High speed permanent magnetism motor rotor and high speed permanent magnetism motor

A permanent magnet motor, high-speed technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electric components, etc., can solve the problems of large eddy current loss, poor heat dissipation, low rigidity, etc., to solve the problem of large eddy current loss and reduce production process. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

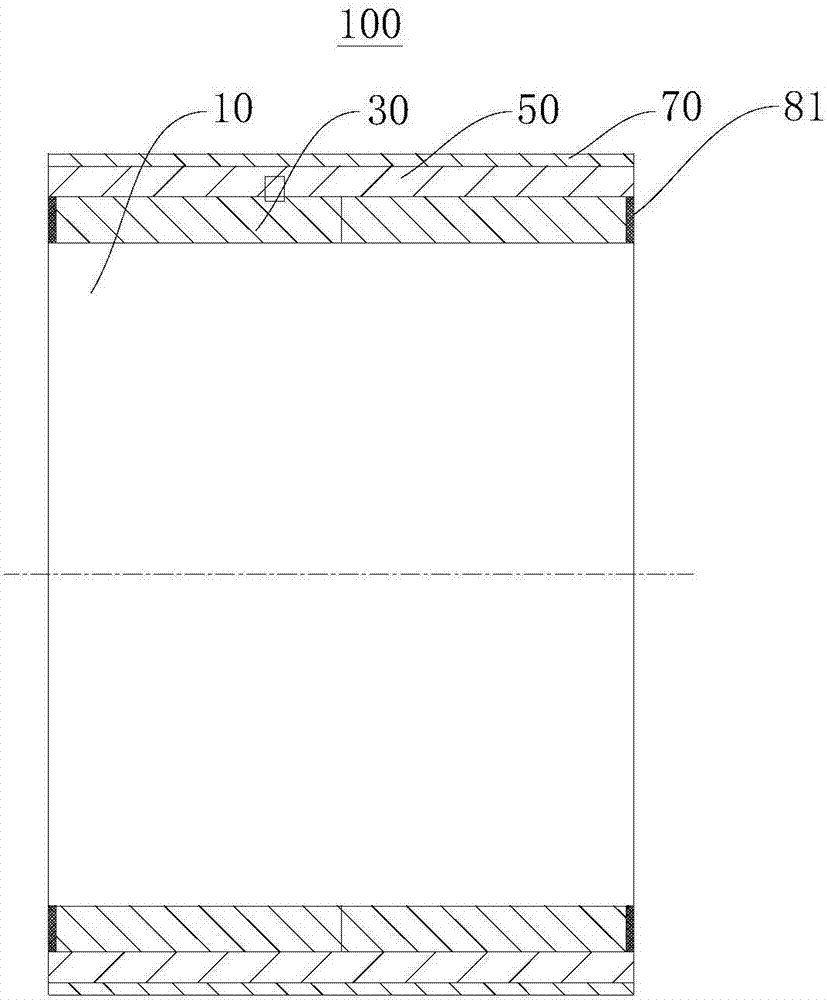

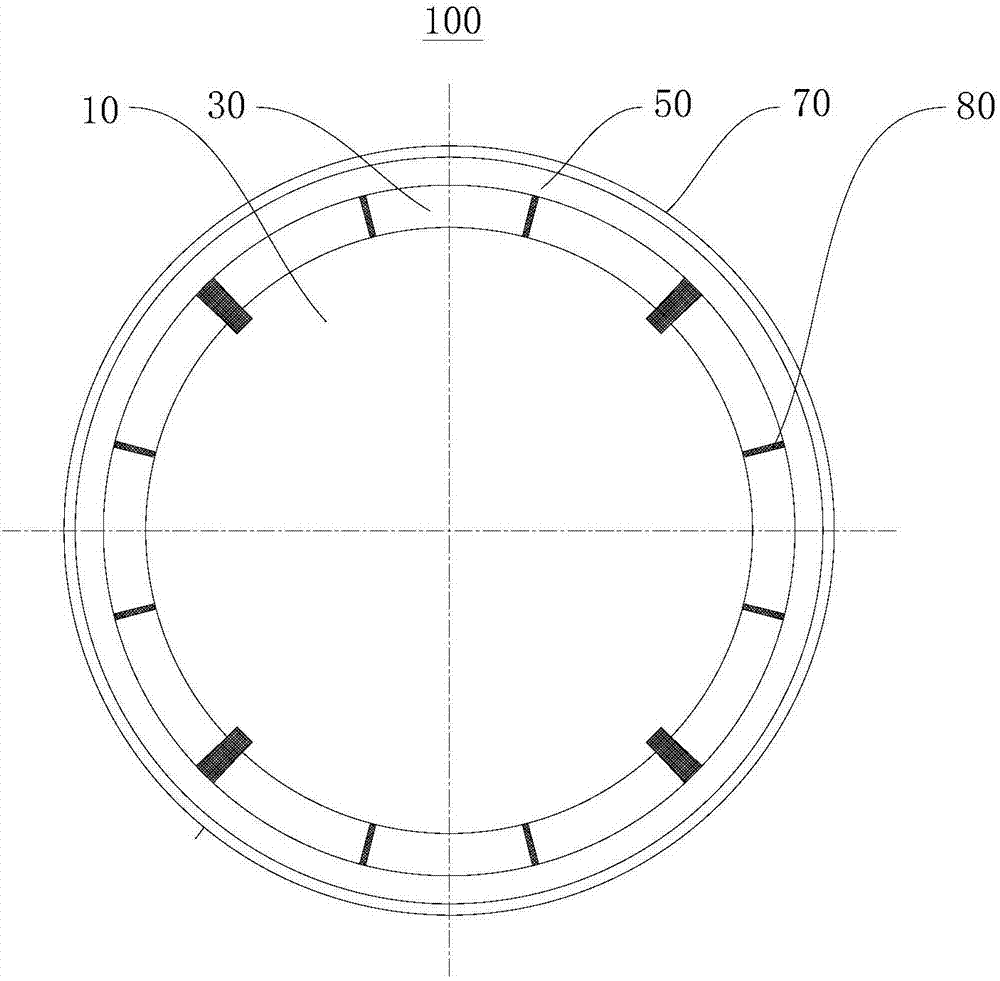

[0043] Please refer to figure 1 and figure 2 , this embodiment provides a high-speed permanent magnet motor rotor 100, including:

[0044] Rotor core 10;

[0045] The number of magnetic steel 30 is multiple, and the multiple magnetic steel 30 is arranged on the outer surface of the rotor core 10 in segments along the axial direction and the circumferential direction of the rotor core 10;

[0046] The shielding layer 50 is wrapped on the outer surface of the magnetic steel 30 and has an interference fit with the magnetic steel 30;

[0047] The outer protective sheath 70 is wrapped around the outer surface of the shielding layer 50; and

[0048] The sealing part is used to fill the interpole gap of the magnetic steel 30 and seal the end faces of the magnetic steel 30 at both ends of the entire high-speed permanent magnet motor rotor 100 .

[0049] Wherein, the magnetic steel 30 is arranged on the outer surface of the rotor core 10 by pasting.

[0050] Wherein, the thicknes...

Embodiment 2

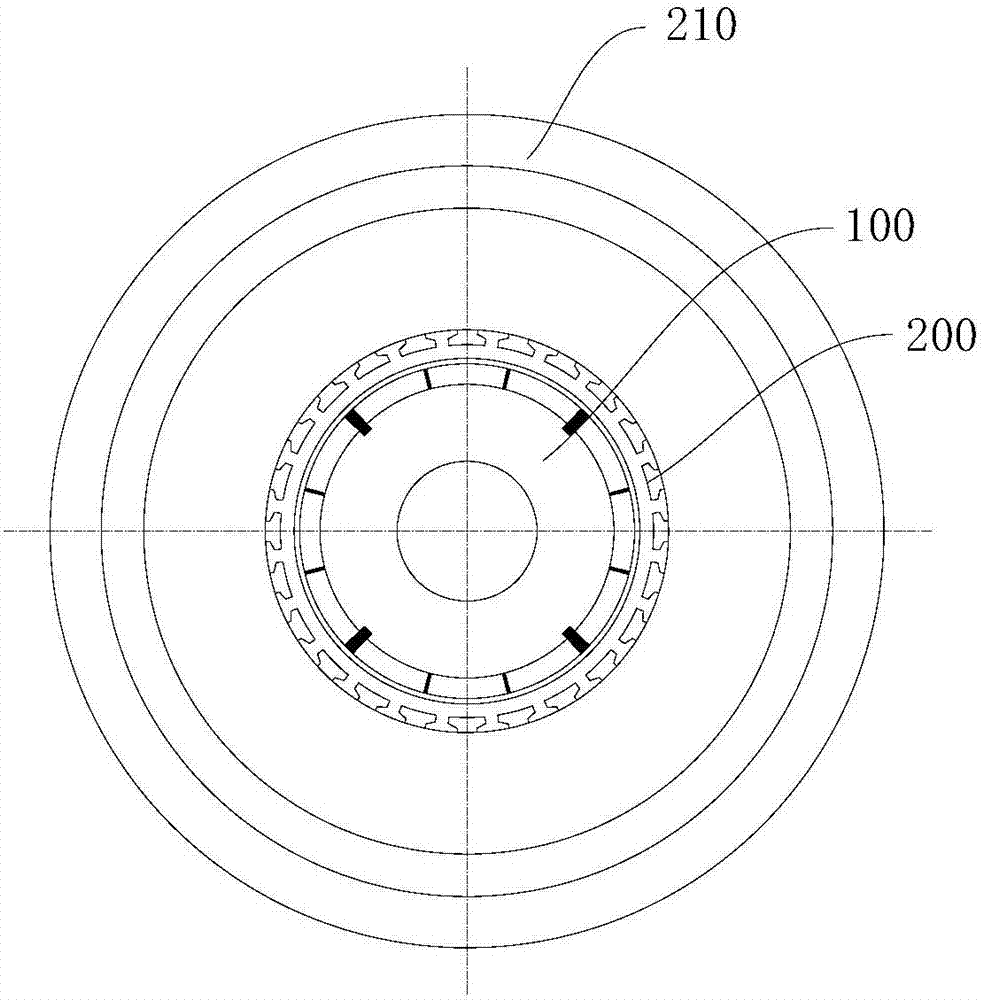

[0068] Please refer to image 3 and Figure 4 This embodiment provides a high-speed permanent magnet motor, including a stator core 200 and the high-speed permanent magnet motor rotor 100 in Embodiment 1. The high-speed permanent magnet motor rotor 100 is installed in the space enclosed by the stator core 200 .

[0069] Further, the high-speed permanent magnet motor also includes a water jacket 210 for cooling, and the water jacket 210 is set outside the stator core 200 . Specifically, a shrink-fit connection can be used.

[0070] There is a heat exchange channel 2101 in the water jacket 210, through which the flow of cooling fluid in the heat exchange channel 2101 can accelerate the heat dissipation of the high-speed permanent magnet motor to avoid excessive temperature.

[0071] There are sealing ring installation grooves on both sides of the water jacket 210, and the sealing rings installed in the grooves can prevent the cooling fluid in the heat exchange channel 2101 fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com