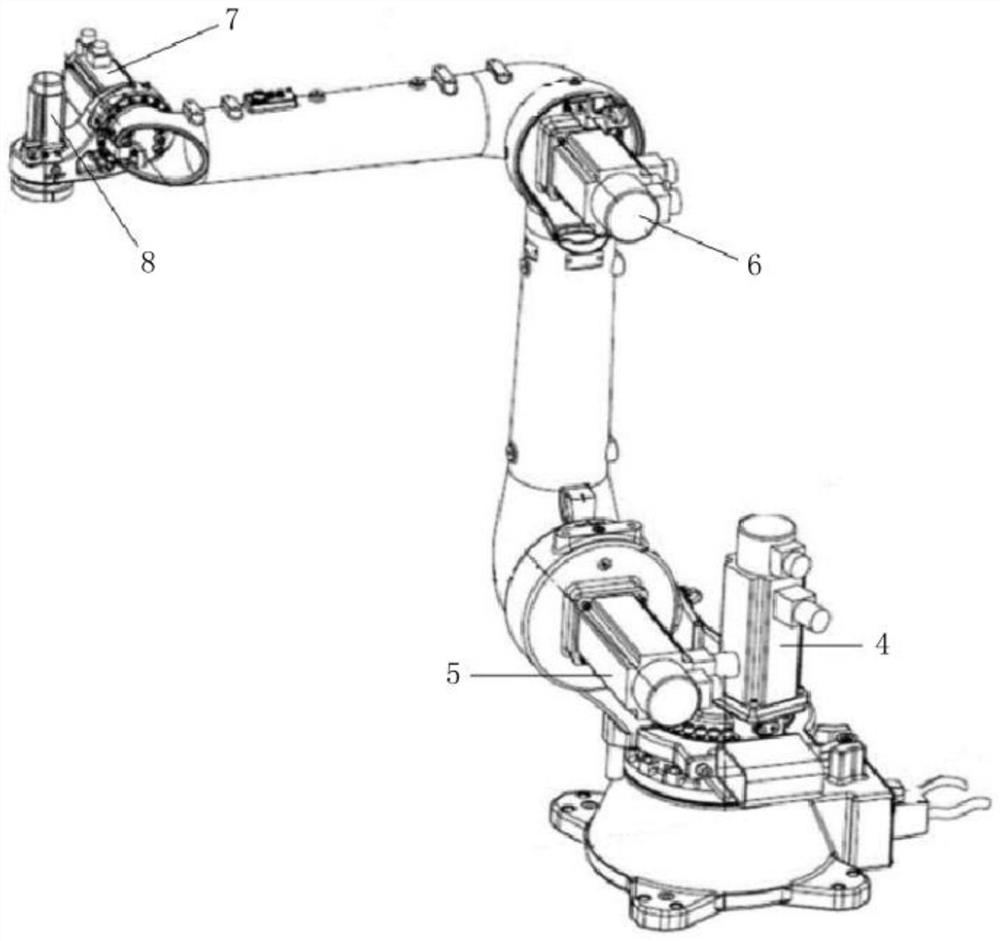

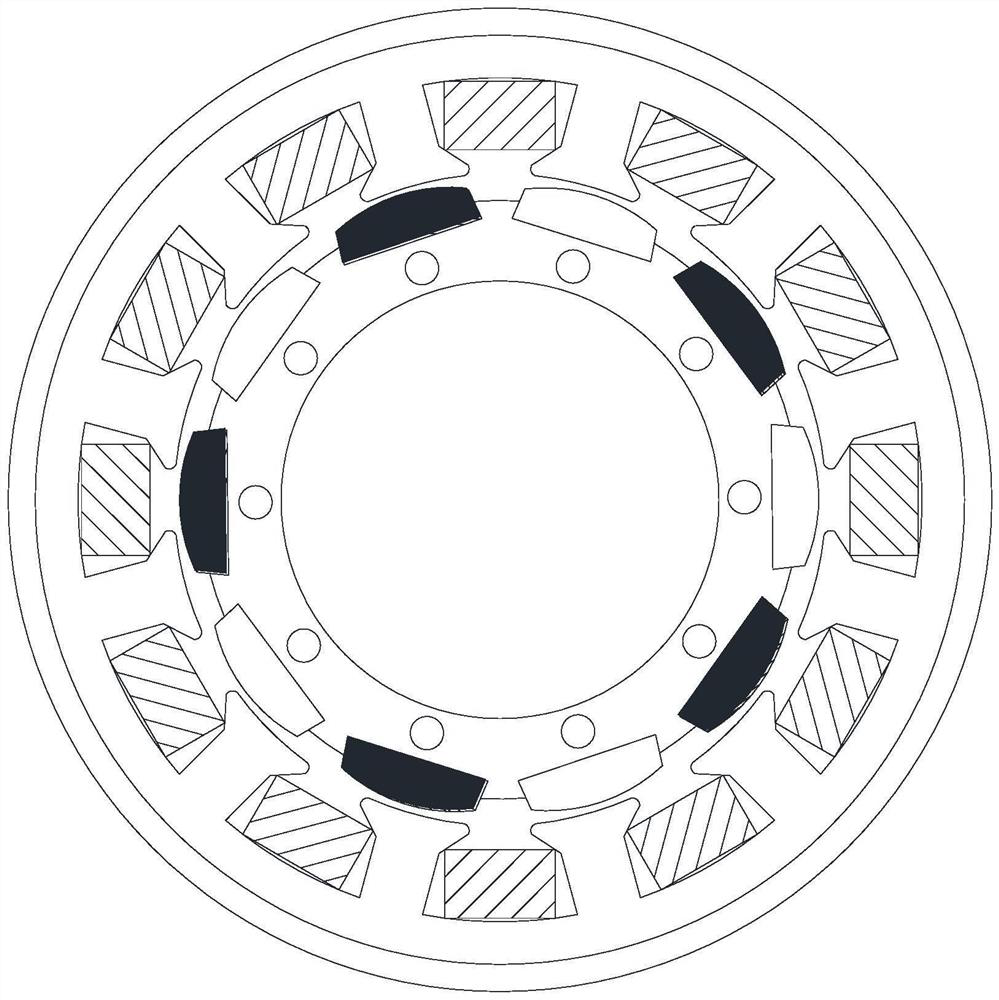

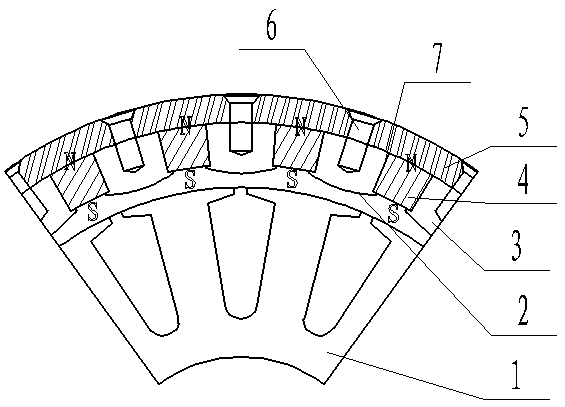

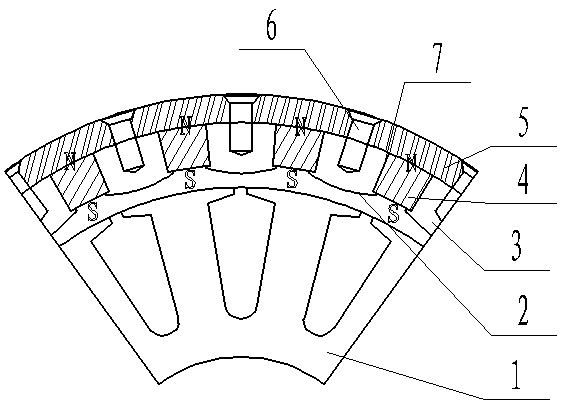

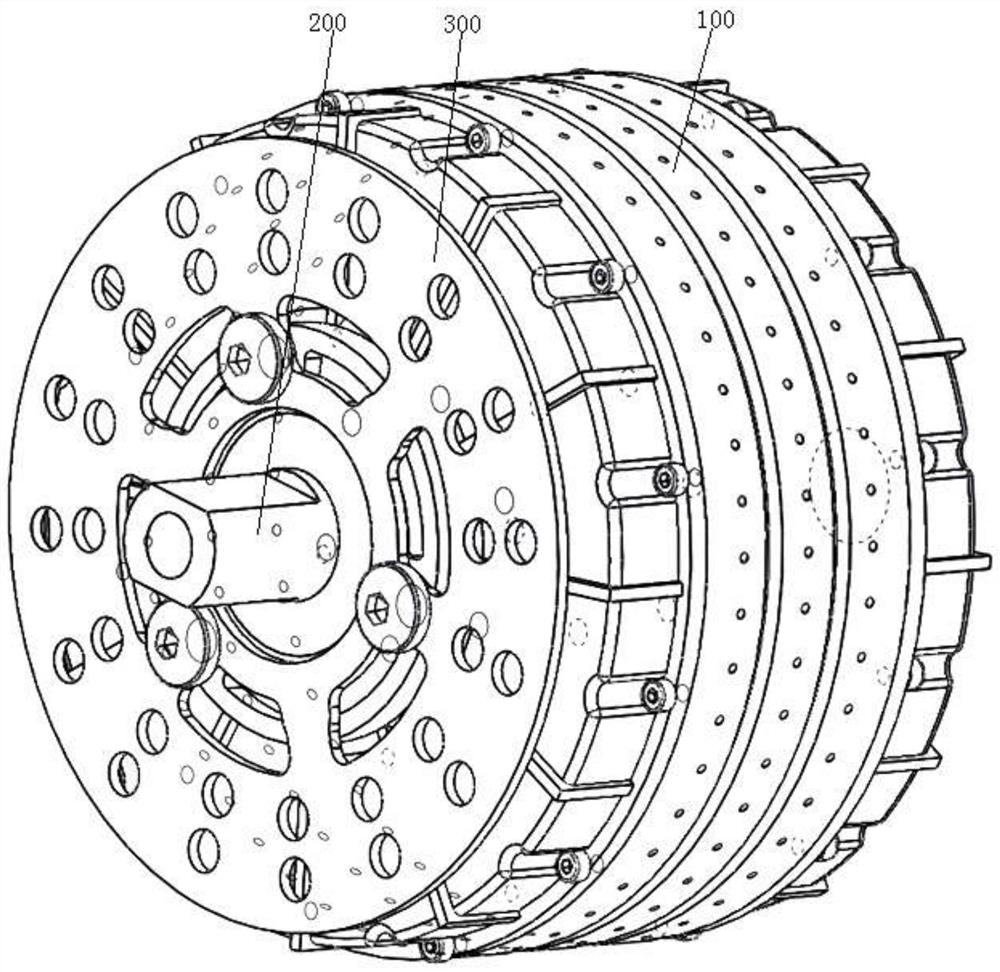

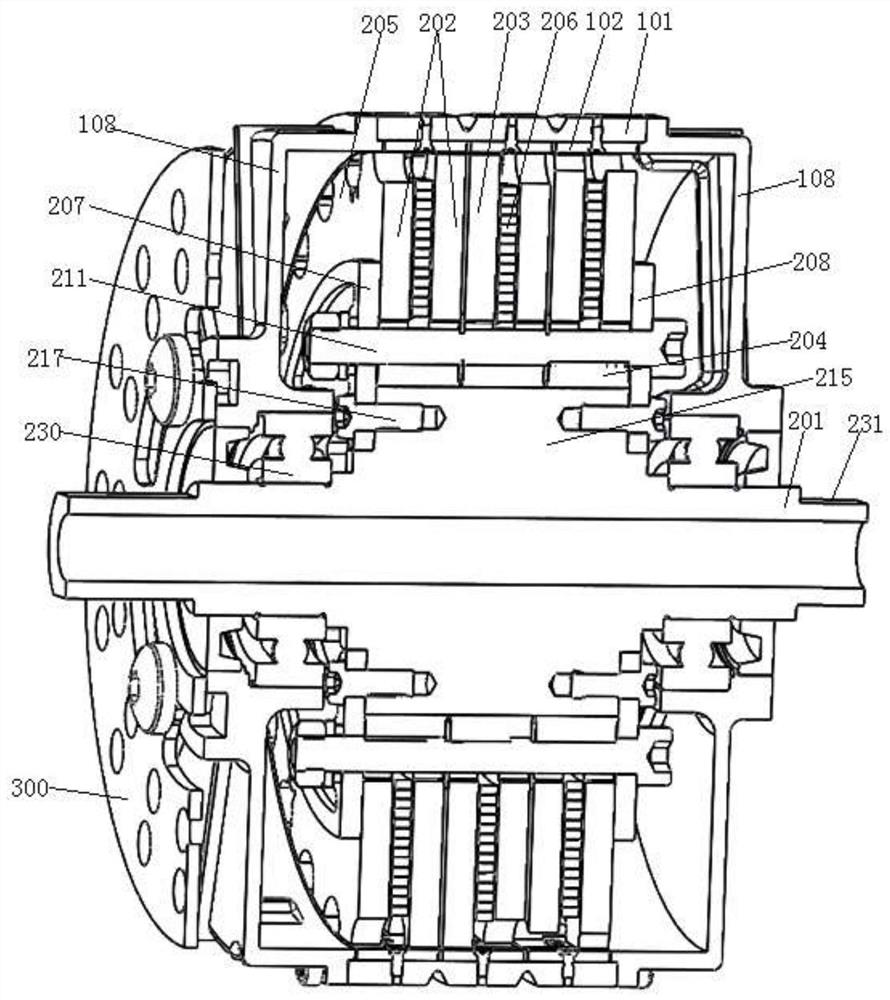

Magnetic field modulation motor magnetic circuit structure for robot arm joint

PendingCN114884235AEquivalent number of poles increasedReduce gear ratioProgramme-controlled manipulatorMagnetic circuit rotating partsReduction driveElectric machine

The invention discloses a magnetic field modulation motor magnetic circuit structure for a robot arm joint, and relates to the technical field of robots, more permanent magnets are adopted, more harmonic magnetic fields are generated through magnetic field modulation, although the harmonic magnetic fields cannot be seen, electromagnetic torque is actually generated to participate in the electromechanical energy conversion process, and the mechanical energy conversion efficiency is improved. Harmonic waves include third-order harmonic waves, fifth-order harmonic waves, seventh-order harmonic waves,... 2k + 1-order harmonic waves, generation of the harmonic waves actually enables the equivalent pole number of the motor to be increased, and therefore the rotating speed is reduced, electromagnetic speed reduction of a traditional servo motor can be achieved, the output rotating speed of a motor rotor shaft is reduced, torque is greatly improved, a speed reducer can be omitted, or the