Patents

Literature

319results about "Shielding from electromagnetic fields" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

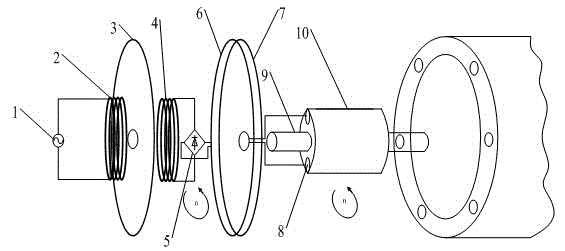

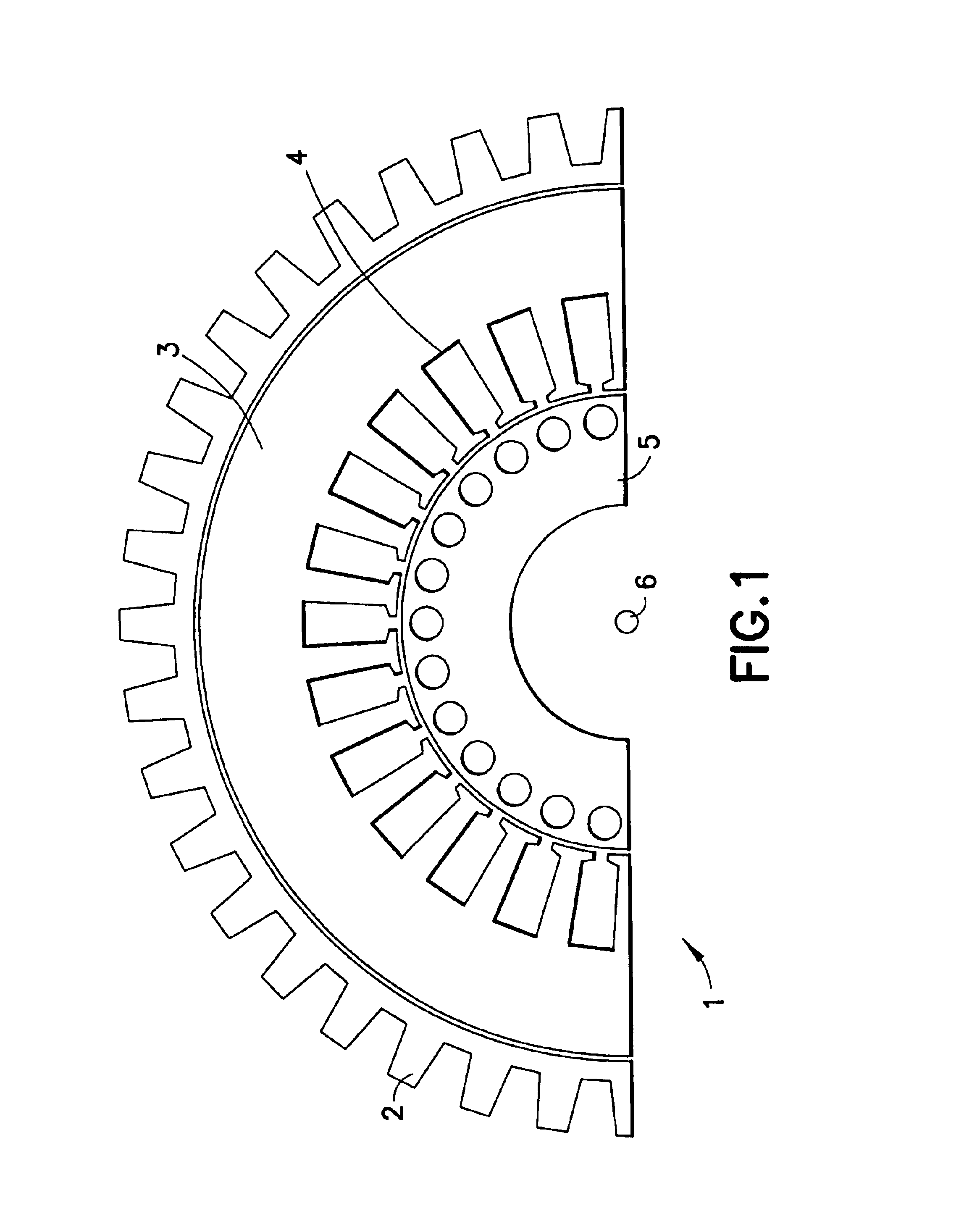

Rotor shield for magnetic rotary machine

InactiveUS20020125779A1Total current dropCurrent lossMagnetic circuit rotating partsWind energy generationEddy currentEngineering

A magnet machine includes a magnet rotor. The rotor includes a sleeve and a magnet. The magnet is positioned within the sleeve. A highly electrically conductive, nonmagnetic shield surrounds the magnet. The shield reduces rotor eddy current losses and lowers rotor operating temperature, thereby improving efficiency of the machine.

Owner:CAPSTONE TURBINE

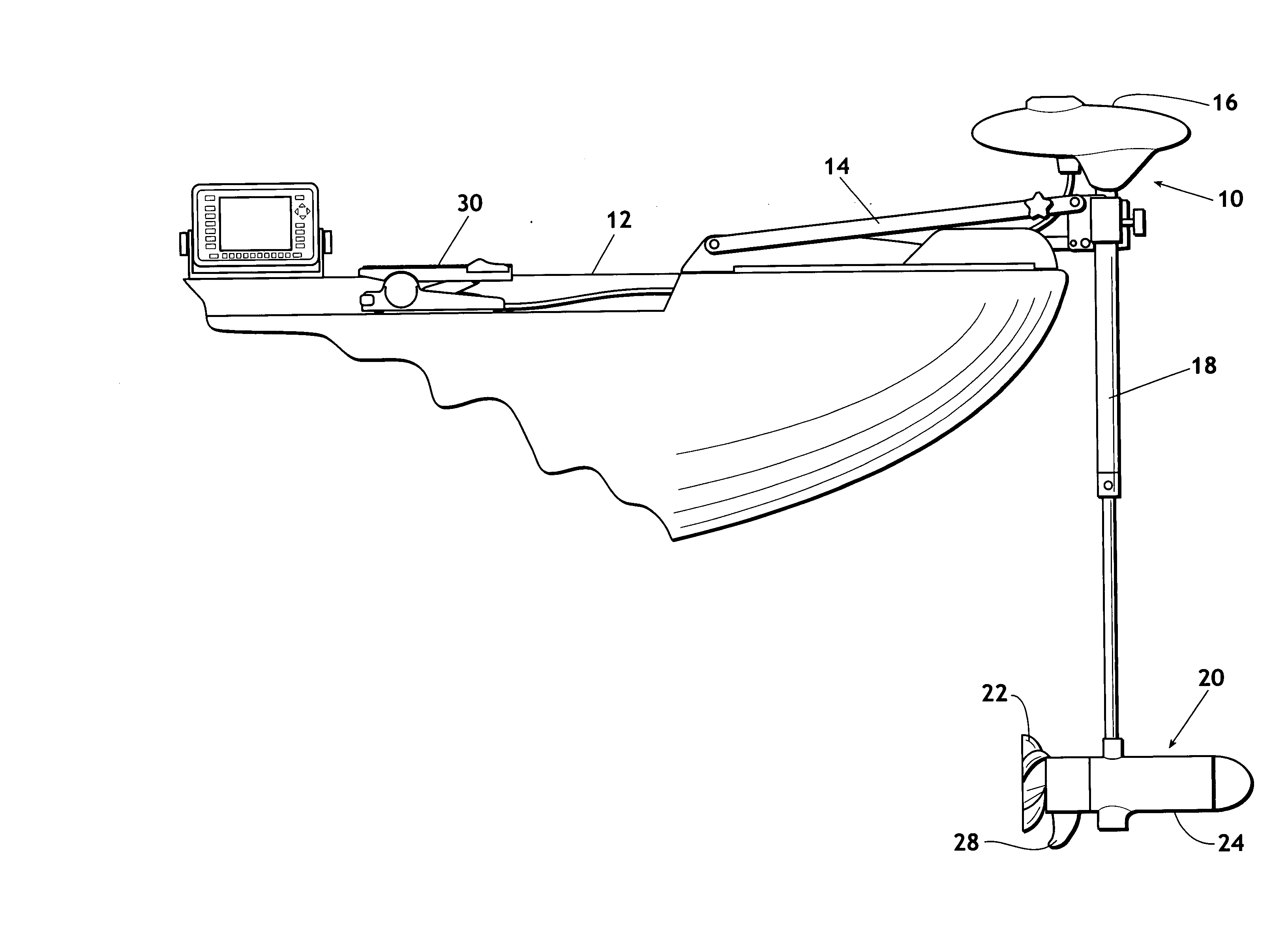

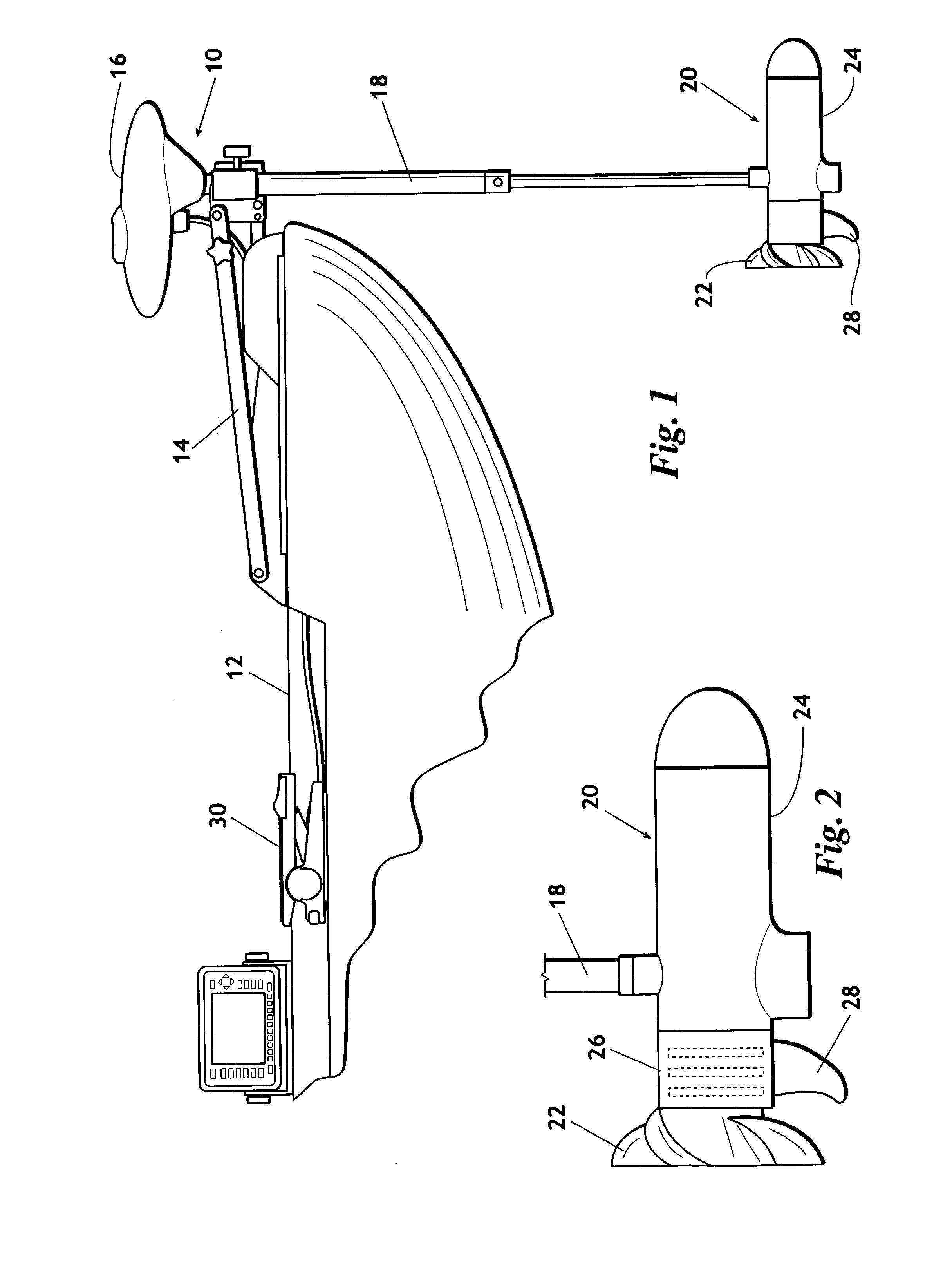

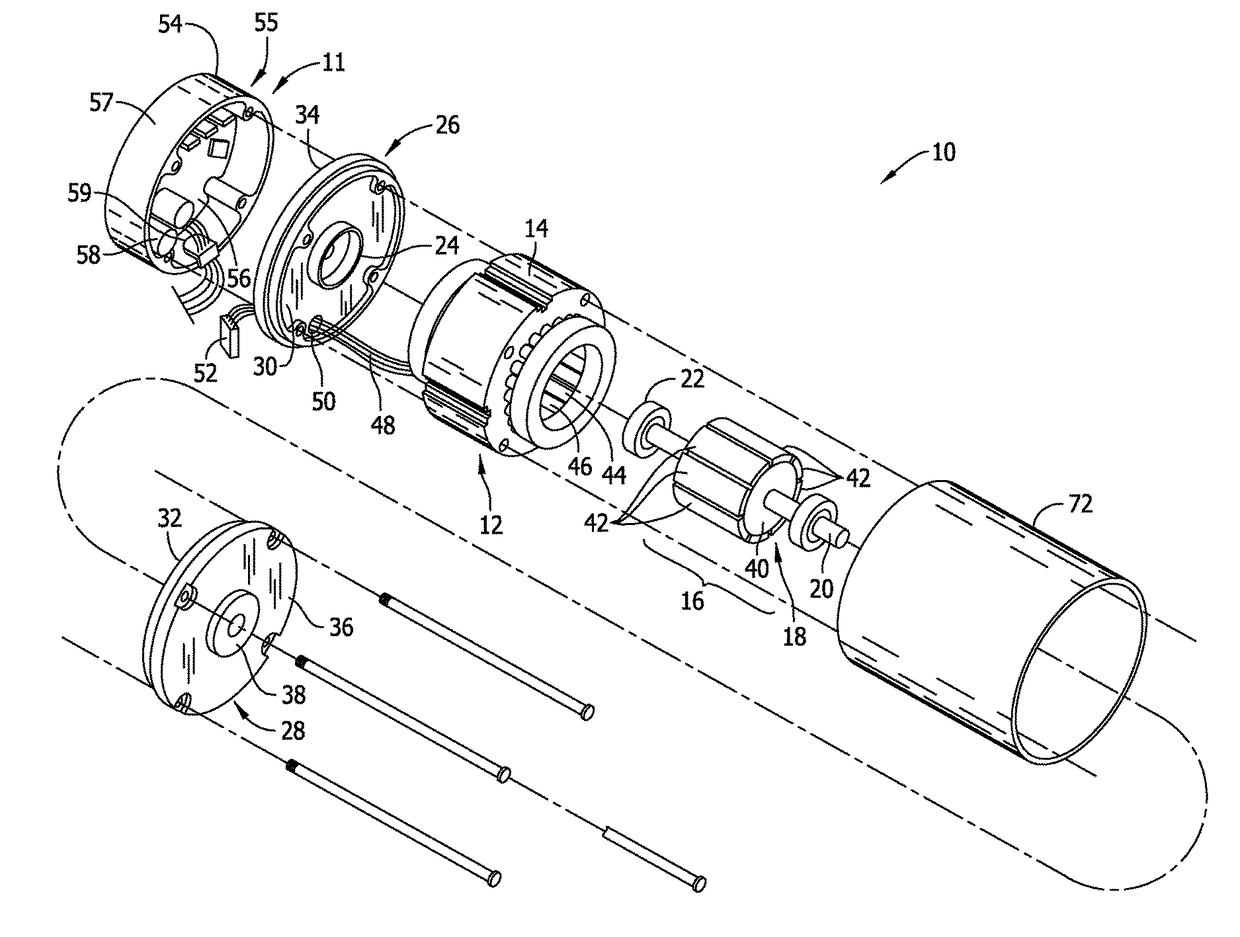

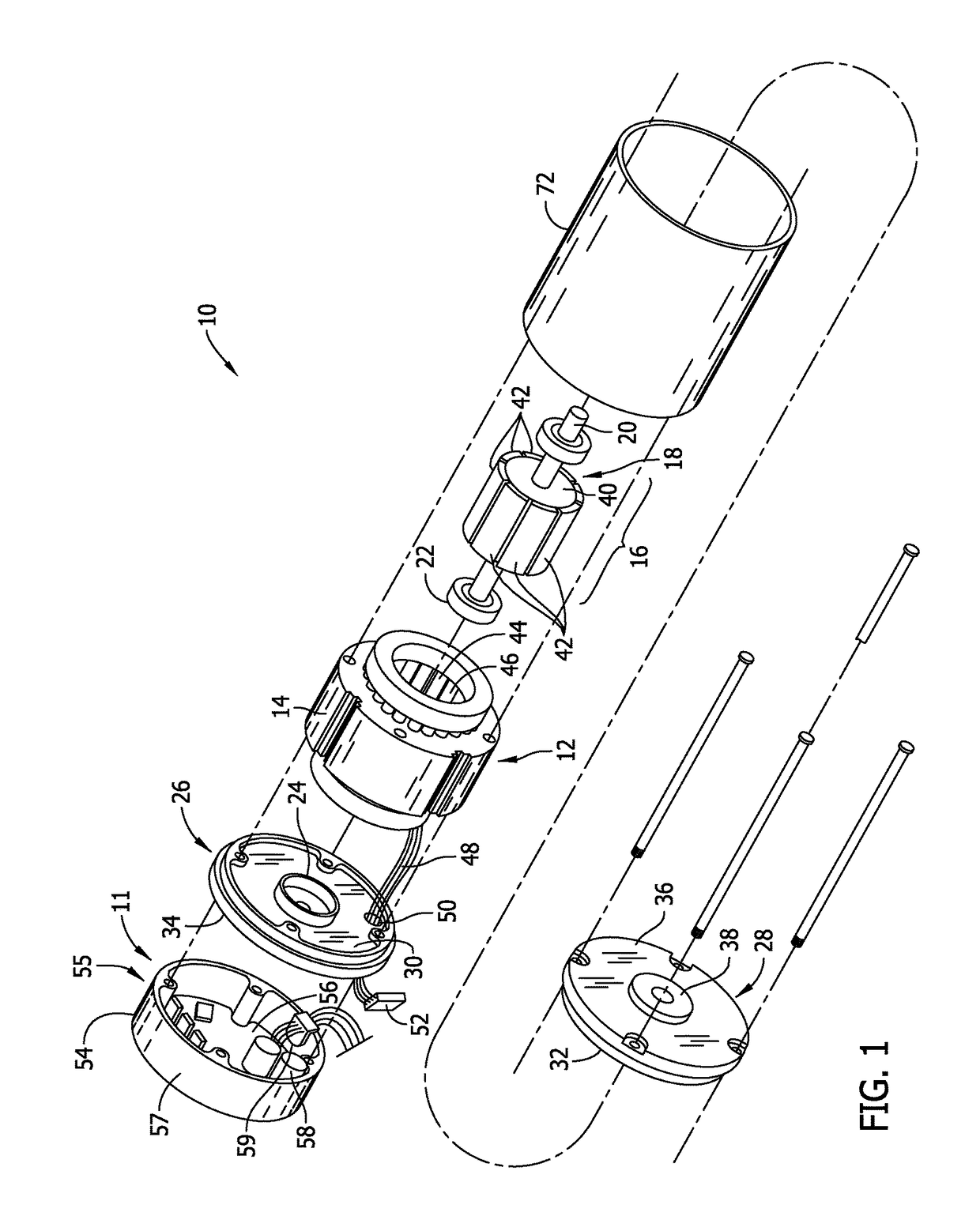

DC motor with integral controller

InactiveUS6902446B1Little and and degradationEmission reductionSteering initiationsControllers with pulse-train output signalIntegral controllerMotor controller

A DC motor having a motor housing and a motor controller housed within the motor housing. In a preferred embodiment the heat producing components of the motor controller are in thermal communication with the housing such that the majority of the heat produced by such components will be readily conducted to the environment in which the motor is operating. When incorporated into a trolling motor, the motor housing of the present invention will be submerged so that controller produced heat will be dissipated into the water in which the trolling motor is operated.

Owner:BRUNSWICK CORPORATION

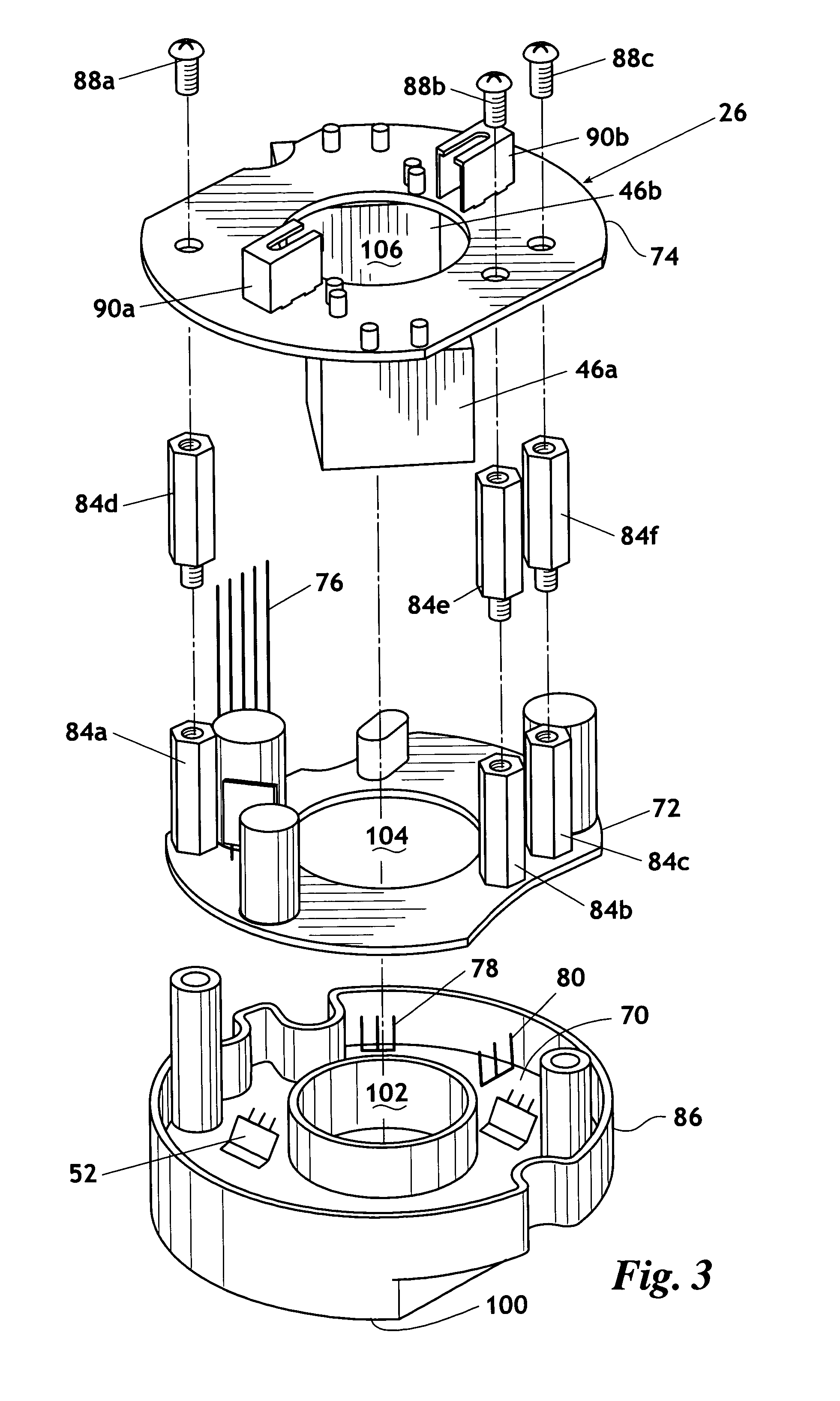

Brushless excitation mechanism based on wireless transmission of electric energy

InactiveCN103560632AOptimize the magnetic fieldRealize wireless excitationSynchronous generatorsElectromagnetic wave systemTransmitter coilMetallic materials

The invention discloses a brushless excitation mechanism based on wireless transmission of electric energy. The mechanism comprises a high frequency excitation source, an auxiliary excitation transmitting coil, an auxiliary excitation receiving coil, a rotating rectifier bridge, a soft magnetism optimization layer and a metal shielding layer, wherein the high frequency excitation source and the auxiliary excitation transmitting coil are arranged outside a motor, the auxiliary excitation receiving coil, the rotating rectifier bridge, the soft magnetism optimization layer and the metal shielding layer are arranged in the motor, an electromagnetic field of an excitation system is optimized and shielded through soft magnetism materials and metal materials, an excitation coil of a rotor of the alternating-current motor is supplied with power through the wireless transmission of the electric energy, mechanical connection between the rotor and external terminals is avoided, and brushless excitation of the motor is achieved.

Owner:SOUTHEAST UNIV

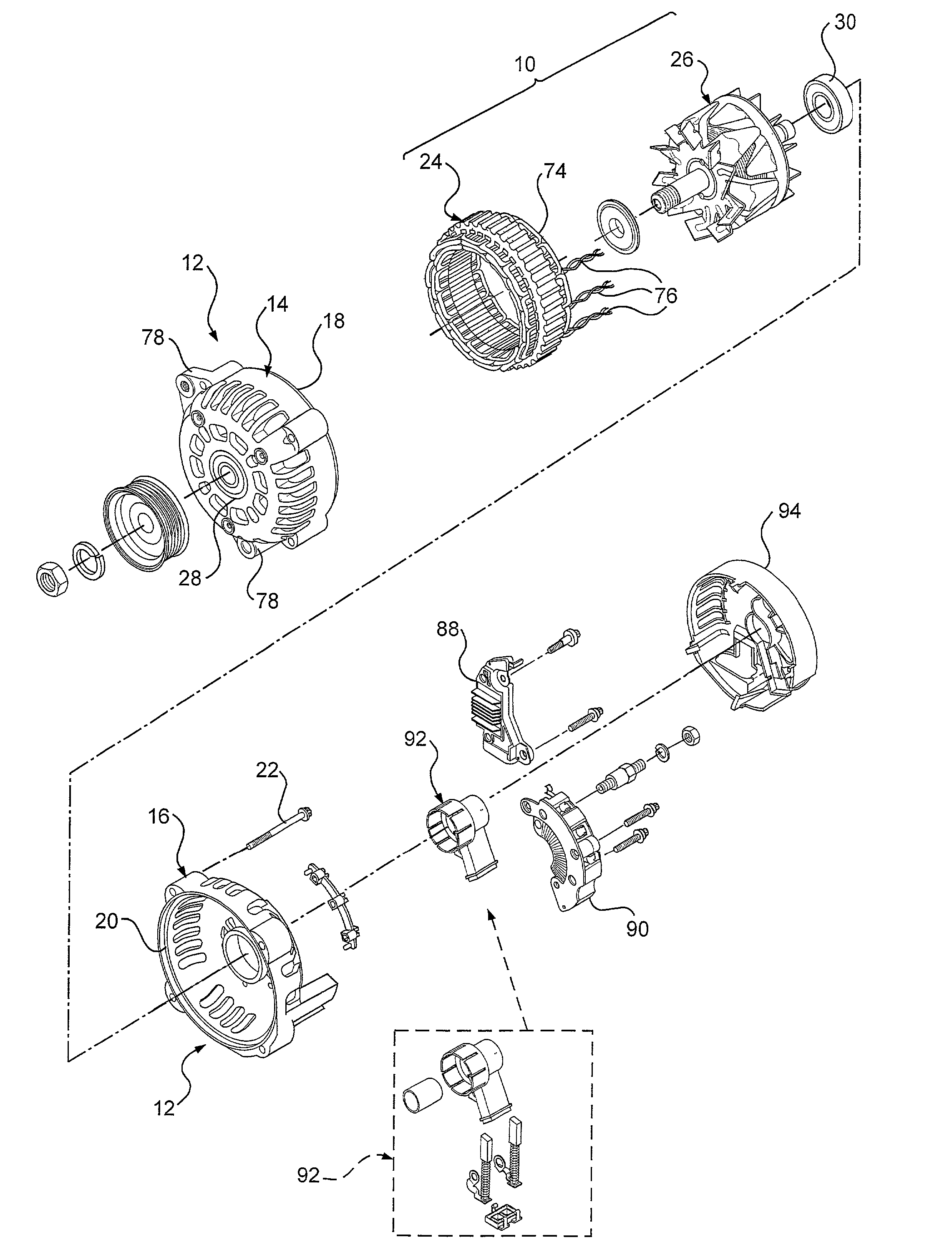

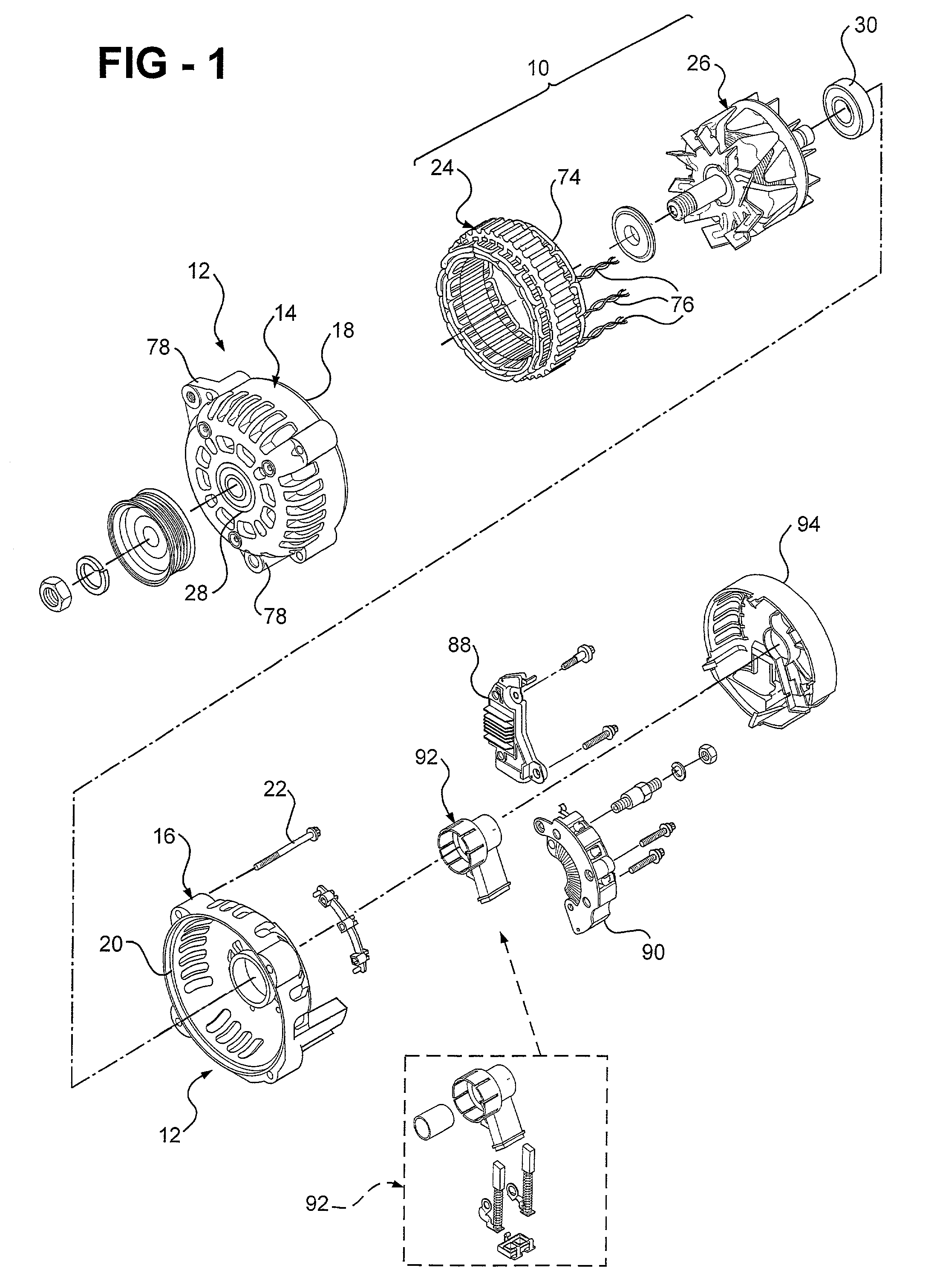

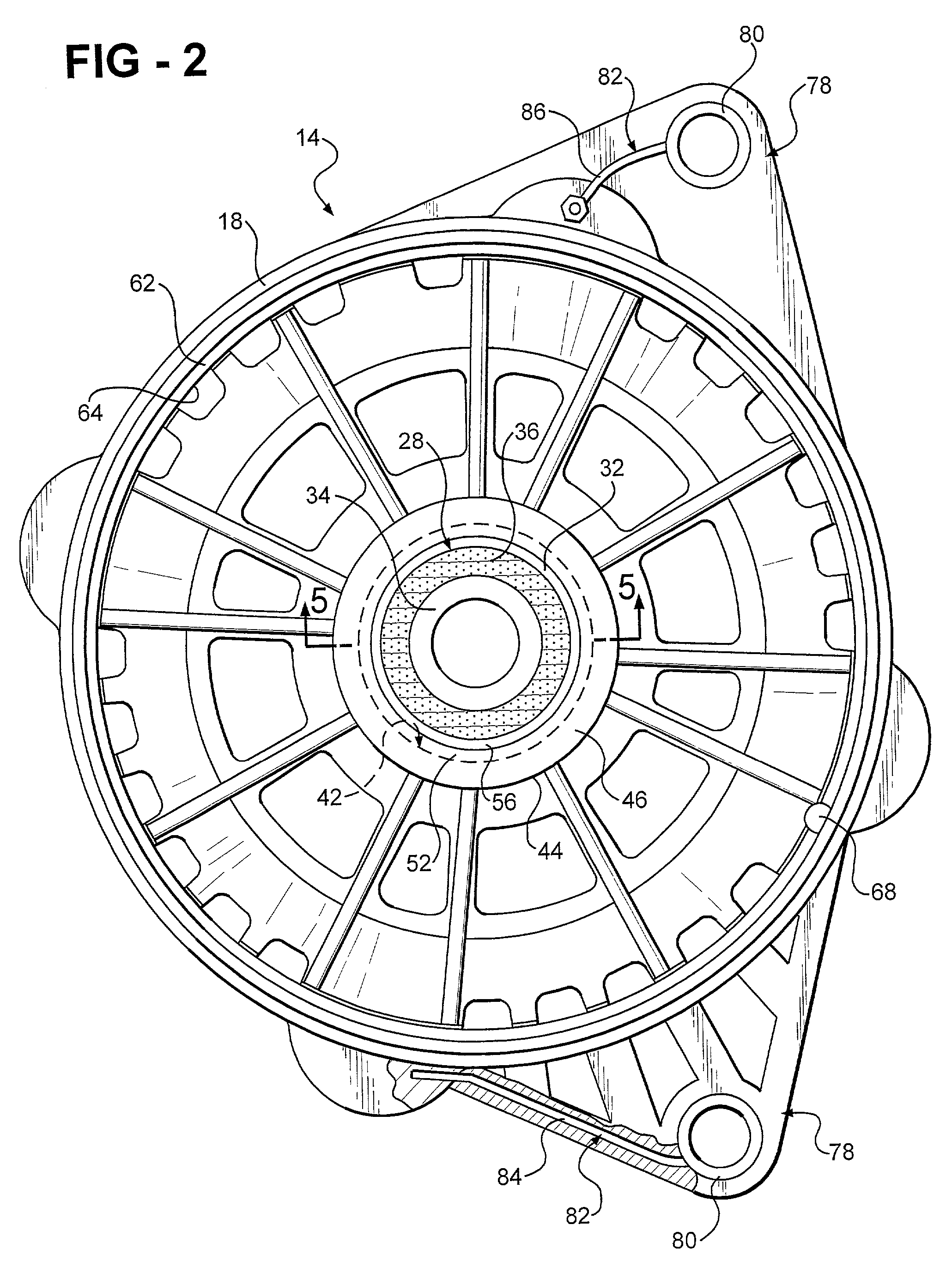

Alternator and method of manufacture

InactiveUS20020130570A1Less costlyThe process is simple and effectiveSynchronous generatorsBearing assemblyAlternatorPlastic materials

An alternator has a molded plastic, electrically conductive D.E. frame in which a sealed bearing is molded in place with the formation of the D.E. frame 14. When the D.E. frame is removed from its plastics injection mold and while the frame is still hot, the stator is installed in the D.E. frame and the frame allowed to cool and constrict about the stator. The companion S.R.E. frame is preferably fabricated of non-conductive plastics material.

