Squirrel-cage rotor for induction motor

一种感应电动机、笼型转子的技术,应用在异步感应电动机、电气元件、机电装置等方向,能够解决转子可靠性未必能提高、制造工序变多、制造成本变高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

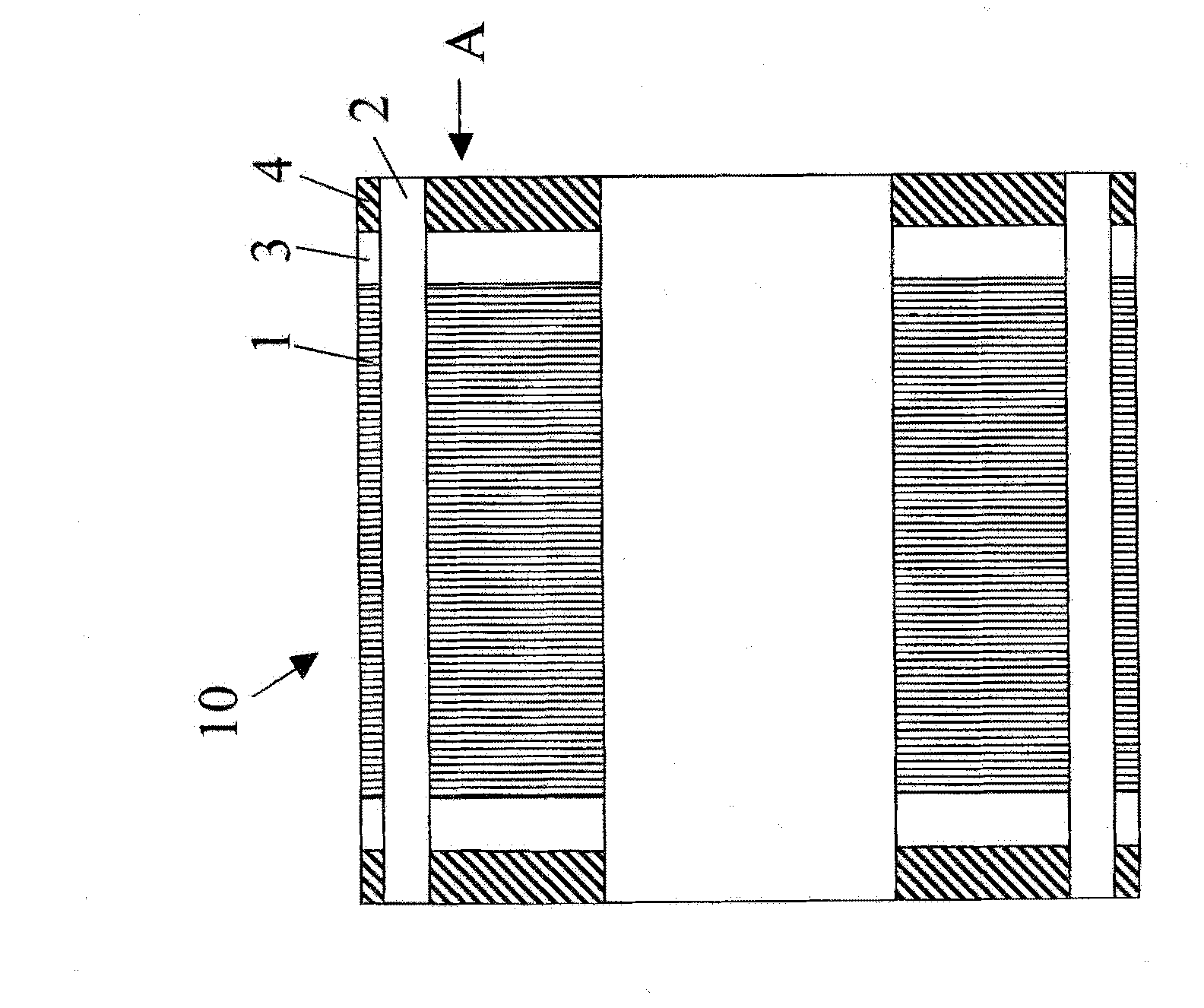

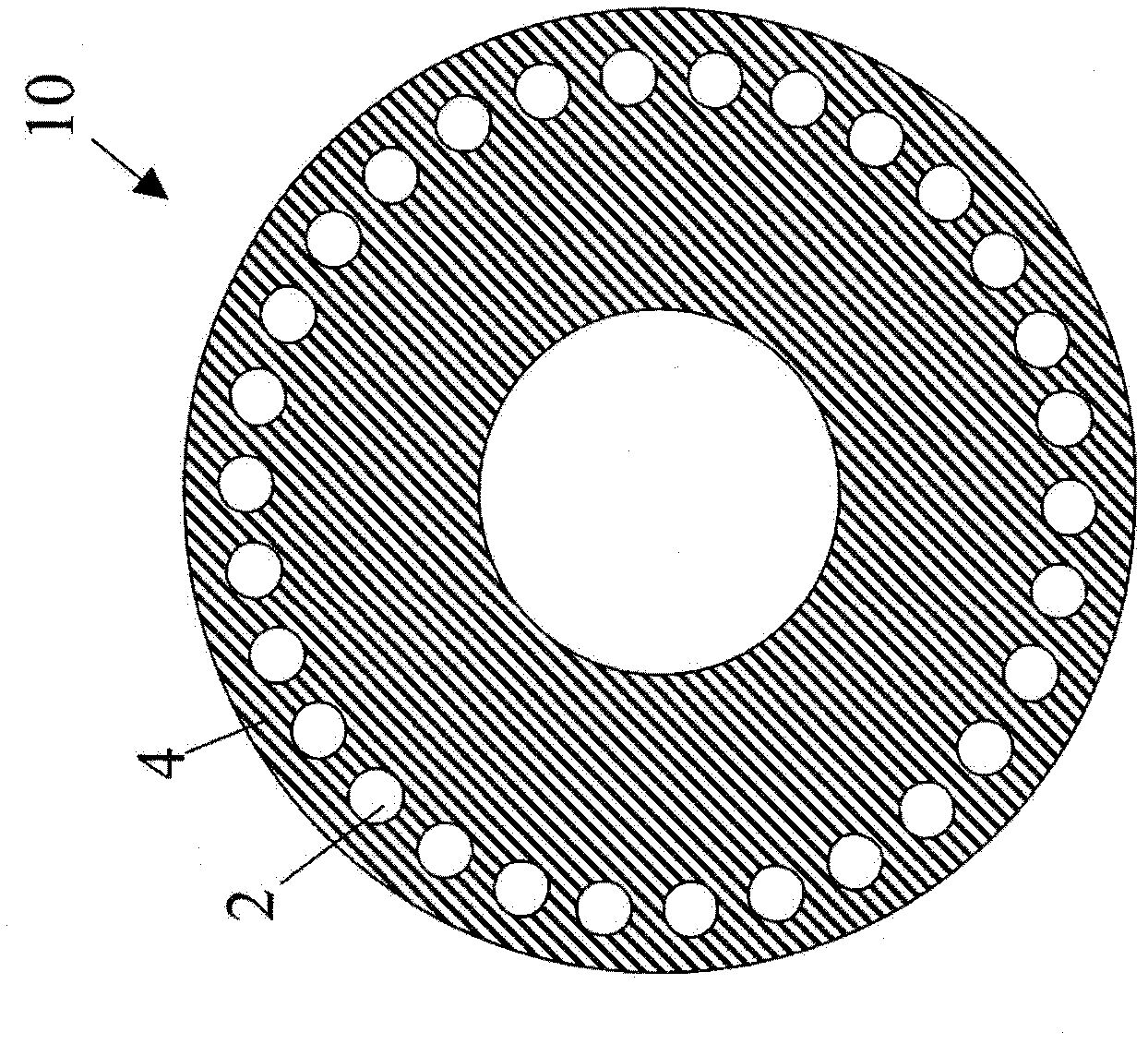

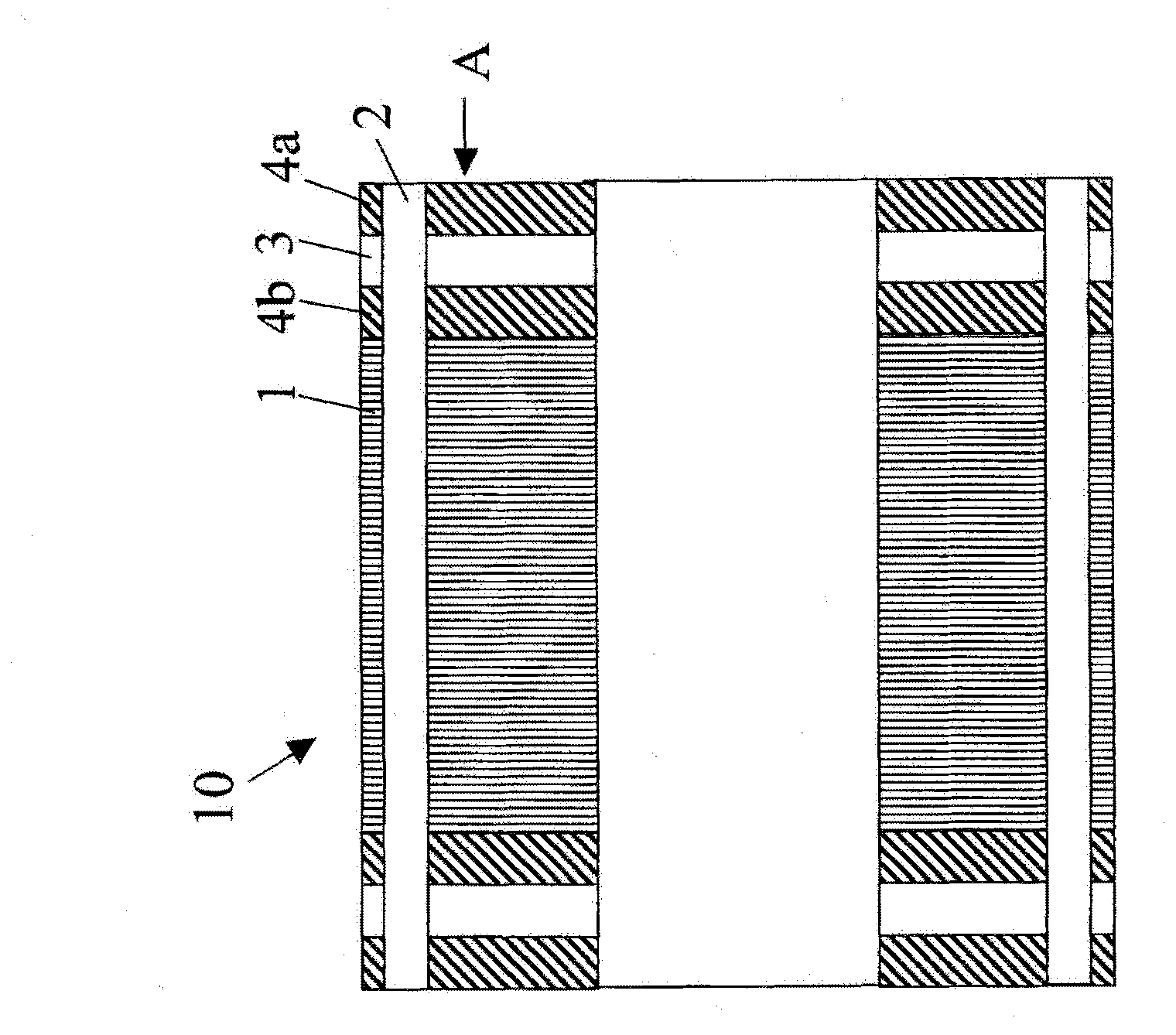

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following drawings, the same reference symbols are attached to the same components. For easy understanding, these drawings are appropriately changed in reduced scale.

[0025] Figure 1a is a side sectional view of the cage rotor according to the first embodiment of the present invention, Figure 1b From Figure 1a The end view of the cage rotor viewed from the arrow A shown. Figure 1a The illustrated cage rotor 10 includes a rotor core 1 . The rotor core 1 as the core of the cage rotor 10 is formed of a general material such as a laminate of electromagnetic steel sheets. Furthermore, a plurality of slots (not shown) extending in the axial direction are formed in the rotor core 1 .

[0026] A conductor rod 2 made of copper or a copper alloy is inserted into each of these slots. The shape of the conductor rod 2 is roughly the same as the shape of the slot. lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com