Patents

Literature

196 results about "Squirrel-cage rotor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

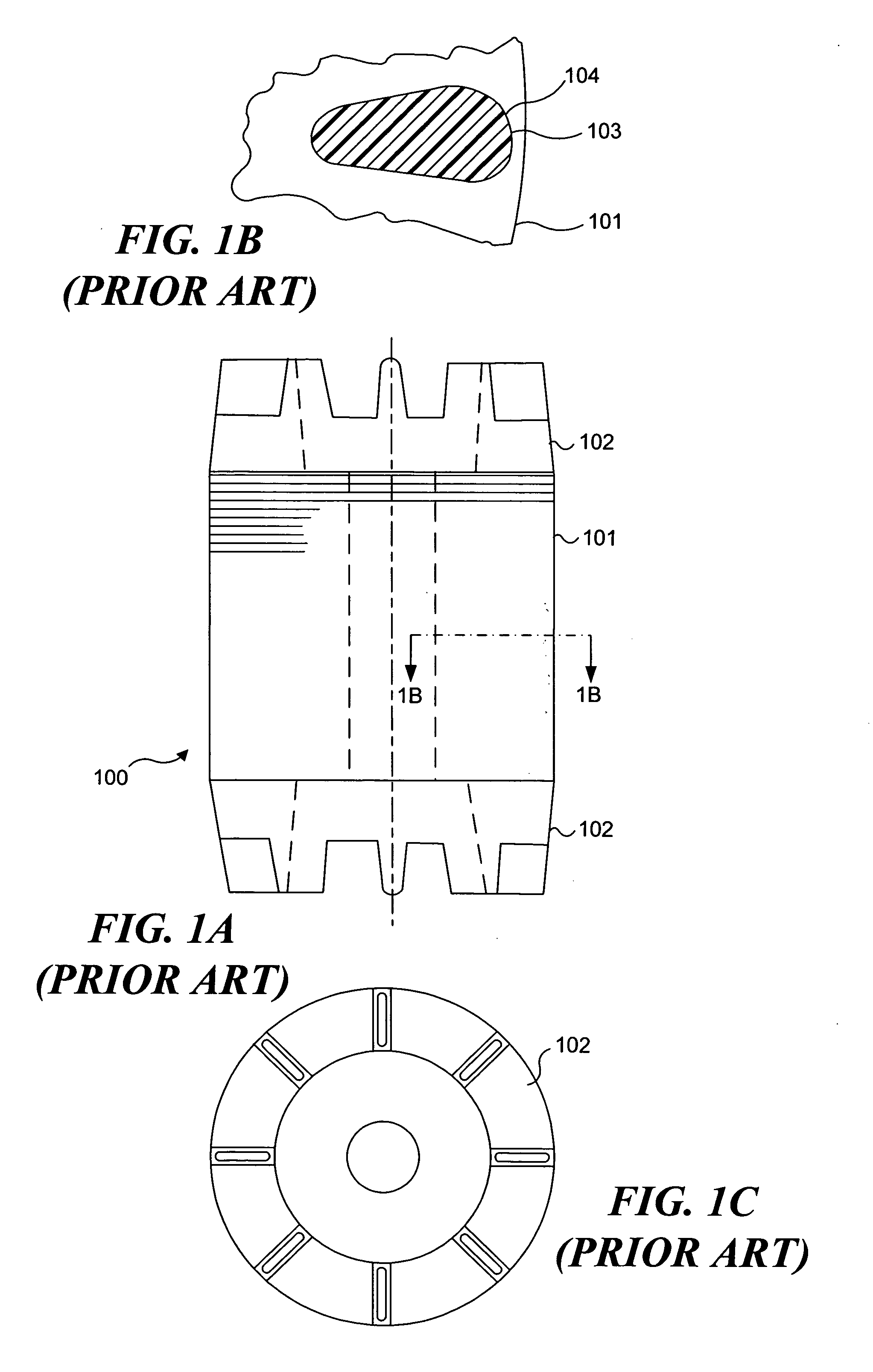

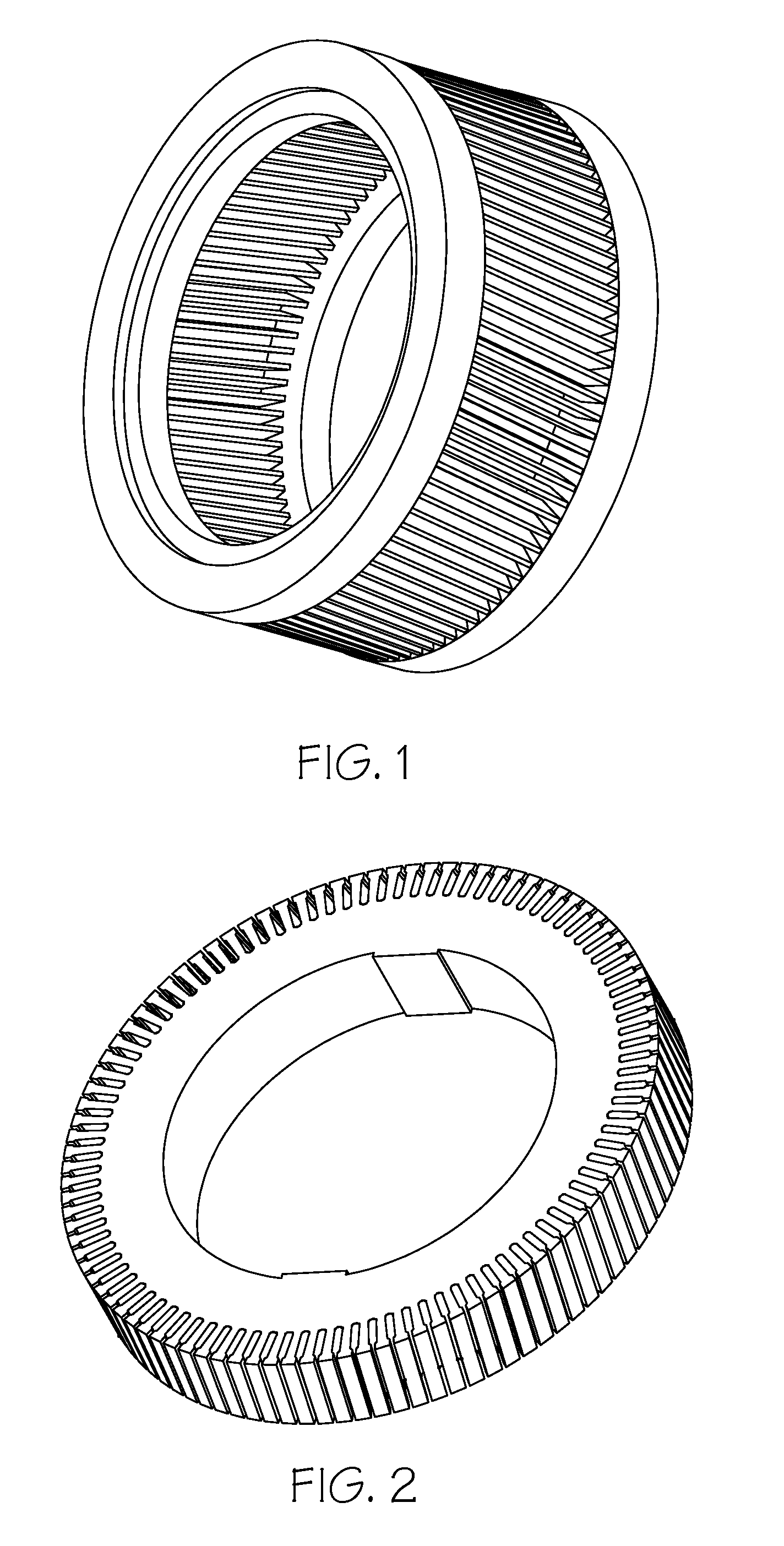

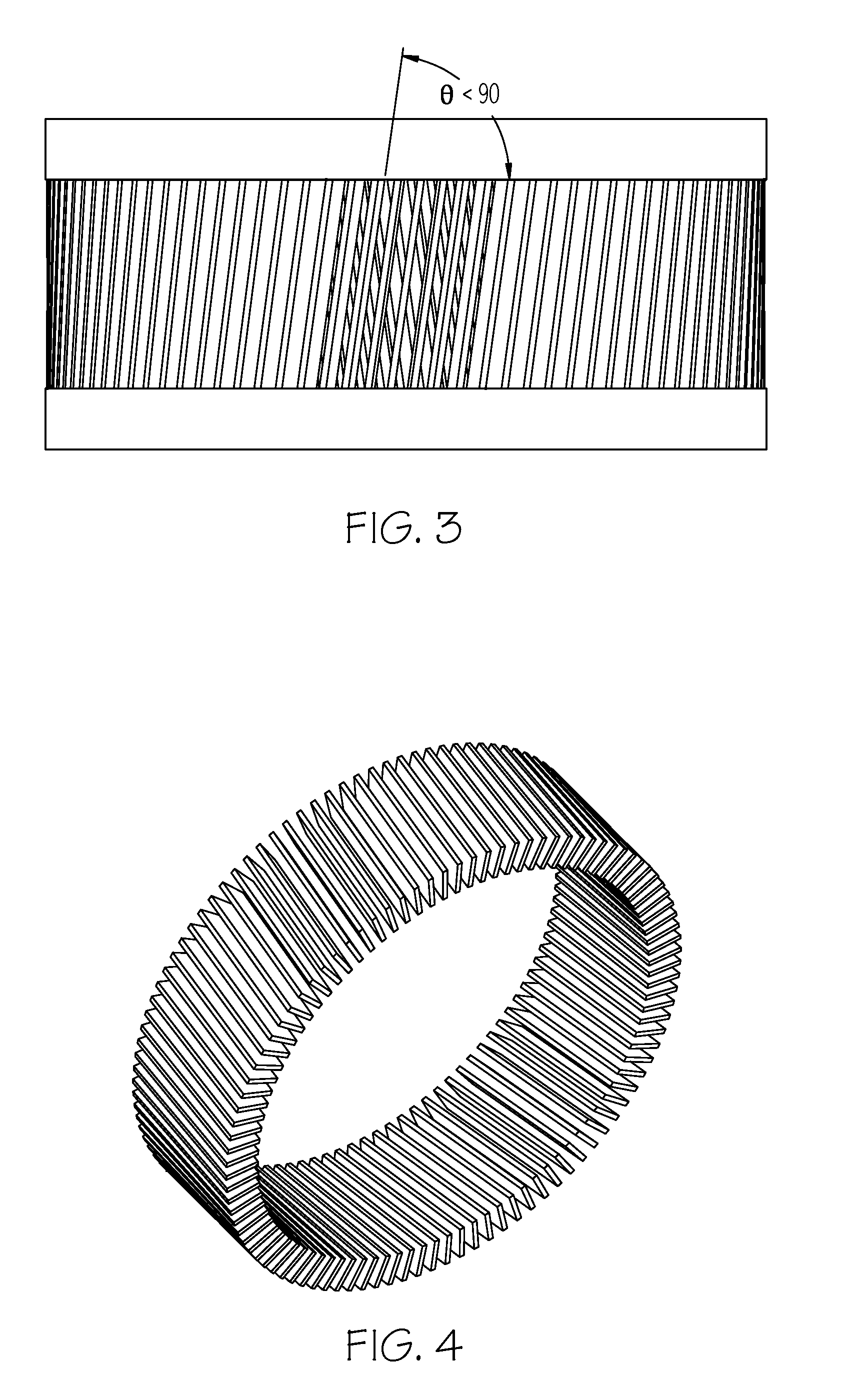

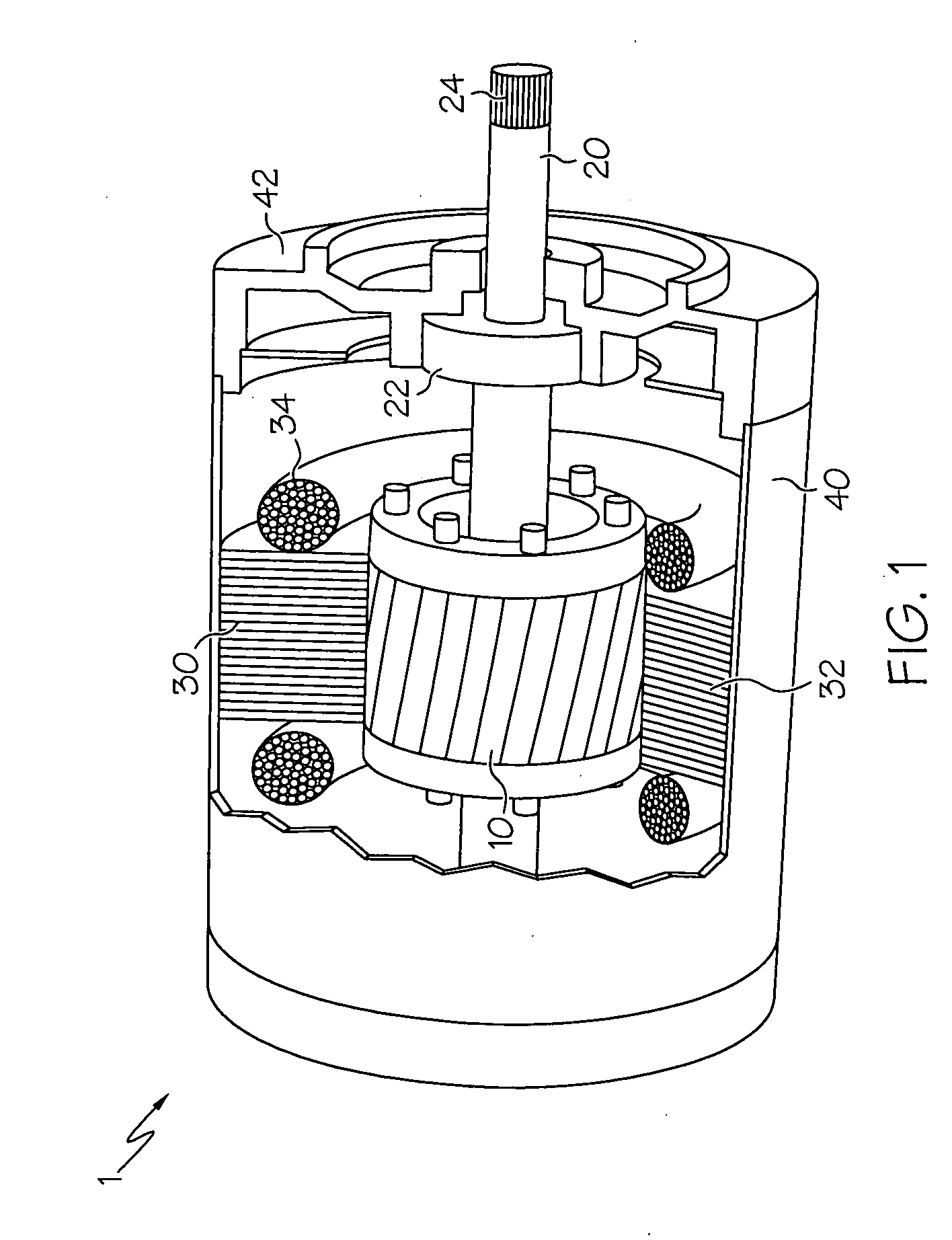

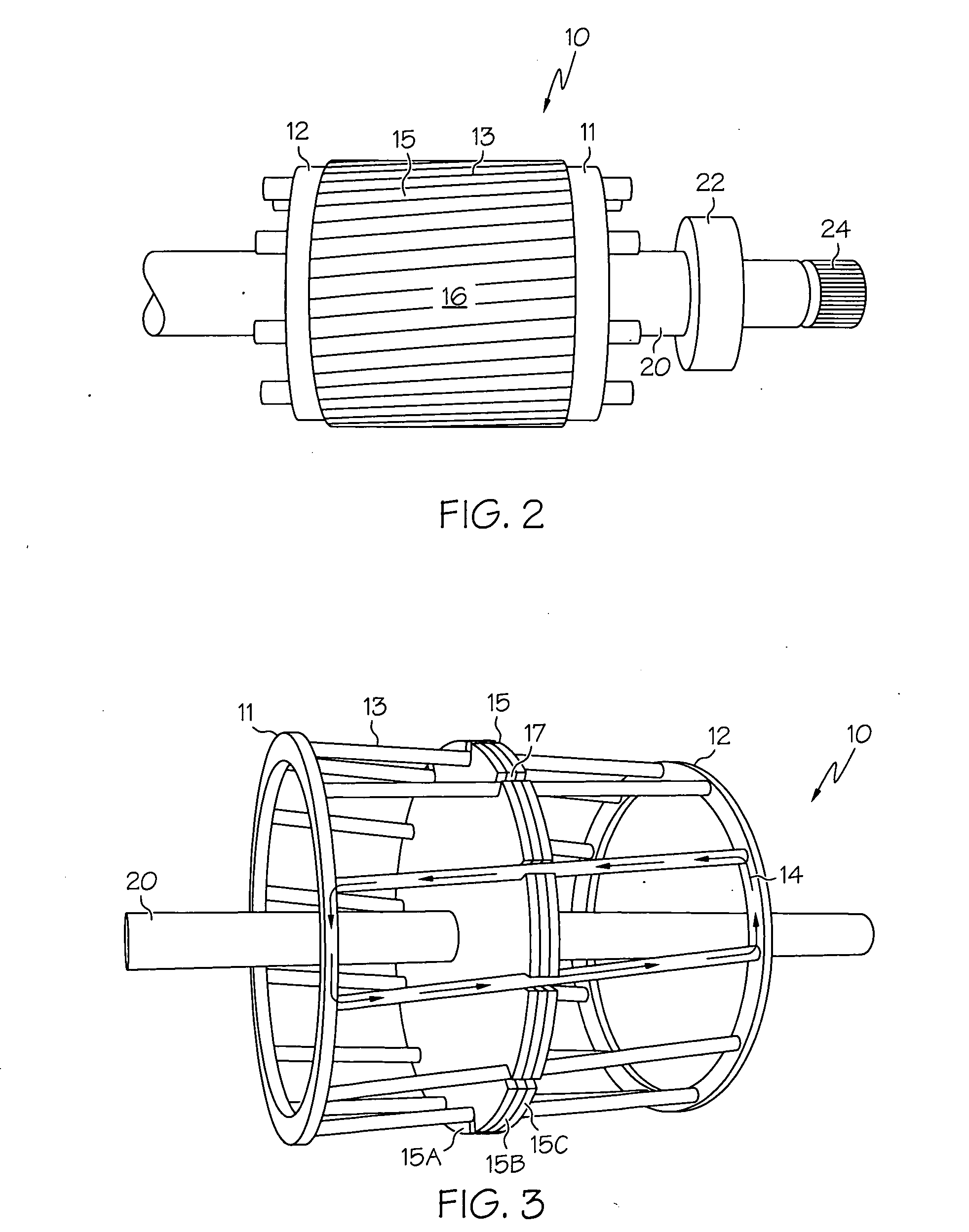

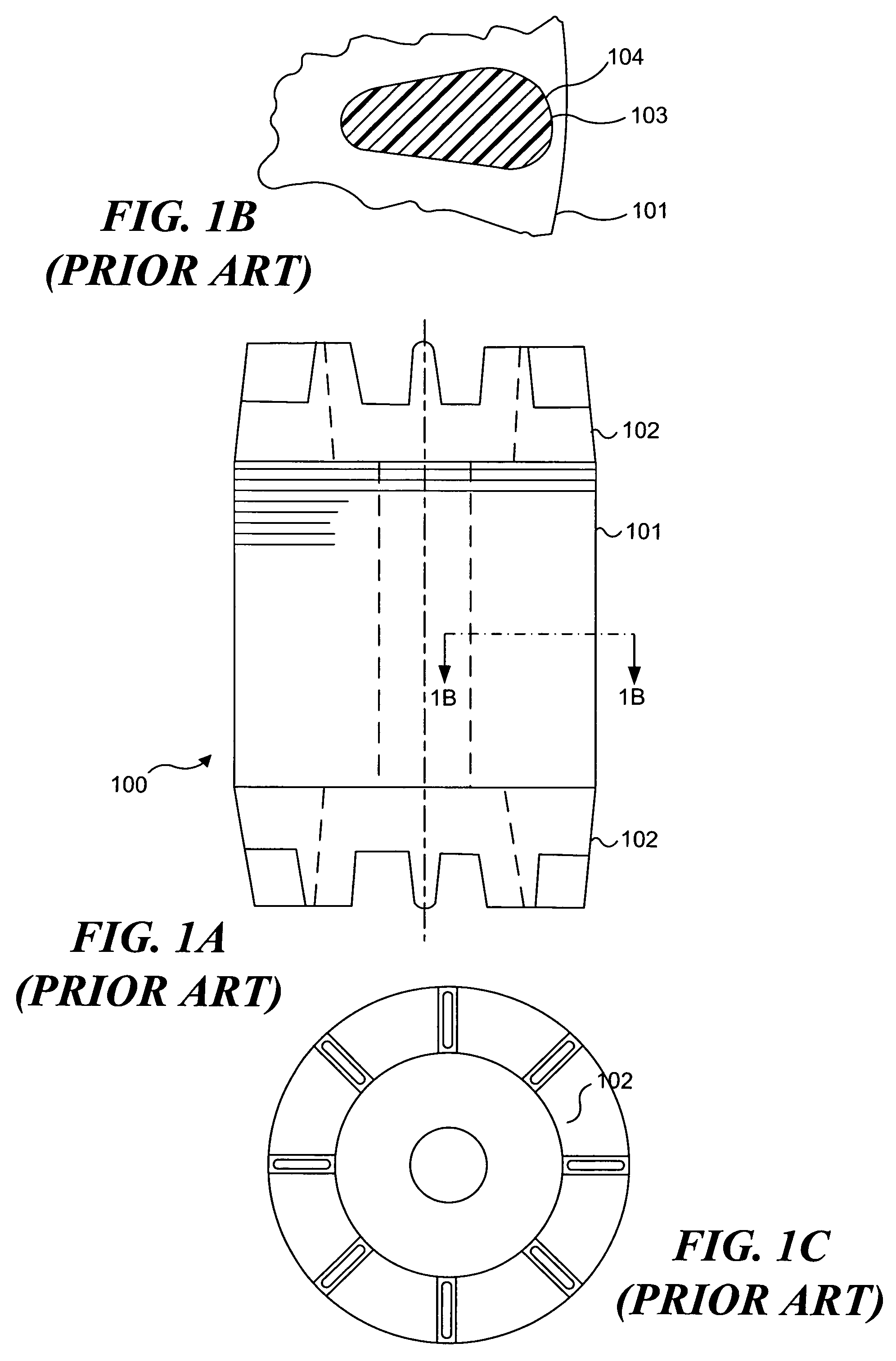

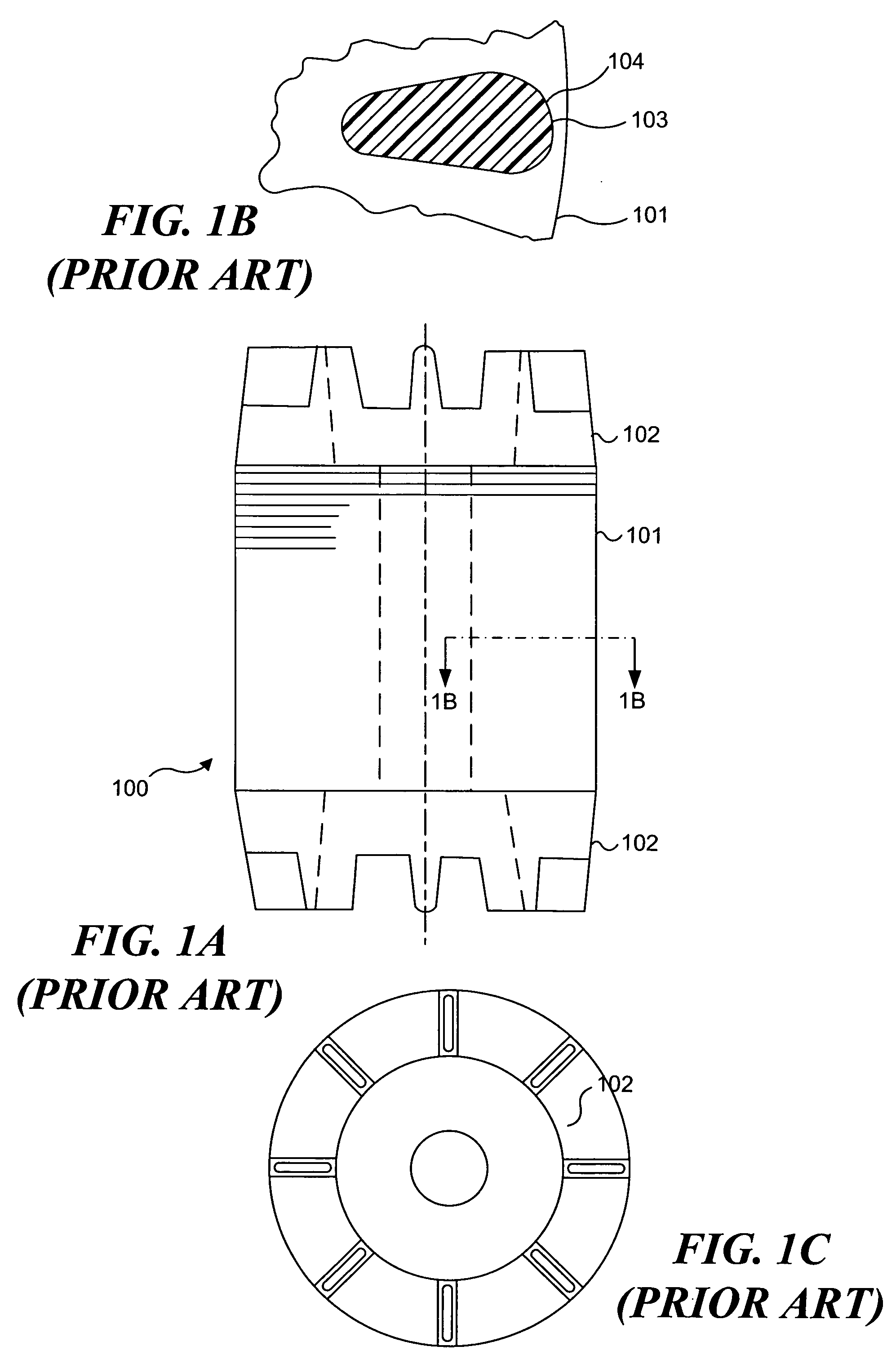

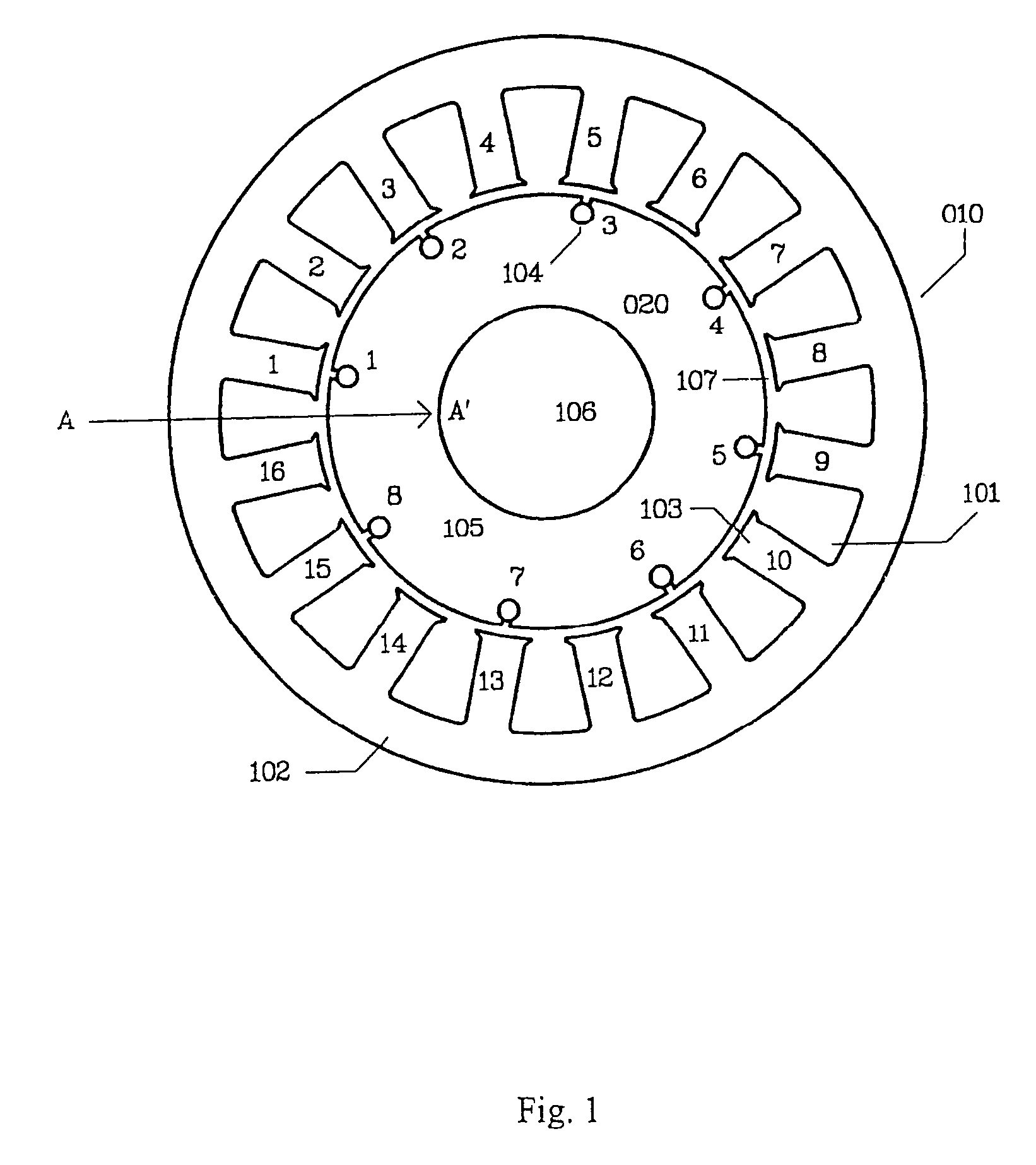

A squirrel-cage rotor is the rotating part of the common squirrel-cage induction motor. It consists of a cylinder of steel laminations, with aluminum or copper conductors embedded in its surface. In operation, the non-rotating stator winding is connected to an alternating current power source; the alternating current in the stator produces a rotating magnetic field. The rotor winding has current induced in it by the stator field, like a transformer except that the current in the rotor is varying at the stator field rotation rate minus the physical rotation rate. The interaction of the magnetic fields of currents in the stator and rotor produce a torque on the rotor.

Method for manufacturing squirrel cage rotor

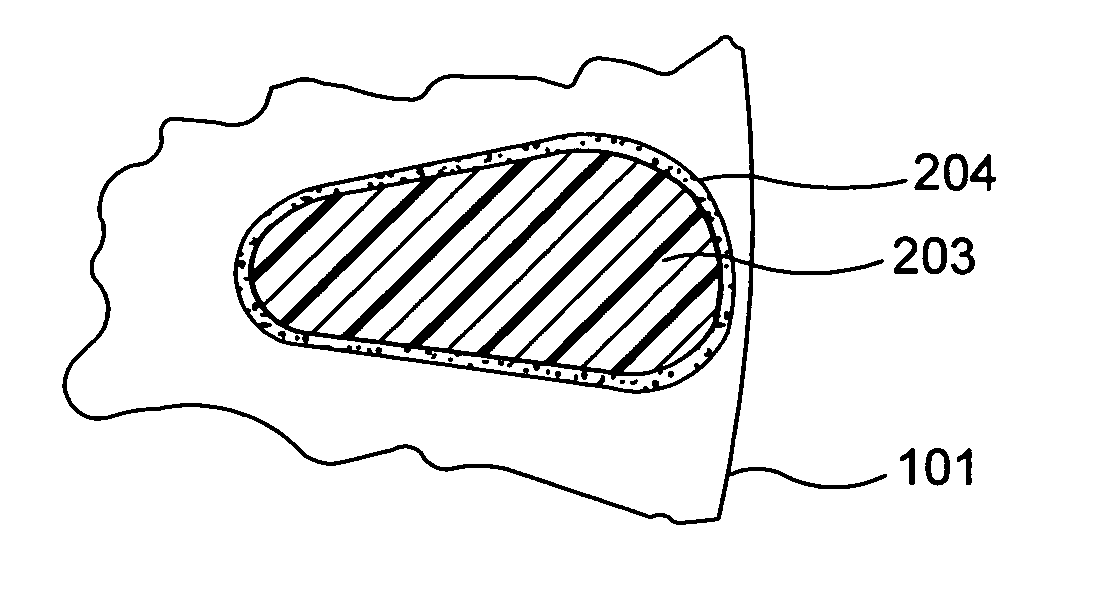

InactiveUS20050134137A1Eliminate its organic contentReduced rotor lossesSynchronous motorsFoundry mouldsElectrical conductorAdhesive

Ceramic adhesive is applied inside the slots of an electric machine squirrel cage rotor prior to casting or insertion of rotor conductors. This heat-resistant insulation provides superior electrical insulation that is also mechanically rugged, thus enabling casting of squirrel cage rotors by die or cost-effective consumable pattern casting. The consumable pattern cast copper rotors are electrically well insulated, thus minimizing rotor losses. The ceramic insulation in cast rotors enables longer conductors to be cast by thermally insulating the molten metal from the cooler laminations. The ceramic insulation in fabricated rotors withstands the high temperatures of end ring attachment. This method is applicable to both conventional induction machine rotors and brushless doubly-fed induction machine rotors and provides the degree of electrical isolation of the bars from the laminations needed to avoid excessive parasitic torques in doubly-fed machines, while ensuring adequate thermal conductivity to dissipate conductive bar heat to the laminations.

Owner:SWEO EDWIN A

Methods of manufacturing induction rotors with conductor bars having high conductivity and rotors made thereby

Squirrel cage rotors of aluminum based material end rings joined with high conductive and durable material (such as copper) conductor bars for use in electric motors and methods of making them are described. The methods include forming conductor bars by casting or other metal forming methods in the slots of laminate steel stack, or positioning the preformed or premade solid conductor bars in the longitudinal slots of the stacked laminated steel, with bar ends extending out of the laminated steel stack ends, optionally coating the extended part of the conductors (bars) with a latent exoergic coating containing Al and one or more conductor bar chemical elements, positioning the laminated steel stack having conductors (bars) in a casting mold that forms the cavity of both end rings of the rotor, filling the end ring cavities with aluminum melt, and allowing the end rings to solidify under pressure. Alternatively, the conductor bars and end rings can be made separately and mechanically joined together.