Owner:ALTECH GENERATING SYST

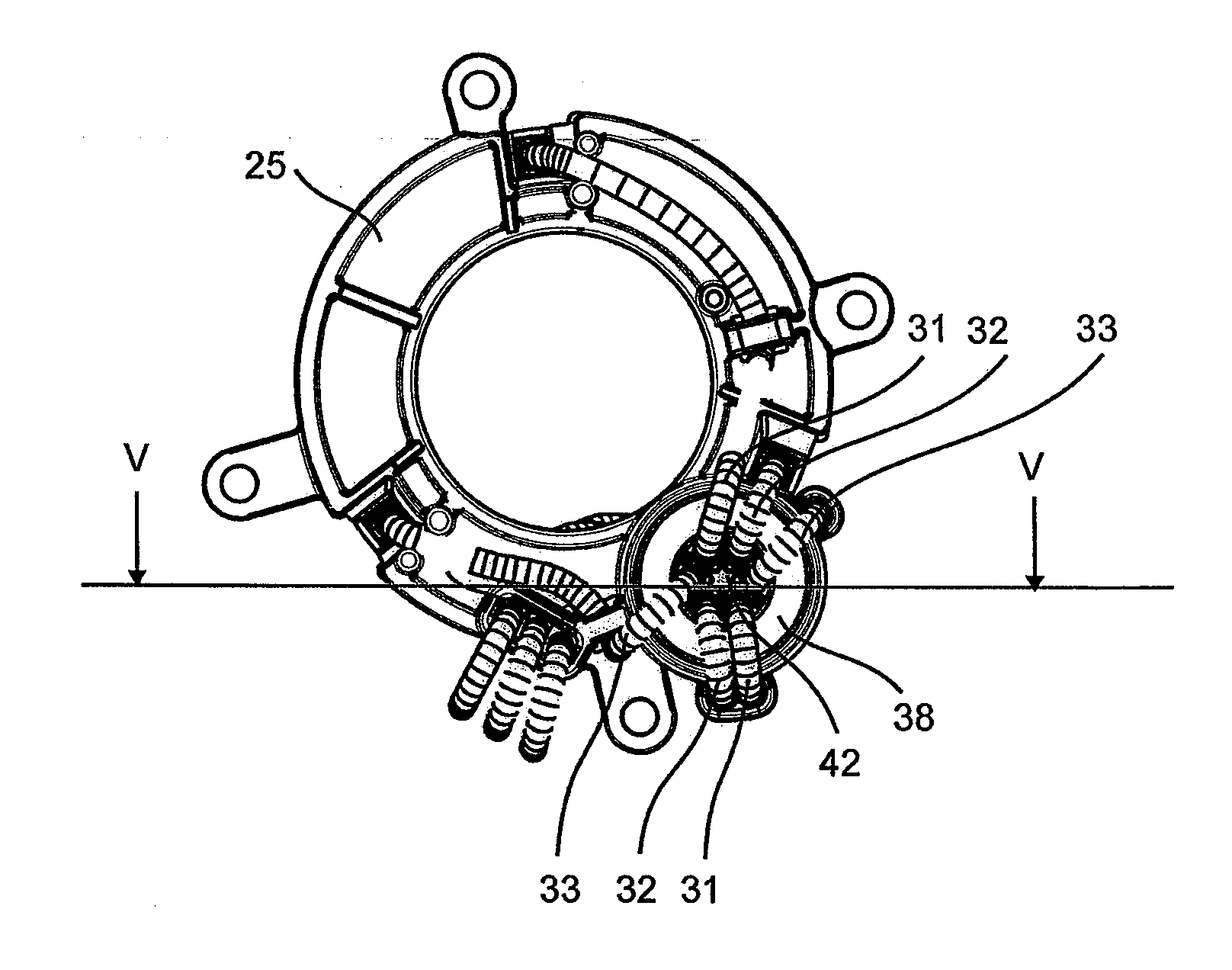

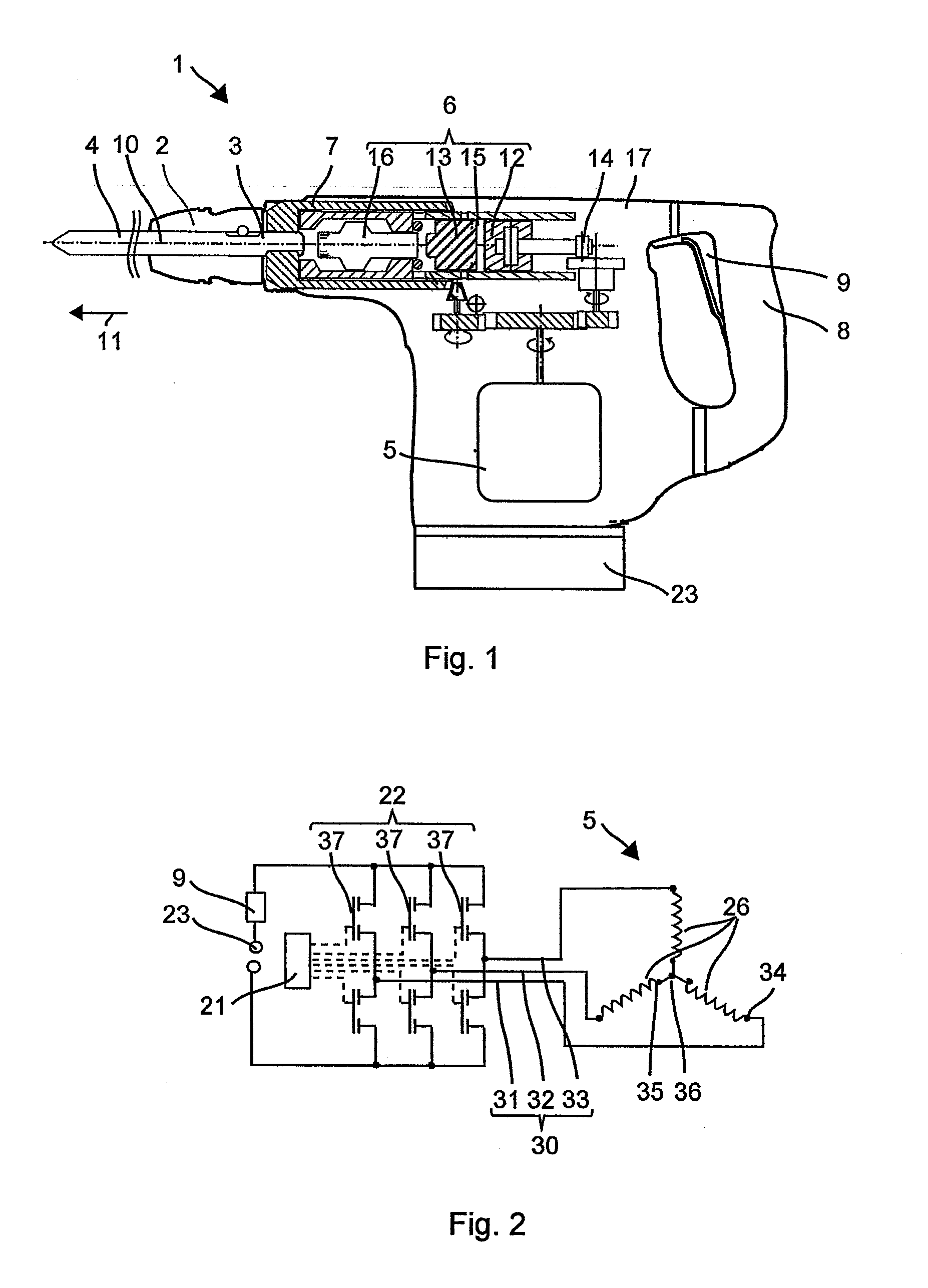

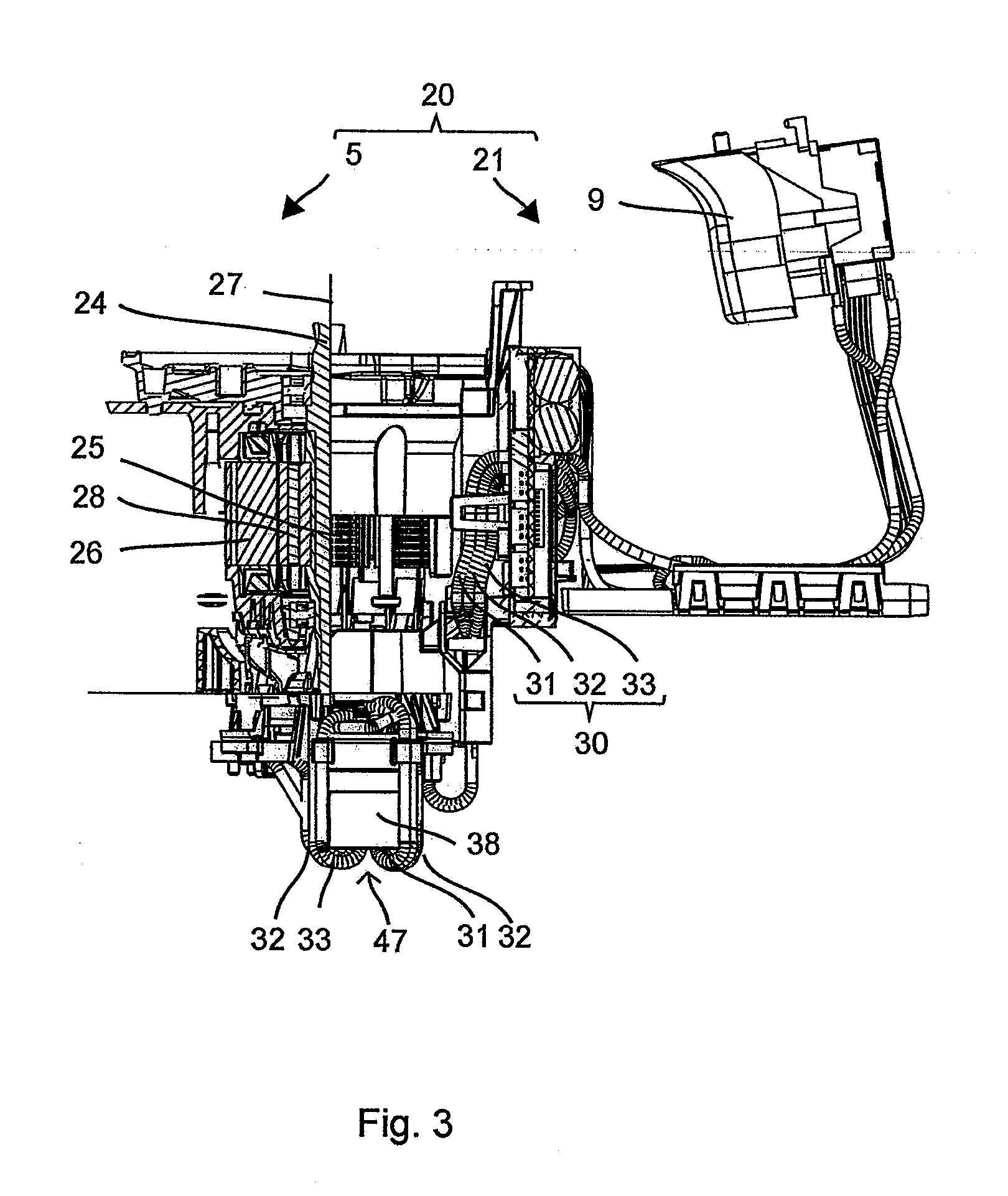

Electric drive for a hand-held power tool

InactiveUS20130133910A1Reduce spacingReduce the number of windingsWindingsConstructionsHand heldEngineering

An electric drive for a hand-held power tool. An electric supply line contains two or more stranded wires. An electric motor is electrically connected to the stranded wires. The stranded wires pass at least twice through the eye of a toroidal core. A partition divides the eye into several sectors. Precisely one of the stranded wires passes through each of the sectors. The stranded wires are arranged along the circumference of the eye so as to follow each other cyclically.

Owner:HILTI AG

Three phase converter fed motor having a shielding device to eliminate capacitive current in stator slots

InactiveUS6756712B1Windings insulation shape/form/constructionSupports/enclosures/casingsCapacitanceThree phase converter

A device for preventing bearing damage from currents through a three-phase motor is provided, including a shield for winding and copper wire within each stator slot of a motor. The shield includes an electrically conductive layer which is insulated from the winding and from the laminated stator core of the three-phase motor. The conductive layer is grounded or conductively connected to the laminated stator core of the three-phase motor on only that side on which the three-phase current is fed to the winding of the motor.

Owner:MANNESMANN AG

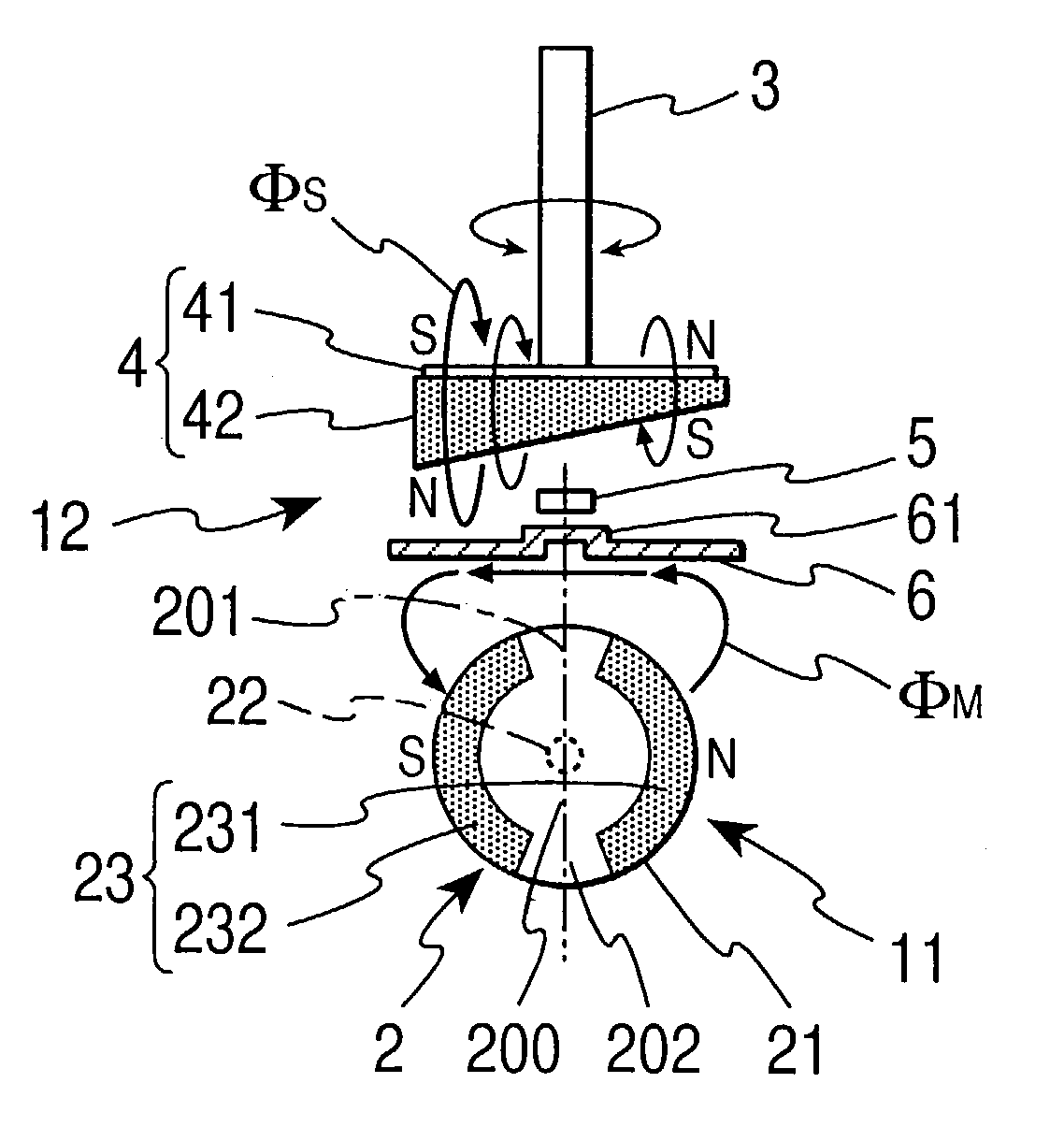

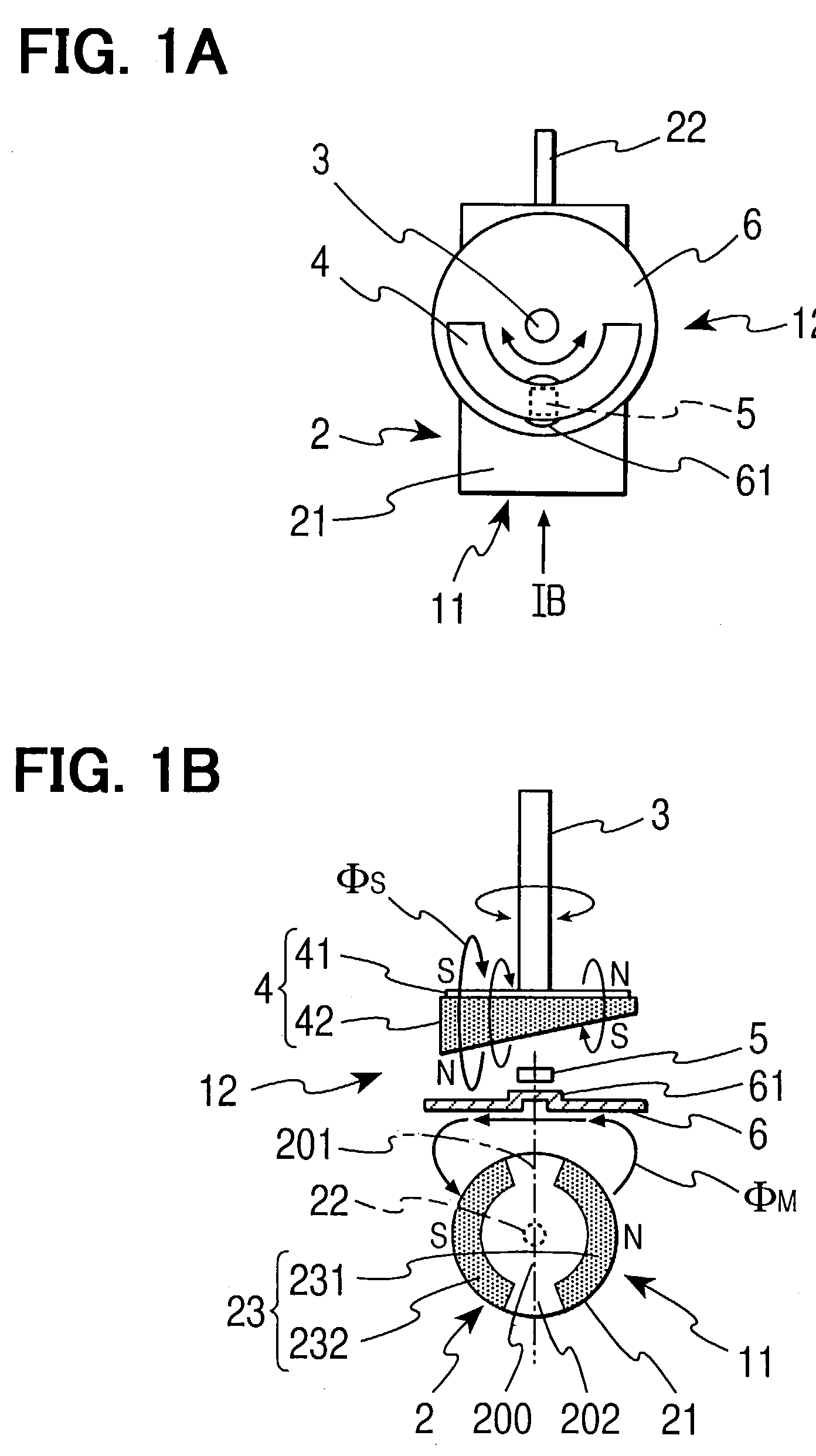

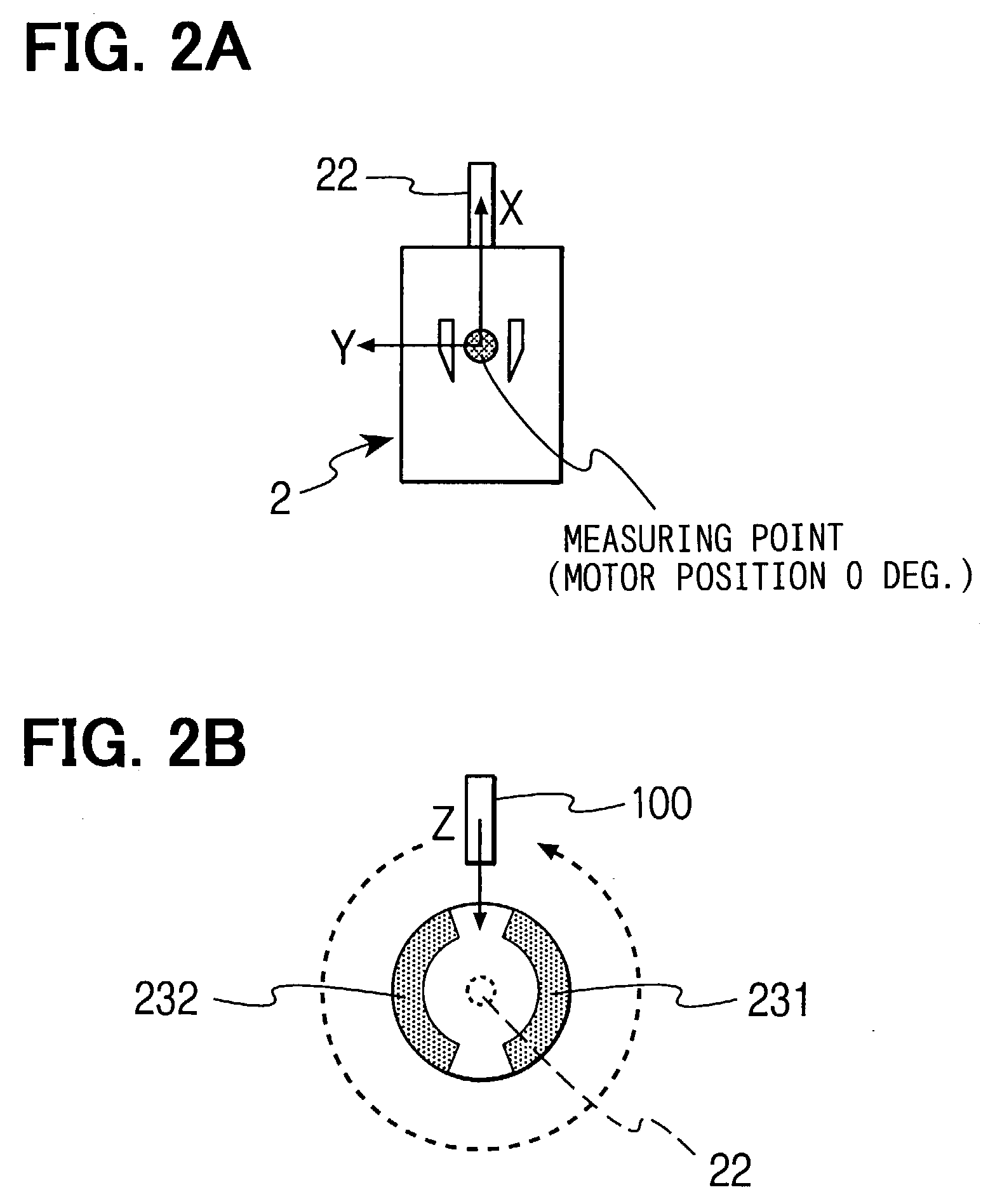

Magnetic sensor unit less responsive to leaking magnetic flux

ActiveUS20040000902A1Simple structureSolid-state devicesMagnetic field measurement using galvano-magnetic devicesHall elementActuator

A magnetic sensor unit includes an actuator motor and a magnetic position sensor. The actuator motor has a magnetic circuit including motor magnets. The magnetic position sensor includes a sensor magnet and a hall element for detecting magnetic flux. Magnet clearances are formed between the motor magnets. The hall element is disposed outside of the motor to detect the magnetic flux in a direction penetrating through the magnet clearances, and which is perpendicular to a direction from one of the motor magnets to the other. In this disposition of the hall element, it is restricted that the hall element detects leaking magnetic flux from the motor magnets.

Owner:NIPPON SOKEN +1

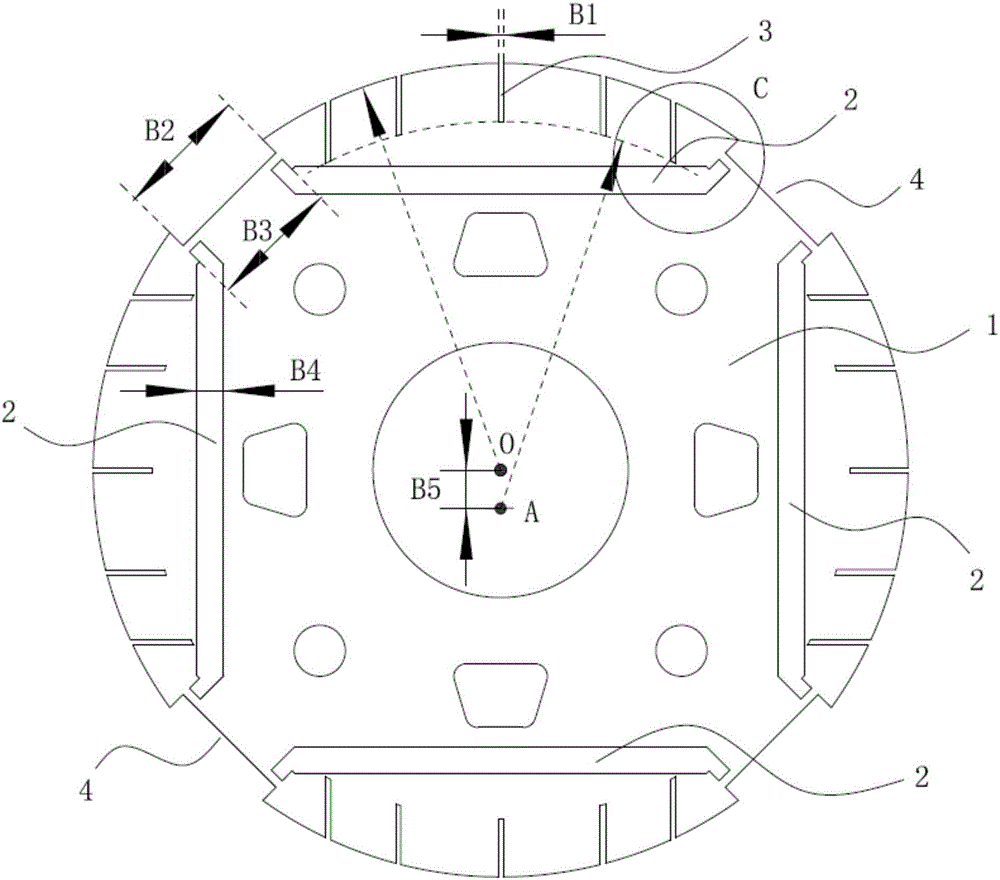

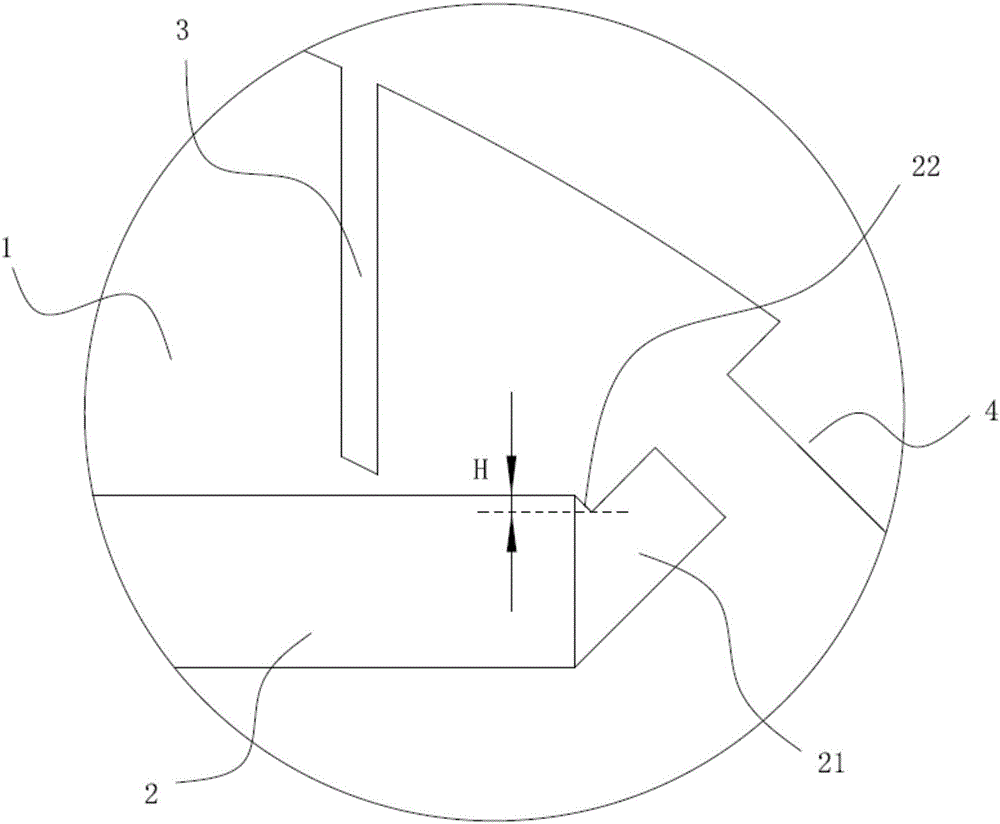

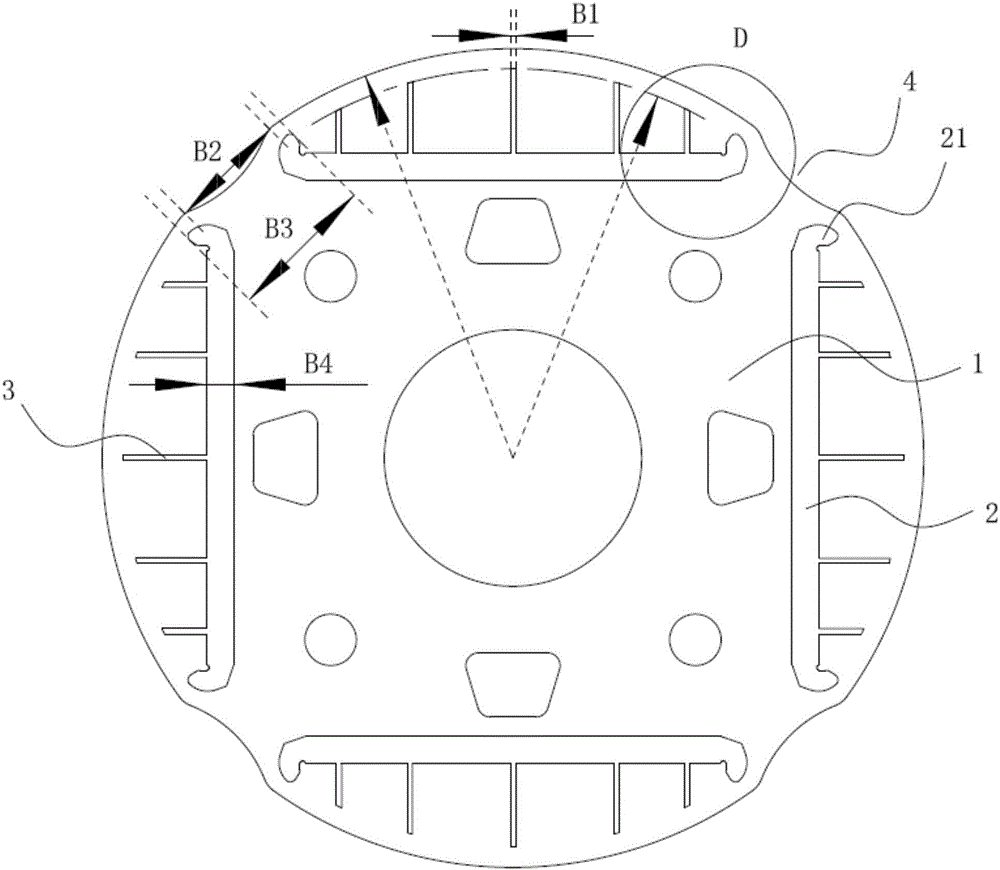

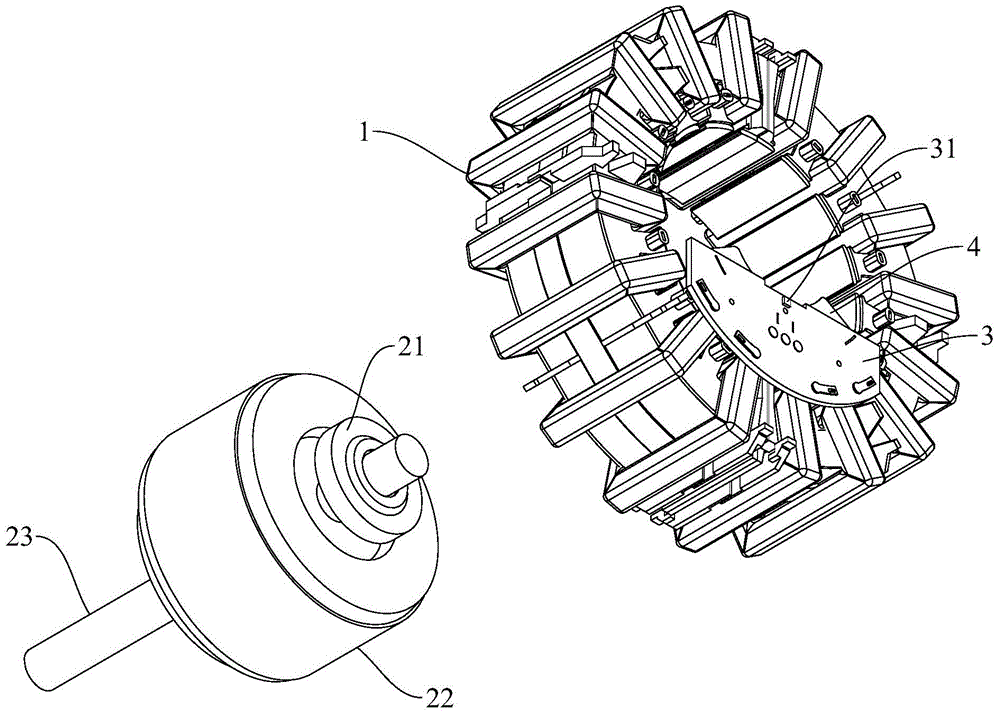

Rotor of permanent magnet synchronous motor and motor

ActiveCN106340982AReduce electromagnetic noiseSolve the problem of a large number of harmonics in the air gapMagnetic circuit rotating partsSynchronous machine detailsHarmonicPermanent magnet synchronous motor

The invention discloses a rotor of a permanent magnet synchronous motor (PMSM) and a motor, belongs to the technical field of motors and solves the problem that a conventional device has a lot of higher harmonic magnetic fields. The rotor of the PMSM has a plurality of magnetic steel grooves uniformly distributed in the circumferential direction of a rotor body, permanent magnets are inserted in the magnetic steel grooves, and the adjacent permanent magnets are opposite in polarity. A plurality of slits are arranged in the outer edge of the rotor body at positions corresponding to the magnetic steel grooves, the slits communicate with an air gap between a stator and the rotor, and the inner ends of the slits are on the same arc line; or, a plurality of slits are arranged in the outer edge of the rotor body at the positions corresponding to the magnet steel grooves, the slits communicate with the magnet steel grooves, and the outer ends of the slits are located on the same arc line. The rotor of the PMSM and the motor solve the problem that lots of harmonics exist in the air gap between the inner side wall of the stator and the outer side wall of the rotor, reduce the electromagnetic noise of the motor and ensure air-gap flux density and sinusoidal features.

