Patents

Literature

248results about How to "Reduce working hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

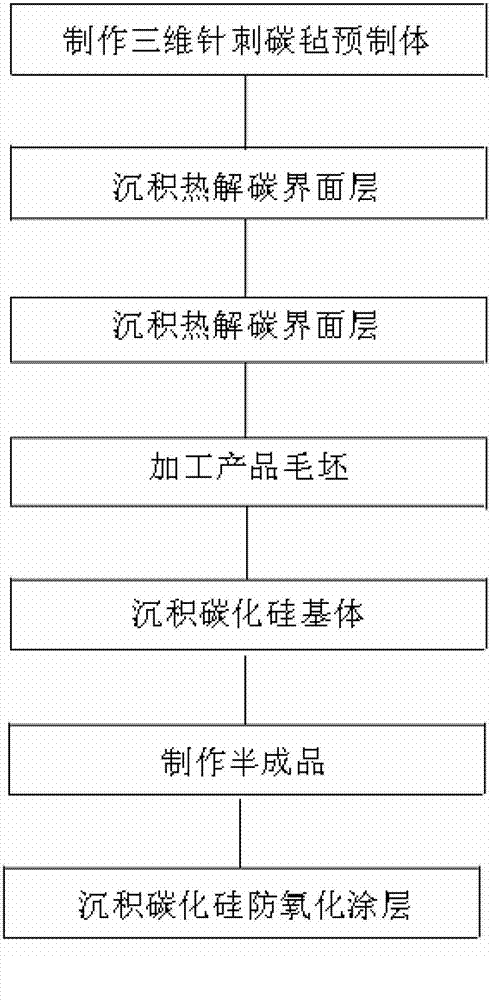

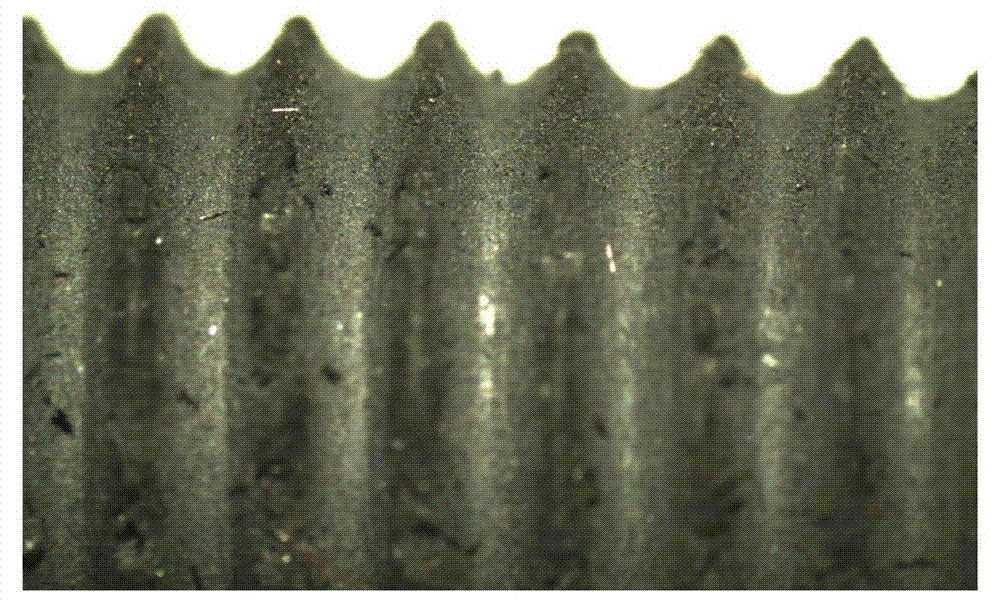

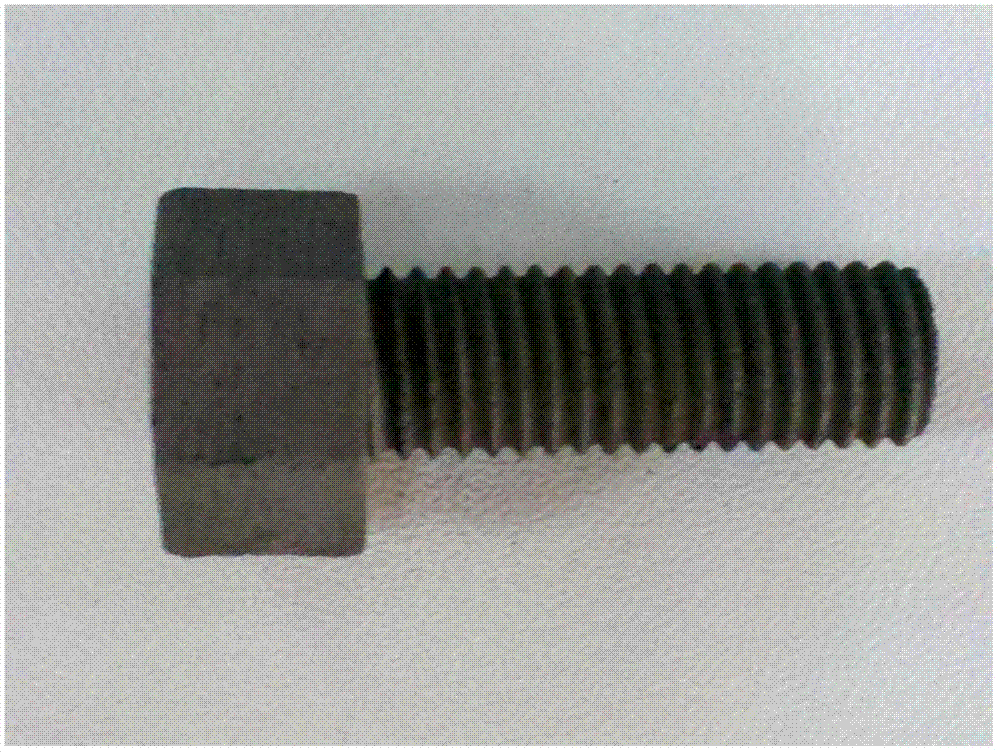

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

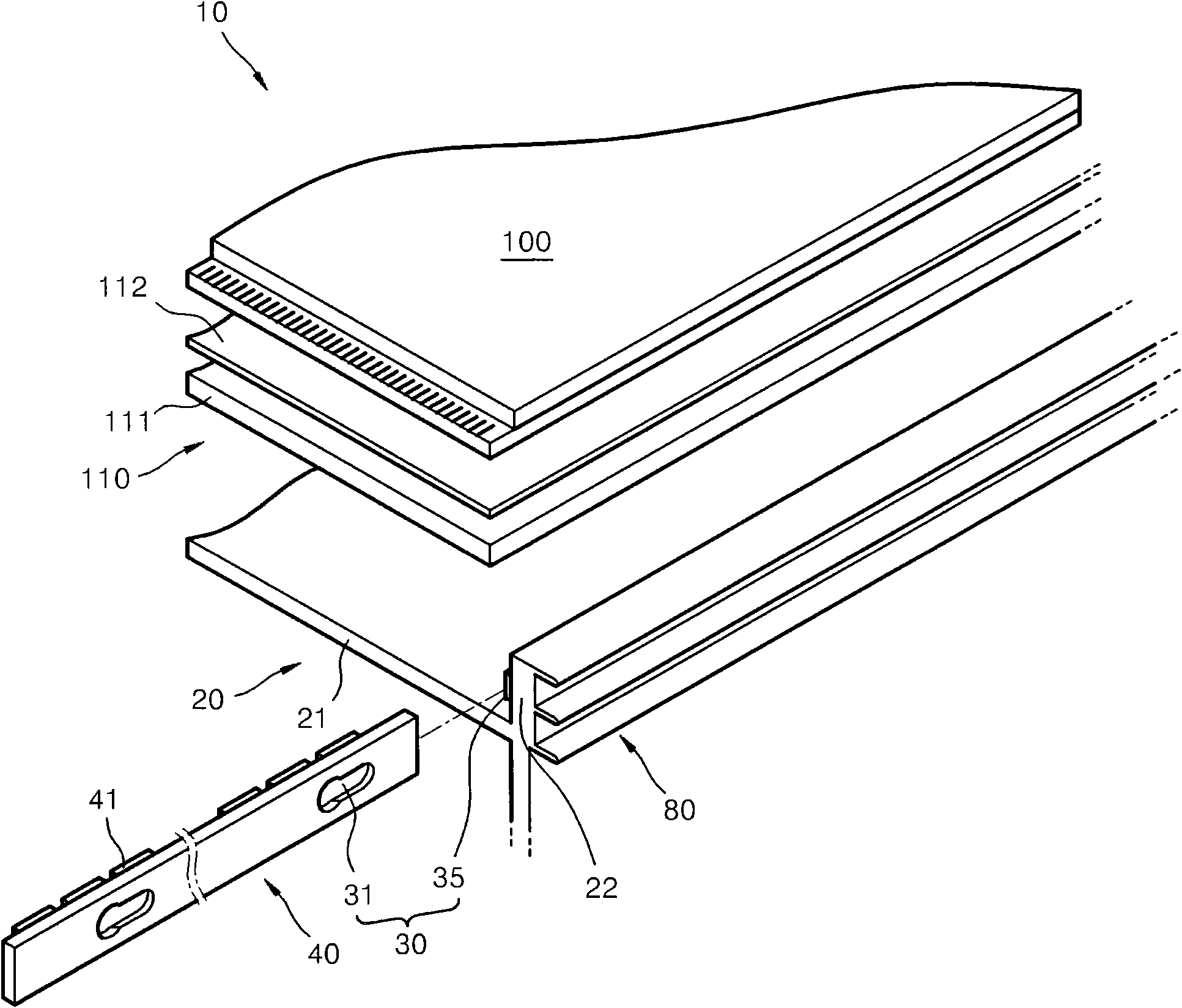

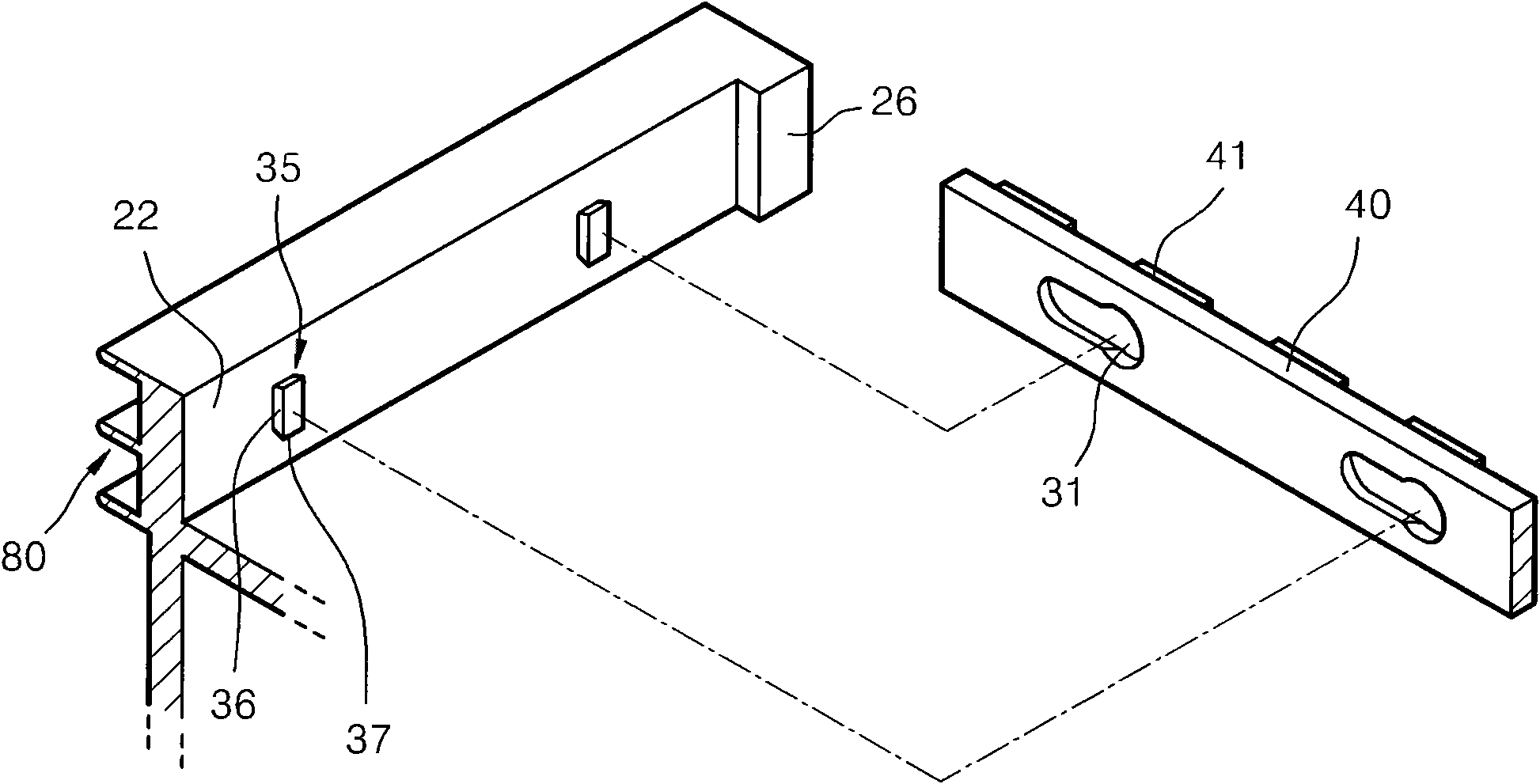

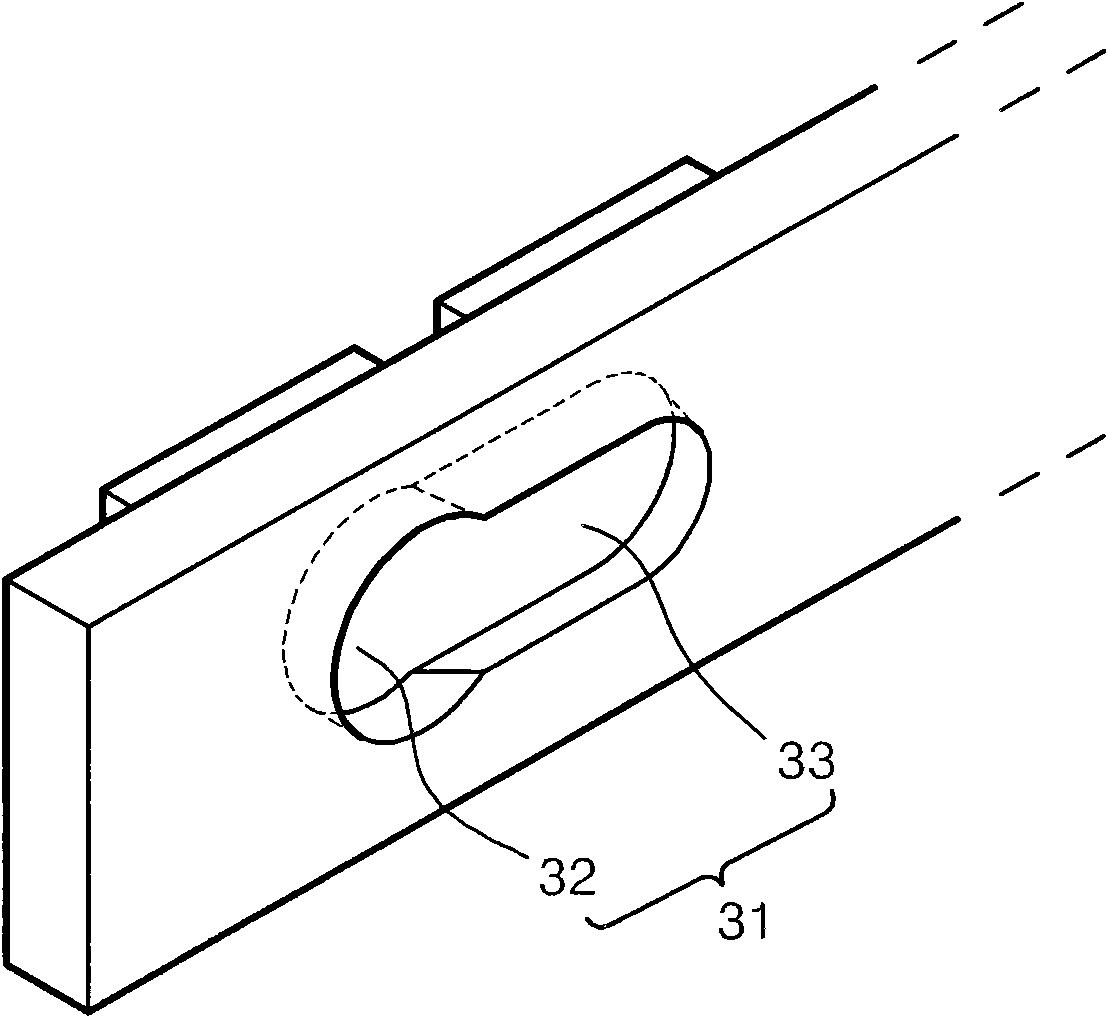

Apparatus for coupling a module circuit board and a frame together, and backlight using same

InactiveCN102067018AImprove bindingImprove reliabilityOptical light guidesNon-linear opticsCouplingComputer module

The present invention provides an apparatus for coupling a module circuit board and a frame together, and backlight using the same, wherein a coupling structure of the module circuit board equipped with light-emitting diodes and the frame is improved. The apparatus comprises: a module circuit board on which light-emitting diodes are arranged into a predetermined pattern; and a frame coupled to the module circuit board by a coupling unit, wherein the coupling unit has coupling grooves formed at the back surface of the module circuit board, and coupling members formed at the frame to be coupled to the respective coupling grooves.