Owner:GM GLOBAL TECH OPERATIONS LLC

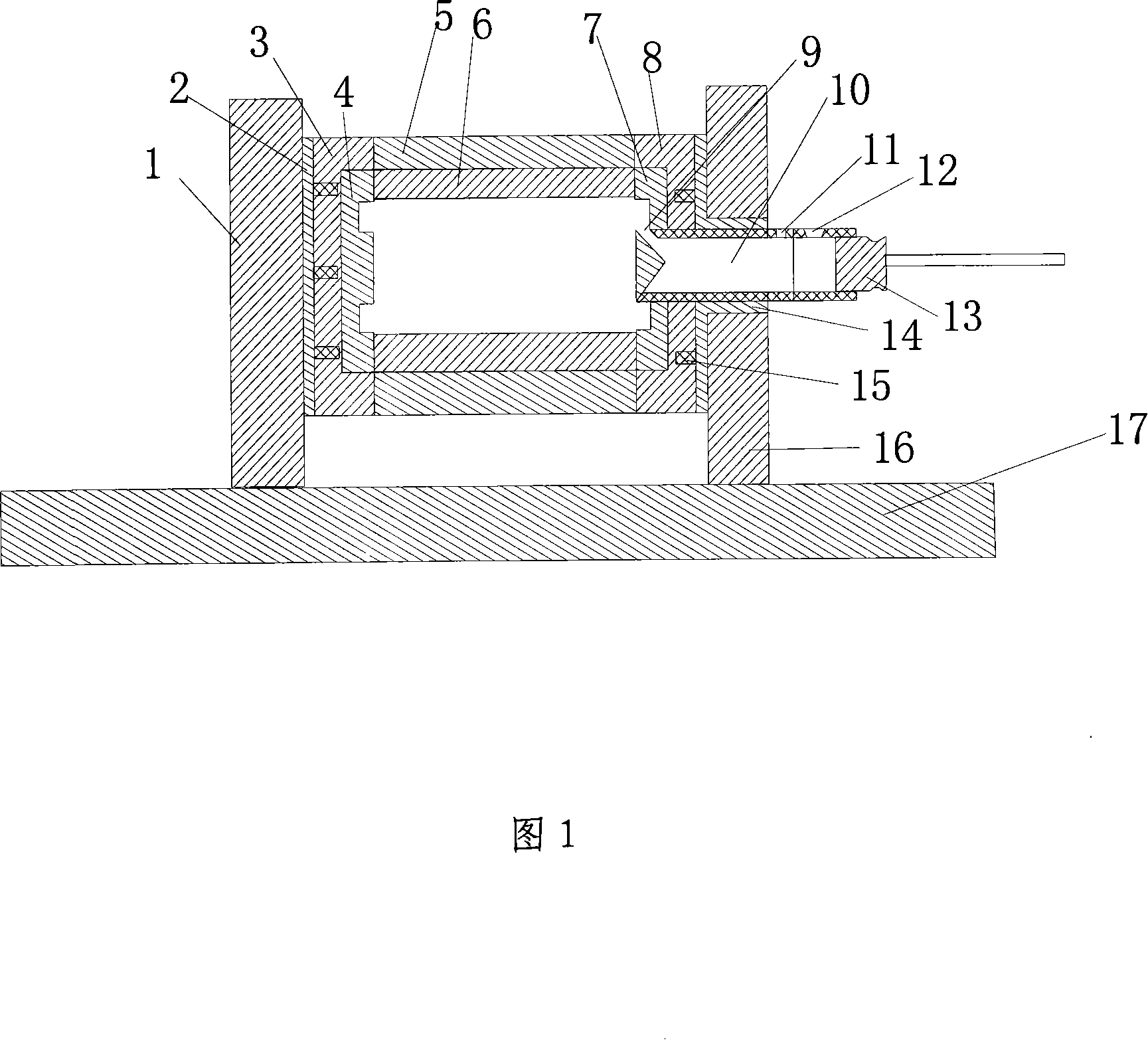

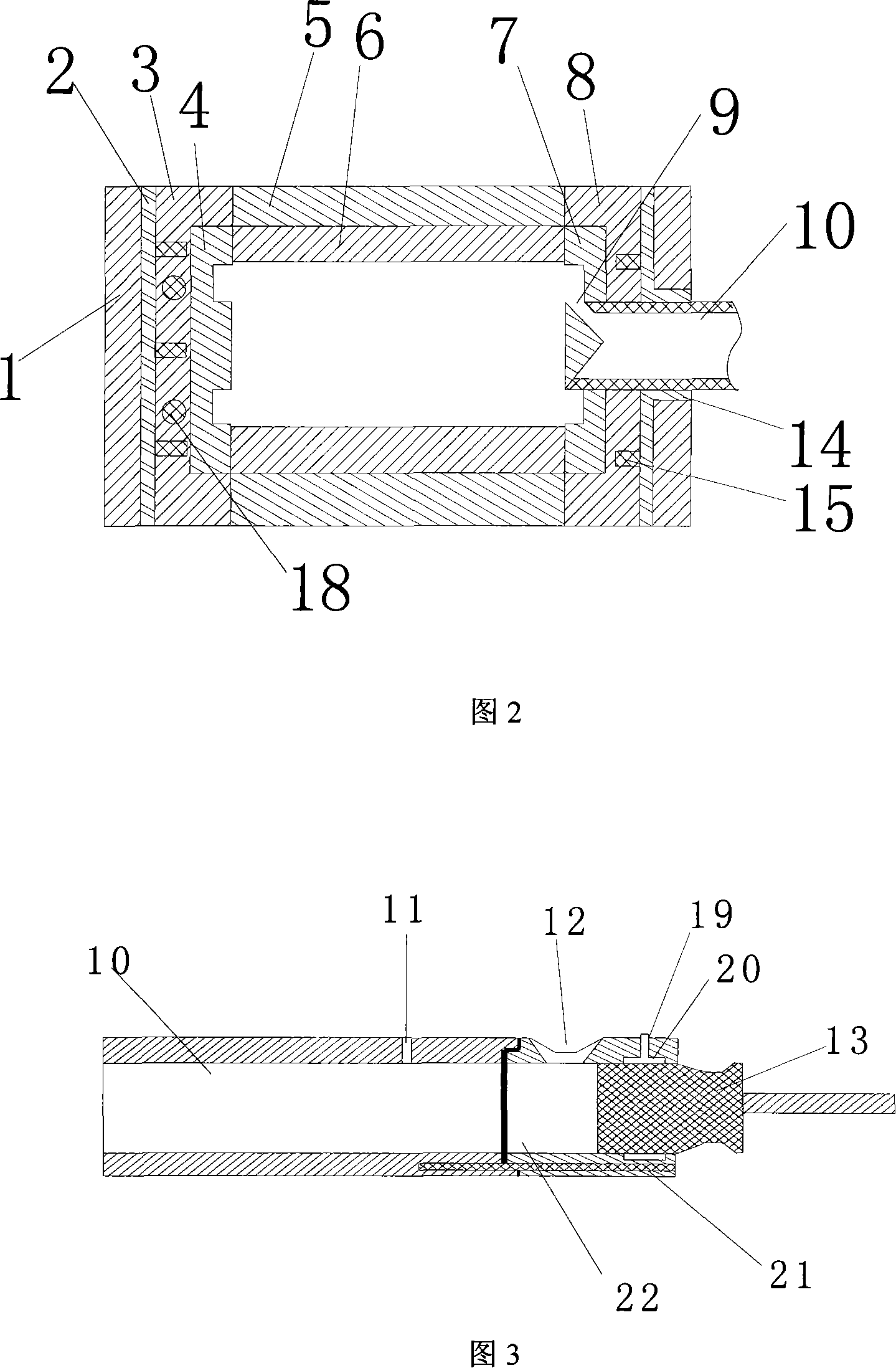

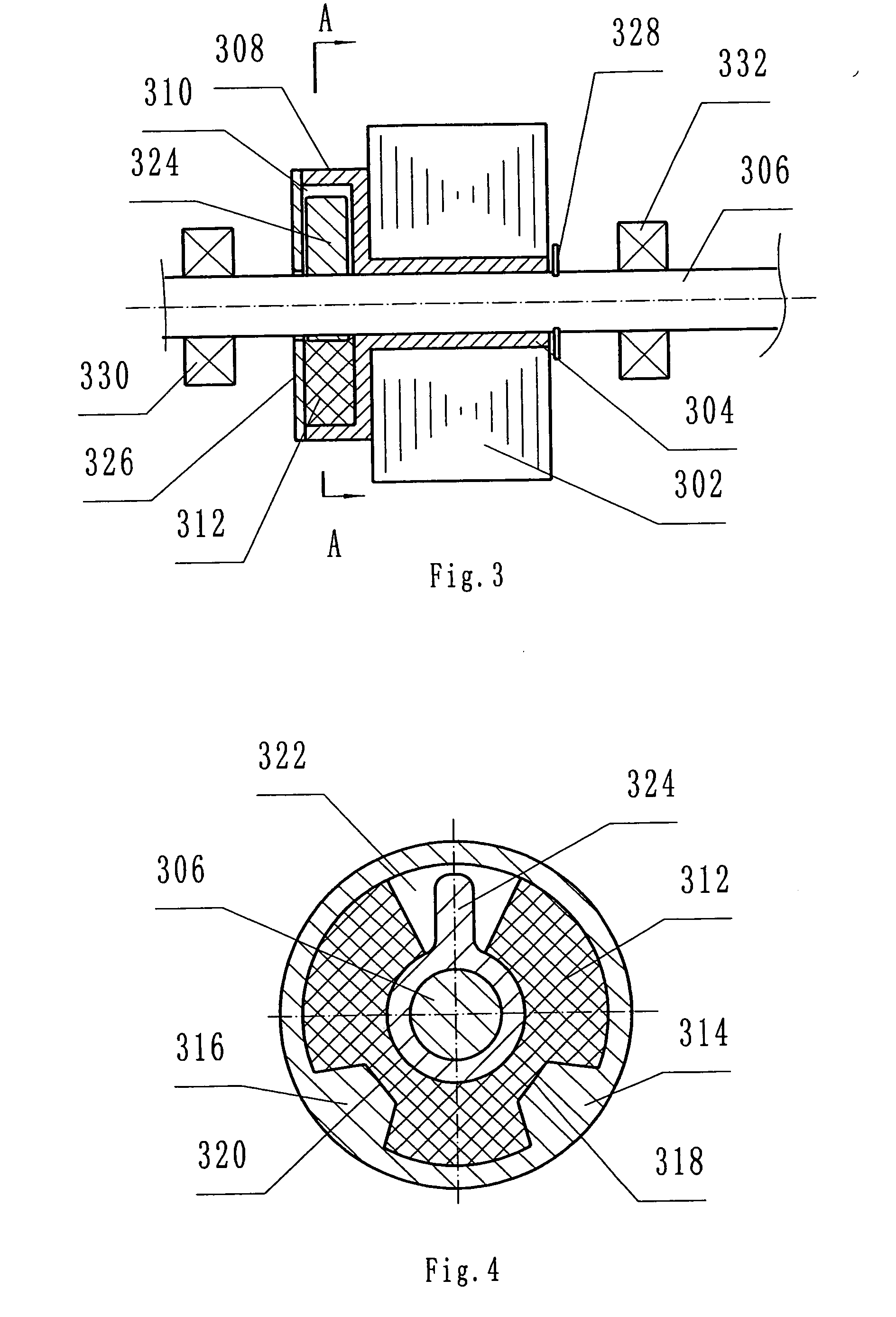

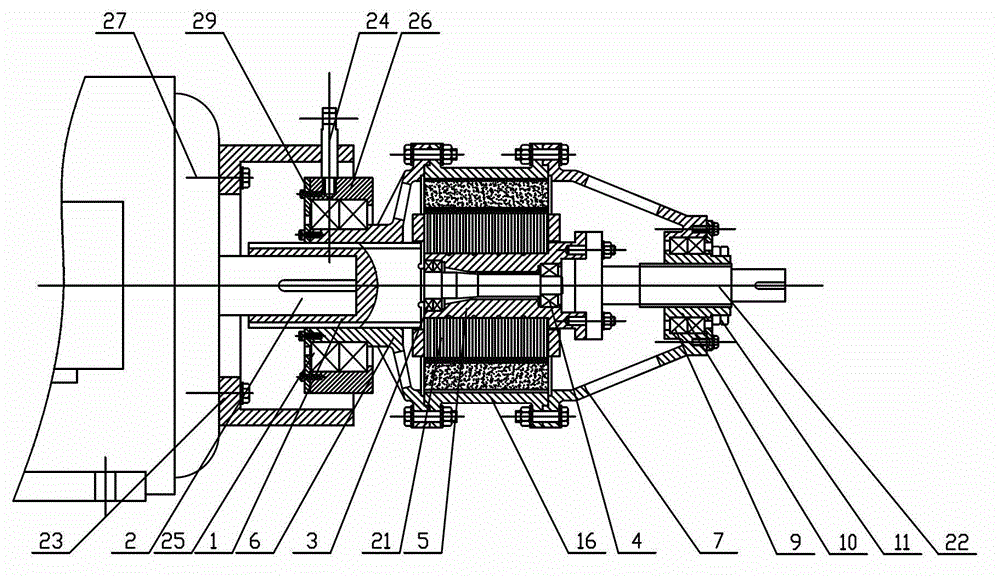

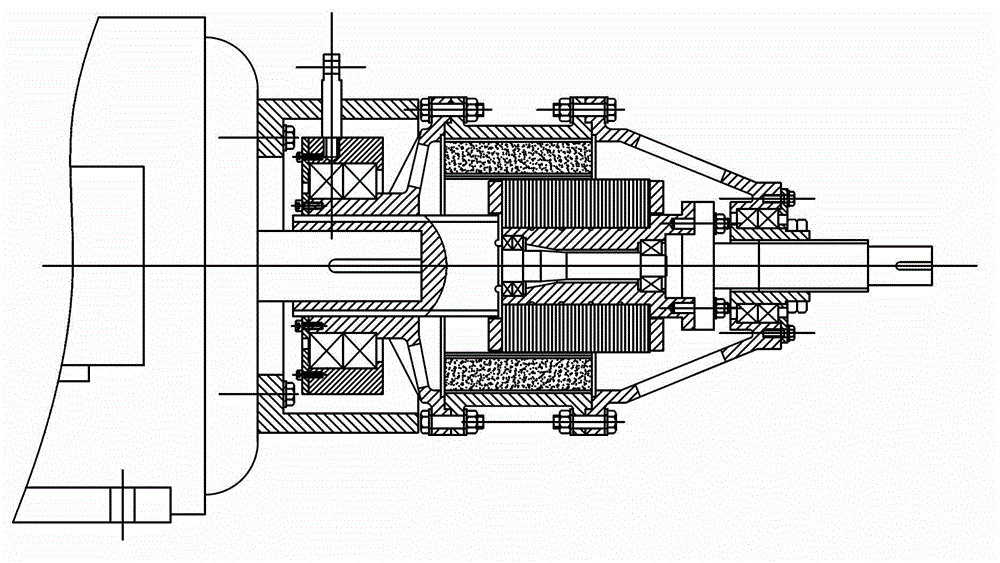

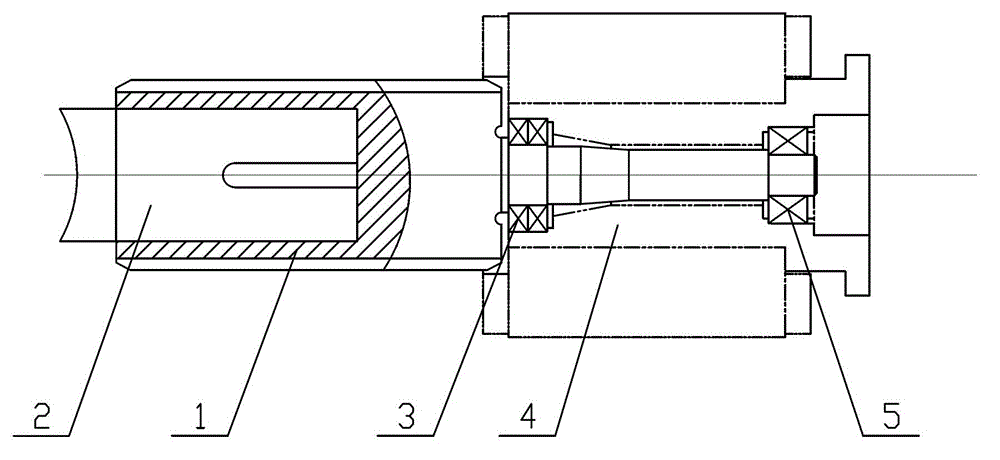

Die-casting method of induction motor copper cage rotor and die casting device thereof

ActiveCN101108416AReduce manufacturing costReasonable workmanshipGearingCylindersMiddle frequencyNon-ferrous extractive metallurgy

The invention relates to a casting method and casting machine of the induction motor cooper squirrel-cage rotor, which is suitable for the casting of pure copper and high copper content alloy. The invention belongs to nonferrous metal smelting and rolling process technology filed. The casting method comprises module pre-process, copper smelting, liquid casting and forming and quench water cooling. The casting method adopts a casting device which is composed of a casting machine and a smelting furnace, wherein, the smelting furnace comprises an integrated pot and middle frequency induction furnace, the heating efficiency of the middle frequency induction furnace is 0 to 100KW; the casting module comprises a group connection which is connected by a plurality of embedded lump. The invention has reasonable technics and equipment, the product has no defects of breakage on casting piece and surface, poor filling and mold sticking, the shaking present value complies with the R degree provision in IEC34-14(1994), which has the advantages of improving by one degree comparing with the N degree stipulated in Y series motor technology condition.

Owner:云南铜业压铸科技有限公司

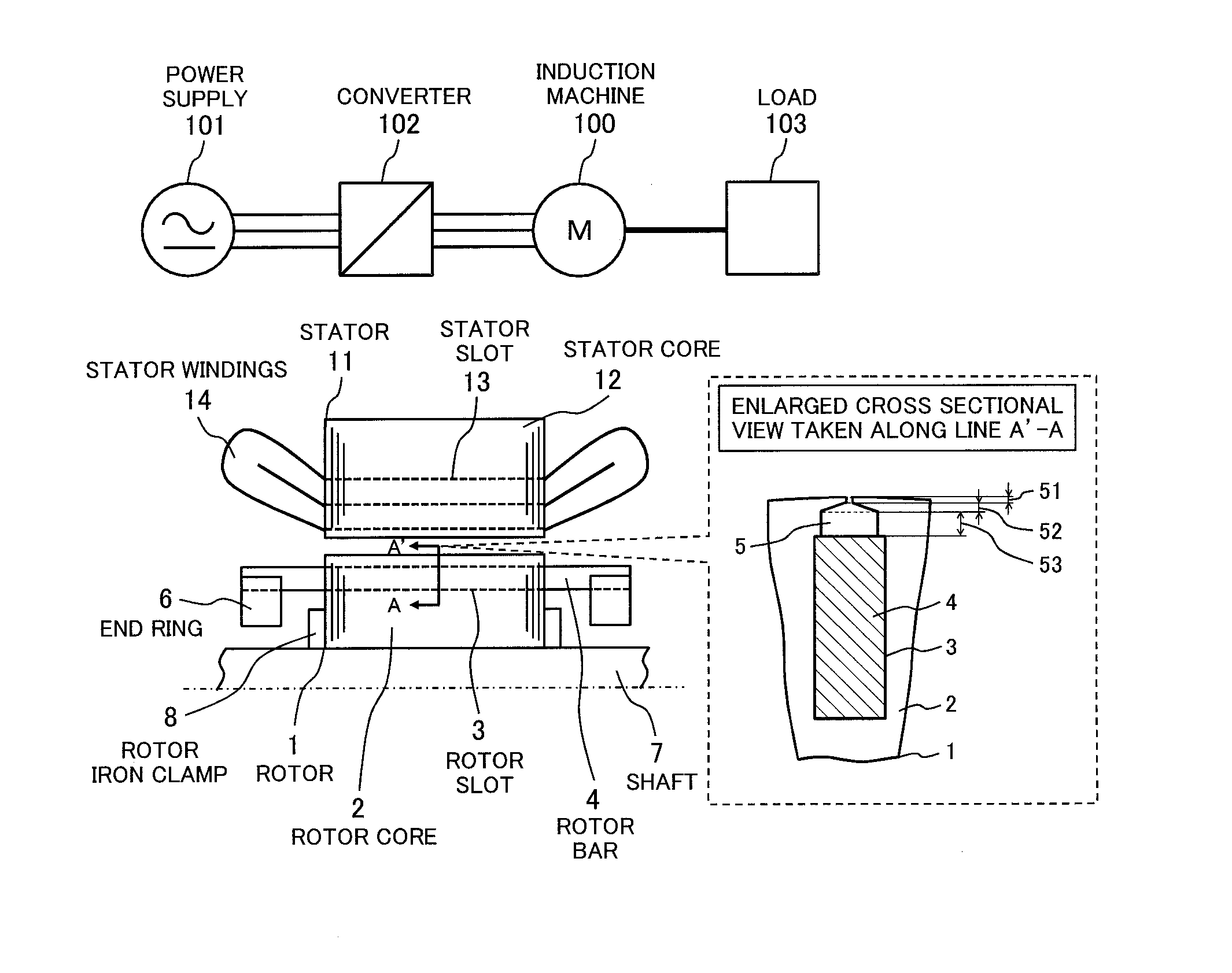

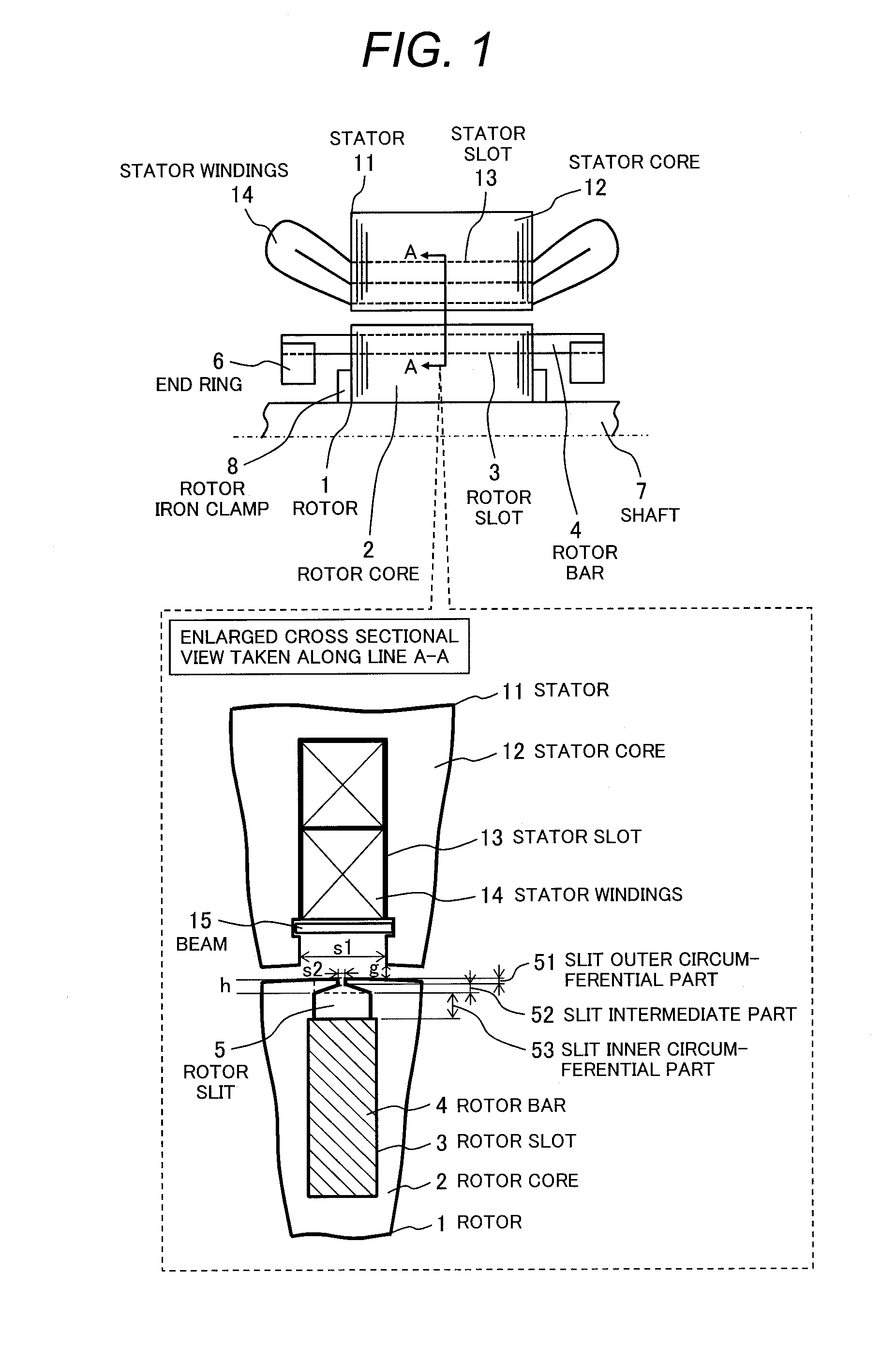

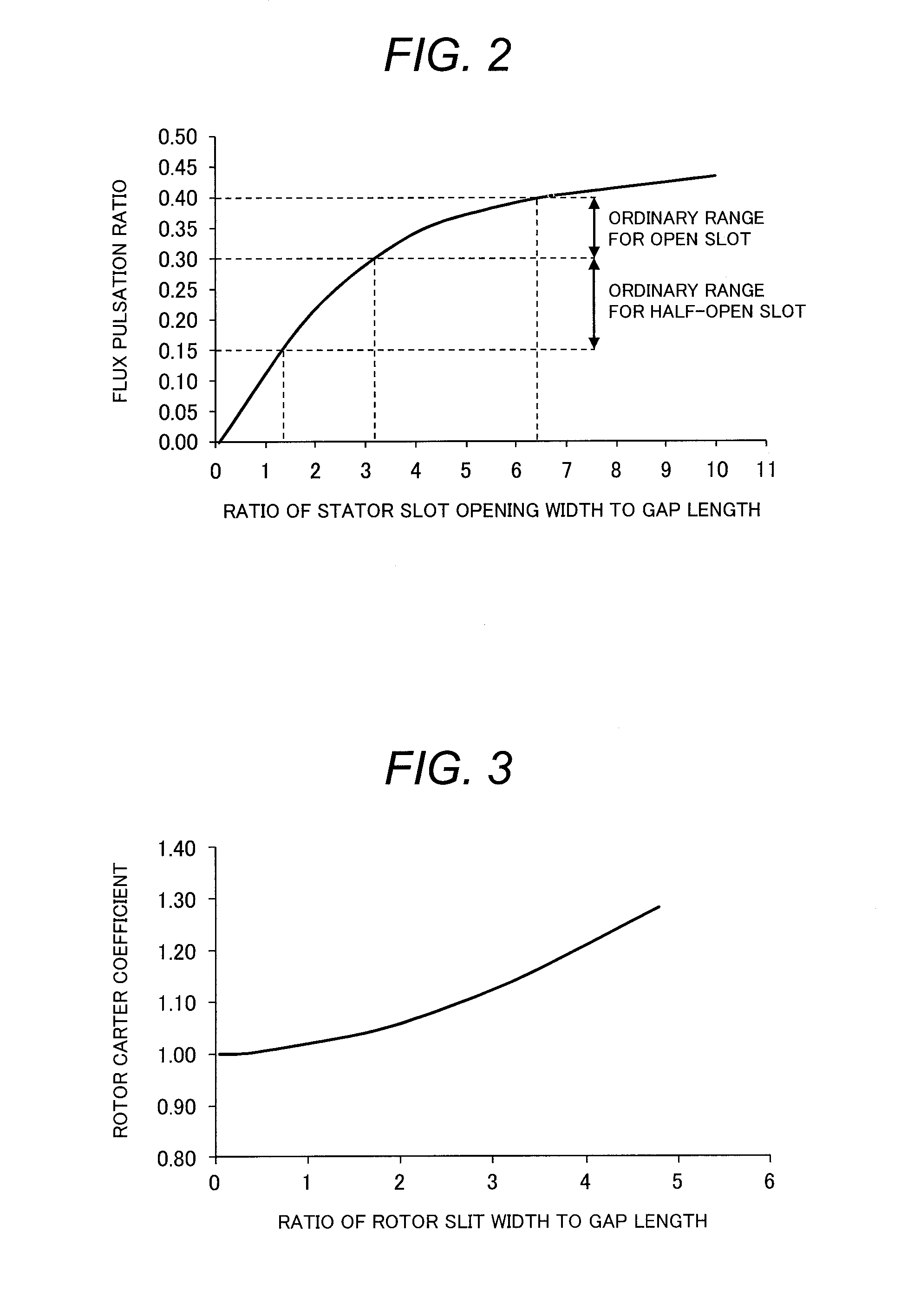

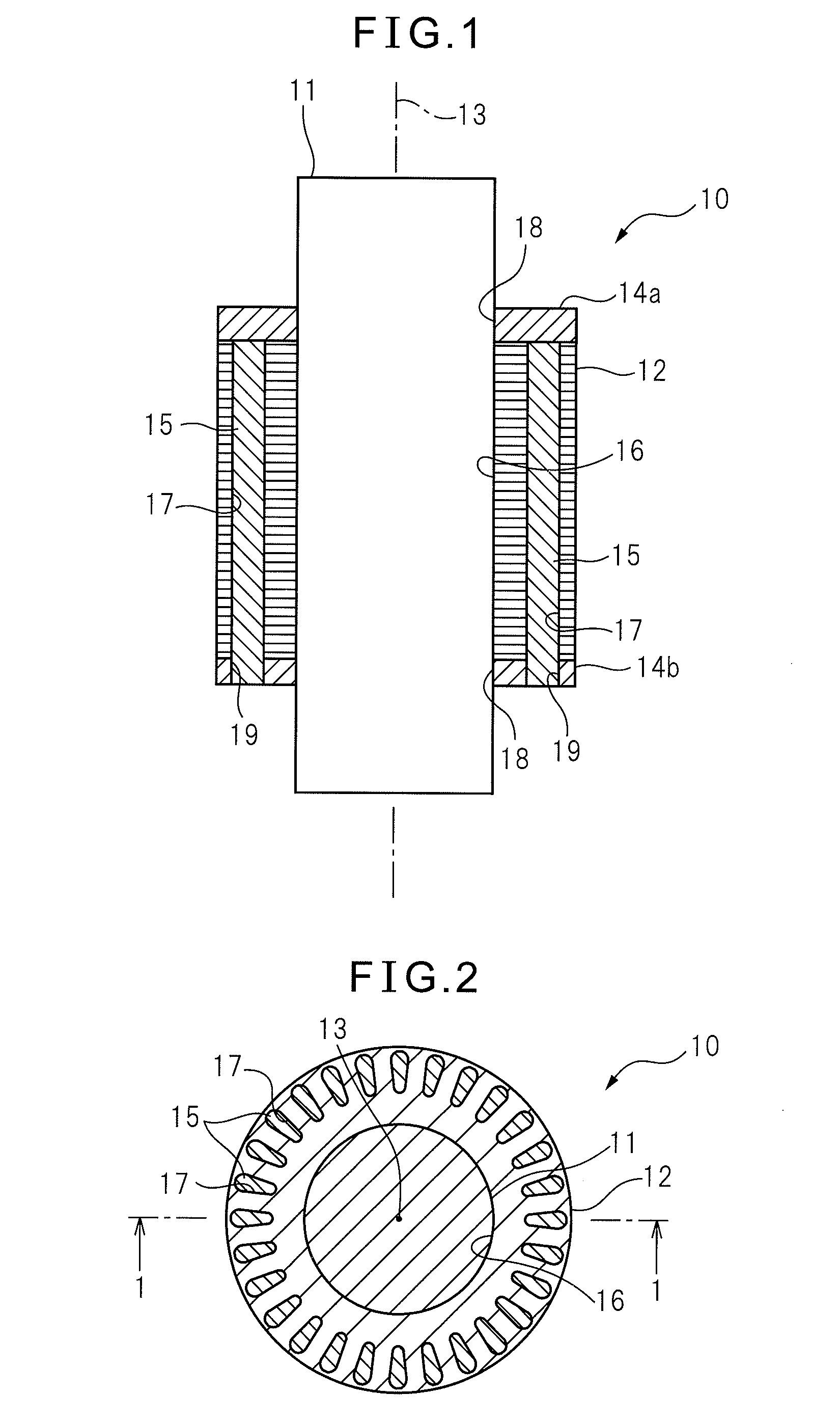

Induction machine

InactiveUS20140252910A1Improve power factorImprove efficiencySynchronous motorsAsynchronous induction motorsElectric machineMechanical engineering

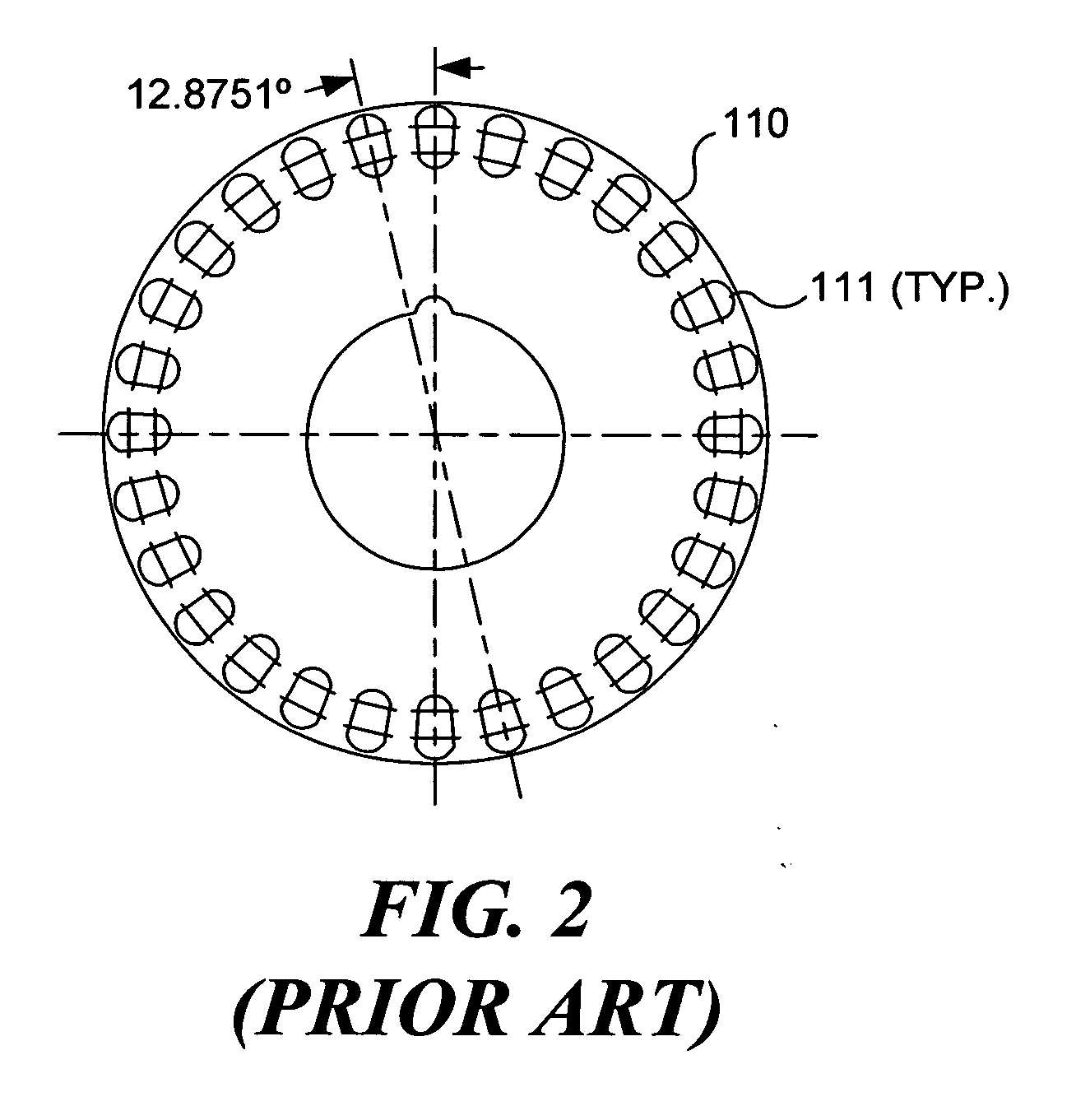

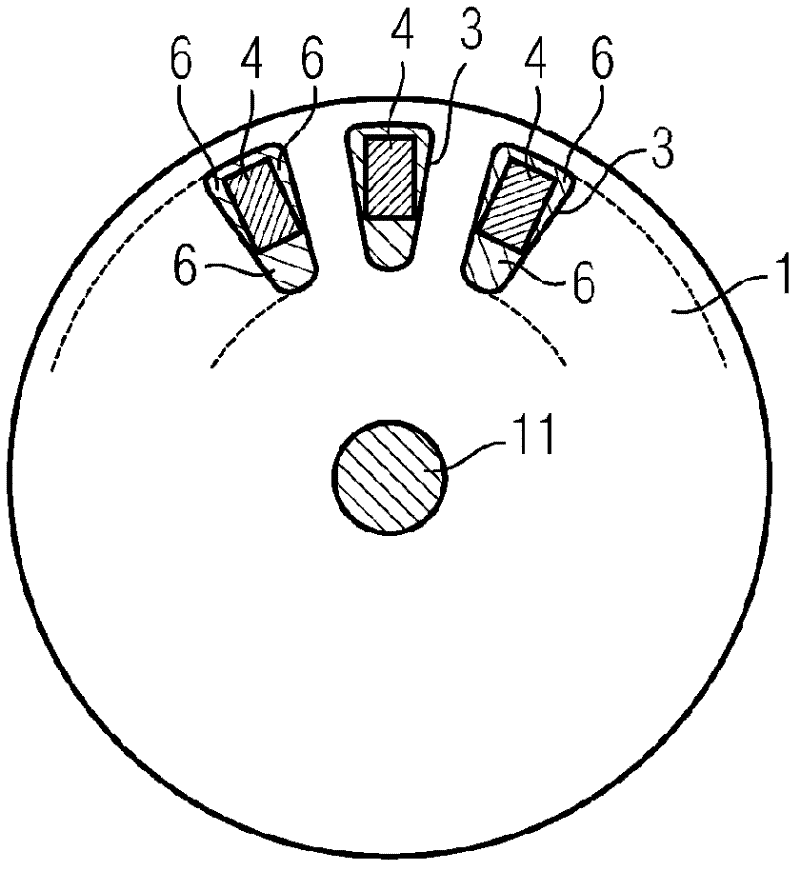

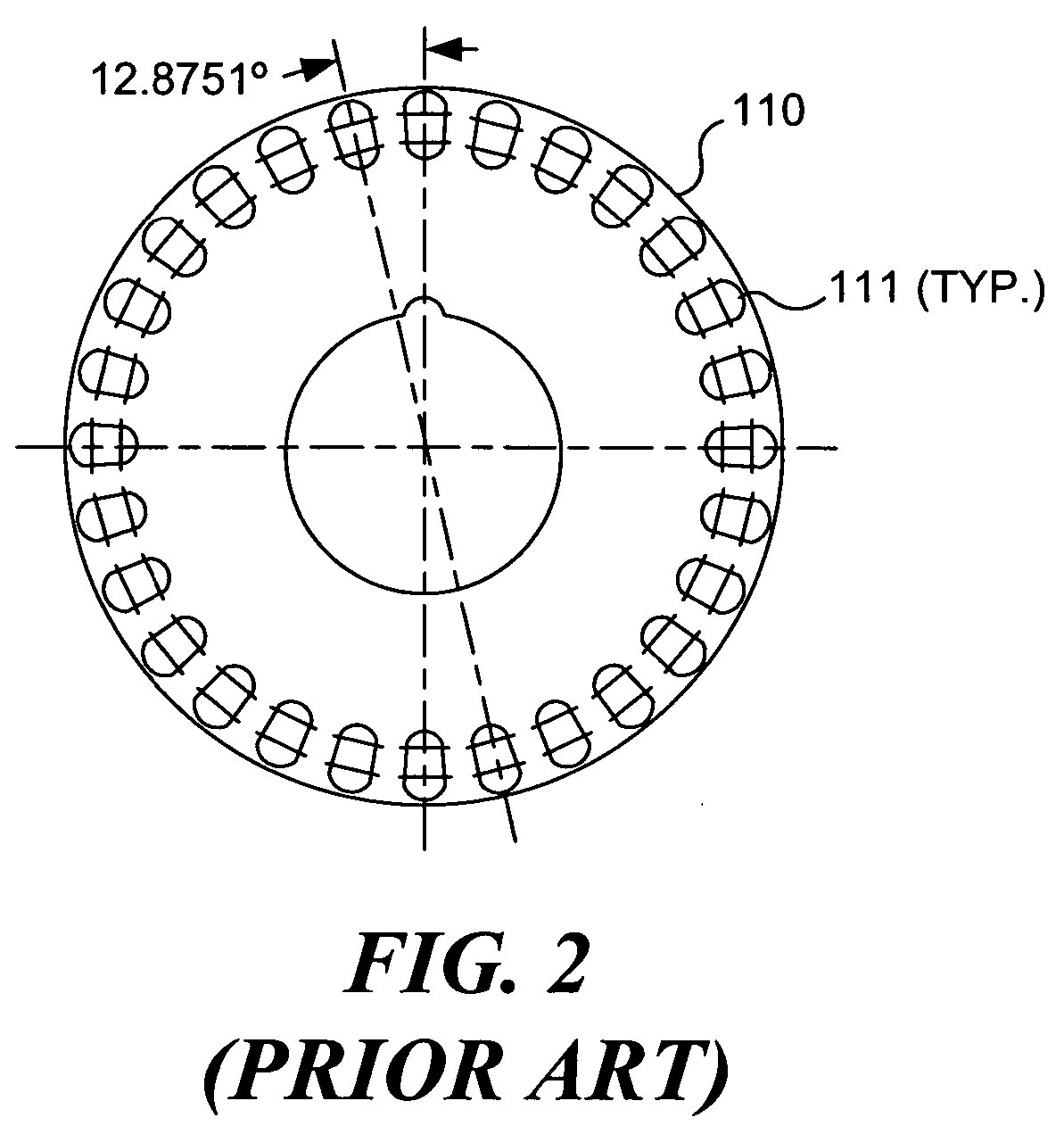

There is provided an induction machine having a squirrel-cage rotor, the rotor including: a rotor core; a plurality of rotor slots formed on the rotor core and aligned circumferentially at a predetermined interval; a plurality of rotor bars inserted into one of the plurality of rotor slots; and a plurality of rotor slits formed adjacent to the plurality of rotor slots on an outer circumferential side of the rotor core. The each rotor slit is formed as a hollow such that a cross sectional shape thereof is distinguished into three parts of a slit outer circumferential part, a slit intermediate part, and a slit inner circumferential part. A circumferential width of the each rotor slit on an innermost circumferential side is larger than that on an outermost circumferential side. A circumferential width of the slit intermediate part increases from an outer circumferential side toward an inner circumferential side.

