Azimuth-drive motor system structure of heavy load inertially stabilized platform

An inertial stable platform and system structure technology, applied in the field of azimuth motor system structure of a large-load inertial stable platform, can solve the problems of increased mass of the large-load inertial stable platform, inability to realize direct drive fine-tuning of attitude, and difficulty in further improving accuracy, etc. It can adapt to a wide range of temperature changes and achieve high-precision control, reduce the unilateral magnetic pull and cogging torque fluctuations, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

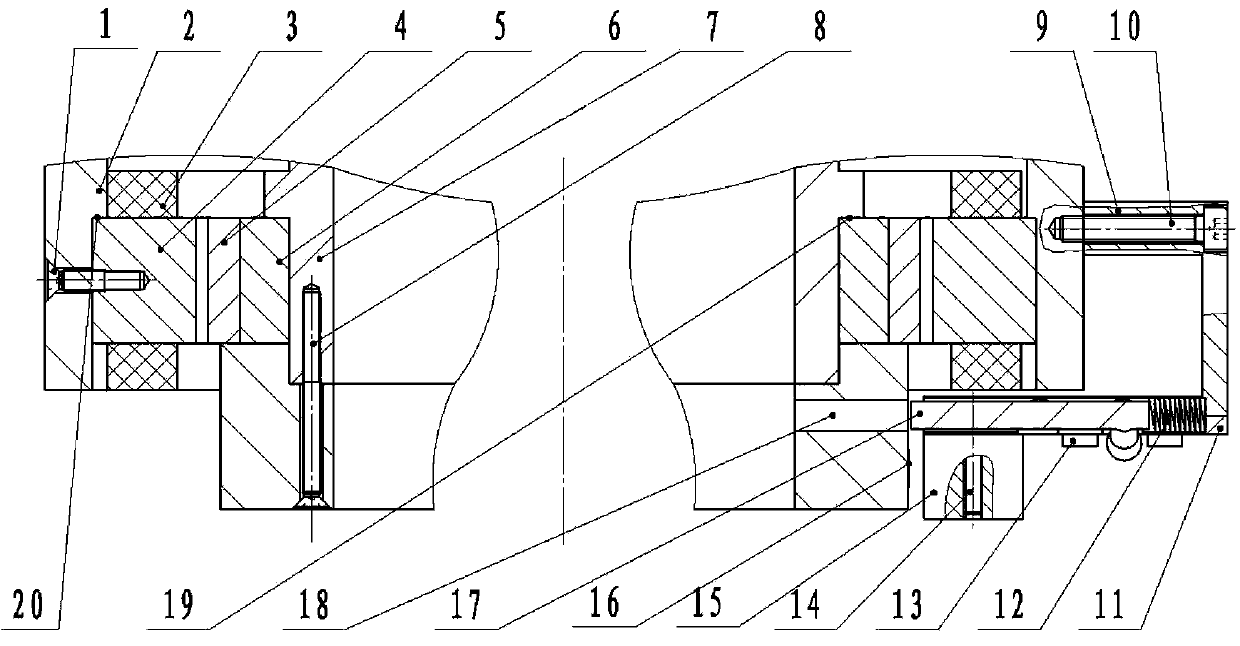

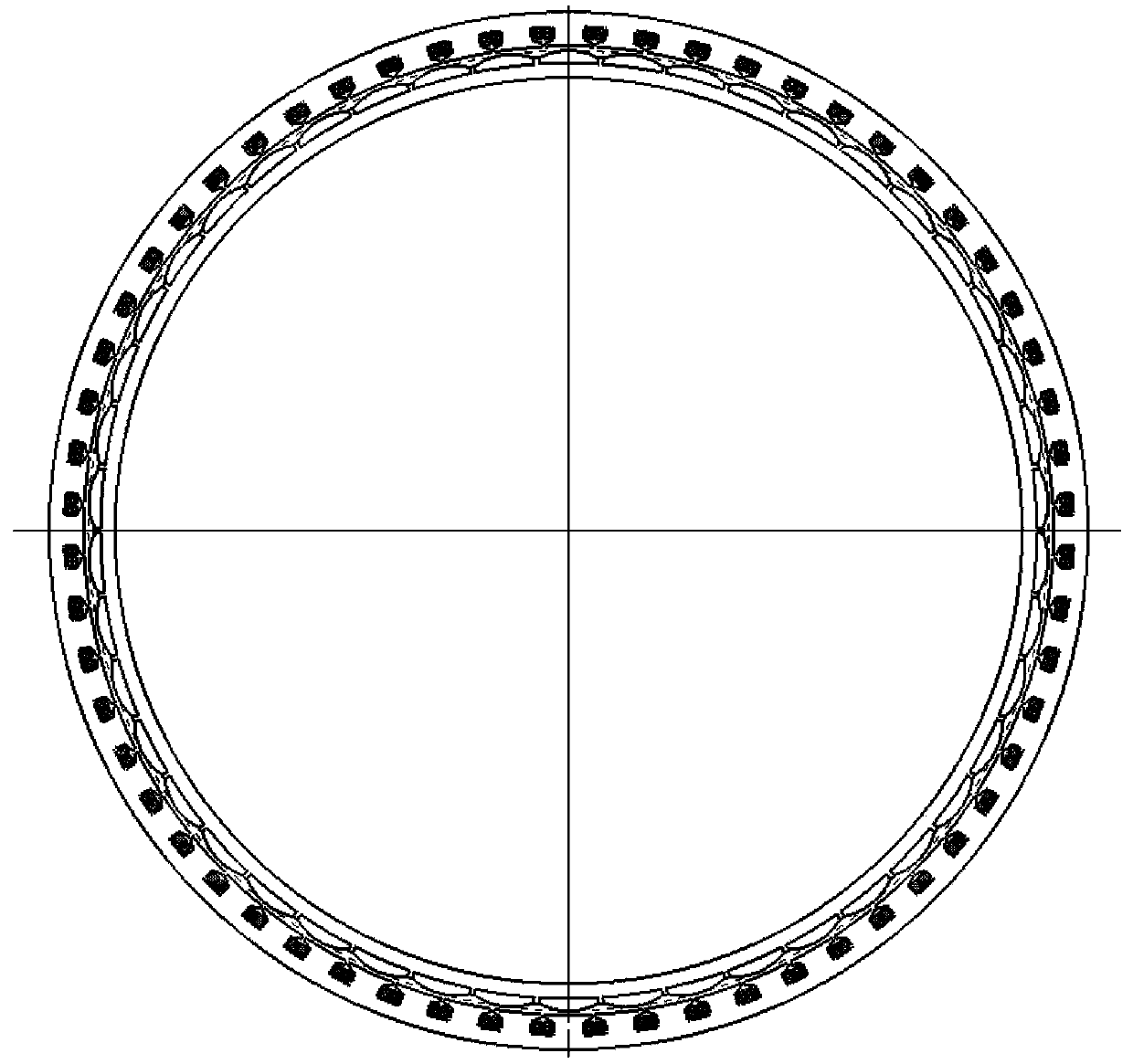

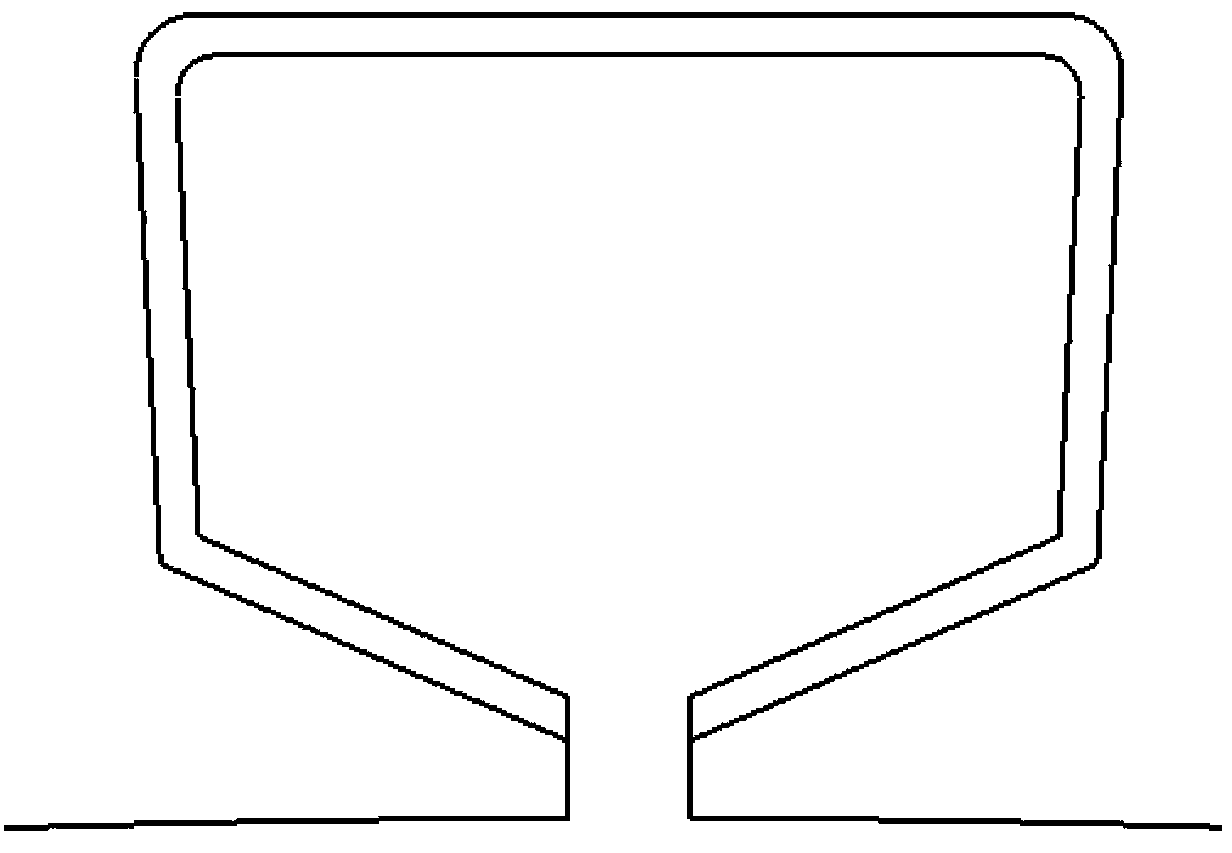

[0029] as attached figure 1 Shown, the present invention is fixed countersunk head screw 1 by stator, motor stator seat 2, stator coil 3, motor stator 4, permanent magnet 5, motor rotor 6, motor rotor seat 7, cover plate fastening countersunk screw 8, reading Head installation transition plate 9, transition plate fastening hexagon socket head screw 10, reading head mounting plate 11, spring 12, reading head mounting plate fastening hexagon socket head screw 13, reading head fixing countersunk head screw 14, grating reading head 15, grating Chi 16, latch 17, motor rotor cover plate 18. Stator fixing countersunk head screw 1, motor stator seat 2, stator coil 3, motor stator 4, permanent magnet 5, motor rotor 6, motor rotor seat 7, and motor rotor cover plate 18 constitute the structural part of the azimuth motor body; Countersunk screw 8, reading head mounting transition plate 9, transition plate fastening hexagon socket head screw 10, reading head mounting plate 11, reading he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com