Owner:LPOINT

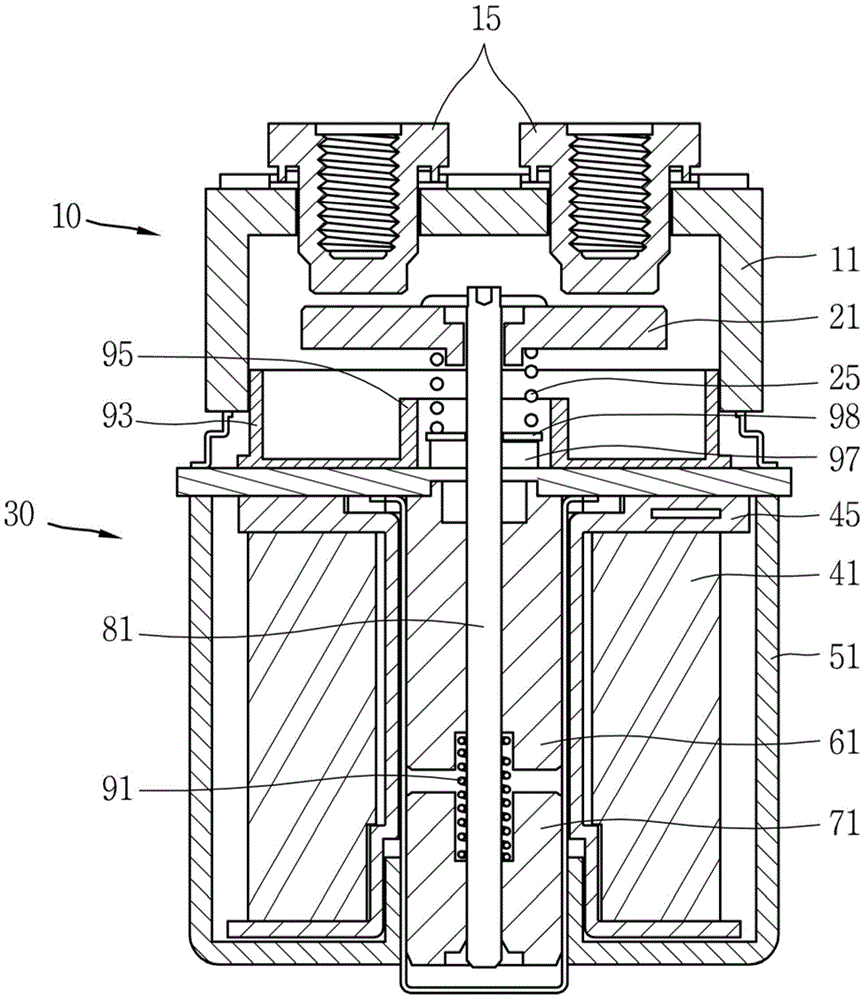

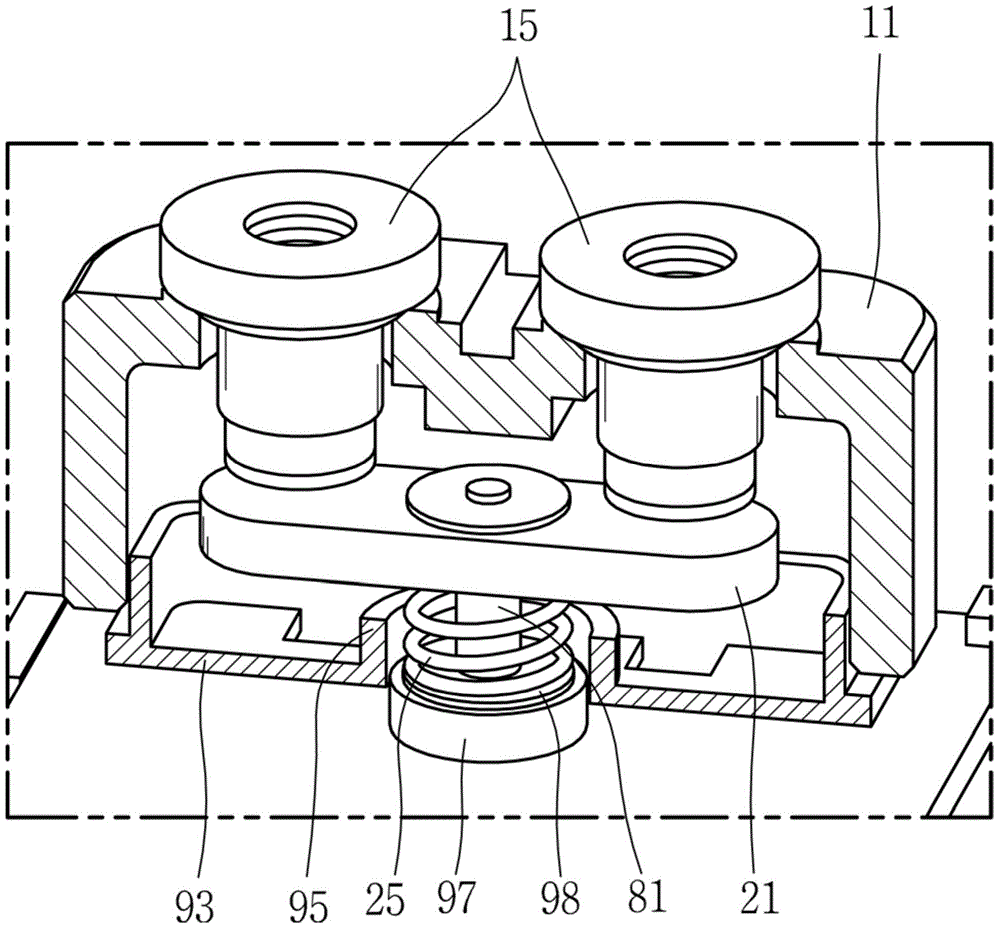

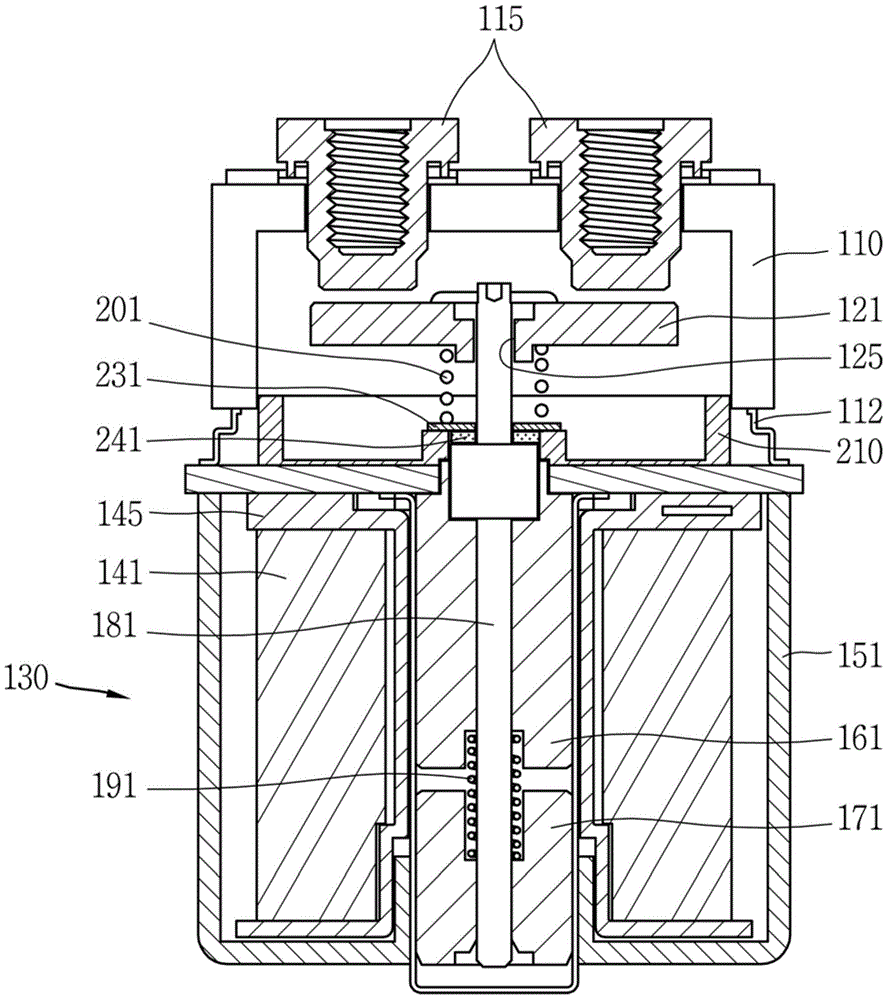

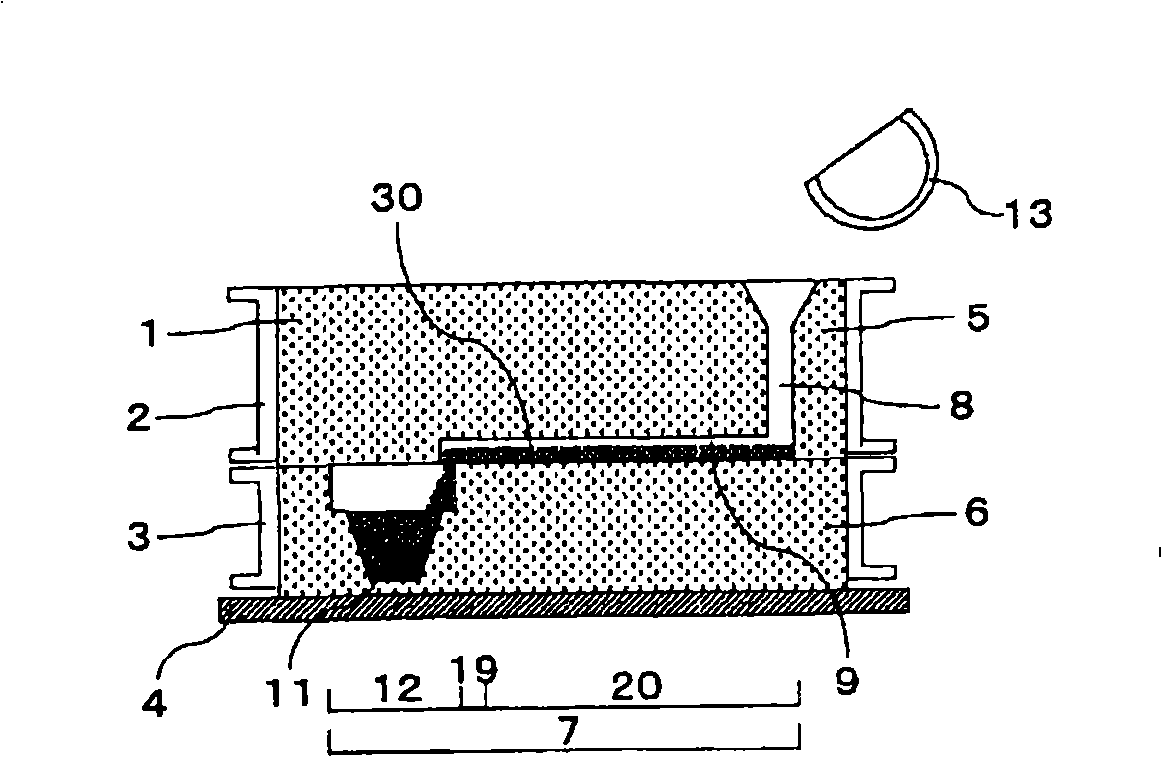

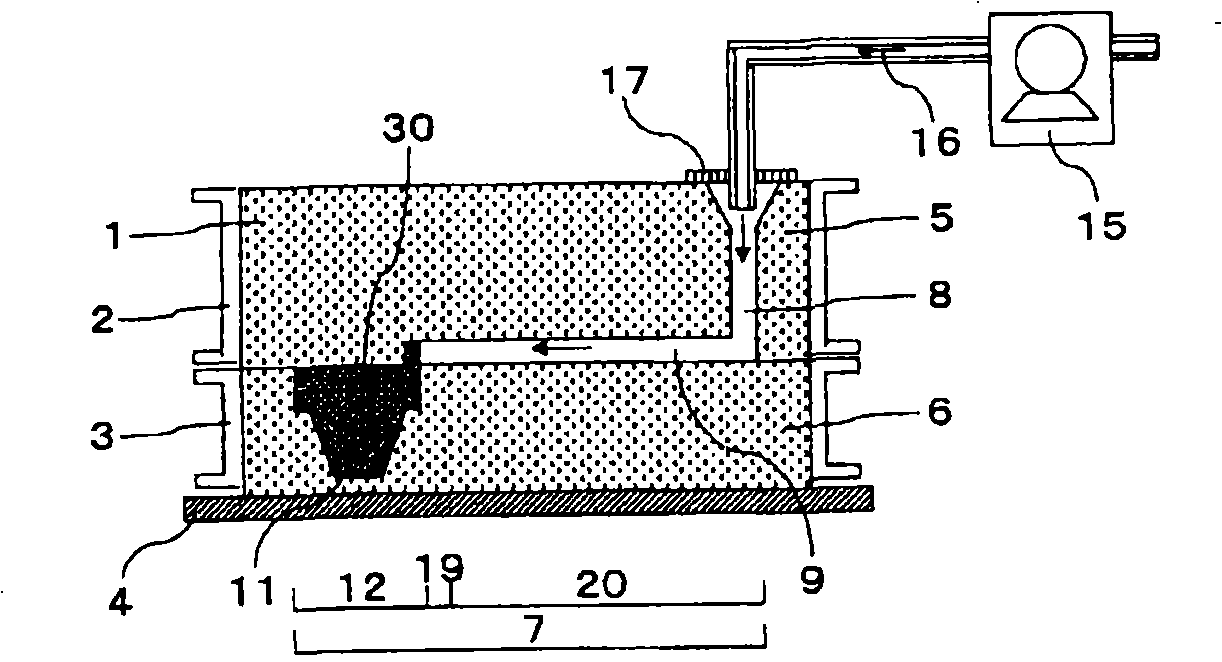

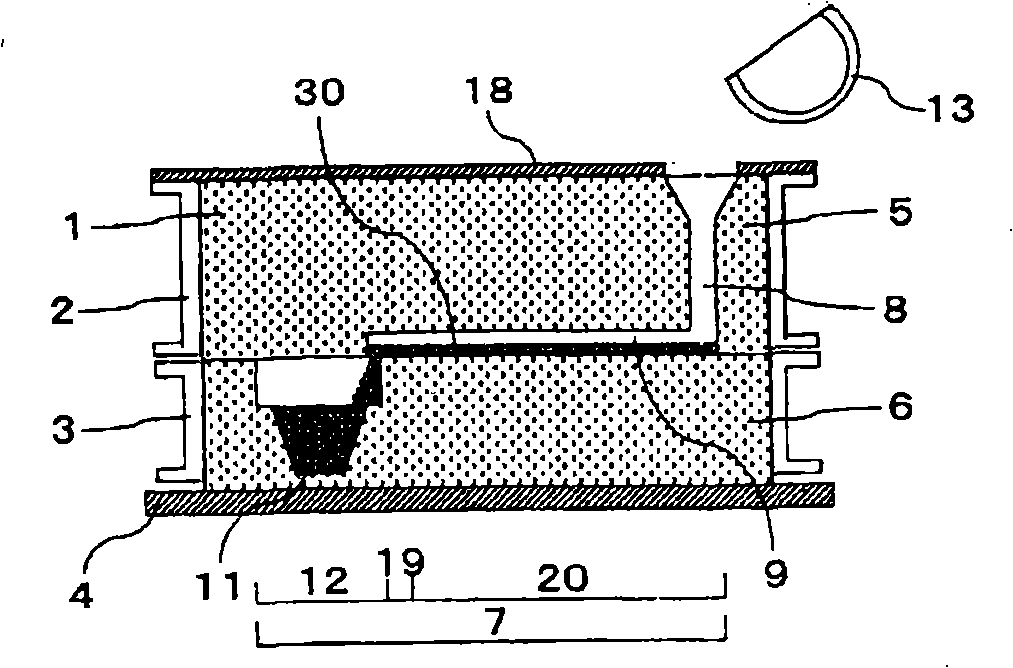

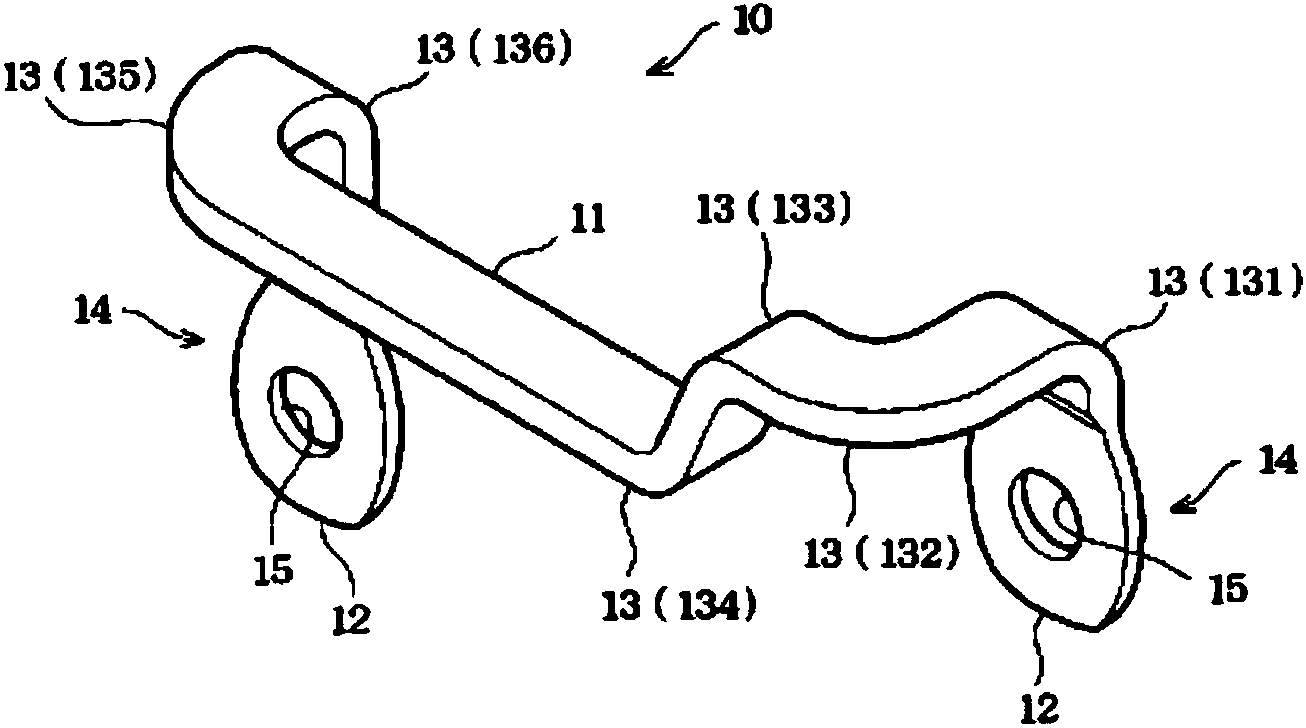

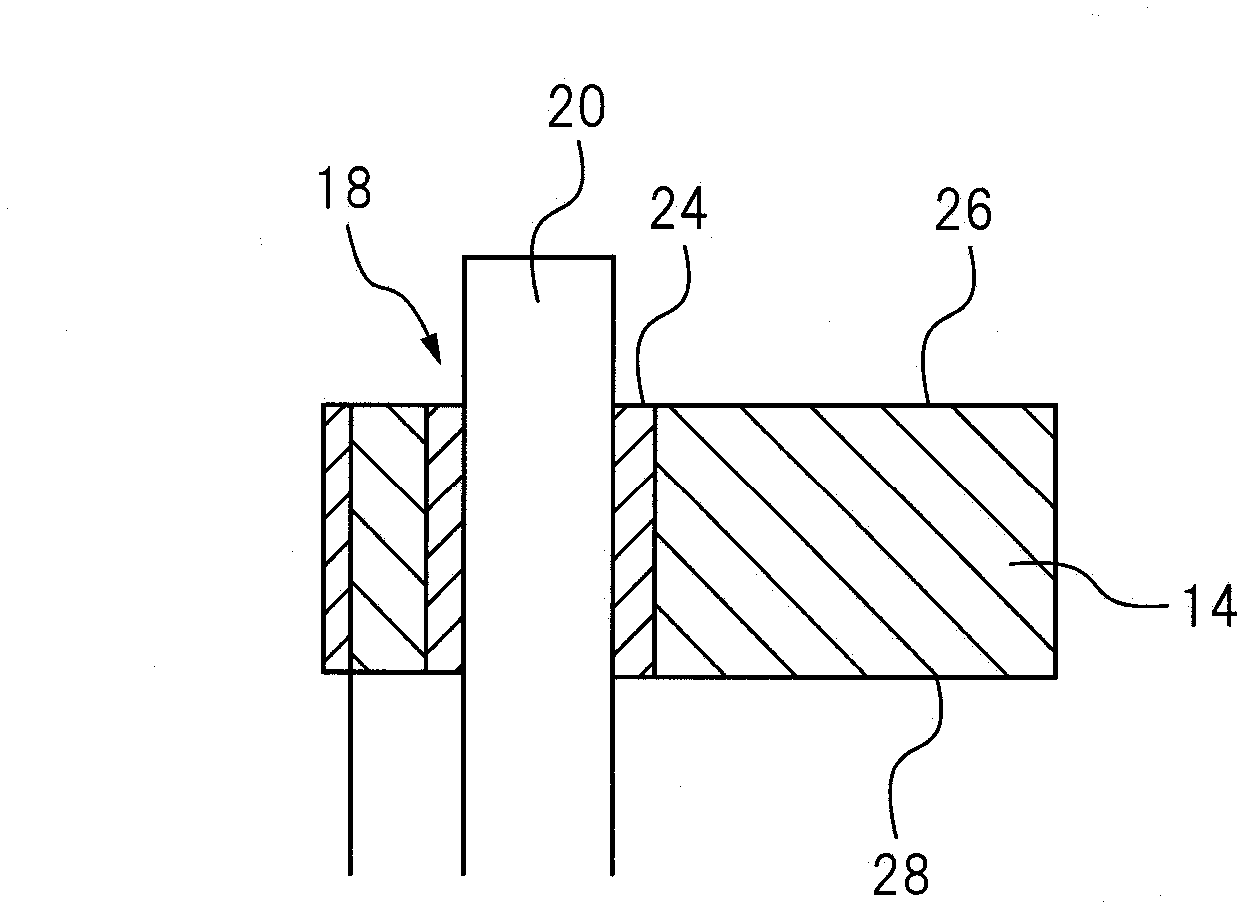

Electromagnetic relay

ActiveCN104810207AReduced parts countReduce working hoursElectric switchesElectromagnetic relay detailsMechanical engineeringRelay

An electromagnetic relay includes a housing; a fixed contact provided within the housing; a movable contact disposed within the housing so as to be contactable to and separable from the fixed contact; a driving unit configured to drive the movable contact, and including a shaft having one end connected to the movable contact and a compression spring for applying an elastic force to the movable contact so as to be in contact with the fixed contact; and an arc protector including an arc shielding portion for shielding an arc, and a compression spring support portion formed to protrude from the arc shielding portion to support the compression spring, the compression spring support portion comprising a shaft accommodating portion for accommodating the shaft therein. Under such configuration, the number of required components can be reduced and generation of a gap can be prevented.