Owner:GREE ELECTRIC APPLIANCES INC

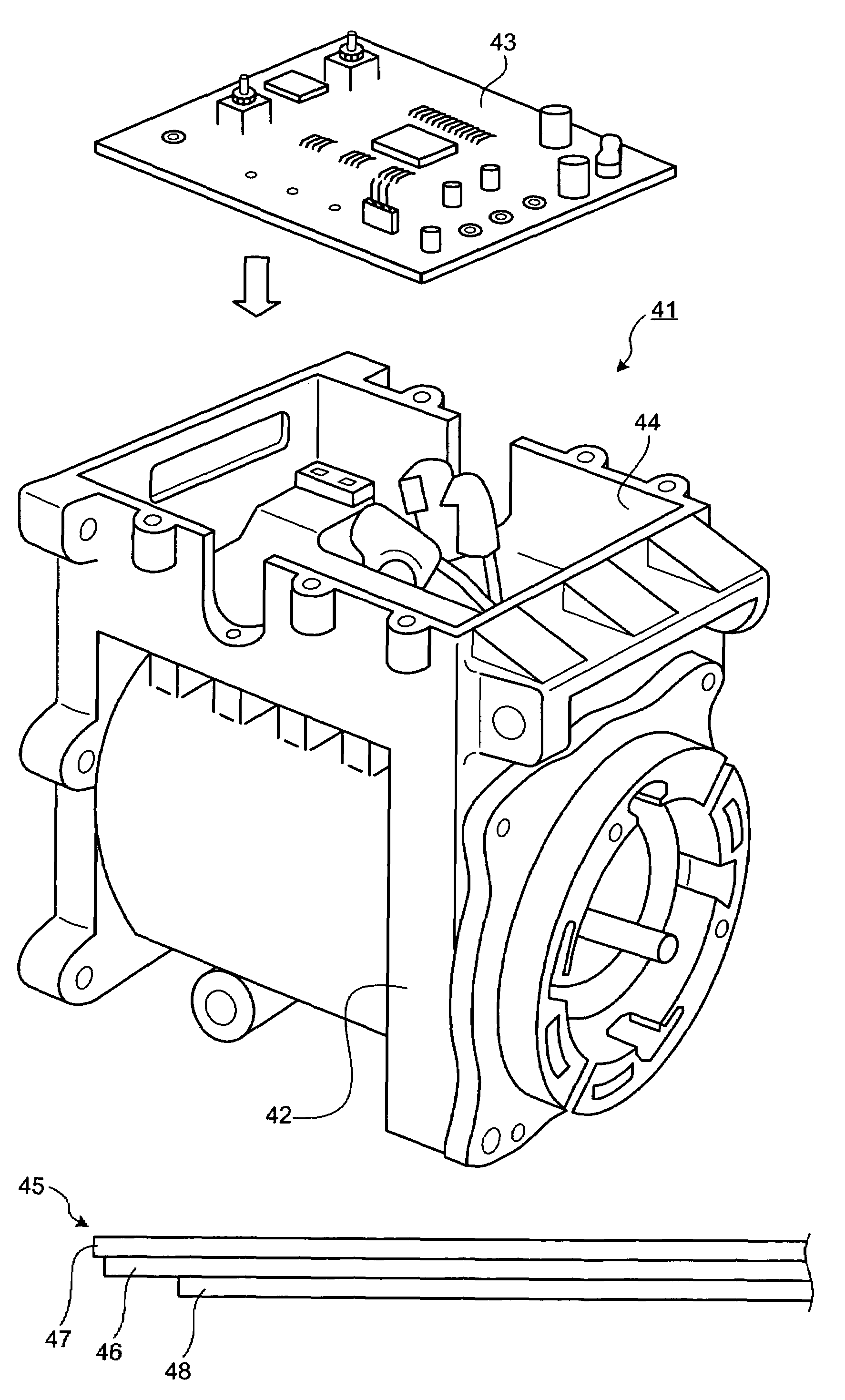

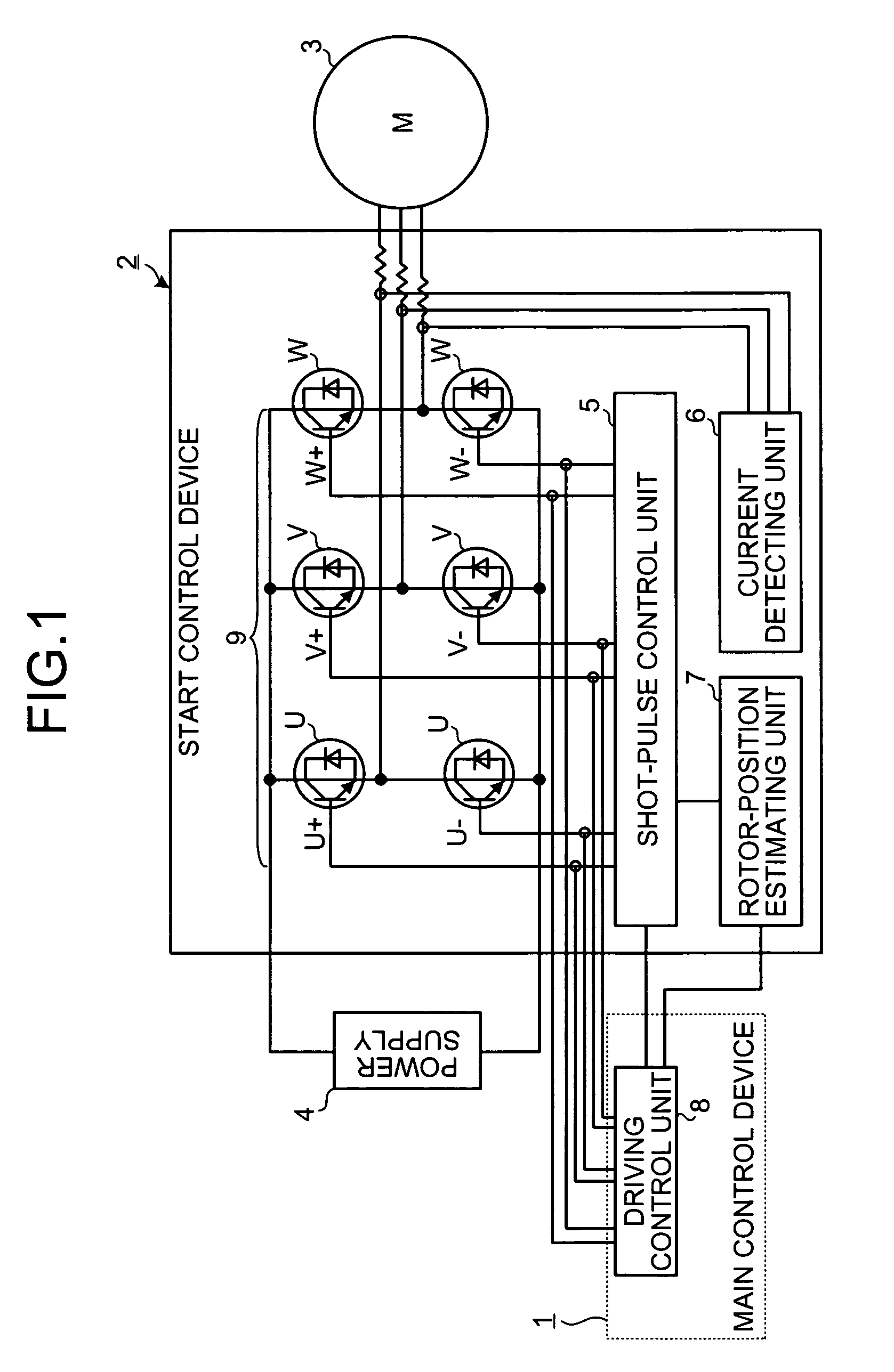

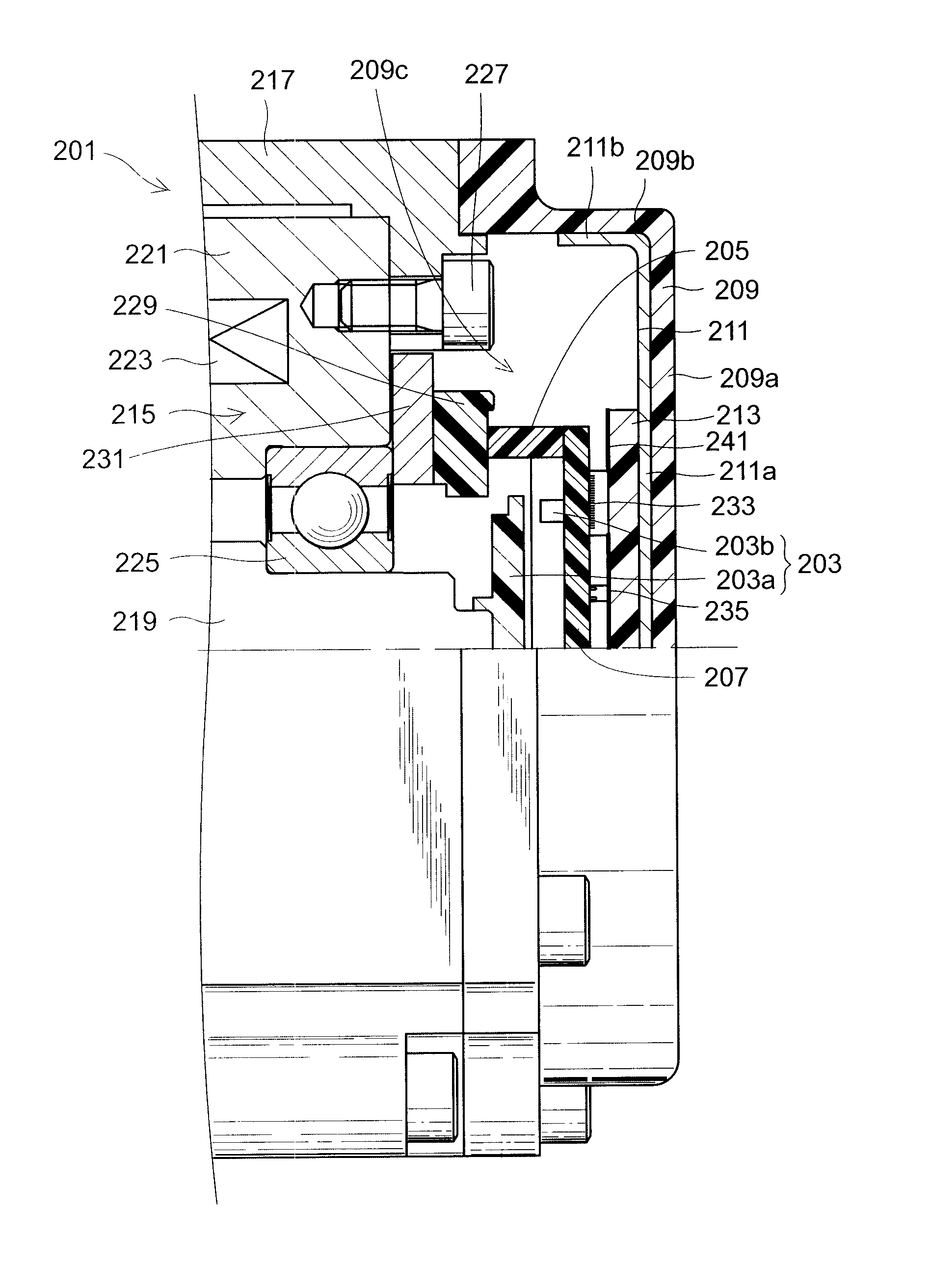

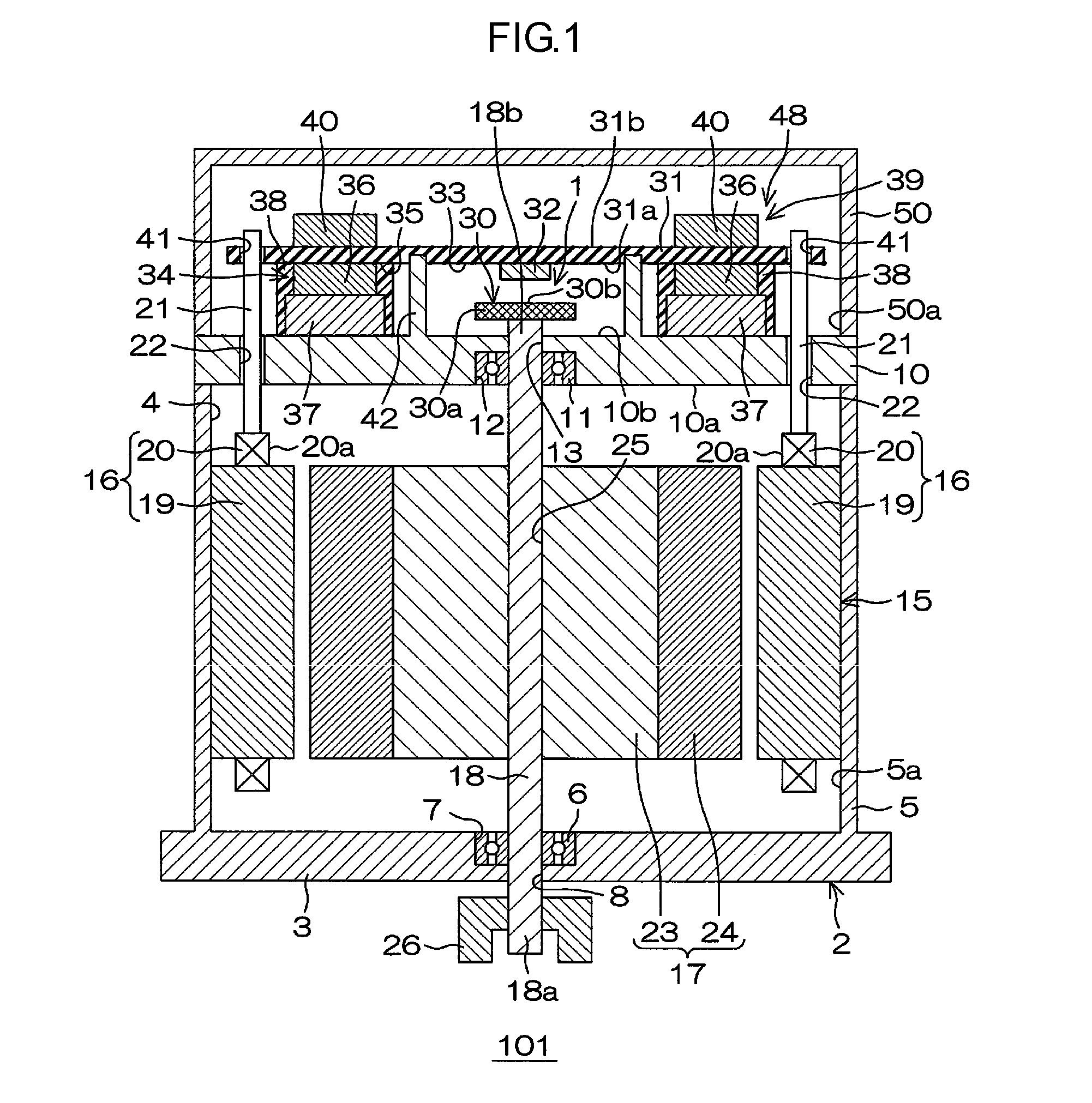

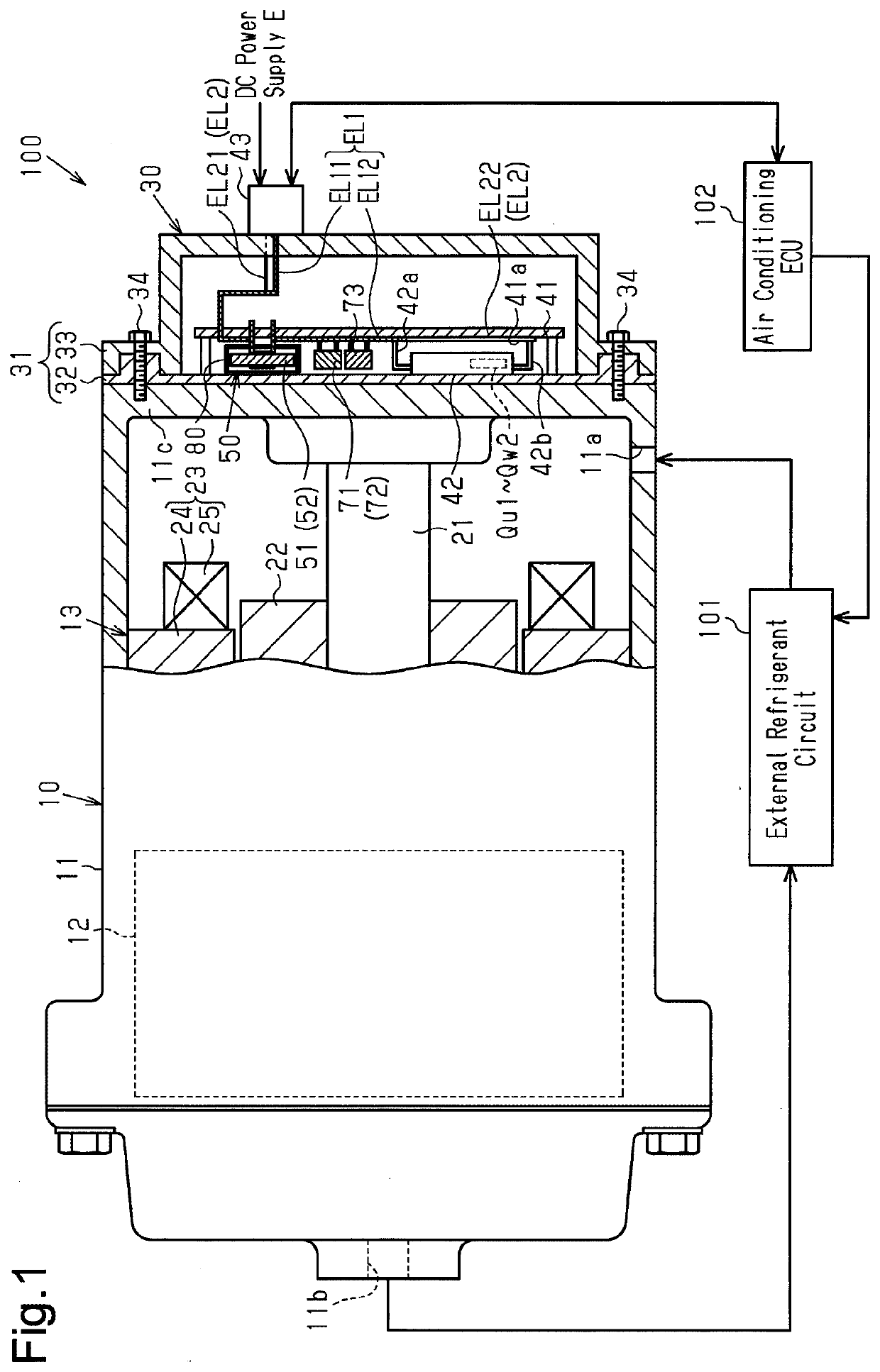

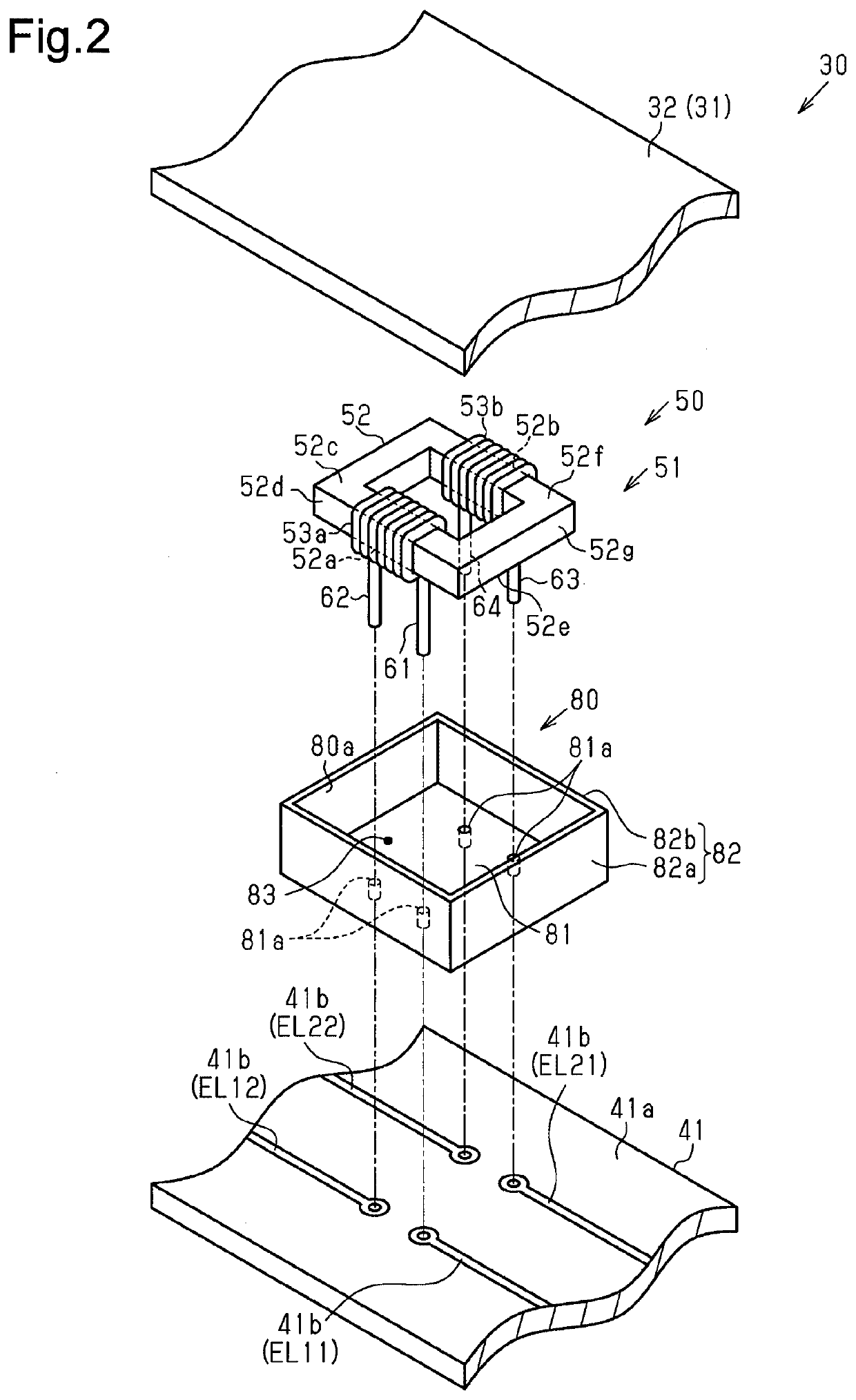

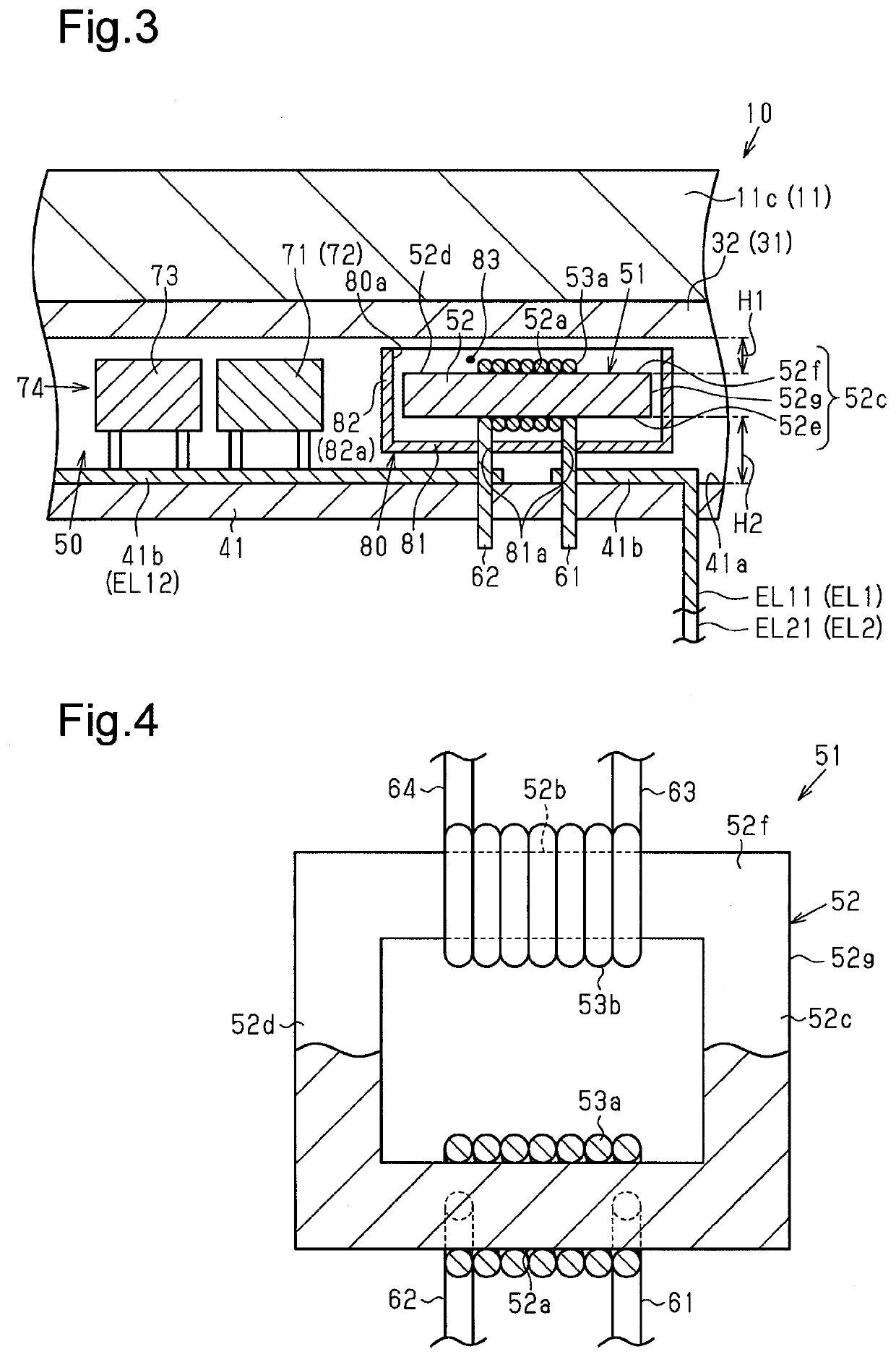

Control device for electric compressor

A control device includes a shot-pulse control unit that provides, at a time of starting a synchronous motor, a predetermined current to each phase of a stator of the motor for a short time; a detecting unit that detects a current flowing through each phase when the predetermined current is provided; an estimating unit that estimates a position of the rotor by comparing detected values; a voltage control unit that controls application of a voltage to the synchronous motor based on a high-pressure side pressure of the compressor when the compressor is failed to be started due to any cause; and a magnetism-resistant section having a conductive layer sandwiched by insulating layers. The magnetism-resistant section covers a portion of a substrate of the control device, and a portion at which the conductive layer is exposed is in contact with the housing or a part conducting heat to the housing.

Owner:MITSUBISHI HEAVY IND LTD

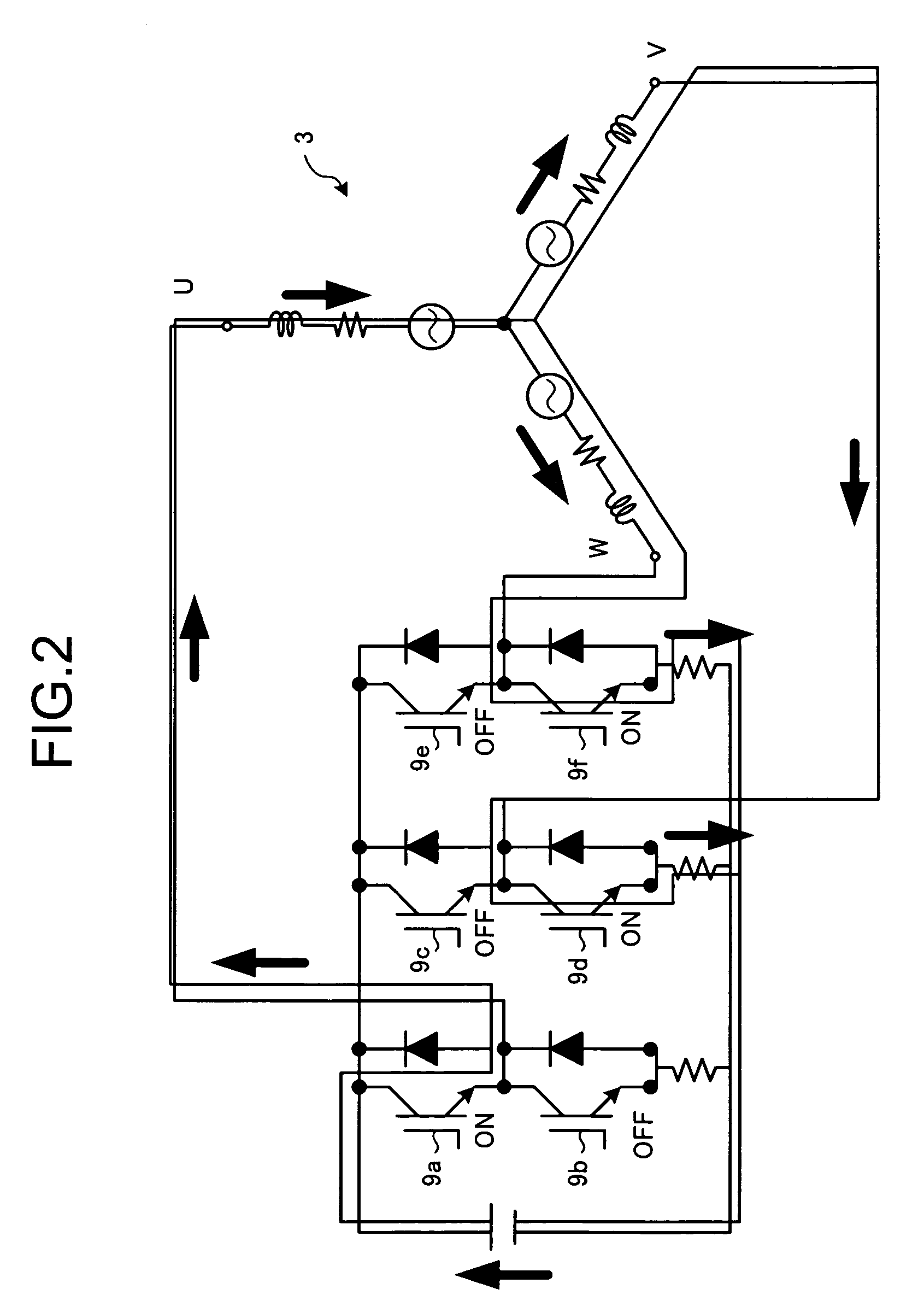

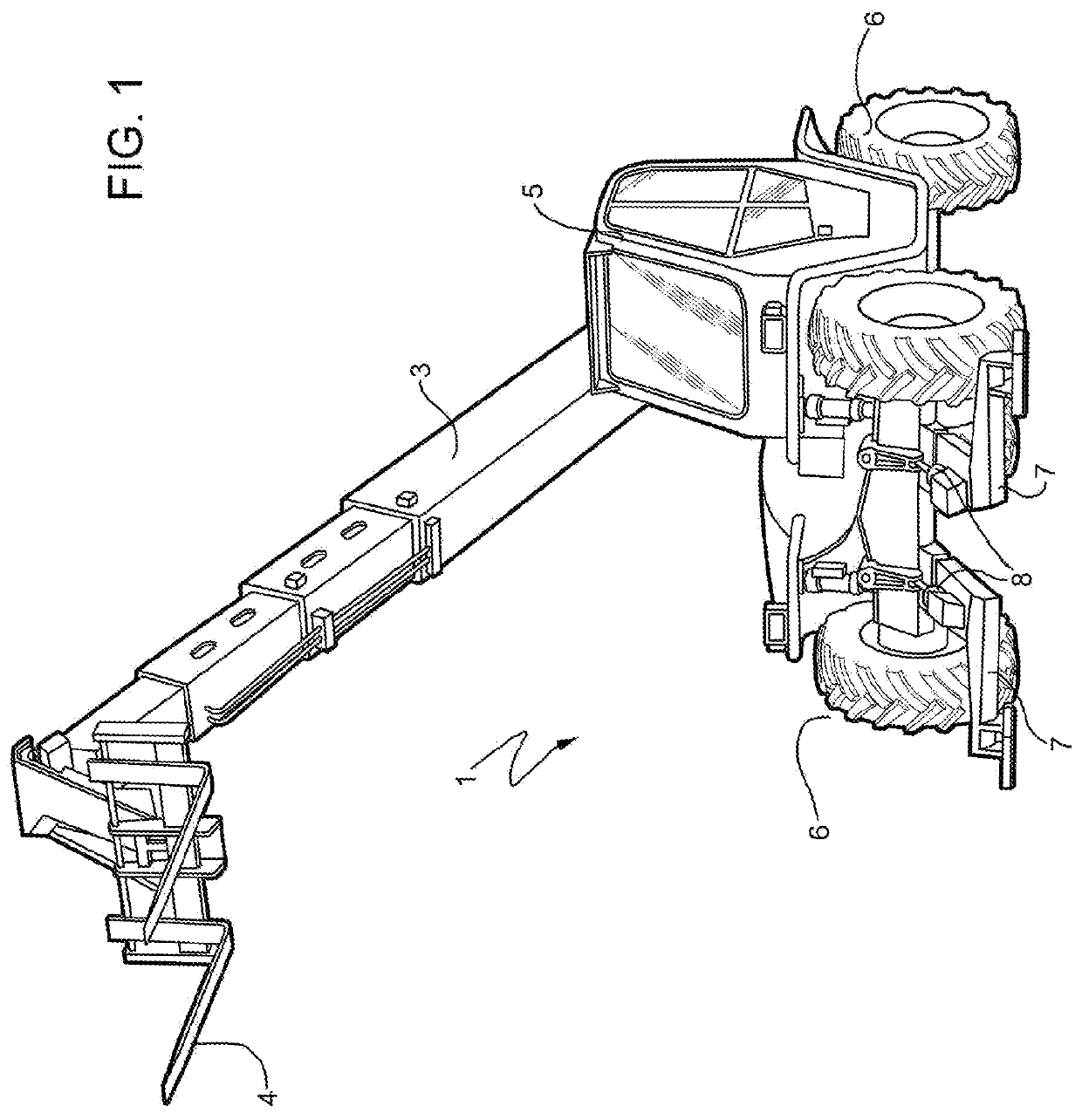

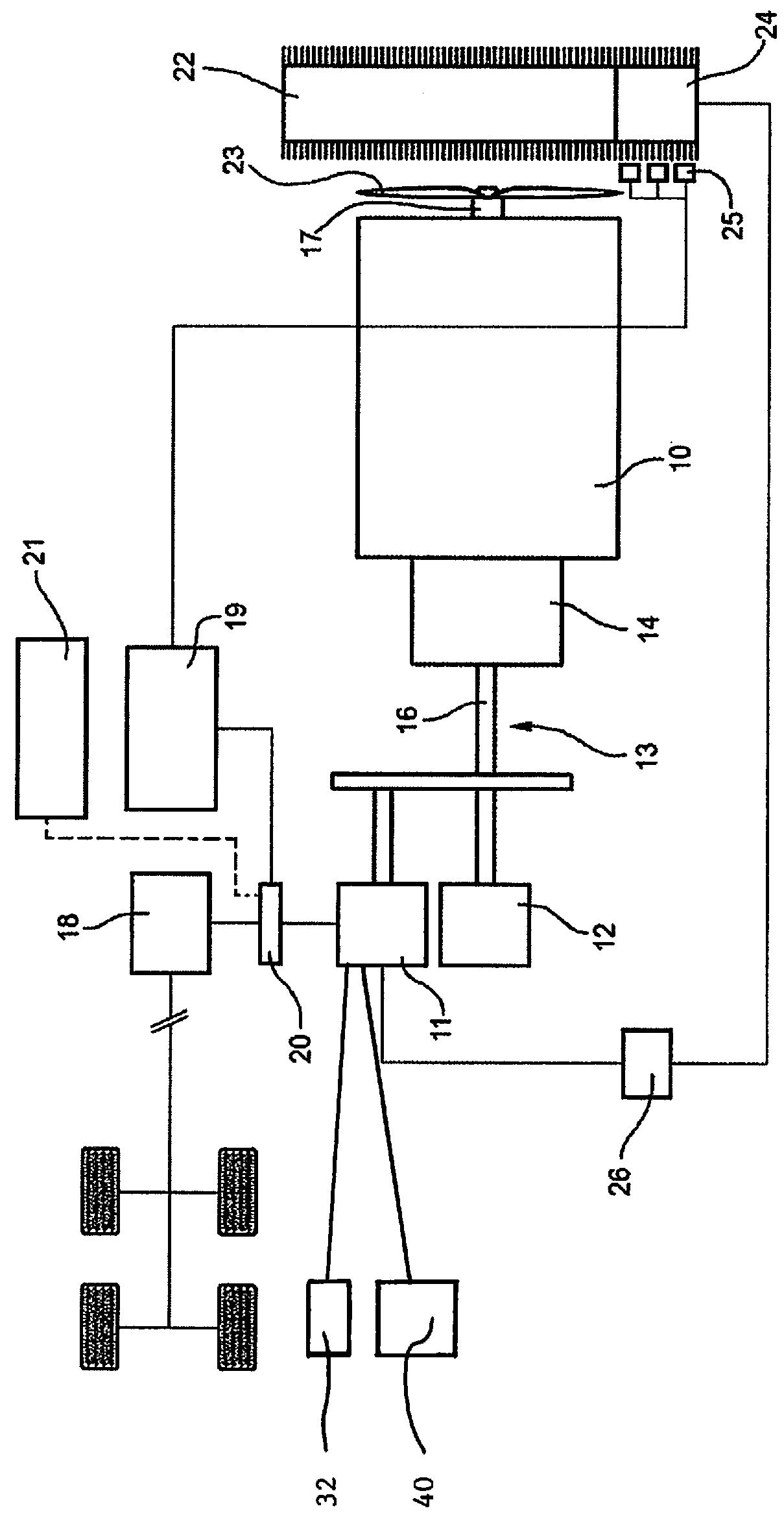

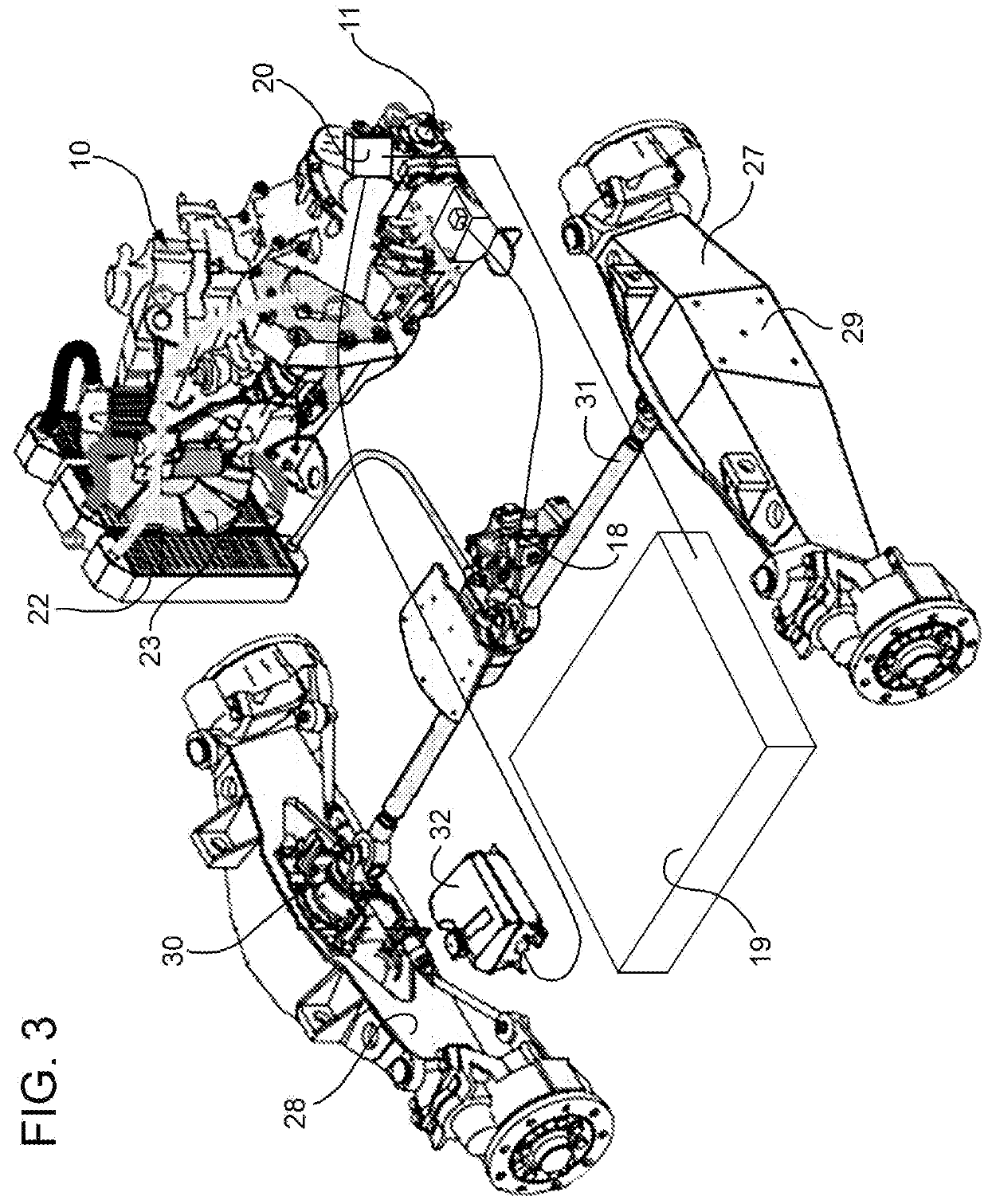

Electrohydraulic hybrid work vehicle

ActiveUS9248731B2OptimizationCheaply and easilyAuxillary drivesAssociation with control/drive circuitsElectric machineElectric power

A hybrid work vehicle having a direct-current electric power bus for connecting at least an electric power controller, an electric machine for driving the vehicle, a reversible electric machine, and a battery.

Owner:MERLO PROJECT SRL CON UNICO SOCIO

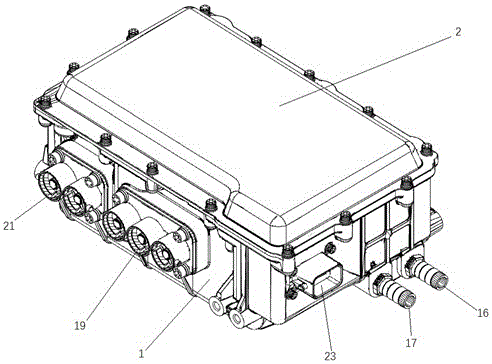

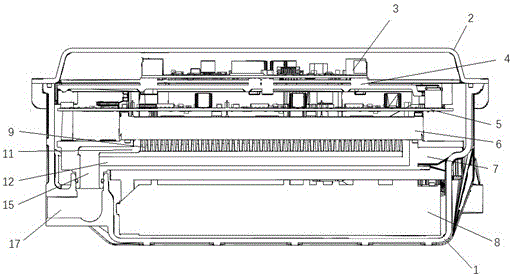

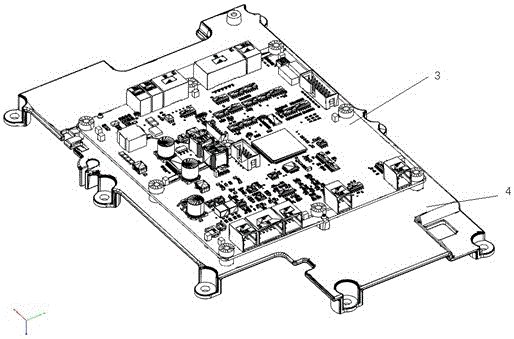

Motor controller

PendingCN106655977AReduce areaImprove power densityAssociation with control/drive circuitsElectric motor controlMotor controllerControl theory

The invention designs a new type of motor controller. The motor controller adopts modular structure design. The whole structure of the motor controller is divided into three parts: a shell, a control module, and a current conversion module. The motor controller has the advantages that the structure is compact, and the assembly is simple and the like.