Owner:HITACHI LTD

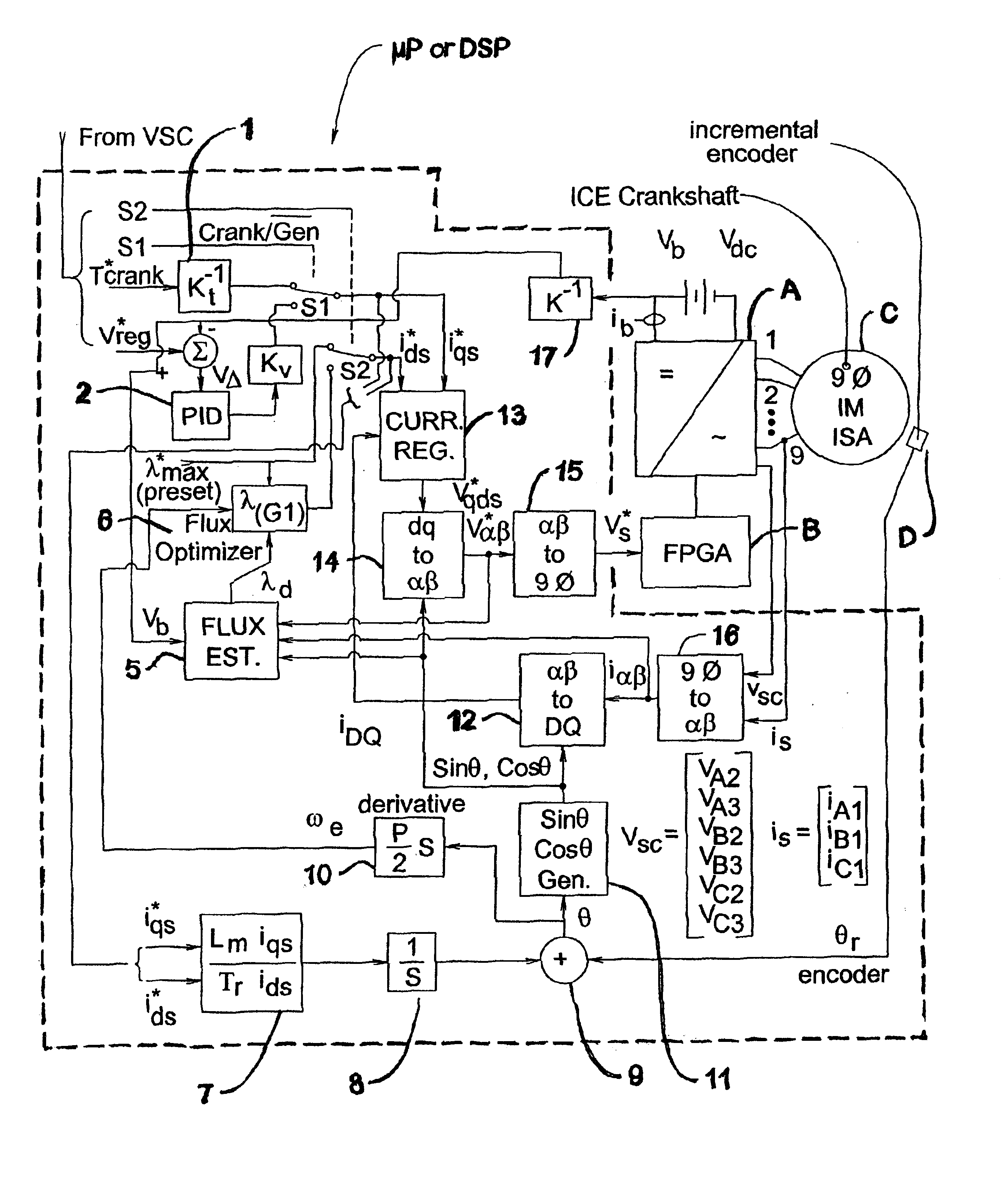

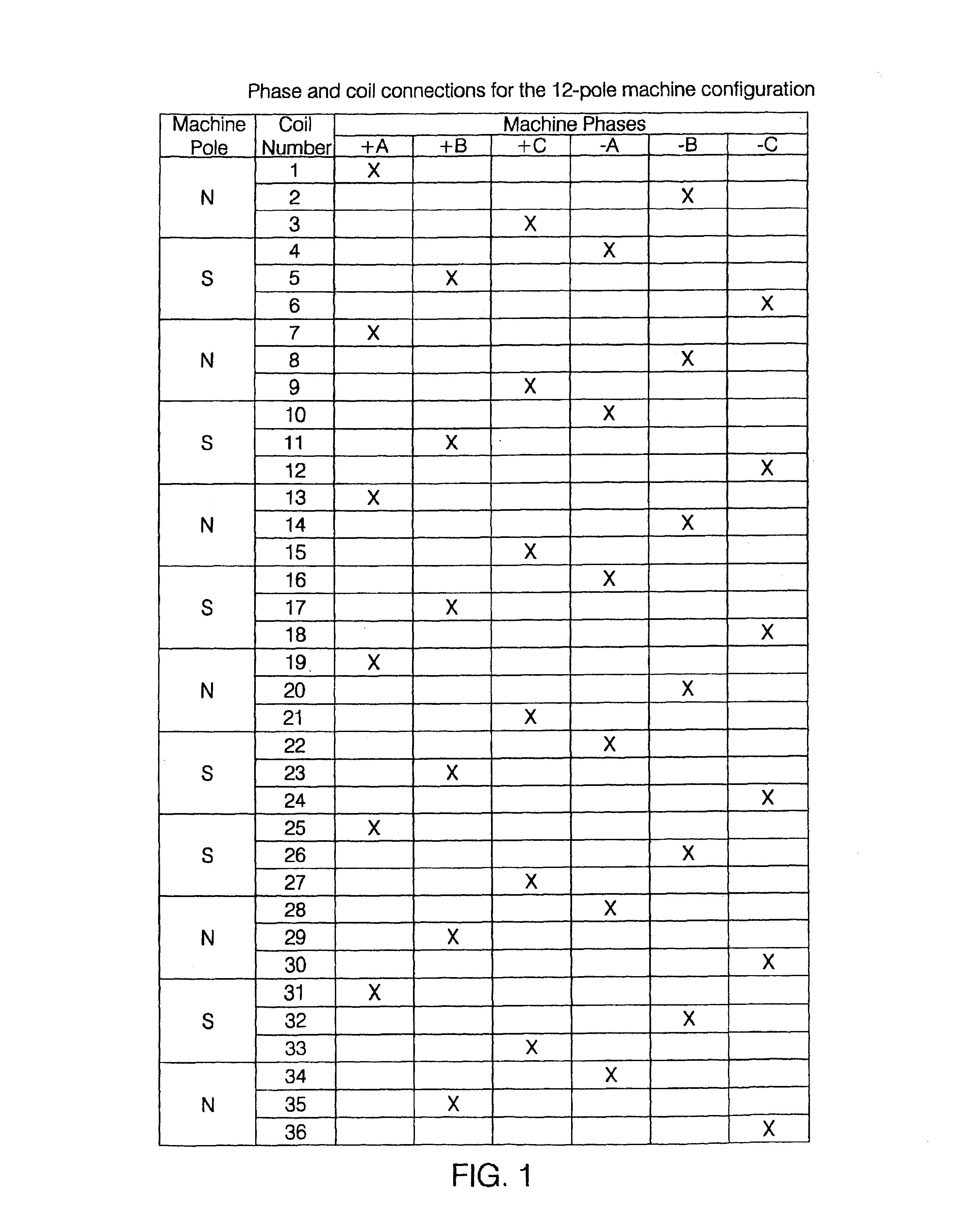

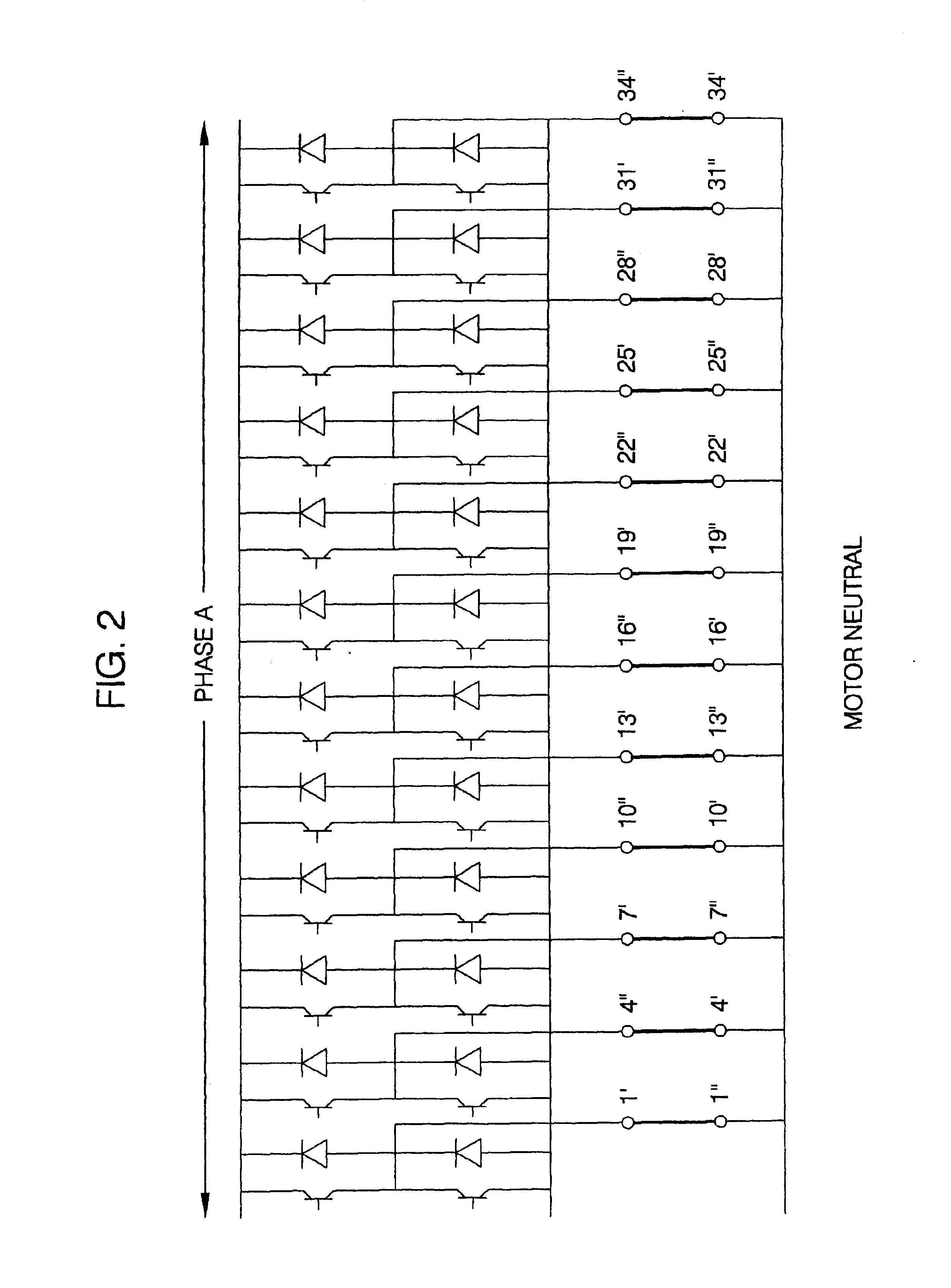

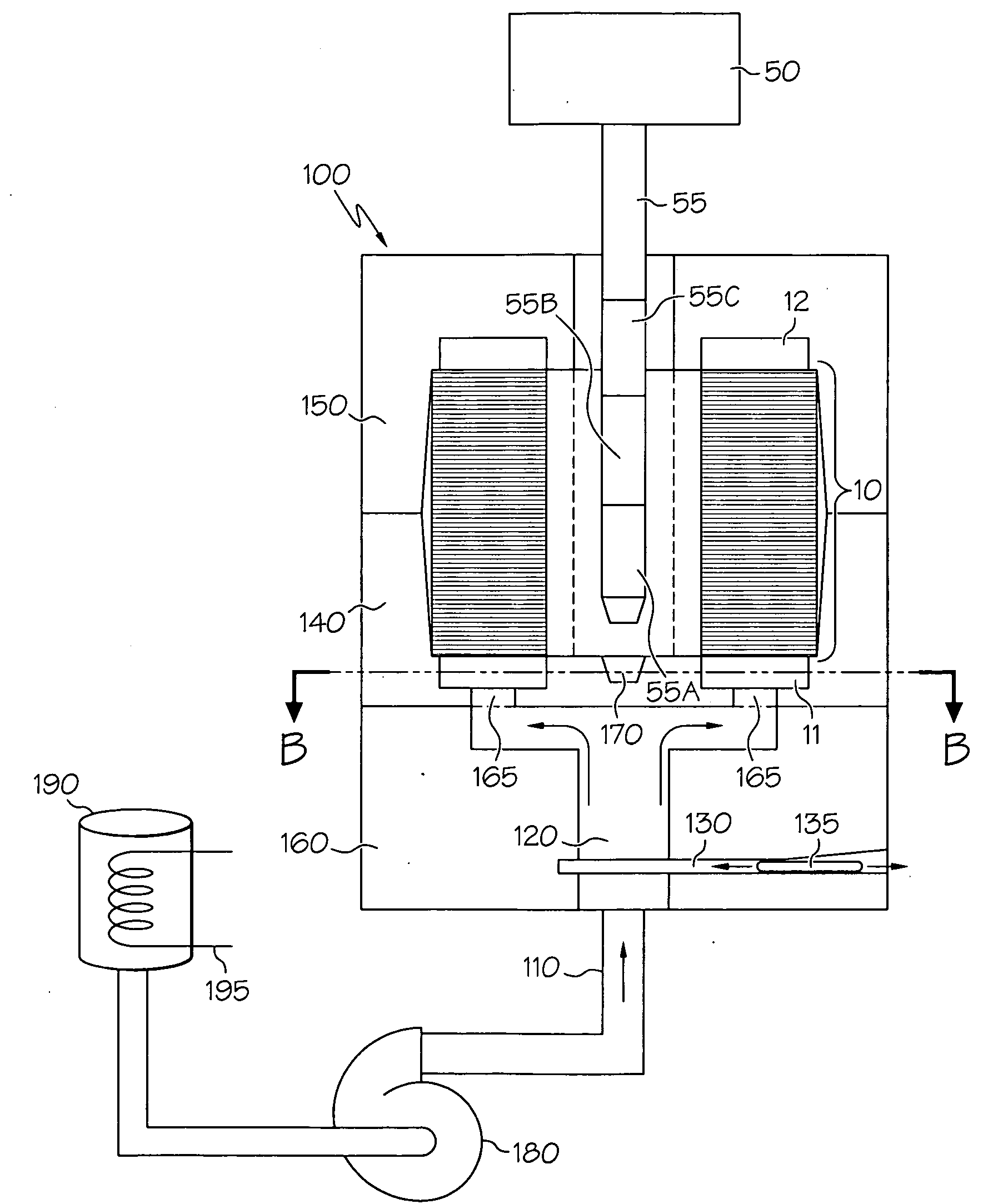

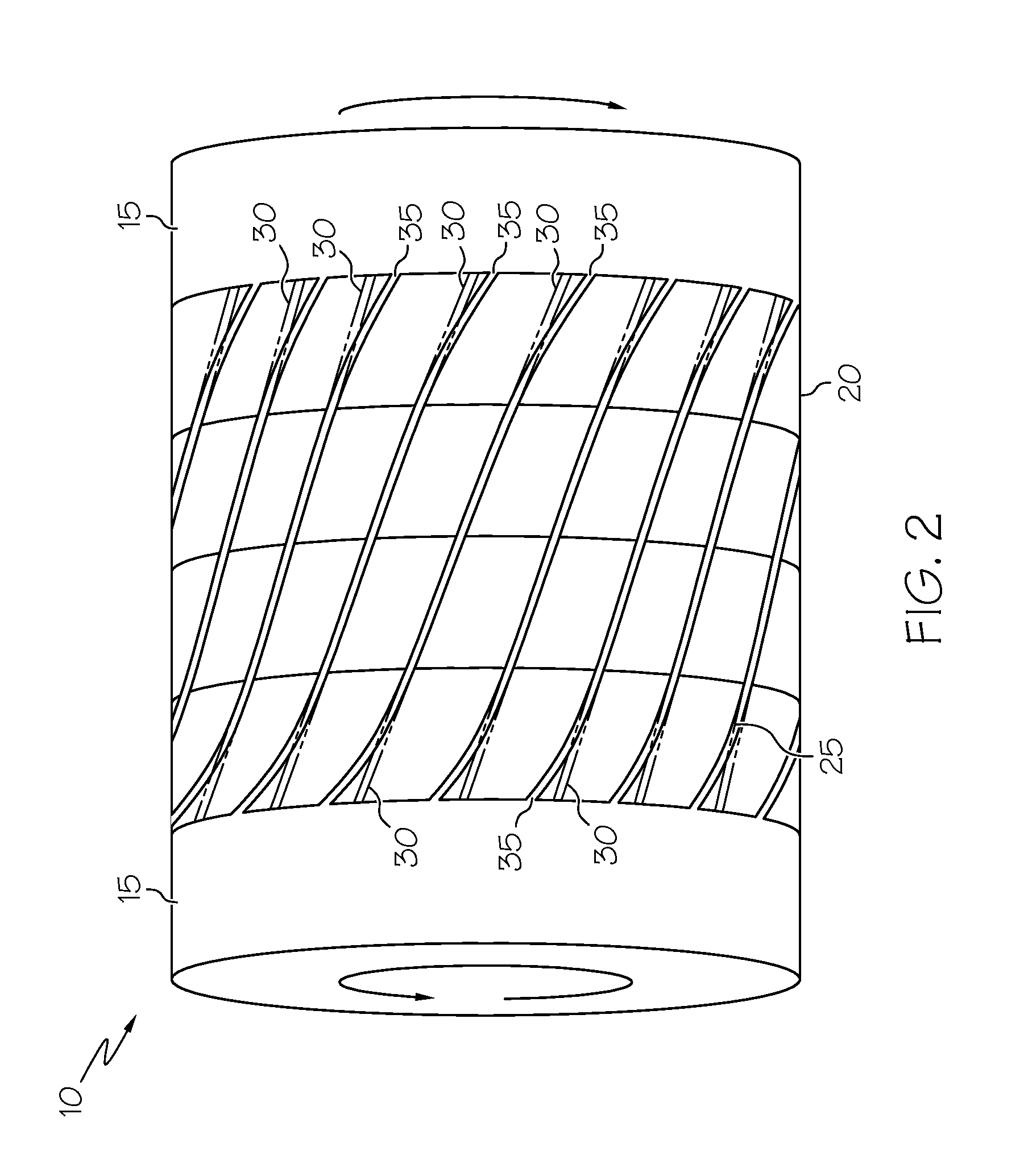

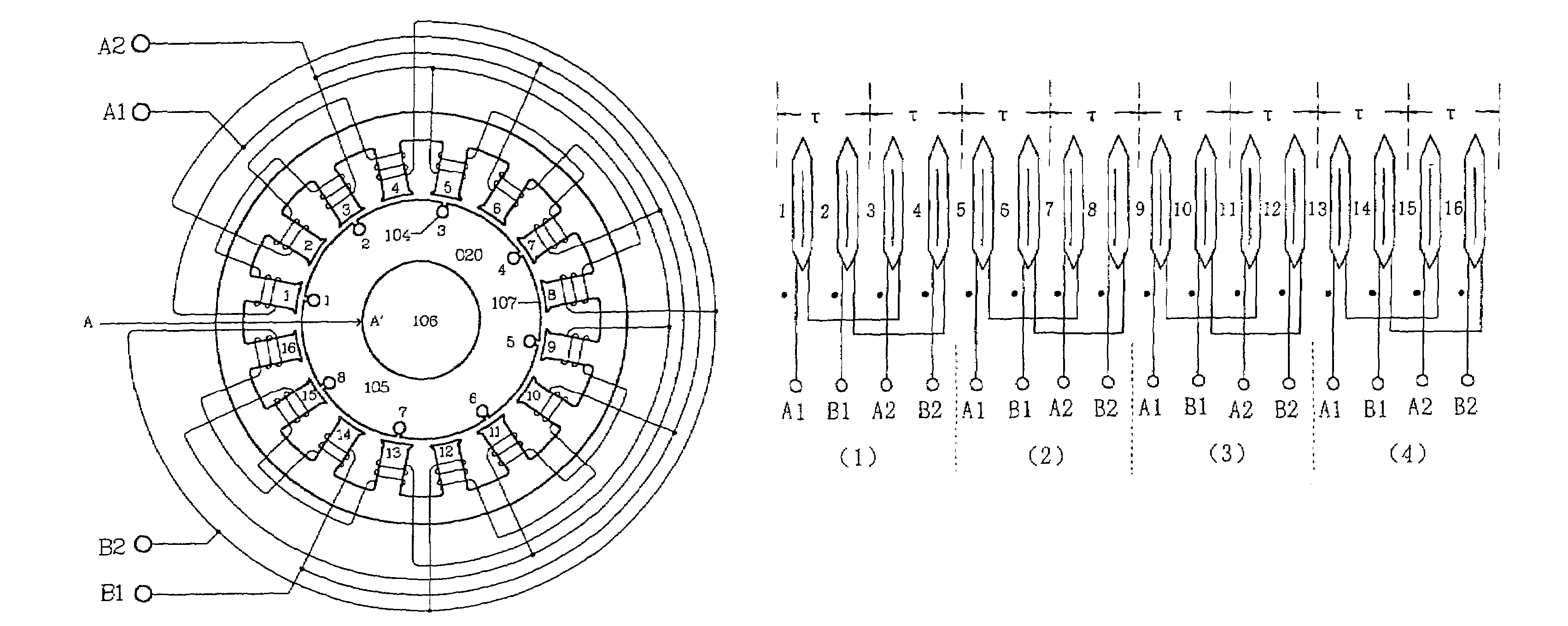

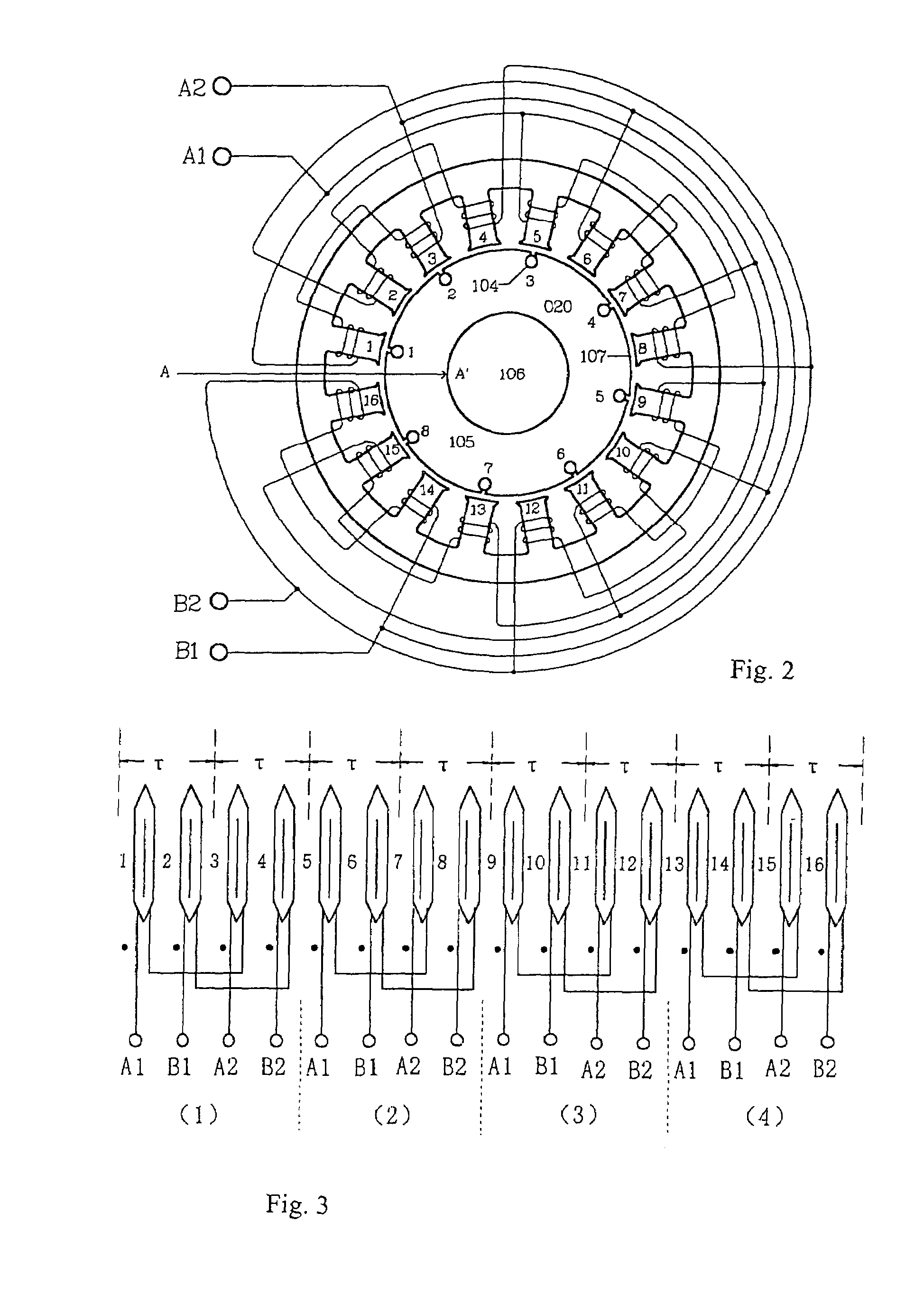

Toroidally wound induction motor-generator with selectable number of poles and vector control

InactiveUS6876176B2Increase torqueReduce speedElectronic commutation motor controlMotor/generator/converter stoppersEngineeringMotor–generator

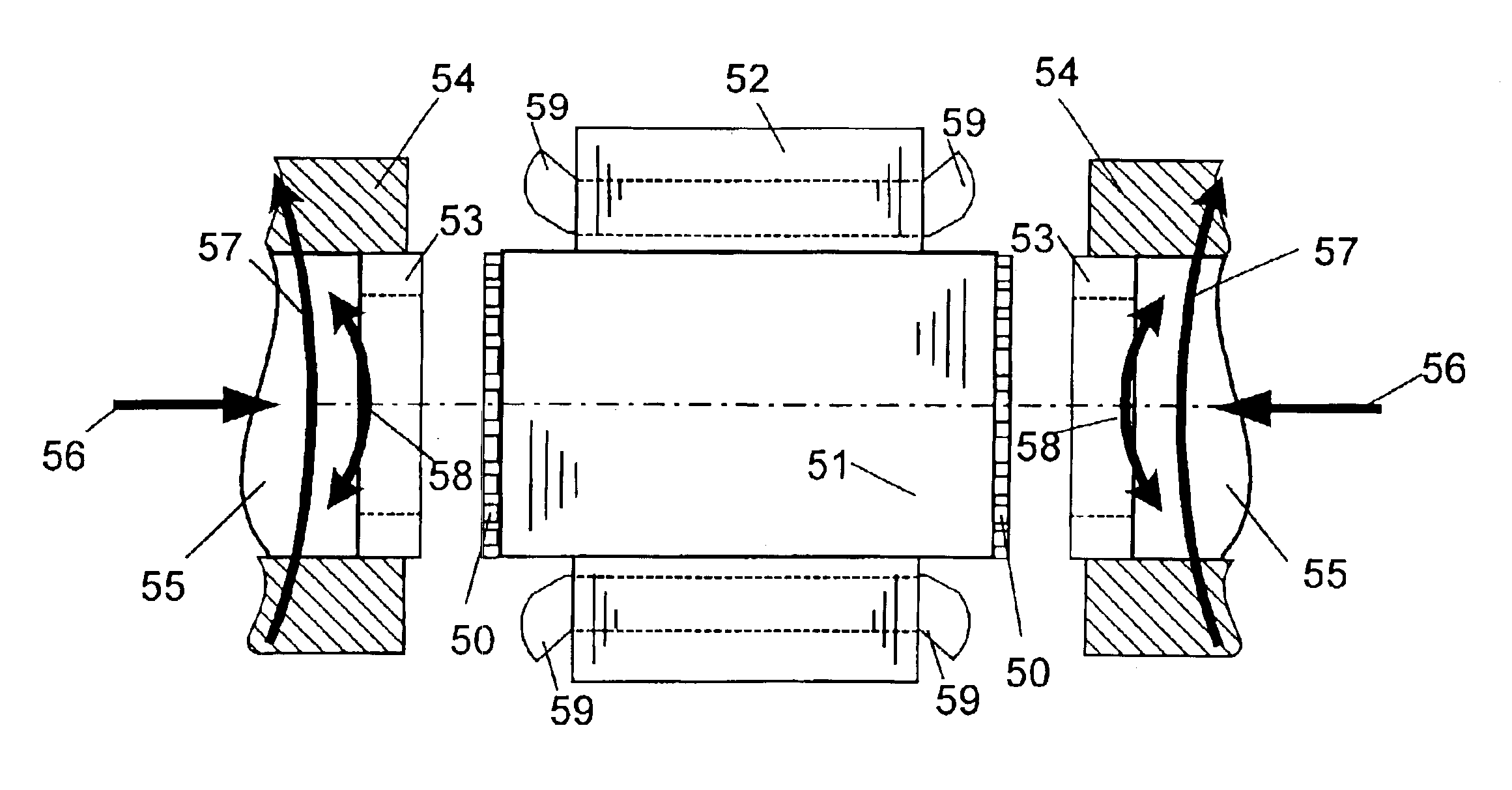

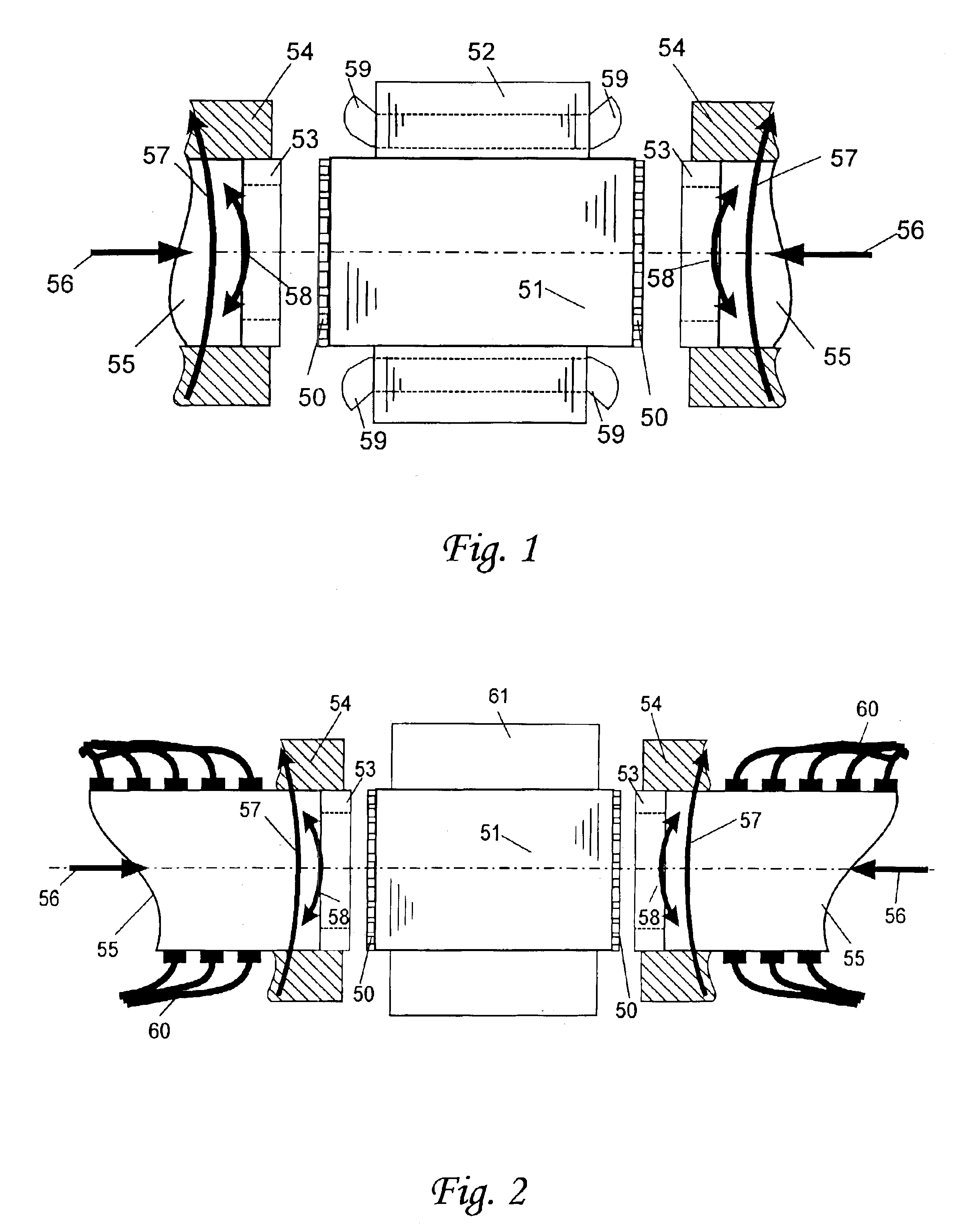

A system including an induction machine with a toroidally wound stator and a squirrel cage rotor is presented. The toroidally wound stator has a plurality of phase windings. A position sensor may be operatively connected to the induction machine for providing a position indication that is indicative of a relative position of the rotor and the stator. The system also includes an inverter having a plurality of solid-state switches and a control system. The inverter has the same number of phases as the toroidal induction machine. The inverter is connected to selectively energize the phase windings. A programmable microprocessor, such as a digital signal processor, is operatively connected to the induction machine and includes a program to implement vector control of the induction machine. The microprocessor can also control the inverter so that the induction machine operates with a predetermined number of poles using pole phase modulation.

Owner:FORD GLOBAL TECH LLC

Pressure casting of electric rotors

InactiveUS20100243197A1Sufficient pressureInhibited porositySynchronous motorsFoundry mouldsMolten statePorosity

A rotor for an induction motor and a method of preparing same. The method includes making a squirrel-cage rotor made up of a cage and a laminate stack by forming a mold around the stack, heating the stack and introducing a molten metal into the mold such that the molten metal substantially fills a space defined in the stack that corresponds to the cage. In one form, the space includes slots or related channels formed in the stack that upon filling with the molten metal become longitudinal bars that form electric current loops with end rings of the cage. By heating the stack and maintaining it at a temperature high enough to keep the molten metal in a substantially molten state at least long enough for it to flow through the slots of the stack, premature freezing of the molten metal is avoided. In addition, by providing low pressure to the molten metal in conjunction with the elevated temperature in the stack, flow is promoted to ensure a substantially porosity-free, fully dense squirrel-cage for the rotor.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrofriction method of manufacturing squirrel cage rotors

InactiveUS6877210B2Smooth connectionReduce area of smallWindingsMagnetic circuitEngineeringConductive materials

A method of making a squirrel cage rotor of copper material for use in AC or DC motors, includes forming a core with longitudinal slots, inserting bars of conductive material in the slots, with ends extending out of opposite ends of the core, and joining the end rings to the bars, wherein the conductive material of either the end rings or the bars is copper. Various methods of joining the end rings to the bars are disclosed including electrofriction welding, current pulse welding and brazing, transient liquid phase joining and casting. Pressure is also applied to the end rings to improve contact and reduce areas of small or uneven contact between the bar ends and the end rings. Rotors made with such methods are also disclosed.

Owner:UT BATTELLE LLC

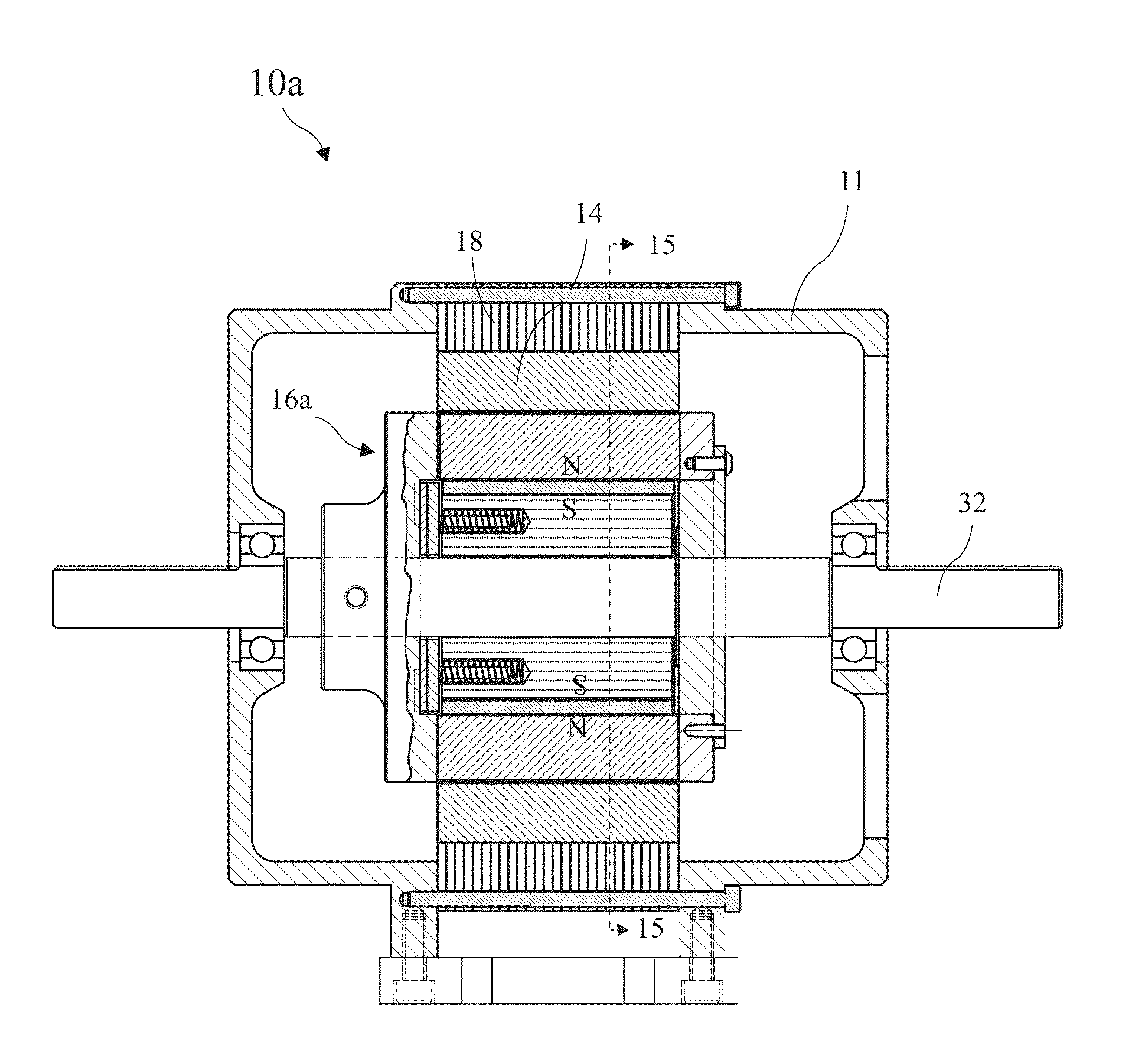

Hybrid Induction Motor with Self Aligning Permanent Magnet Inner Rotor

ActiveUS20130278096A1Avoids magnetic overloadAvoid stallingMagnetic circuit rotating partsAsynchronous induction motorsPermanent magnet rotorSynchronous motor

A hybrid induction motor includes an inductive rotor and an independently rotating permanent magnet rotor. The inductive rotor is a squirrel cage type rotor for induction motor operation at startup. The permanent magnet rotor is axially displaced and variably coupled to the inductive rotor (or to a motor load) through a clutch and is allowed to rotate independently of the inductive rotor at startup. The independently rotating permanent magnet rotor quickly reaches synchronous RPM at startup. As the inductive rotor approaches or reaches synchronous RPM, the coupling between the inductive rotor and the permanent magnet rotor increases until the two rotors are coupled at the synchronous RPM and the motor transitions to efficient synchronous operation.