Owner:LSIS CO LTD

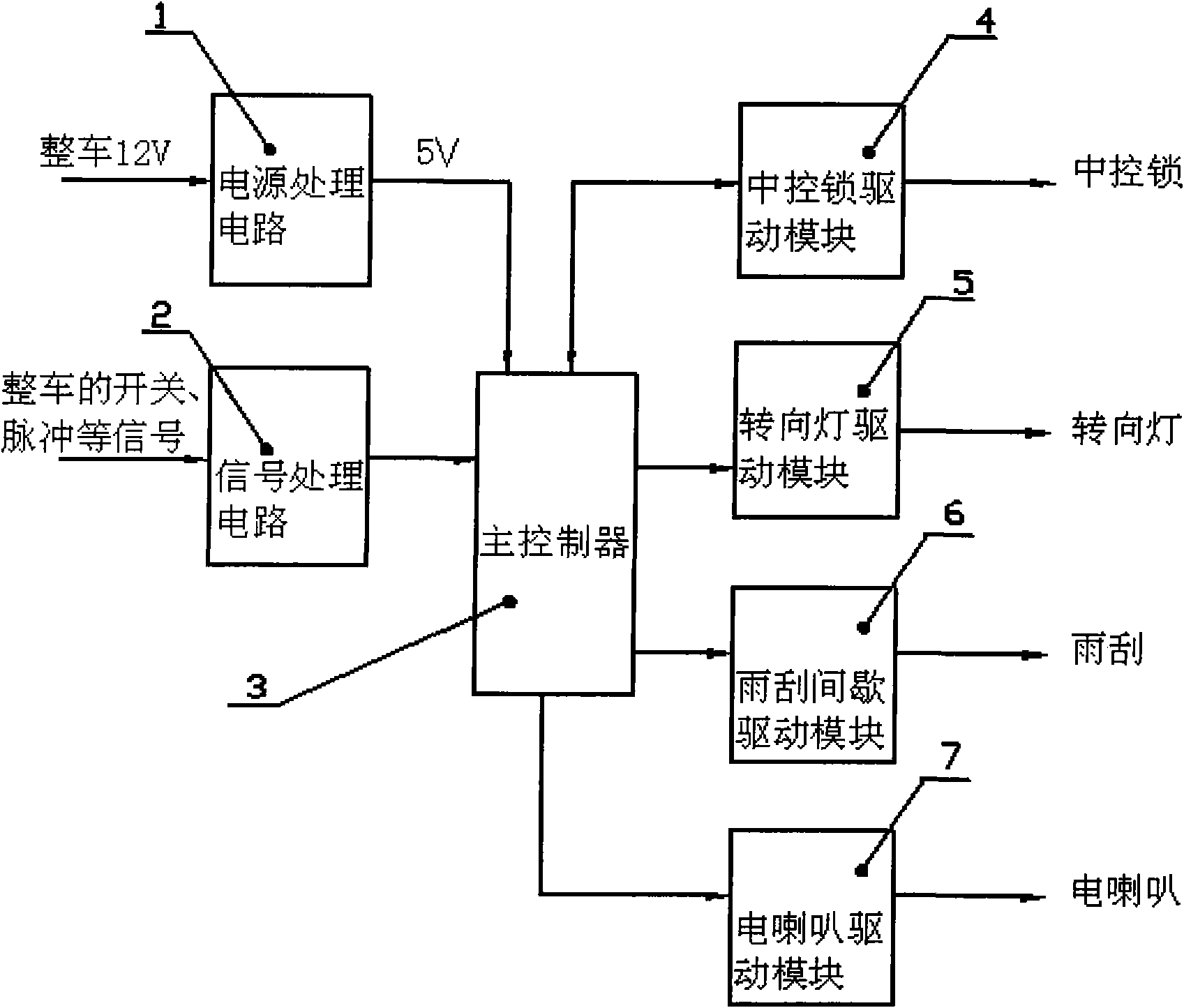

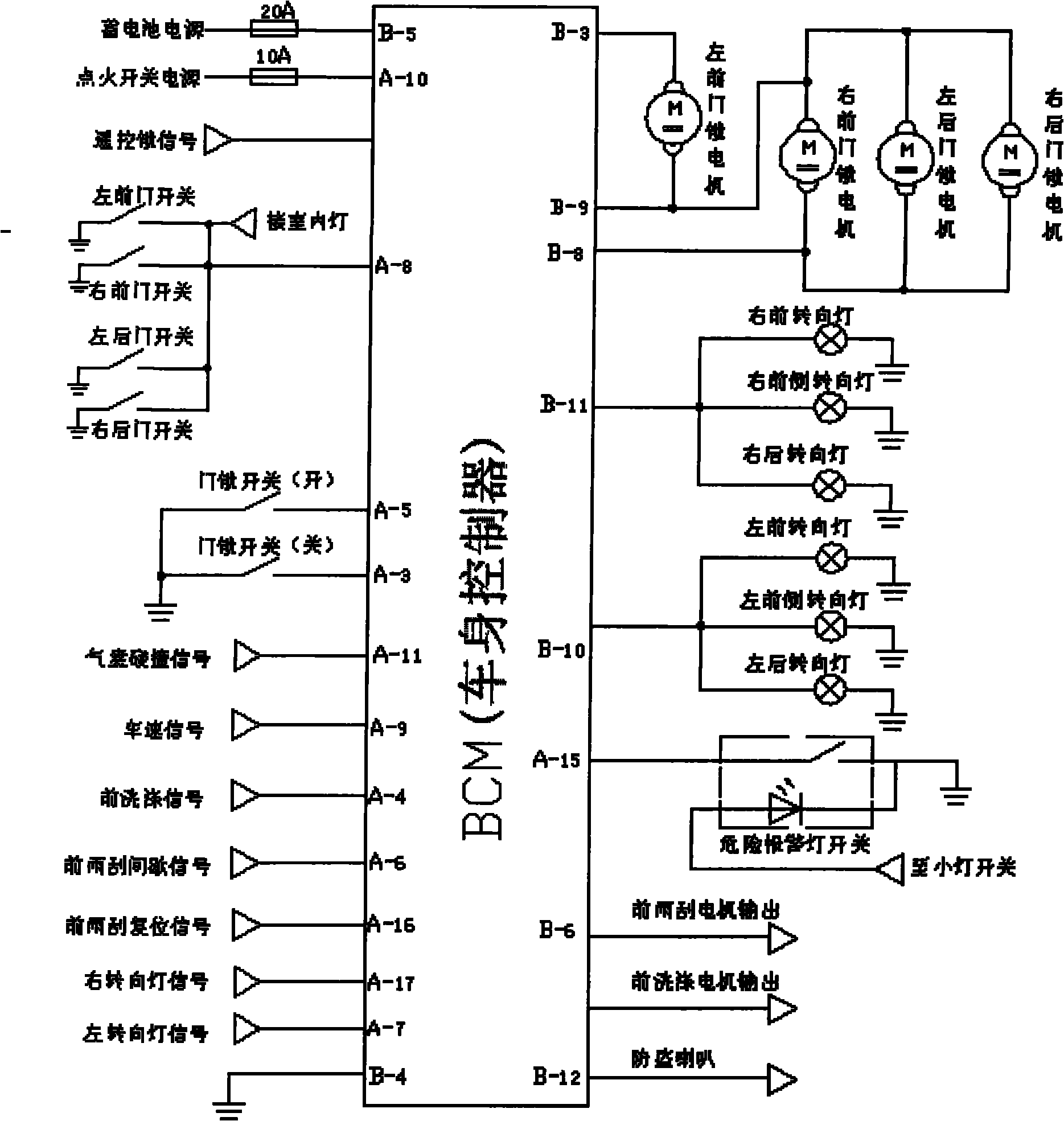

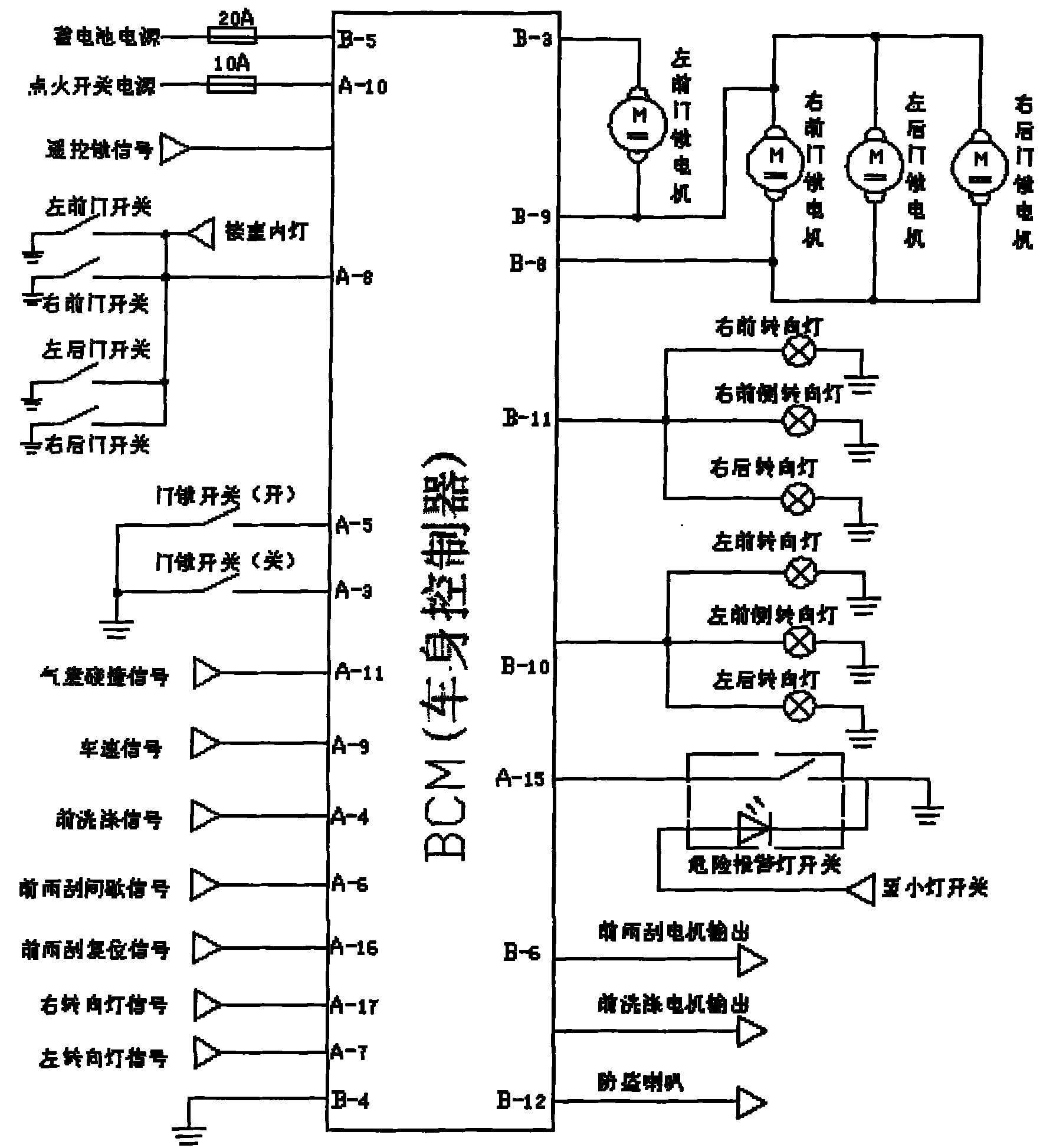

Vehicle body controller and control method thereof

InactiveCN101863253AReduce in quantityEasy to upgradeElectric/fluid circuitSignal processing circuitsLight driven

The invention relates to a vehicle body controller and a control method thereof. The vehicle body controller integrates a windscreen wiper intermittent controller, a remote-control door lock controller and a turn light controller which are originally independently controlled into a whole for uniform control by adopting an integral control mode so as to not only save the installation structure of the controller, but also decrease chips of an internal control circuit. The vehicle body controller realizes windscreen wiper intermittent control, remote-control door lock and central-control door lock control and turn light control and increases the functions of collision unlocking, traveling vehicle automatic locking, claxon anti-theft alarm, and the like on the basis. The vehicle body controller internally comprises a main controller module, a power supply processing circuit, a signal processing circuit, a central-control lock driving module, a turn light driving module, a windscreen wiper intermittent driving module and a claxon driving module. The control method can overcome the defect of high fault rate of an independent control unit and also reduces the integral vehicle cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