Owner:ANJILI ELECTRIC CONTROL TECH NANJING CO LTD

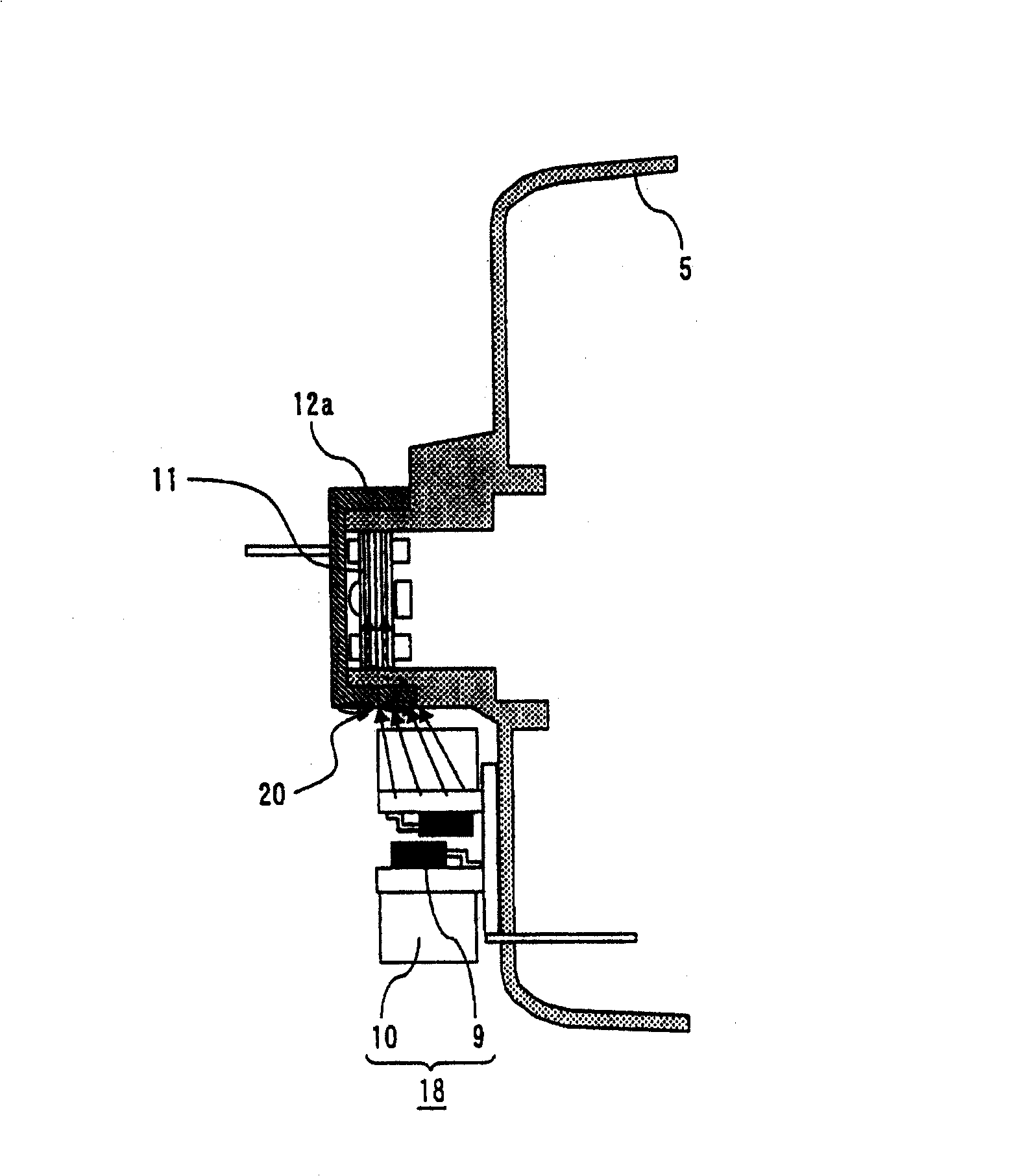

Heat radiation structure of electric apparatus

ActiveUS20100302736A1Low costAvoid corrosionAssociation with control/drive circuitsMagnetic/electric field screeningElectrical devicesEngineering

A heat radiation structure of an electric apparatus provided herein is capable of readily releasing heat of electronic components to the outside and suppressing heat conduction to a rotational position sensor. A metal electromagnetic wave shielding member is fixed to a casing body of a casing. The electromagnetic wave shielding member includes a first portion that is connected to an opposed wall portion of the casing body to face a circuit substrate and a cylindrical second portion that is extending from a peripheral end of the first portion and along a peripheral wall portion of the casing body without being in contact with a housing. A heat conductive member having electrical insulating and heat conductivity properties as well as flexibility is disposed between the circuit substrate and the electromagnetic wave shielding member to closely contact both of the plurality of electronic components and the first portion of the electromagnetic wave shielding member.

Owner:SANYO DENKI CO LTD

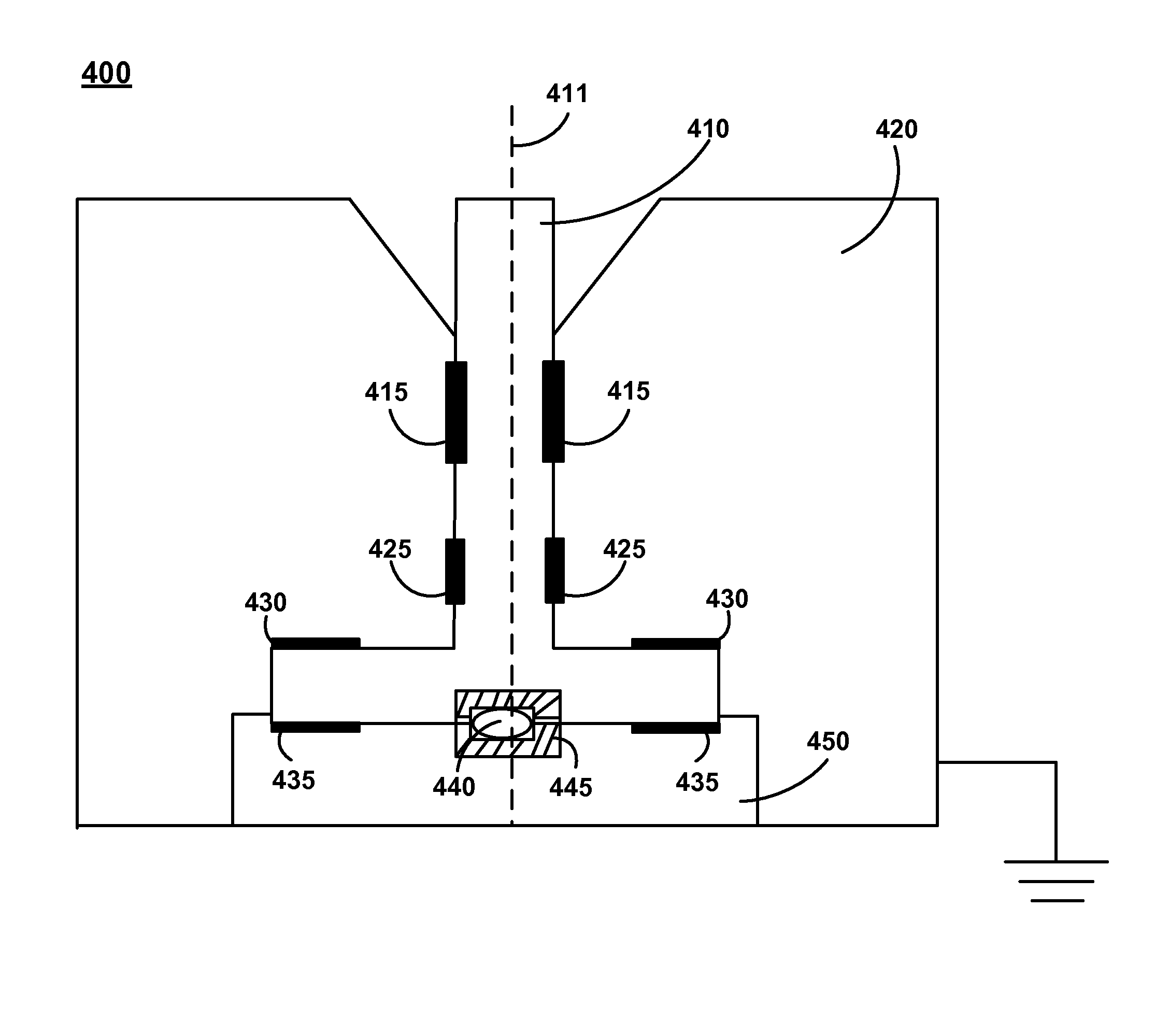

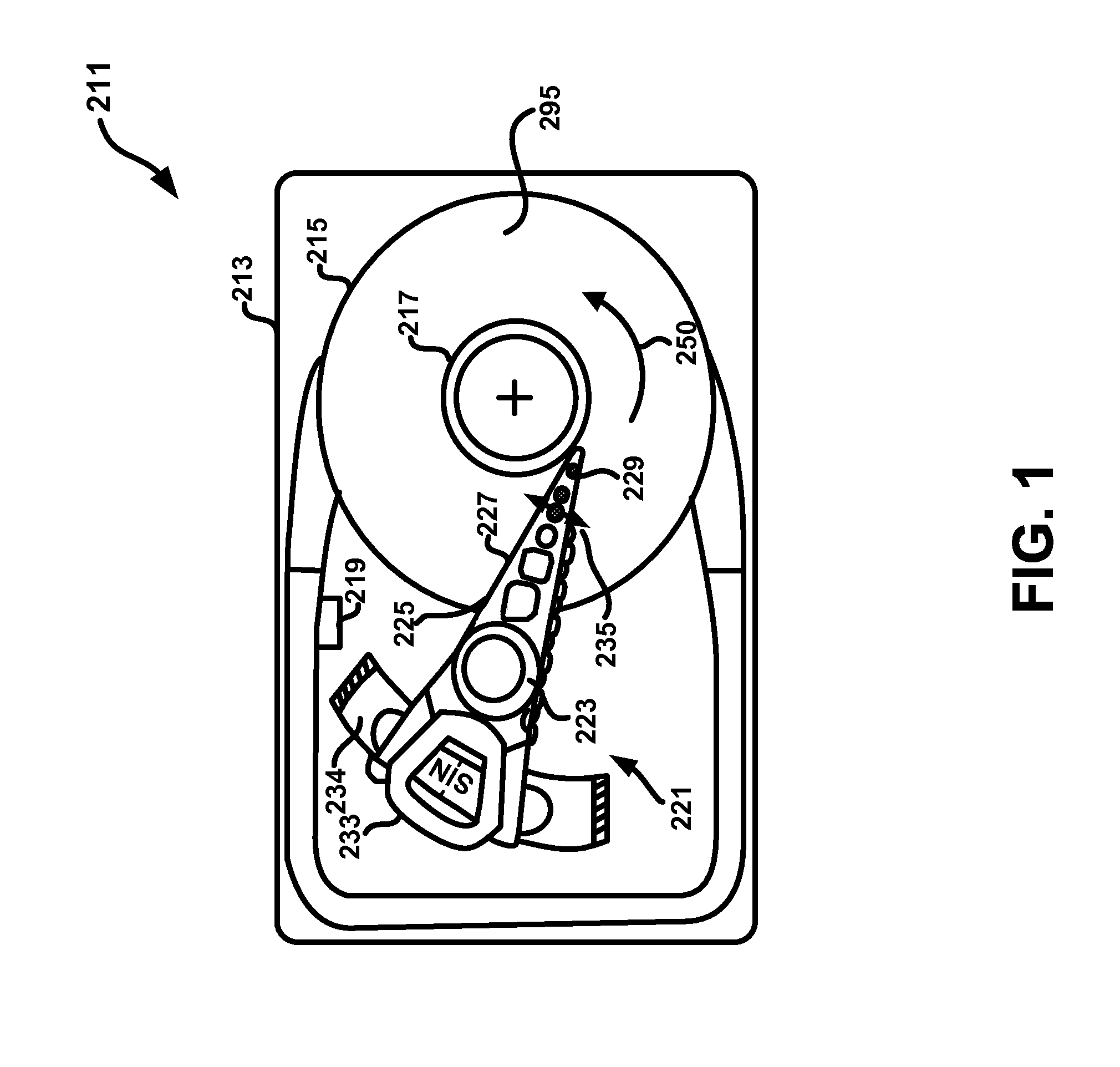

System and method to electrically ground fluid dynamic bearings

ActiveUS8248725B2Apparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionElectricityElectrical resistance and conductance

A spindle motor assembly that utilizes a fluid dynamic bearing electrically grounded to provide a conductive path through the spindle motor assembly. In one embodiment, the fluid dynamic bearing includes a liquid metal that is conductive and of low electrical resistance that provides the conductive path between the spindle and the spindle housing.

Owner:WESTERN DIGITAL TECH INC

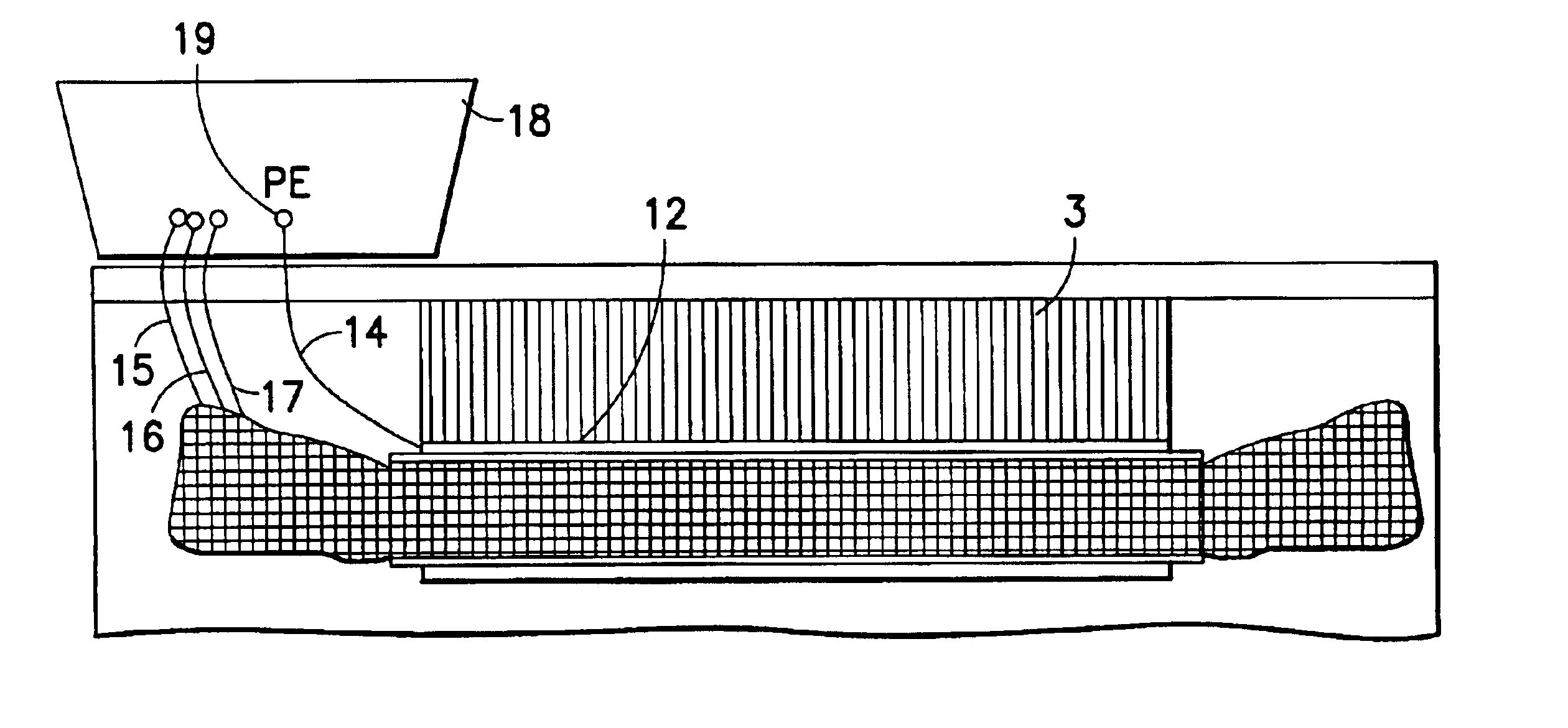

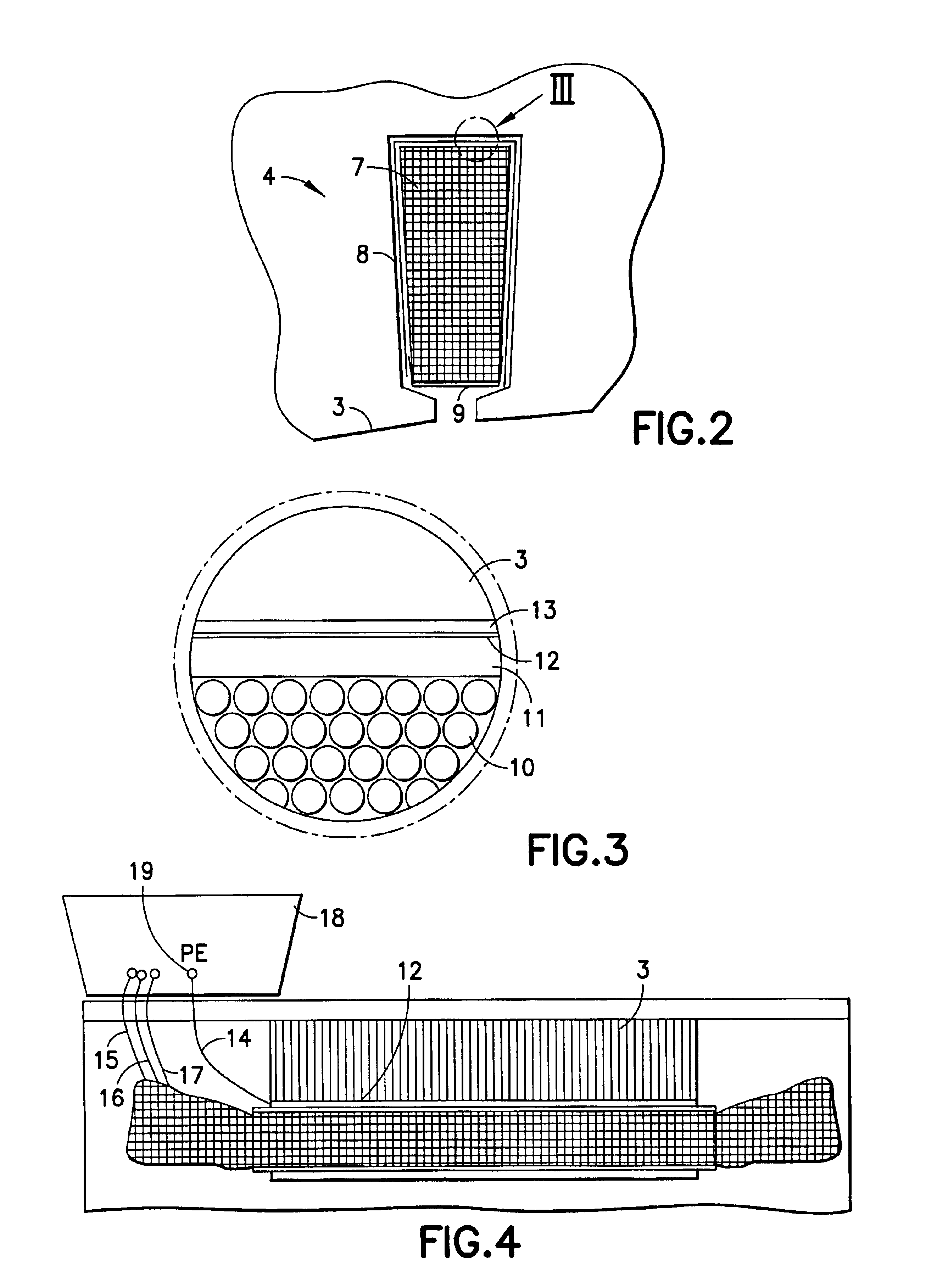

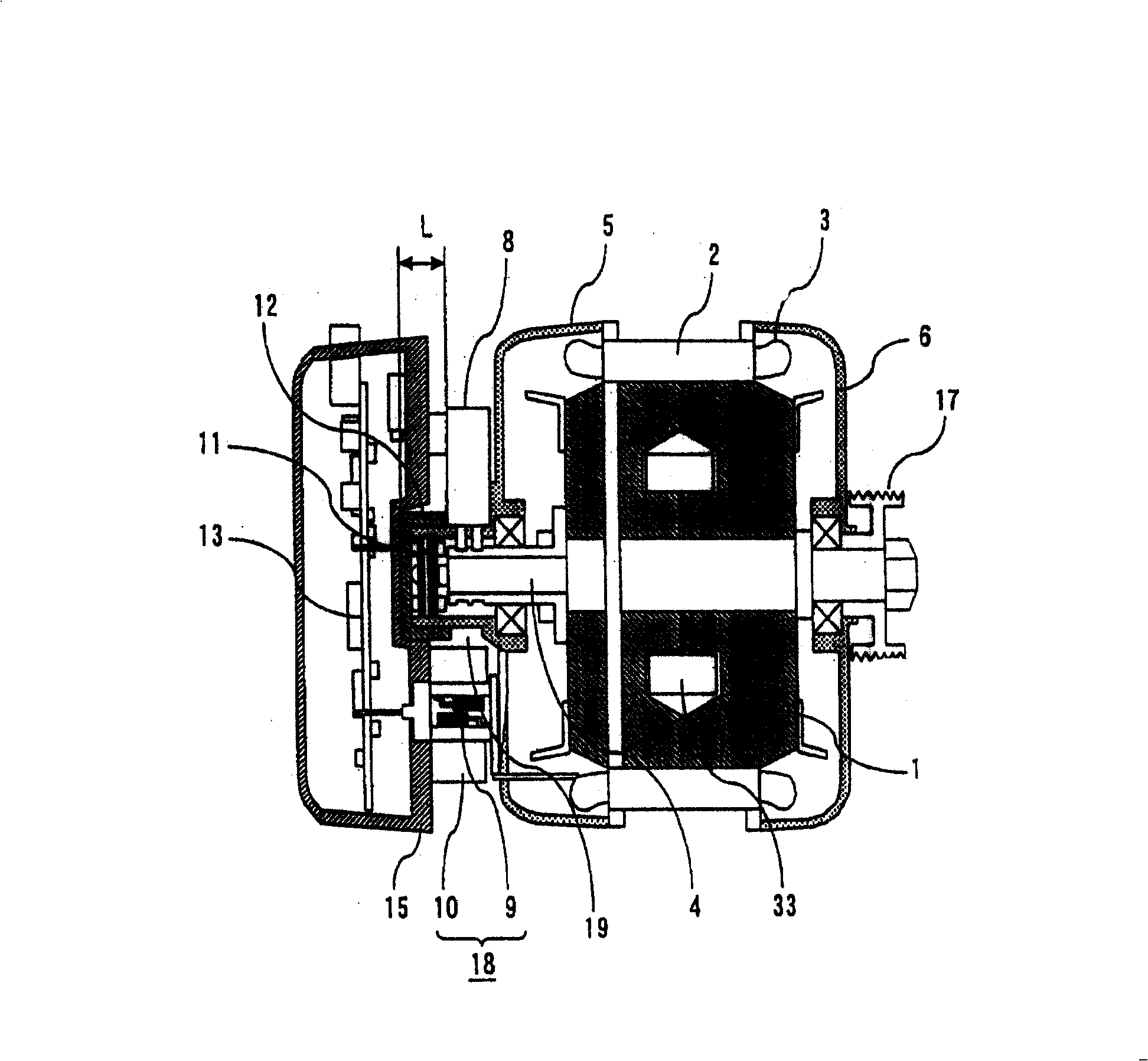

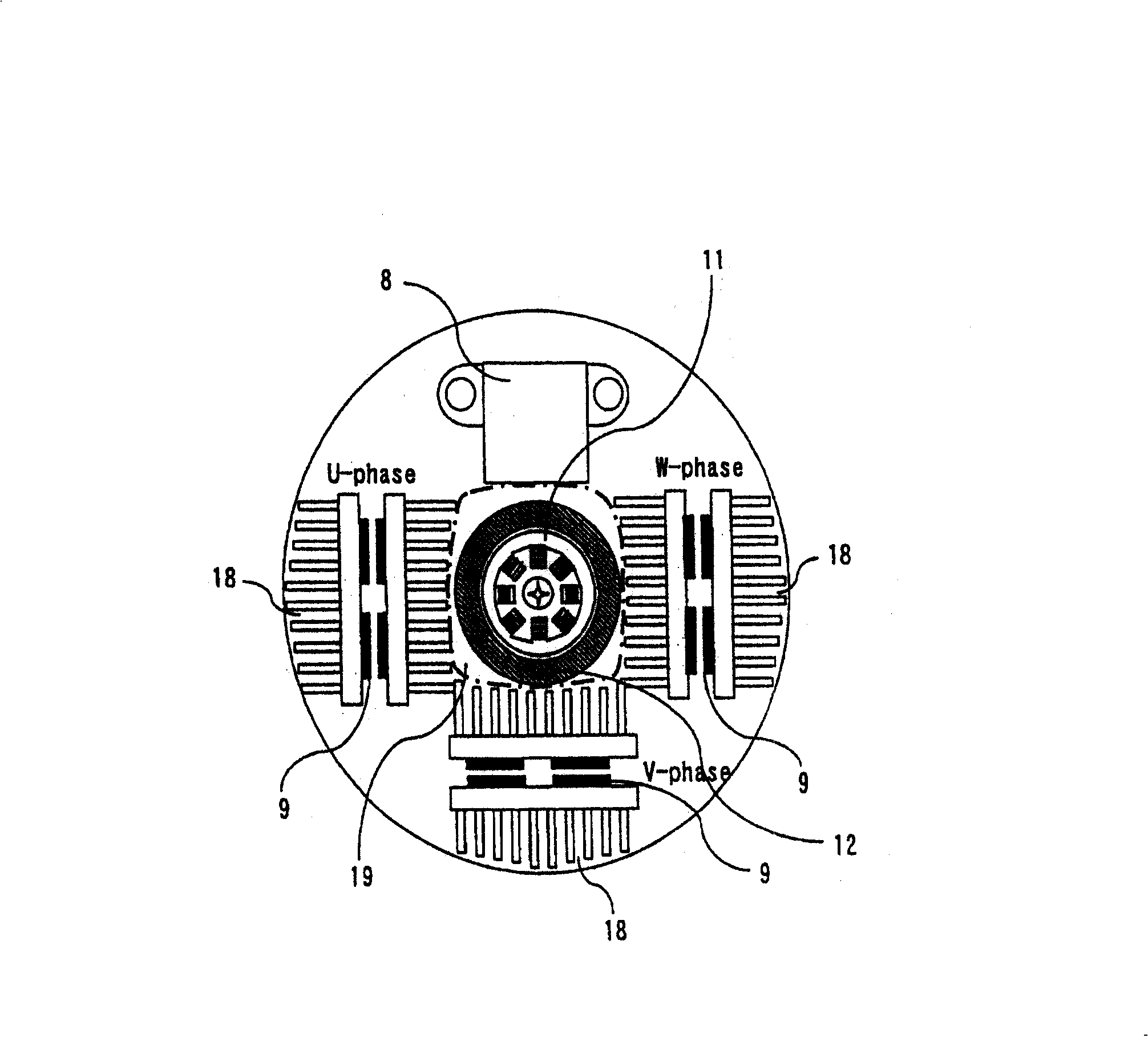

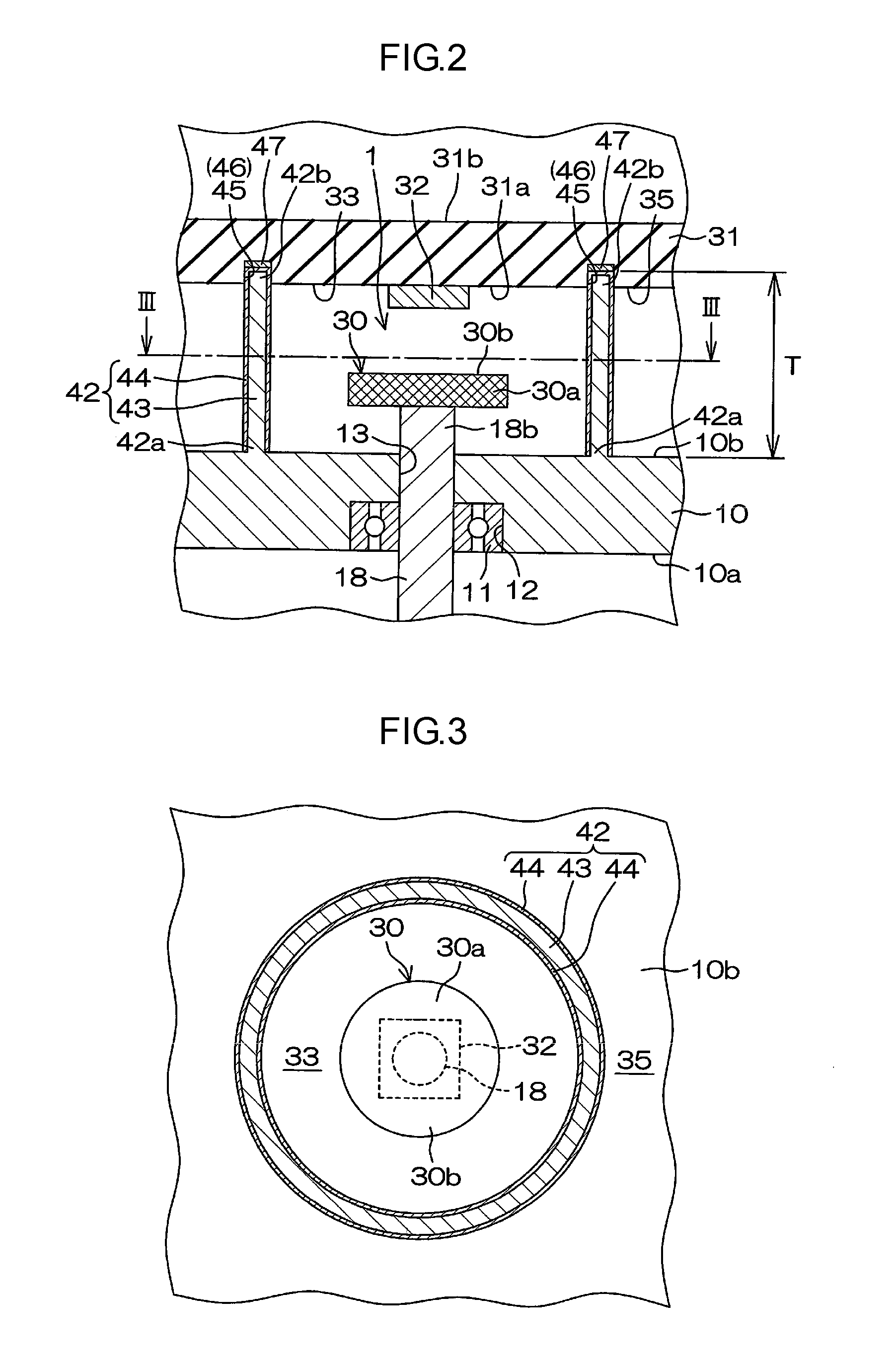

Electric rotating machine

InactiveCN101247062ANo malfunctionReduce magnetic field strengthShielding from electromagnetic fieldsSuppressing electromagnetic interferenceElectric machineMagnetic field

The present invention leads to that the rotating position detector is not effected by the outer magnetic field, reduces the interference included in the output of the rotating position detector and prevents the false action of the rotating position detector. The rotating electric machine comprises the following components: a stator (2); a rotor (1) which has a rotation axis (4) and rotates axially with the stator (2); end caps (5) and (6) which support and fix the stator (2) and at the same time support the rotation axis (4) to facilitate the rotation; a rotating position detecting part (11) which is arranged on the rotation axis (4) at the side opposite to the load and detects the rotating position of the rotor (1); and a power part (18) which is arranged at the external circumferential side of the rotating position detecting part (11) and is provided with a switching element (9). In the rotating electric motor the rotating position detecting part (11) is arranged with a shielding component (12) which covers the external circumference to shield the magnetic field generated by the switching element (9).

Owner:MITSUBISHI ELECTRIC CORP

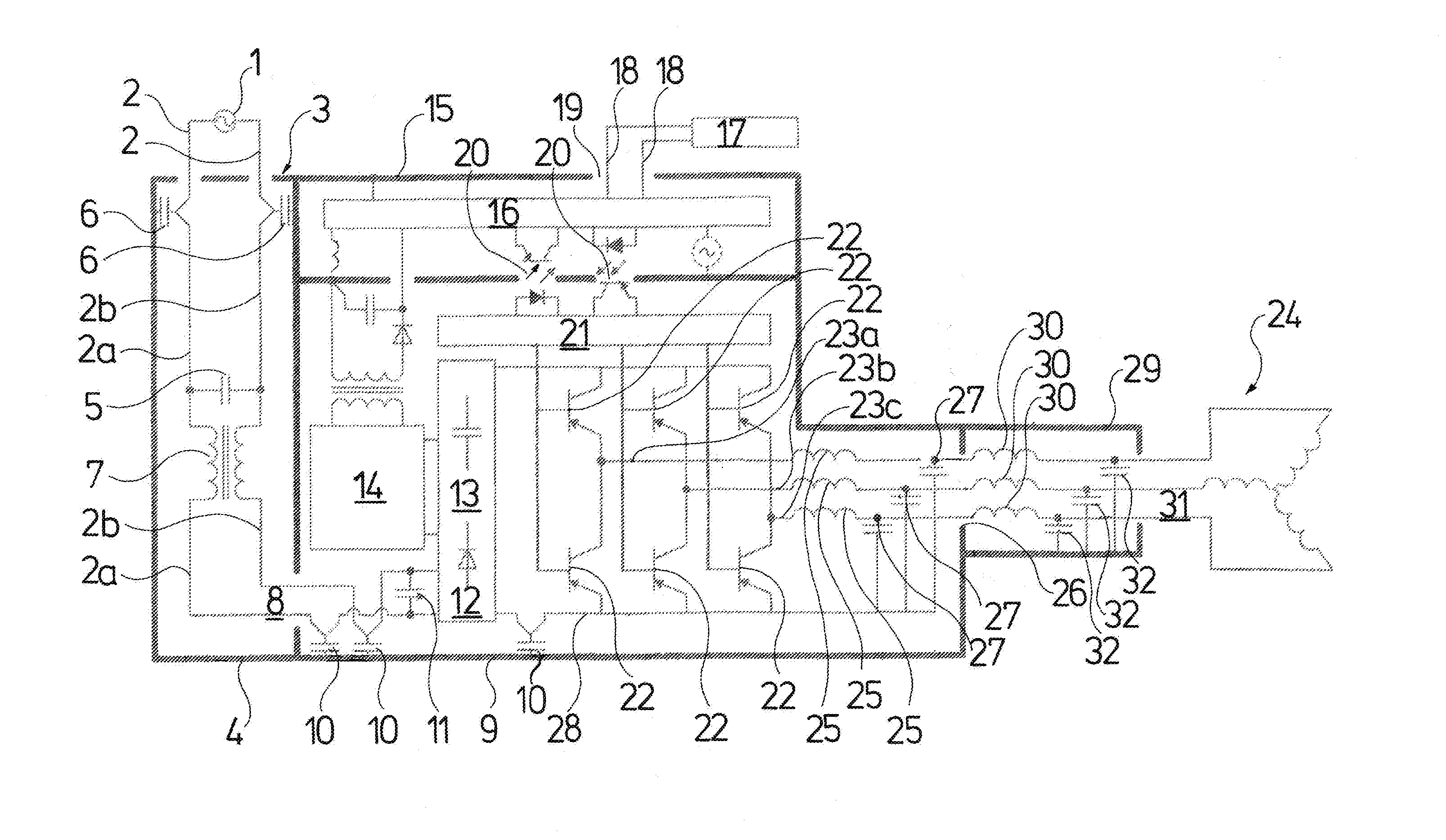

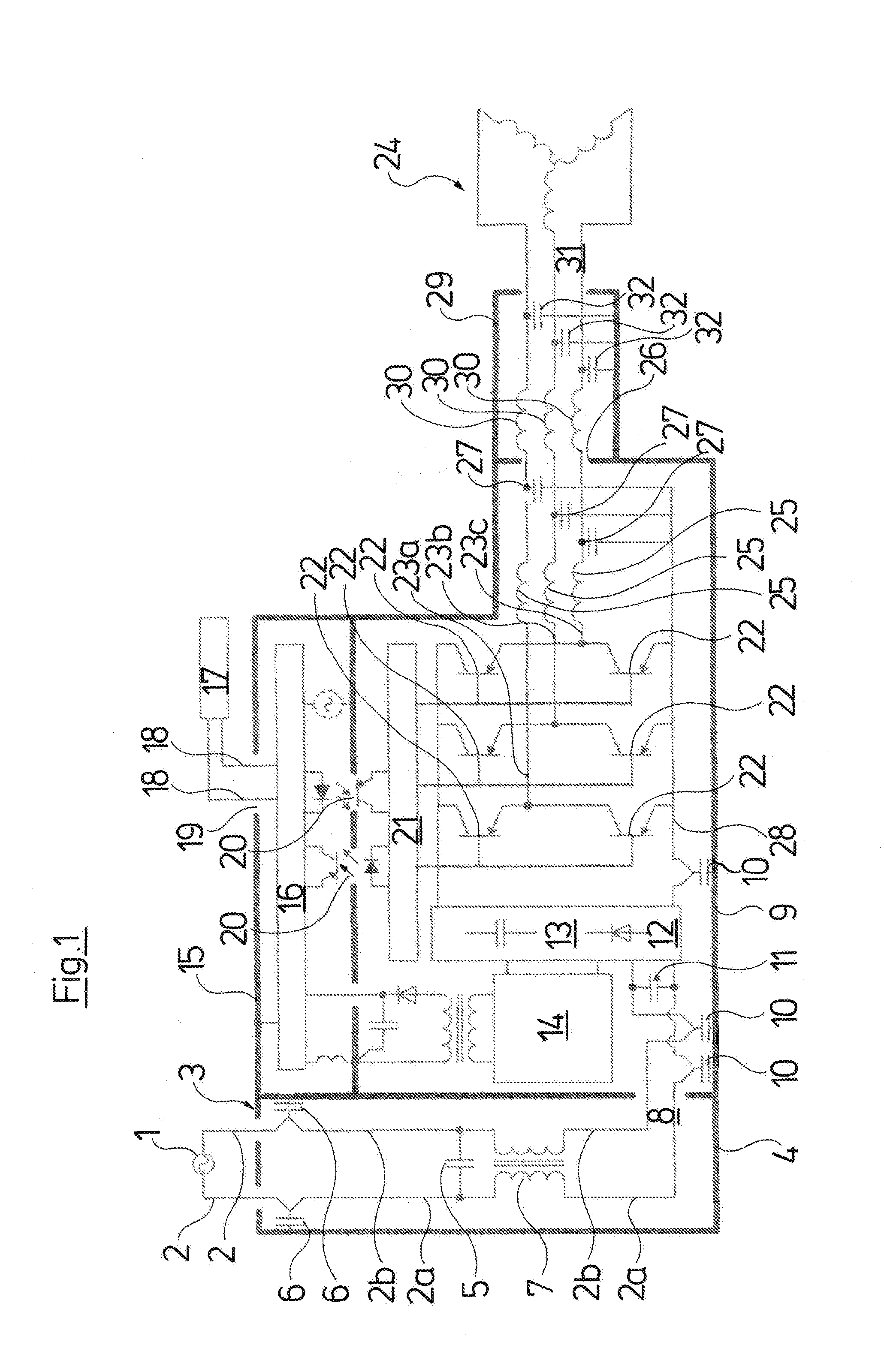

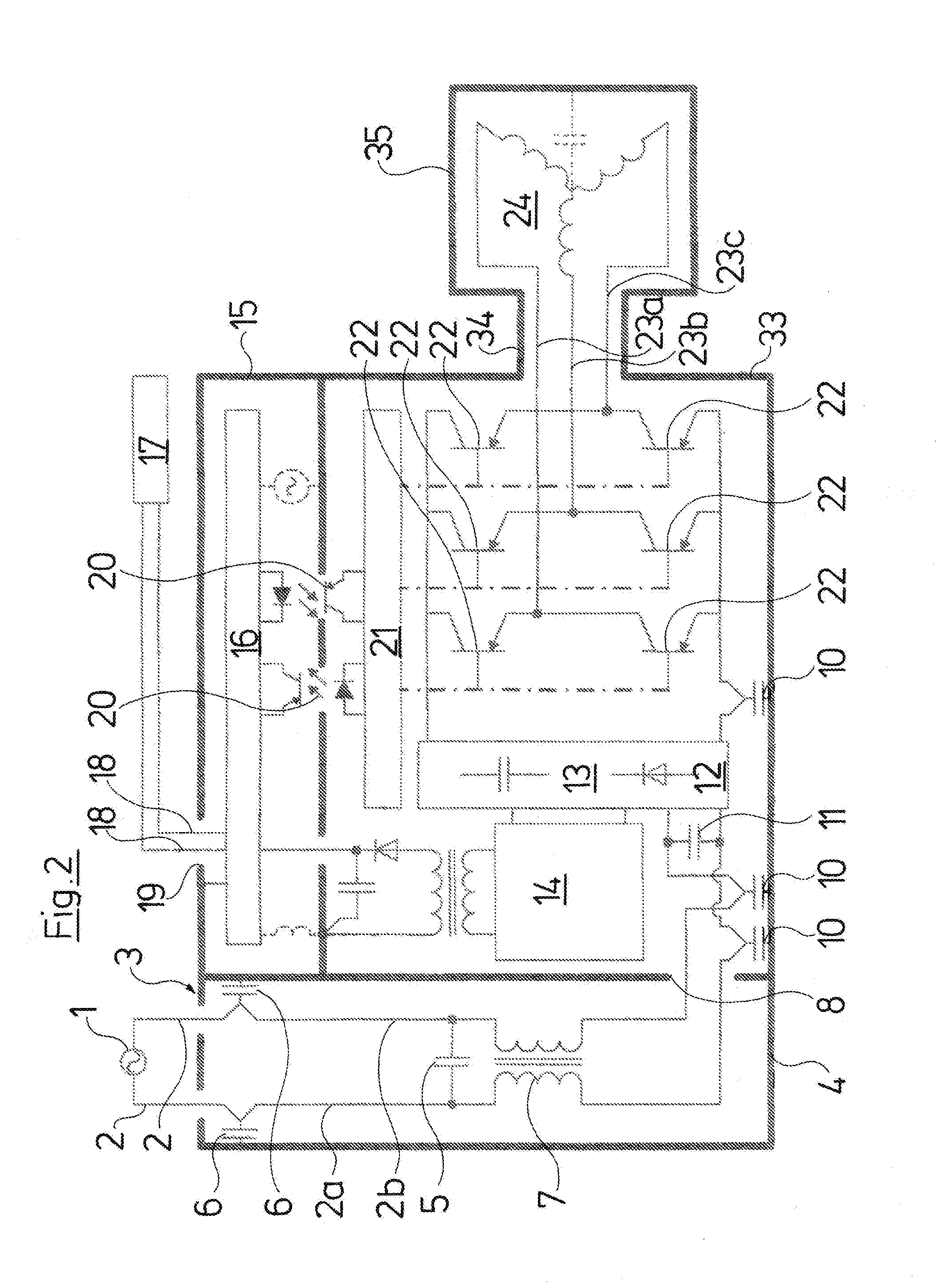

Power converter

ActiveUS20160352187A1Improve electromagnetic compatibilityPerformance is not affectedAssociation with control/drive circuitsAC motor controlFrequency changerElectronic component

A frequency converter includes an enclosure, in which electrical and electronic components (5, 6, 7, 22) are arranged and which at least partly is designed as a Faraday cage. At least two Faraday cages (4, 9, 15, 29) are provided within the enclosure, in order to improve the electromagnetic compatibility (EMC).