speed ratio of the speed reducer can be greatly reduced. Therefore, the technical threshold of mechanical manufacturing is reduced, low-speed direct drive and large-torque output of the motor are achieved, the transmission structure is greatly simplified, the weight of the transmission structure is reduced, and the dynamic response capacity and control precision of the system are improved.

Owner:ZHONGZHI NANJING ELECTRIC CO LTD

Process for using oscillatingmagnetic separation barrel mineral concentration

InactiveCN101077486AIncrease the number of polesSolve the phenomenon of magnetic agglomerationMagnetic separationEngineeringNon magnetic

The present invention relates to magnetic mineral separation, and is especially mineral drilling process with swing type magnetic separating cylinder. The technological process includes adding material to the magnetic separating cylinder, rotating the outer magnetic separating cylinder to separate magnetic mineral from non-magnetic mineral, and swinging the inner cylinder reciprocally in the swinging angel of 25-35 deg and swinging speed of 80-260 times each min. Swinging the inner cylinder can reach the effect similar to that of doubling pole number of the magnetic system so as to avoid magnetic coagulation, raise the grade of separated iron mineral and lower the iron content in the tailing.

Owner:衣大明

Transverse magnetic field linear generator adapting to variable-speed operation within low-speed range

InactiveCN106533115AIncrease the number of polesIncrease the output voltageMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedTransverse magnetic field

The invention provides a transverse magnetic field linear generator adapting to variable-speed operation within a low-speed range. The transverse magnetic field linear generator comprises a stator and a rotor, wherein the stator comprises stator cores, a stator fixing shaft and stator windings; the rotor comprises rotor cores, first permanent magnets, second permanent magnets and first non-magnetic conducting material structures; each stator core and the corresponding stator winding assembled in stator slots in the stator core form one phase of the stator, so that implementation of modularization is achieved; the number of phases of the generator and the arrangement mode among the phases are not limited; the number of poles of the generator is increased; on one hand, the stator and the rotor can be freely combined according to the amount of to-be-converted energy, and on the other hand, the generator can obtain relatively high output voltage during low-speed operation; the wire length of a single-phase armature coil of the generator for effectively cutting a magnetic line is increased by the structure, so that the magnitude of single-phase output voltage of the generator is increased, the low-speed output capability of the generator is improved and improvement of the energy conversion efficiency of the generator is finally facilitated.