Owner:MOTOR GENERATOR TECH INC

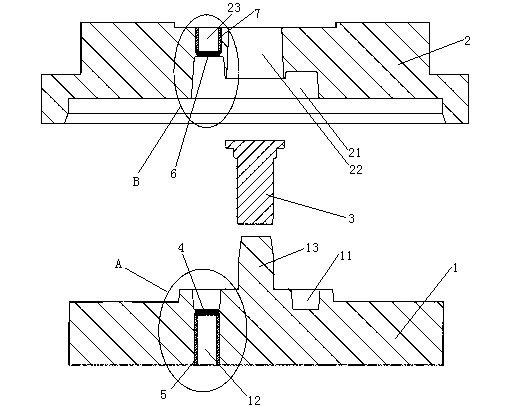

Permanent magnet synchronous motor of sine pole width modulation

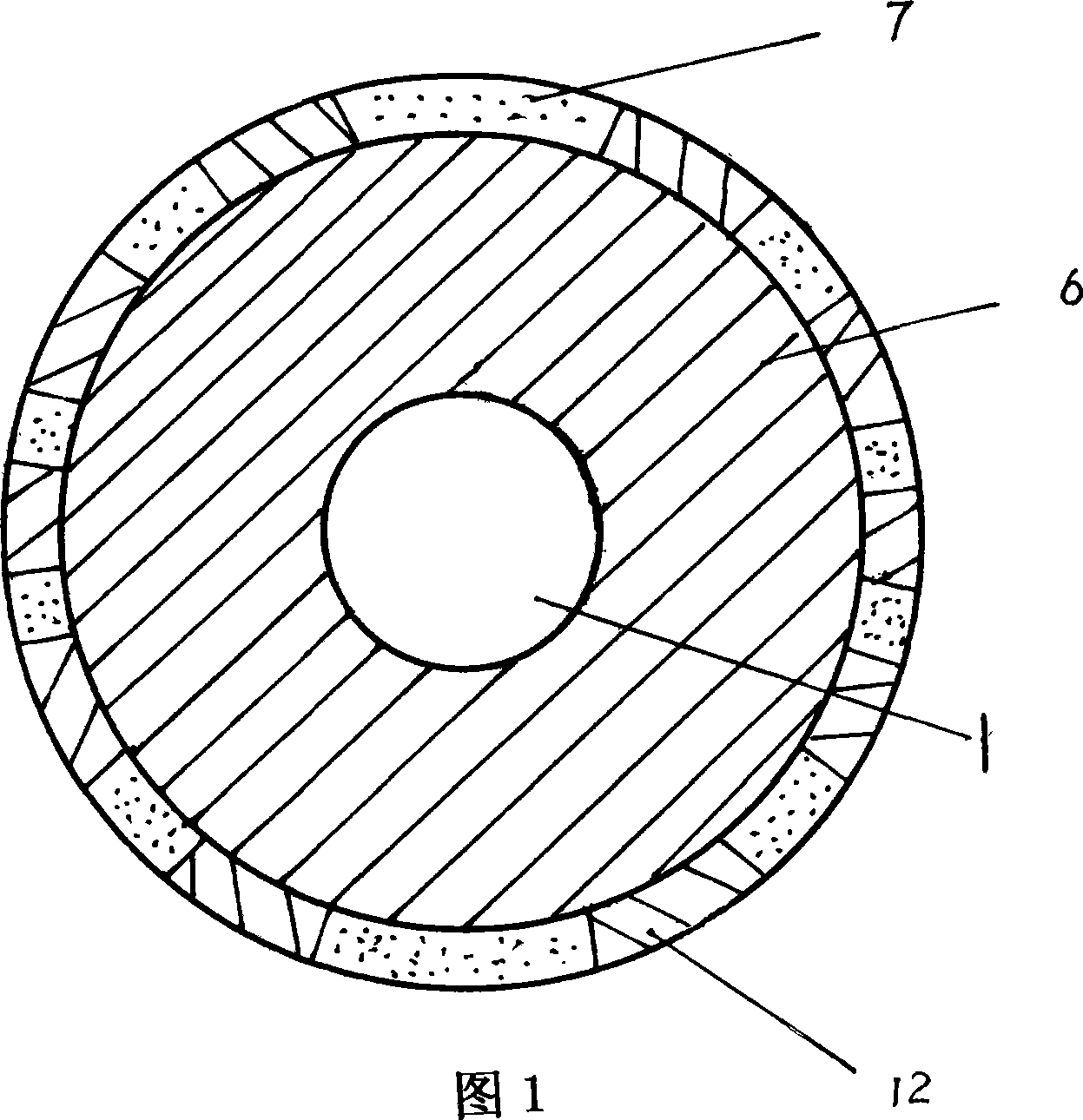

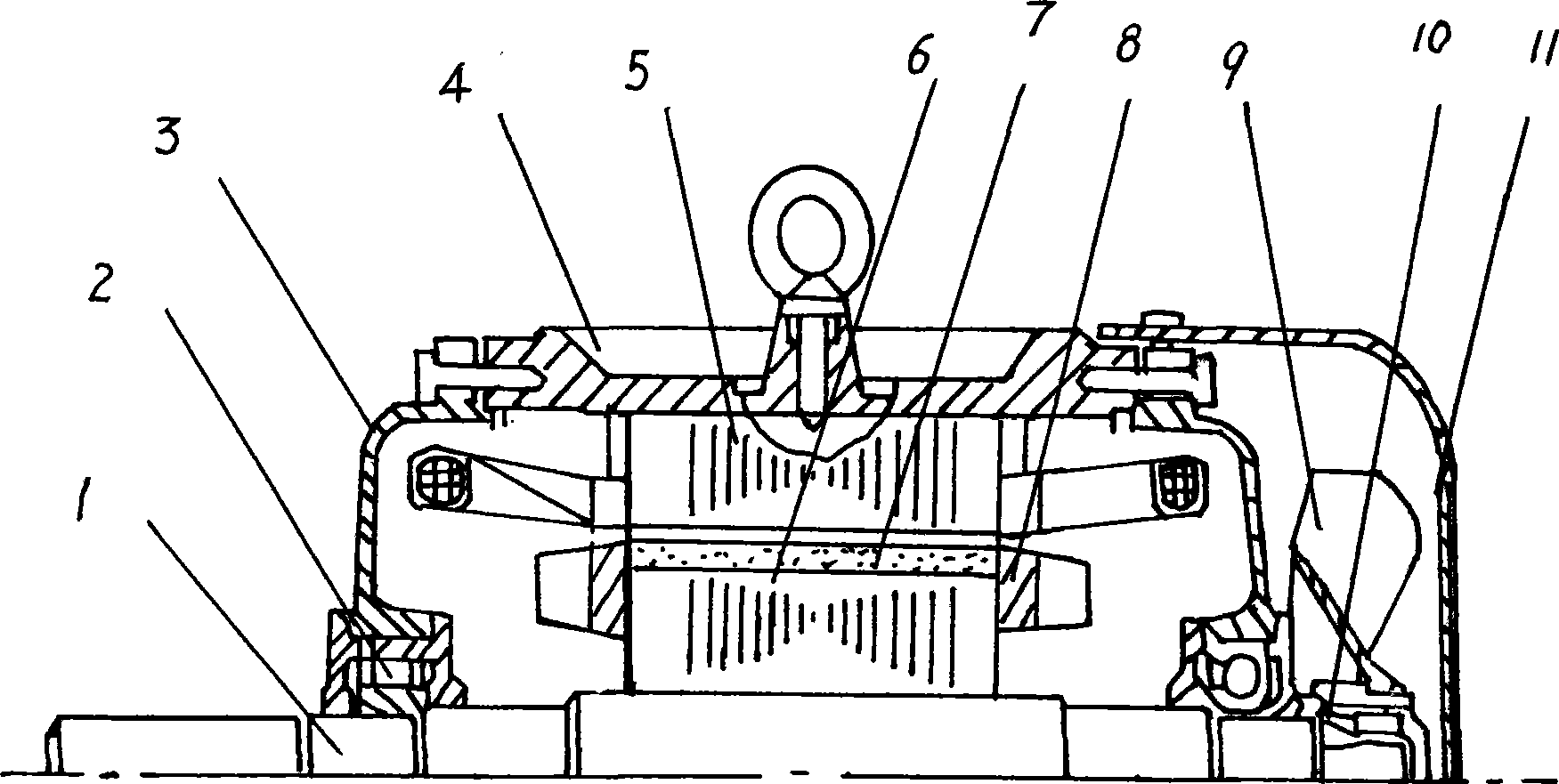

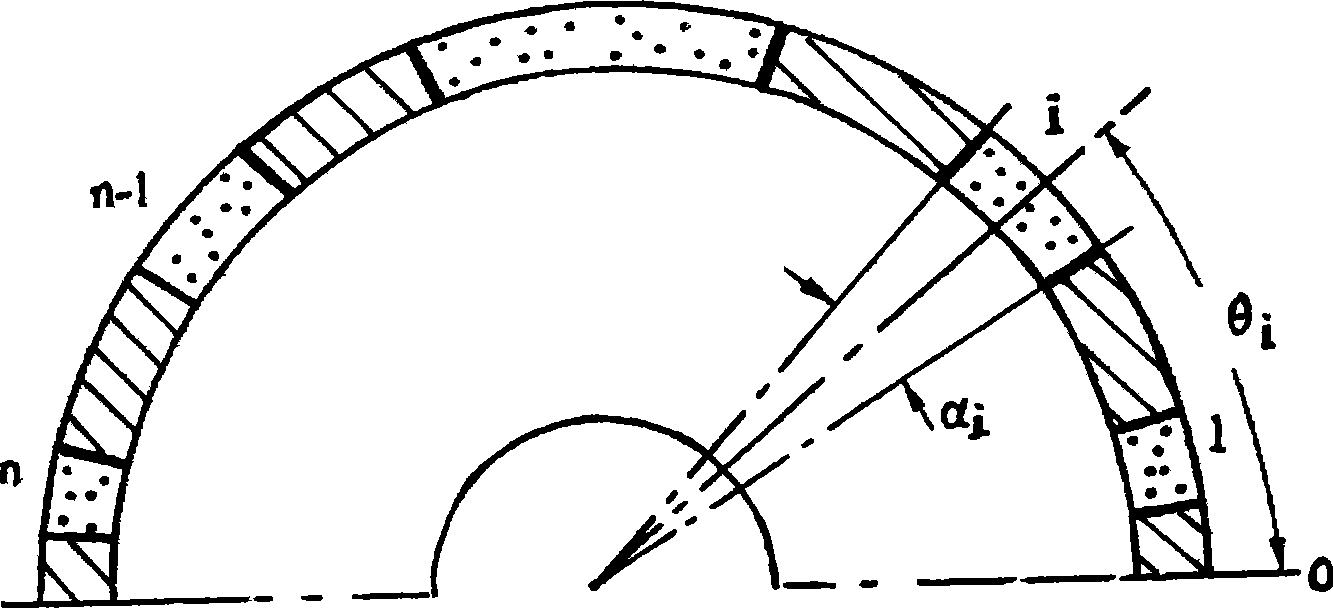

InactiveCN101420160AOvercome deficienciesSelf-startingSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

The invention relates to a permanent magnet synchronous motor of sinusoidal pole width modulation, belonging to the technical field of motors. The motor comprises a rotation shaft (1), a bearing (2) which is matched with the rotation shaft (1), an end cover (3), a stator core (5) and a rotor core (6) which is matched with the rotation shaft (1); the motor is characterized in that n distribution-typed permanent magnetic pole (7), with unequal widths and intermittent spacings, are fixed at the circumference of the rotor core (6); the central line of the distribution-typed permanent magnet of No. i (i is equal to 1, 2, 3,..., n) and the central line of a magnetic pole have an electric angle of Theta which is equal to (2i-1)*pi / (2n); the width arc angle Alpha of the distribution-typed magnetic pole of No. i is equal to cos((i-1)*pi / n-cos(i*pi / n)); a squirrel cage rotor (8) is arranged outside the rotor core (6) and carries out circumference separation and circumferential positioning on the distribution-typed permanent magnetic pole (7). The invention has the advantages of high work efficiency, stable and reliable operation and obvious energy-saving characteristic.