Owner:GRUNDFOS HLDG

Rotation angle detection device

ActiveUS20160352190A1Reduce inconvenienceImprove reliabilityAssociation with control/drive circuitsConverting sensor outputElectric machineEngineering

A rotation angle detection device detects a rotation angle of a motor having a shaft passing through a heat-dissipation plate. The rotation angle detection device includes: a permanent magnet attached to a base end of the shaft; a board that is disposed above the heat-dissipation plate and on which a drive circuit of the motor and a control circuit of the drive circuit are mounted; a magnetic sensor that is provided on the board so as to face the permanent magnet; and a magnetic shielding member that has a tubular shape and is disposed between the heat-dissipation plate and the board to surround the permanent magnet in plan view.

Owner:JTEKT CORP

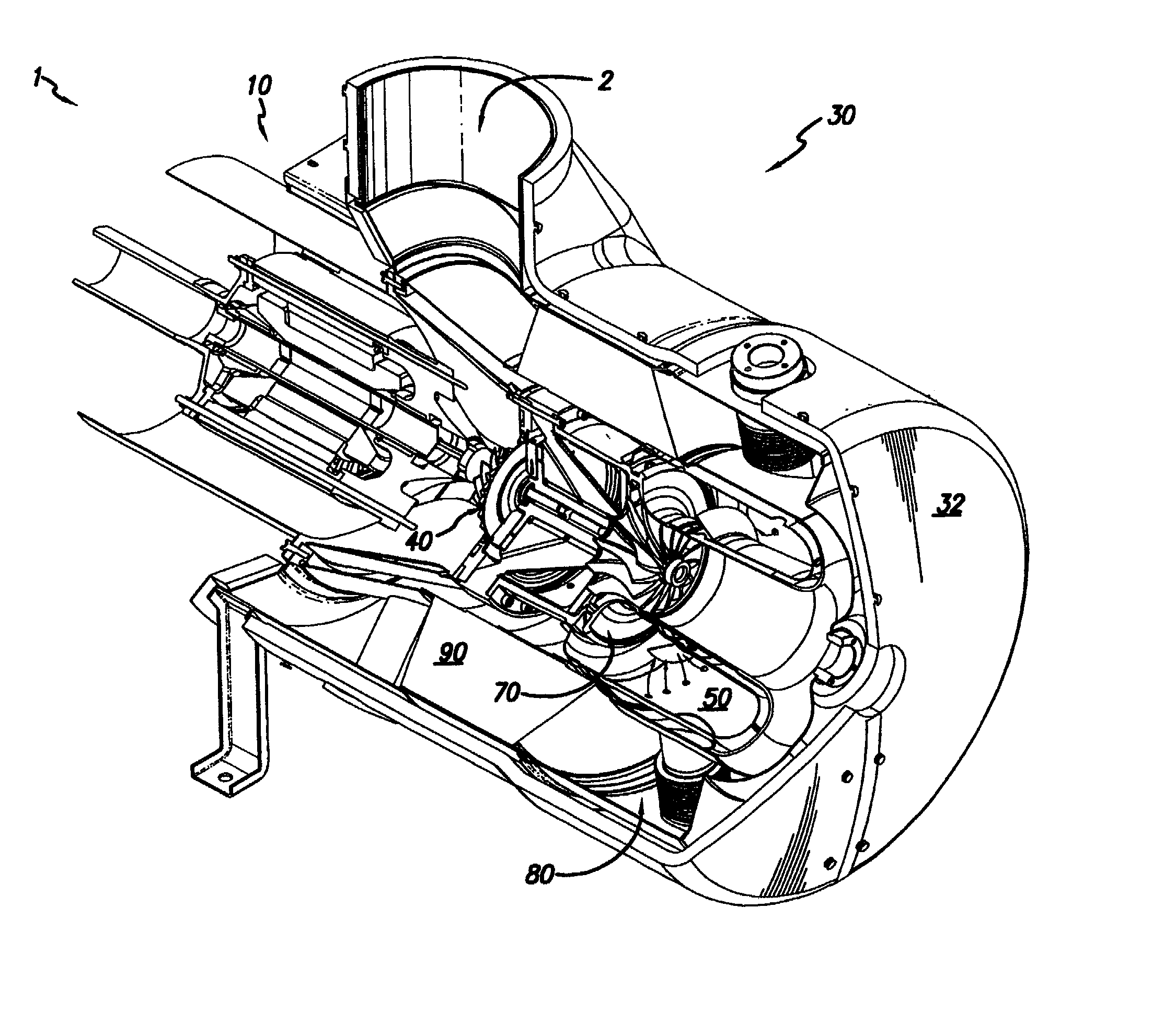

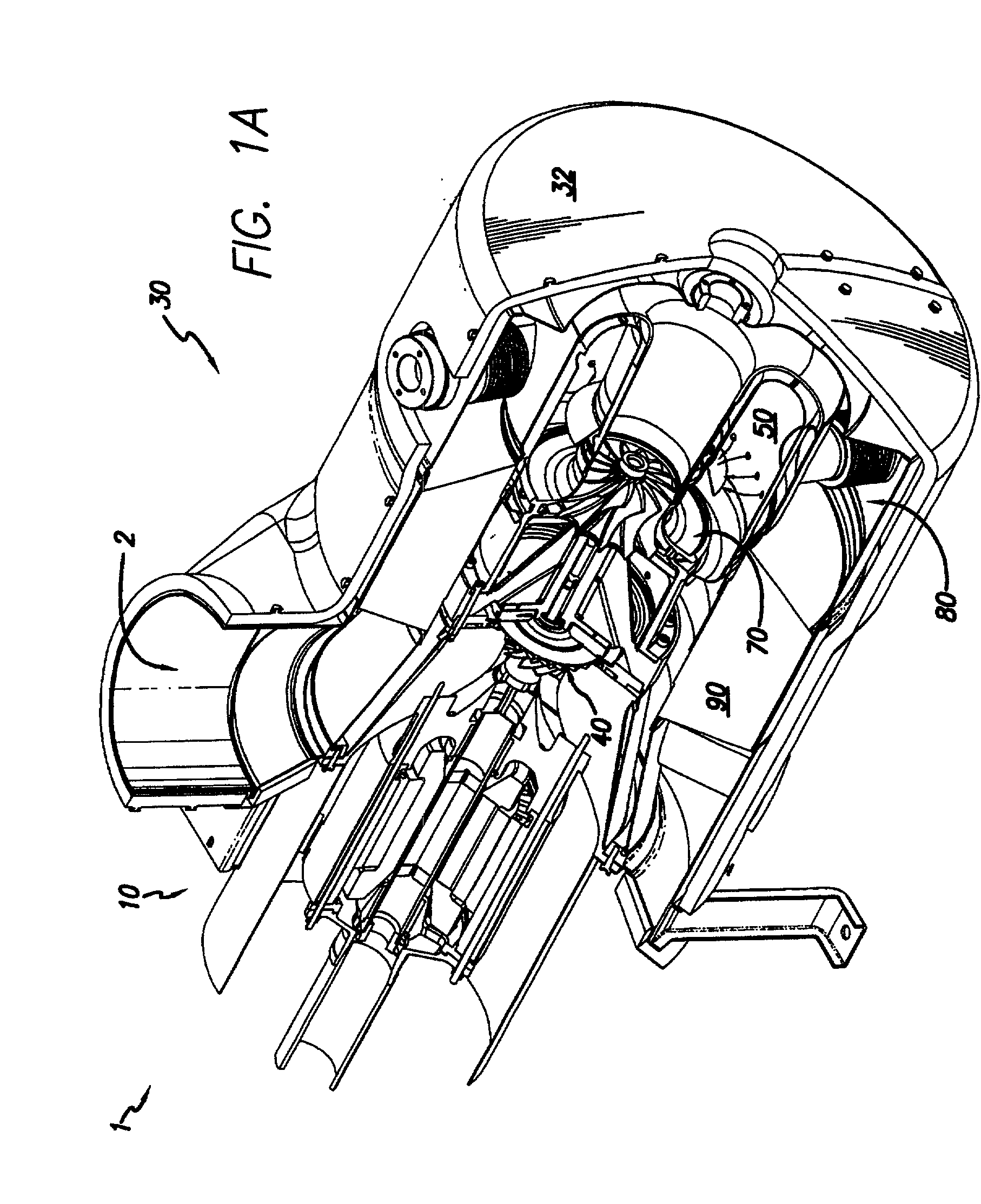

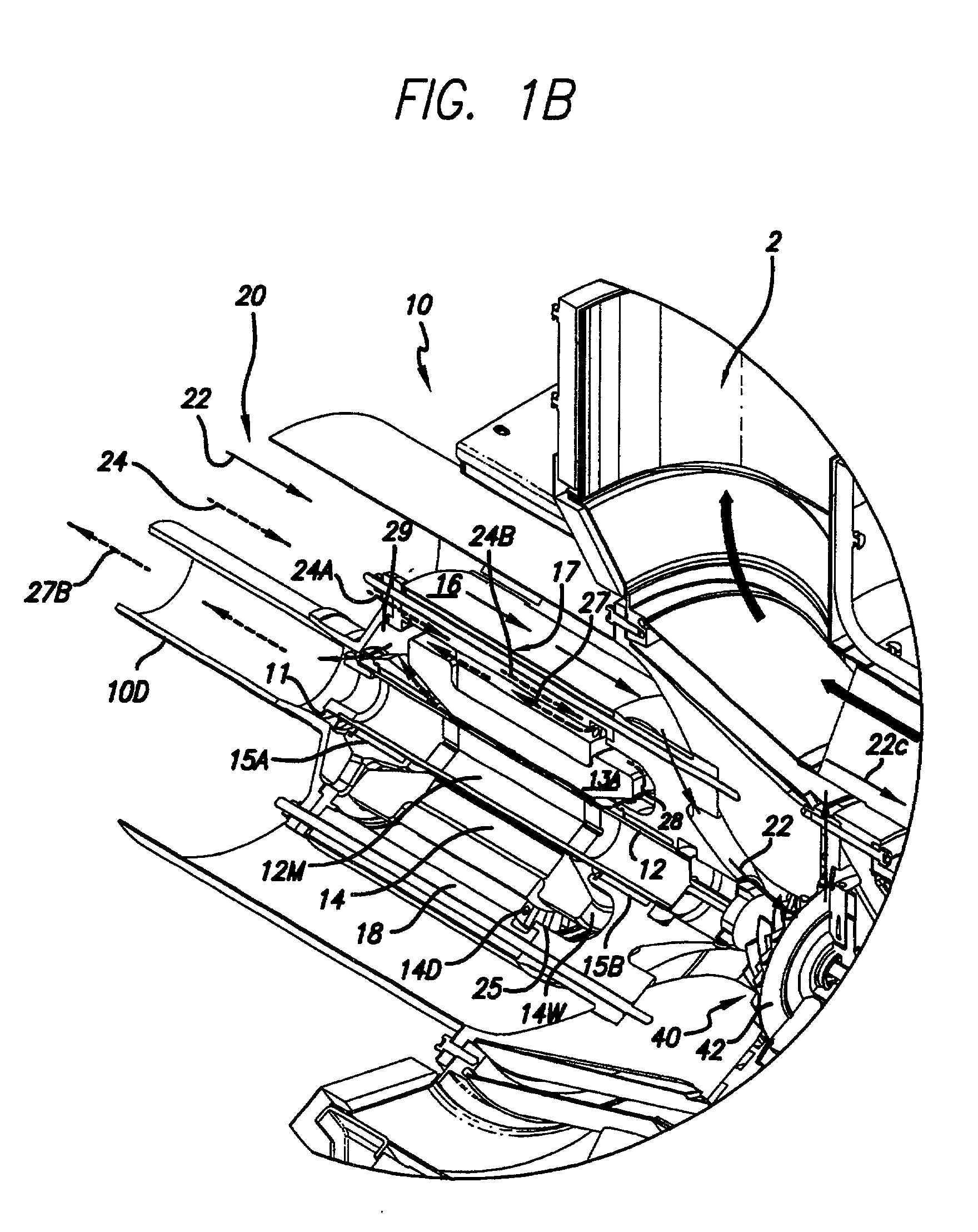

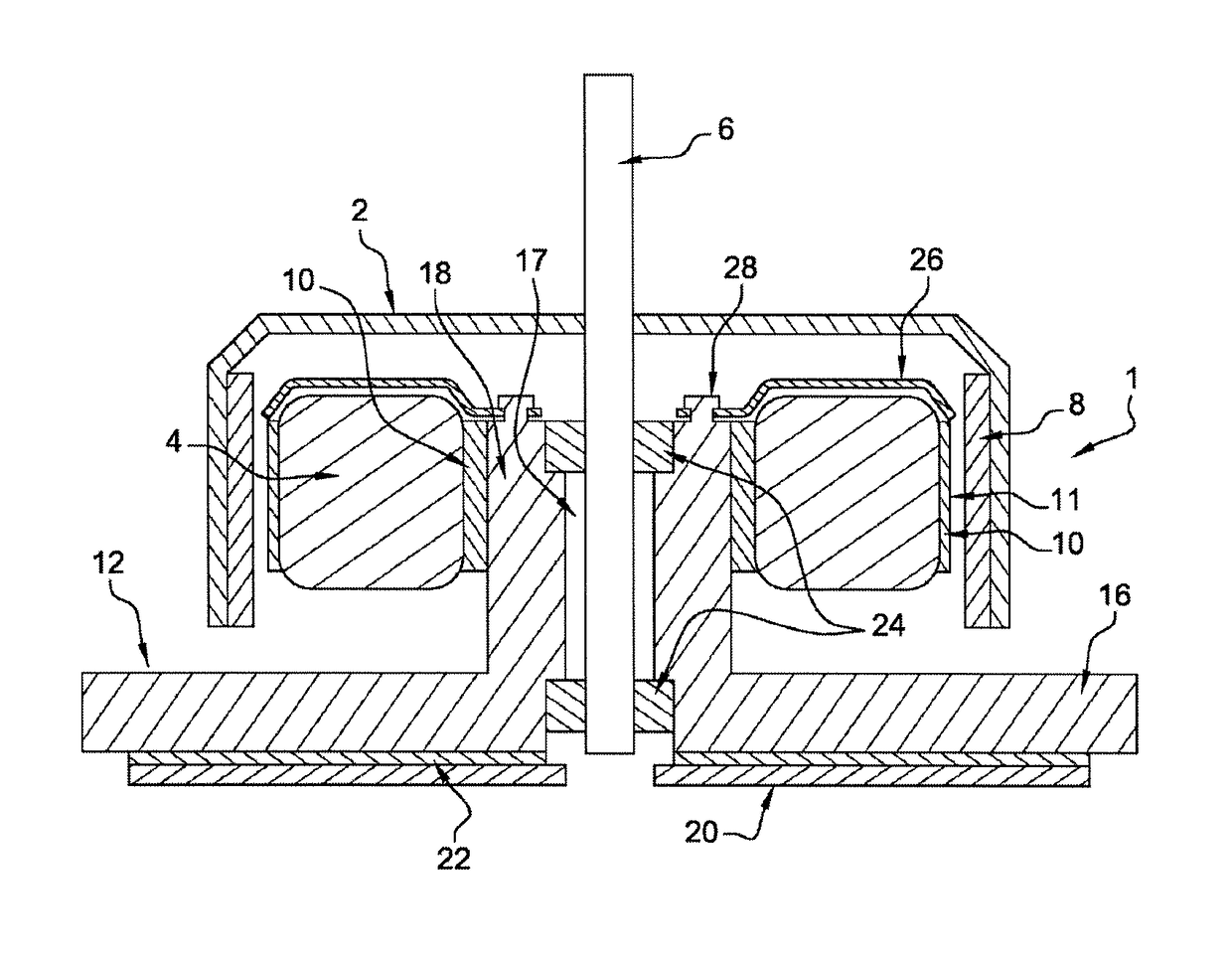

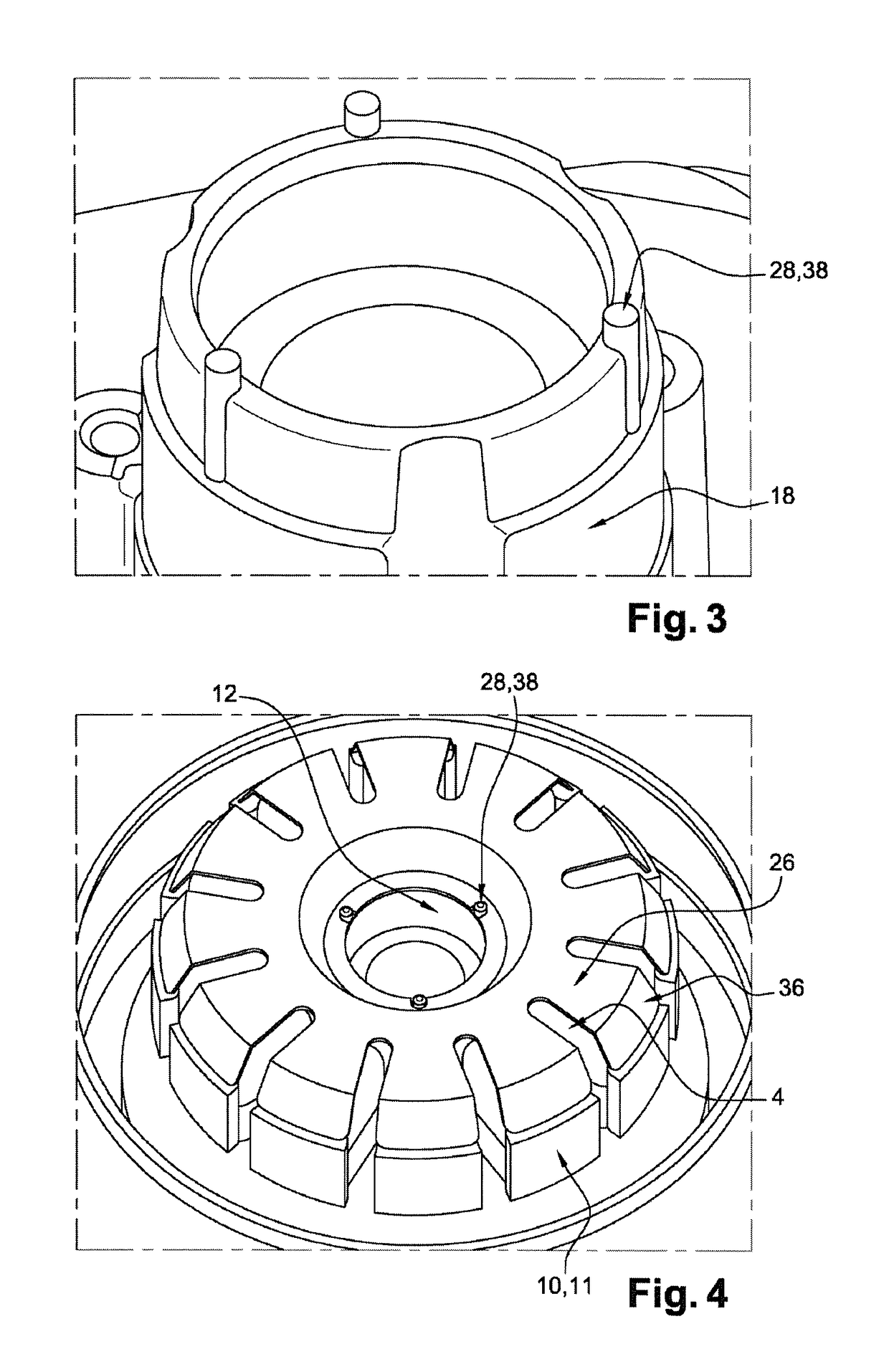

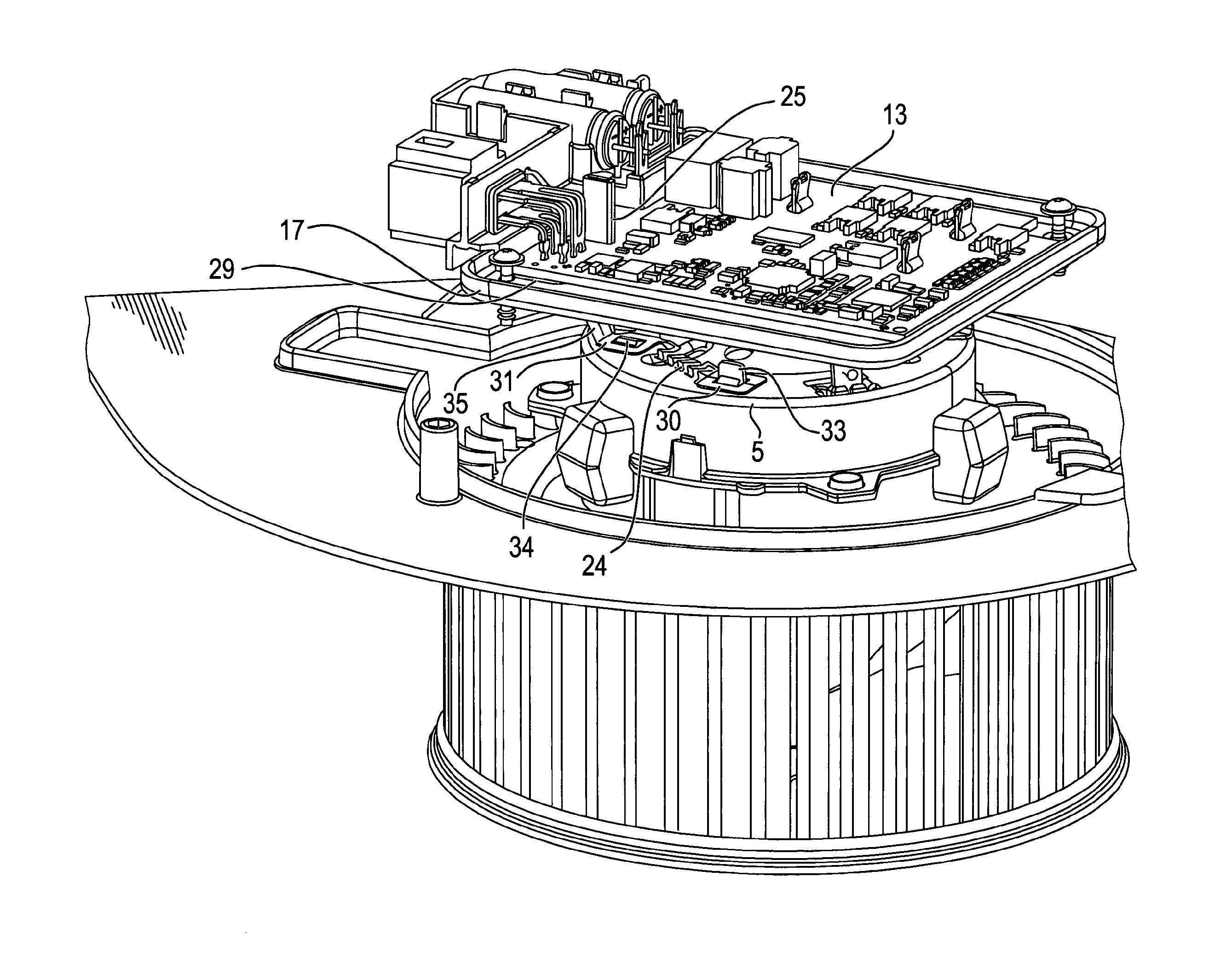

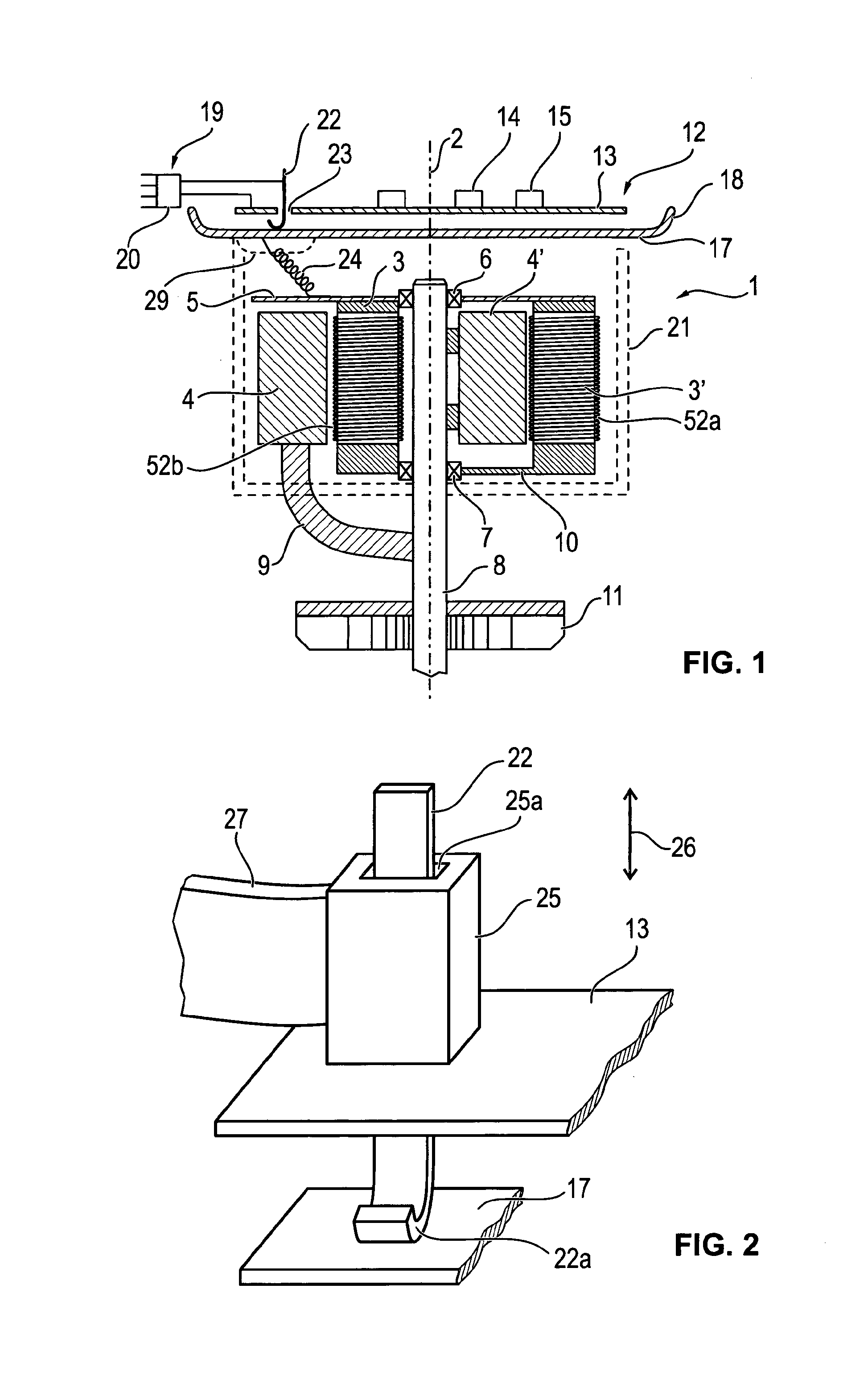

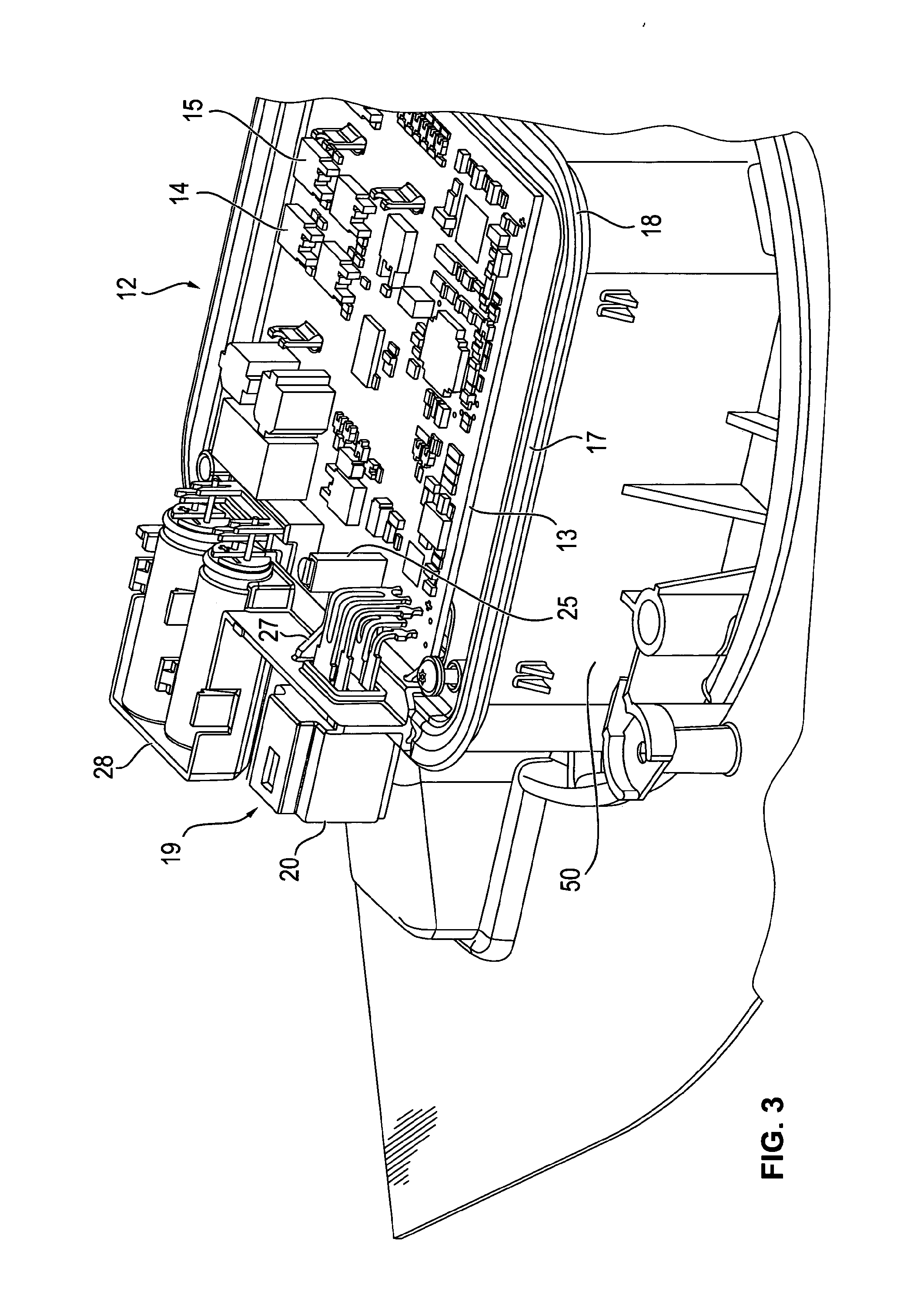

Electric motor for an air blowing device and air blowing device

InactiveUS20180298908A1Restrict propagationPrecise positioningAssociation with grounding devicesMagnetic circuit stationary partsEngineeringElectric motor

Electric motor (1) for an air blowing device, comprising a rotor (2), a stator (4), a support (12) for said rotor (2) and said stator (4) able to dissipate heat and a screening cap (26), characterized in that the screening cap (26) is fixed to the support (12) of said rotor (2) and of said stator (4) by a fixing means (28). The invention also relates to an air blowing device comprising such an electric motor (1).