Owner:SHANGHAI OCEAN UNIV

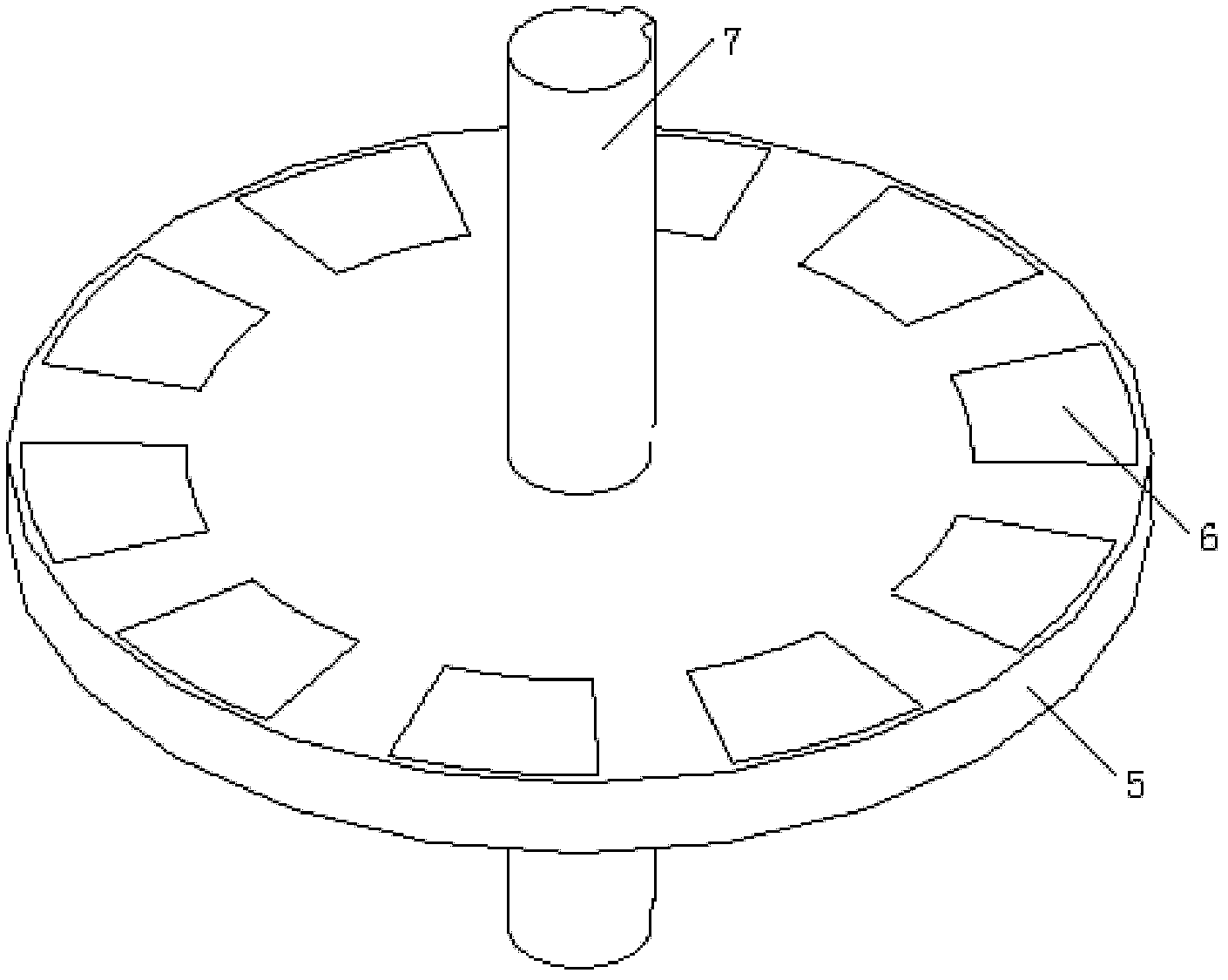

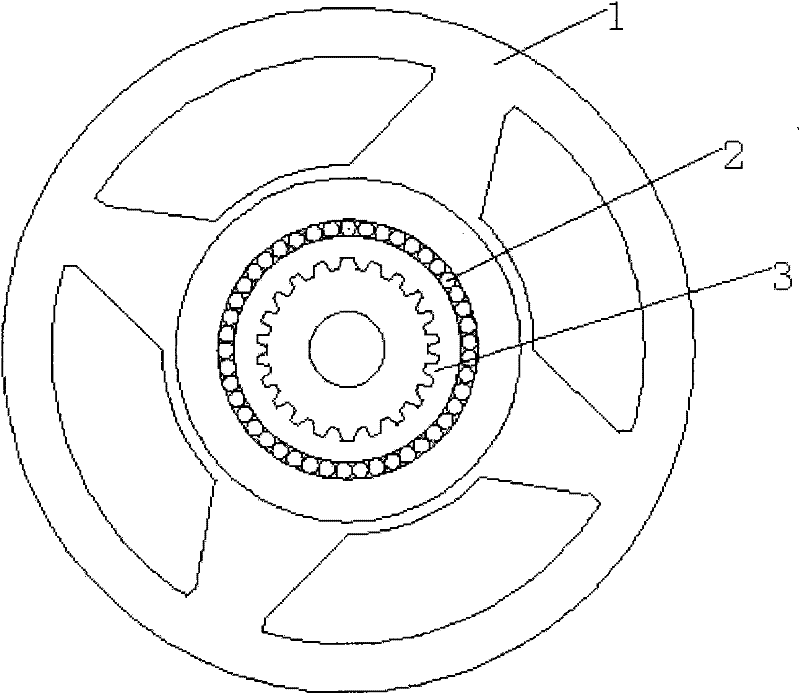

Motor rotor

The rotor of motor includes a body of rotor, a rotating shaft, and multiple magnetic elements. The body of rotor possesses multiple accommodation parts, which are arranged in radiation form by using axle center of body of rotor as center. The rotating shaft is setup at axle center of body of rotor. Multiple magnetic elements are setup in the accommodation parts. Each magnetic element possesses an N pole and an S pole. Joint seam between N pole and S pole, and extension direction of seam passes through the axle center of body of rotor.

Owner:DELTA ELECTRONICS INC

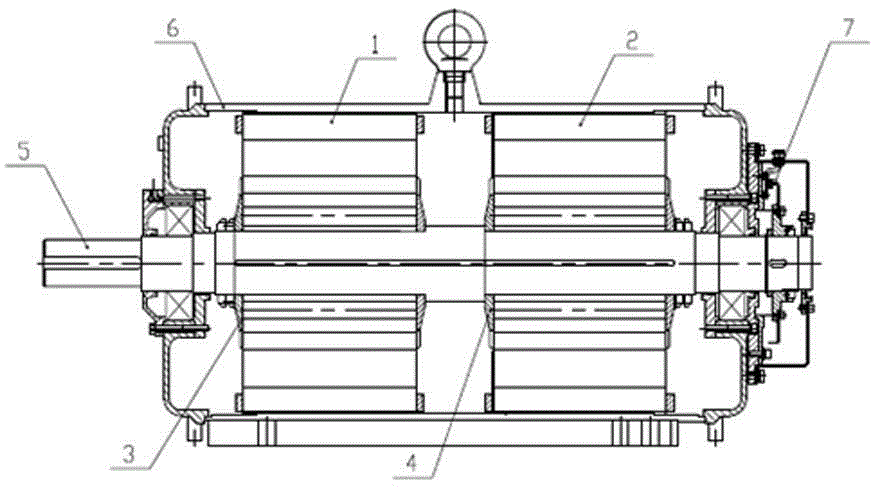

Dual-machine two-dimensional integrated three-phase asynchronous hub motor and frequency conversion driving control system

InactiveCN102195539AIncrease the number of polesIncrease inductanceElectric motor speed/torque regulationRegenerative brakeControl system

The invention discloses a dual-machine two-dimensional integrated three-phase asynchronous hub motor and a frequency conversion driving control system. The motor consists of two three-phase asynchronous frequency conversion motors with the same structure; and two integrated modes and three operating modes are adopted by left and right sides of a rear-wheel dual machine and front and rear wheels of the dual machine respectively. The motor has excellent working environment adaptability and energy-saving efficiency and is combined with a frequency conversion driving controller so as to form a novel two-wheel electric vehicle electrically-driven system; and the motor and the system have the advantages of frequency conversion and energy conservation, regenerative brake energy conservation, replacement of motor reverse brake from mechanical friction brake, and the like.