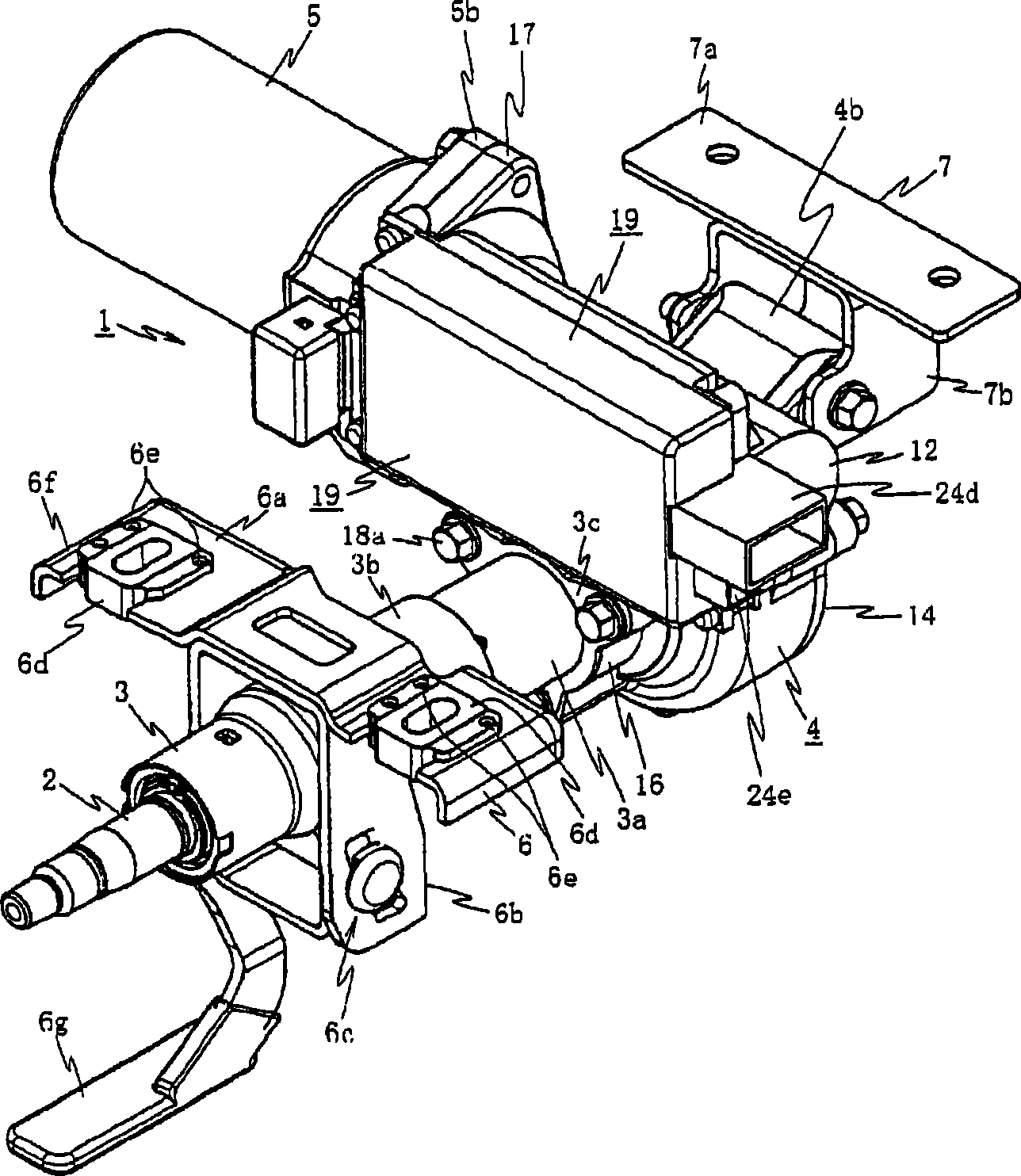

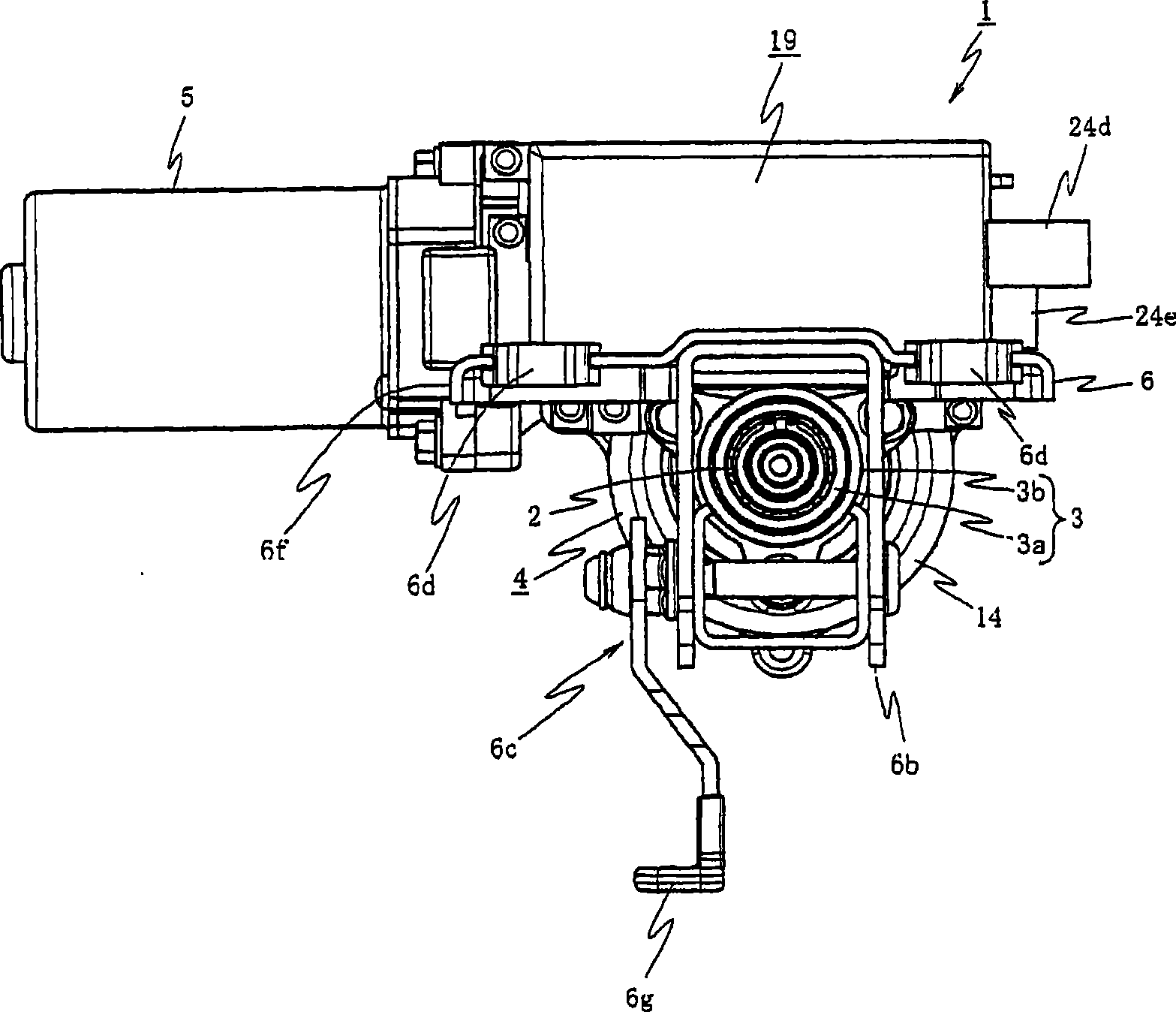

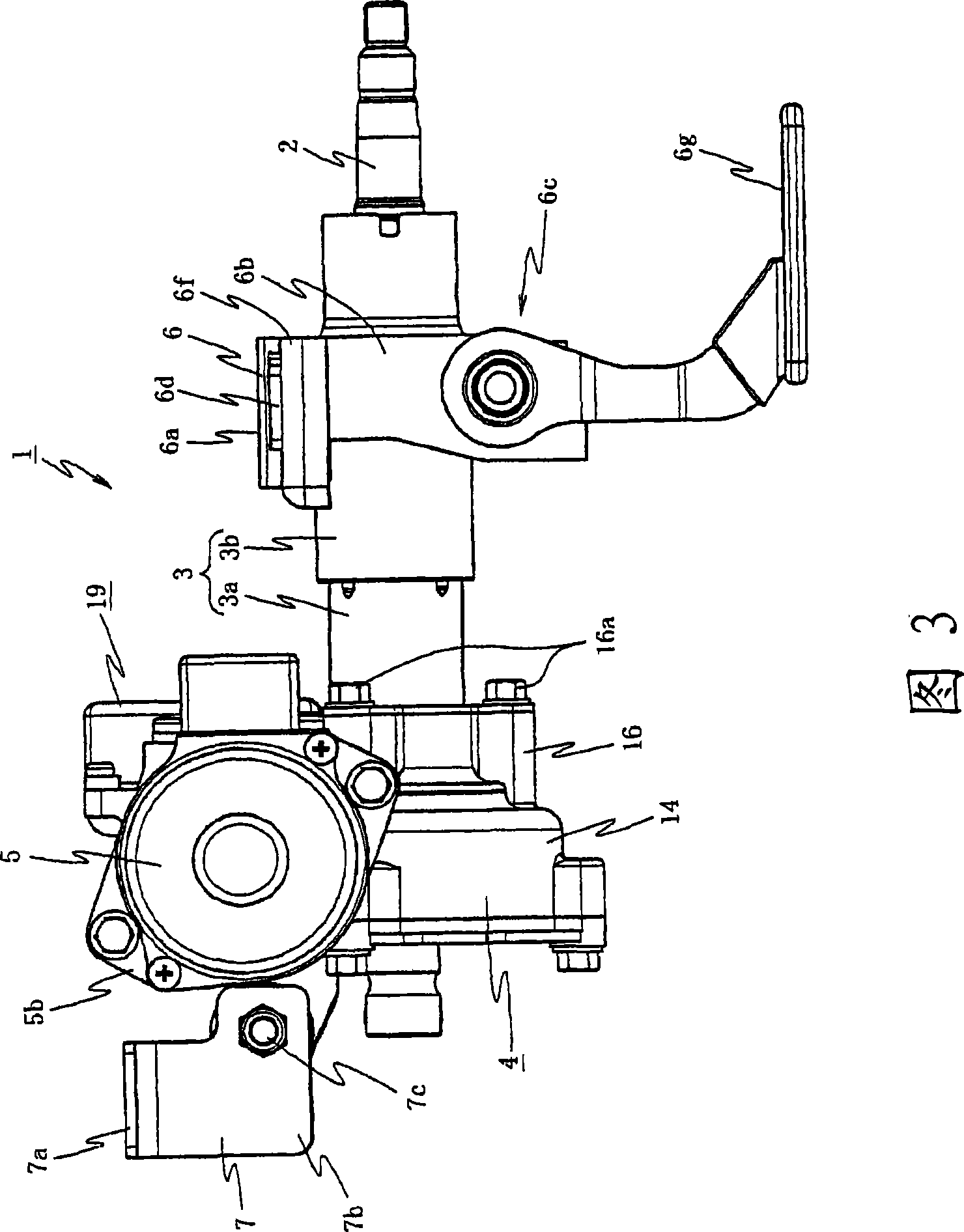

Electric power steering system

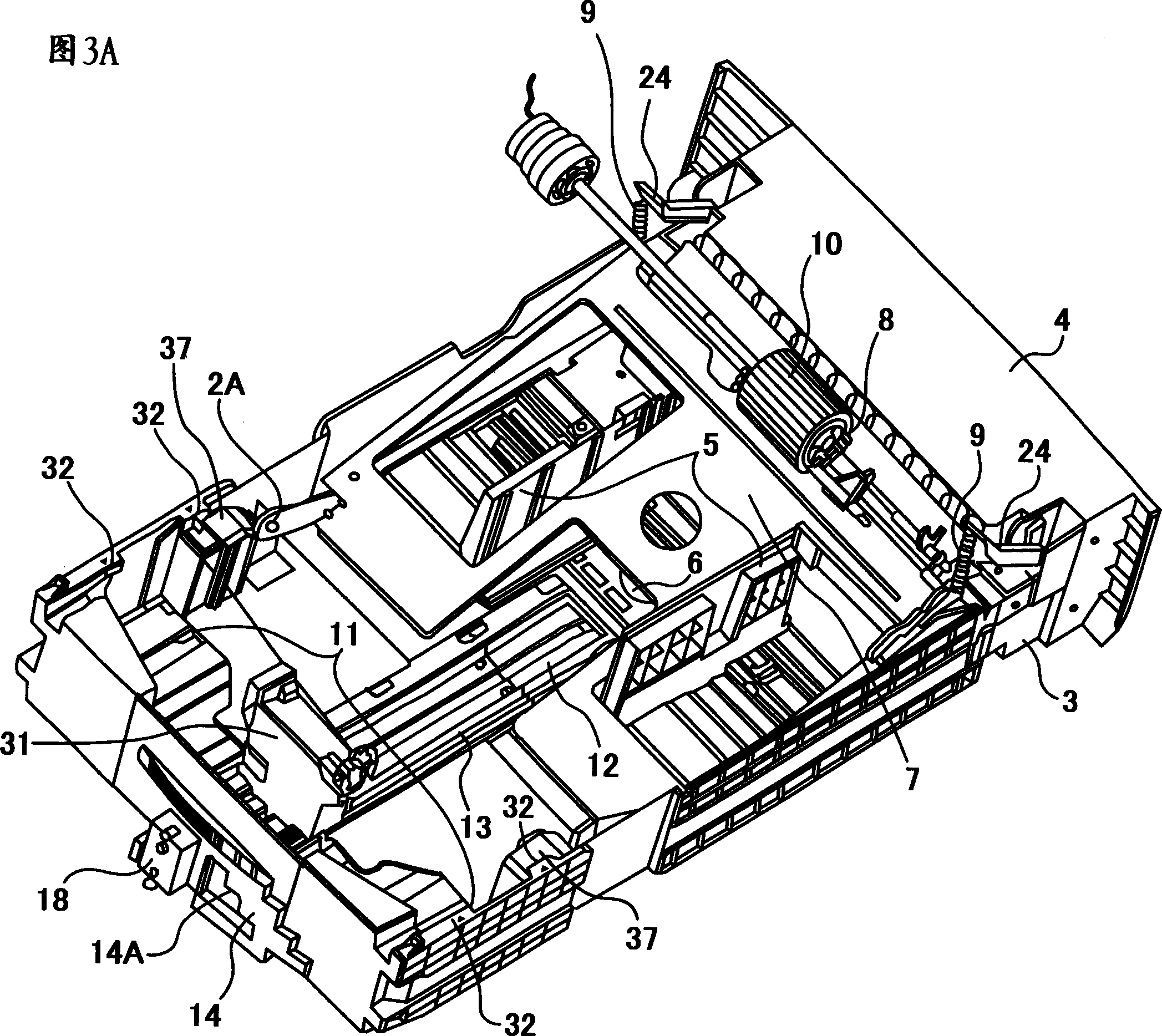

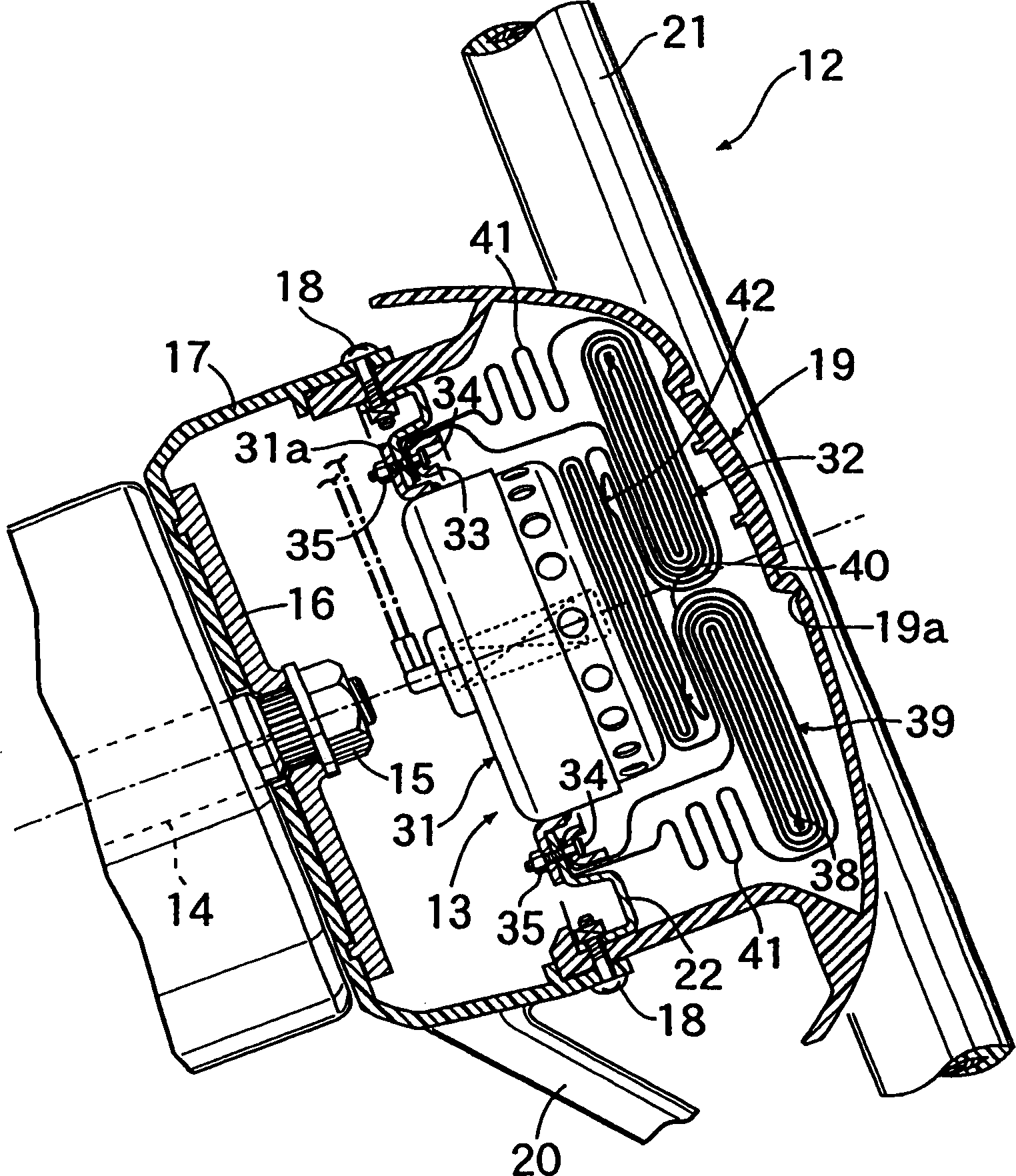

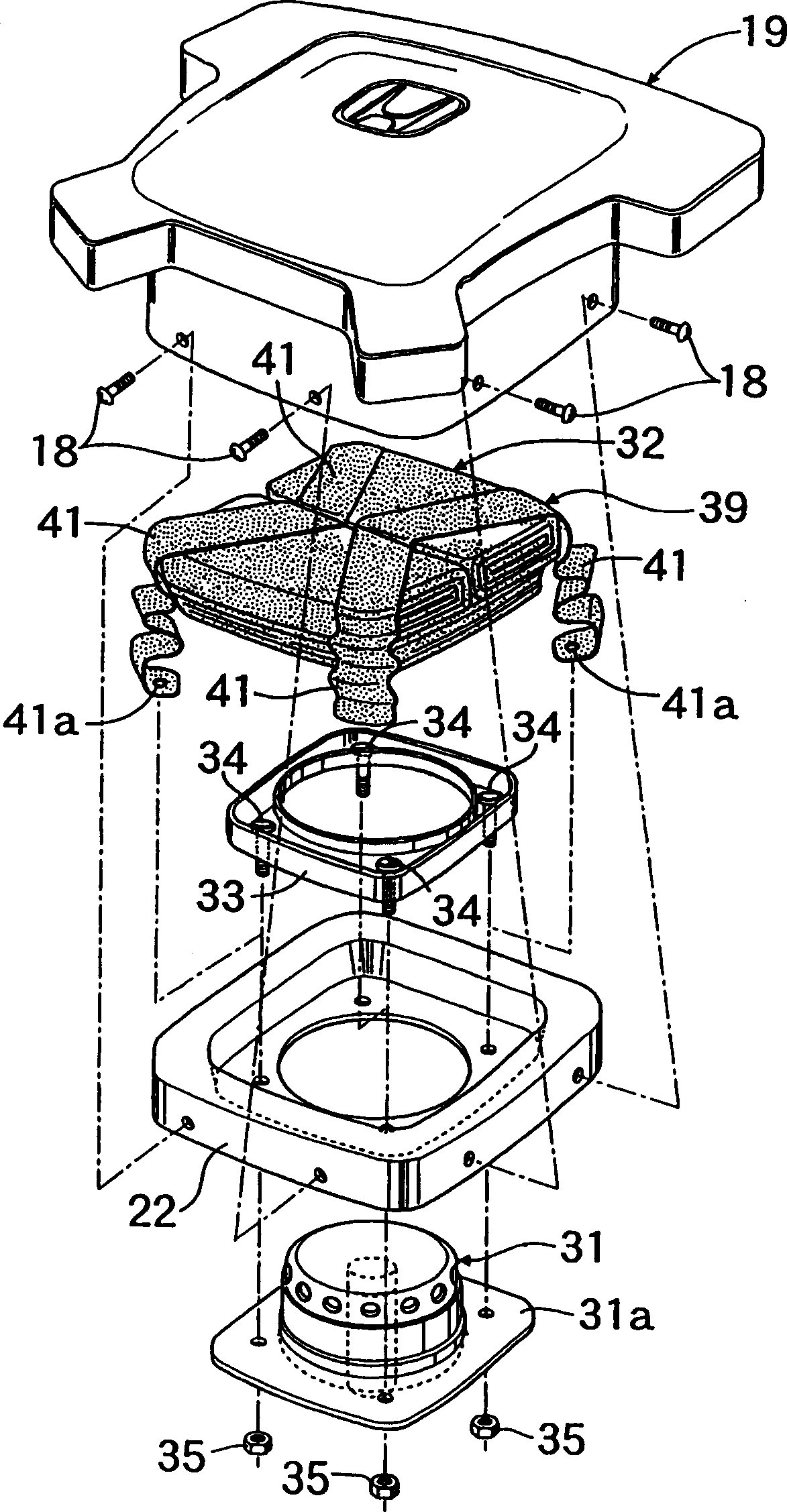

InactiveCN101378944AImproved adaptability to electromagnetic environmentImprove assembly workabilityAssociation with control/drive circuitsElectrical steeringElectricityElectric power steering

An electric power steering system in which assembling workability can be enhanced by reducing to a minimum required ground processing of each portion requiring grounding. The electric power steering system comprises a steering column (3) incorporating a steering shaft (2) to which steering torque is transmitted, and an electric motor (5) for transmitting a steering auxiliary power to the steering shaft (2) through the reduction mechanism in a reduction gear box (4), wherein a control unit (19) including substrates (23, 25) mounting a control circuit performing drive control on the electric motor is attached to the reduction gear box (4), the joint of the electric motor (5) is electrically connected with the control unit (19) directly, and connection of the reduction gear box (4) and the control unit (19) to the ground is made through a ground connection wire (29) arranged between the control unit (19) and a power supply section (30).