Owner:VALEO SYST THERMIQUES

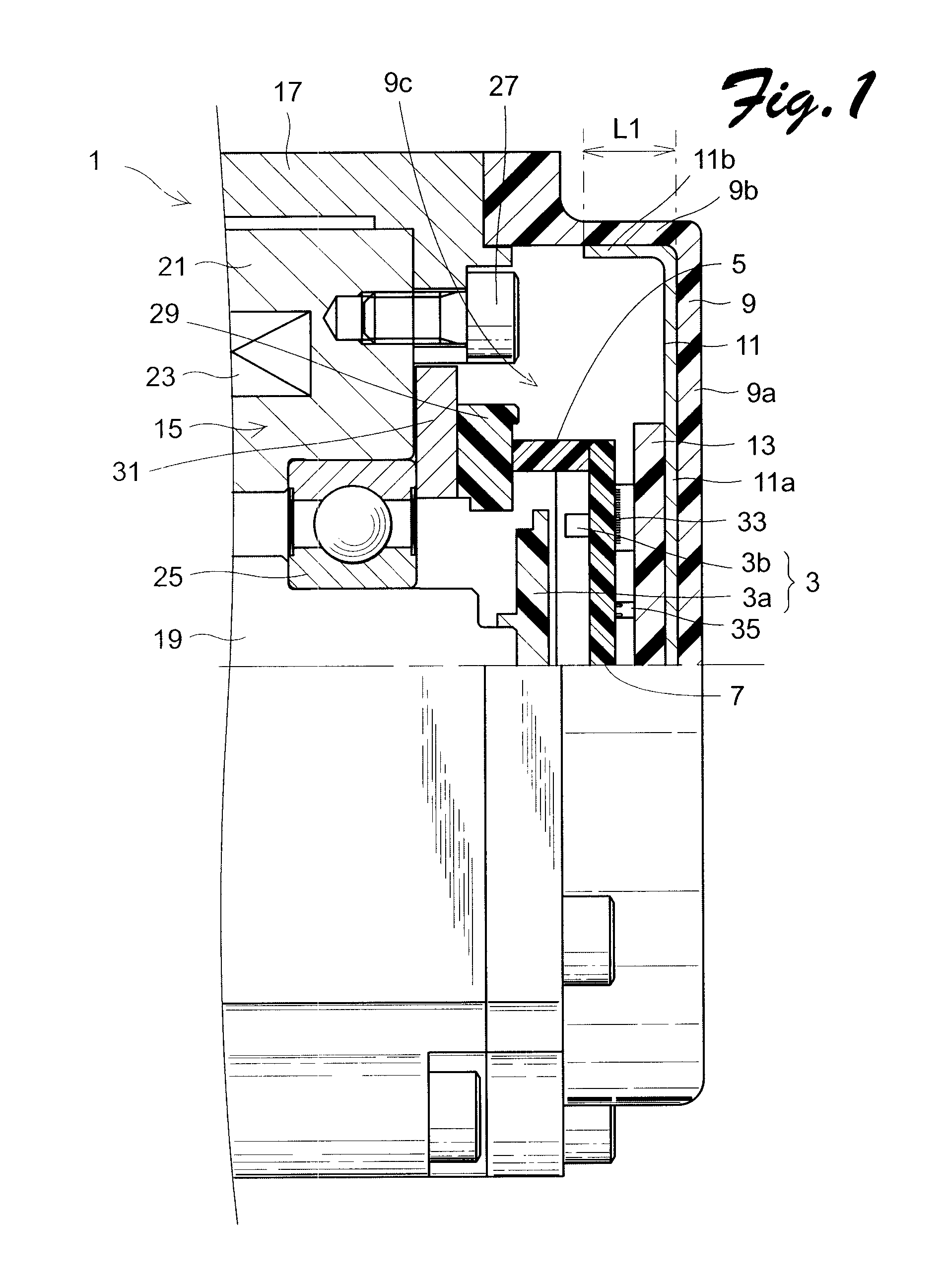

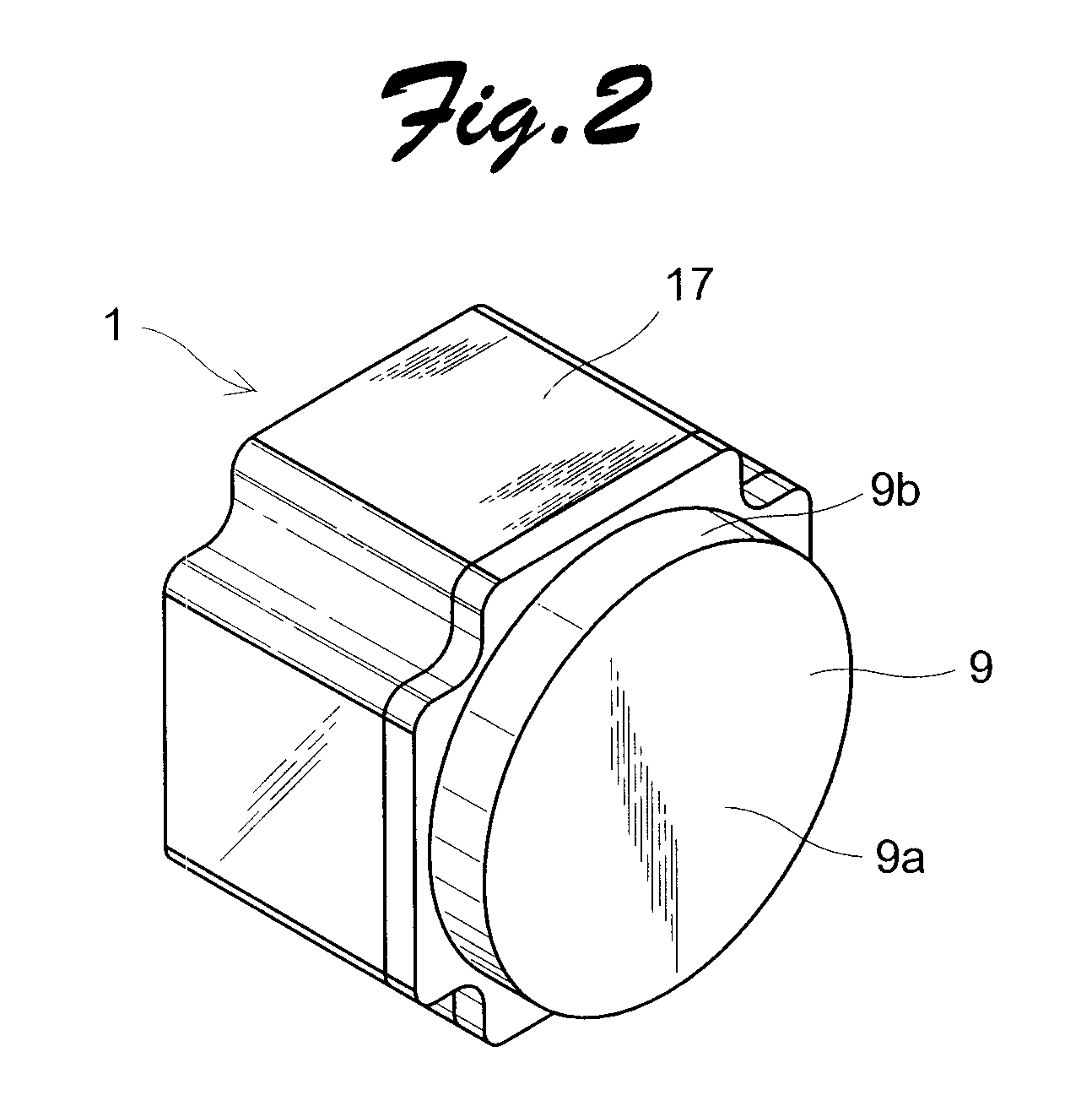

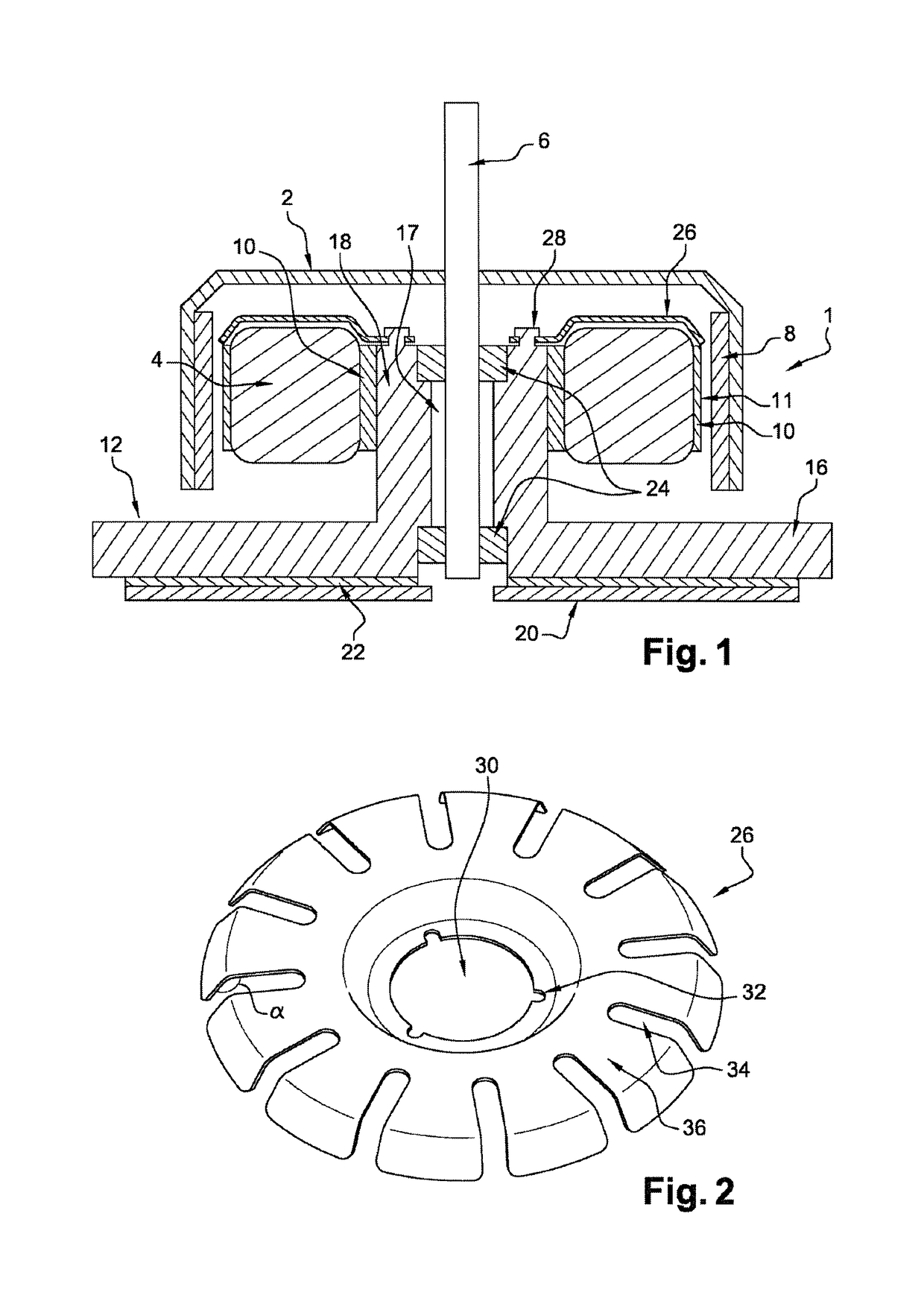

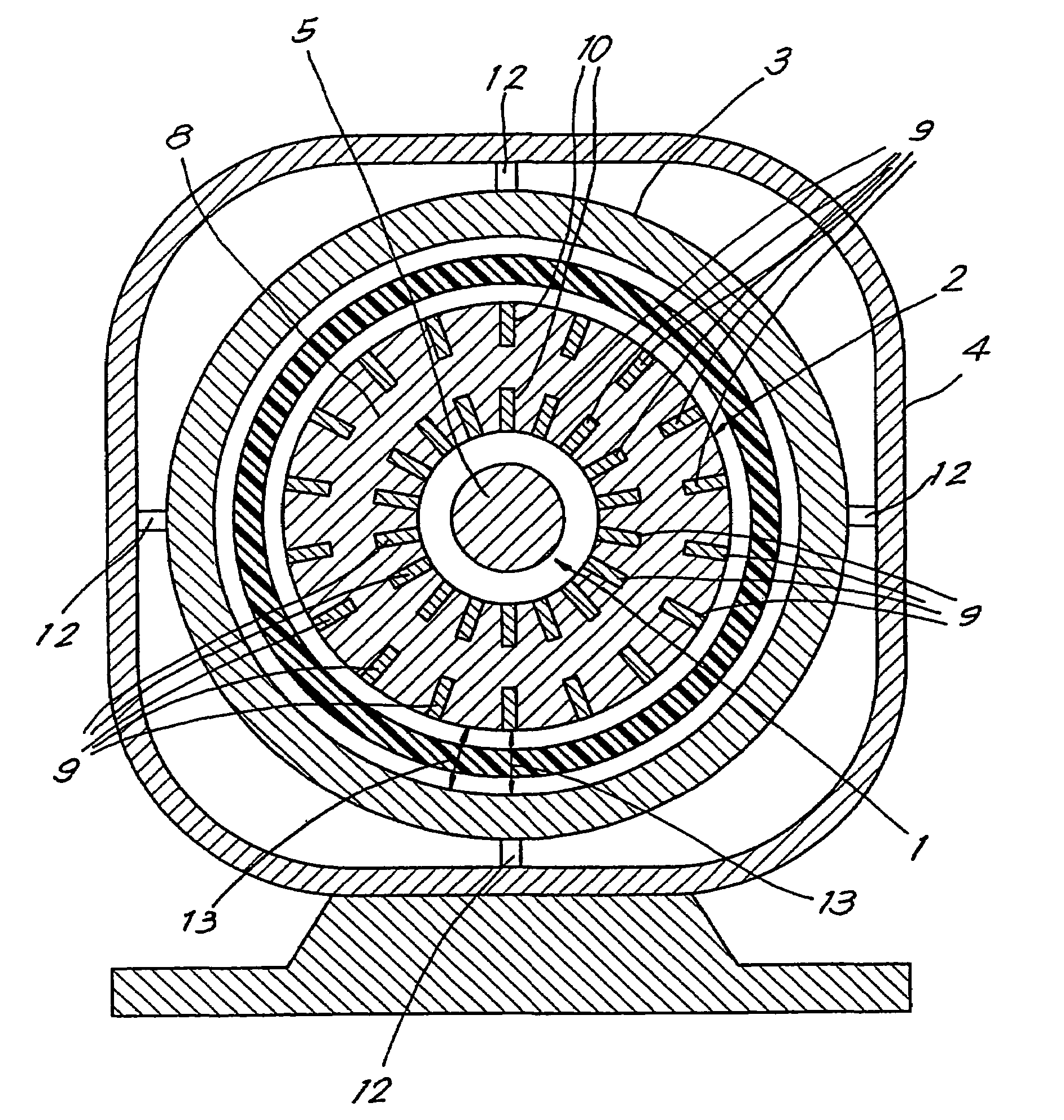

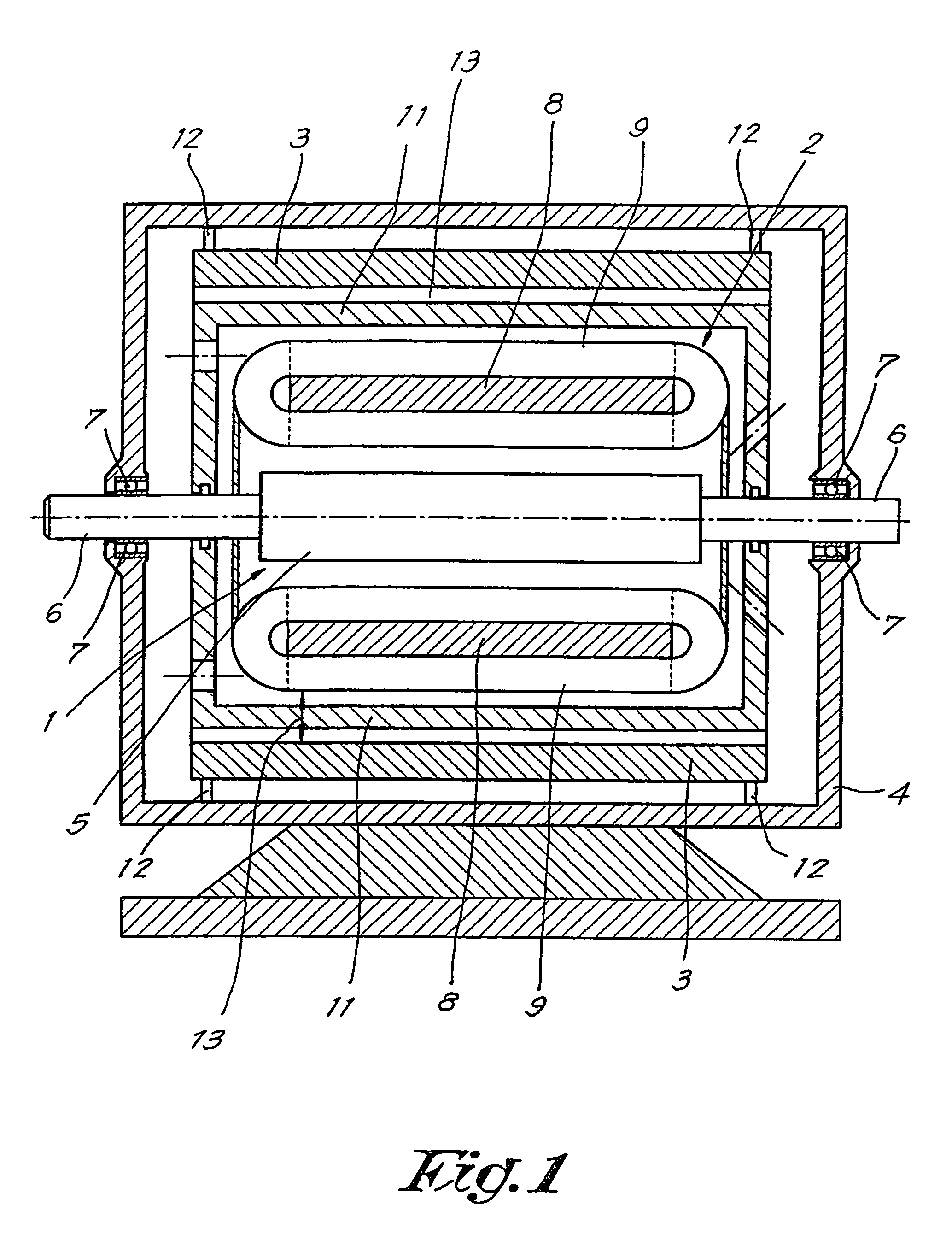

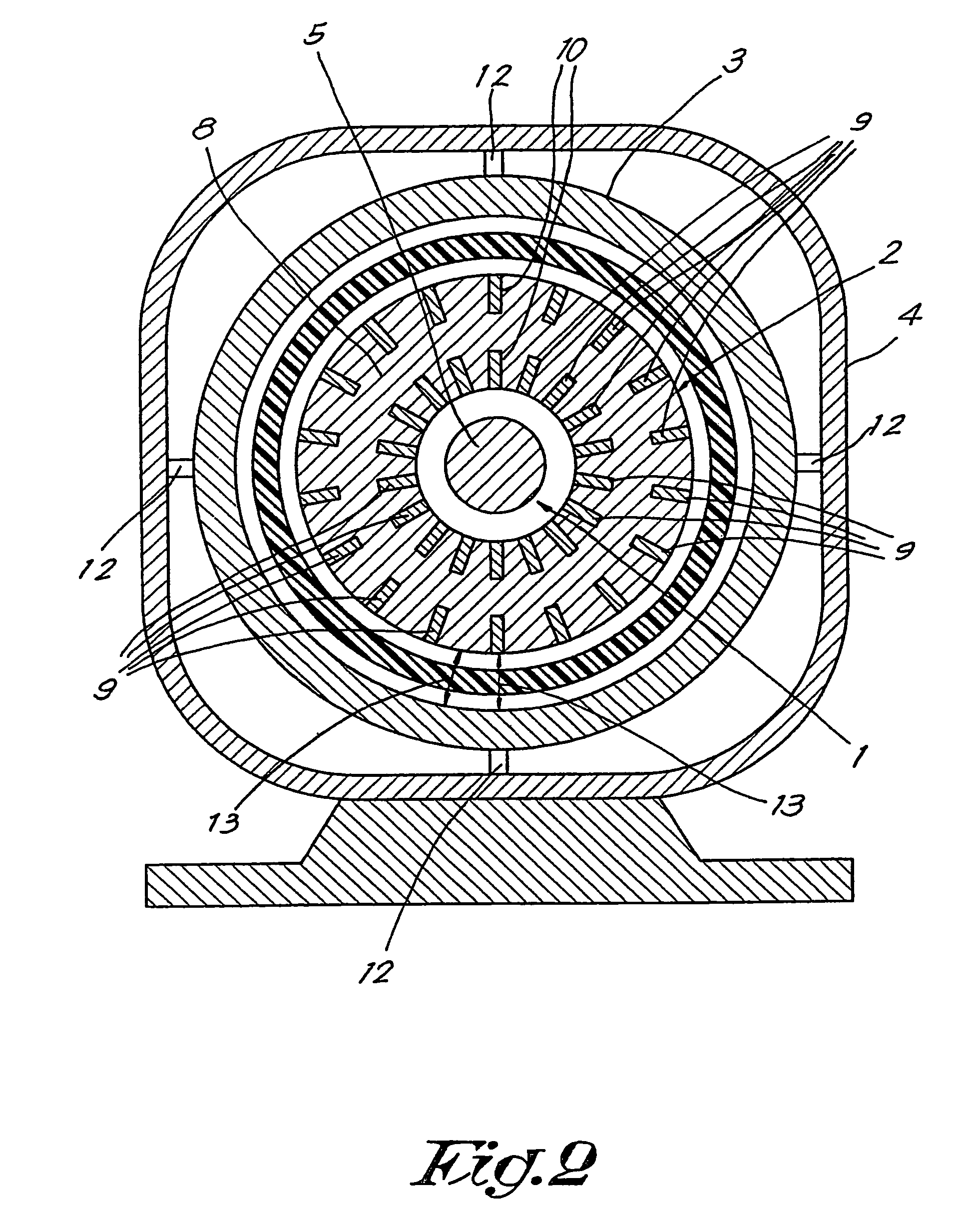

Electric motor

InactiveUS6989620B2Prevent leakageIncrease spaceSynchronous machine detailsMagnetic circuit stationary partsLeakage inductanceElectric motor

The invention relates to an electric motor, in particular for high speed operation, comprising a motor housing (4); inside the housing (4), a stator (2) having a core (8) and windings (9) toroidally wound on the core (8); and a rotor (1) inside the stator (2). The motor comprises an inductance controlling ring (3) in soft-magnetic material around the stator core (8), increasing for each phase the leakage inductance and forming for each phase an integrated filter inducatnce (L1, L2, L3) outside the core (8) of the stator (2) but still inside the motor housing (4).

Owner:ATLAS COPCO AIRPOWER NV

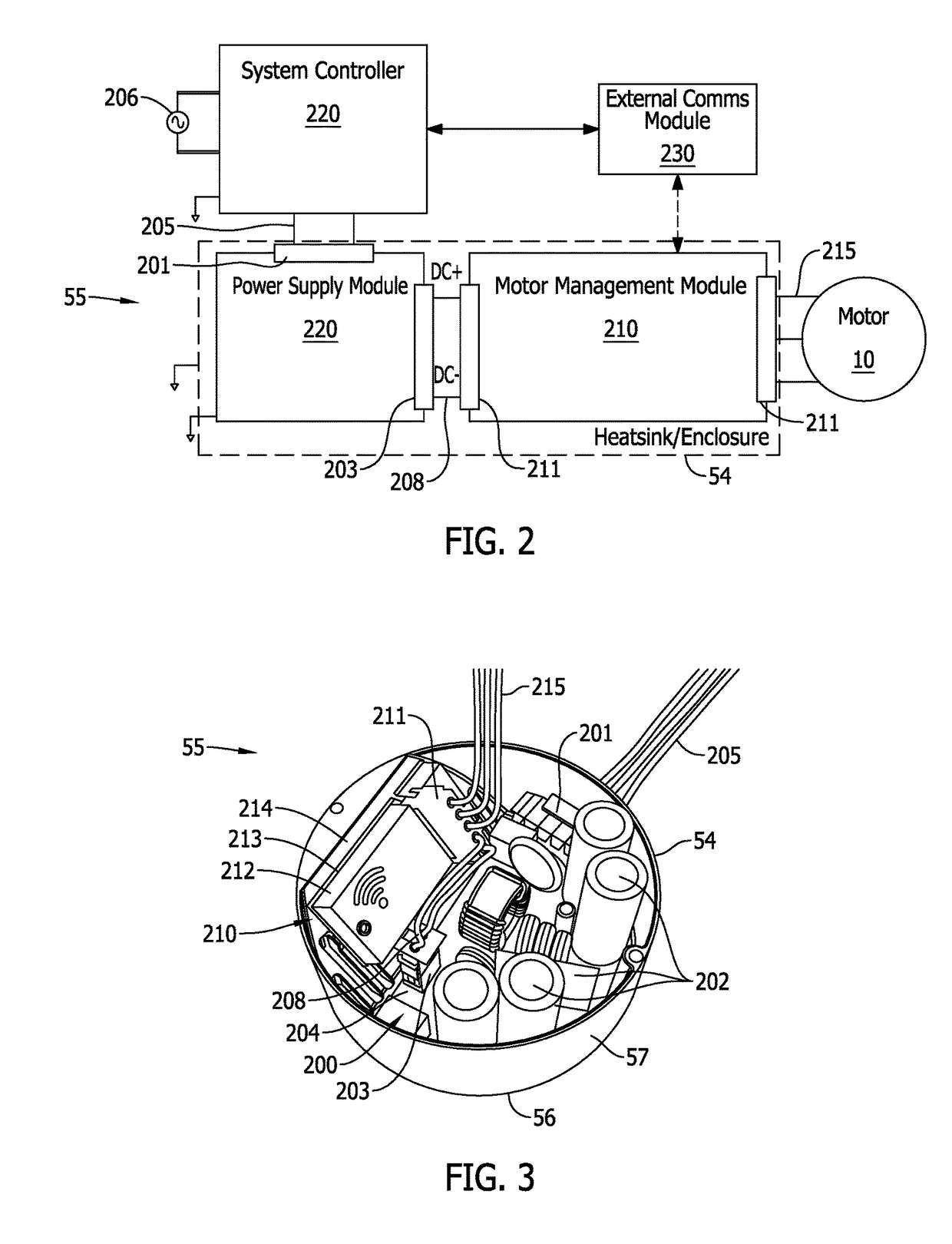

Electric motor controller for high-moisture applications and method of manufacture

ActiveUS20170310187A1Association with control/drive circuitsAC motor controlPower processingControl system

An electric motor control system and methods of manufacture are provided. The system includes a power supply module including a printed circuit board (PCB) and a plurality of power processing components configured to convert an input voltage into an output voltage. The system also includes a motor management module including an encapsulated, heat-sharing package for housing a plurality of moisture-sensitive driver components configured to convert the output voltage from the power supply module and provide output voltages for application to windings of the electric motor.

Owner:REGAL BELOIT AMERICA

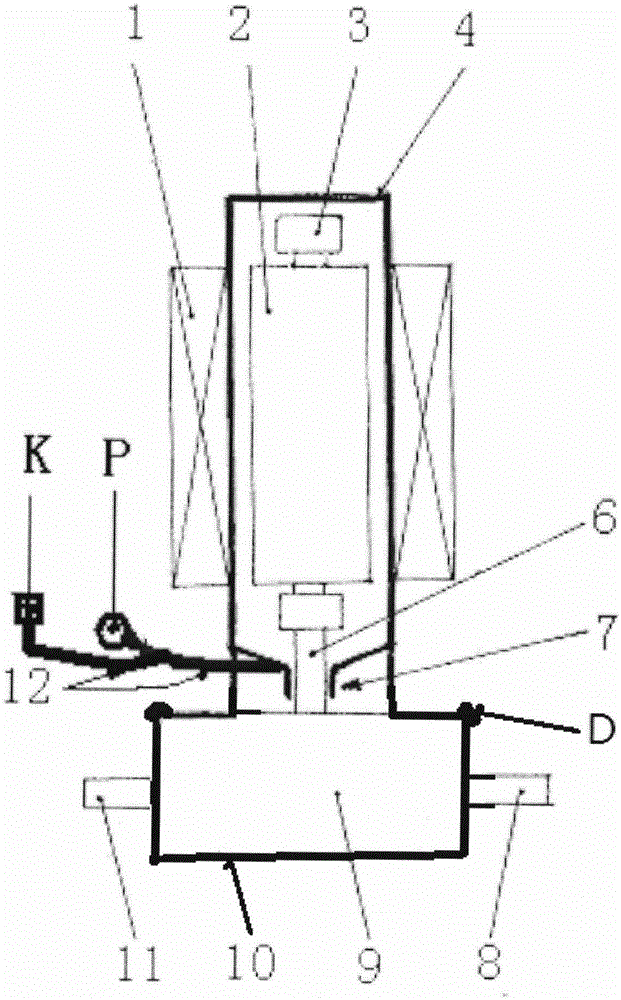

Pump structure capable of enabling liquid molecules in pump not to be leaked during operation through air jacking sealing and including immersion pump and application method of pump structure

InactiveCN106438392A"Great value for moneyPenetration rate slowed downPump componentsPump installationsDisplay deviceEngineering

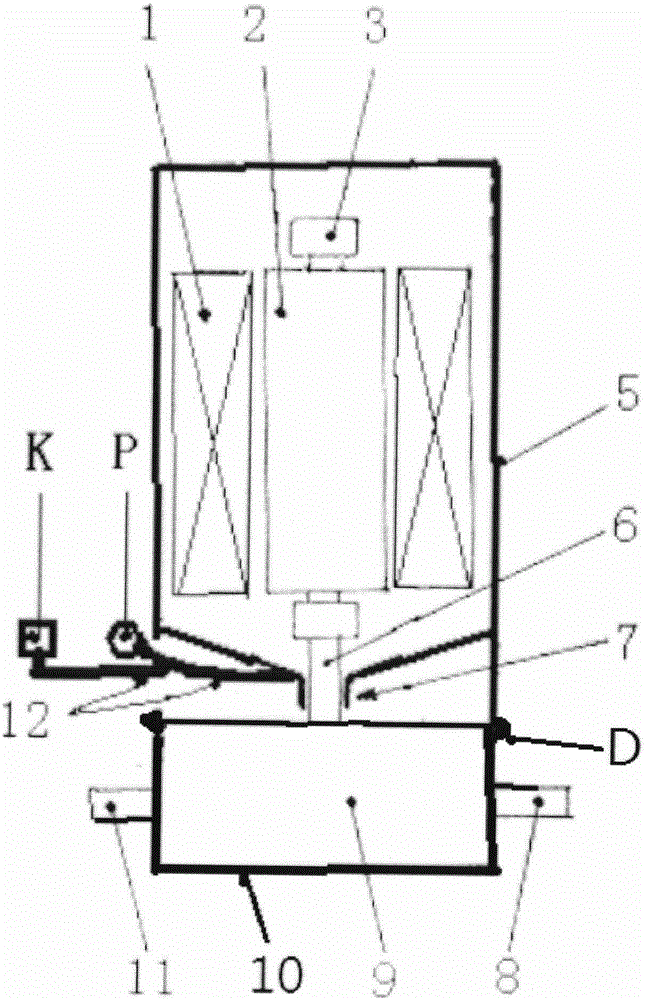

The invention discloses a pump structure capable of enabling liquid molecules in a pump not to be leaked during operation through air jacking sealing and including an immersion pump and an application method of the pump structure. According to the structure, firstly, at least a rotor (2) is surrounded by a narrow metallic seal isolator (4) or a wide metallic seal isolator (5) in a stereoscopic manner, and a motor shaft seal (7), a charging connector mechanism (P) and a pressure display device connector (K) are arranged at the bottom of the narrow metallic seal isolator (4) or the wide metallic seal isolator (5); secondly, the periphery and the bottom for forming a liquid pump (9) are surrounded by a nondetachable metallic seal structure (10) in a stereoscopic manner; and all joint gaps of a full-sealed metallic seal isolation cavity of the pump structure are achieved through a welding process. Due to the fact that the underwater one-time working and idling duration cumulative time of the pump structure depends on the service life (about 30 years) of a motor and the infinite diving depth, and the extremely high cost performance is achieved, conditions are created for the pump structure to become an upgrade product of an immersible pump, and the structure is probably more suitable for a common water pump.

Owner:CHINA JILIANG UNIV

Rotary electric machine

ActiveUS20150333595A1MinimizationAssociation with control/drive circuitsAssociation with grounding devicesElectric machineElectromagnetic interference

A rotary electric machine having a stator and a rotor, in addition to an electric control device and a connection device which comprises at least one coupling element for electrically connecting the control device to one or several electrical lines and a mass element provided to connect to an electric mass potential. In order to improve the machine with respect to electromagnetic interference, the stator is connected to the mass element by a contact bridge which has a first securing section and a second securing section in addition to a bridge element arranged between the securing sections and includes a single-piece spring steel sheet which is at least partially sinuous.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

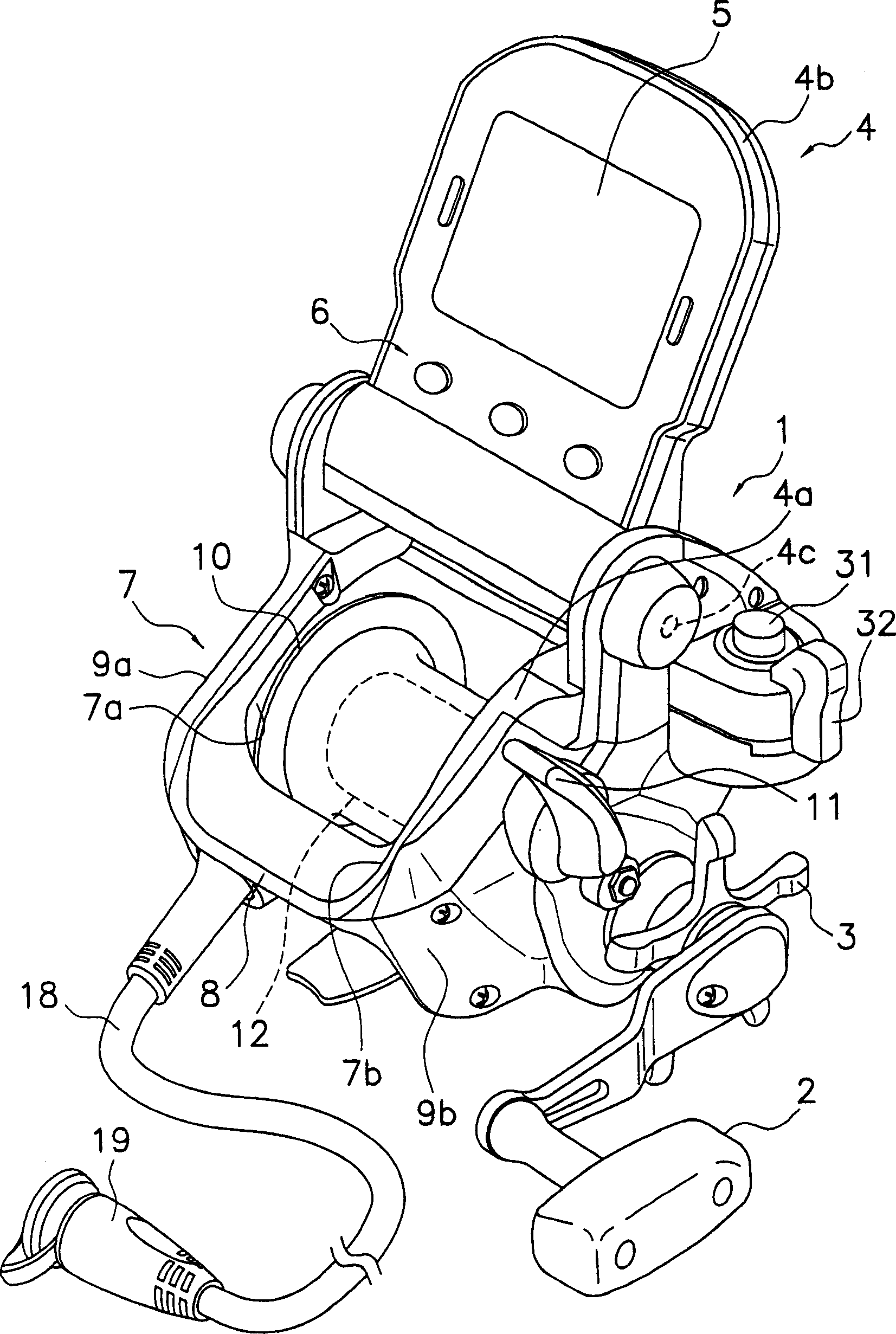

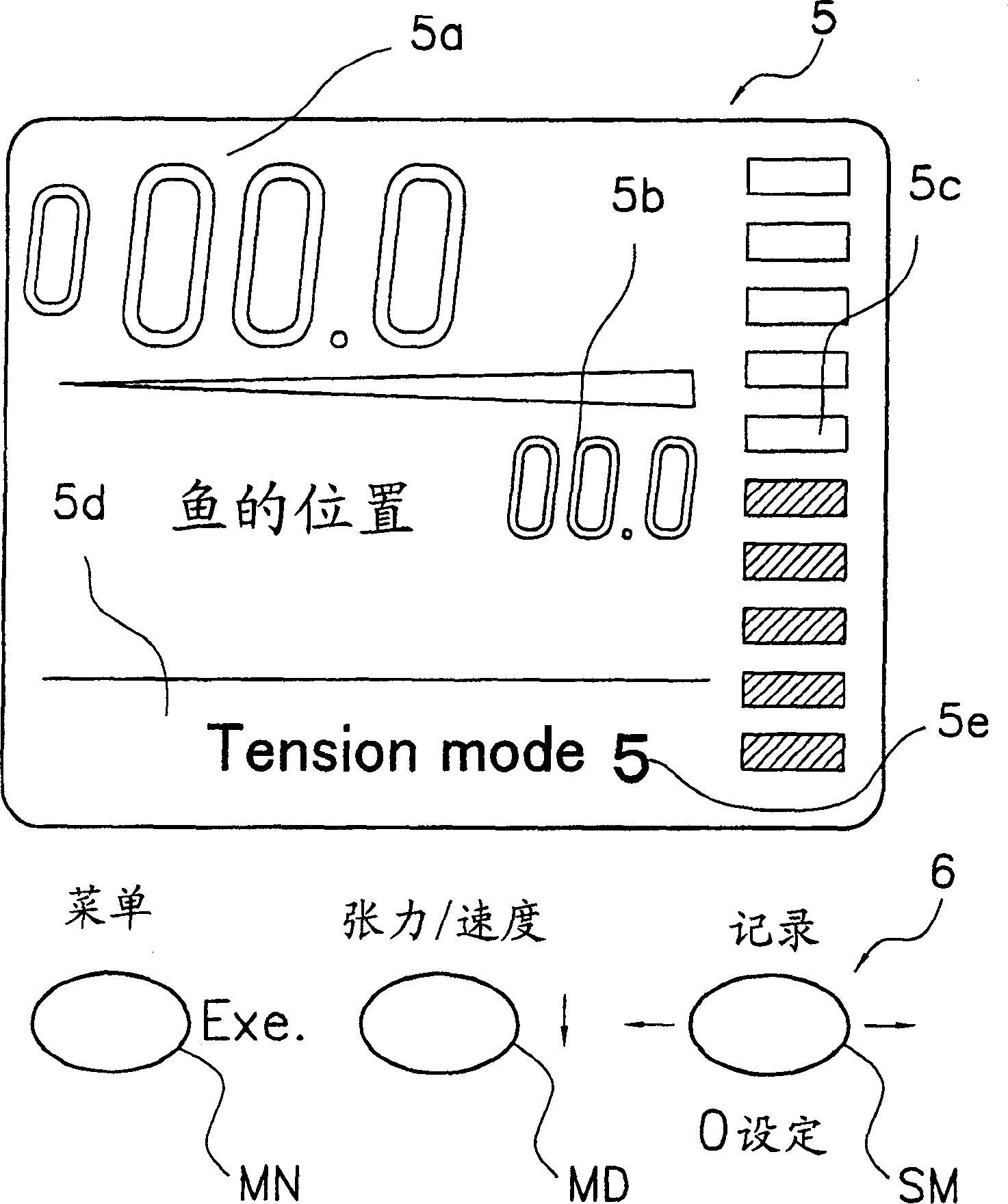

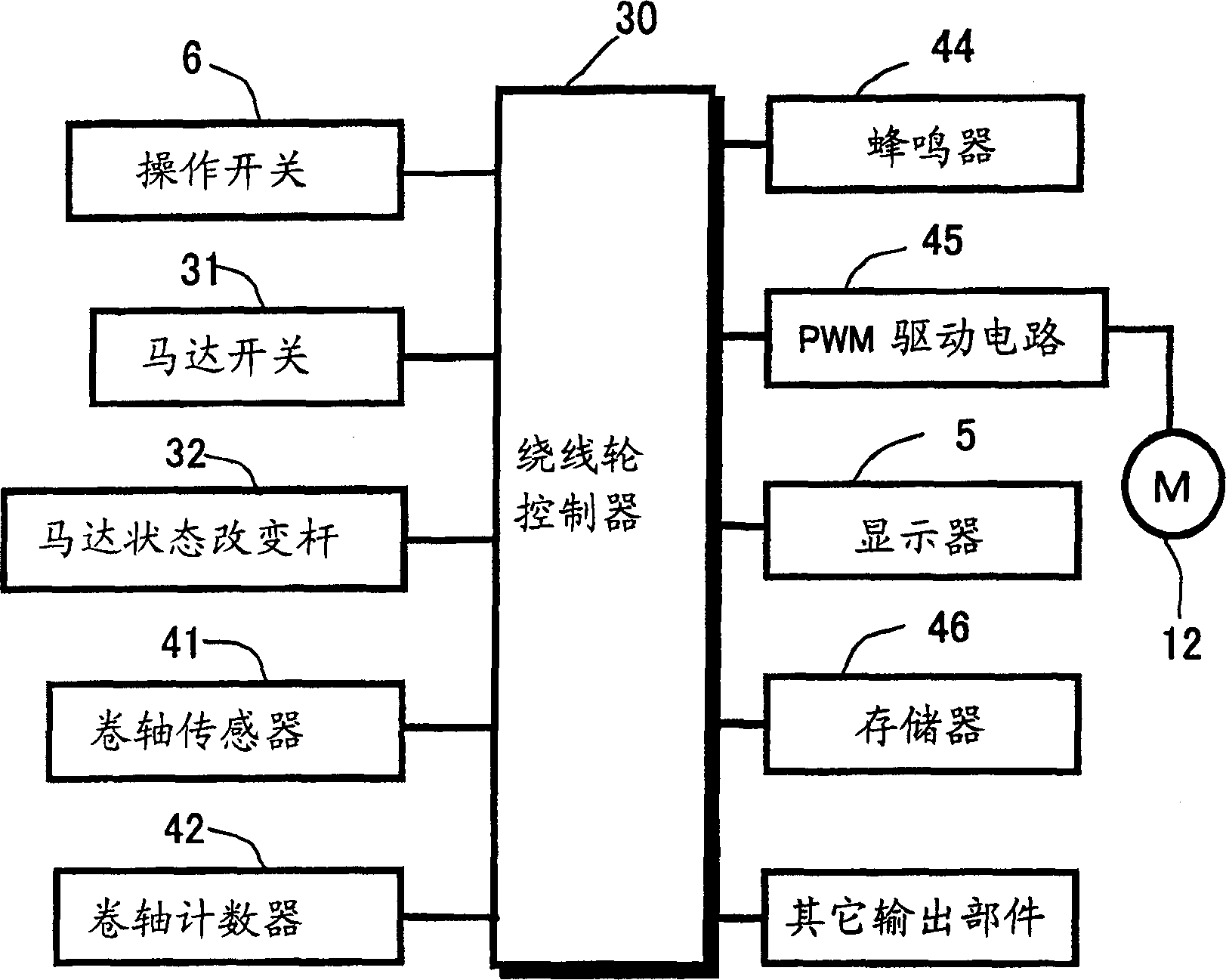

Motor control device for motor driven reel

Provided is a motor controller of an electric reel, which does not give a trouble to outer equipment disposed close to the motor controller. In the motor of the electric reel, a varistor 66 for reducing noises is built. The varister 66 is built in the motor 12, and connected to a terminal of the motor in parallel. A PWM-driving circuit 45 for PWM-driving the motor 12 is connected to a choke coil for reducing noises. The choke coil 65 is disposed in the PWM-driving circuit 45 and connected in parallel to the motor 12. The choke coil 65 and the varister 66 are noise-reducing elements for reducing the noises of the motor 12.