Owner:XUZHOU CURRENCY MAGNETOELECTRICITY

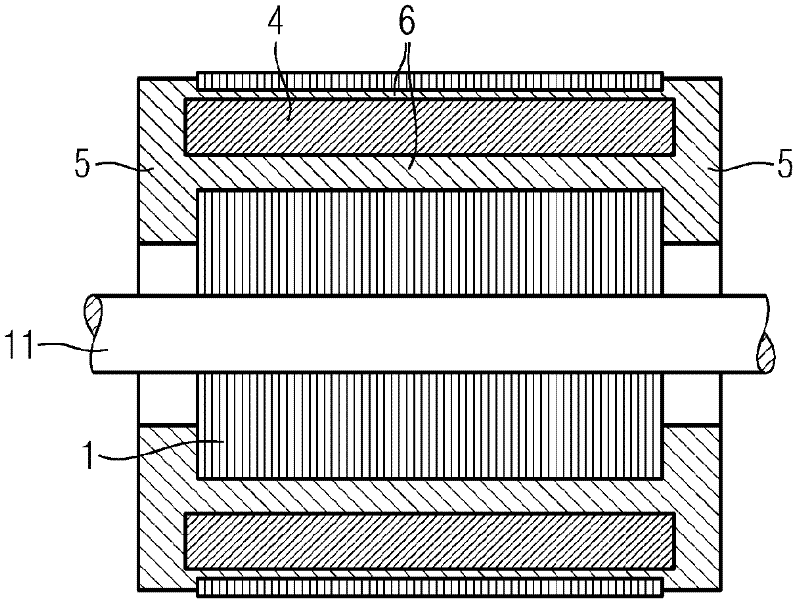

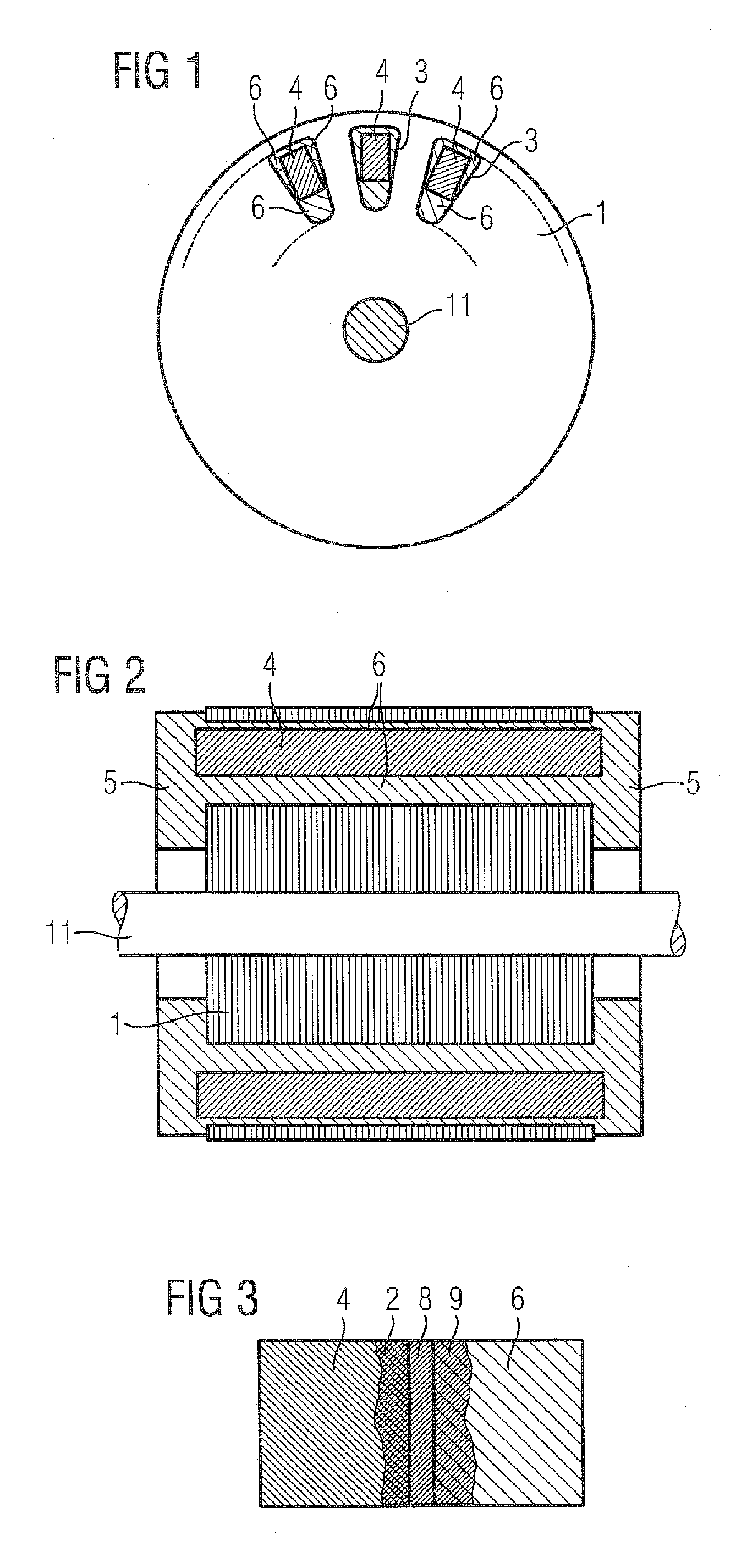

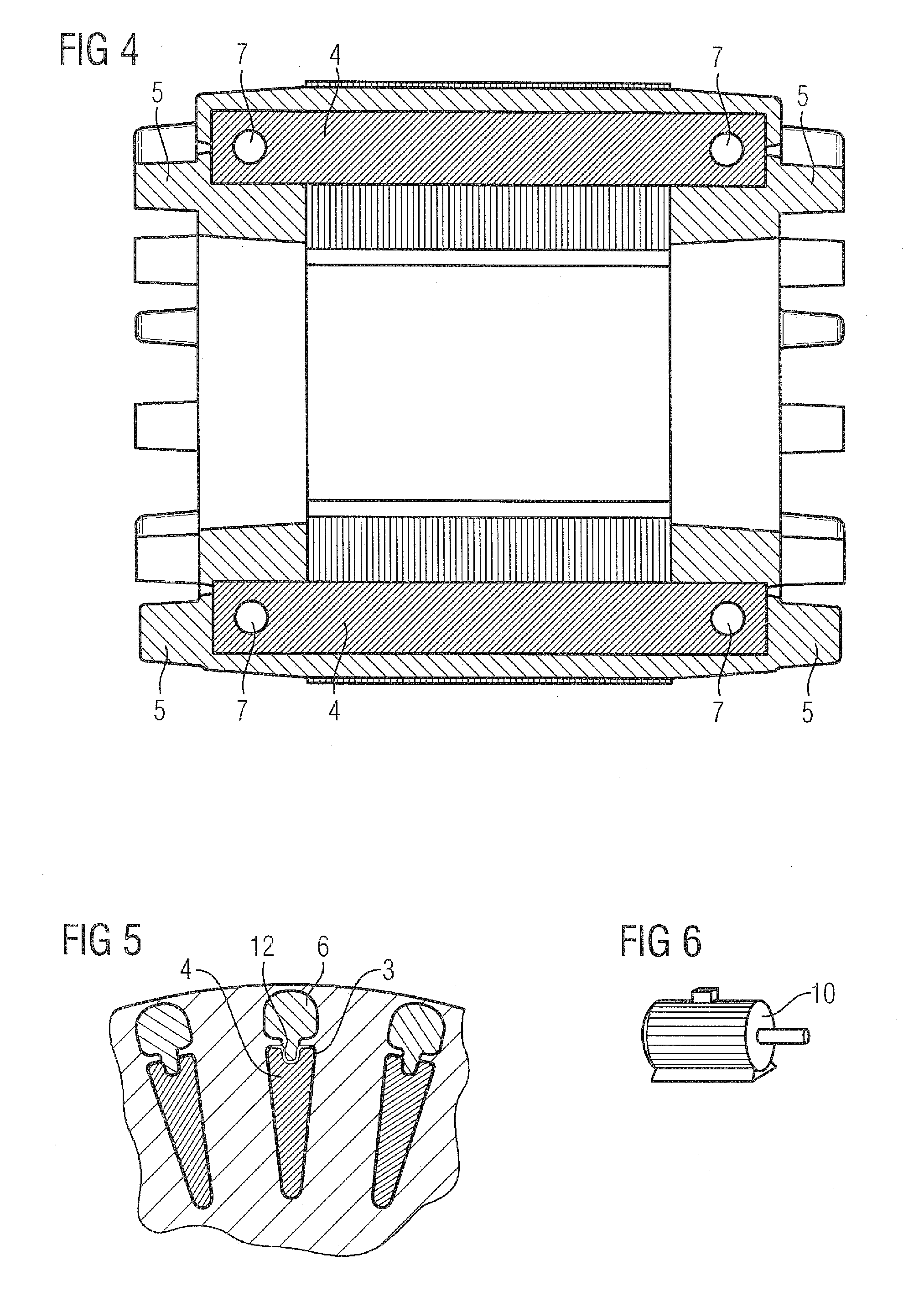

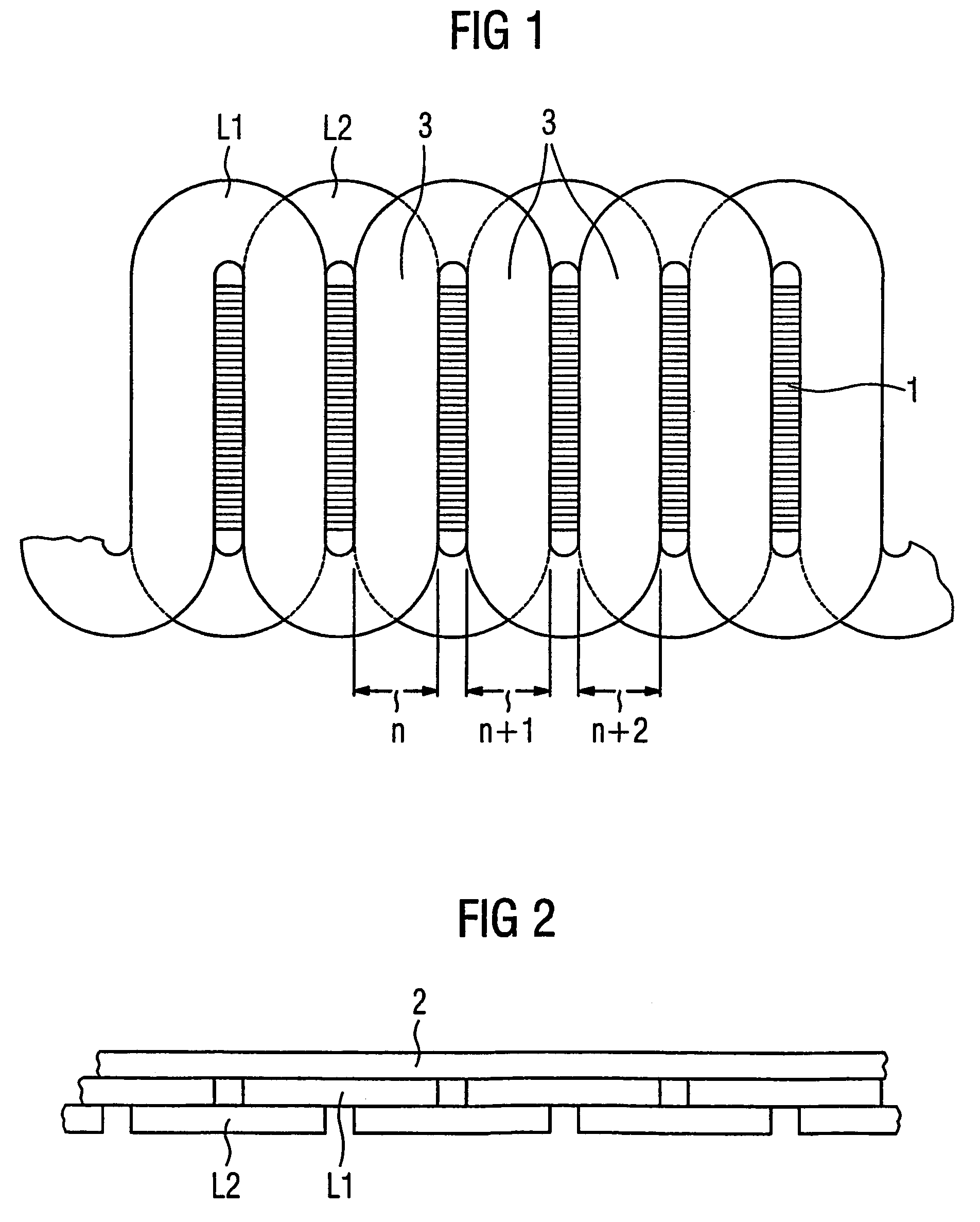

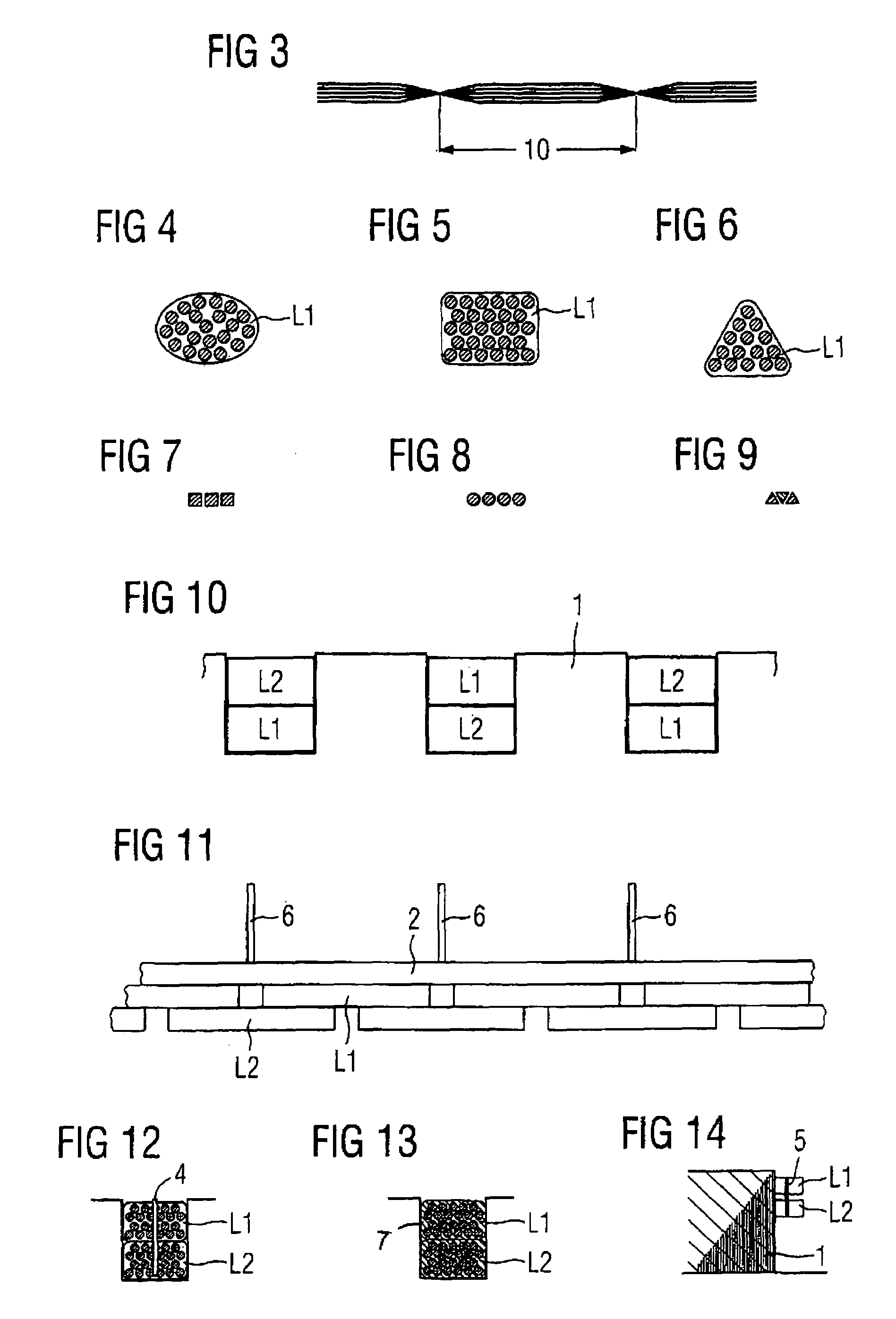

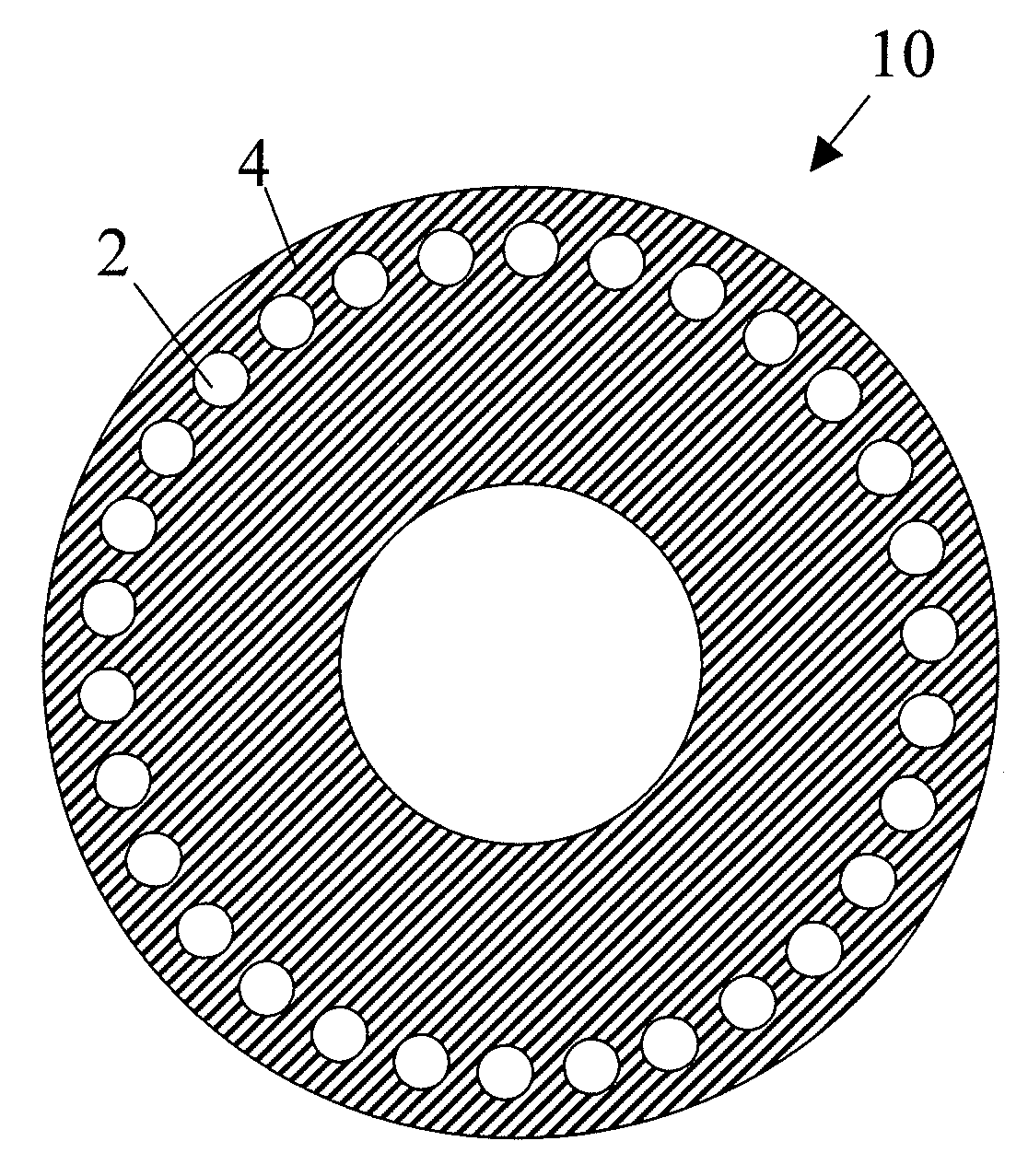

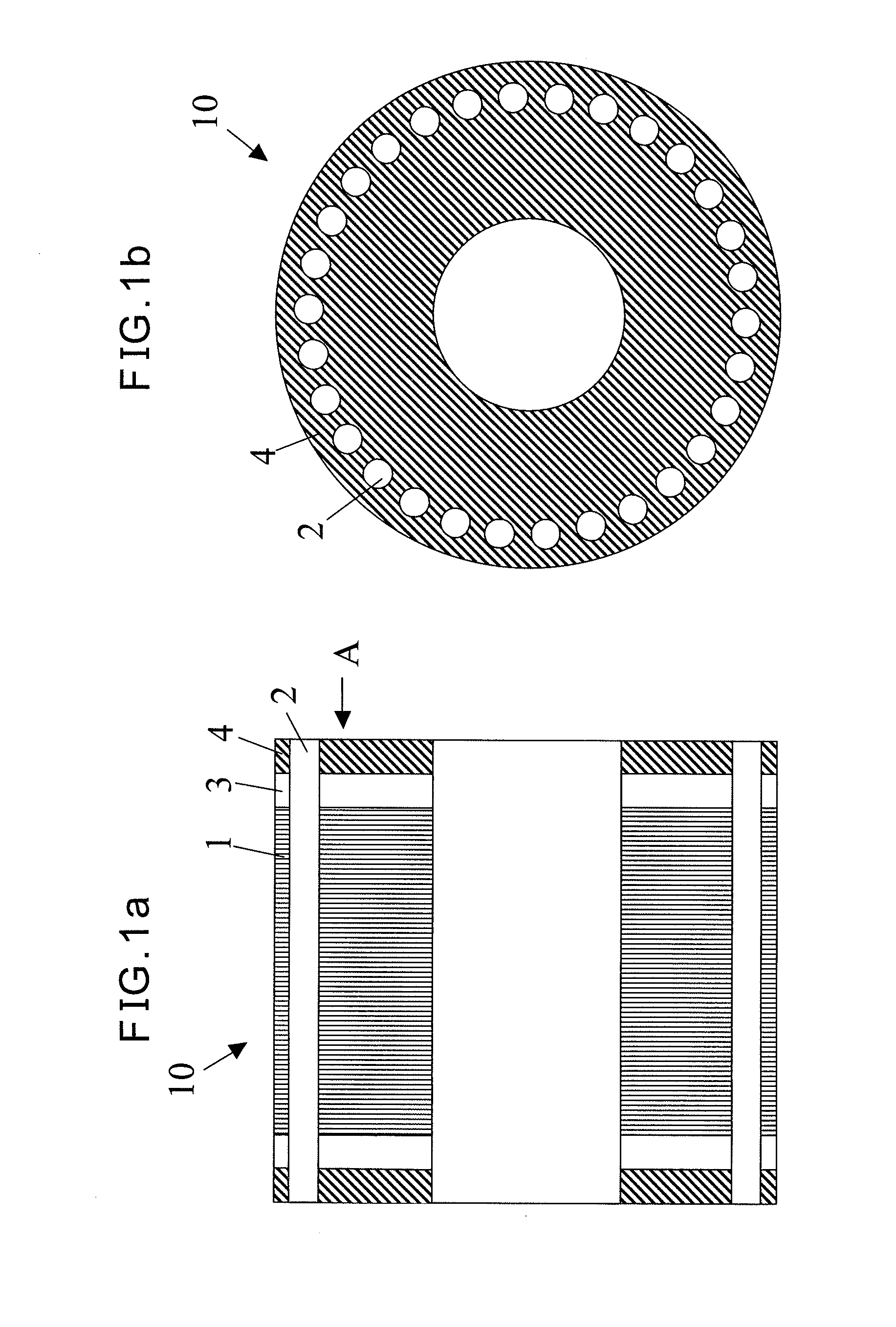

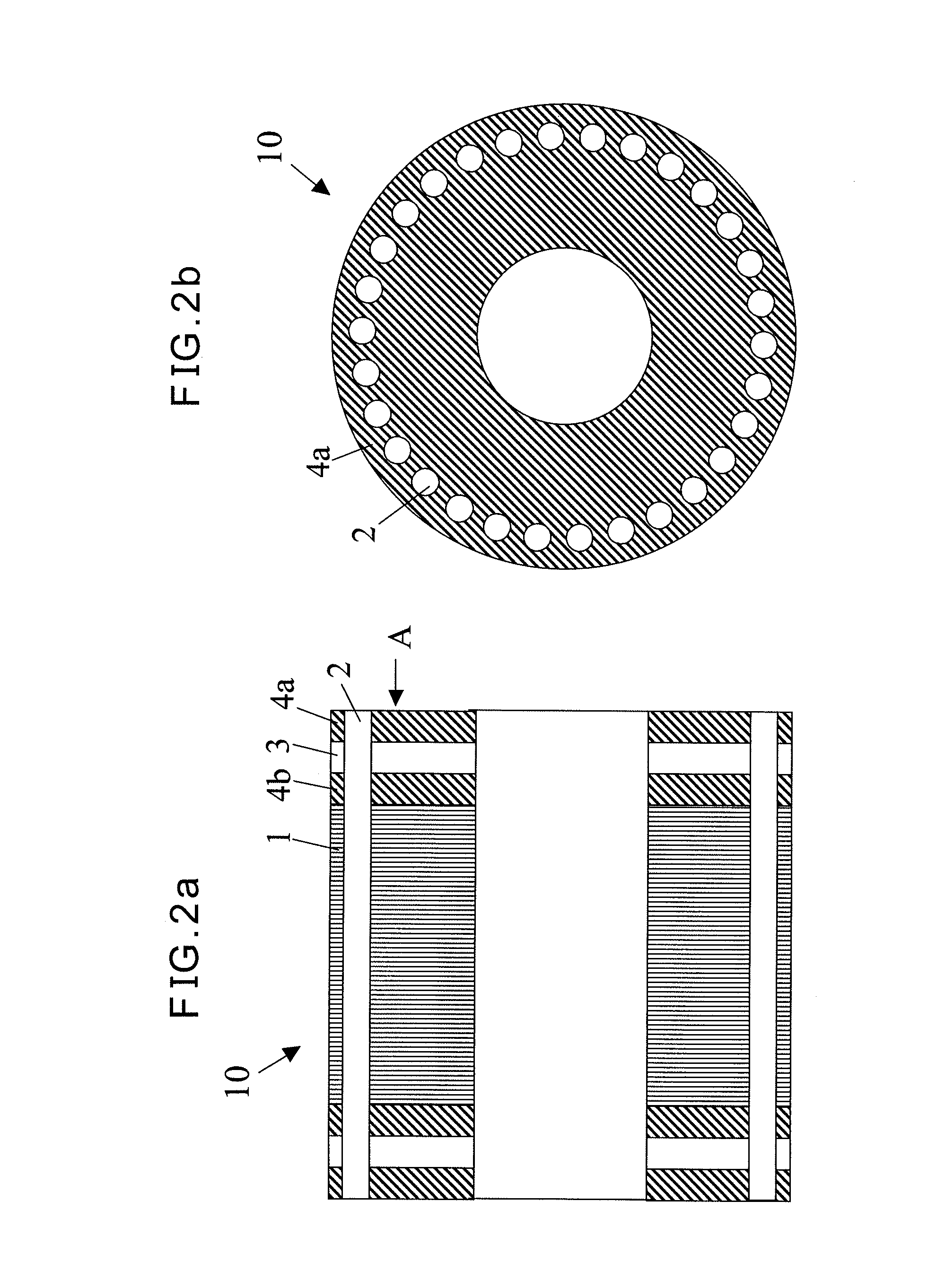

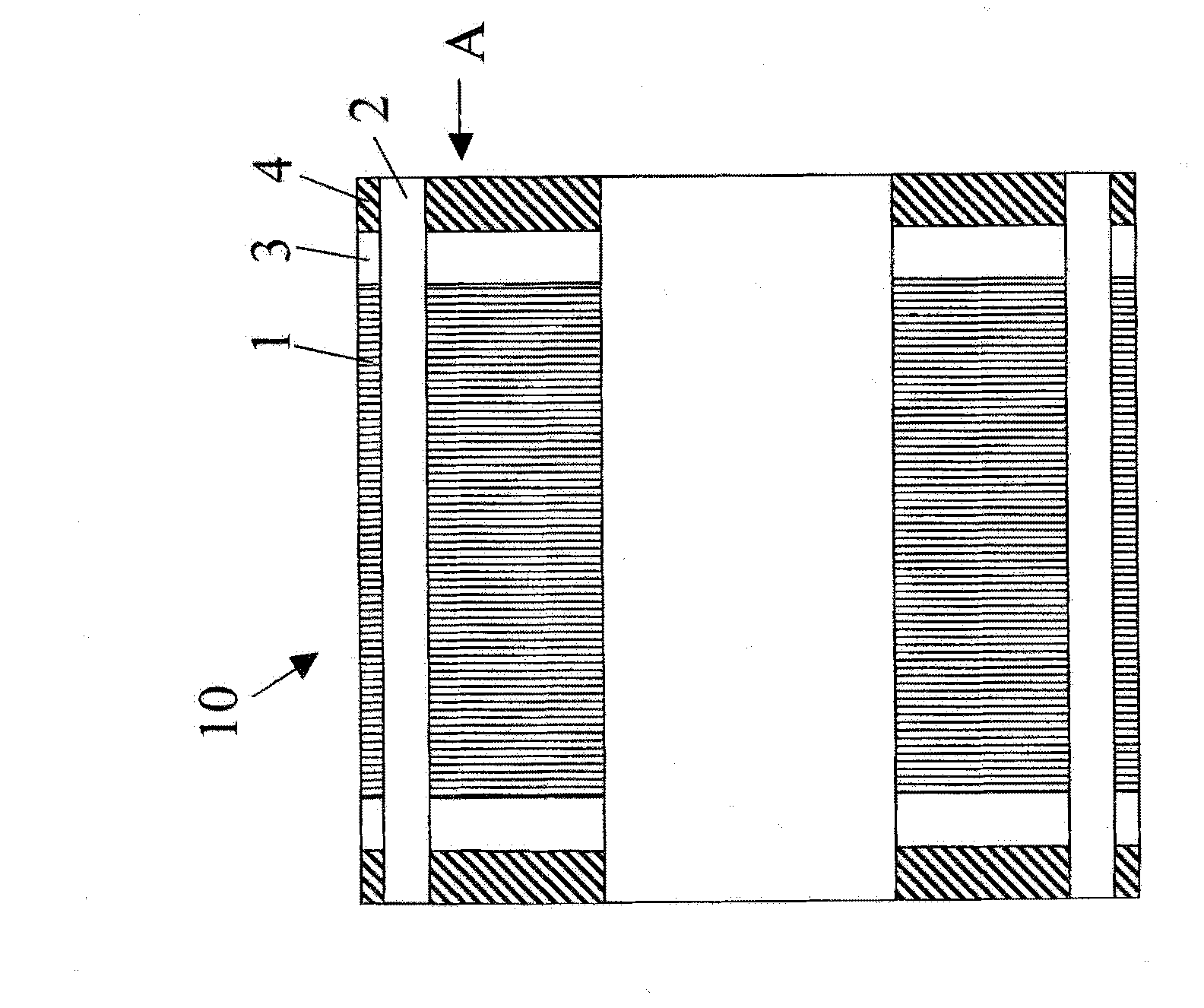

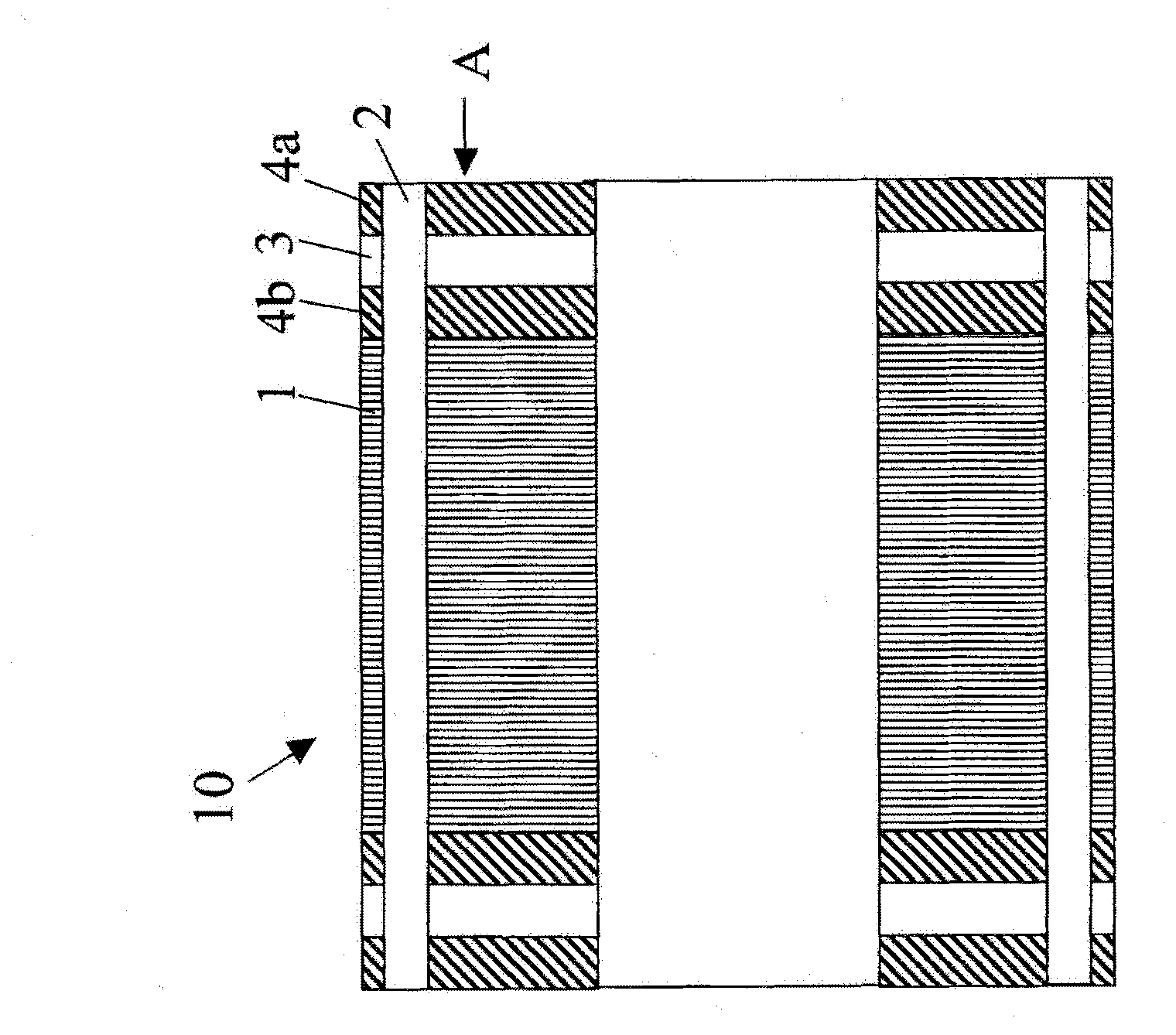

Squirrel-cage rotor

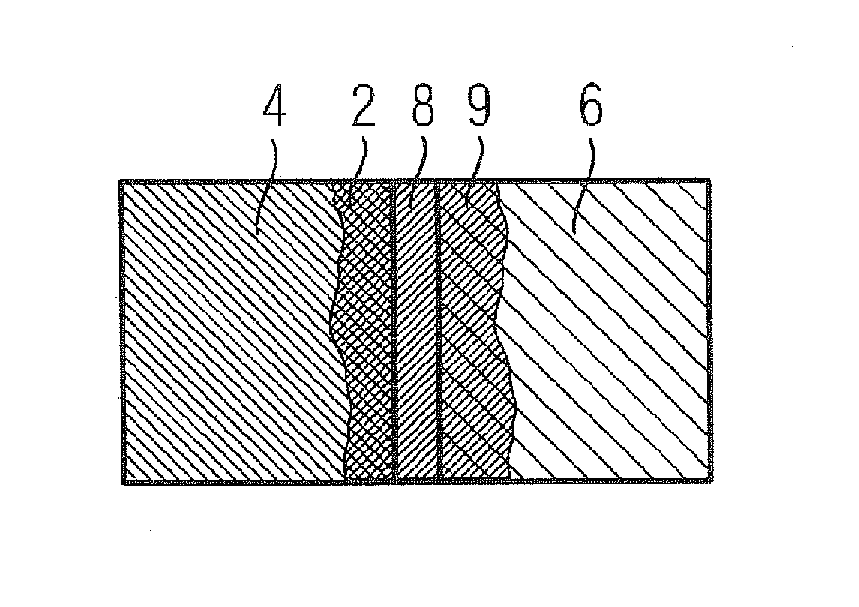

ActiveCN102318169AAsynchronous induction motorsManufacturing dynamo-electric machinesElectrical conductorEngineering

he invention relates to a squirrel-cage rotor for an asynchronous machine. In order to increase the electrical efficiency for a cage rotor composed of two materials, the cage rotor comprises a rotor core (1) having grooves (3), end rings (5) of a first material that are cast onto the rotor core on the end face, and conductors (4) that are arranged in the grooves and that are made of a second material that has a specific electric conductance that is higher than the specific electric conductance of the first material, wherein the conductors (4) comprise a coating (8) made of a coating material on the surface of the conductors, wherein the coating adjoins the second material of the conductors (4) by means of a first alloy layer (2) made of the second material and the coating material and adjoins the cast first material by means of a second alloy layer (9); made of the first material and the coating material.

Owner:SIEMENS AG

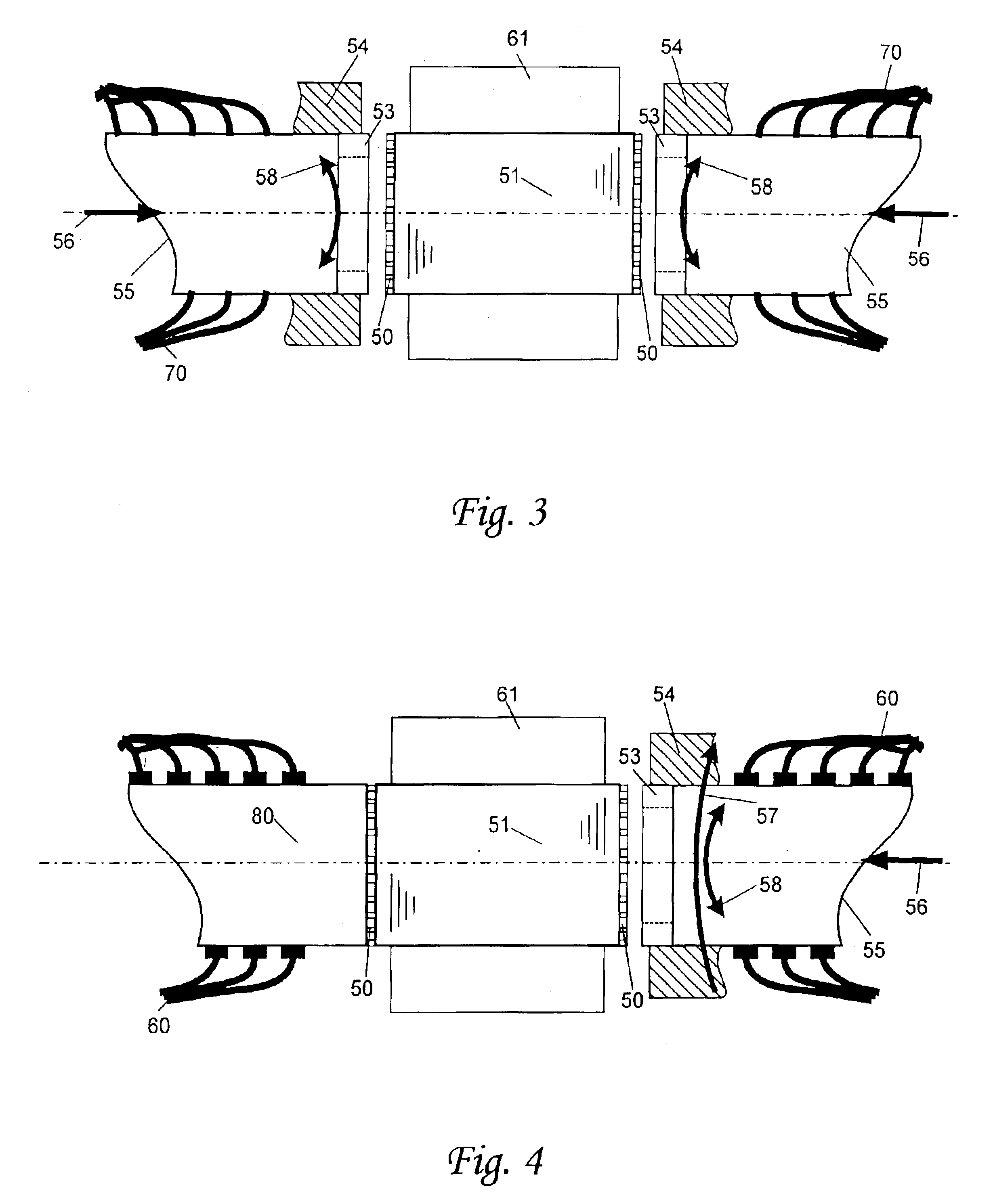

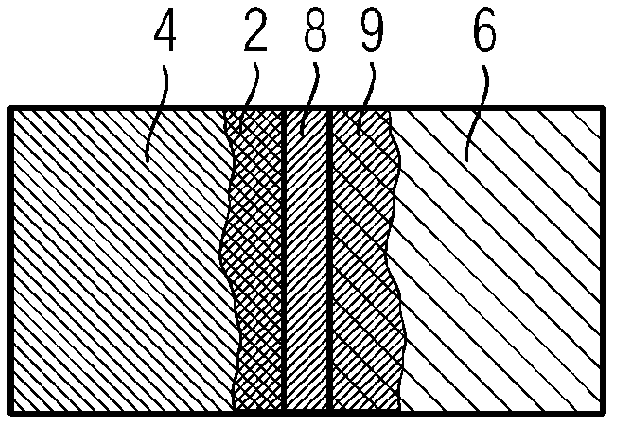

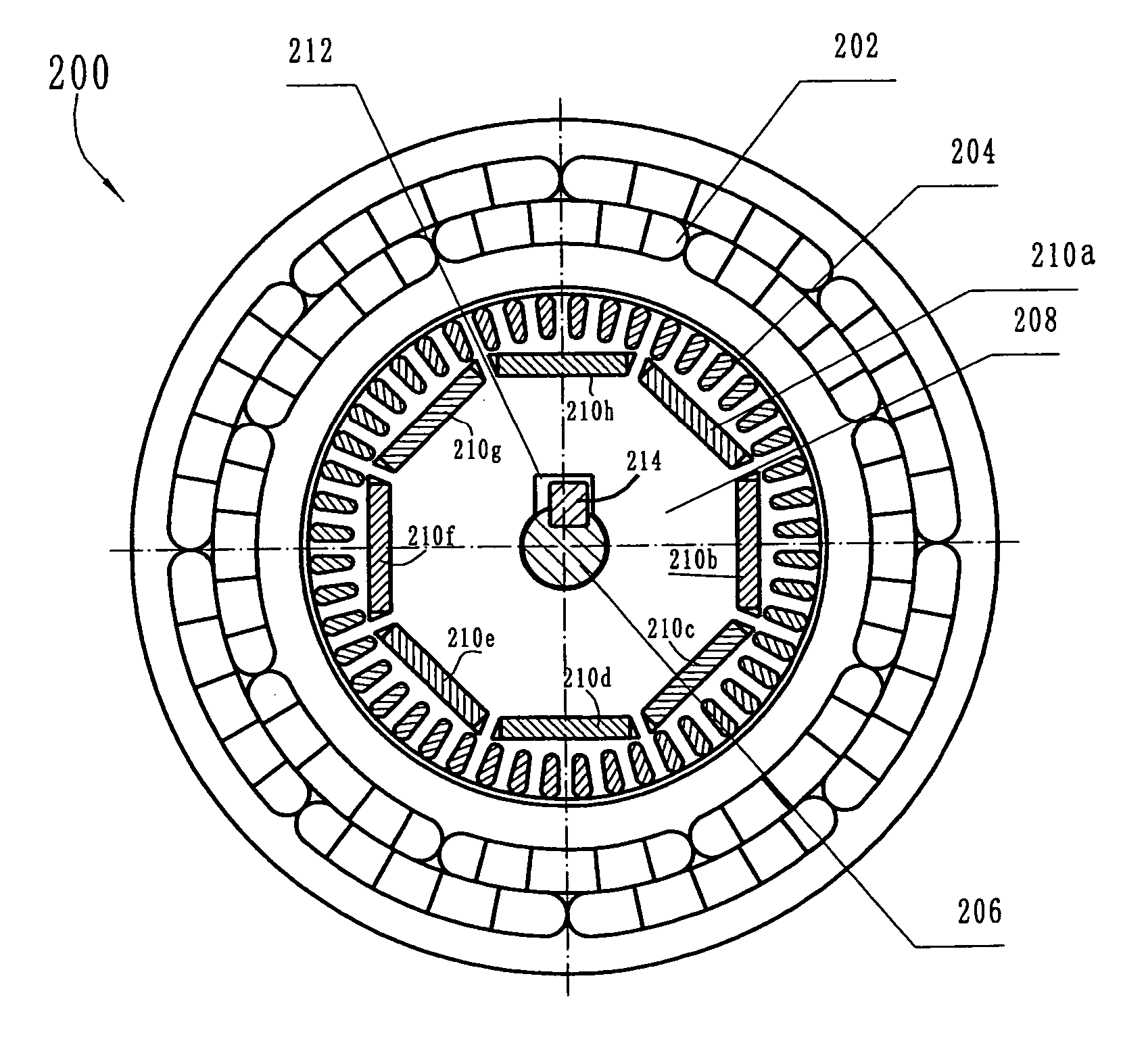

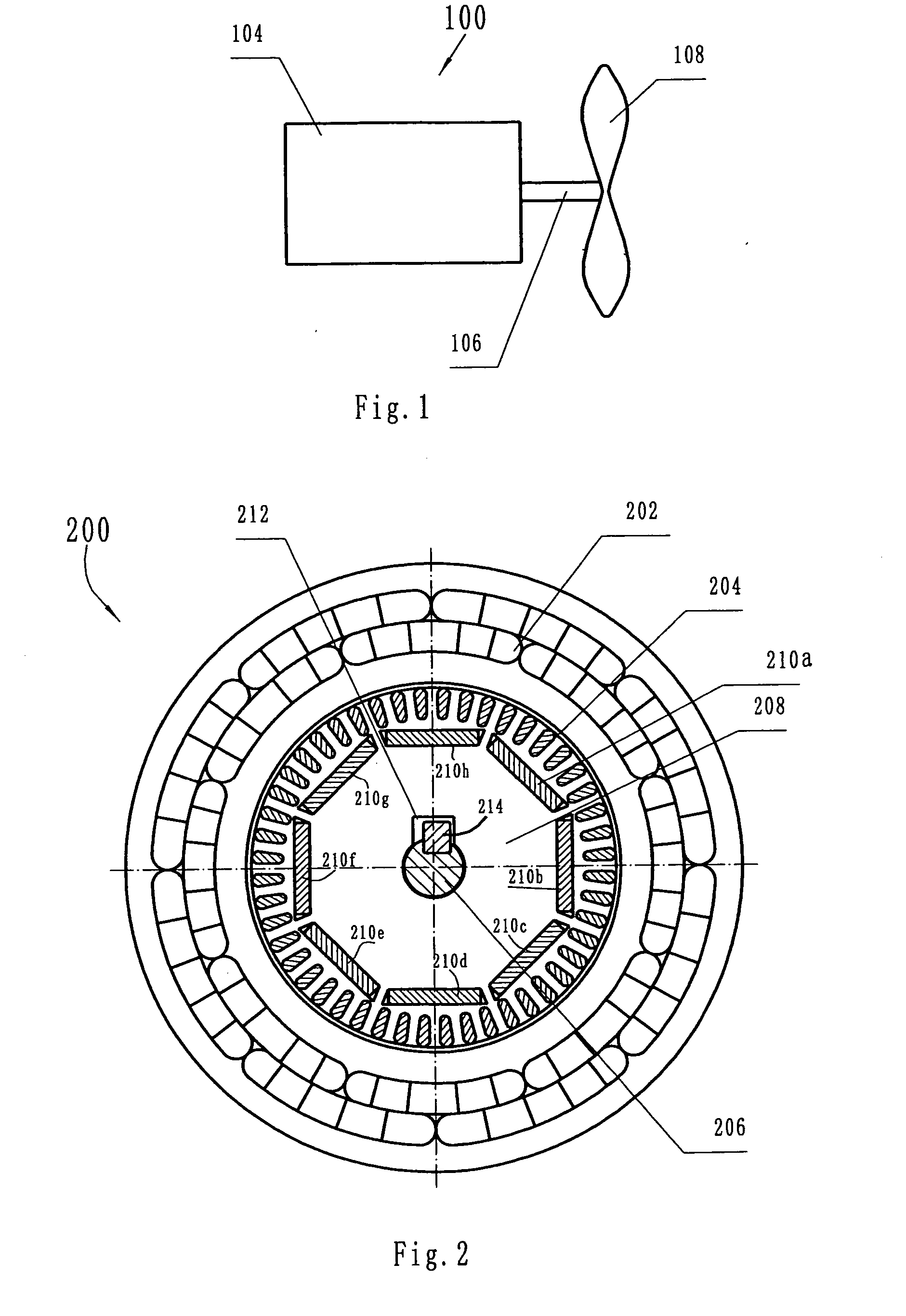

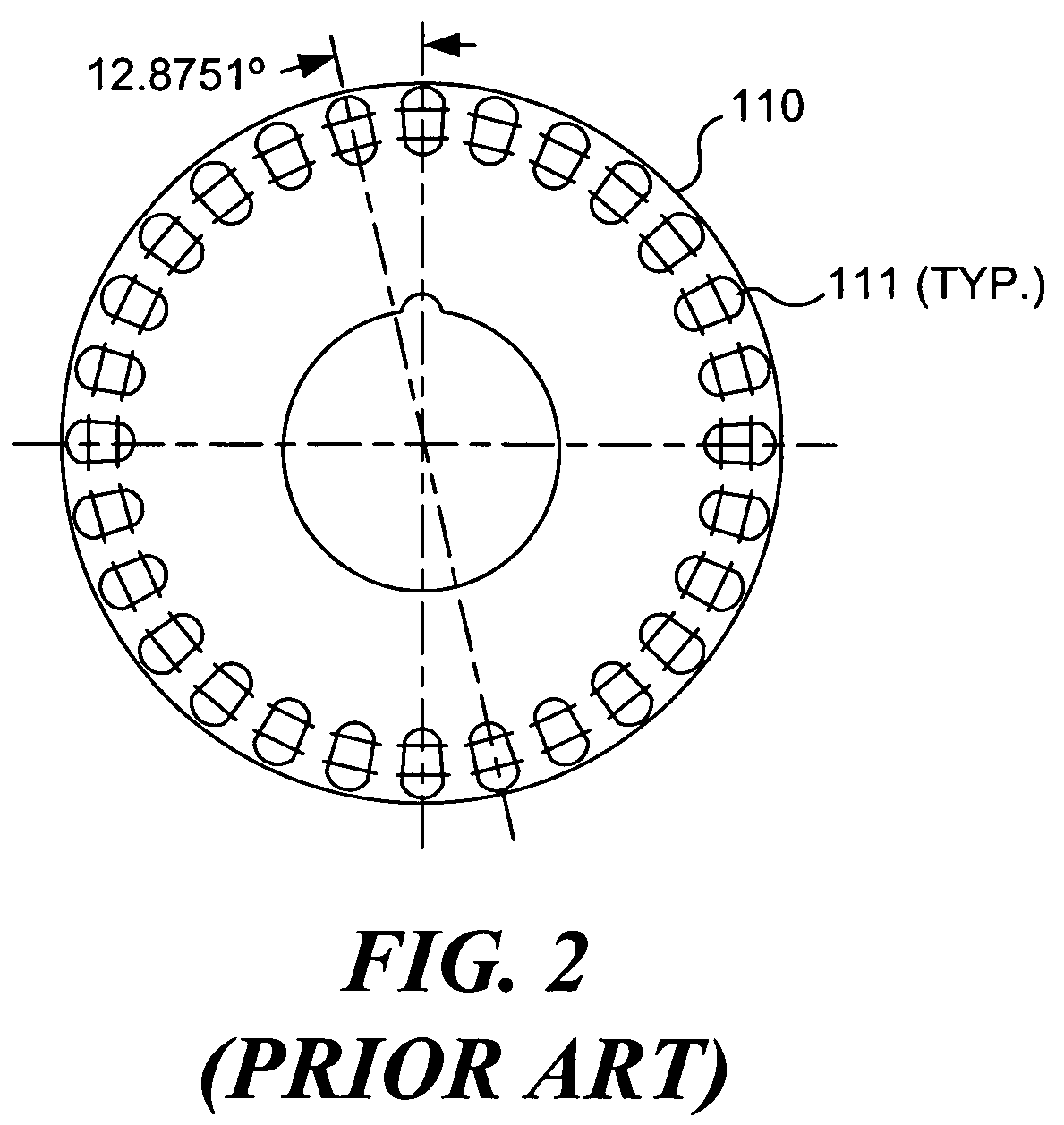

Fan assemblies employing LSPM motors and LSPM motors having improved synchronization

InactiveUS20070132330A1Readily achieve synchronous speedMagnetic circuit rotating partsMechanical energy handlingElectric machinePermanent magnet motor

A fan assembly includes at least one fan blade for moving air and a line-start permanent magnet (LSPM) motor having a shaft. The fan blade is coupled to the shaft of the line-start permanent magnet motor such that rotation of the shaft causes rotation of the fan blade for moving air. Also disclosed is an LSPM motor that includes a shaft and a squirrel cage rotor having a plurality of embedded magnets. The LSPM is configured to permit limited rotation of the squirrel cage rotor relative to the shaft as a speed of the motor approaches a synchronous speed. This LSPM motor can be used in a variety of applications including, without limitation, fan assemblies, fluid pumps, etc.

Owner:EMERSON ELECTRIC CO

Method for manufacturing squirrel cage rotor

InactiveUS7337526B2Reduced rotor lossesAvoid loopsSynchronous motorsFoundry mouldsElectrical conductorAdhesive

Ceramic adhesive is applied inside the slots of an electric machine squirrel cage rotor prior to casting or insertion of rotor conductors. This heat-resistant insulation provides superior electrical insulation that is also mechanically rugged, thus enabling casting of squirrel cage rotors by die or cost-effective consumable pattern casting. The consumable pattern cast copper rotors are electrically well insulated, thus minimizing rotor losses. The ceramic insulation in cast rotors enables longer conductors to be cast by thermally insulating the molten metal from the cooler laminations. The ceramic insulation in fabricated rotors withstands the high temperatures of end ring attachment. This method is applicable to both conventional induction machine rotors and brushless doubly-fed induction machine rotors and provides the degree of electrical isolation of the bars from the laminations needed to avoid excessive parasitic torques in doubly-fed machines, while ensuring adequate thermal conductivity to dissipate conductive bar heat to the laminations.

Owner:DUAL STATOR TECH INC

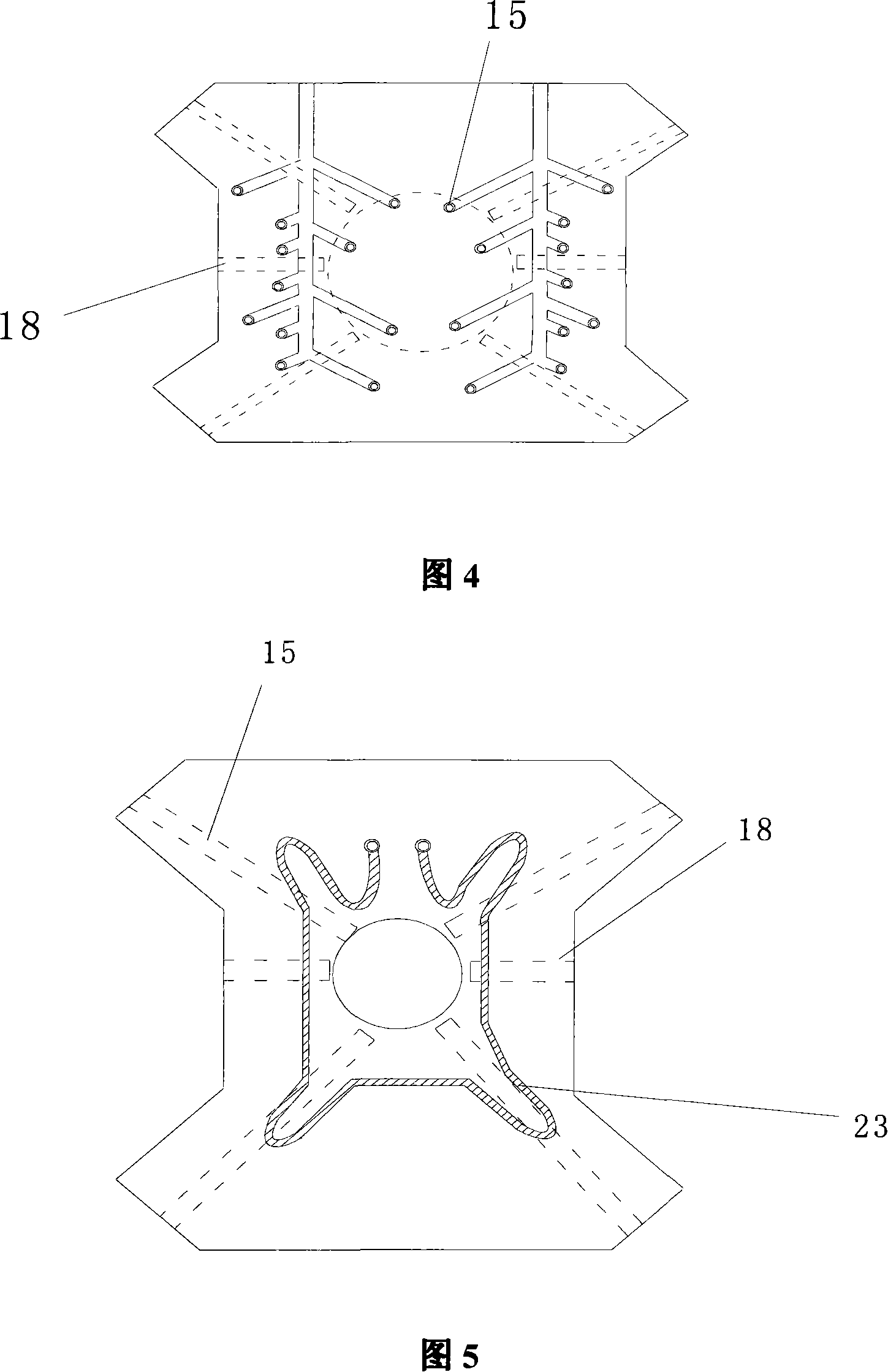

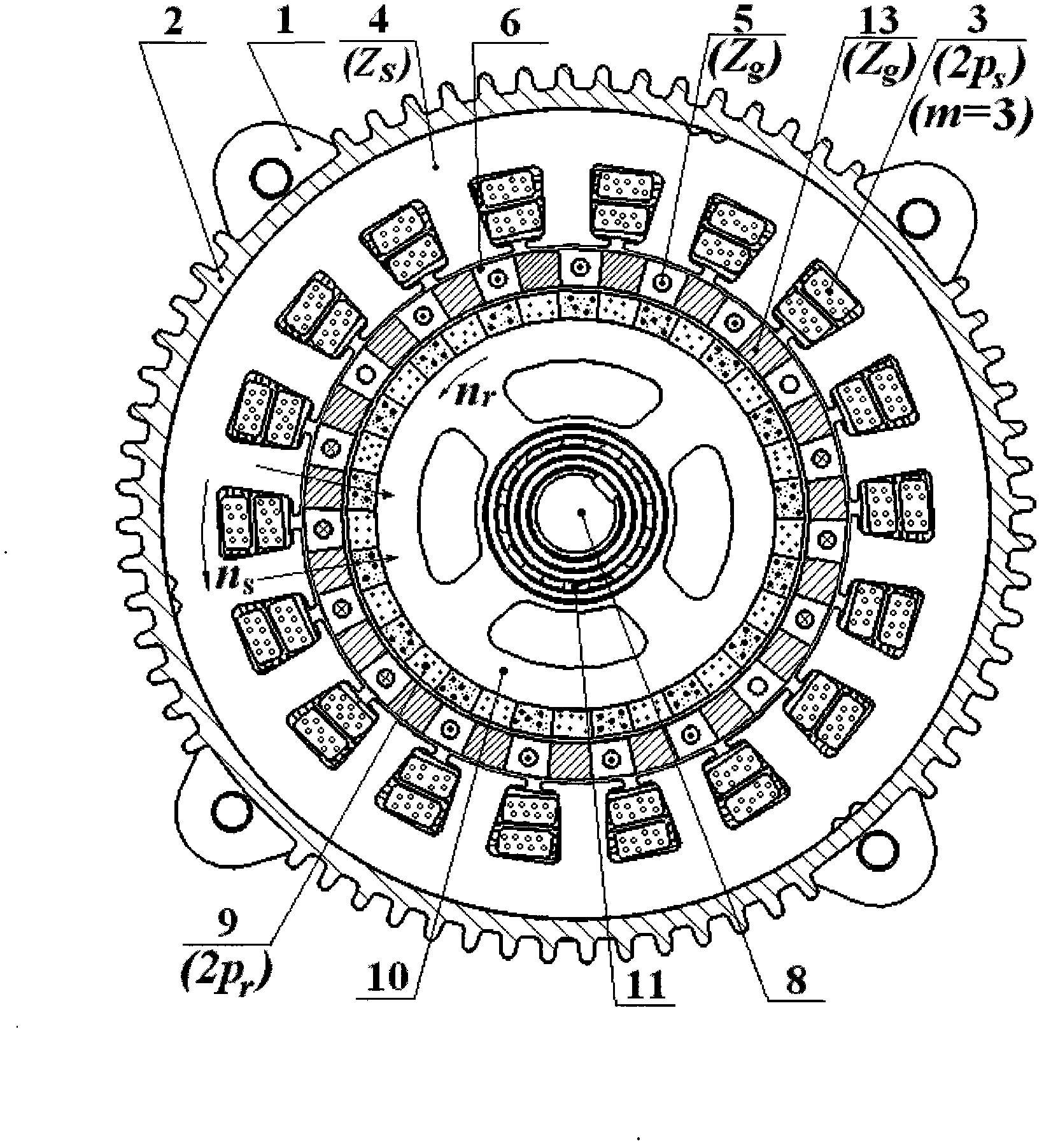

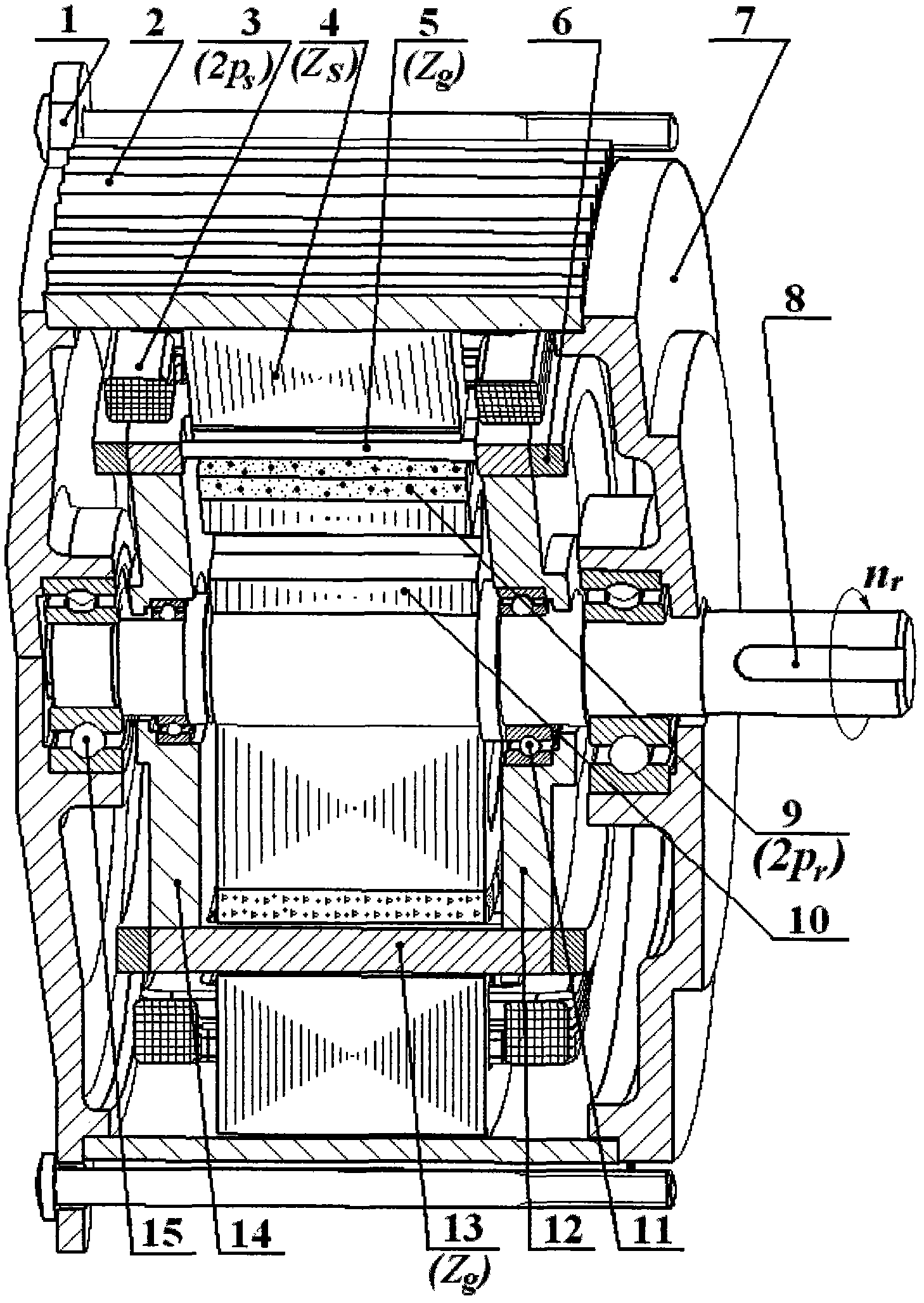

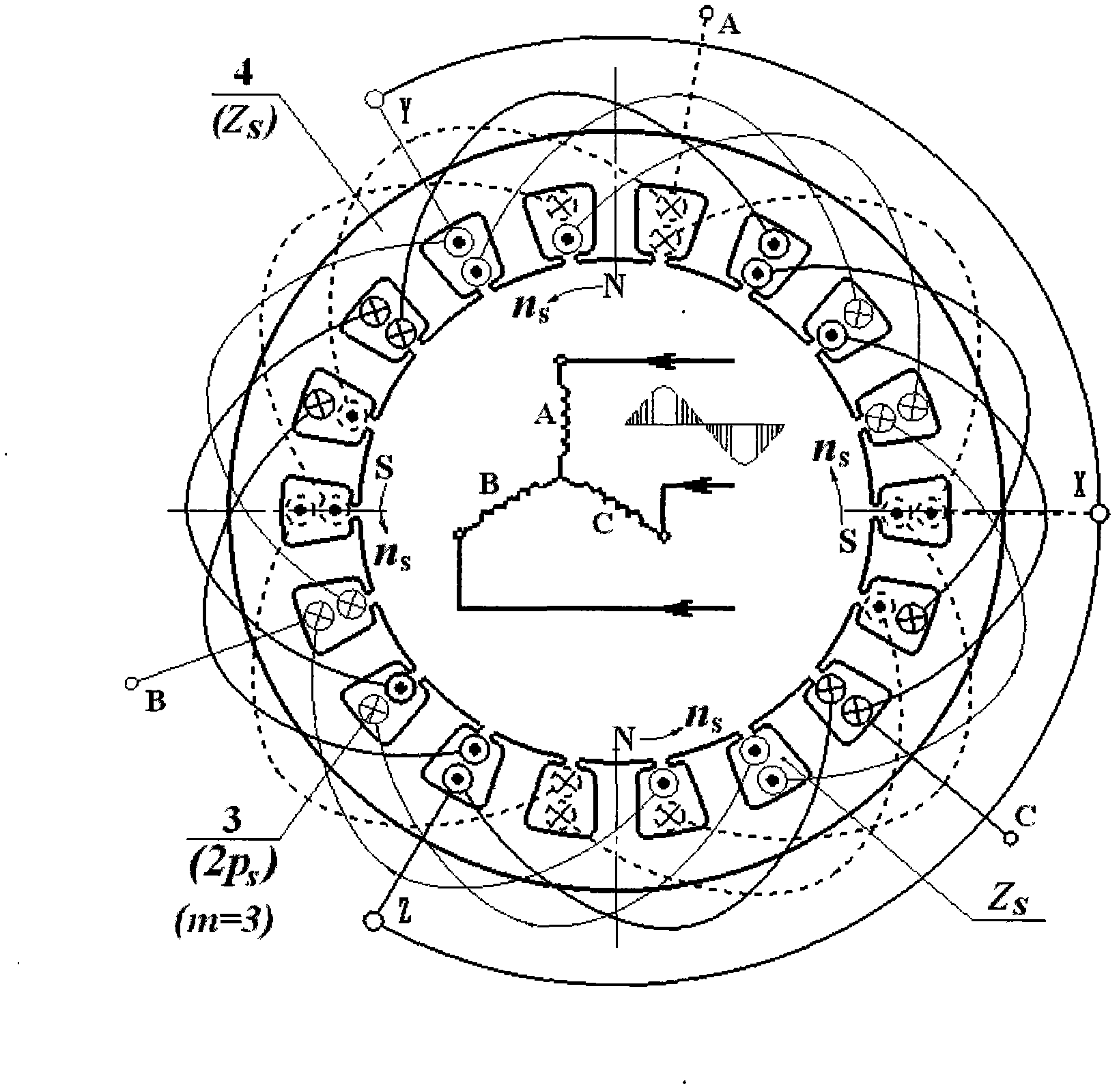

Novel air gap magnetic field electromagnetic modulation permanent magnet motor with double squirrel cage structure

InactiveCN102868268ATo achieve technical and economic effectSimple structureElectric machinesDynamo-electric machinesPermanent magnet rotorLow speed

A novel air gap magnetic field electromagnetic modulation permanent magnet motor with a double squirrel cage structure is a novel direct drive motor for directly realizing low-speed and high-torque output by means of electromagnetic modulation of high-speed air gap rotation magnetic fields, and can be applied to the transmission field of wind power generation, electric vehicles, ship drive and the like needing direct drive. The permanent magnet motor is characterized by comprising a stator with 2ps poles, an electromagnetic modulation hollow double squirrel cage rotor and a permanent magnet rotor with 2pr poles, wherein the stator, the electromagnetic modulation hollow double squirrel cage rotor and the permanent magnet rotor are of a radially concentric structure and have two air gaps respectively corresponding to two air gap rotation magnetic fields with different synchronous speeds. When running, three-phase symmetric alternating current flows through a stator winding 3 in the stator core 4 to generate the high-speed air gap rotation magnetic fields with fewer 2ps poles, the high-speed air gap rotation magnetic fields are modulated into high-order harmonic rotation magnetic fields with more 2pr poles by squirrel cages 13 of the hollow double squirrel cage rotor through electromagnetic modulation, and accordingly, the permanent magnet rotor is driven at a low speed and a high torque.

