Transverse flux outer rotor motor

An external rotor motor, transverse magnetic flux technology, applied in the direction of motor, magnetic circuit, electromechanical device, etc., can solve the problems of complex motor stator yoke structure, influence of motor load capacity, reduction of stator magnetic flux, etc., and achieve high stator space utilization. , The effect of increasing the motor torque and increasing the number of motor poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

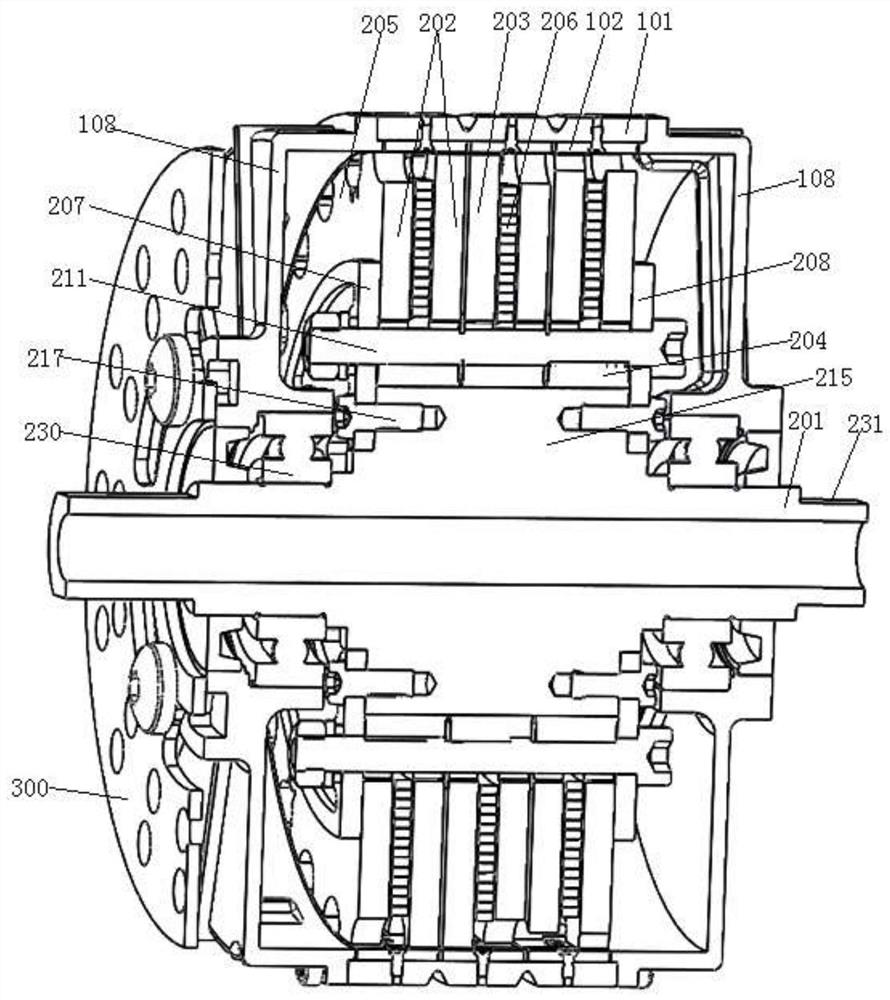

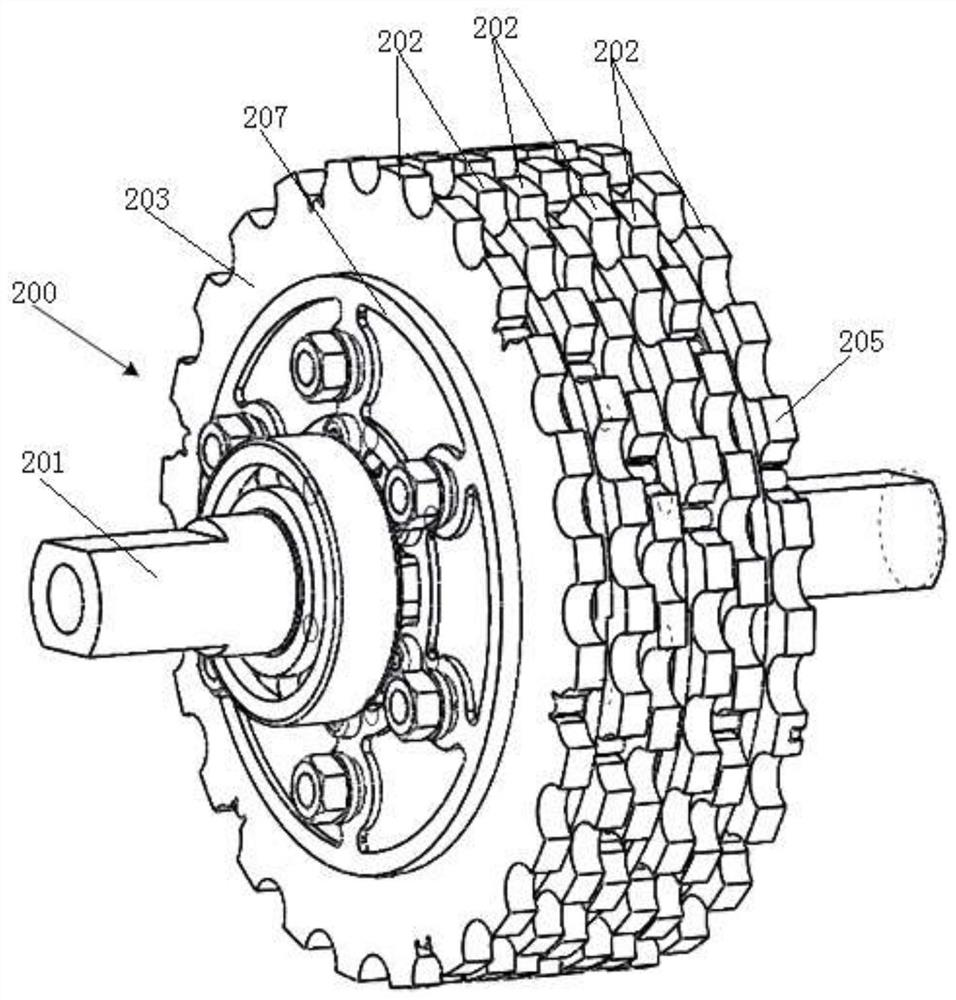

[0080] In this example, for example image 3 , 4 , 11-13, the first side plate 207 and the second side plate 208 are symmetrical in shape, the first side plate 207 and the second side plate 208 are provided with a third set of bolt holes 214, and the stator shaft 201 is provided with A plurality of protruding structures 215, the outer surface of the protruding structure 215 is in contact with the inner circle of the stator yoke ring 204, a fourth group of bolt holes 216 are opened on both sides of the protruding structure 215, and the second group of bolts 217 pass through the first The three sets of bolt holes 214 and the fourth set of bolt holes 216 connect the first side plate 207 and the second side plate 208 to the two sides of the protruding structure 215 respectively.

[0081] In this example, two side plates are used to clamp the multi-phase stator module, and the first set of bolts are passed through the multi-phase stator module to secure the first set of bolts to t...

example 2