Owner:NSK LTD

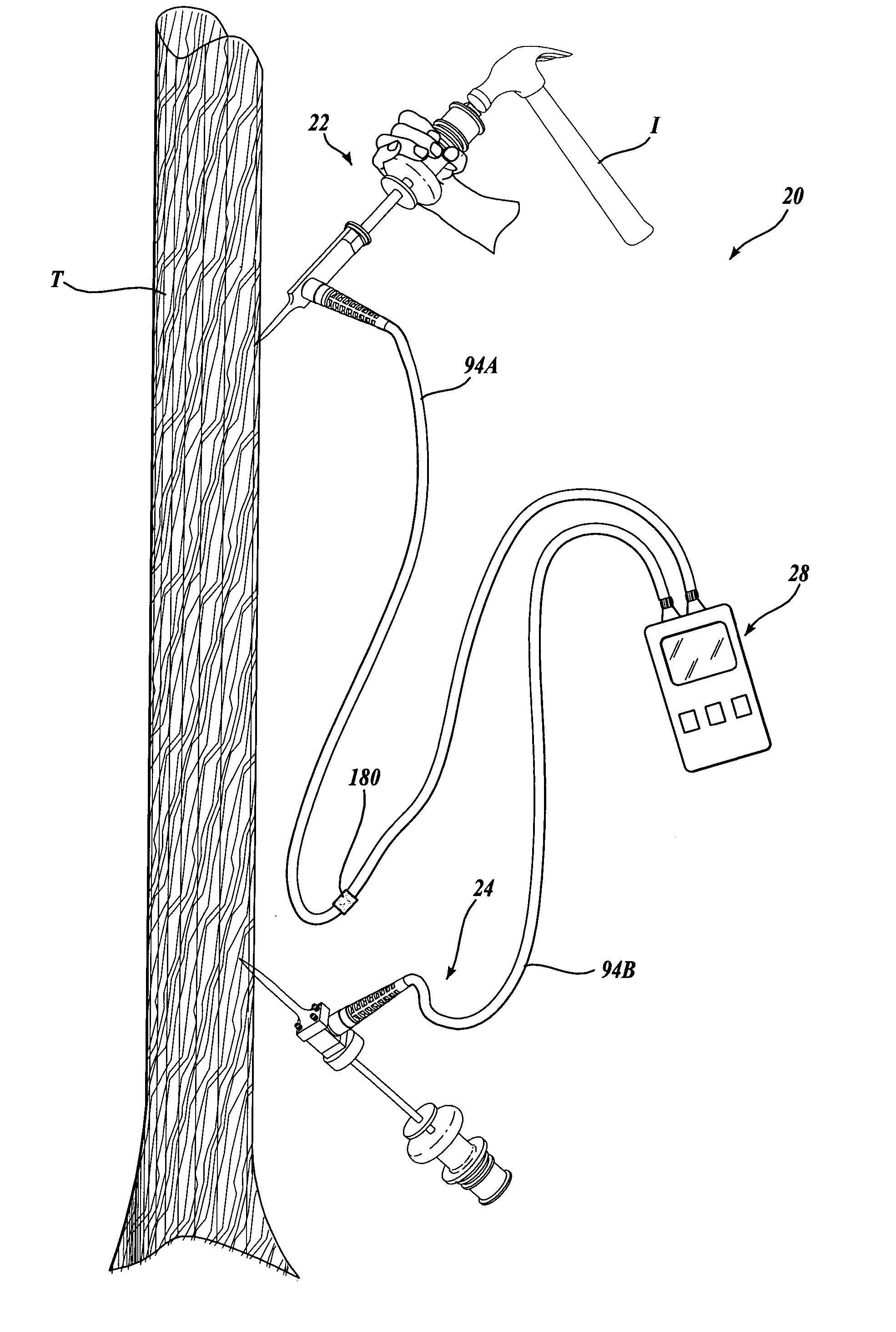

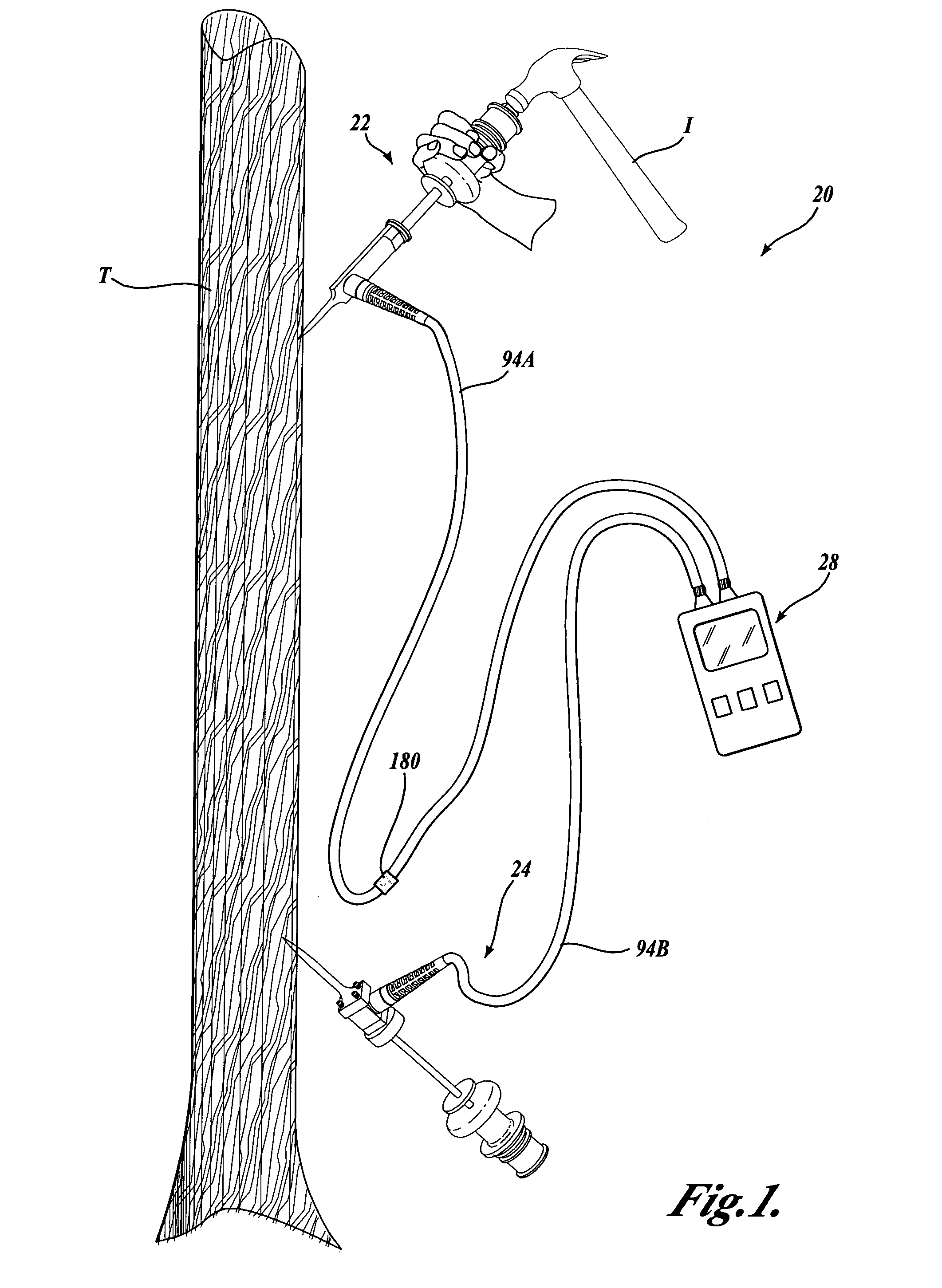

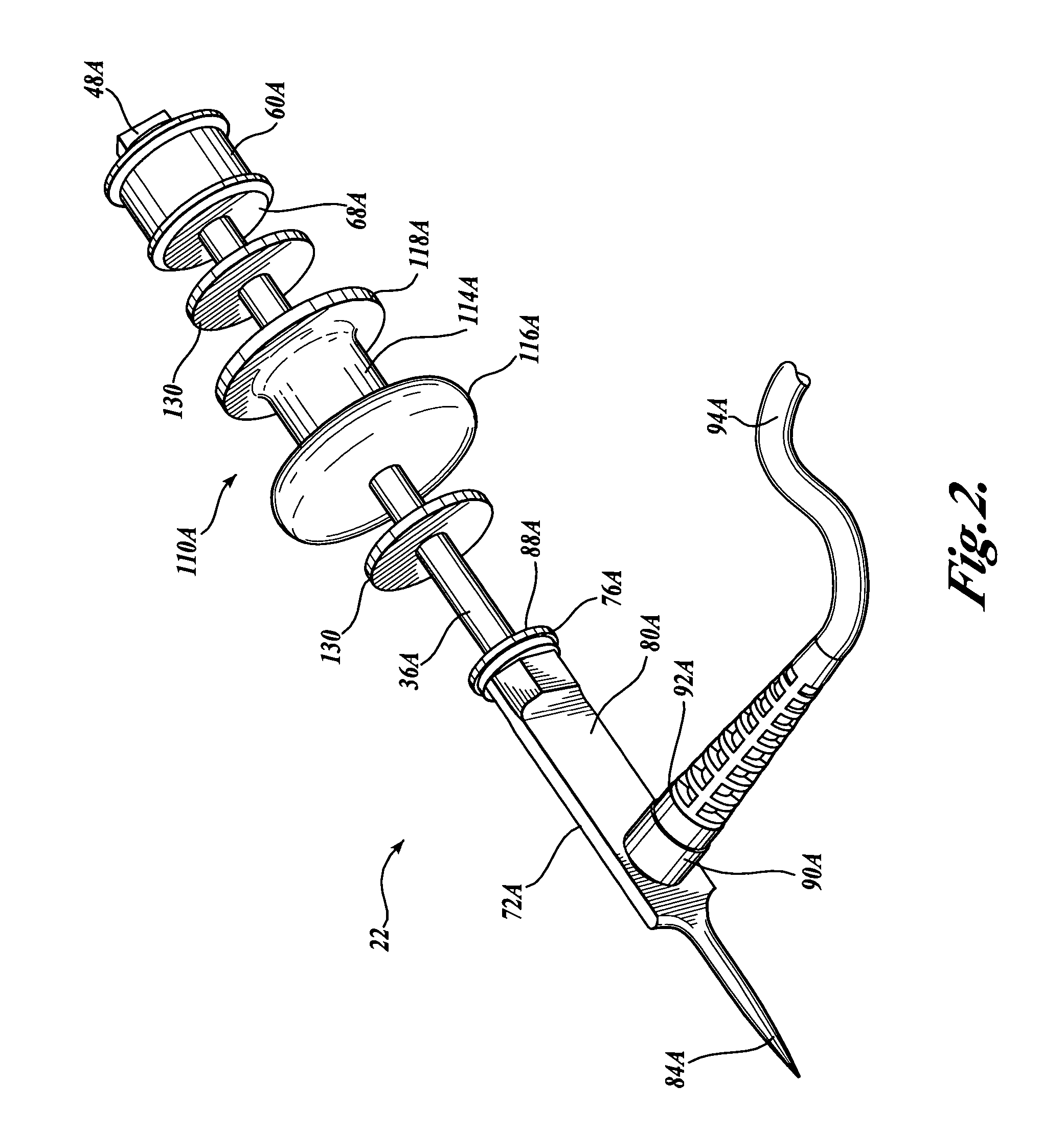

System and method for measuring stiffness in standing trees

InactiveUS20050005699A1Increase speedReduce working hoursVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesNon destructiveTransducer

A system for non-destructive testing using acoustic techniques includes first and second measuring probes and an electronic unit. Each probe includes a penetrating end and a retaining flange end. Each probe further includes a handle slideably coupled to the probe and a transducer for detecting stress waves. The probes are lightweight, portable, and rugged for field testing wood products.

Owner:WEYERHAEUSER NR CO

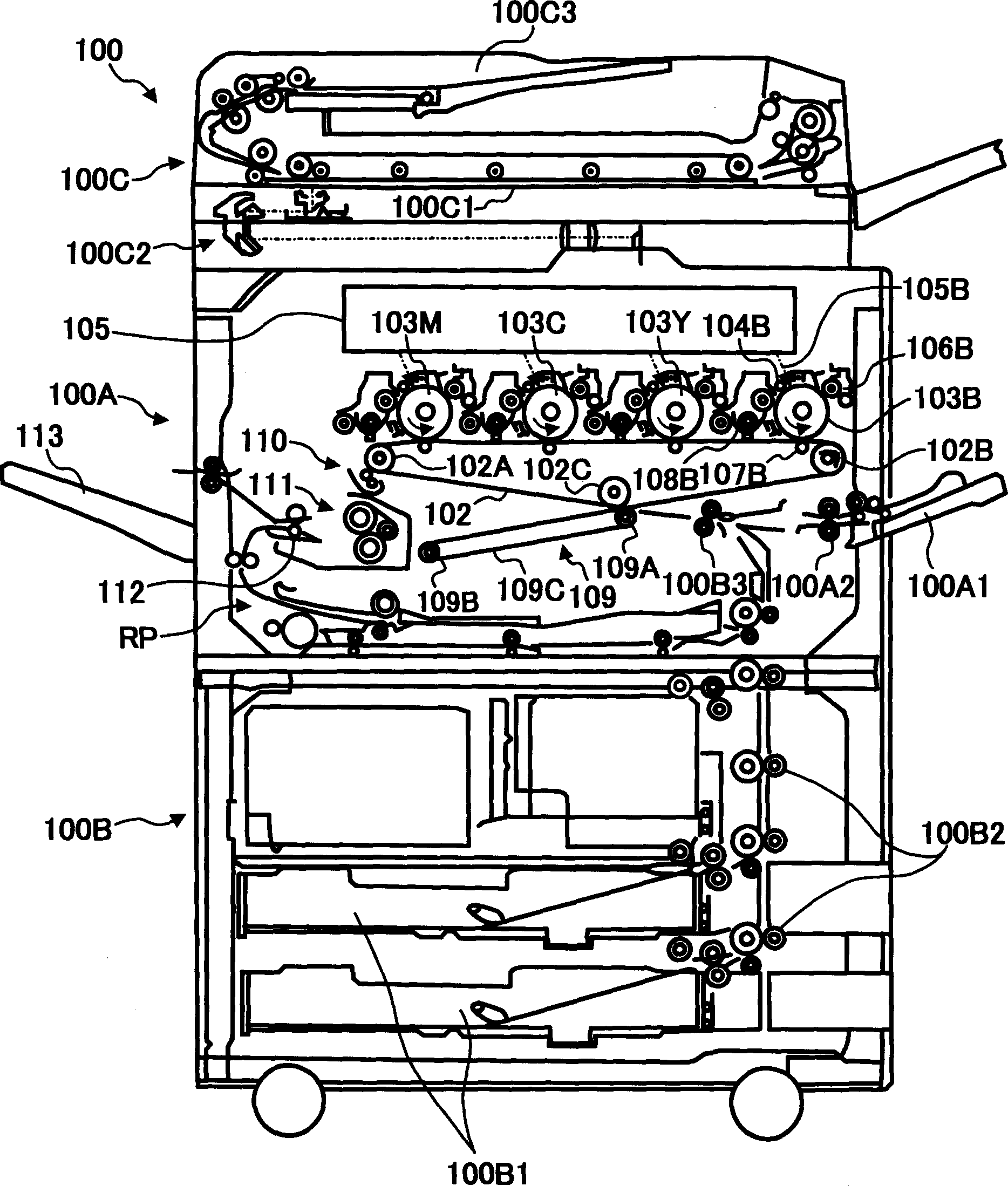

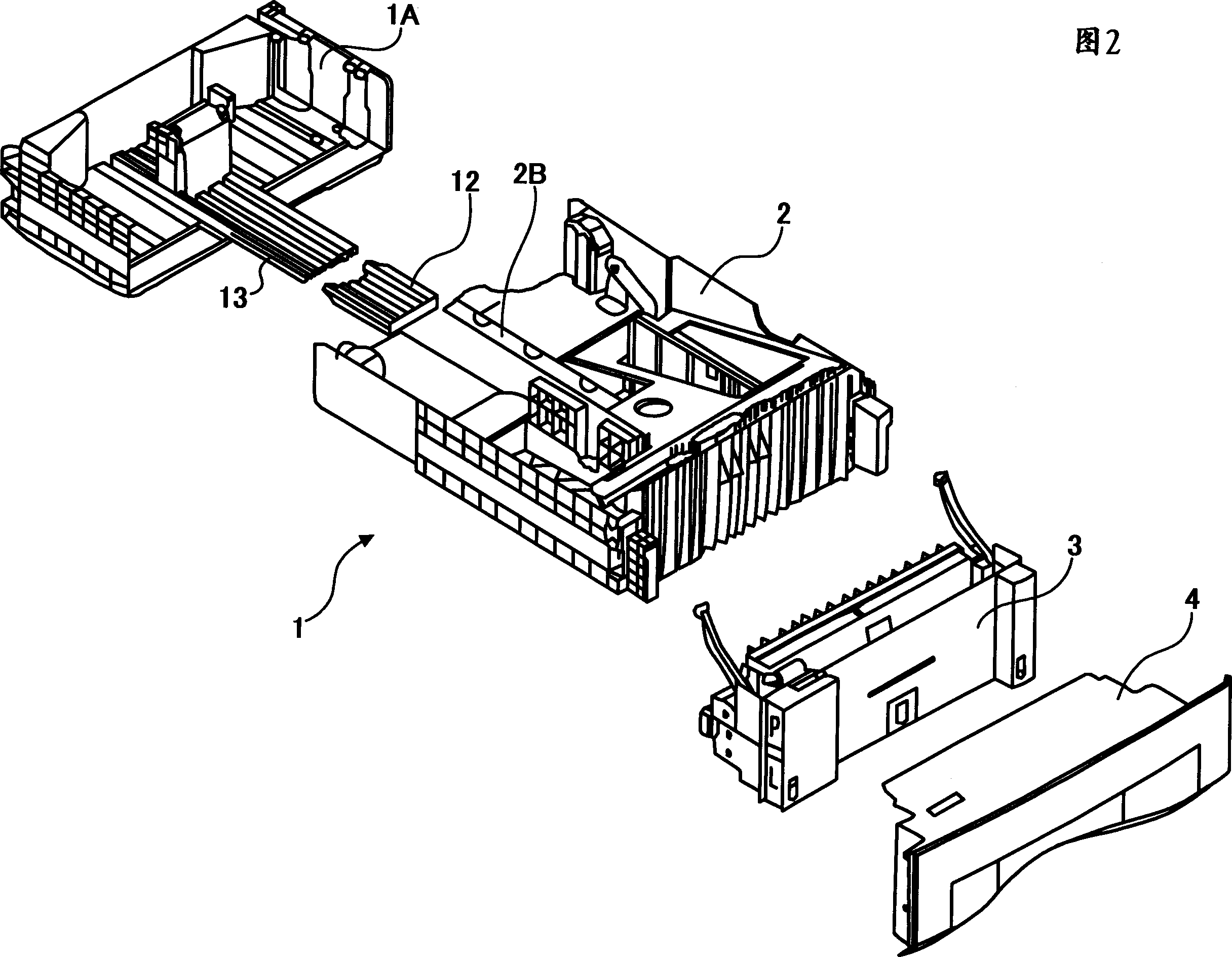

Paper feeding device and image forming apparatus

InactiveCN1534394AIncrease management costsExhaustion status correctly judgedFunction indicatorsShoe lace fasteningsImage formationEngineering