Owner:杜哮宇

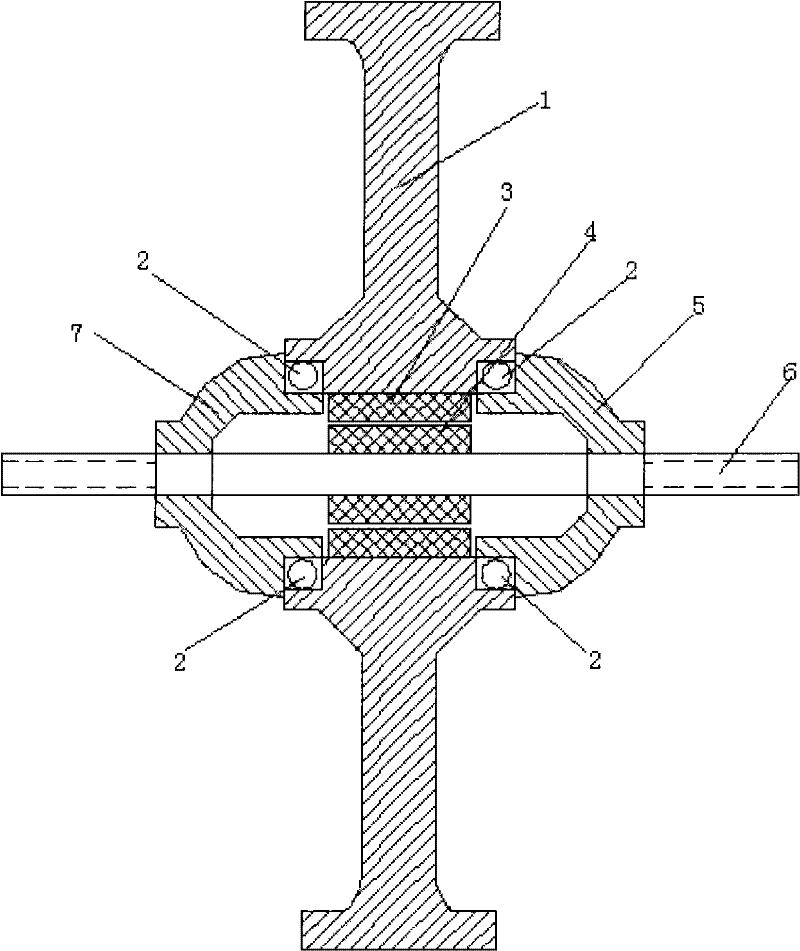

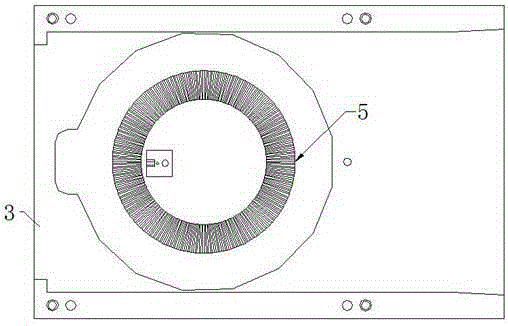

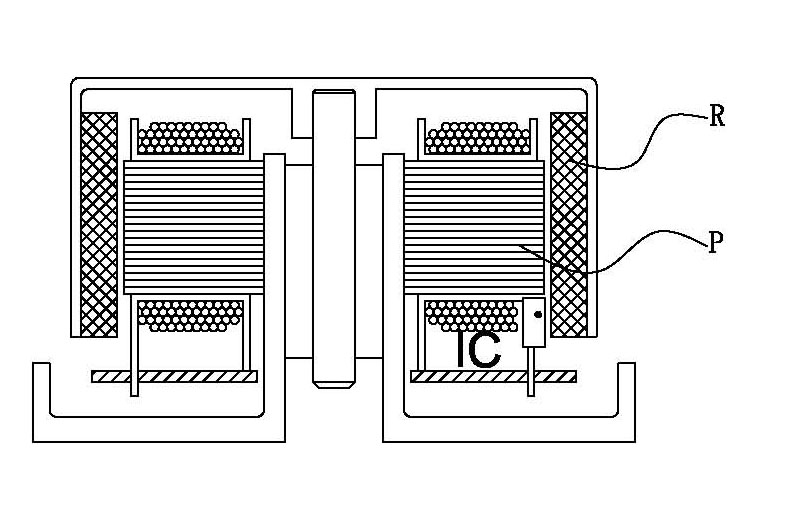

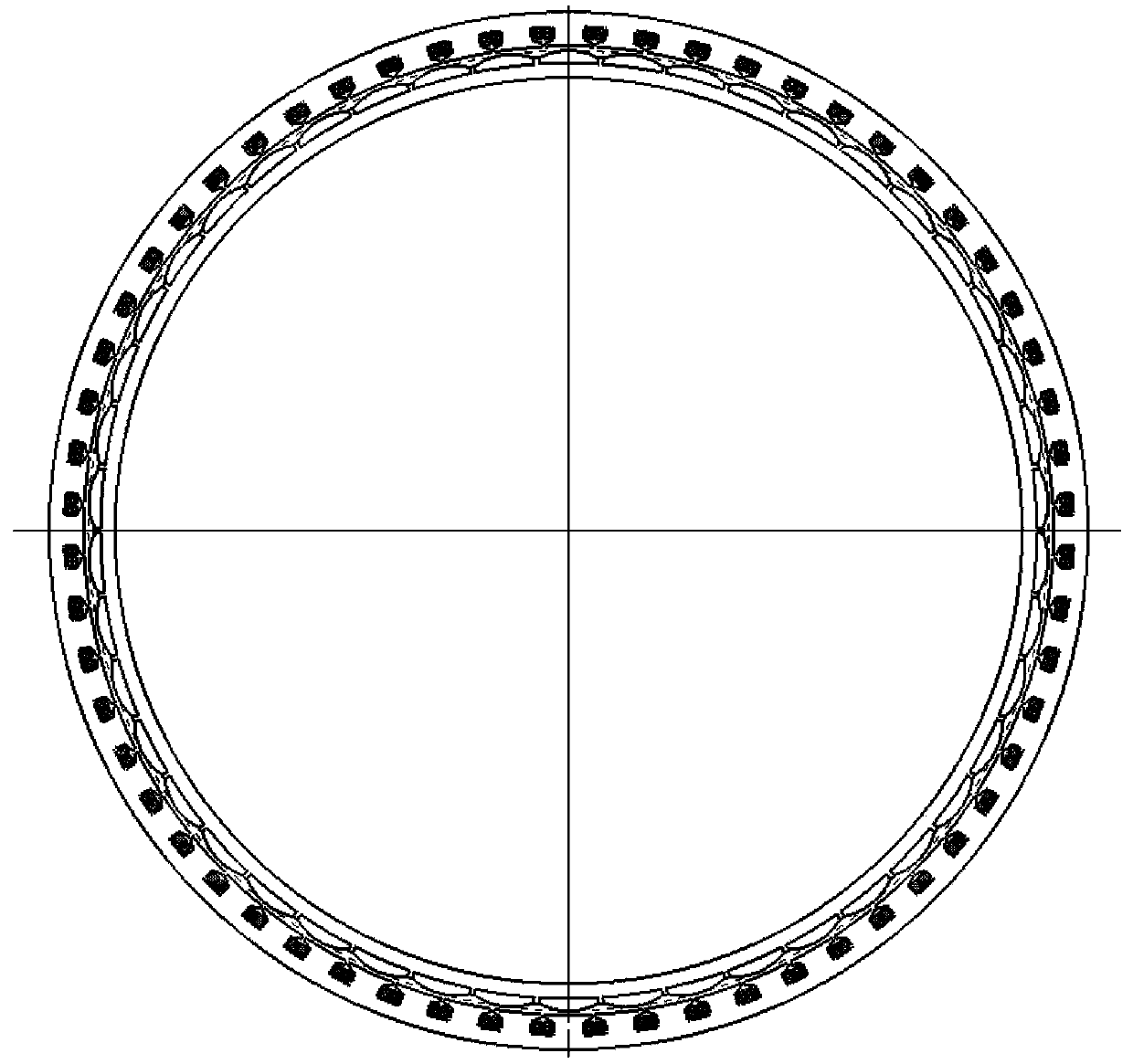

Manufacturing method and tool of magnetic ring of high-precision magnetic encoder

ActiveCN105336469AHigh-resolutionImprove uniformityConverting sensor output electrically/magneticallyCoils manufactureEngineeringMechanical engineering

The invention discloses a manufacturing method and tool of a magnetic ring of a high-precision magnetic encoder, which are used for manufacturing the magnetic ring of the magnetic encoder. The tool comprises coils located above and under the magnetic ring; the two coils are magnetizing coils with a plurality of poles; with the adoption of a magnetizing manner, the precision of the magnetic ring can be improved and a non-magnetic region between the poles of the magnetic ring can be relatively thin, so that the quantity of the poles of the magnetic ring is improved and the resolution of the magnetic encoder is also improved; and the uniformity between the poles also can be improved.

Owner:麦格雷博电子(深圳)有限公司

A three-phase U-shaped stator tooth external rotor switched reluctance motor and its driving method

ActiveCN104009605BSimple structureDoes not affect the winding spaceSingle motor speed/torque controlDynamo-electric machinesElectric machineMagnetic poles

The invention discloses an outer rotor switch reluctance motor with three-phase U-shaped stator teeth and a driving method of the outer rotor switch reluctance motor with the three-phase U-shaped stator teeth. The motor comprises three different kinds of U-shaped stator teeth, three different annular windings and a finger-shaped rotor installed outside stator magnetic poles. The total number of the stator teeth is even times of three. The numbers of the stator teeth in all sizes are identical. U-shaped stators are sequentially and evenly arranged in the circumferential direction of the motor in an intersected mode according to the sizes, and the stators mutually independent are fixed to an outer shell of a generator. The rotor is arranged outside the circumferences of the stators and provided with no brush, no winding and no permanent magnet. The three windings of the motor are wound in tooth grooves of the three different kinds of U-shaped stator teeth. The switch reluctance motor is simple in structure, corresponding driving circuits are simple, few switch components are used for the motor, control is easy, the cost for the motor and a power converter is low, winding of the windings is convenient, increasing of the number of the stator magnetic poles and rotor magnetic poles of the motor will not affect the winding space of the windings, and the outer rotor switch reluctance motor is more suitable for being applied at a low rotation speed.