Owner:余虹锦

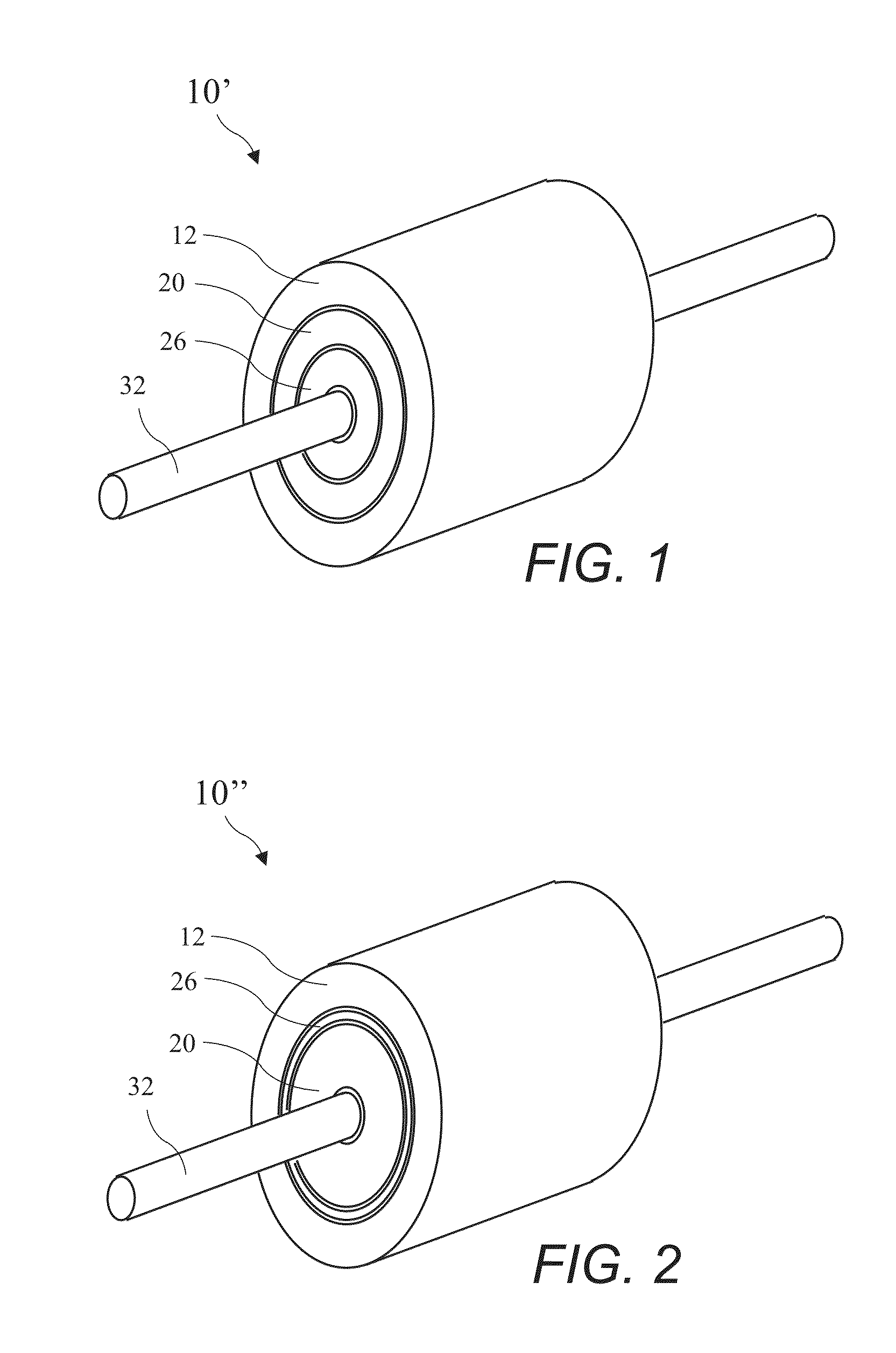

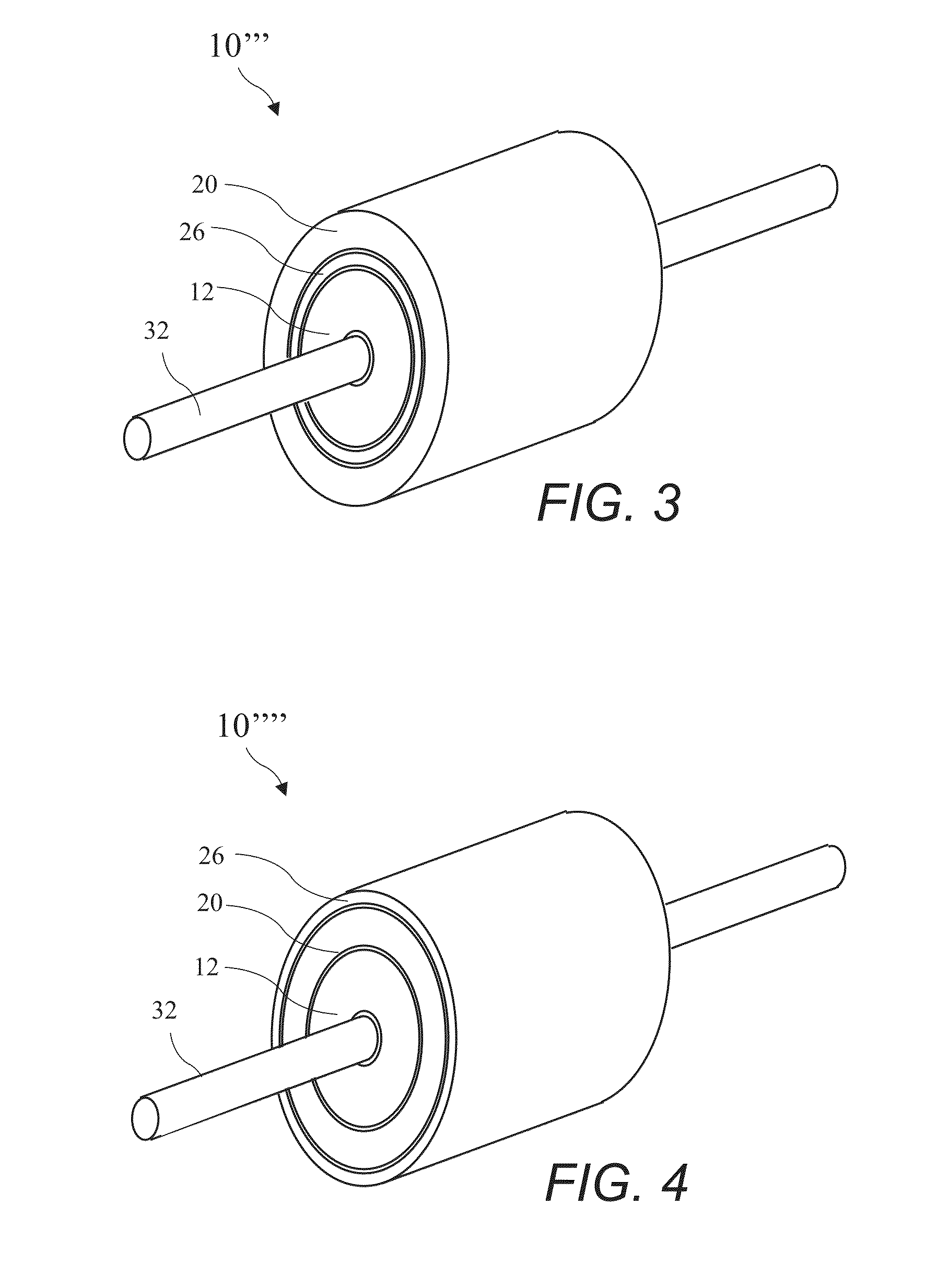

Squirrel-cage rotor

ActiveUS8836193B2Improve bindingAvoid tearingSynchronous motorsAsynchronous induction motorsElectrical conductorAlloy

The invention relates to a squirrel-cage rotor for an asynchronous machine. In order to increase the electrical efficiency for a cage rotor composed of two materials, the cage rotor comprises a rotor core (1) having grooves (3), end rings (5) of a first material that are cast onto the rotor core on the end face, and conductors (4) that are arranged in the grooves and that are made of a second material that has an electric conductivity that is higher than the electric conductivity of the first material, wherein the conductors (4) comprise a coating (8) made of a coating material on the surface of the conductors, wherein the coating adjoins the second material of the conductors (4) by means of a first alloy layer (2) made of the second material and the coating material and adjoins the cast first material by means of a second alloy layer (9); made of the first material and the coating material.

Owner:SIEMENS AG

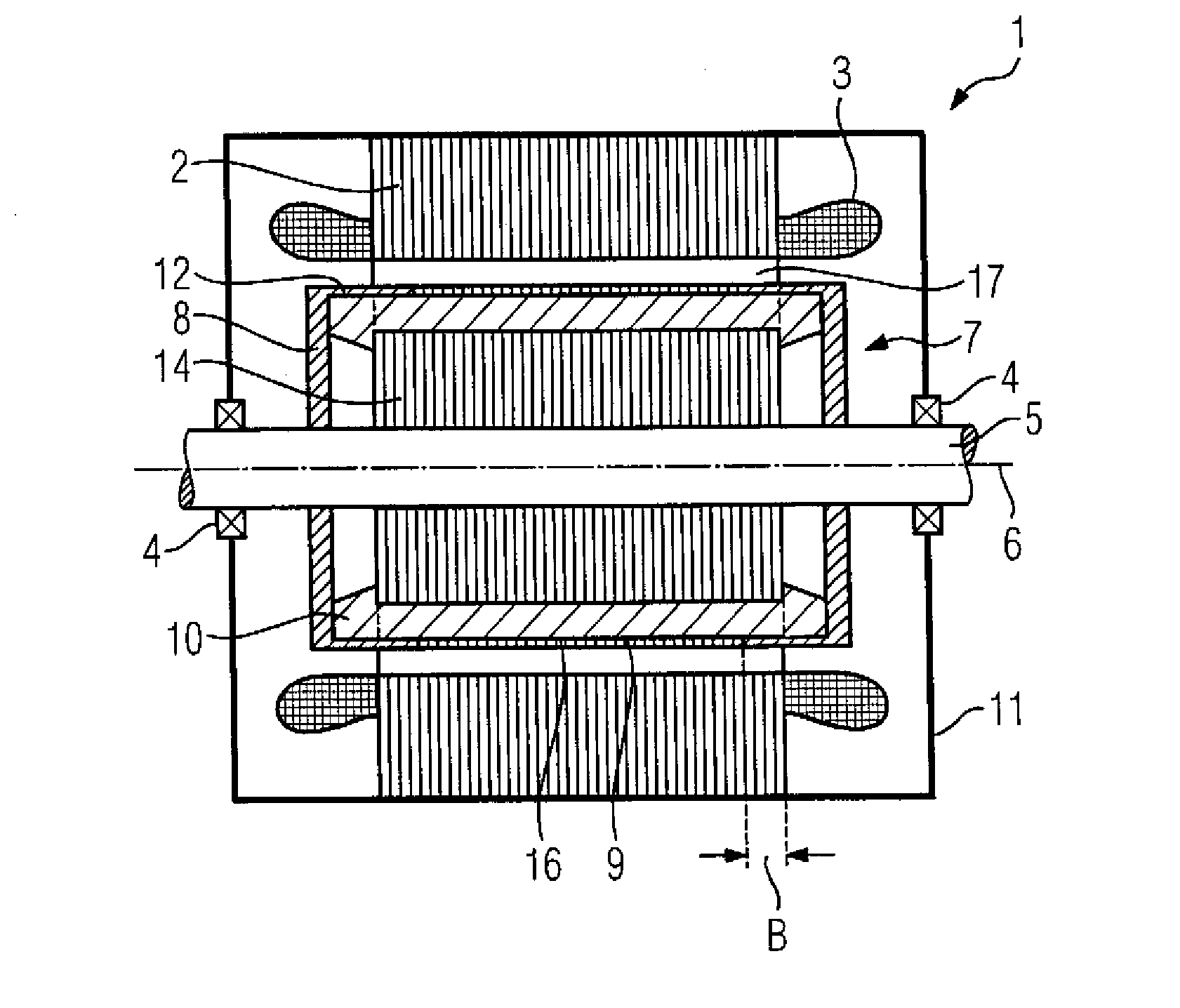

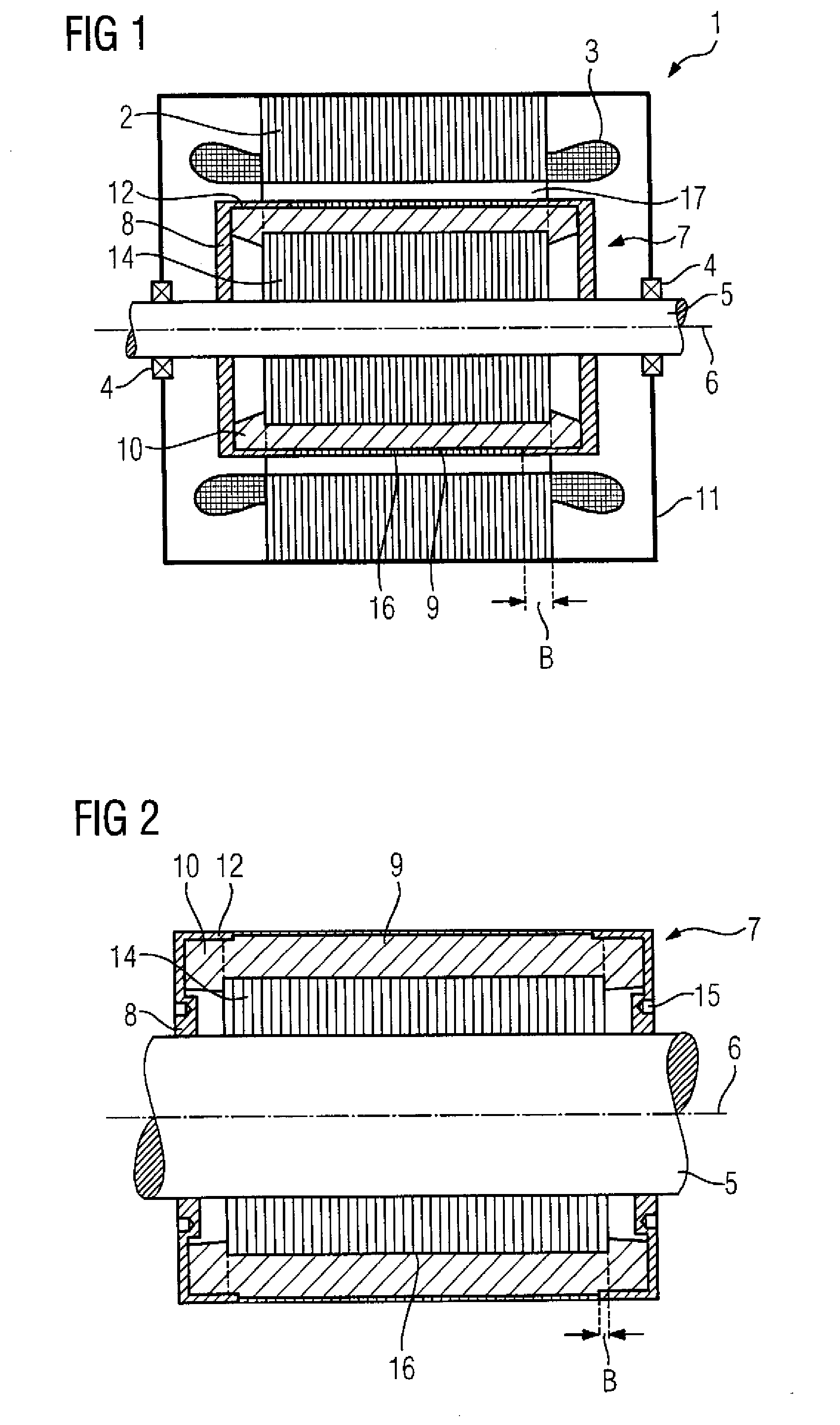

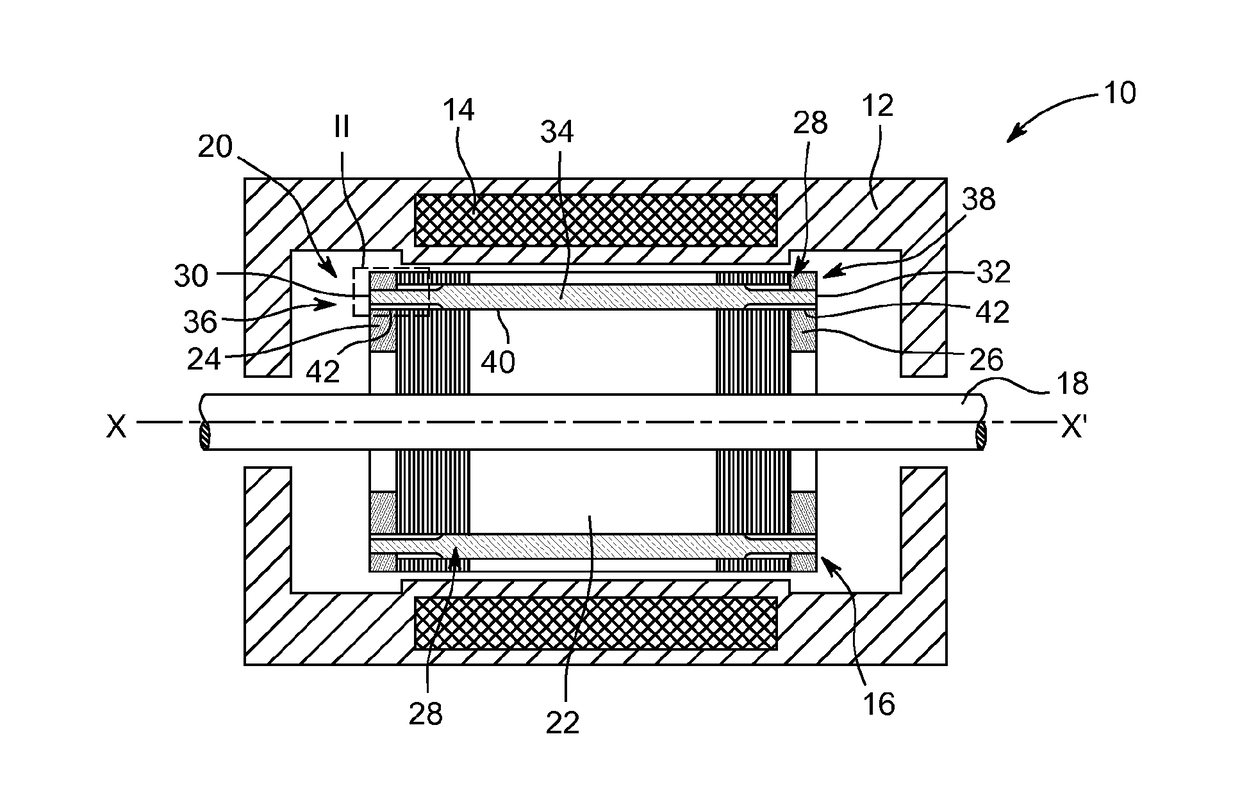

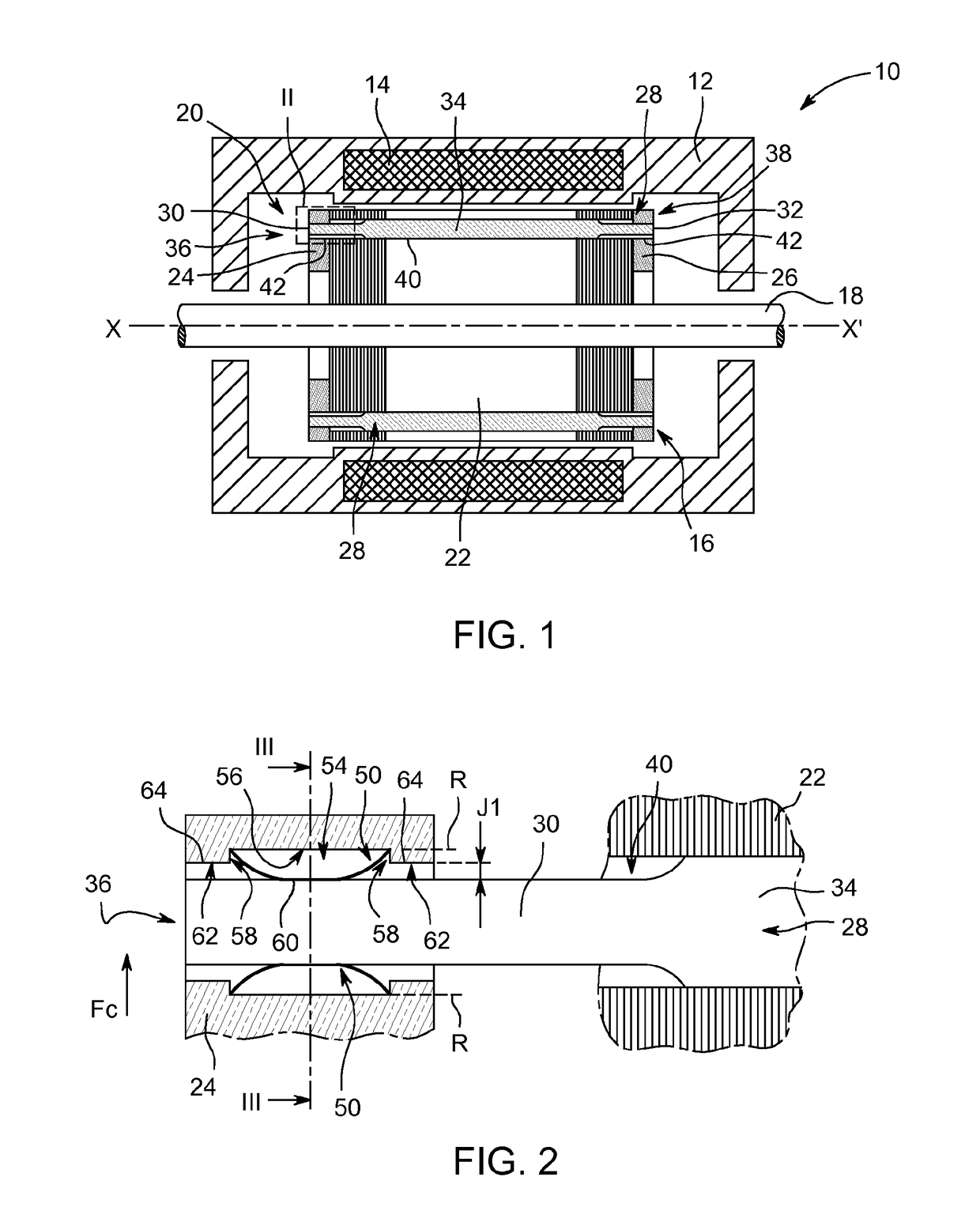

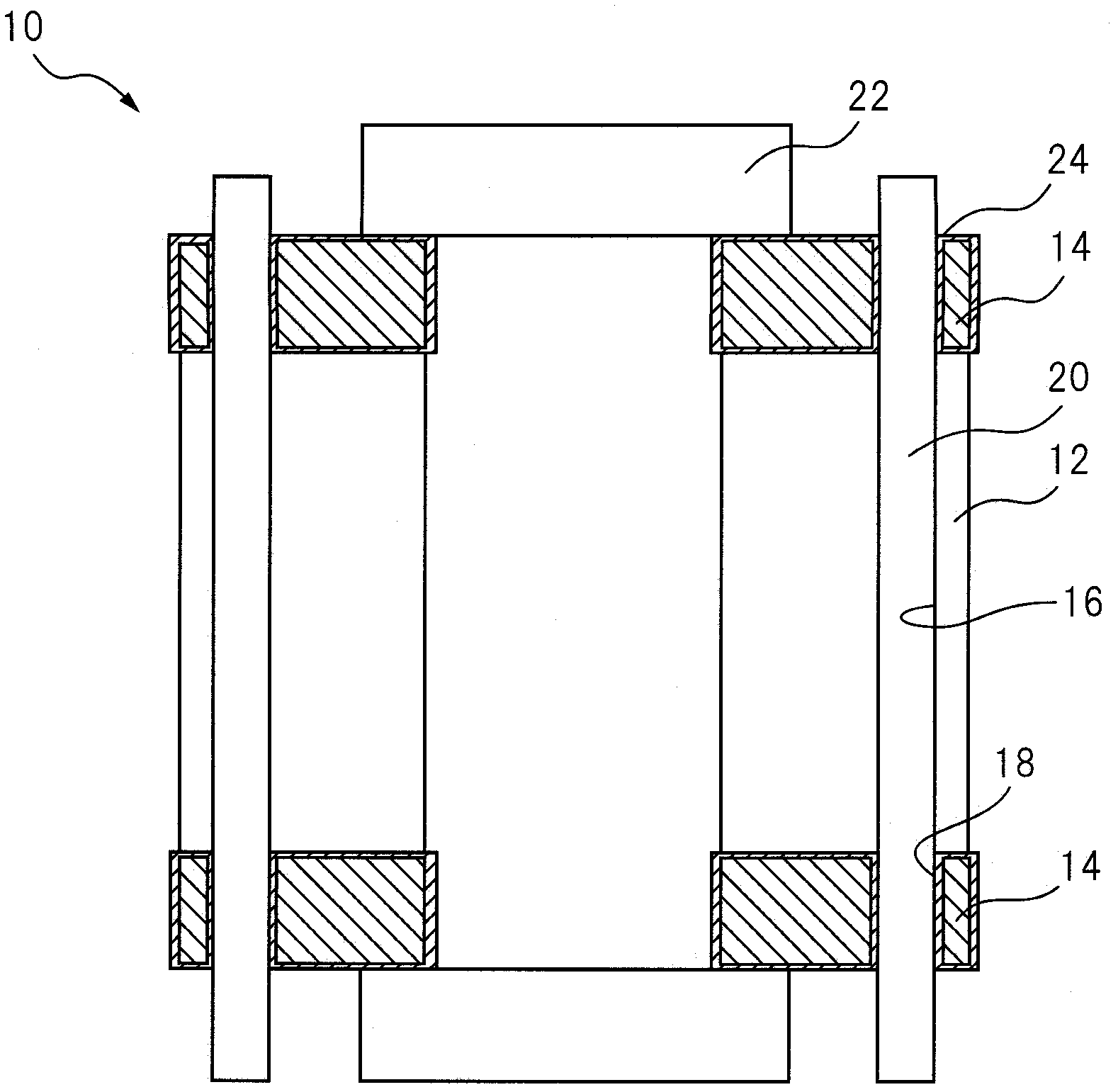

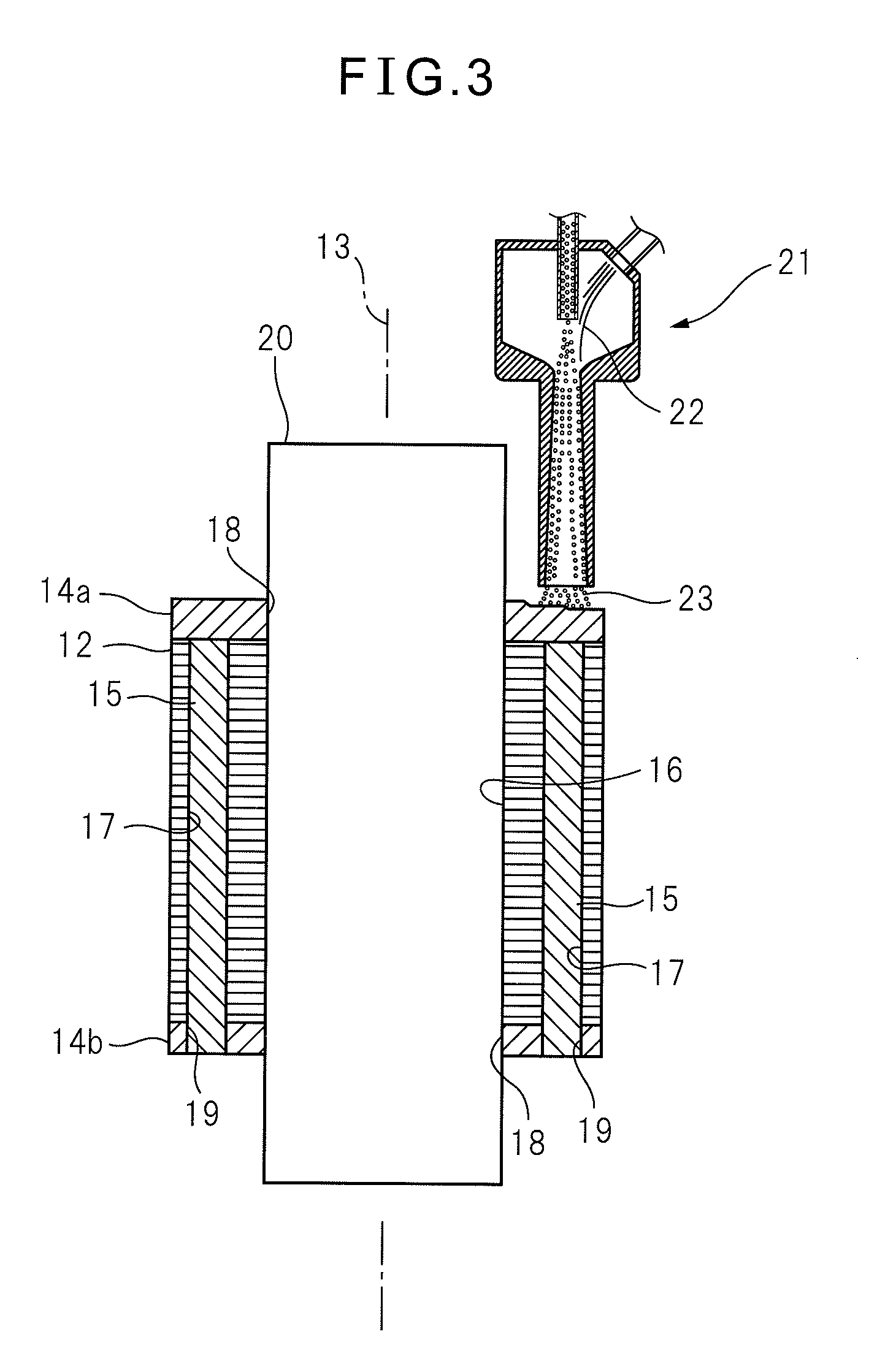

Rotor of an asynchronous machine with retaining element

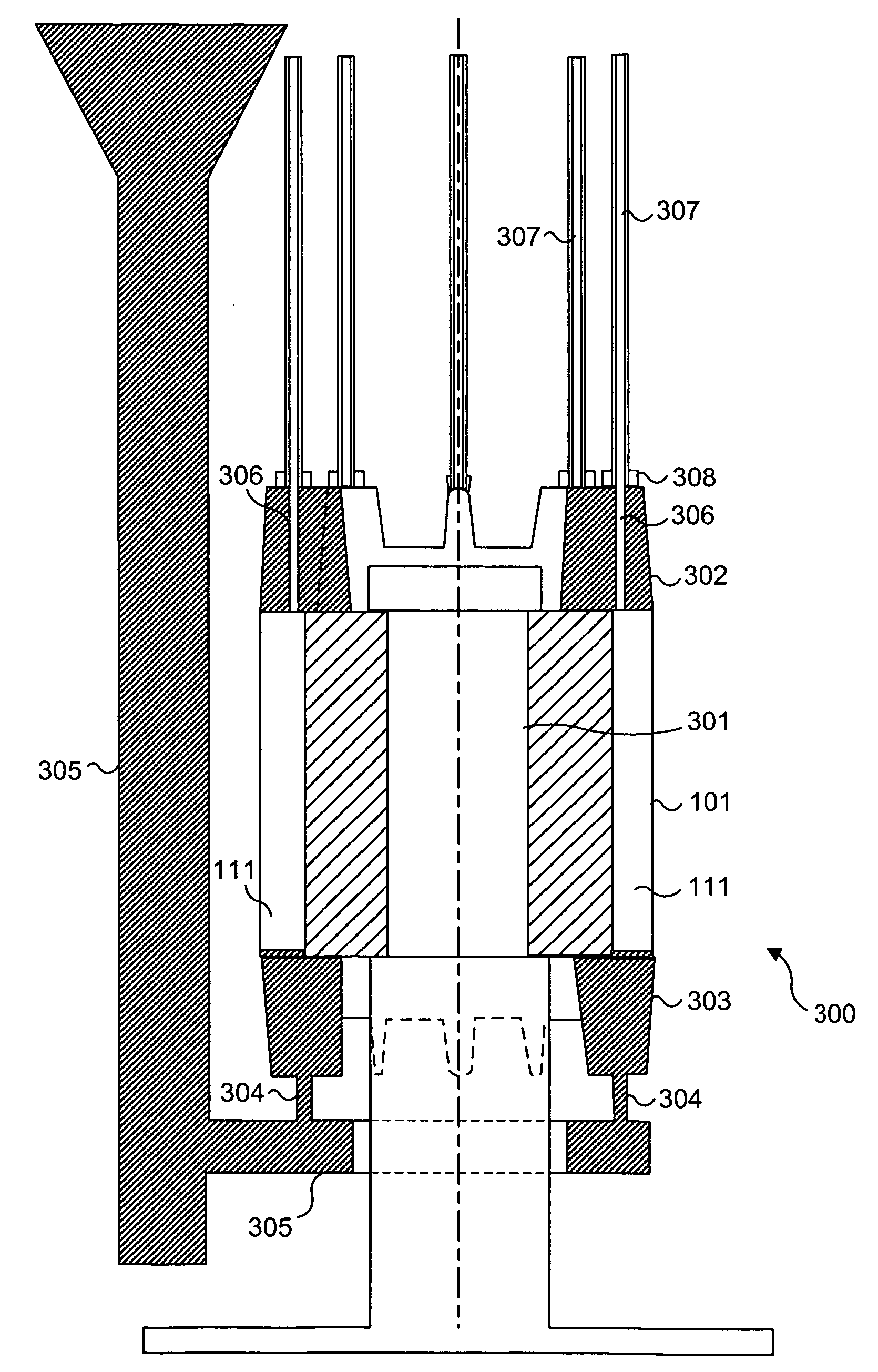

ActiveUS20130113331A1Increase pressureIncrease shear stressSynchronous motorsAsynchronous induction motorsElectric machineDie casting

A squirrel-cage rotor of an asynchronous machine, in particular a die-cast rotor, includes a rotatable shaft, a laminated core being rotation-locked on the shaft and having grooves and opposing end faces. A squirrel-cage winding has rotor rods disposed in the grooves and a cage ring disposed on each of the end faces and electrically connecting the rotor rods. A pair of retaining elements is disposed on the shaft, wherein each retaining element extends in a radial direction in form of a disk or a spoke and has in an axial direction a wall and / or an axially extending finger. The wall overlaps on a radial periphery in the axial direction both the cage ring and a predefined axial section of the rotor rods that terminate in the cage ring, without increasing an external diameter of the laminated core.