[0088] In this example, for example Figure 14-17 As shown, the first side plate 207 is integrated with the stator shaft 201, and the outer surface of the stator shaft 201 is in contact with the inner circle of the stator yoke ring 204; one side of the second side plate 208 is pressed on the stator tooth plate 203, and the other A weight reducing groove 218 is provided on the side, an inward positioning block 221 is provided on the inner circle of the second side plate 208 , and a positioning groove 222 is provided on the stator shaft 201 .

[0089] The stator shaft 201 is a hollow shaft, the stator shaft 201 is provided with an outlet slot 223, the two ends of the stator shaft 201 are provided with a positioning plane 231, and the two ends of the stator shaft 201 are arranged on an arc 233 outside the positioning plane 231. thread.

[0090] The difference between this example and Example 1 is that the structures of the first side plate, the second side plate and the stator s...

example 3

[0093] In this example, for example Figure 18-24 As shown, the middle part of the first side plate 207 and the second side plate 208 is sunken toward the middle part of the stator shaft, the first side plate 207 is fixed on the stator shaft 201 by a third set of bolts 224, and the second side plate 208 is fixed by the shaft The sleeve 225 is fixed on the stator shaft 201 , and there is a space between the outer surface of the stator shaft 201 and the inner circle of the stator yoke ring 204 .

[0094] The first side plate 207 is provided with a fifth group of bolt holes 226 in the recess, and the stator shaft 201 is provided with a plurality of protruding sheet structures 227, and the sheet structure 227 is provided with a sixth group of bolt holes 228, and the third group Bolts 224 pass through the fifth set of bolt holes 226 and the sixth set of bolt holes 228 to fix the first side plate 207 on the stator shaft 201 .

[0095] The shaft sleeve 225 is welded on the inner cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com