Owner:冬雷

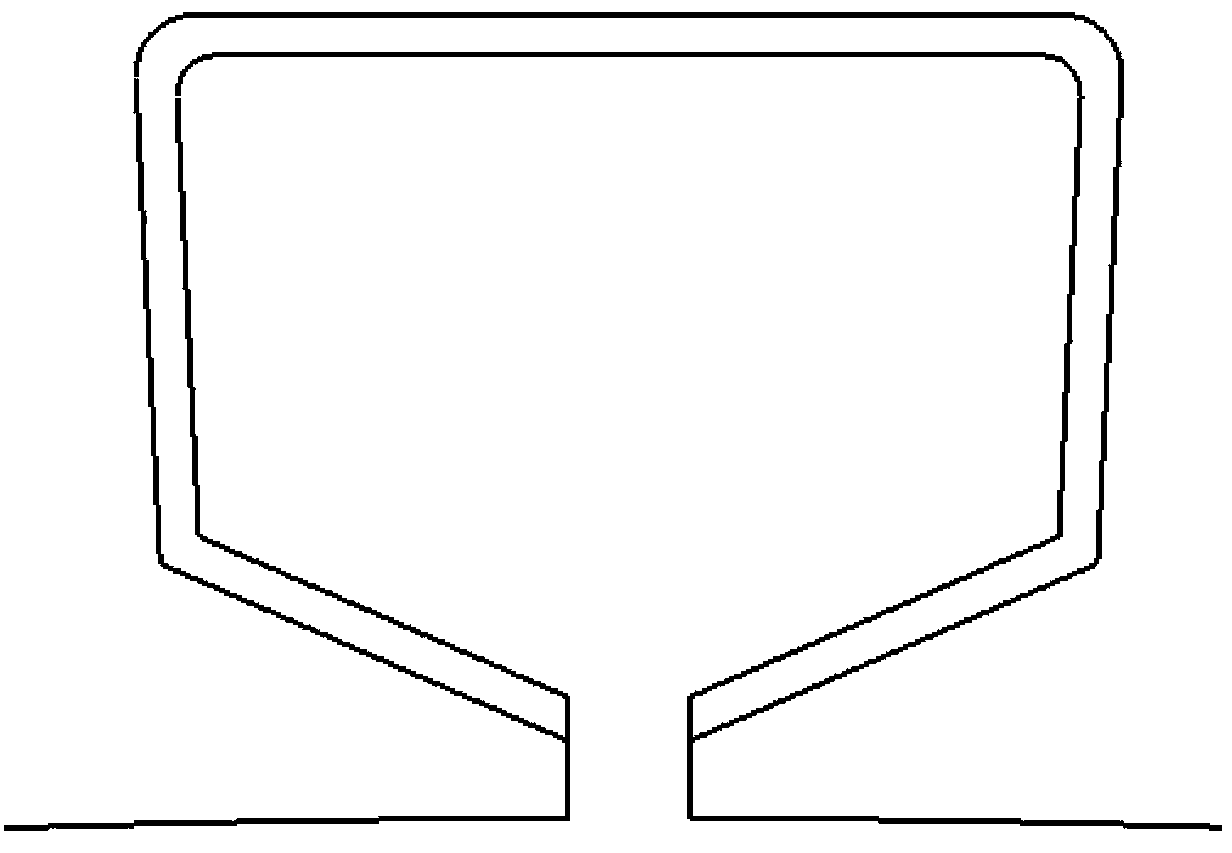

Permanent magnet synchronous motor stator core

InactiveCN111181267AReasonable structureEasy to useMagnetic circuit stationary partsSupports/enclosures/casingsElectric machinePermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motorstator core. The stator corecomprises a stator mechanism and a rotor mechanism. A shell sleevesan outer portion of an iron core; the shellisconnected with the iron core through a screw; permanent magnets are arranged in gaps among the iron cores; the adjacent permanent magnets have the same magnetism; baffles are arranged at two ends ofthe permanent magnet; and each baffle is fixedly connected with the iron core.In the invention, a center height of the shellmade of magnetism isolating metal and the center height of a low-speed large-torque motor with the same power are obviously reduced; and adiameter of the permanent magnet synchronous motor is reduced, the magnetism of the adjacent permanent magnets is set to be the same, thenumber of poles of the motor is doubled under acondition that the same number of permanent magnets are used, and the motor can rotate at a lower speed under the condition that the number of the permanent magnets is the same as that of the existing permanent magnets.

Owner:河南全新机电设备有限公司

Manufacturing method and tooling of a high-precision magnetic encoder magnetic ring

ActiveCN105336469BHigh-resolutionImprove uniformityConverting sensor output electrically/magneticallyCoils manufactureNon magneticEncoder

The invention discloses a manufacturing method and tool of a magnetic ring of a high-precision magnetic encoder, which are used for manufacturing the magnetic ring of the magnetic encoder. The tool comprises coils located above and under the magnetic ring; the two coils are magnetizing coils with a plurality of poles; with the adoption of a magnetizing manner, the precision of the magnetic ring can be improved and a non-magnetic region between the poles of the magnetic ring can be relatively thin, so that the quantity of the poles of the magnetic ring is improved and the resolution of the magnetic encoder is also improved; and the uniformity between the poles also can be improved.

Owner:麦格雷博电子(深圳)有限公司

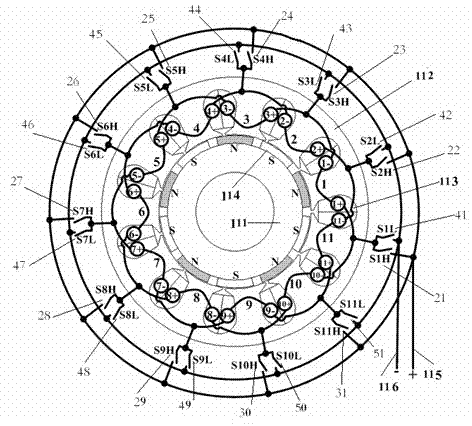

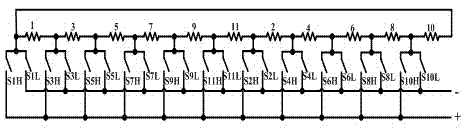

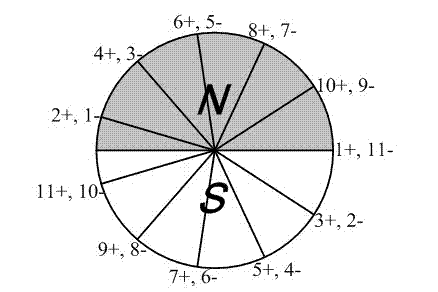

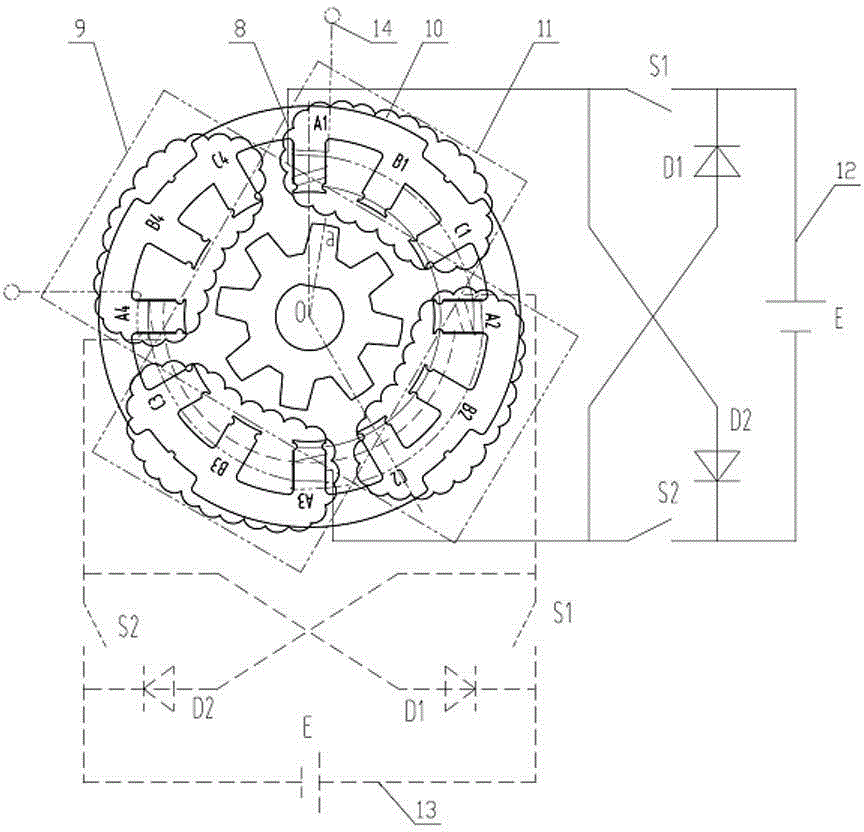

Staggered multi-driving direct-current brushless motor

ActiveCN102163902AImprove torque characteristicsRunning without dead endsMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsPhase time

