Process for using oscillatingmagnetic separation barrel mineral concentration

A magnetic separator, swinging technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high magnetic iron content in tailings and low iron selection grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

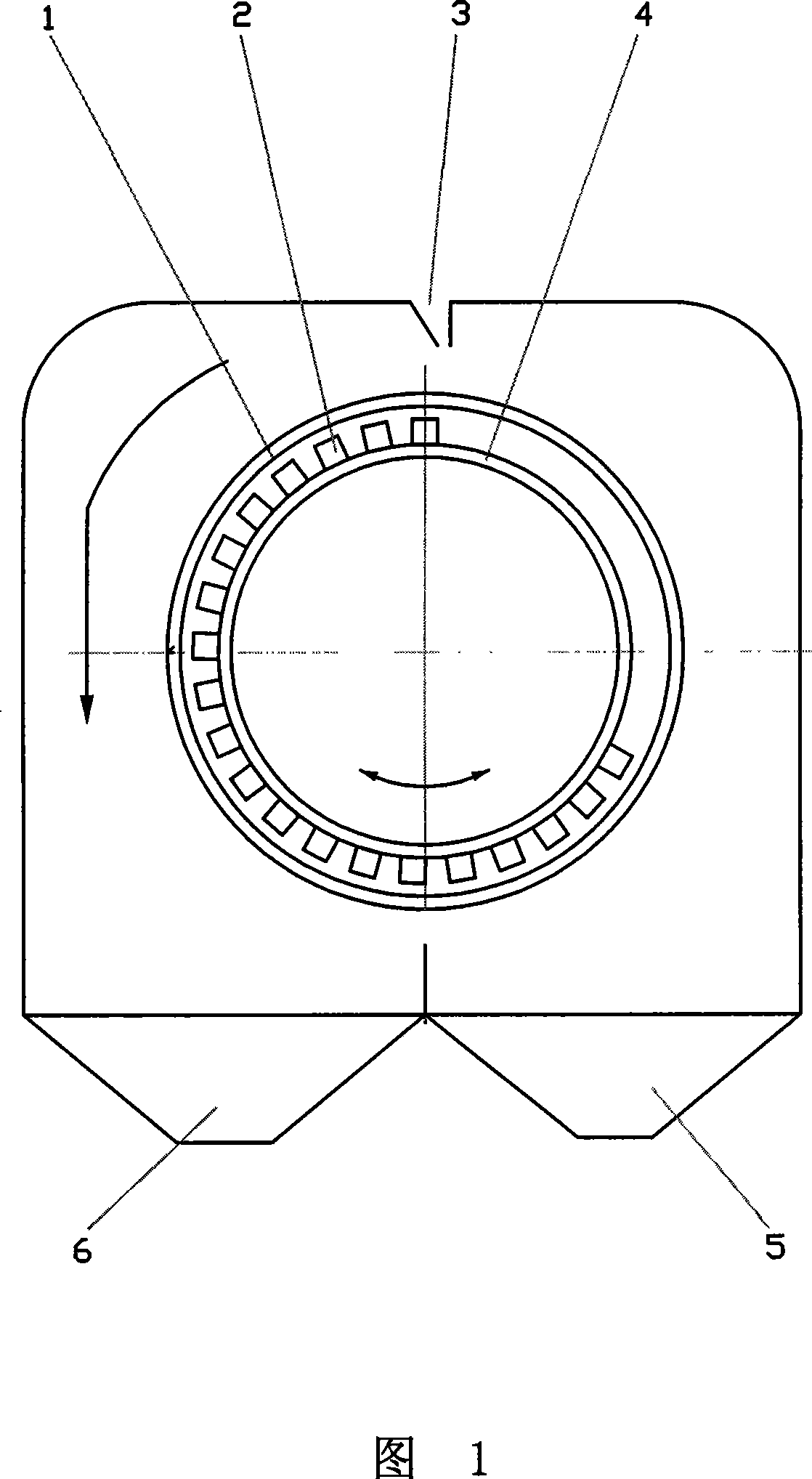

[0007] This process is to continuously add ground magnetic iron ore powder to the magnetic separation cylinder 3, and separate the magnetic minerals and non-magnetic minerals through the rotation of the magnetic separation cylinder outer selection cylinder 1, and then pass through the non-magnetic minerals discharge port 6 Flow out from the discharge port 5 of the magnetic minerals, and when the outer cylinder rotates for 1 revolution, the inner cylinder 4 swings back and forth around its own axis, the swing angle is 30°, and the swing speed is 230 times / min. 2 is the permanent magnet on the inner tube 4 surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com