Owner:RICOH KK

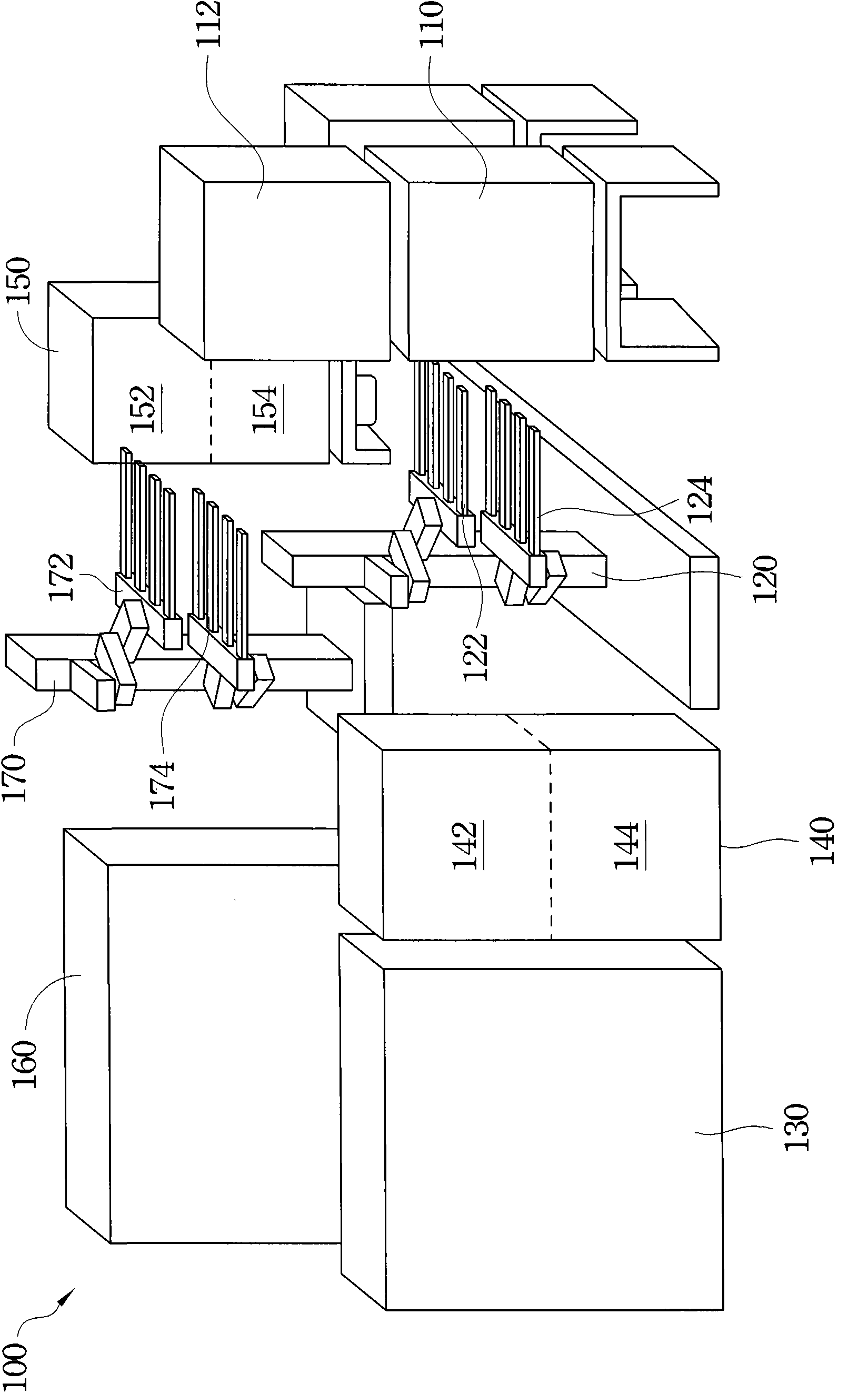

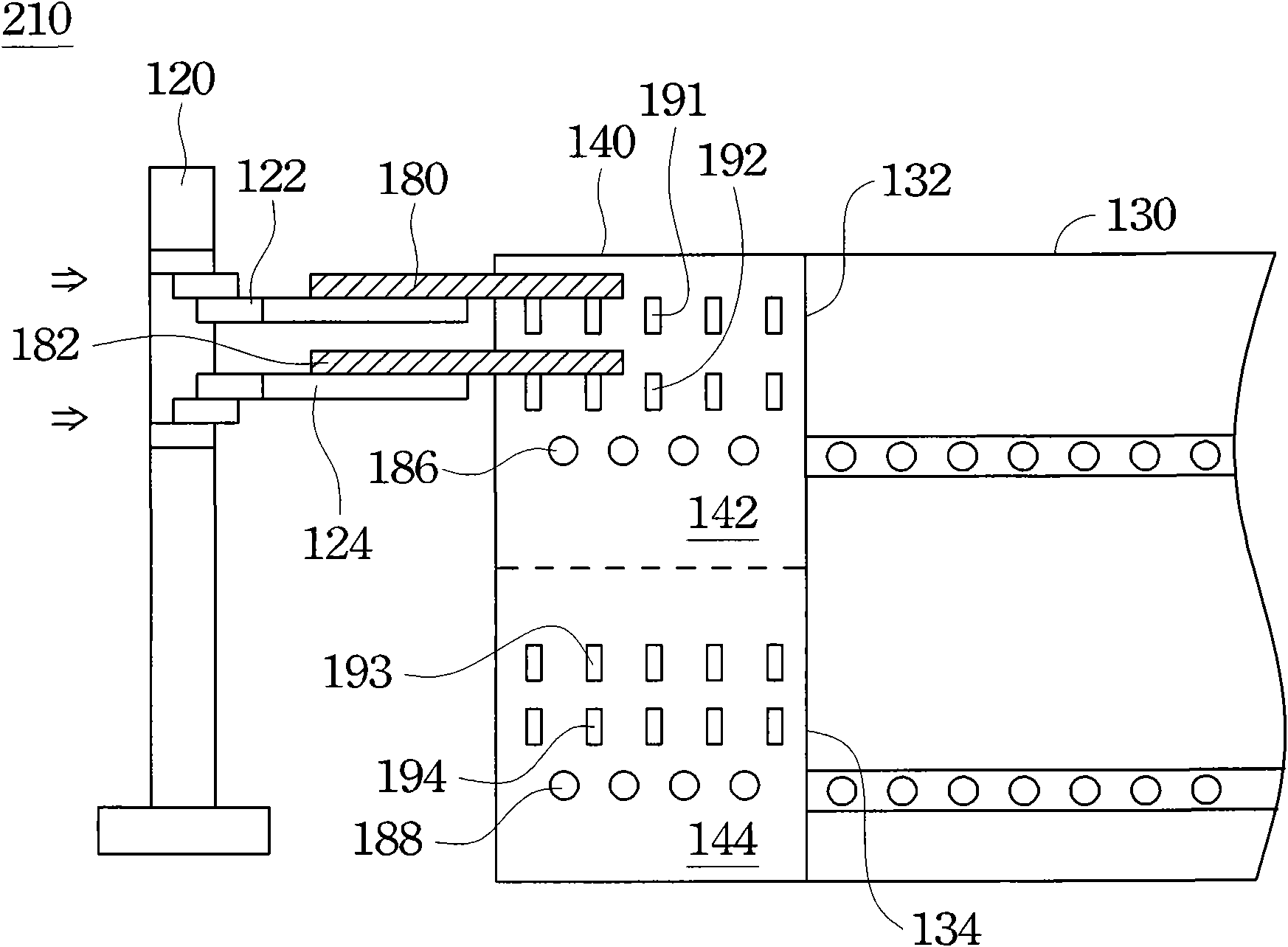

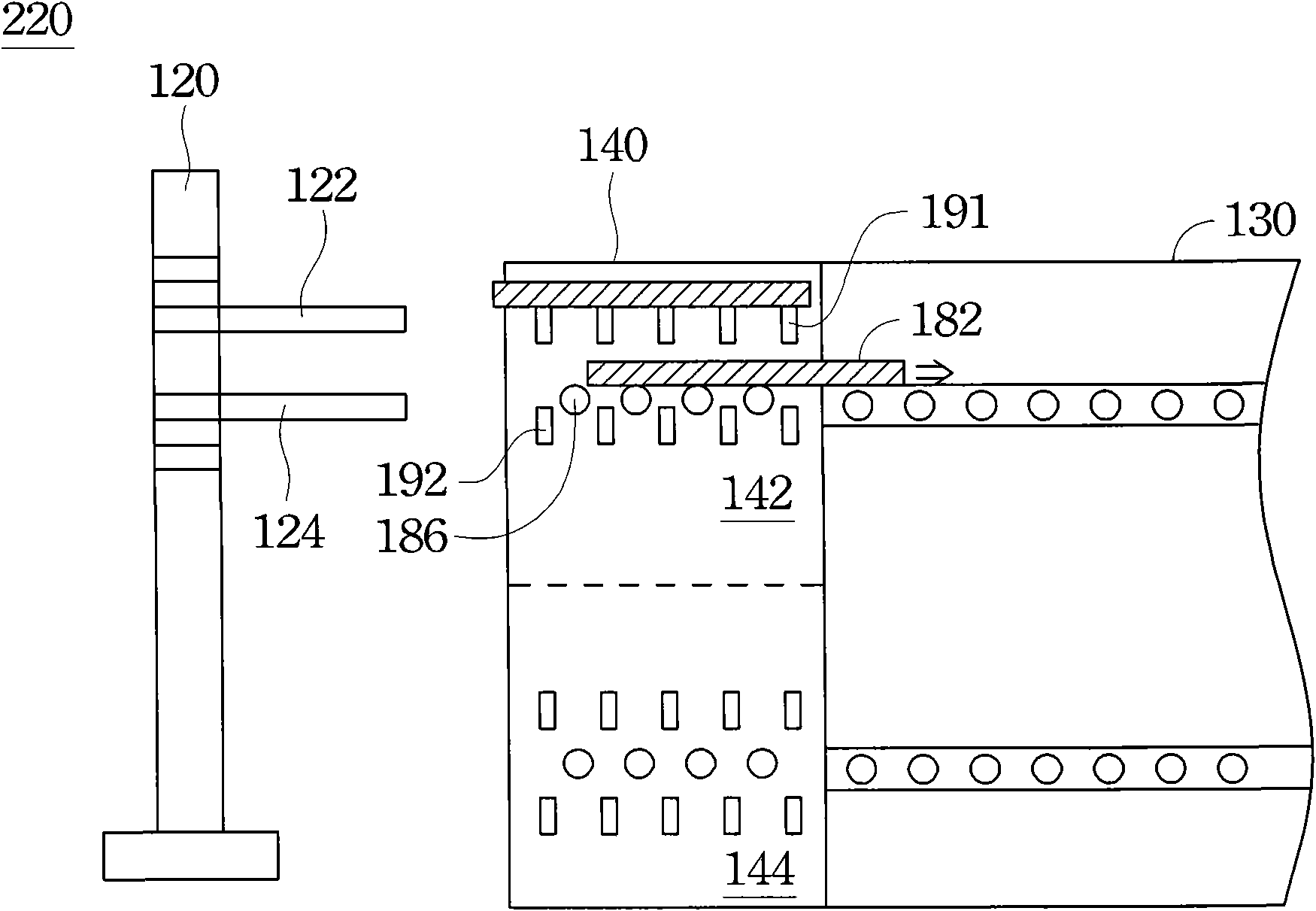

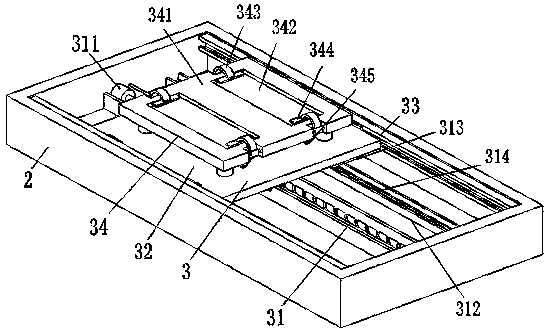

System for processing base plate conveyance and method

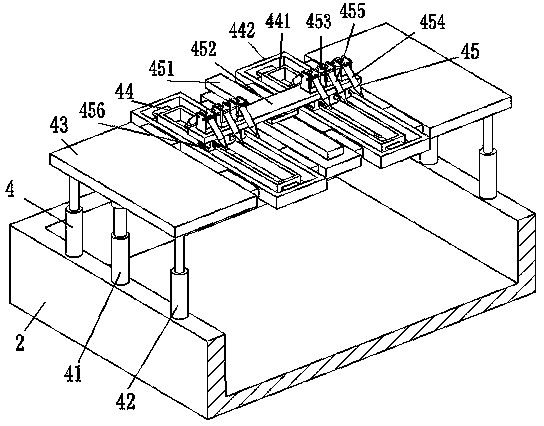

InactiveCN102064126AReduce working hoursShorten critical timeSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention discloses a method for processing base plate conveyance, comprising: providing a plurality of base plates in a base plate containing cassette, taking two base plates of the base plates out from the base plate containing cassette by using a first upper manipulator and a first lower manipulator, and conveying to a double-layered sheet feeder, the double-layered sheet feeder conveying the two base plates to a base plate cleaning machine bench, the cleaning machine bench conveying the two base plates to a double-layered sheet discharger; the first upper manipulator and the first lower manipulator taking the cleaned two base plates out of the double-layered sheet discharger, and conveying to a first double-layered sheet feeder / discharger, rotating a rotatable temporary storage machine bench by a first angle, a second upper manipulator and a second lower manipulator taking the cleaned two base plates from the first double-layered feeder / discharger, and conveying to a base plate processing machine bench for processing and the second upper manipulator and the second lower manipulator taking the processed two base plates from the base plate processing machine bench, and conveying the processed two base plates to a second double-layered feeder / discharger. The method improves the conveying and processing efficiency of the base plate.

Owner:AU OPTRONICS CORP

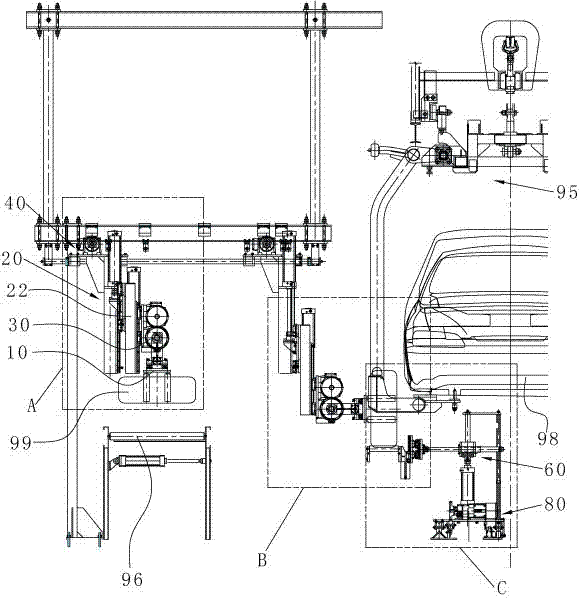

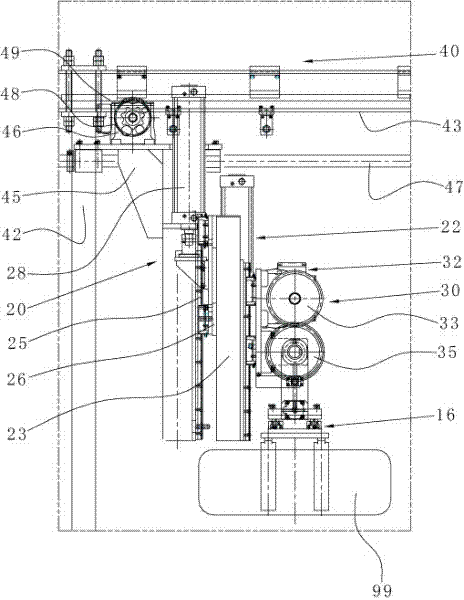

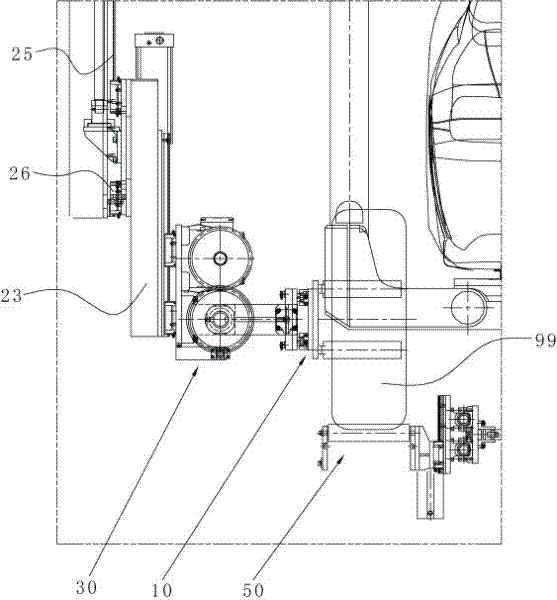

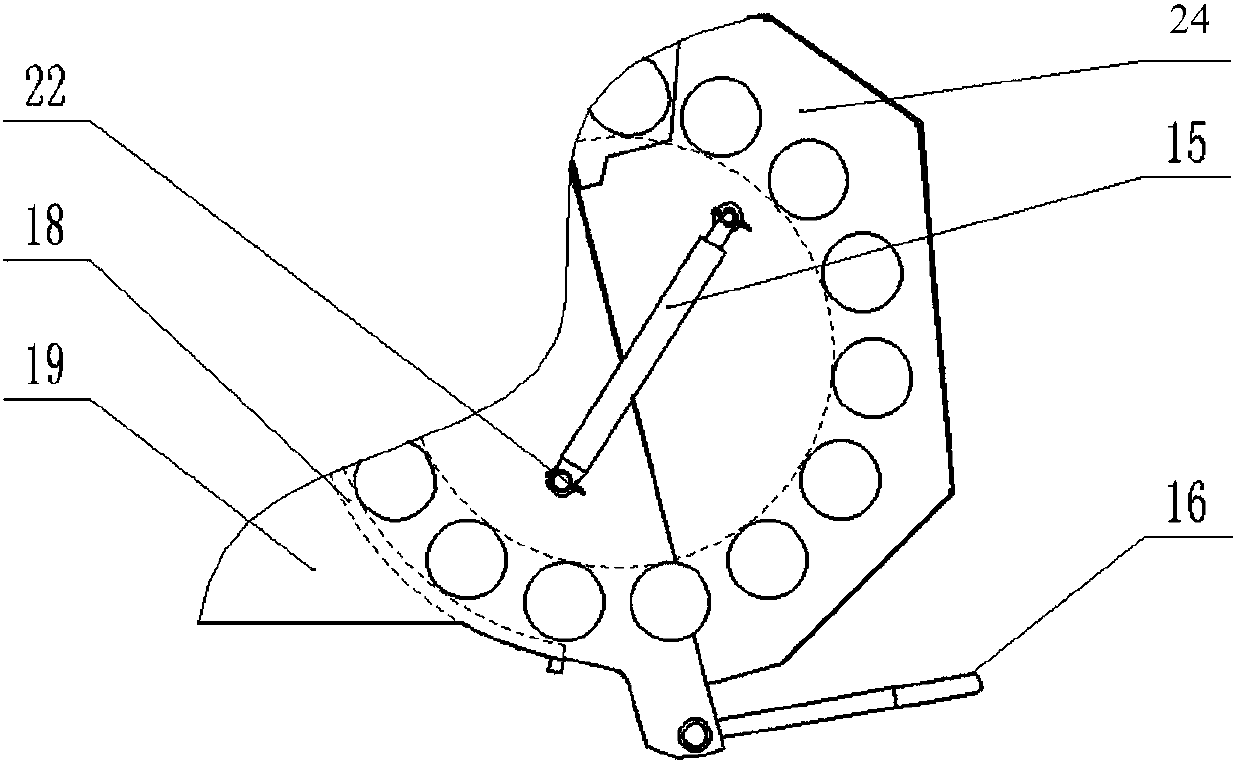

Automatic tire-supplying system

The invention discloses an automatic tire-supplying system, which is used for automatically transferring tires on a tire conveying raceway to side edges of wheel hubs at an assembly line. The automatic tire-supplying system comprises a clamping device, a lifting and turnover device and a line-shifting device which are sequentially connected, a vehicle-side supporting bracket, a three-way aligning device used for adjusting the position of the vehicle-side supporting bracket, and a following device used for supporting the three-way aligning device to synchronously move along with a vehicle body at the assembly line, wherein the vehicle-side supporting bracket, the three-way aligning device and the following device are sequentially connected and arranged at the lower side part of the assembly line; and a pre-inflated tire is clamped through the clamping device, is then lifted and overturned into a vertical state, is conveyed to the side of the moving trajectory of a wheel hub through the line-shifting device and is placed at the vehicle-side supporting bracket, then the position of the tire is adjusted under the control of the three-way aligning device, and the tire is aligned with the wheel hub and synchronously moves with the vehicle body. According to the automatic tire-supplying system disclosed by the invention, automatic carrying, conveying and aligning of machinery are realized, the assembly of the tire can be completed without manual carrying, conveying and aligning, the labor intensity is reduced, and the automation level is improved.