Owner:SHIMANO INC

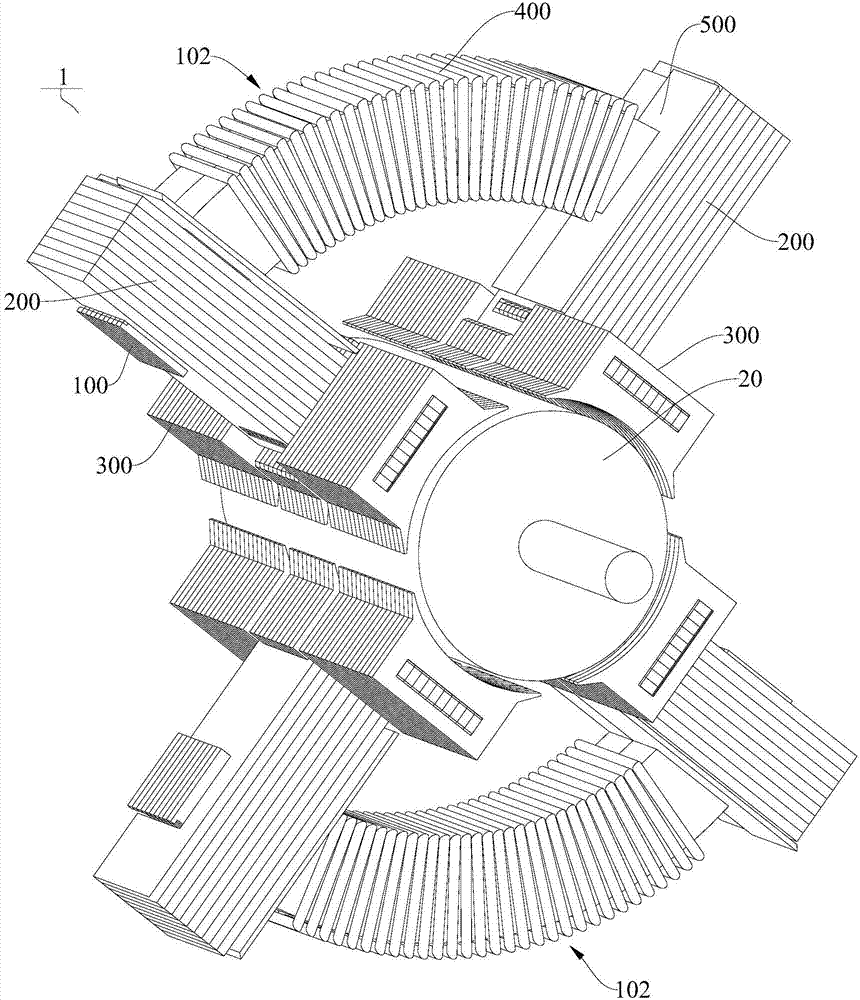

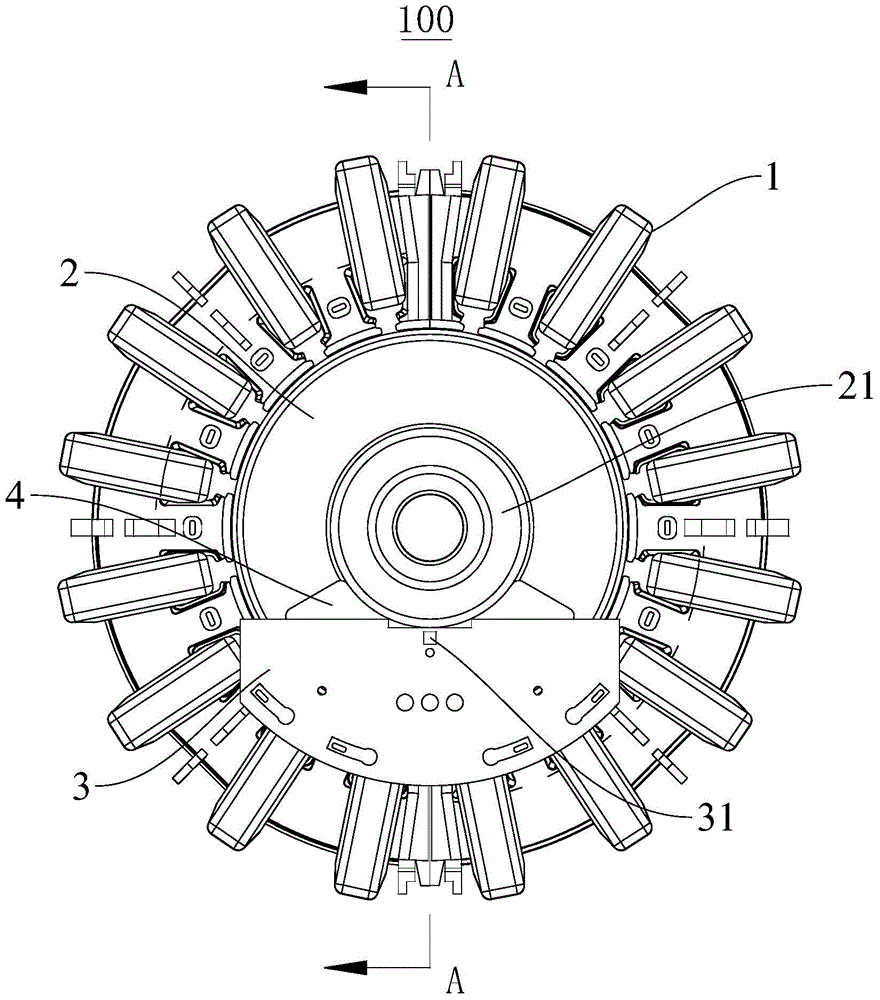

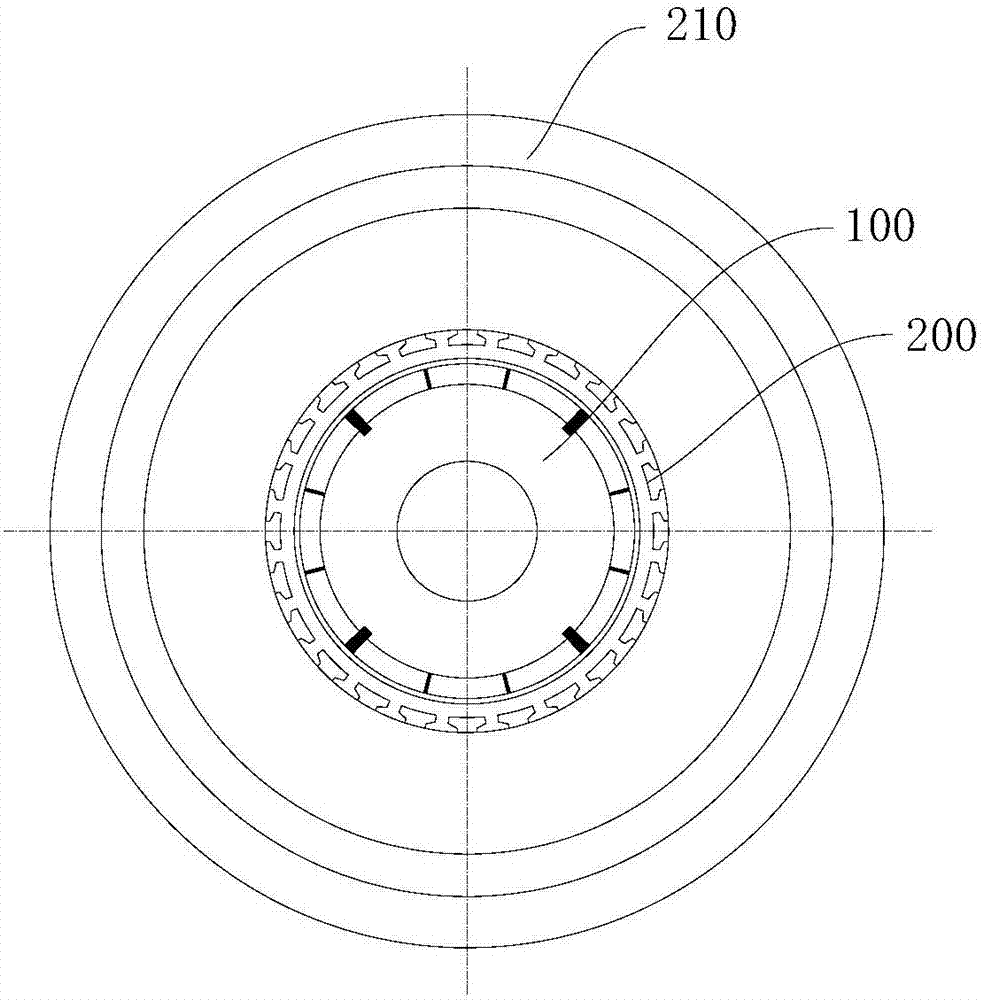

Stator iron core, stator and motor

ActiveCN106961169AImprove the magnetic effectLow costMagnetic circuit stationary partsShielding from electromagnetic fieldsPunchingEngineering

The invention discloses a stator iron core, a stator and a motor. The stator iron core is arranged on the periphery of the rotor and includes a plurality of stator individuals arranged in the circumferential direction in a spaced manner. Each stator individual includes a yoke part formed through stacking a plurality of yoke part punching sheets together; two main tooth parts clamped at the two circumferential ends of the yoke part and formed by stacking a plurality of tooth part punching sheets perpendicular to the yoke part punching sheets together, wherein each main tooth part is therein provided with an extension part extending along the axial direction of the yoke part and having at least one end protruding from the main tooth part, and a closed-mouth groove penetrating through the main tooth part in the stacking direction of the tooth part punching sheets; a main tooth boot part formed through stacking a plurality of main tooth boot punching sheets perpendicular to the tooth part punching sheets together and provided with a clip tongue through arranging an open groove whose opening direction is parallel with the stacking direction of the tooth part punching sheets, wherein the clip tongue is clamped in the closed-mouth groove from one side of the closed-mouth groove; an end tooth boot part formed through stacking a plurality of end tooth boot punching sheets together and clamped on the extension part. According to the embodiment of the invention, the magnetic concentrating capability of the stator iron core is enhanced and the cost is reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

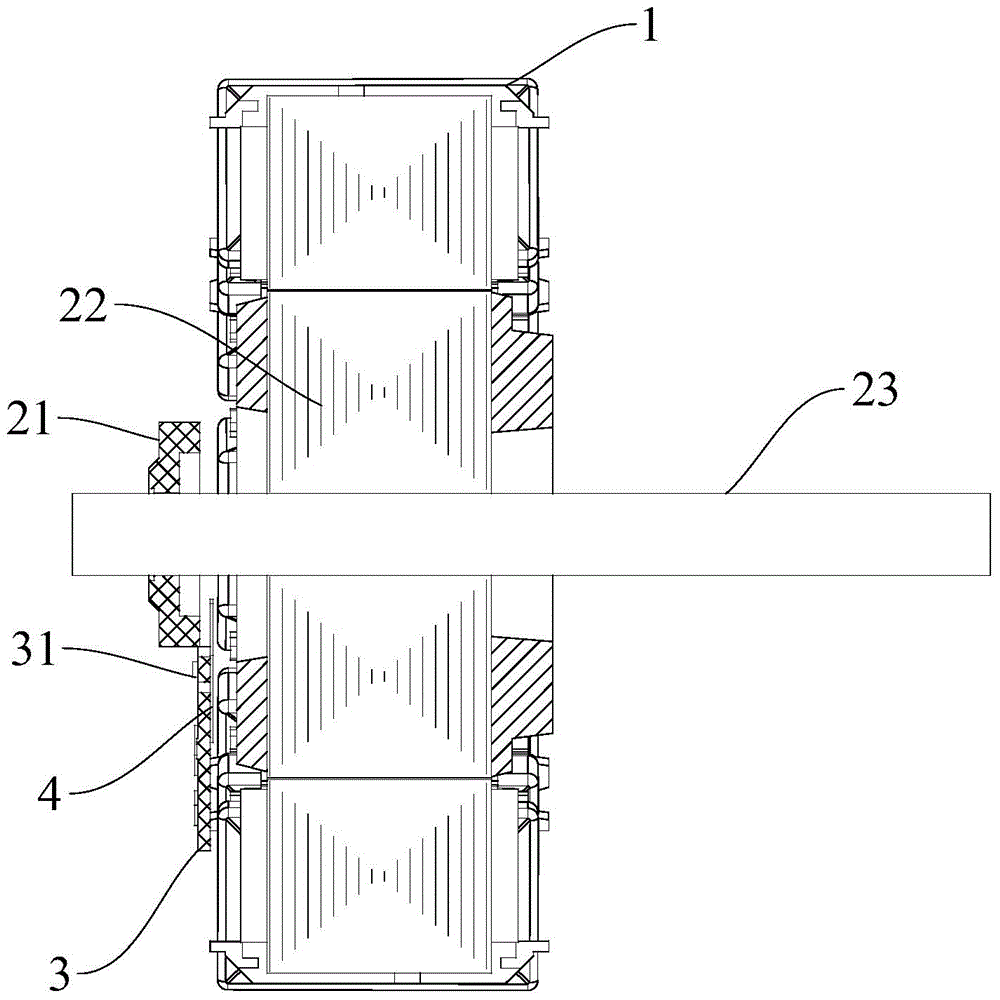

Induction machine

ActiveCN104617711AGuaranteed stabilityAssociation with control/drive circuitsShielding from electromagnetic fieldsPrinted circuit boardMagnetic loop

The invention discloses an induction machine. The induction machine comprises a stator, a rotor, a printed circuit board and a shielding element; the rotor is rotatably arranged in the stator and a magnetic ring is arranged on the rotor; the printed circuit board is arranged on the stator and located at one end, adjacent to the magnetic ring, of the stator, and a hall device is arranged on the printed circuit board; the shielding element is arranged on the printed circuit board to shield leakage flux of the stator and the leakage flux of the rotor so that the hall device is only capable of sensing the magnetic field of the magnetic ring. According to the induction machine, the shielding element is arranged on the printed circuit board to effectively avoid the superposition of the magnetic field of the induction motor and the magnetic field of the magnetic ring, and therefore, the stability of the magnetic field of the magnetic ring is guaranteed, and furthermore, the stability of hall output signals is ensured.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

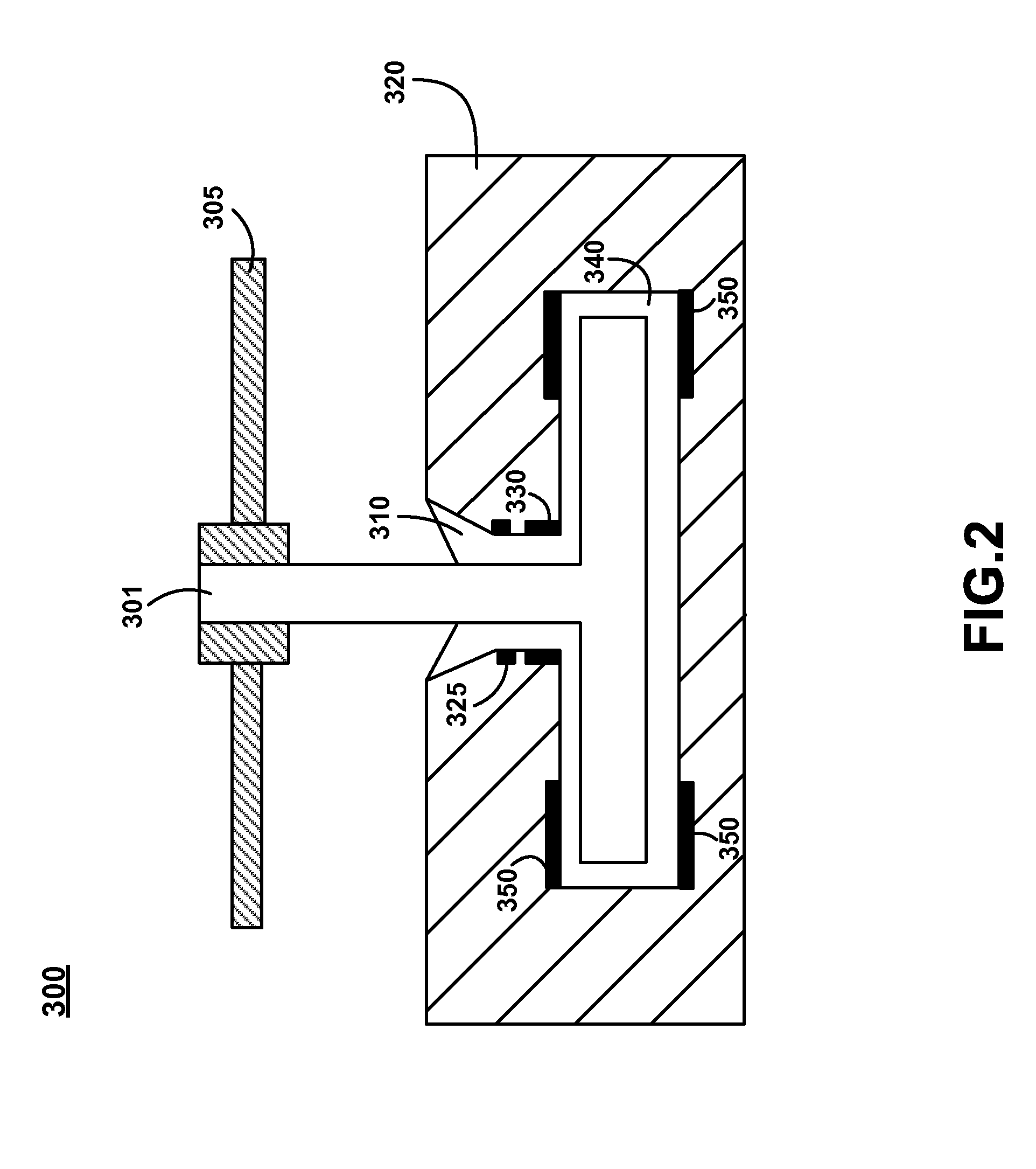

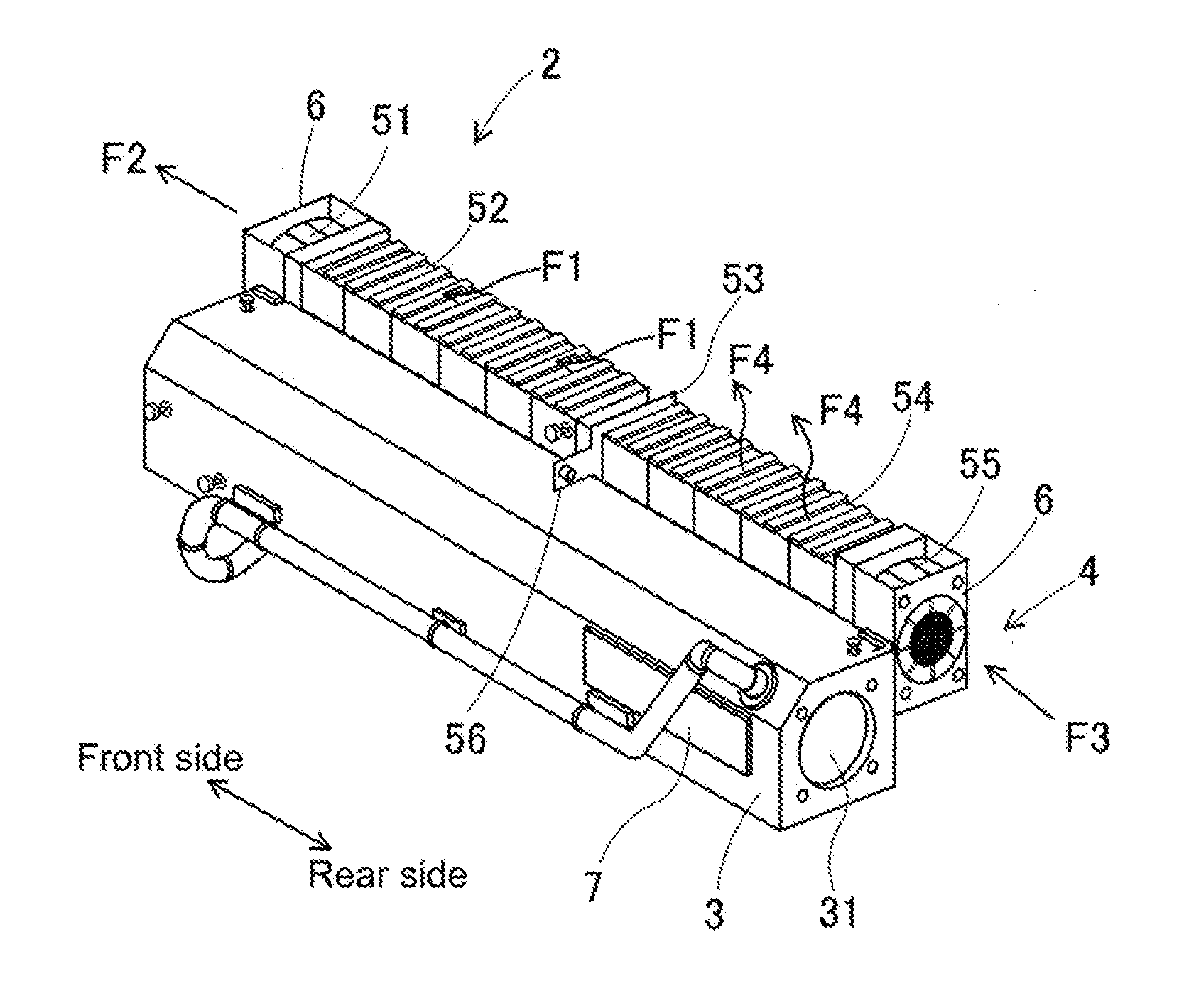

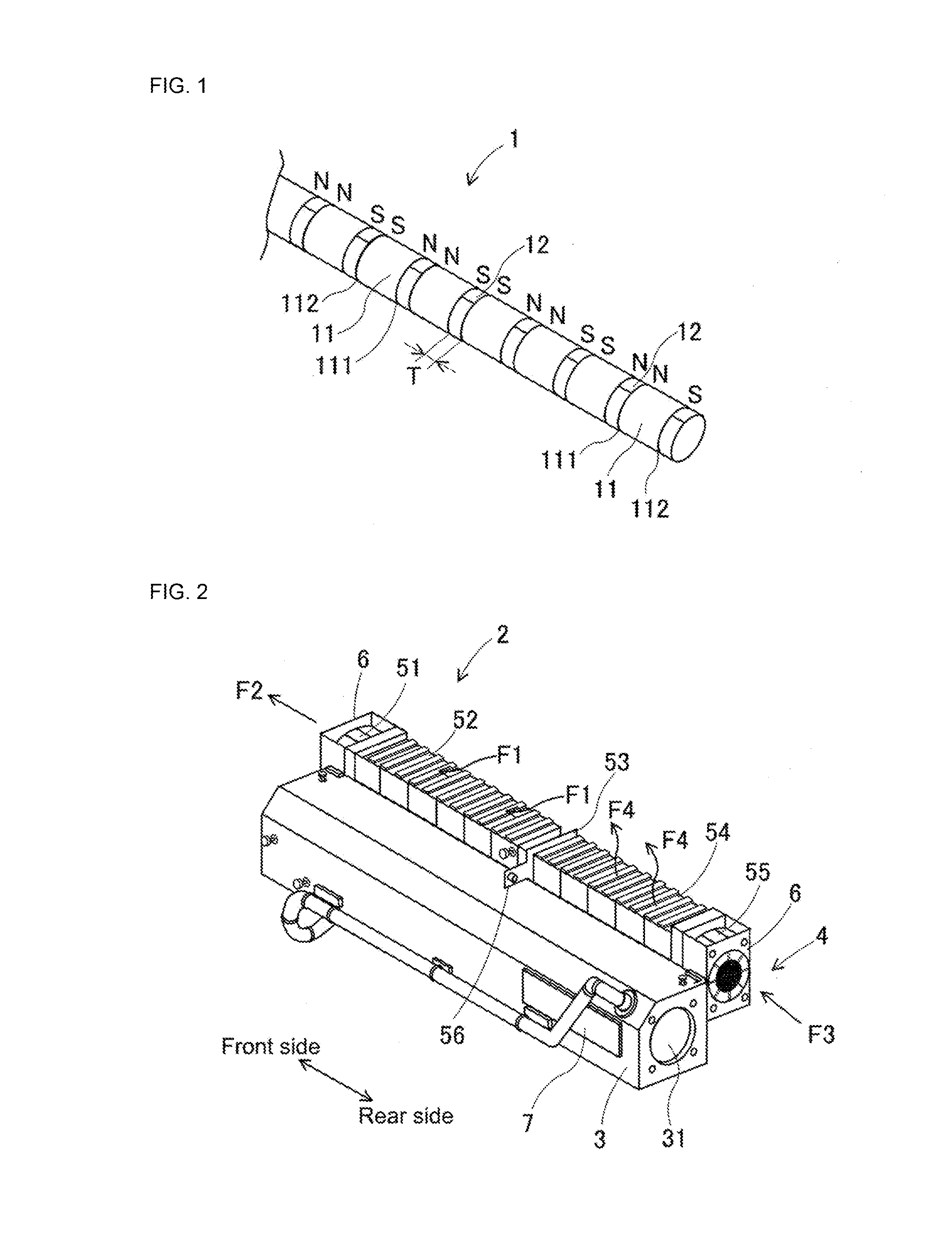

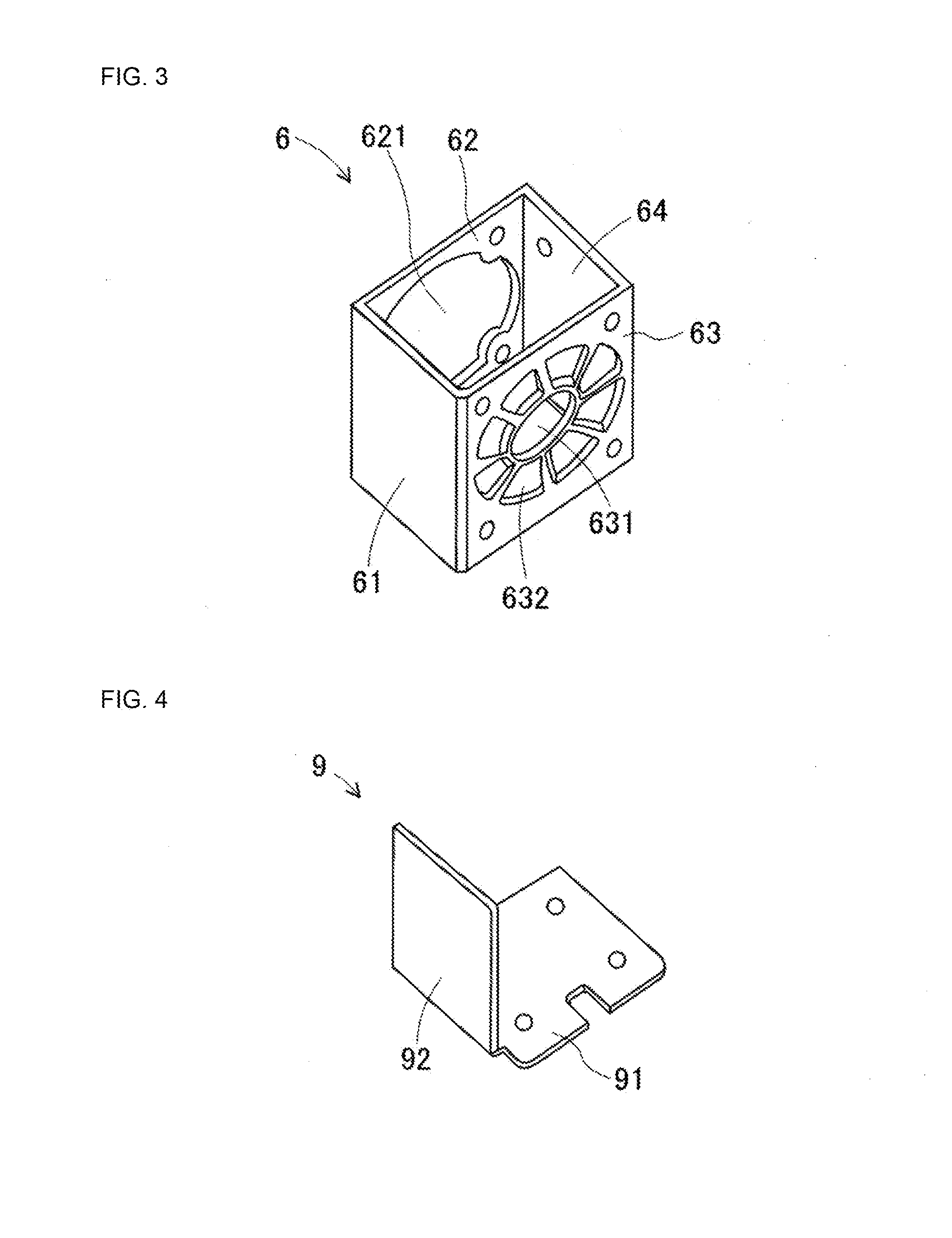

Linear motor device

ActiveUS20160301287A1Improve the magnetic shielding effectMagnetic attractive force can be enhancedReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsPower flowEngineering

A linear motor device comprising: a path member including a magnet extending in a movement direction; and a moving body including a coil that is movably mounted on the path member; the linear motor device generates thrust in the movement direction between the magnet and the coil by current being passed through the coil; the moving body further includes a magnetic shielding target object, and a magnetic shielding member formed from strongly magnetic material that shields the magnetic shielding target. The magnetic shielding member includes a parallel shielding plate provided parallel to the movement direction between the magnetic shielding target object and the magnet, and a perpendicular shielding plate provided extending away from the magnet in a direction perpendicular to the movement direction at at least one of a front edge and a rear edge of the parallel shielding plate in the movement direction.