Owner:SIEMENS AG

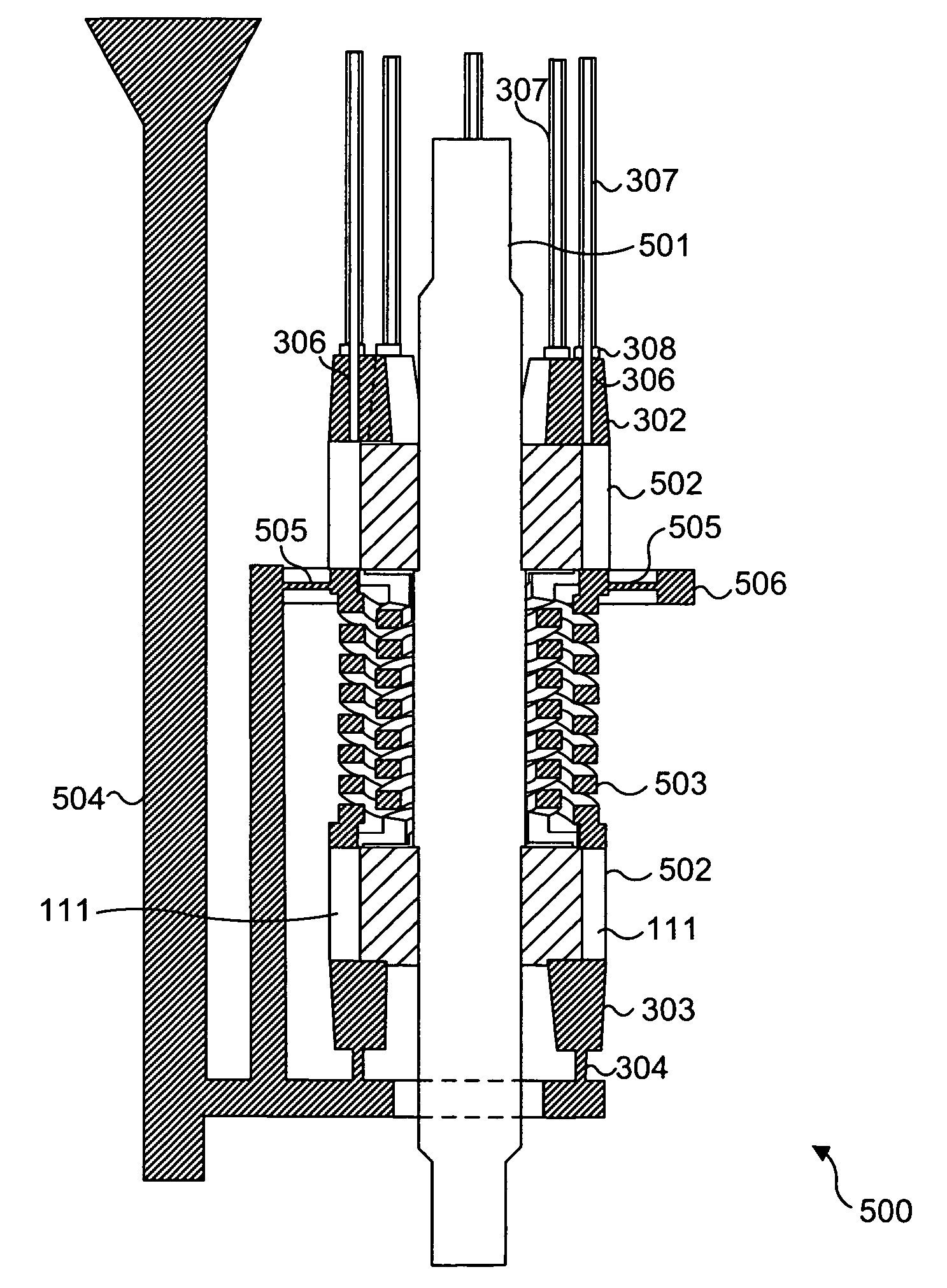

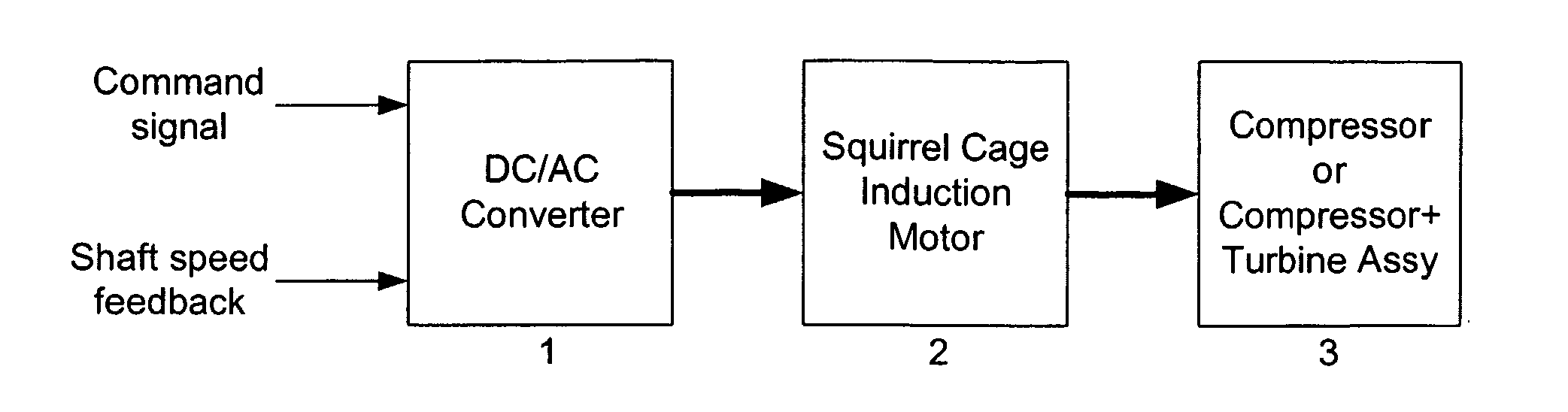

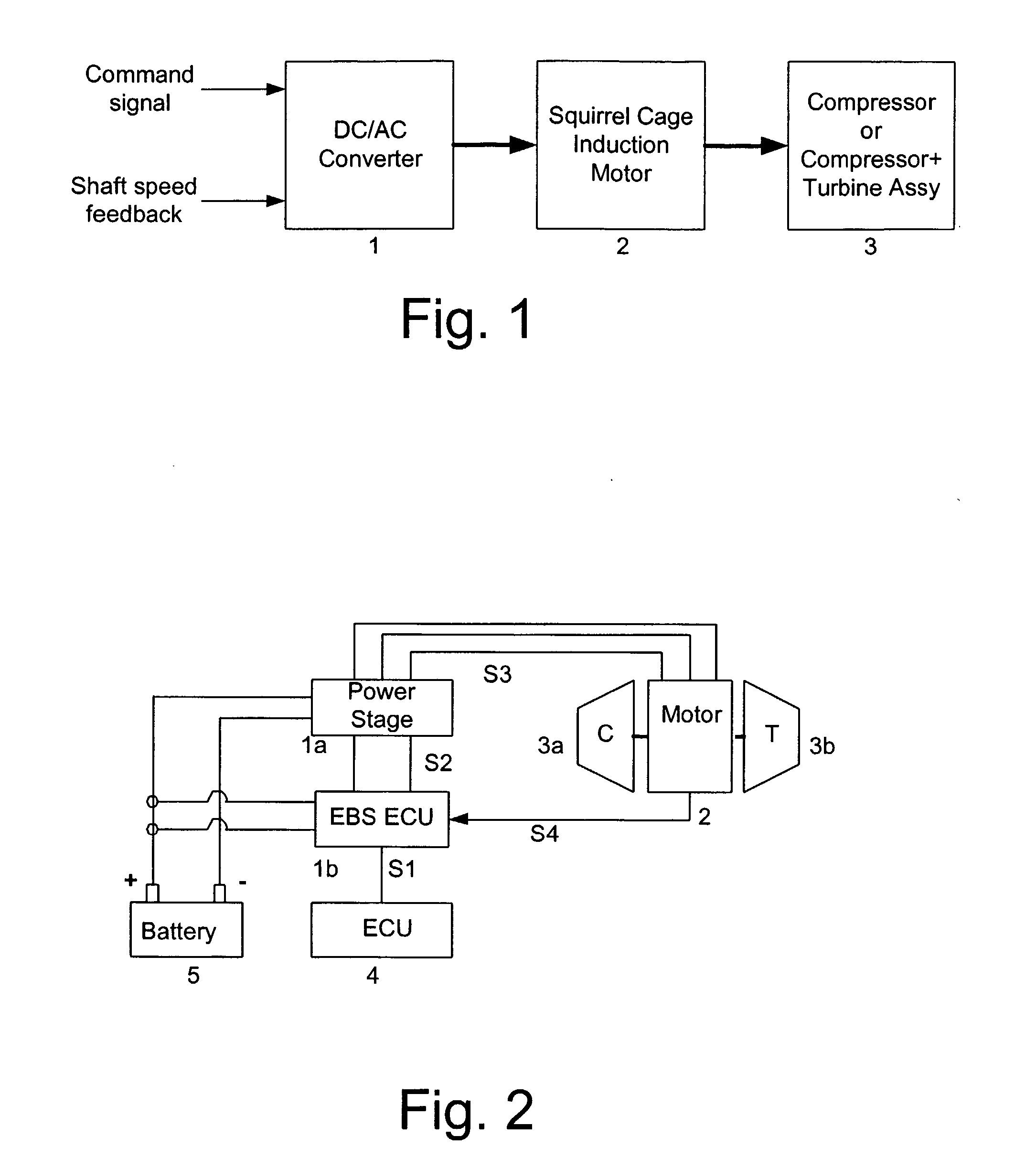

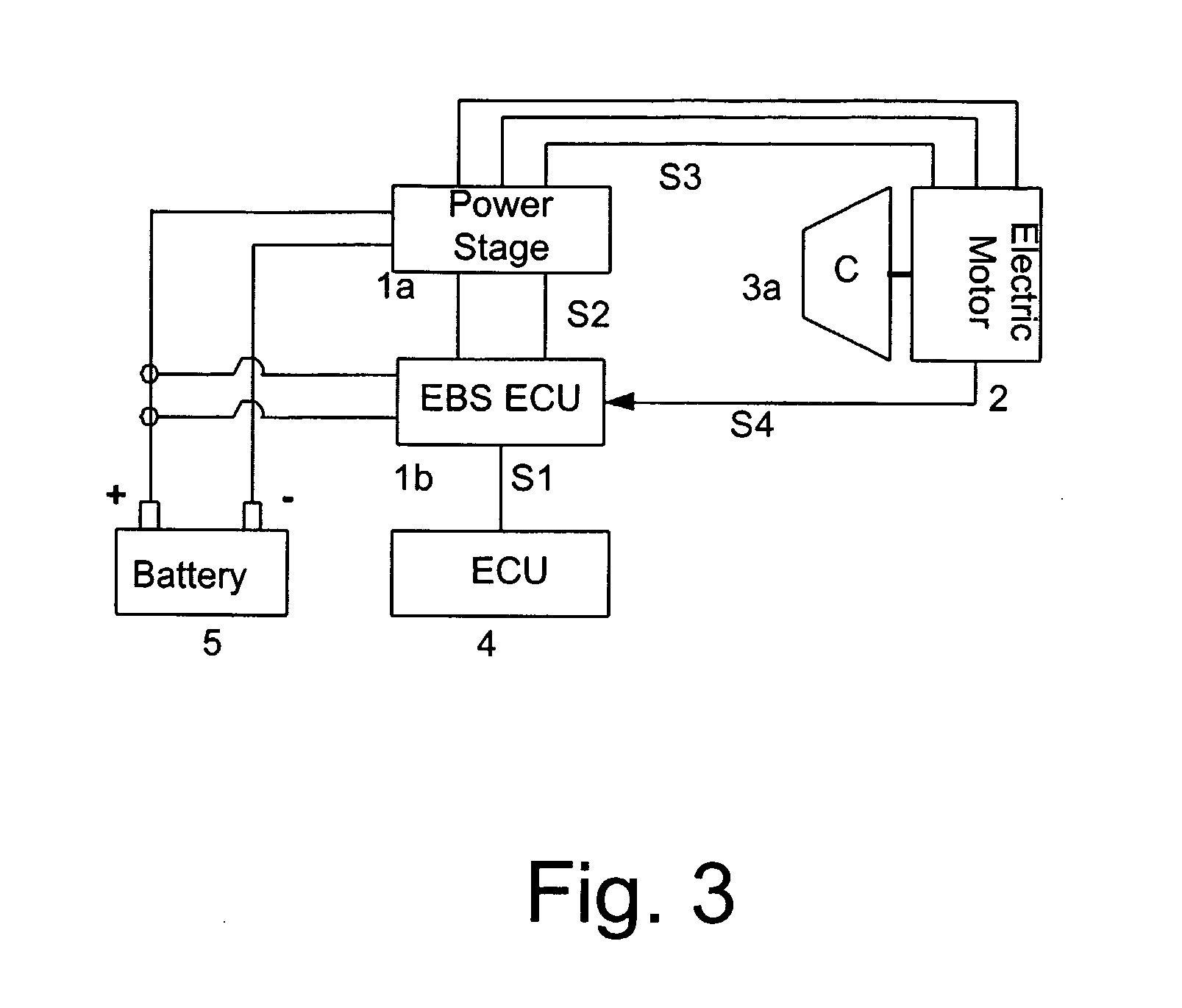

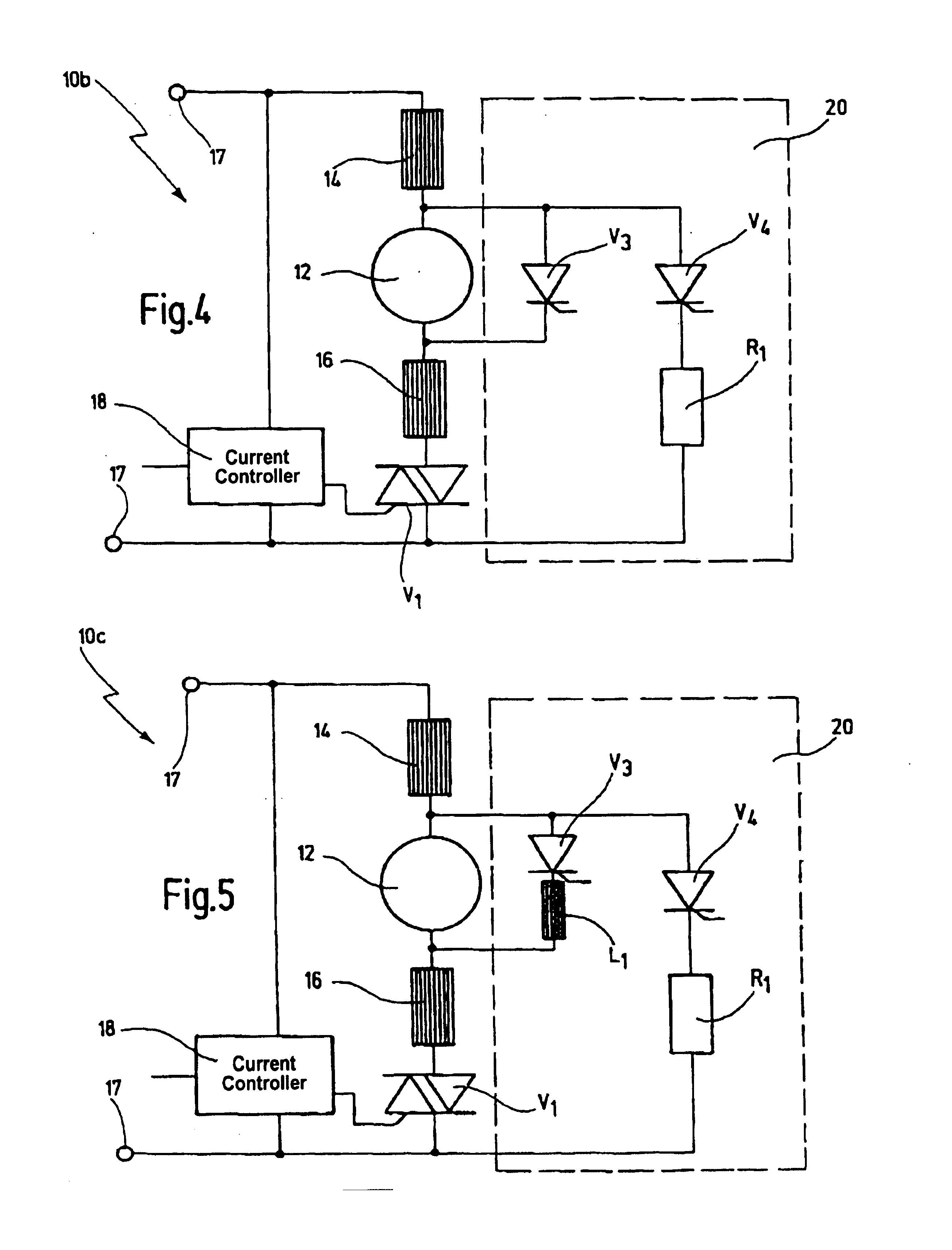

Motor Control and Driver for Electric Boosting Application

ActiveUS20070251236A1Increase speedRun at high speedVector control systemsCombustion enginesTransient stateFrequency generation

The invention proposes a system for driving a compressor, comprising an induction motor (2) for driving the compressor (3), said induction motor including a squirrel cage rotor, and a controller (1) for controlling the induction motor, said controller comprising a memory for storing drive patterns for driving the induction motor, a first frequency generation means for generating a field frequency based on a field command and / or a second field generation means for generating a voltage frequency based on a voltage command, wherein a drive pattern in extracted from the memory based on the generated frequency or frequencies. Alternatively, the invention proposes a system for driving a compressor, comprising an induction motor (2) for driving the compressor (3), said induction motor including a squirrel cage rotor, and a controller (1) for controlling the induction motor, wherein the controller is adapted to distinguish between a steady state and a transient state of the induction motor.

Owner:GARRETT TRANSPORATION I INC

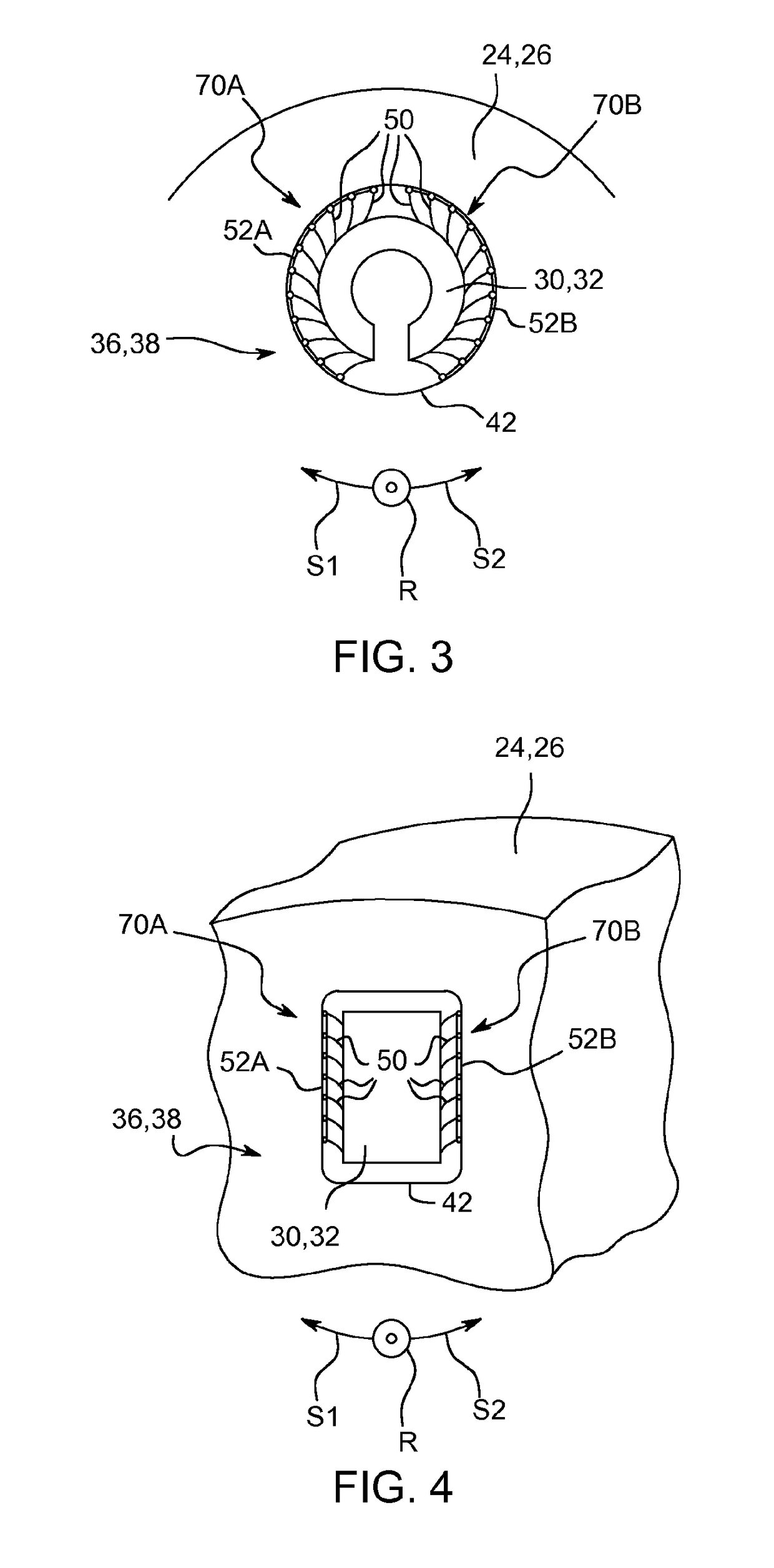

Squirrel-cage rotor, and asynchronous motor comprising such a rotor

An electric machine rotor, which extends along an axis of rotation, including a short-circuit cage, the or each first connection means between a respective first end part of the or each bar and the first short-circuit ring includes a plurality of flexible electrically conductive blades.

Owner:GE ENERGY POWER CONVERSION TECH

Electrical machine

InactiveUS7215056B2Reduce proximity effectReduce projectionSynchronous motorsAsynchronous induction motorsElectrical conductorElectric machine

Owner:SIEMENS AG

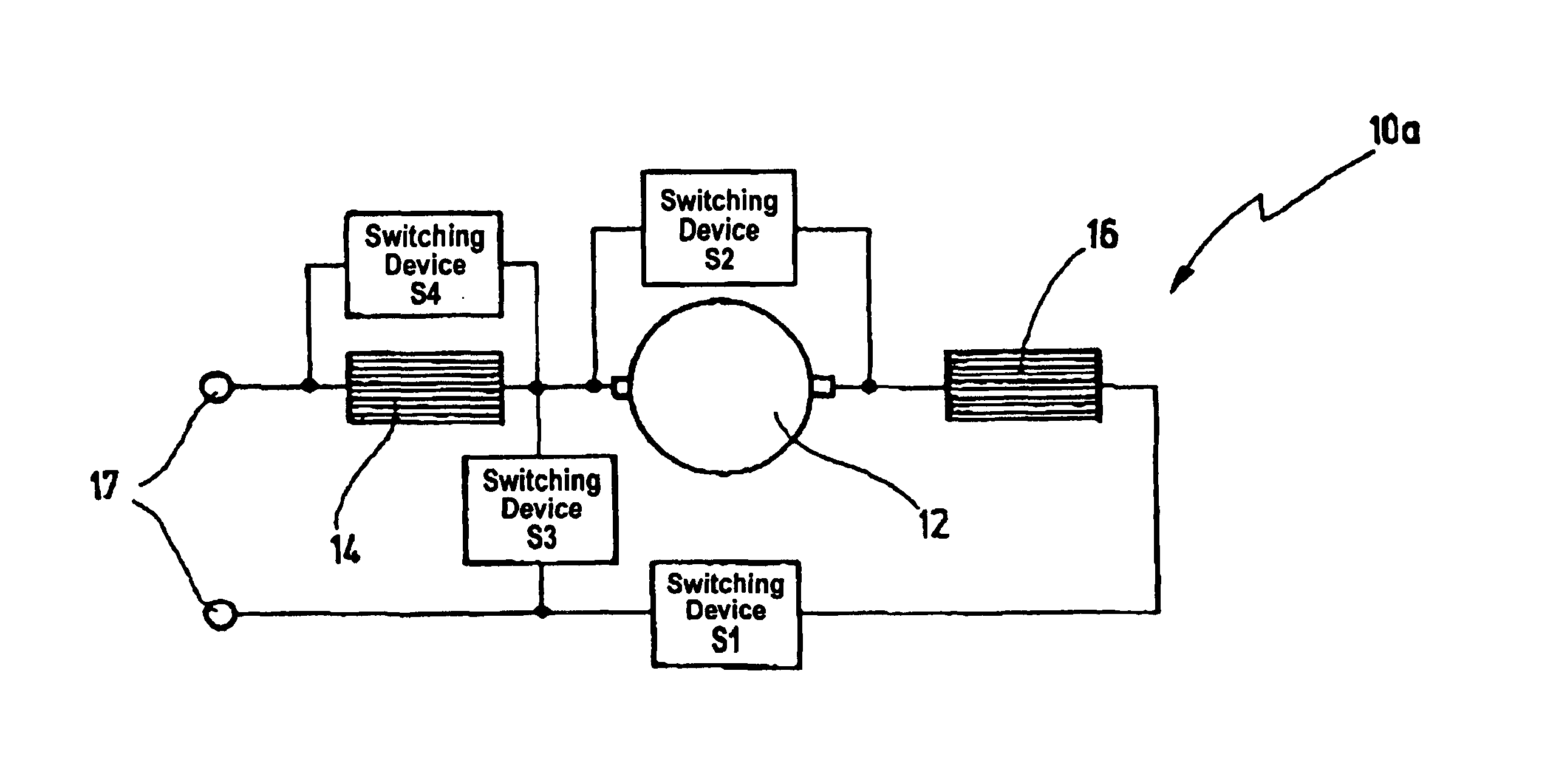

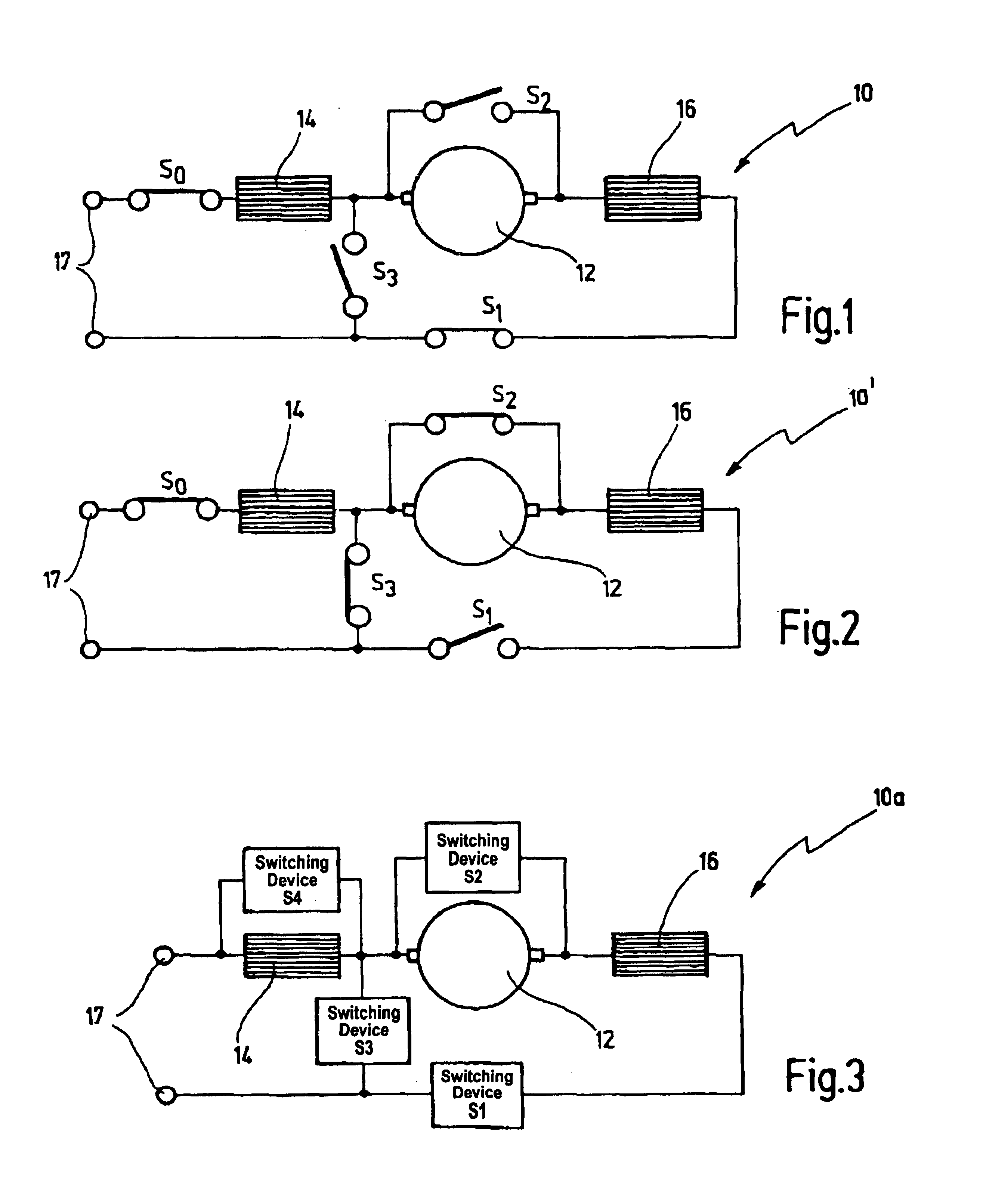

Electric motor with electronic brake

InactiveUS6998804B2Easy to useReduce voltageAC motor controlElectric motor controlControl theoryDirect current

A retarded electric motor designed as a series motor or an asynchronous motor having a squirrel cage rotor. A valve is provided for switching between motor operation and braking operation. During motor operation the motor is operated in a known configuration as series motor or as asynchronous motor. If configured as a series motor, the valve (S1, S2, S3) allows to bypass the armature and to operate the motor as an externally excited direct current generator when switching into braking operation. If configured as an asynchronous motor, a switch is utilized to disconnect at least two field windings from mains. A valve is utilized to excite the motor externally from mains with a pulsating direct current during braking.

Owner:C & E FEIN GMBH & CO KG

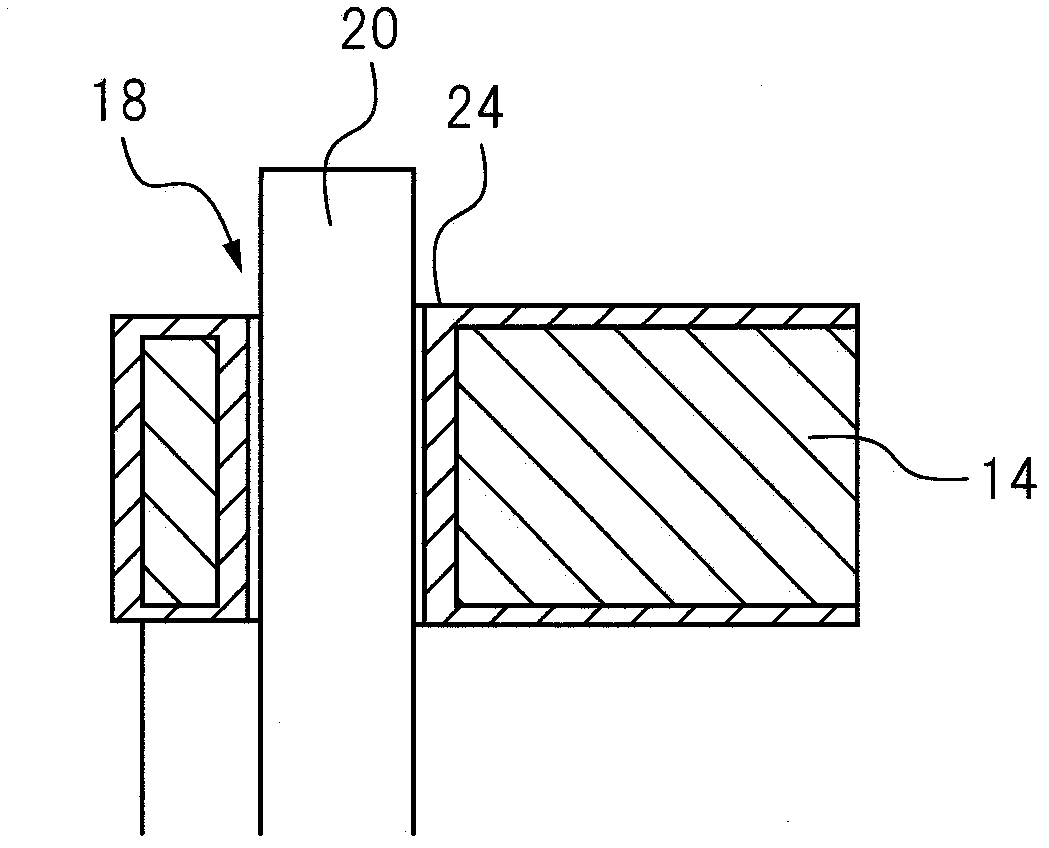

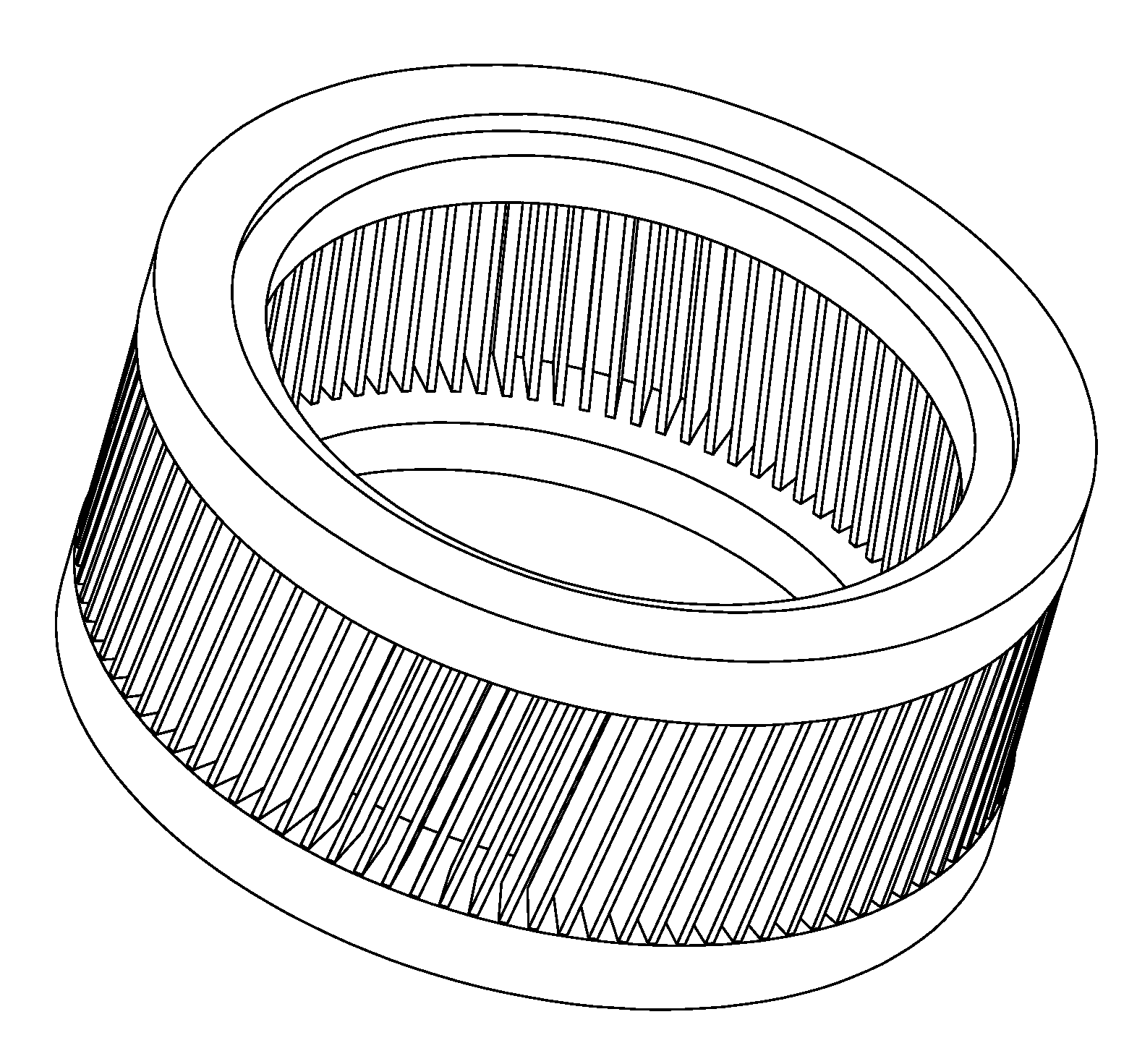

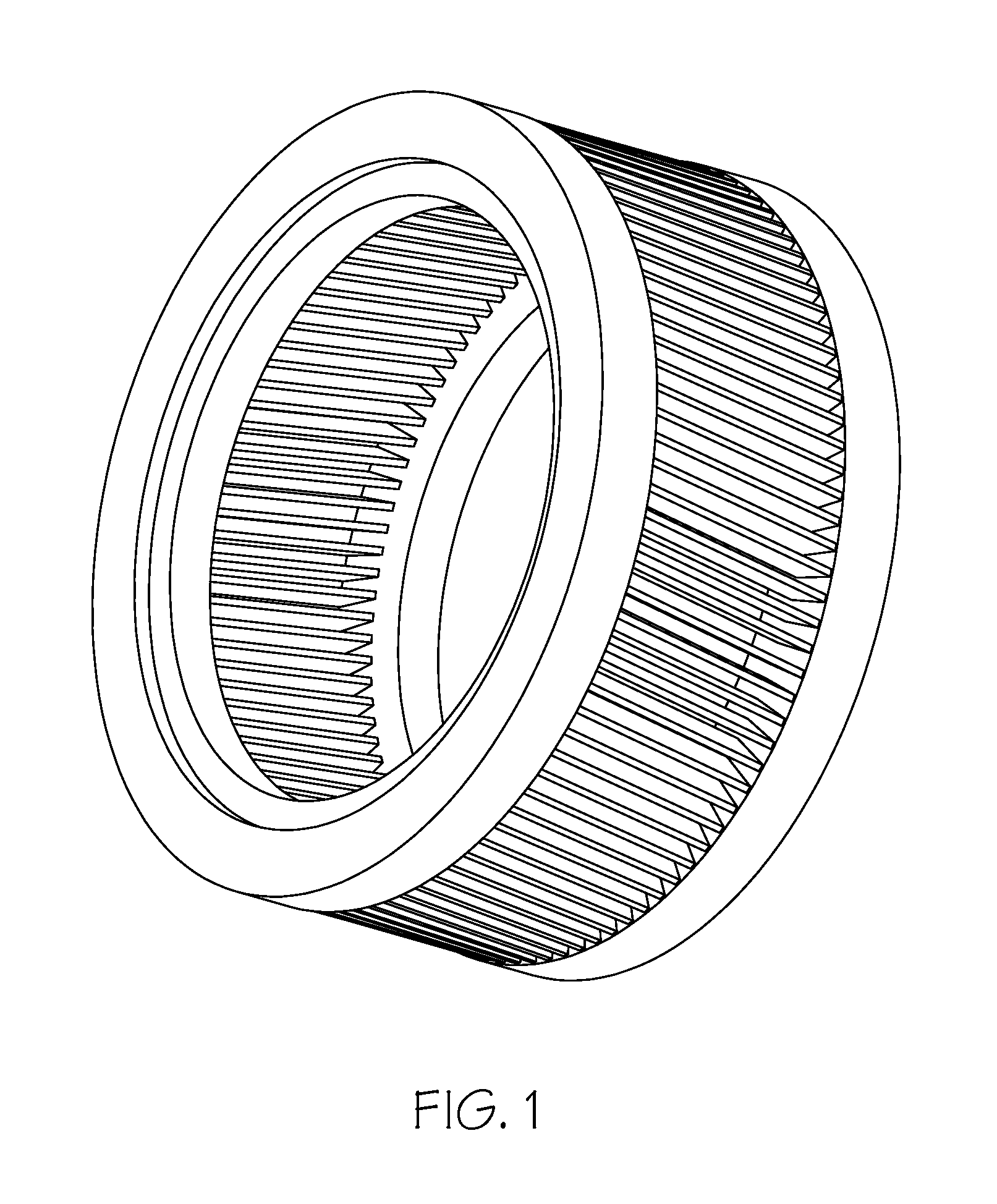

Squirrel-cage rotor for induction motor

ActiveUS20120217839A1Easy to confirmSynchronous motorsAsynchronous induction motorsElectrical conductorDie casting

A squirrel-cage rotor includes a rotor core formed having a plurality of slots, a plurality of conductor bars inserted into the slots respectively and made of copper or copper alloy, two conductor end rings joined to the plurality of conductor bars on both end faces of the rotor core and made of copper or copper alloy and a reinforcing-member end ring attached to at least one of the conductor end rings and made of material having a specific strength greater than that of either copper or copper alloy. The plurality of conductor bars are arranged so as to extend through the conductor end rings and the reinforcing-member end ring. Consequently, the rotor can be manufactured by any manufacturing method but die-casting. Further, the conductor end rings can be reinforced with an easily-obtainable material and additionally, the junction of conductor end rings can be easily viewed from an outside.