Owner:GUANGQI HONDA +1

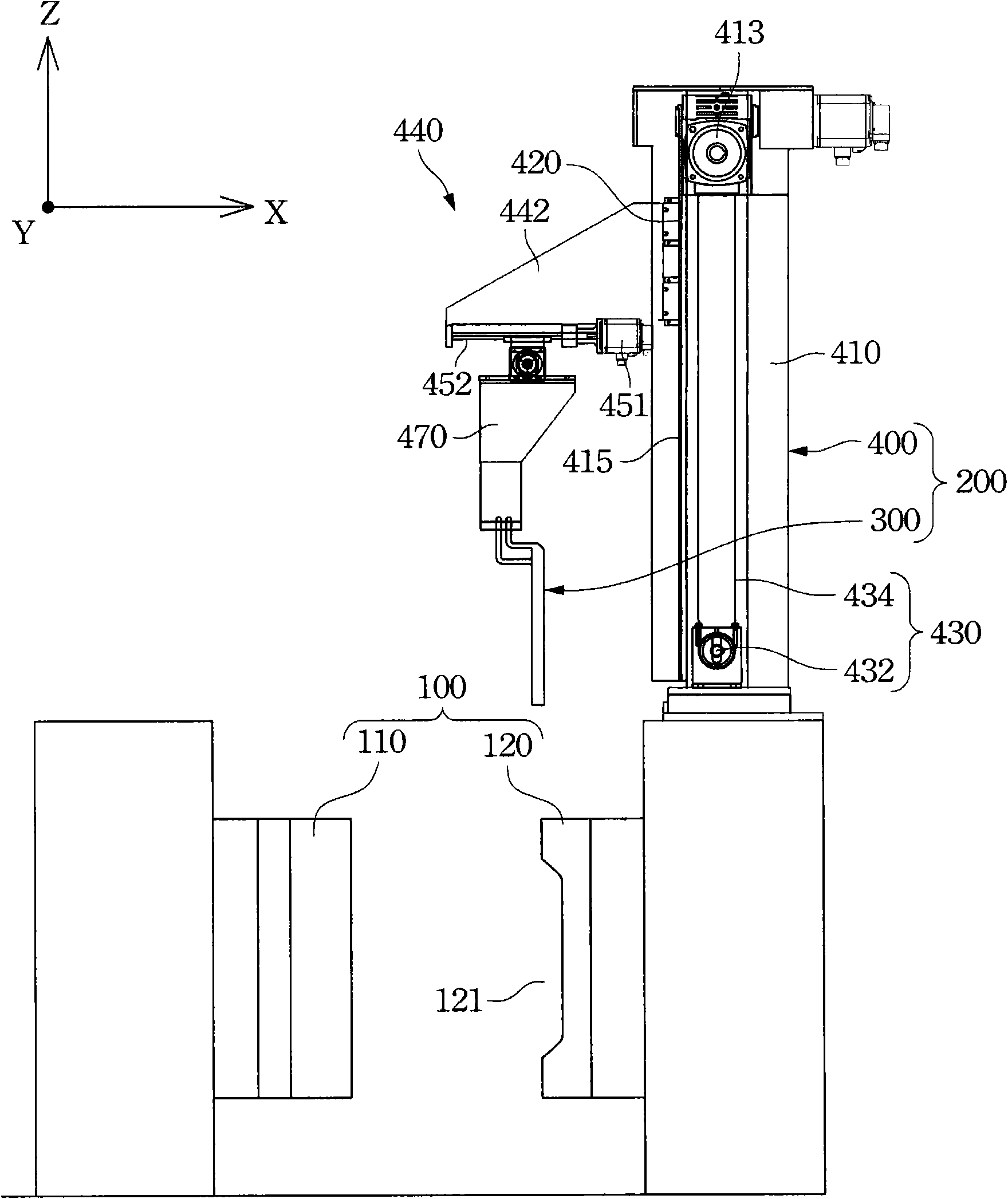

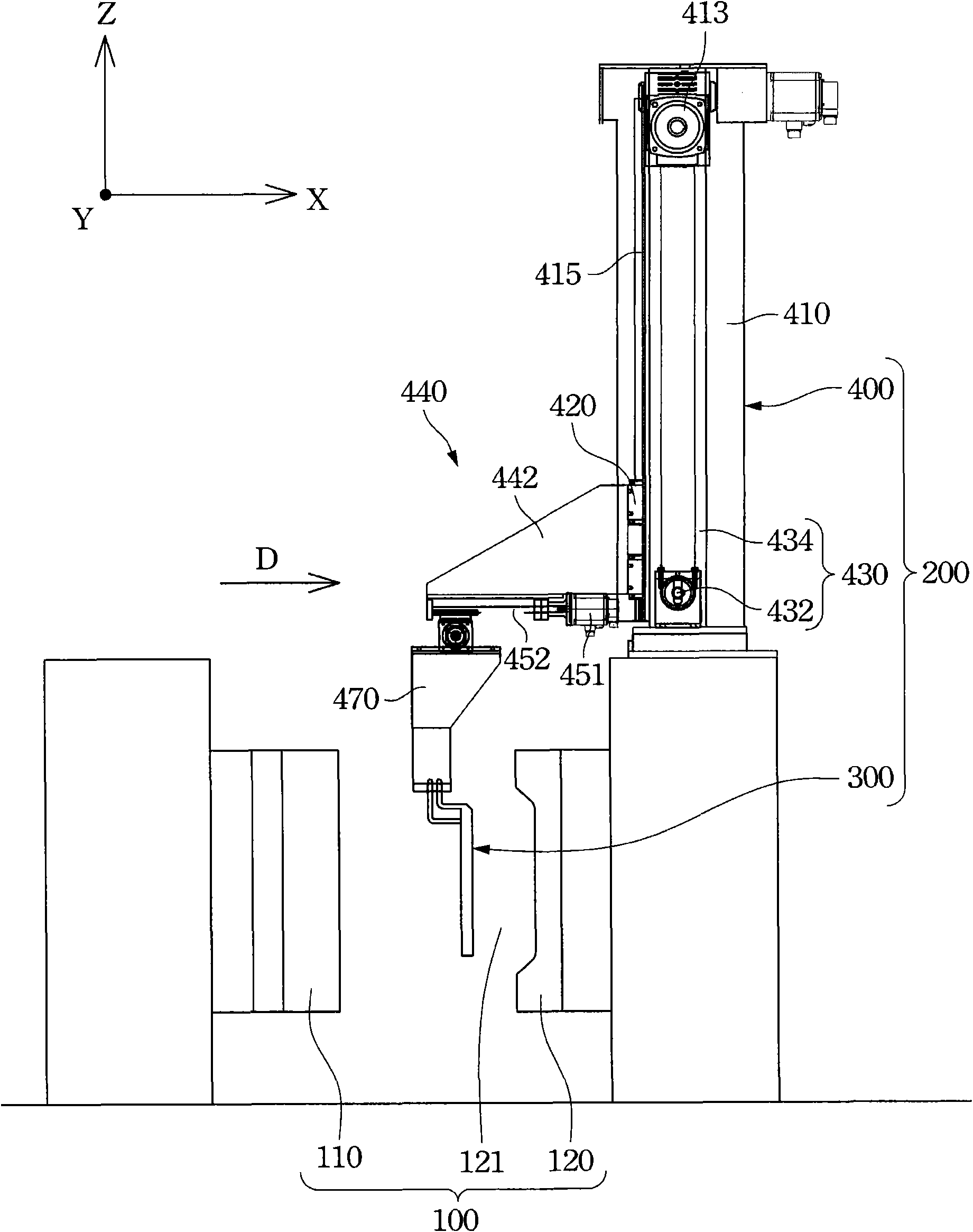

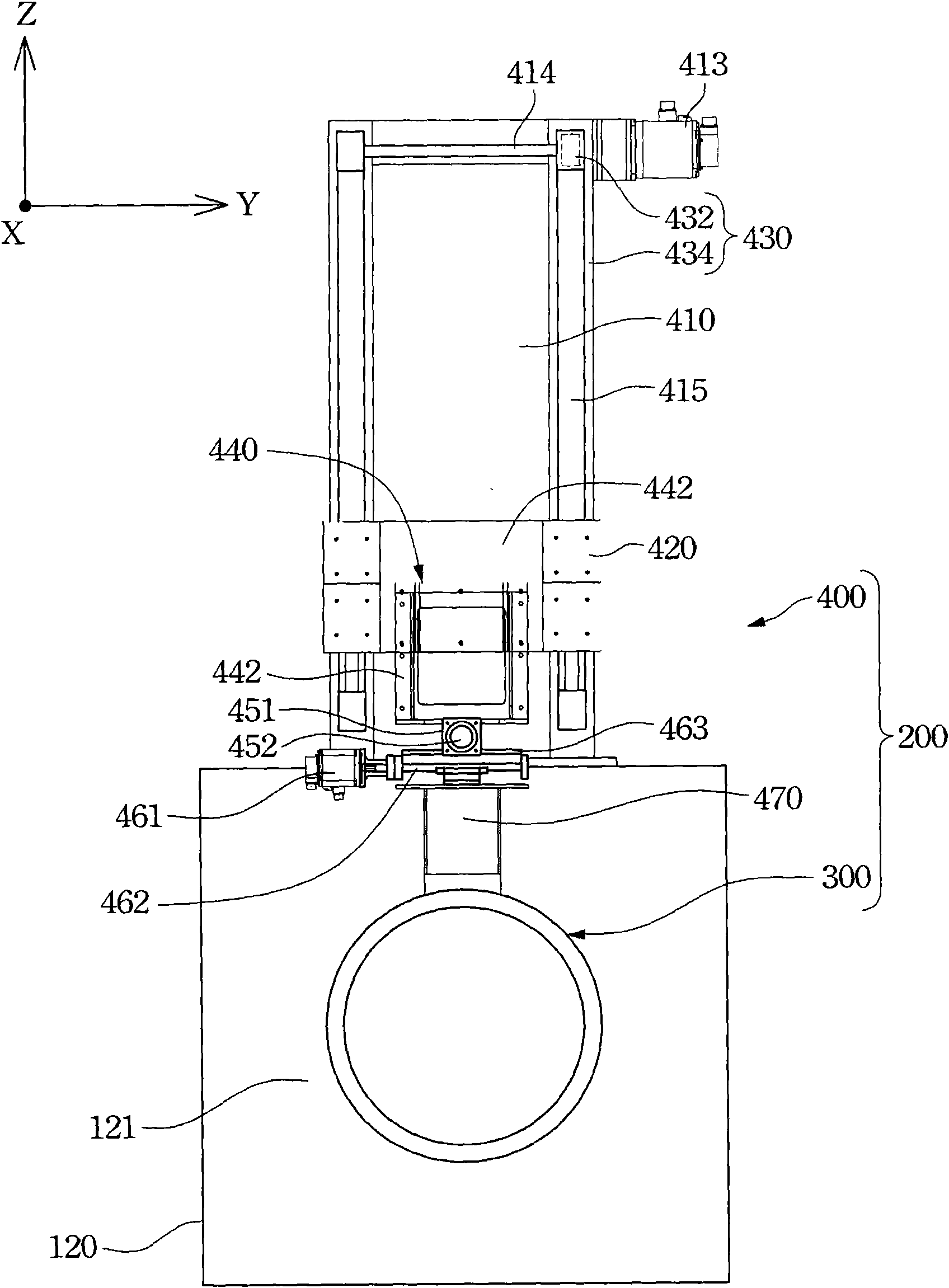

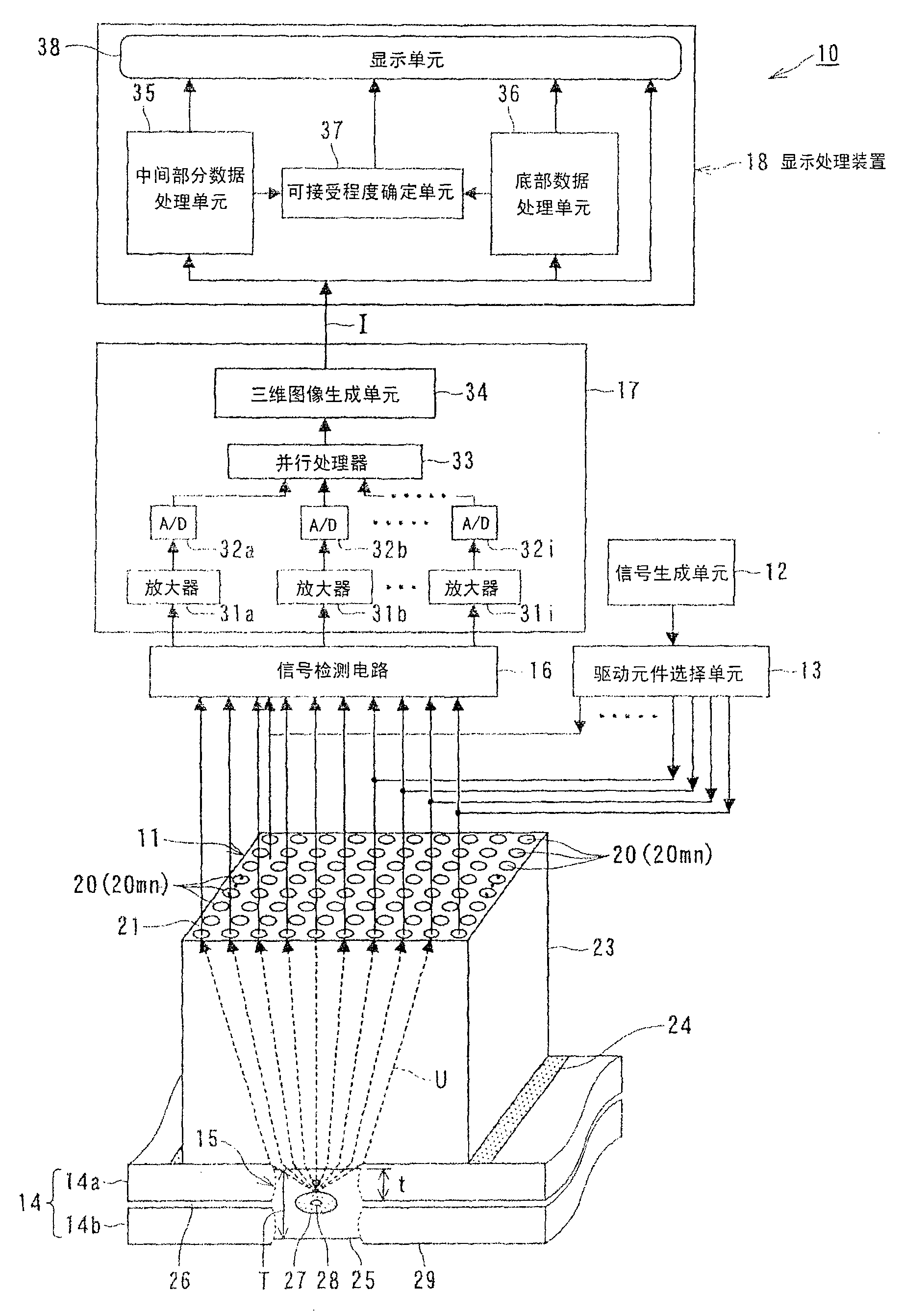

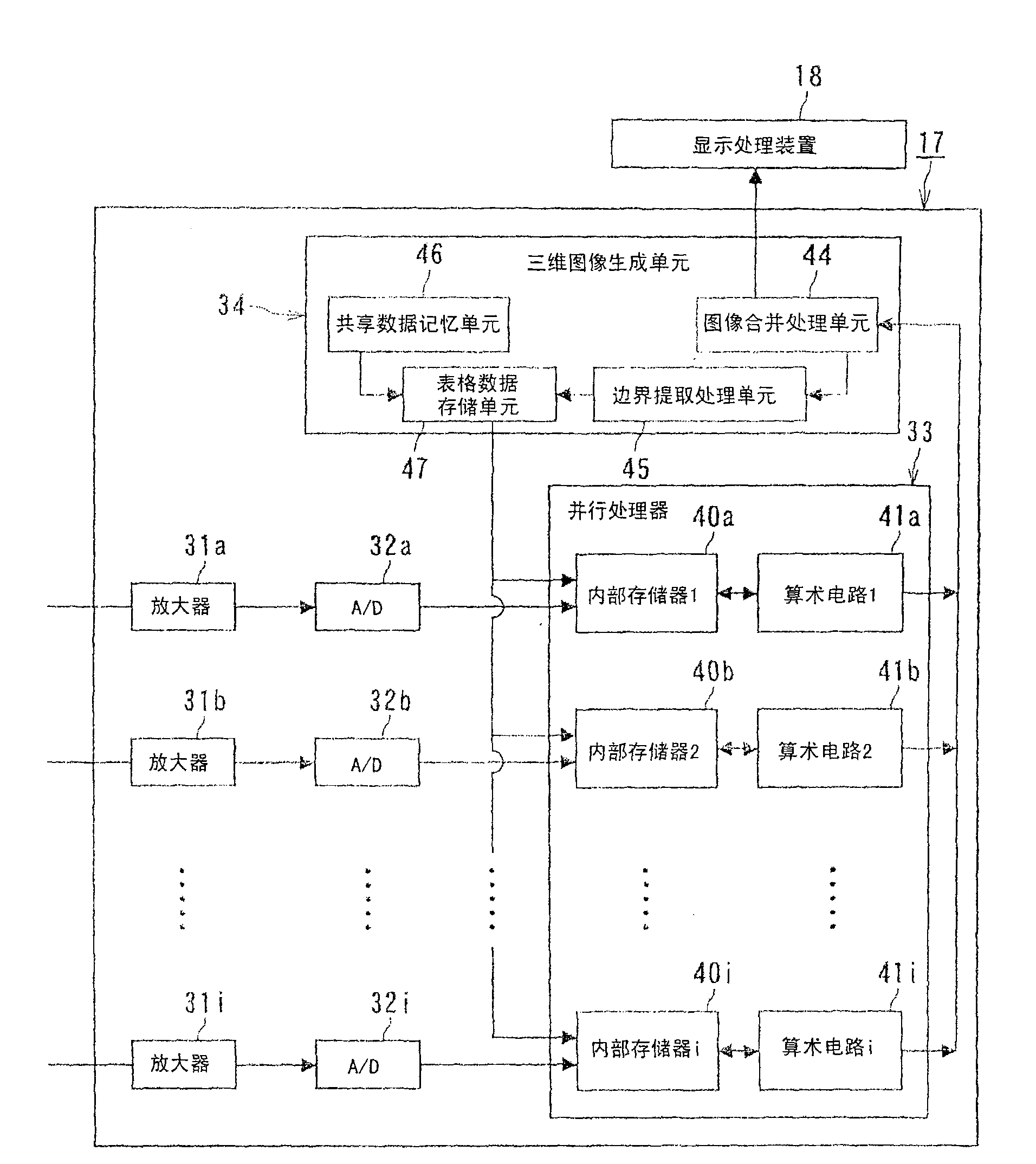

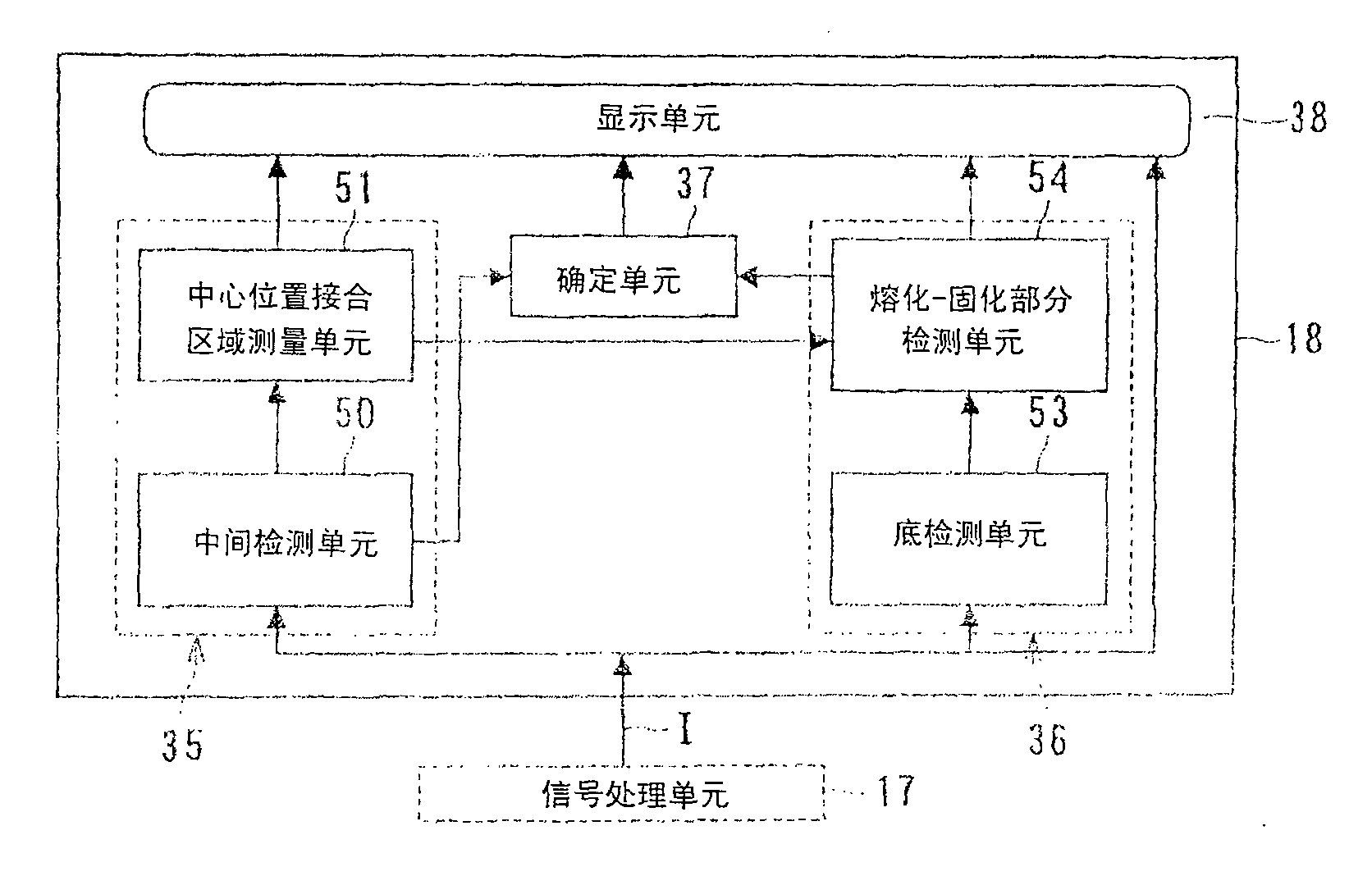

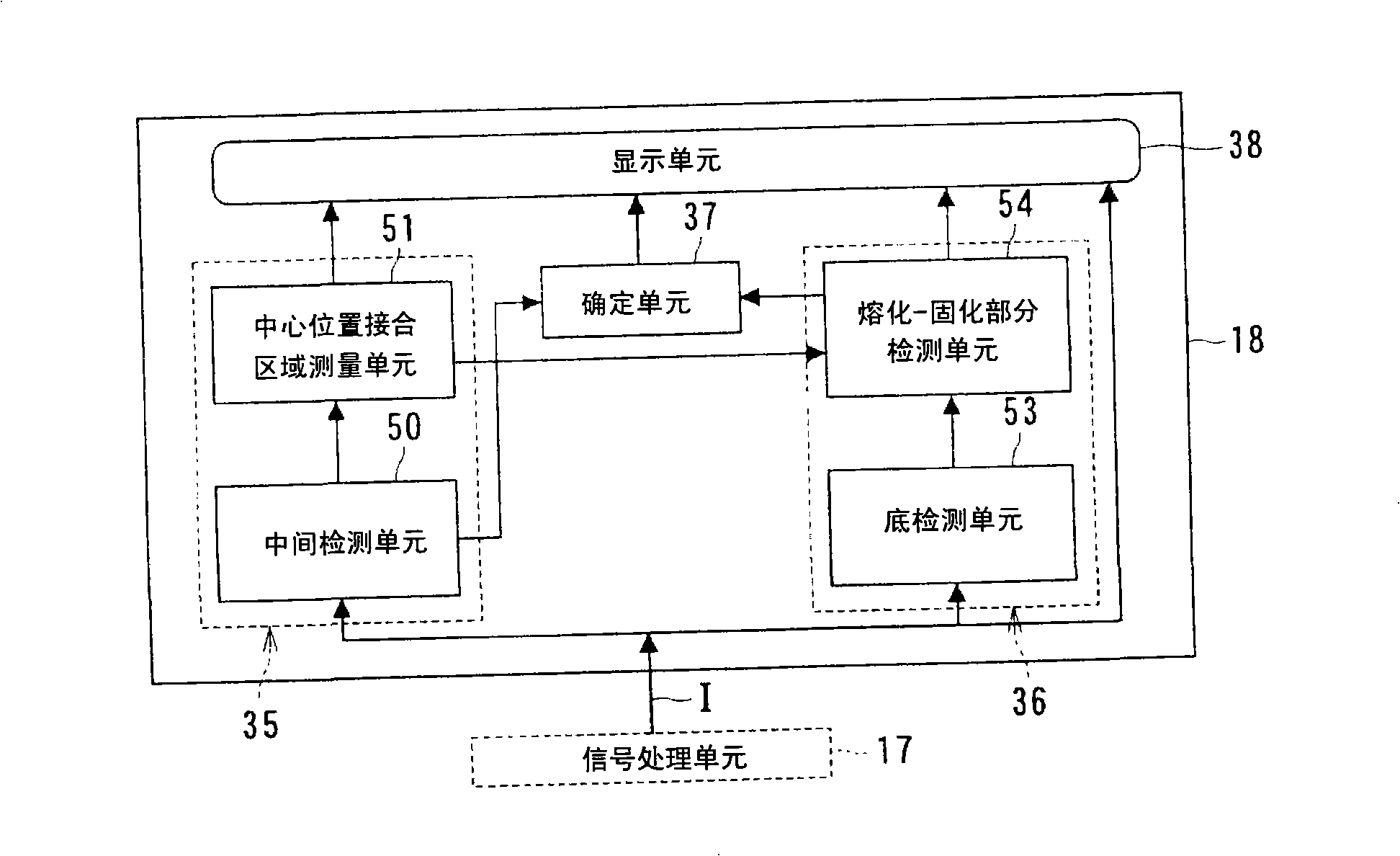