Owner:FUJI MASCH MFG CO LTD

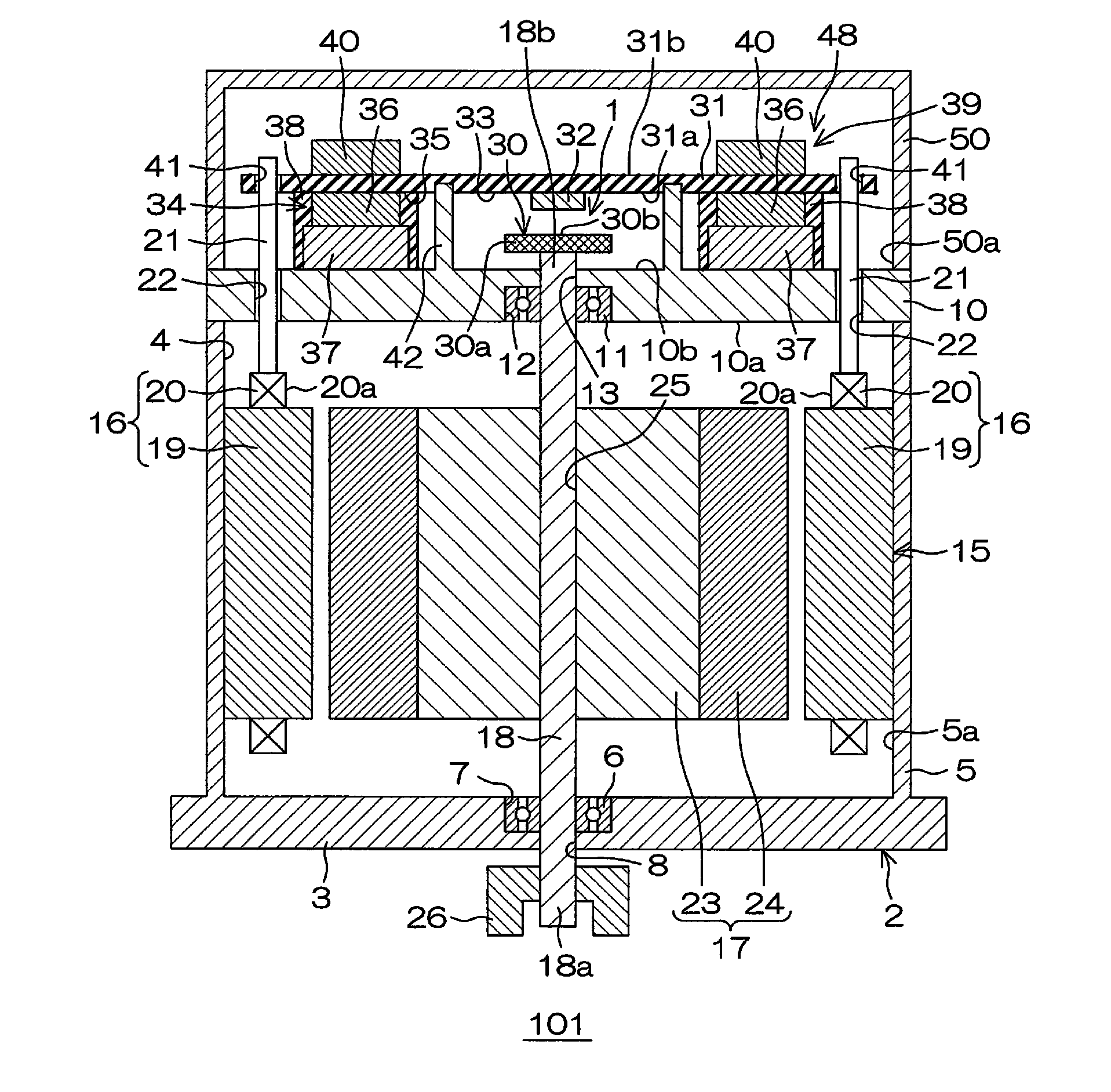

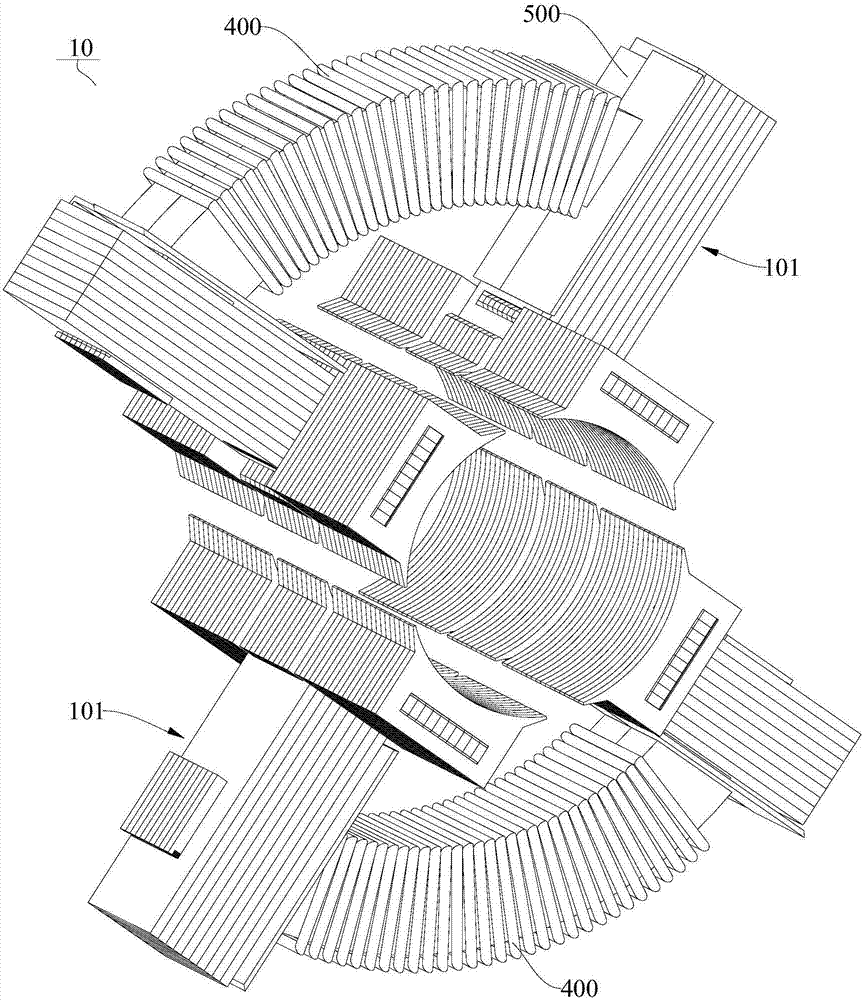

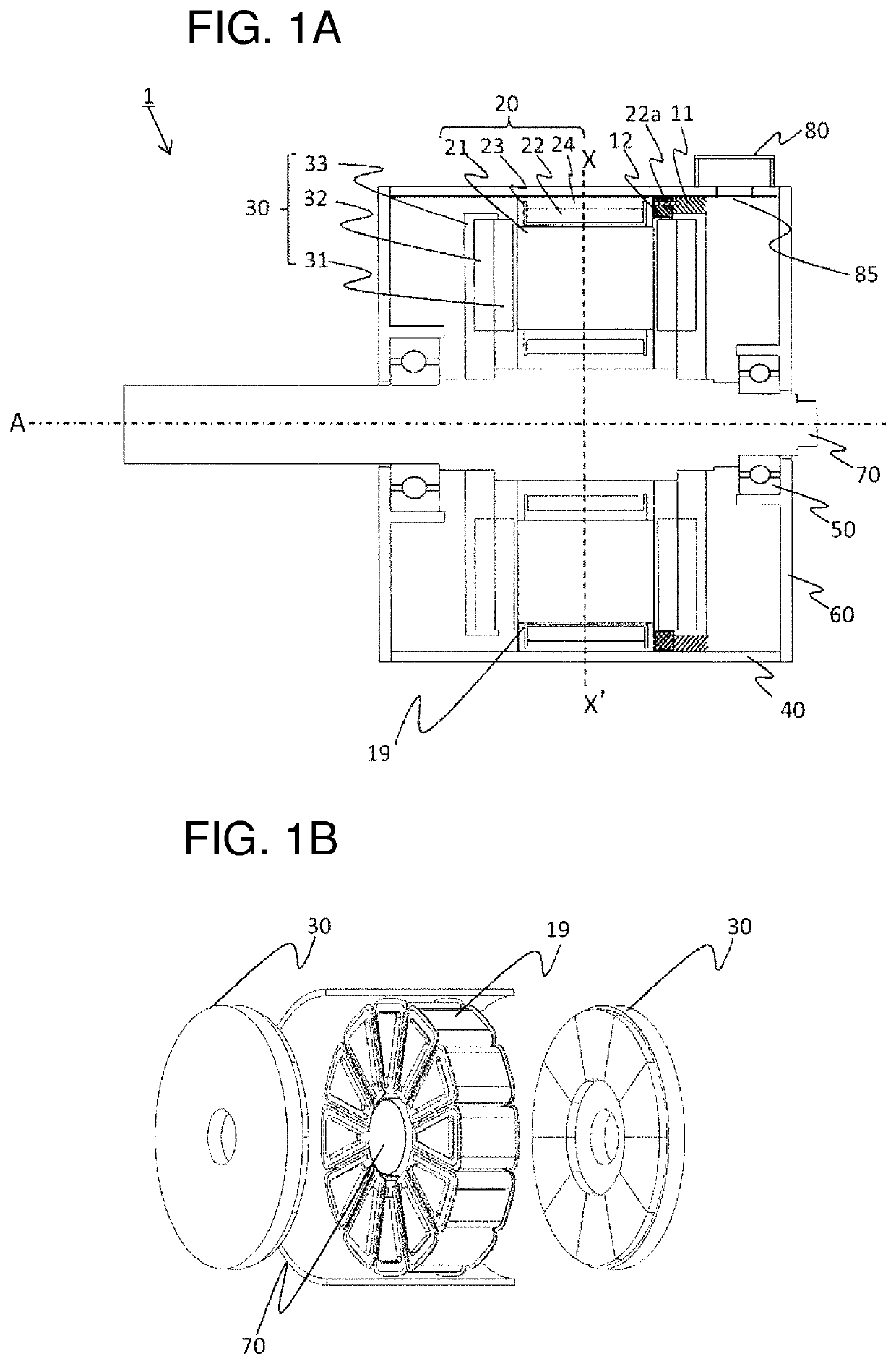

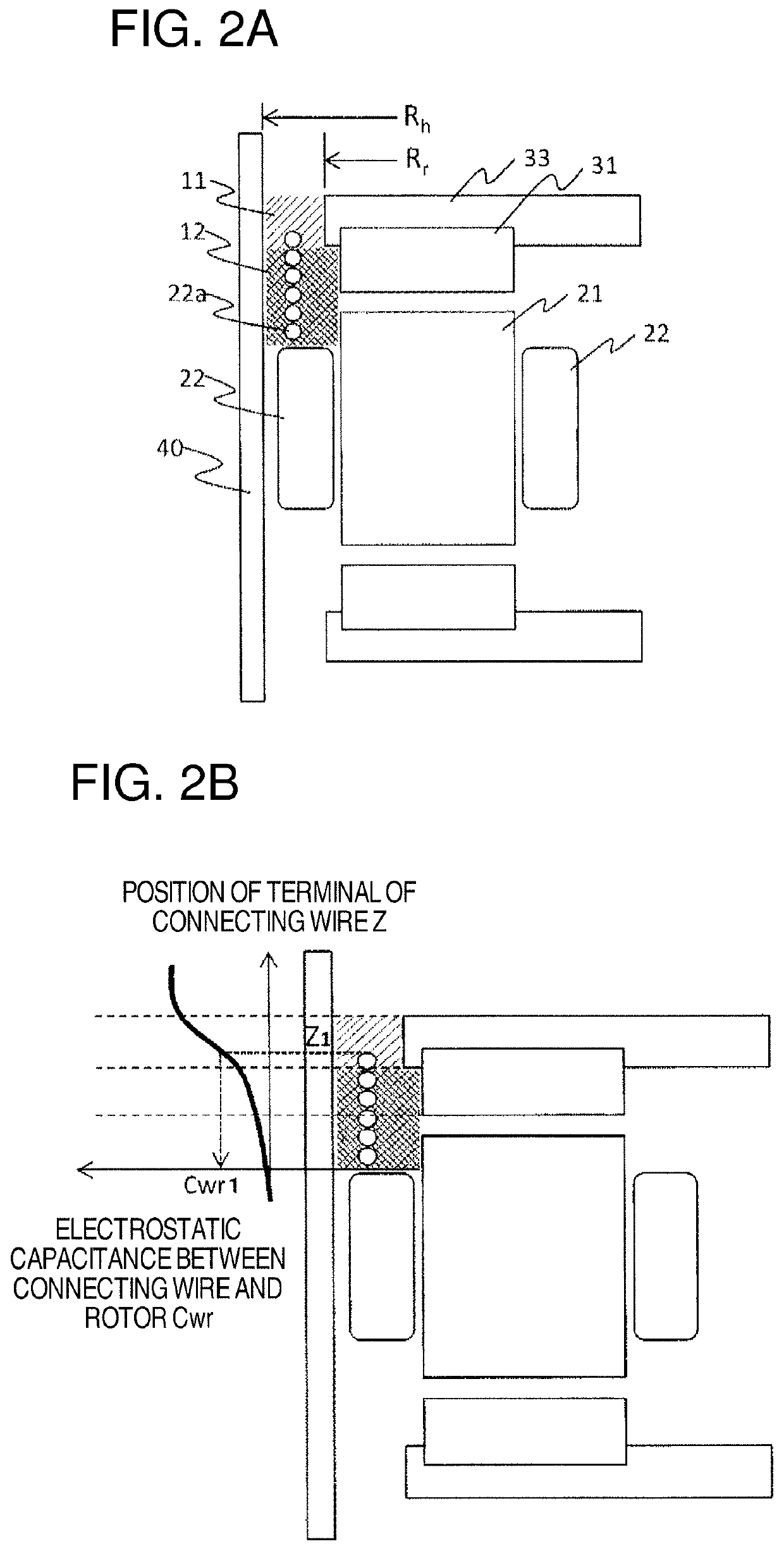

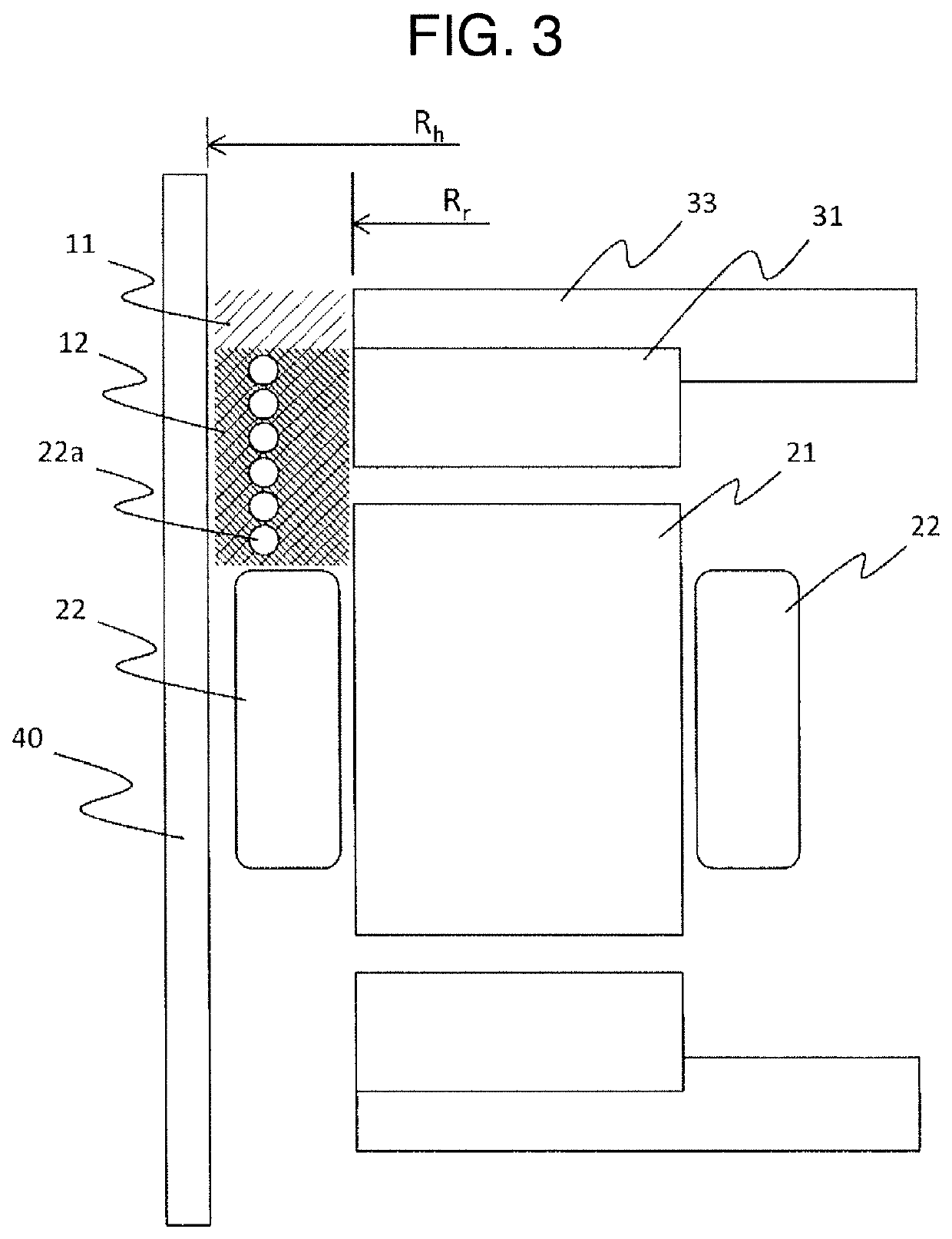

Axial-gap dynamo-electric machine

ActiveUS11165312B2Reduce shaft voltageImprove reliabilityWindingsAssociation with grounding devicesElectric machineEngineering

This invention reduces the shaft voltage of an axial-air-gap dynamo-electric machine while ensuring high output and high efficiency. Said axial-air-gap dynamo-electric machine comprises the following: a stator comprising a plurality of stator cores, each of which comprises a core and a coil, arranged in a circle around a shaft; a housing, the inside surface of which faces the stator radially; and at least one rotor, the surface of which faces the surface of the stator with a prescribed air gap interposed therebetween in the radial direction of the shaft. The rotor has, on the outside thereof, a conductive section comprising a conductive member. This axial-air-gap dynamo-electric machine has a first region where the inside surface of the housing faces the aforementioned conductive section radially and a second region, closer to the stator than the first region is, that extends to the coil side surfaces that face the rotor. The proportion of connecting wires in the second region is higher than in the first region.

Owner:HITACHI IND EQUIP SYST CO LTD

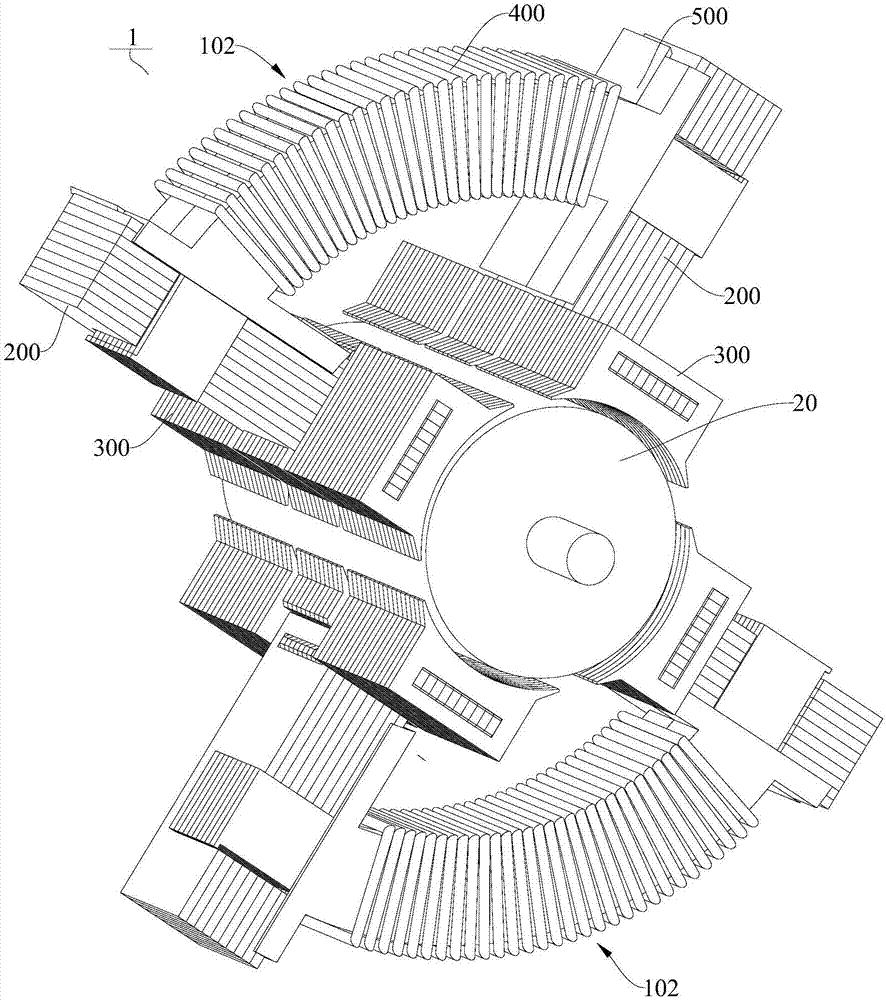

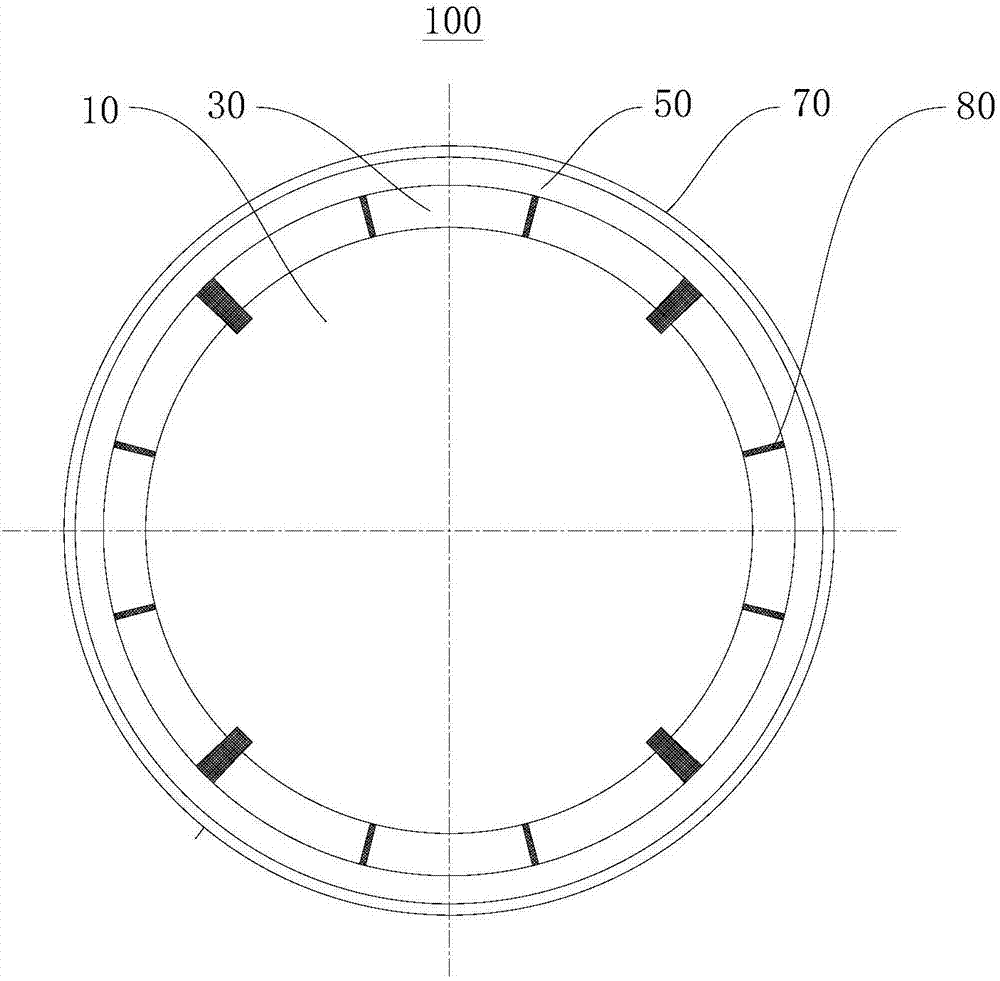

High speed permanent magnetism motor rotor and high speed permanent magnetism motor

PendingCN107425632ASolve lossSolve the temperature riseMagnetic circuit rotating partsShielding from electromagnetic fieldsInterference fitElectric machine

The invention provides a high speed permanent magnetism motor rotor and a high speed permanent magnetism motor, and relates to the motor making technical field; the high speed permanent magnetism motor rotor comprises the following units: a rotor iron core; a plurality of magnetic steels arranged in peripheral sections on the outer surface of the rotor iron core along the rotor iron core axis direction; a shielding layer wrapping the magnetic steel outer surface and in interference fit with the magnetic steels; a protection cover sheath wrapping the shielding layer outer surface; a sealing portion used for filling the magnetic steel inter-electrode gaps and sealing end faces of the magnetic steels on two ends of the whole high speed permanent magnetism motor rotor; the high speed permanent magnetism motor comprises a stator iron core and the high speed permanent magnetism motor rotor; the high speed permanent magnetism motor rotor is arranged in a space enclosed by the stator iron core; the high speed permanent magnetism motor rotor and the high speed permanent magnetism motor can solve the problems that a conventional motor rotor is large in eddy current loss, high in temperature rise, poor in heat radiation capability and low in rigidity; the high speed permanent magnetism motor and the high speed permanent magnetism motor rotor can be more conveniently manufactured with high efficiency, thus better adapting to the present usage demands.

Owner:NEW UNITED RAIL TRANSIT TECH

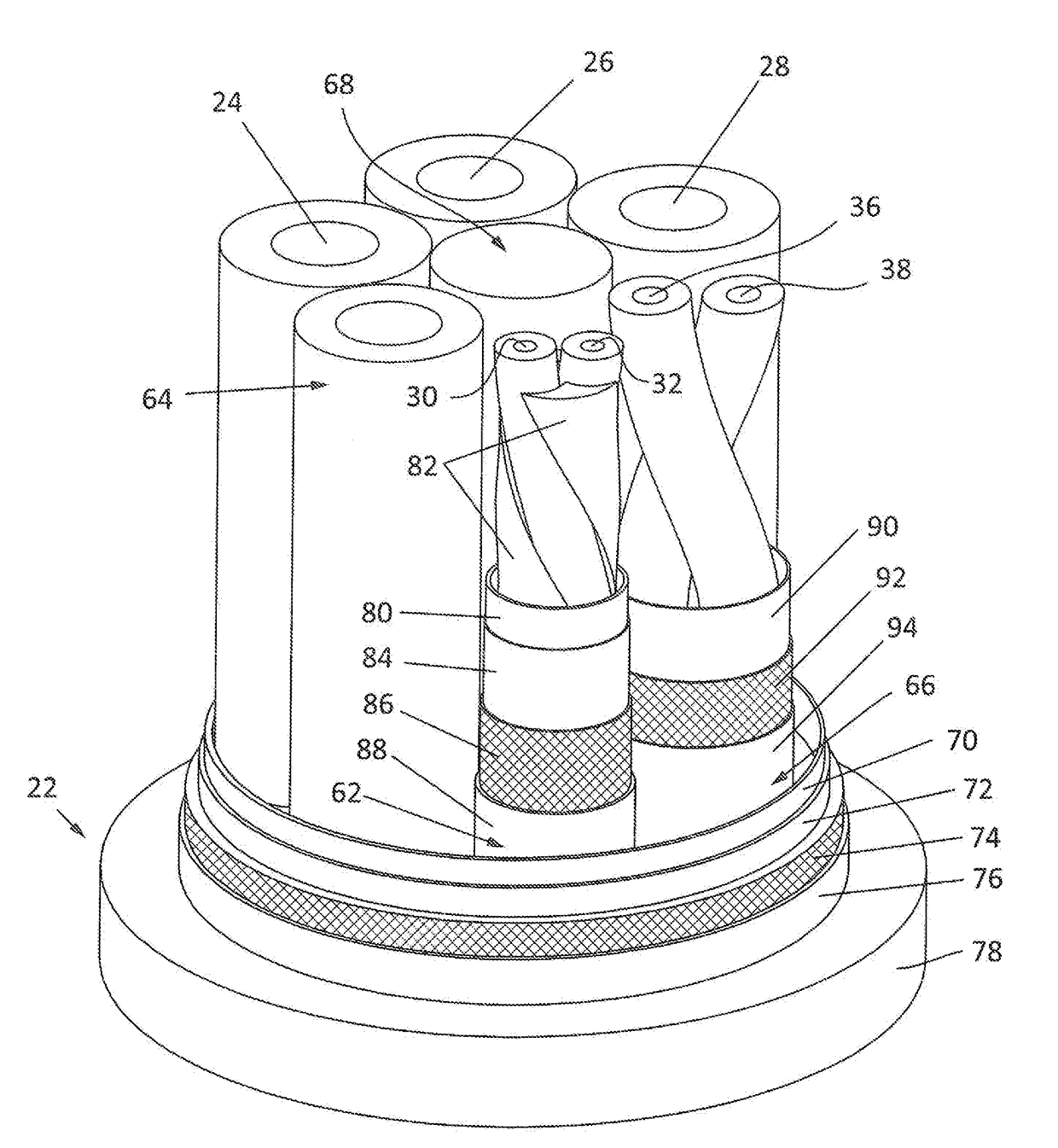

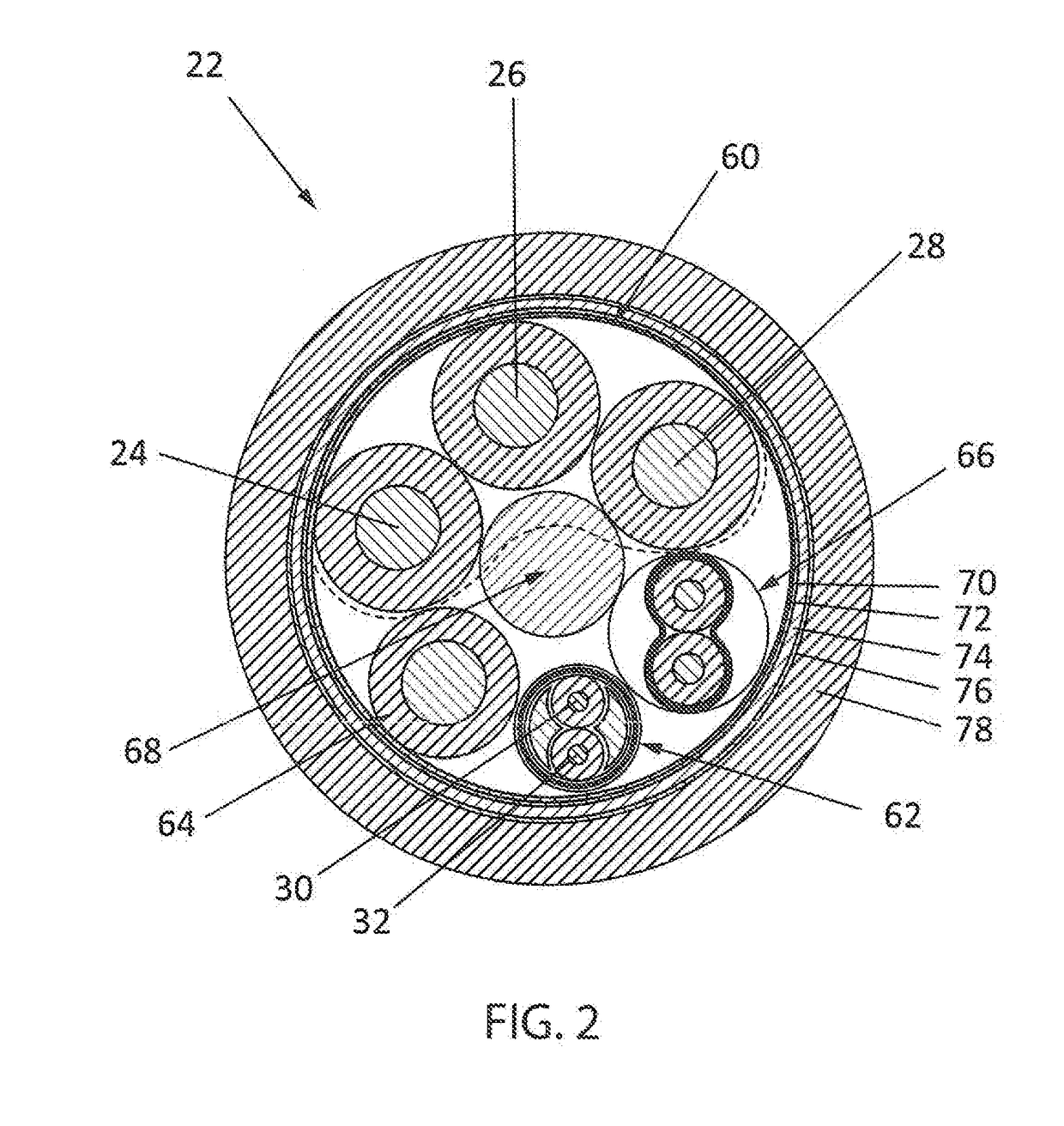

Combined Power and Communications Cable

ActiveUS20180151271A1Reduced cross sectionEasy to handleAssociation with control/drive circuitsPlastic/resin/waxes insulatorsElectric power transmissionElectrical conductor

Aspects of the present invention provide an improved cable having a reduced cross section while continuing to provide high voltage (noisy) power signals alongside low voltage (noise-susceptible) data signals. The improved cable can be used for power delivery and communications between a motor and a drive in an industrial control system. The reduced cross section advantageously improves handling. By providing separate groups between a group delivering the power signals and a group providing the data signals, thereby enforcing a physical separation, and by twisting together individual conductors of the group delivering the power signals with the group providing the data signals and the groups providing the separation, the reduced cross section can be achieved while continuing to minimize noise and interference onto the data signals due to the power signals.

Owner:ROCKWELL AUTOMATION TECH

On-board electric compressor

ActiveUS20200321836A1Reduce common mode noiseCompressorMultiple-port networksNoise reductionCapacitor

An on-board electric compressor that comprises: a housing; a compression unit; an electric motor; and an inverter device. The inverter device comprises: an inverter circuit that converts direct current power to alternating current power; and a noise reduction unit that is provided on an input side of the inverter circuit and that reduces common mode noise and normal mode noise that are included in the direct current power The noise reduction unit comprises: a common mode choke coil; and a smoothing capacitor that, in cooperation with the common mode choke coil, constitutes a low pass filter circuit. The common mode choke coil has: a core that has a first core part and a second core part; a first winding that is wound around the first core part; and a second winding that is wound around the second core part.

Owner:TOYOTA IND CORP

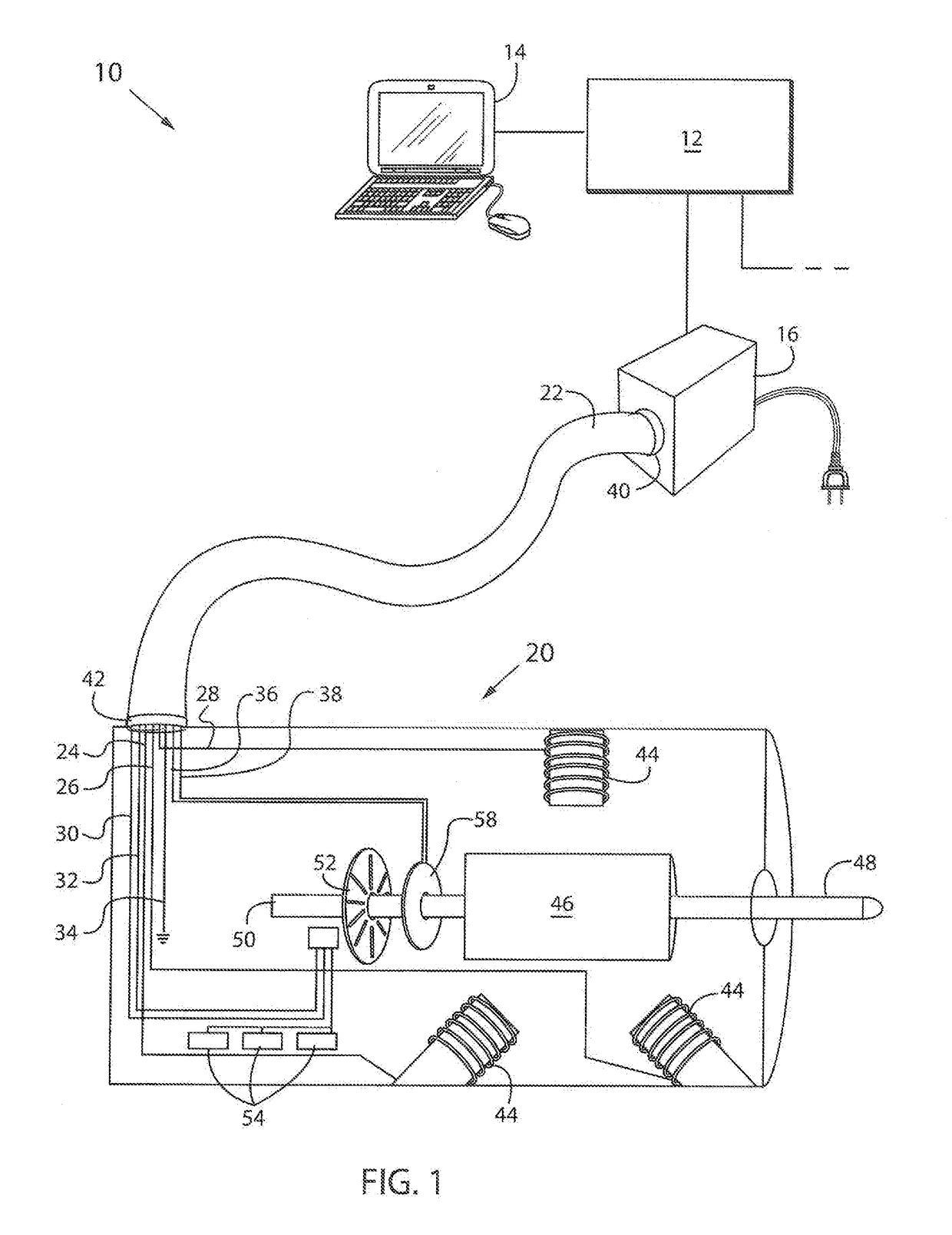

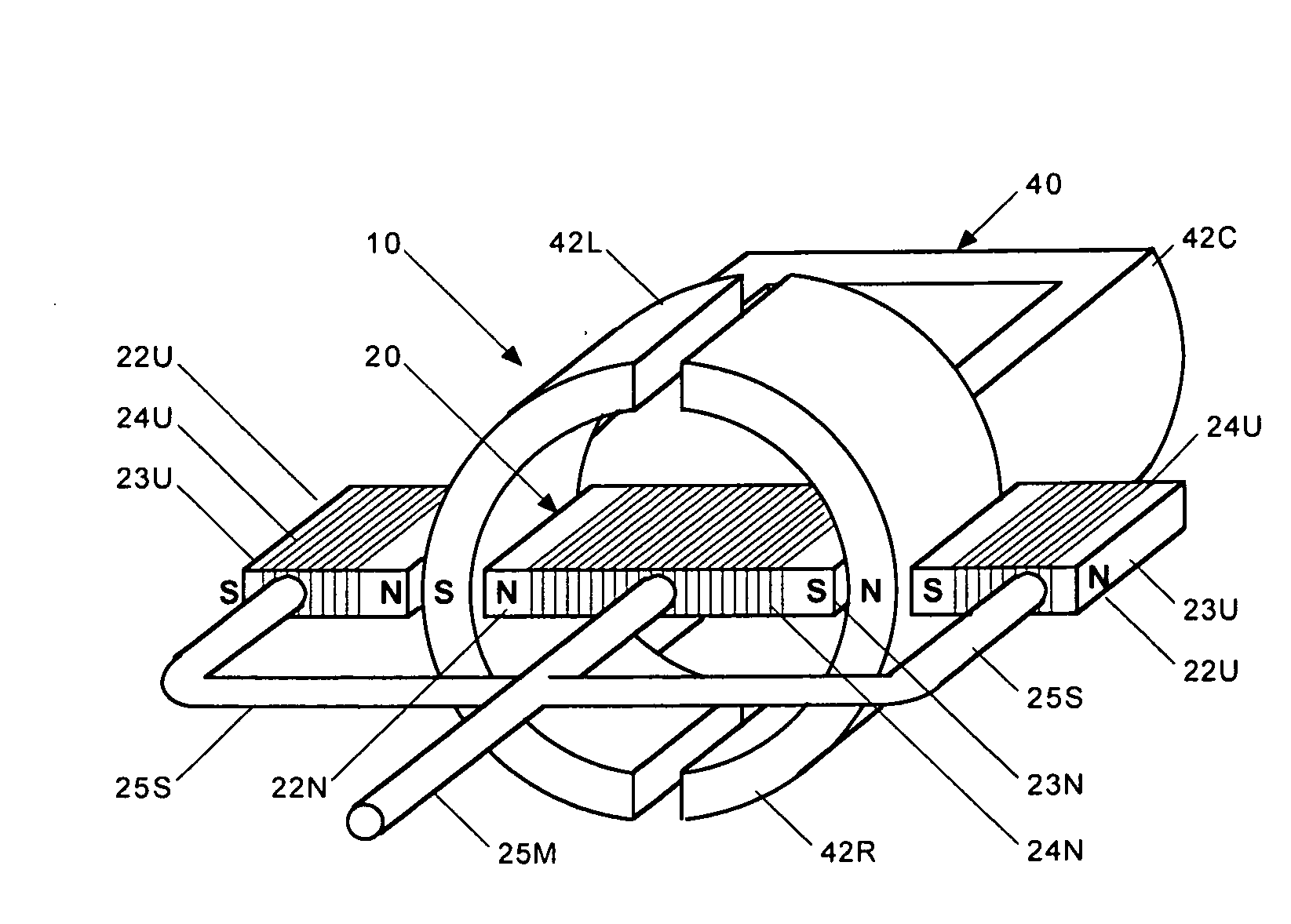

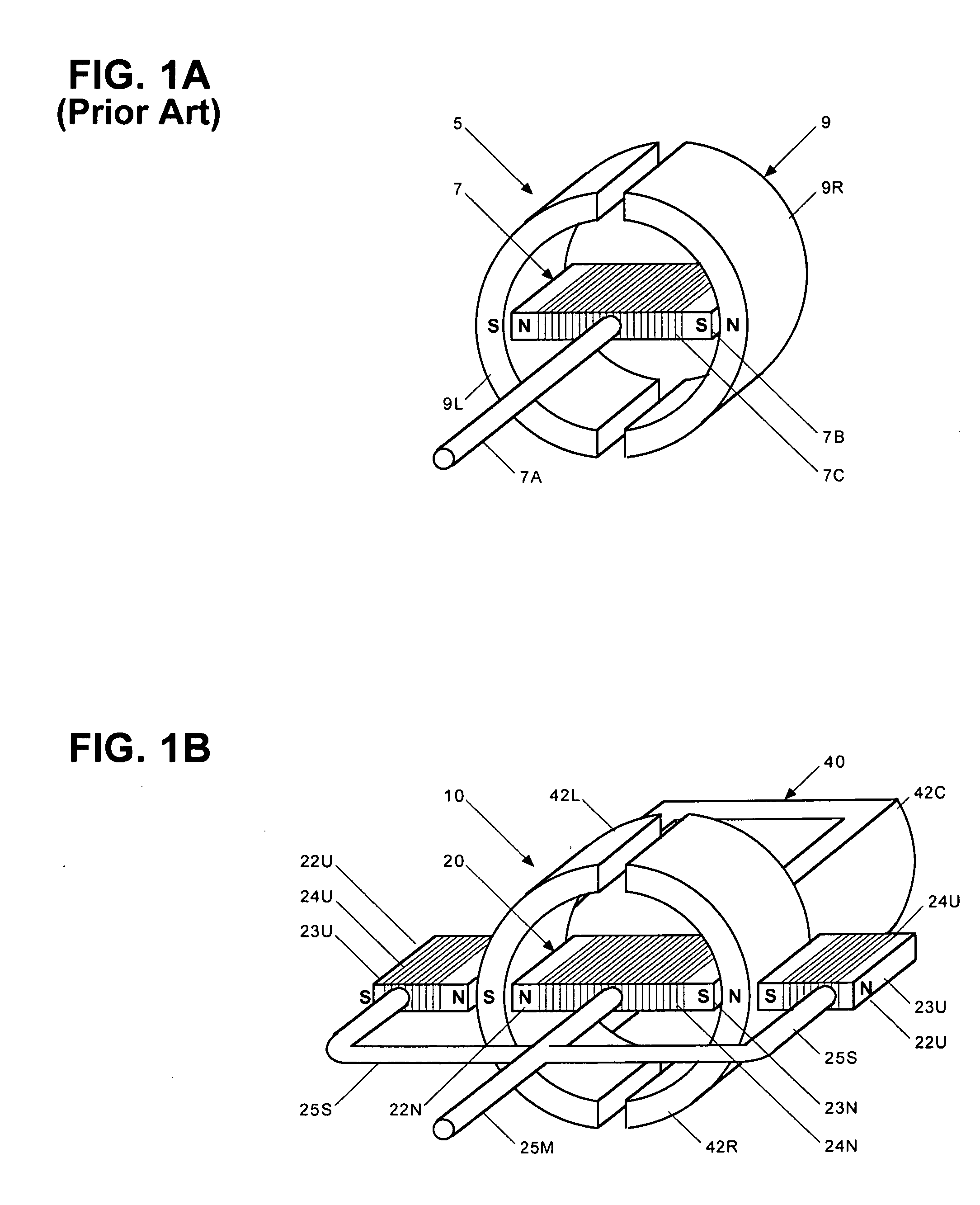

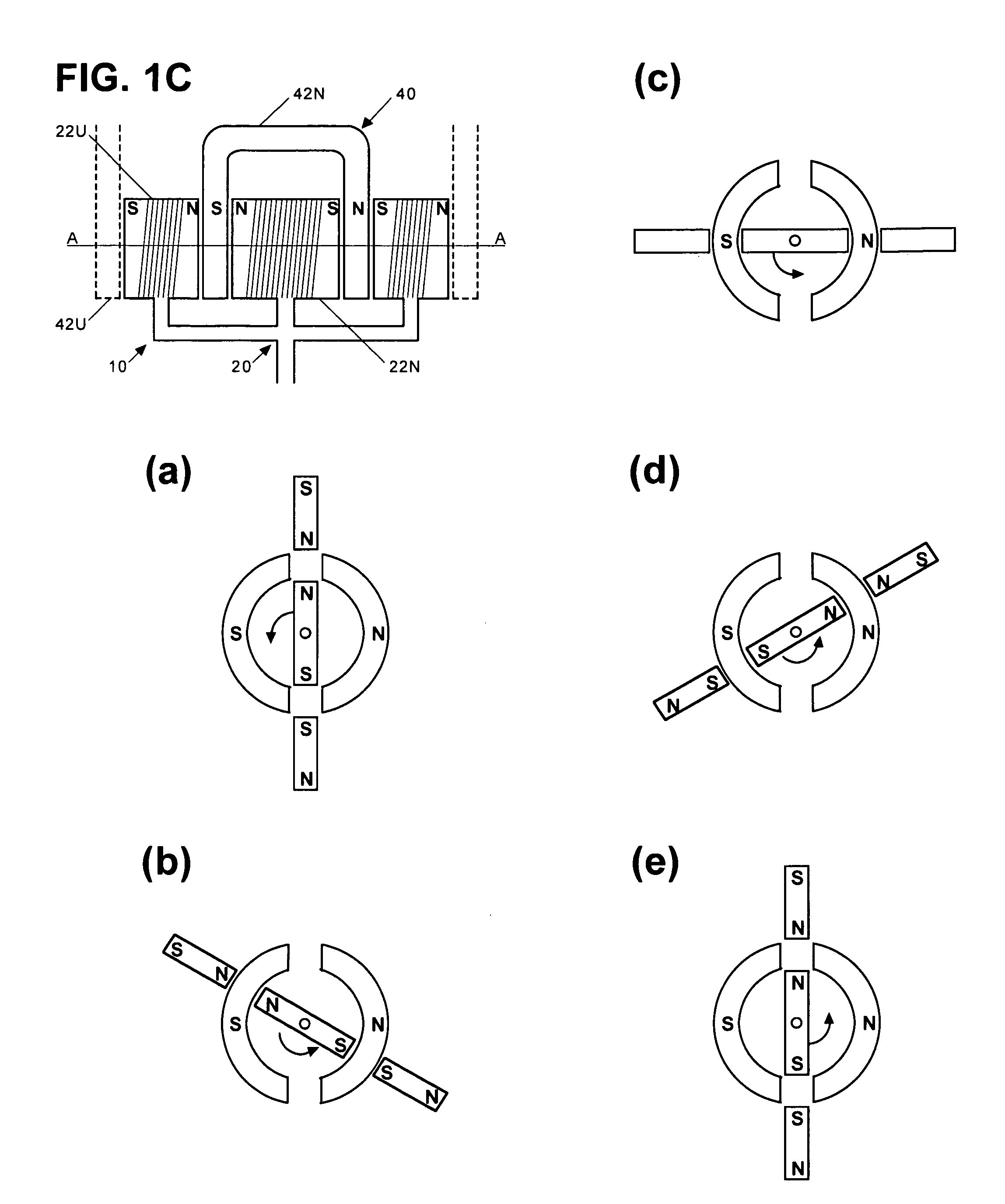

Electromagnetically-countered actuator systems and methods

InactiveUS20100164321A1Reduce radiationReduce the amount requiredSynchronous generatorsMagnetic circuit rotating partsMagnetic polesEngineering

The present invention generally relates to electric motor systems which minimize irradiation of harmful electromagnetic waves by various means. More particularly, the present invention relates to an electric motor system with one or more counter units which minimize the irradiation of such harmful waves by suppressing the harmful waves to their sources and / or by emitting counter electromagnetic waves capable of canceling a desired portion of the harmful waves. Such counter units may then be incorporated into various locations for opposing magnetic poles of basic rotor units and / or basic stator units of the system. The present invention also relates to various methods of minimizing irradiation of such harmful waves by various electric motor systems, various methods of suppressing the harmful waves toward their sources, and various methods of canceling such harmful waves by the counter waves. The present invention further relates to various processes for providing such electric motor systems, various processes for making such counter units for the suppressing and / or canceling, and various processes for incorporating such counter units into various locations of the systems.

Owner:SHIM YOUNGTACK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com