Owner:FANUC LTD

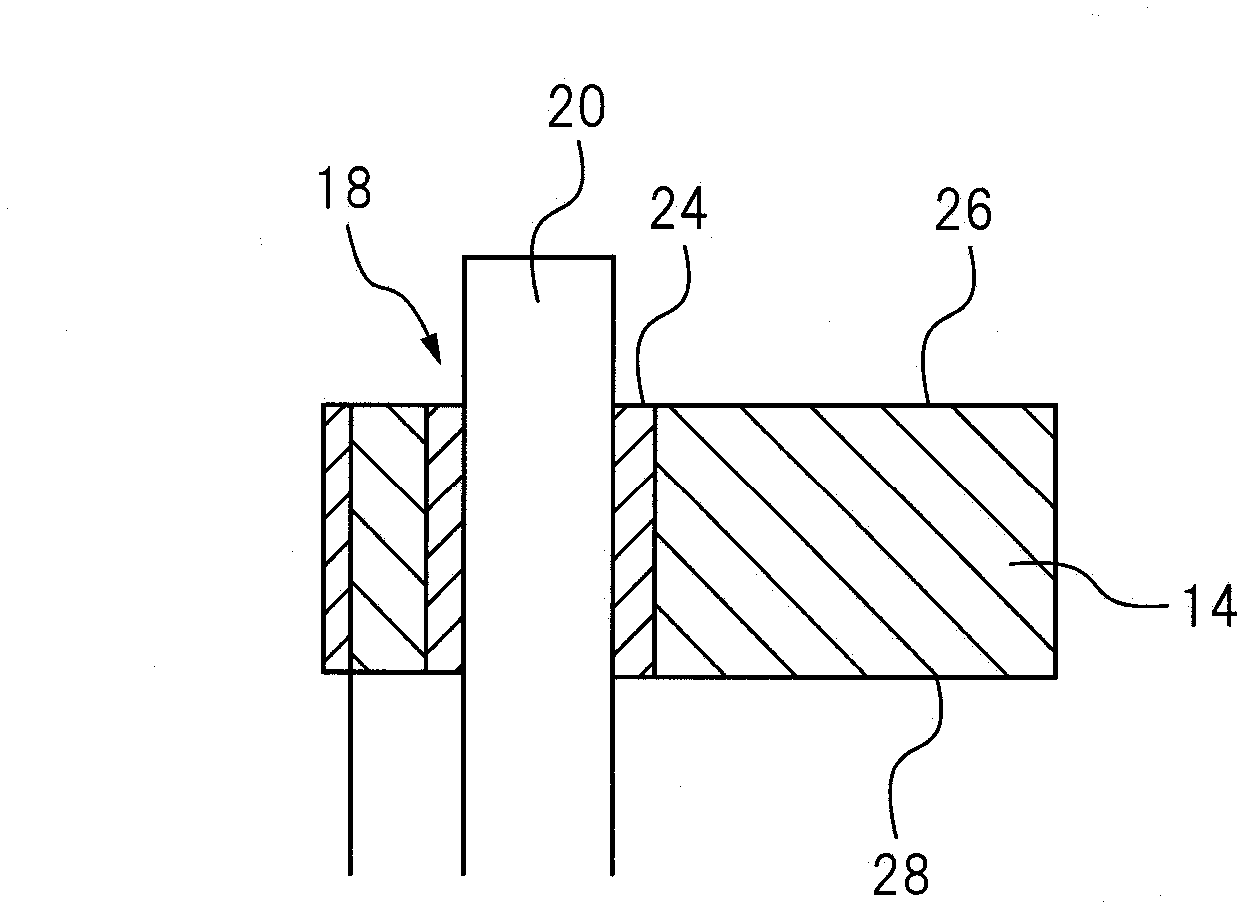

Squirrel-cage rotor of induction motor and production method thereof wherein end ring is brazed with bar

ActiveCN102684435AReduce working hoursMagnetic circuit rotating partsAsynchronous induction motorsSilver plateElectrical conductor

The present invention relates to a squirrel-cage rotor of an induction motor and a production method thereof, wherein an end ring is brazed with a bar. An object of the present invention is to provide a squirrel-cage rotor of an induction motor and a production method thereof, wherein locating of the brazing material is not necessary in order to reduce manhours for brazing, and a bar is easily connected to an end ring. Before assembling a rotor, a silver plated layer is formed on at least one of an end ring and a conductive bar. In order to melt the silver plated layer, the rotor is heated to a temperature which is equal to or larger than the melting point of the silver plated layer. The melted layer functions as a brazing material, whereby the end ring and the conductive bar are connected.

Owner:FANUC LTD

Centrifugal casting air discharging method for squirrel cage rotor and centrifugal casting die for implementing method

ActiveCN103084557AImprove compactnessImprove processingAsynchronous induction motorsManufacturing dynamo-electric machinesElectric machineEngineering

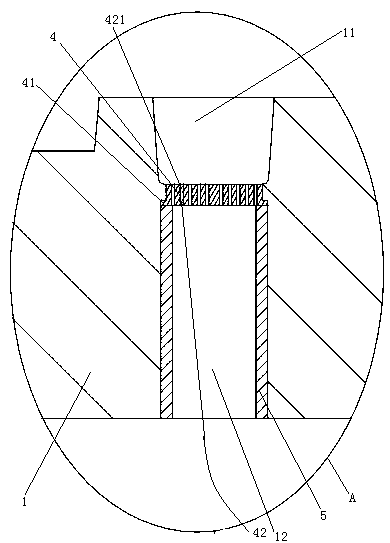

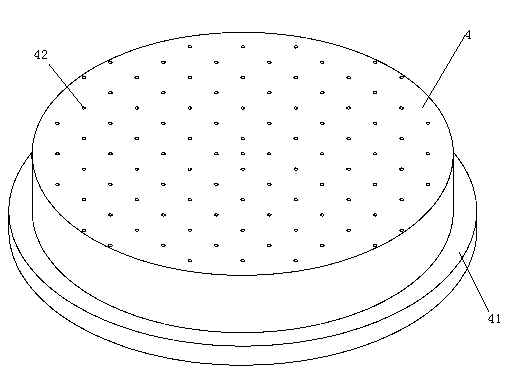

The invention relates to a squirrel cage rotor. A squirrel cage rotor centrifugal casting die comprises an upper die and a lower die; the upper die is provided with a rotor upper end annular cavity; the lower die is provided with a rotor lower end annular cavity; the bottom wall of the rotor lower end annular cavity is provided with a plurality of lower air discharging holes of which opening areas are less than three square millimeters; and air is discharged by the lower air discharging holes in a casting process. The invention provides a centrifugal casting air discharging method for the squirrel cage rotor, and the squirrel cage rotor centrifugal casting die. By the method, air can be discharged efficiently, conveniently and comprehensively; and by the method and the die, the problems of low production efficiency and complex equipment structure, and the problem that energy conversion efficiency of a motor is reduced due to low compactness of an aluminum cage, broken ribs and air bubble entrainment in the conventional air discharging method and the process that the squirrel cage rotor is cast by the centrifugal casting die can be solved.

Owner:HANGZHOU FUSHENG ELECTRICAL APPLIANCE

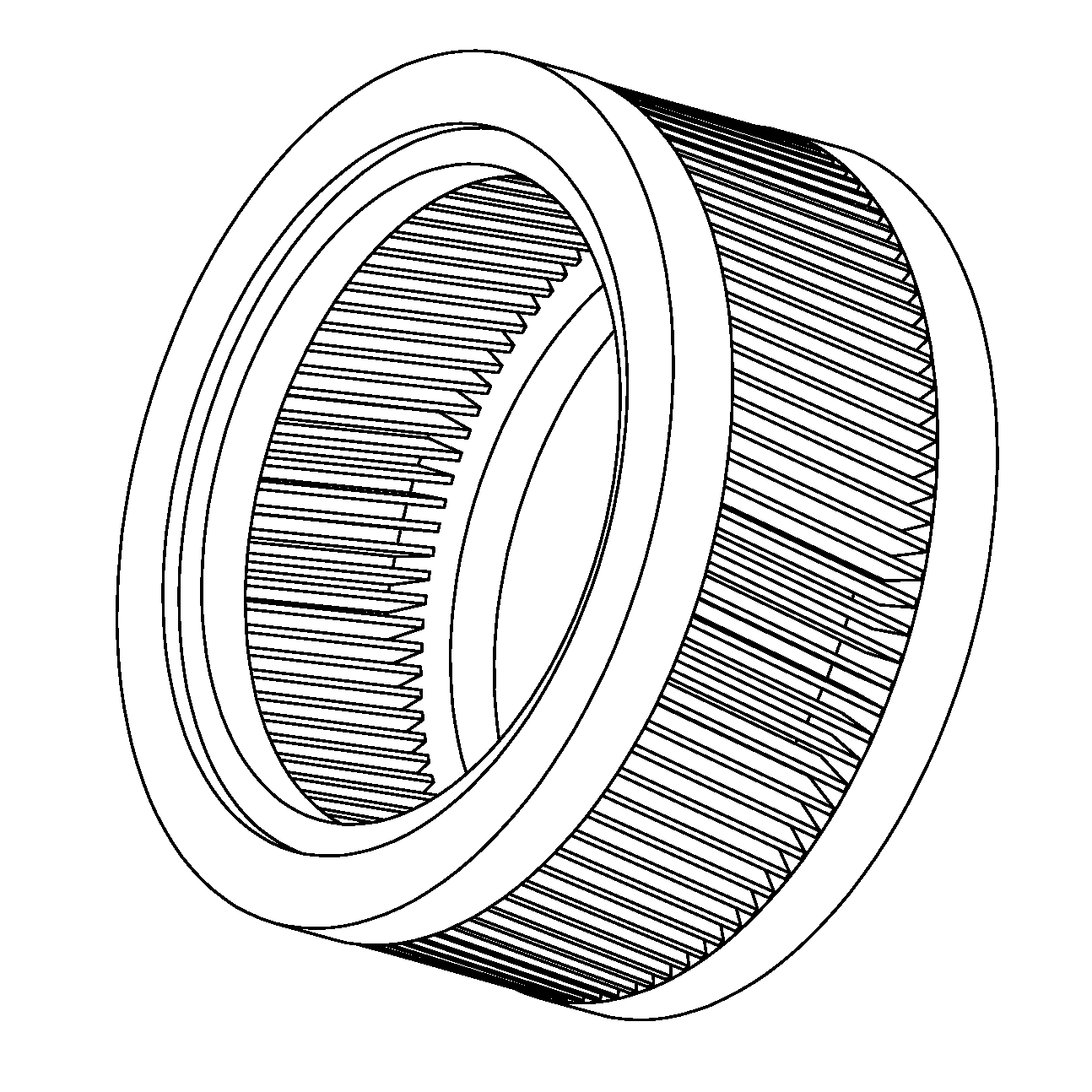

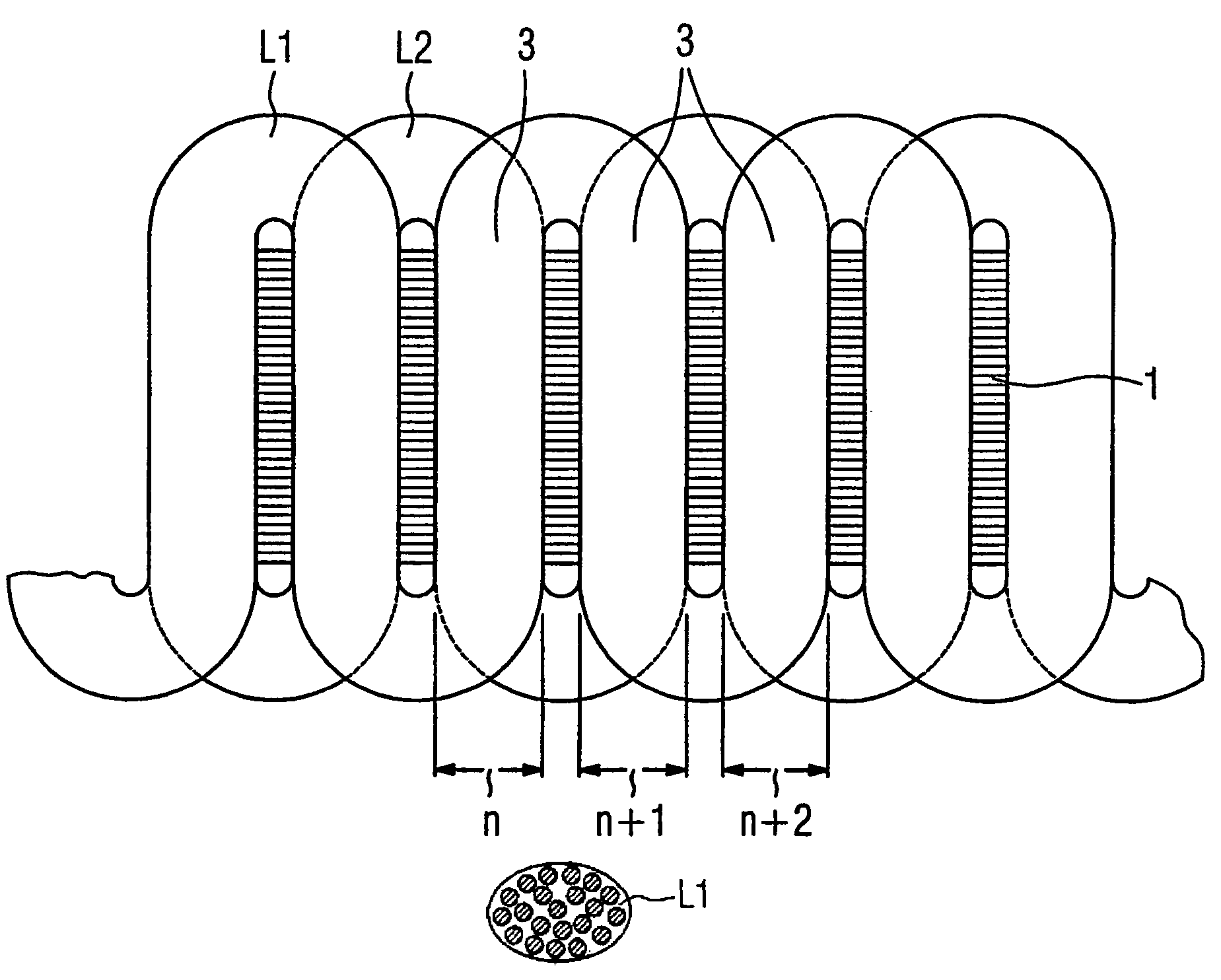

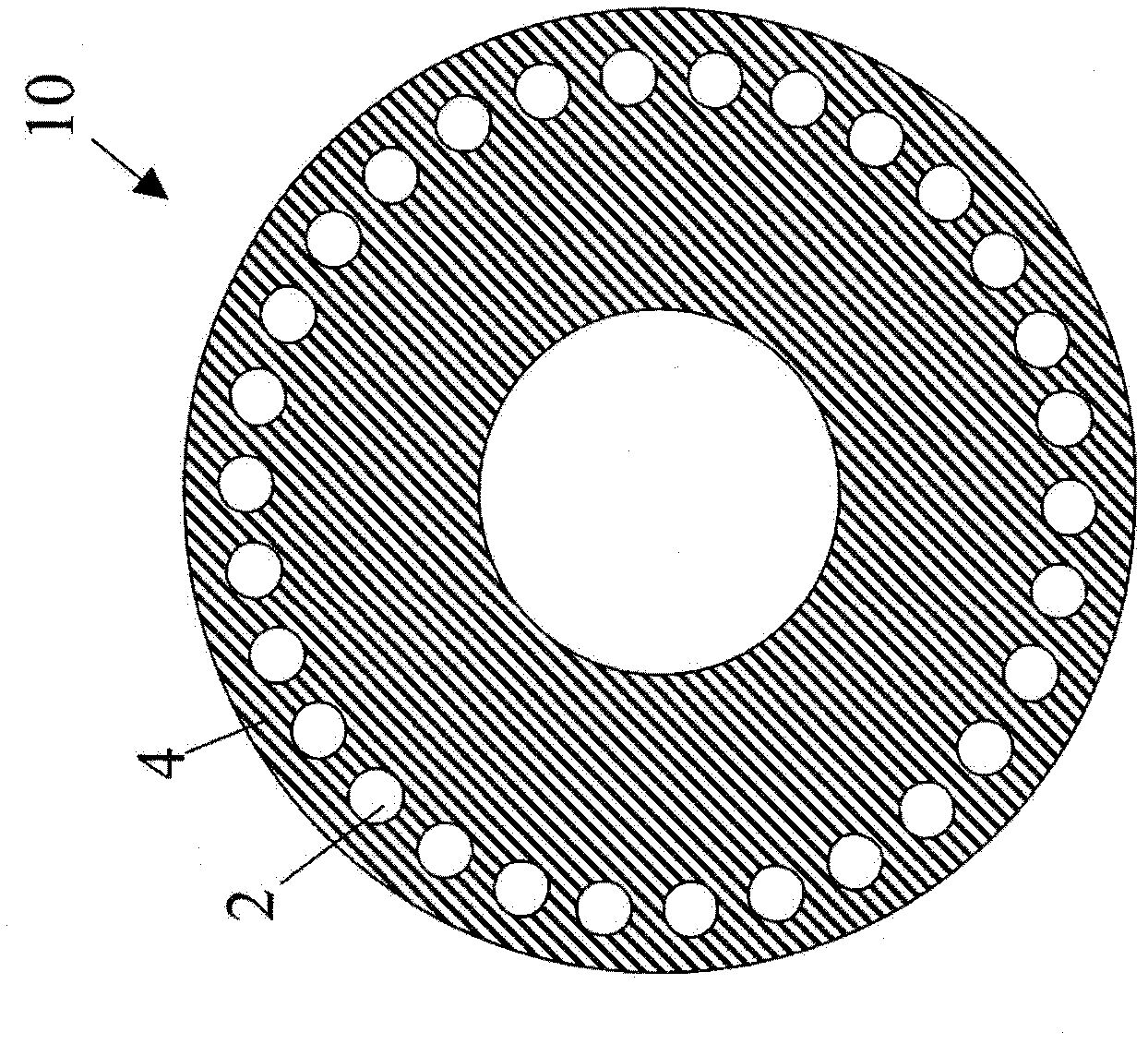

Squirrel-cage rotor

InactiveUS20070210667A1Improved squirrel-cage rotorReduce material stressSynchronous motorsStatorsElectrical conductorEngineering

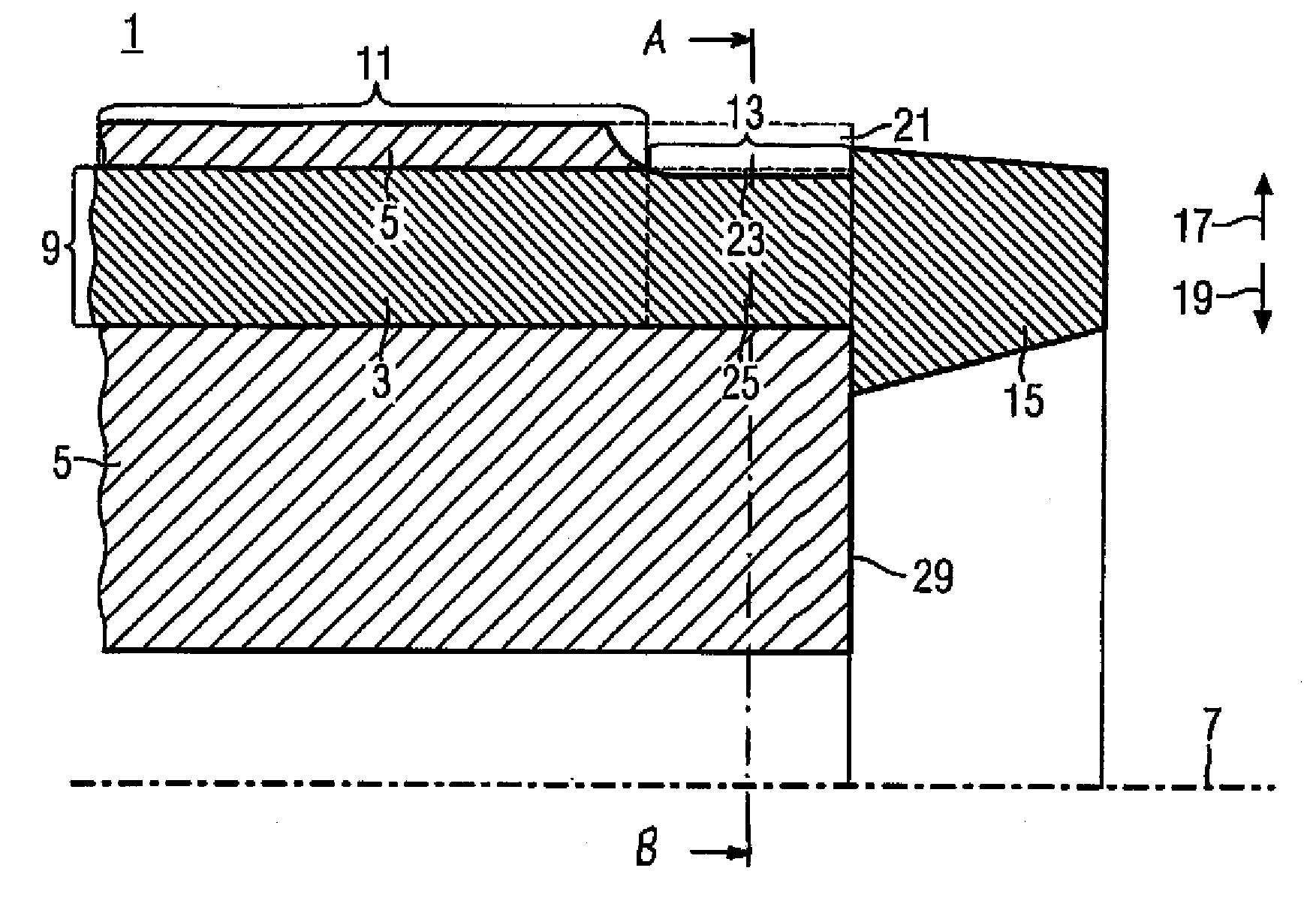

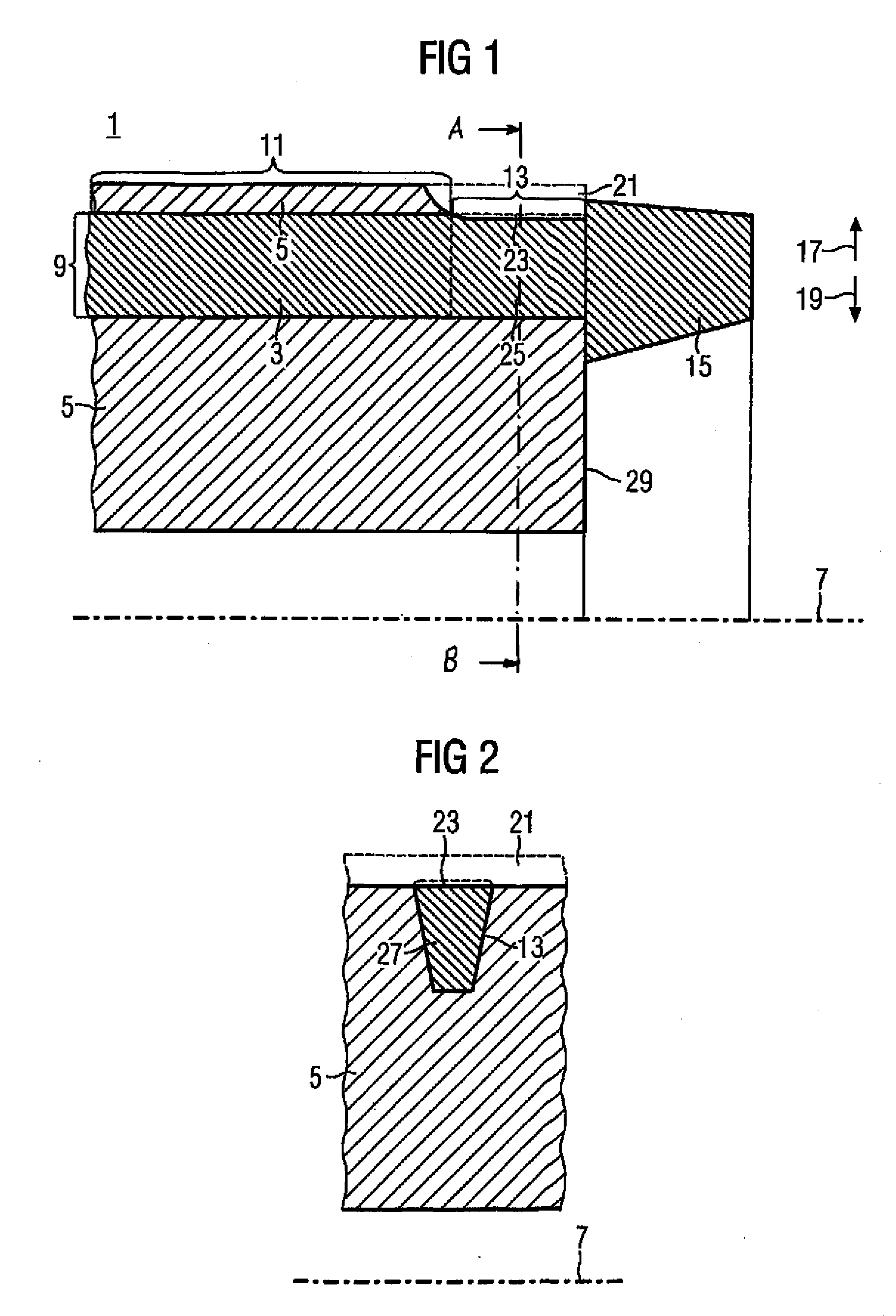

A squirrel-cage rotor (1) includes squirrel-cage rotor conductors (3) and a carrier (5) for the squirrel-cage rotor conductors (3). The carrier (5) is provided with axial slots (9) in which the squirrel-cage rotor conductors (3) are accommodated. An axial slot (9) includes at least one closed slot portion (11) and an open slot portion (13), with the open slot portion (13) located between the closed slot portion (11) and a cage ring (15). In a method for producing a squirrel-cage rotor (1) having a carrier (5) for squirrel-cage rotor conductors (3), with the carrier (5) having closed slots (9), the squirrel-cage rotor conductors (3) are cast into the slots or are inserted therein as bars, whereupon carrier material is removed in the area of the end surfaces (29) of the carrier (5) in such a way that an open slot portion (13) is formed.

Owner:SIEMENS AG

Method for manufacturing squirrel cage rotor

InactiveUS20060150396A1Reduced rotor lossesAvoid loopsSynchronous motorsFoundry mouldsElectricityElectrical conductor

Ceramic adhesive is applied inside the slots of an electric machine squirrel cage rotor prior to casting or insertion of rotor conductors. This heat-resistant insulation provides superior electrical insulation that is also mechanically rugged, thus enabling casting of squirrel cage rotors by die or cost-effective consumable pattern casting. The consumable pattern cast copper rotors are electrically well insulated, thus minimizing rotor losses. The ceramic insulation in cast rotors enables longer conductors to be cast by thermally insulating the molten metal from the cooler laminations. The ceramic insulation in fabricated rotors withstands the high temperatures of end ring attachment. This method is applicable to both conventional induction machine rotors and brushless doubly-fed induction machine rotors and provides the degree of electrical isolation of the bars from the laminations needed to avoid excessive parasitic torques in doubly-fed machines, while ensuring adequate thermal conductivity to dissipate conductive bar heat to the laminations.

Owner:DUAL STATOR TECH INC

Squirrel-cage rotor and production method thereof

ActiveUS20120248901A1High strengthAsynchronous induction motorsManufacturing cage rotorsElectrical conductorEngineering

A squirrel-cage rotor and a production method thereof, the rotor having conductors with sufficient strength. In the invention, conductor particles are sprayed onto a core and / or conductive bars in a solid-state. As a result, in the coating material, the enlargement of the crystal grain of the conductors is significantly restricted, whereby conductive end rings are connected to the core and / or the conductive bars. Since conductor particles do not melt, a gap formed by thermal contraction when the conductor melts between different kinds of members is prevented from being formed. Therefore, the deterioration of the conductor may be limited, and the conductor may have sufficient strength. The reliability of the rotor is improved.

Owner:FANUC LTD

Squirrel-cage rotor for induction motor

InactiveCN102651596AEasy to joinConfirm engagement statusAsynchronous induction motorsElectrical conductorDie casting

Owner:FANUC LTD

Solid phase welding of aluminum-based rotors for induction electric motors

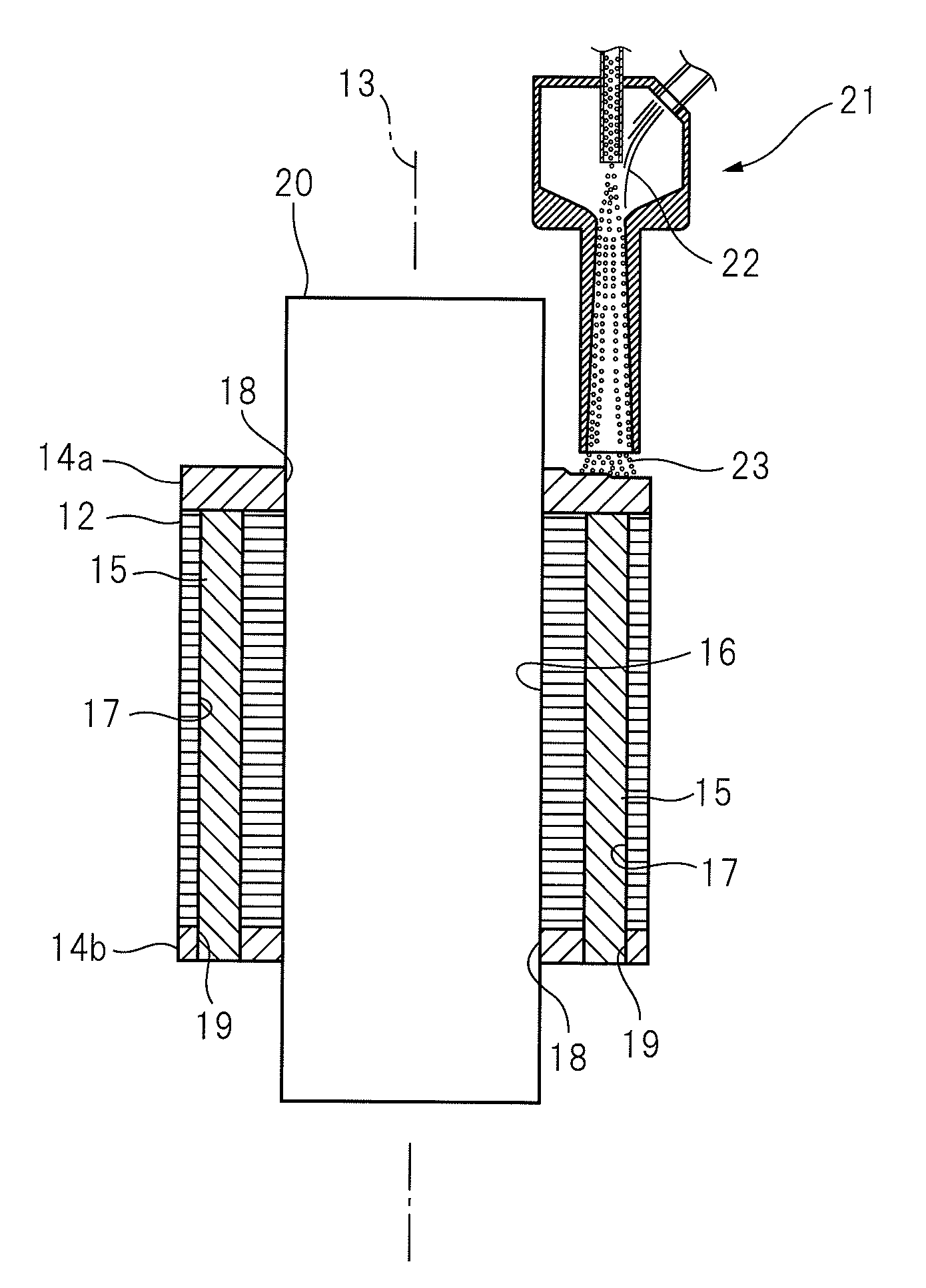

ActiveUS20120049687A1Improve mechanical propertiesIncreased durabilitySynchronous motorsAsynchronous induction motorsFriction weldingElectrical conductor

Squirrel cage rotors of aluminum end rings solid state welded to aluminum conductor bars for use in electric motors and methods of making them are described. In one embodiment, the method includes: providing a laminated steel stack having a plurality of longitudinal slots; placing a plurality of aluminum conductor bars in the longitudinal slots, the conductor bars having first and second ends extending out of the longitudinal slots; contacting the first and second ends of the conductor bars with a pair of aluminum end rings under pressure; and oscillating the first and second ends of the conductor bars, the end rings, or both to form an oscillation friction weld.

Owner:GM GLOBAL TECH OPERATIONS LLC

Casting process of copper squirrel rotor

The casting process of copper squirrel cage rotor includes the following steps: 1. pre-treating silicon steel sheet through heating in a furnace a 500-600 deg.c and cooling outside the furnace to form oxide film automatically; 2. laminating, pressing and installing mold; 3. heating the pressed silicon sheets inside furnace to 650-750 deg.c, and setting in a centrifuge; 4. smelting copper material; 5. casting to the squirrel cage groove and mold cavity while turning on the centrifuge to exhaust air; and cooling outside the furnace. The present invention has the advantages of power saving of motor, reduced motor size, saving in material, low cost, etc.

Owner:河南福顺电磁科技有限公司

Cage-shaped rotor magnetic coupling capable of regulating speed

InactiveCN102916558AImprove reliabilityImprove operational efficiencyAsynchronous induction clutches/brakesCouplingMagnetic poles

The invention discloses a cage-shaped rotor magnetic coupling capable of regulating speed. The cage-shaped rotor magnetic coupling comprises a power input shaft, a connection device, a permanent magnet outer rotor assembly, a cage-shaped inner rotor assembly, a power output shaft and a mechanical speed regulating device, the permanent magnet outer rotor assembly is sleeved outside the cage-shaped inner rotor assembly, and even air gaps are arranged between the permanent magnet outer rotor assembly and the cage-shaped inner rotor assembly. A layout mode of permanent magnets in the permanent magnet outer rotor assembly adopts a radial layout mode or a circumferential layout mode. The cage-shaped rotor magnetic coupling adopts an inside-outside-inside sleeved mode, an outer rotor adopts a structure with alternative magnetic poles, an inner rotor adopts a squirrel-cage rotor structure in an asynchronous motor, a rotating magnetic field produced by rotation of the outer rotor is used, induced current is produced in a squirrel-cage guide strip of the inner rotor, and the rotating magnetic field and the induced current drive the inner rotor to rotate under effects of ampere force. The magnetic coupling is high in reliability and operating efficiency, and reduces design and production cost.

Owner:葛研军

Switching pattern AC induction motor

InactiveUS7239061B2Wide speed rangeReduce manufacturing costSingle-phase induction motor startersAC motor controlFrequency characteristicPulse width modulated

Both the stator core and the rotor core of a switching pattern AC induction motor are fabricated by soft magnetic material laminations or ferrite material, etc., both of which have corresponding frequency characteristic. The rotor is a squirrel cage rotor. Switching pattern excitation is adopted in the stator pole, of which the excitation voltage is sine wave pulse width modulated or sine wave pulse amplitude modulated within the frequency range of voice and ultrasonic. Under the condition of the same power output, the present motor reduces its size and mass to a fraction of or tenth of that of an ordinary one. Meanwhile, it reduces the cost of manufacture. It realizes stepless speed regulating from zero to several thousand rpm while keeping well mechanical characteristic performance.

Owner:HUANG YOUGUO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com