The invention discloses a staggered multi-driving direct-current brushless motor. The motor comprises a rotor, a stator and a plurality of driving circuits with staggered induction phases, wherein the rotor encircles the stator or is encircled by the stator, and is provided with a plurality of magnetic poles; the stator is provided with a plurality of polar teeth and the number of the polar teethof the stator is smaller than the number of the magnetic poles of the rotor; the stator comprises multiple groups of coils and one group of coils passes by one or more polar teeth of the stator; the plurality of driving circuits respectively correspond to multiple groups of coils; a phase time alternation for polar switching is performed between the polar teeth of the stator, namely in the switching process of each or each group of the polar teeth of the stator, the rest polar teeth of the stator are in a non-switching working state; torsions which are generated between the polar teeth of thestator and the magnetic poles of the rotor are staggered in phase and overlapped to form torsion of the motor; the torsion of the motor is always more than zero and the minimum torsion of the motor is close to an average torsion; the motor has no running deal angle and the motor has relatively low cost and occupies relatively small space.

Owner:湖州佳星电机有限公司

Transverse flux outer rotor motor

ActiveCN114079327ANot easy to saturateHigh outputElectric machinesMagnetic circuit stationary partsTransverse fluxElectric machine

The invention discloses a transverse flux outer rotor motor, and belongs to the field of motors. The motor comprises an outer rotor assembly and a stator assembly. The stator assembly comprises a stator shaft and multi-phase stator modules, each phase of stator module comprises two stator toothed plates and a stator yoke ring, and a coil wound around the axial direction as the center is arranged between the two stator toothed plates. The outer rotor assembly comprises a rotor yoke ring, the inner surface of the rotor yoke ring is provided with a plurality of rows of magnetic steel distributed in the axial direction, the number of the rows of the magnetic steel is the same as the number of phases of the stator modules, the magnetizing direction of the magnetic steel is the radial direction, and the number of the magnetic steel in each row is two times of the number of stator teeth on one stator toothed plate. The magnetic field directions of the two adjacent magnetic steels in each row are opposite, and the magnetic field directions of the two adjacent magnetic steels in the adjacent row are the same. A three-dimensional magnetic circuit structure is realized by combining the silicon steel sheet stator toothed plates and the SMC stator yoke ring, the manufacturing difficulty is low, the working time and the cost are low, the coil winding is convenient, more poles can be manufactured, and the torque pulsation of the motor is reduced.

Owner:山东精创磁电产业技术研究院有限公司

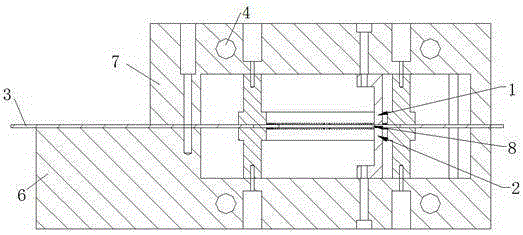

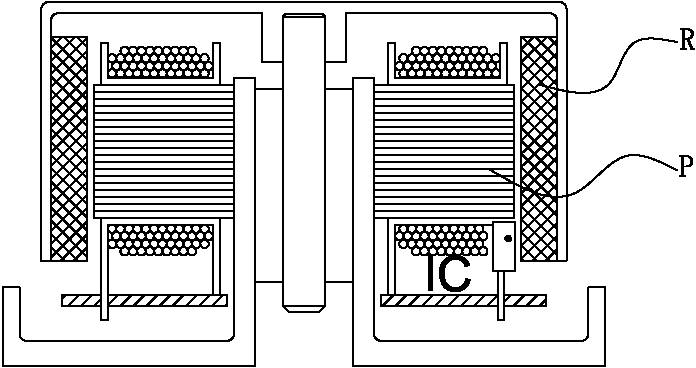

Azimuth-drive motor system structure of heavy load inertially stabilized platform

InactiveCN103023222BHigh precisionReduce volumeStructural associationWindings conductor shape/form/constructionGratingAzimuth direction

An azimuth-drive motor system structure of a heavy load inertially stabilized platform comprises an azimuth-drive motor body structure, a motor measuring structure and a motor locking mechanism. The azimuth-drive motor body structure comprises a motor stator and a motor rotor. The motor measuring structure comprises a grating measuring ruler structure and a grating read head structure. The motor locking mechanism comprises a motor locking spring and a motor locking pin. The azimuth-drive motor body structure realizes control of azimuth direction freedom degree, and realizes isolation of airplane azimuth direction angle motions according to control instructions. The motor measuring structure finishes angle information measurement of azimuth direction relative rotary angles, and feeds back to a processor to complete accurate control of azimuth direction. The motor locking mechanism realizes static state of the heavy load inertially stabilized platform, and guarantees fixed azimuth pose during aerial photography and absolute static during non-working state.

Owner:BEIHANG UNIV

Staggered multi-driving direct-current brushless motor

ActiveCN102163902BImprove torque characteristicsRunning without dead endsMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsPhase time

The invention discloses a staggered multi-driving direct-current brushless motor. The motor comprises a rotor, a stator and a plurality of driving circuits with staggered induction phases, wherein the rotor encircles the stator or is encircled by the stator, and is provided with a plurality of magnetic poles; the stator is provided with a plurality of polar teeth and the number of the polar teeth of the stator is smaller than the number of the magnetic poles of the rotor; the stator comprises multiple groups of coils and one group of coils passes by one or more polar teeth of the stator; the plurality of driving circuits respectively correspond to multiple groups of coils; a phase time alternation for polar switching is performed between the polar teeth of the stator, namely in the switching process of each or each group of the polar teeth of the stator, the rest polar teeth of the stator are in a non-switching working state; torsions which are generated between the polar teeth of the stator and the magnetic poles of the rotor are staggered in phase and overlapped to form torsion of the motor; the torsion of the motor is always more than zero and the minimum torsion of the motor is close to an average torsion; the motor has no running deal angle and the motor has relatively low cost and occupies relatively small space.

Owner:湖州佳星电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com