Three-dimensional ultrasonic inspection device

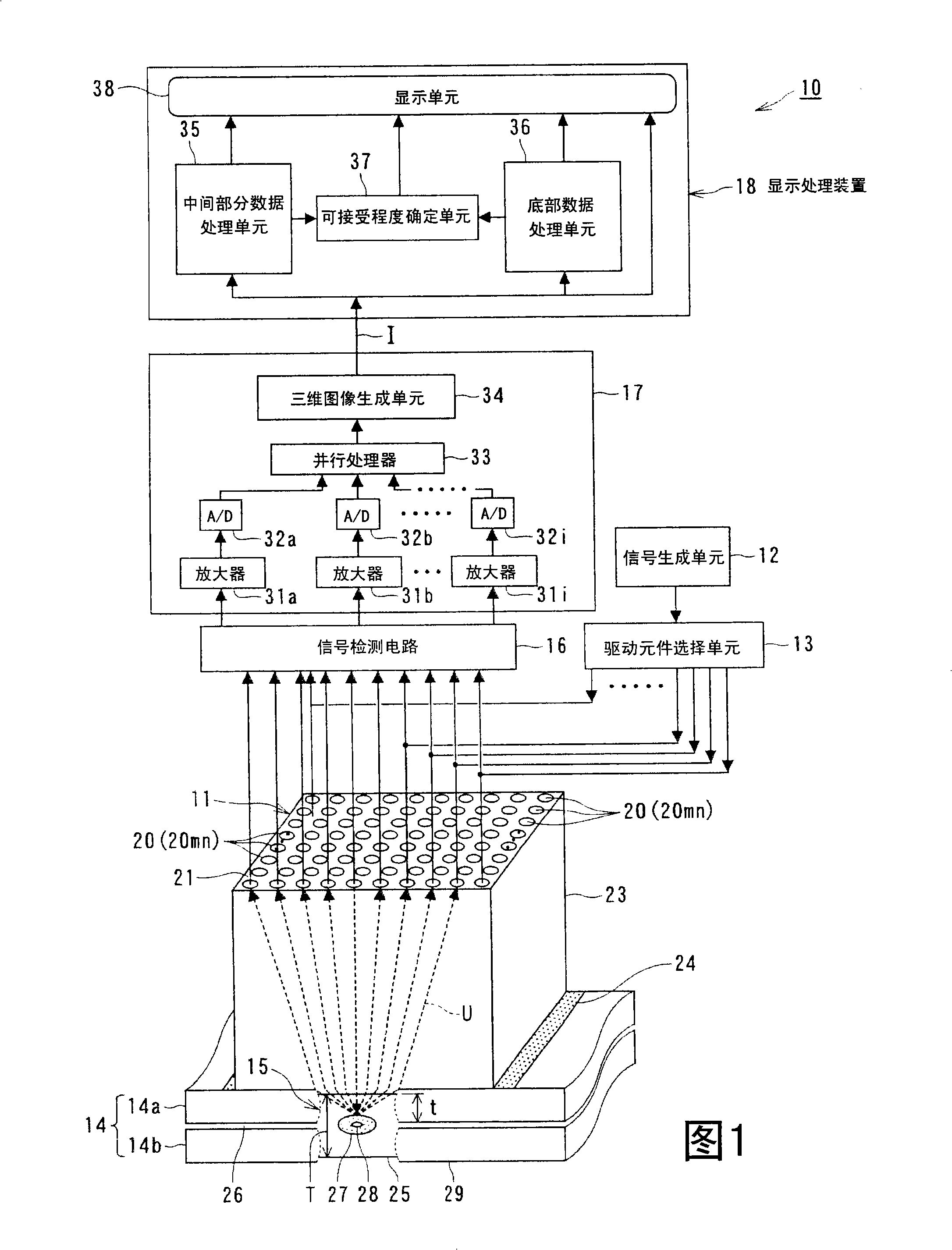

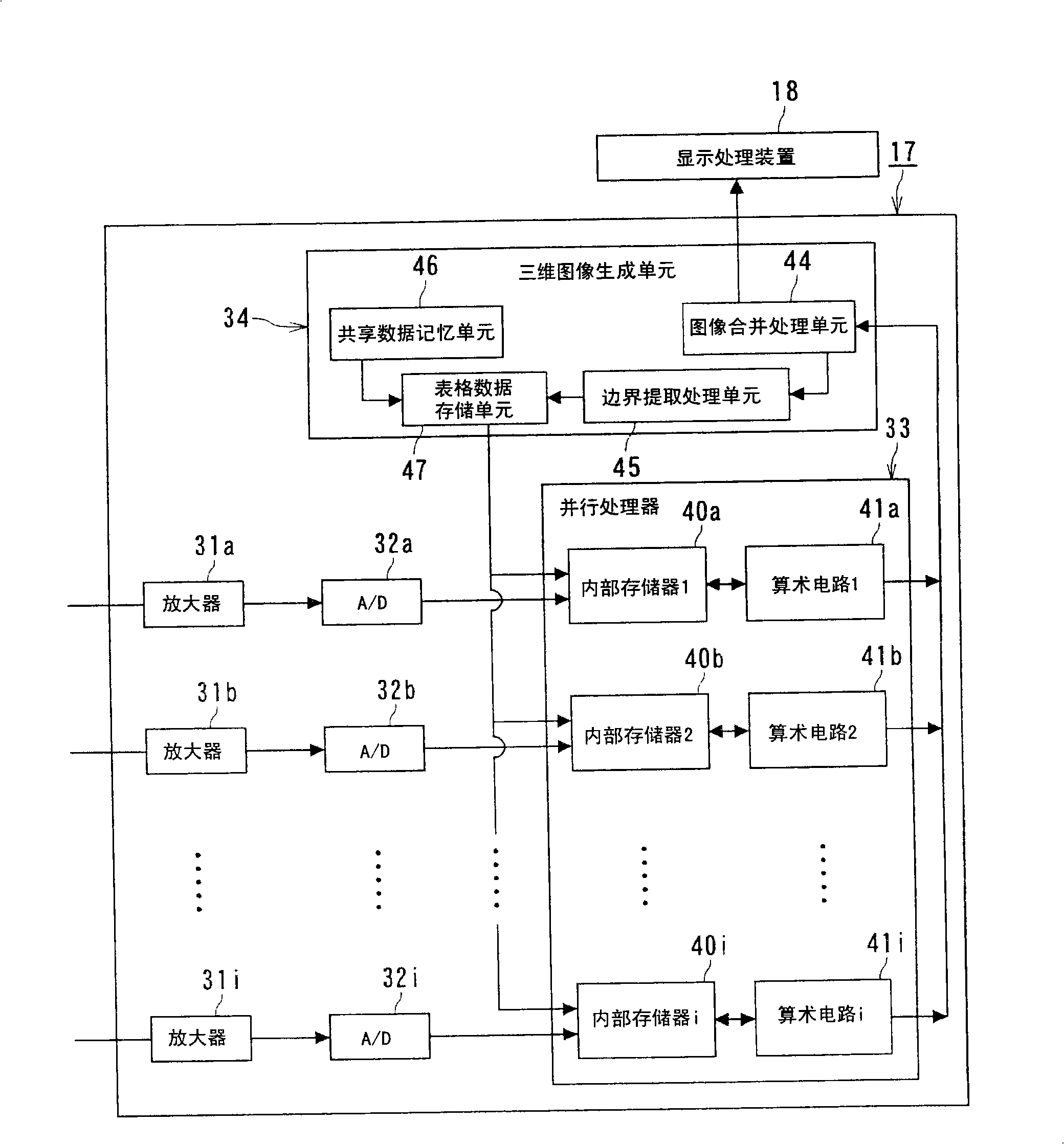

ActiveCN1977161AQuick internal checkAccurate and correct internal inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic sensorSonification

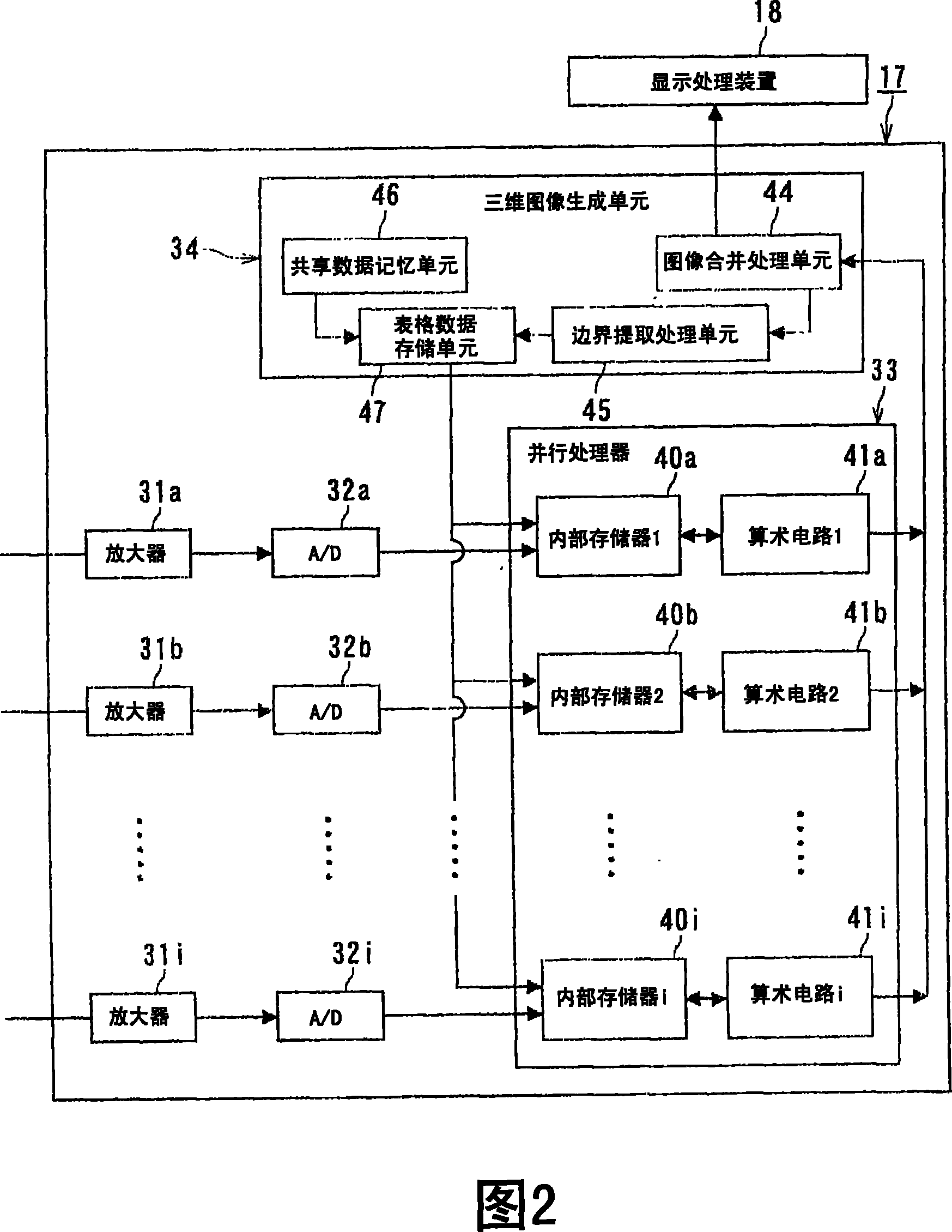

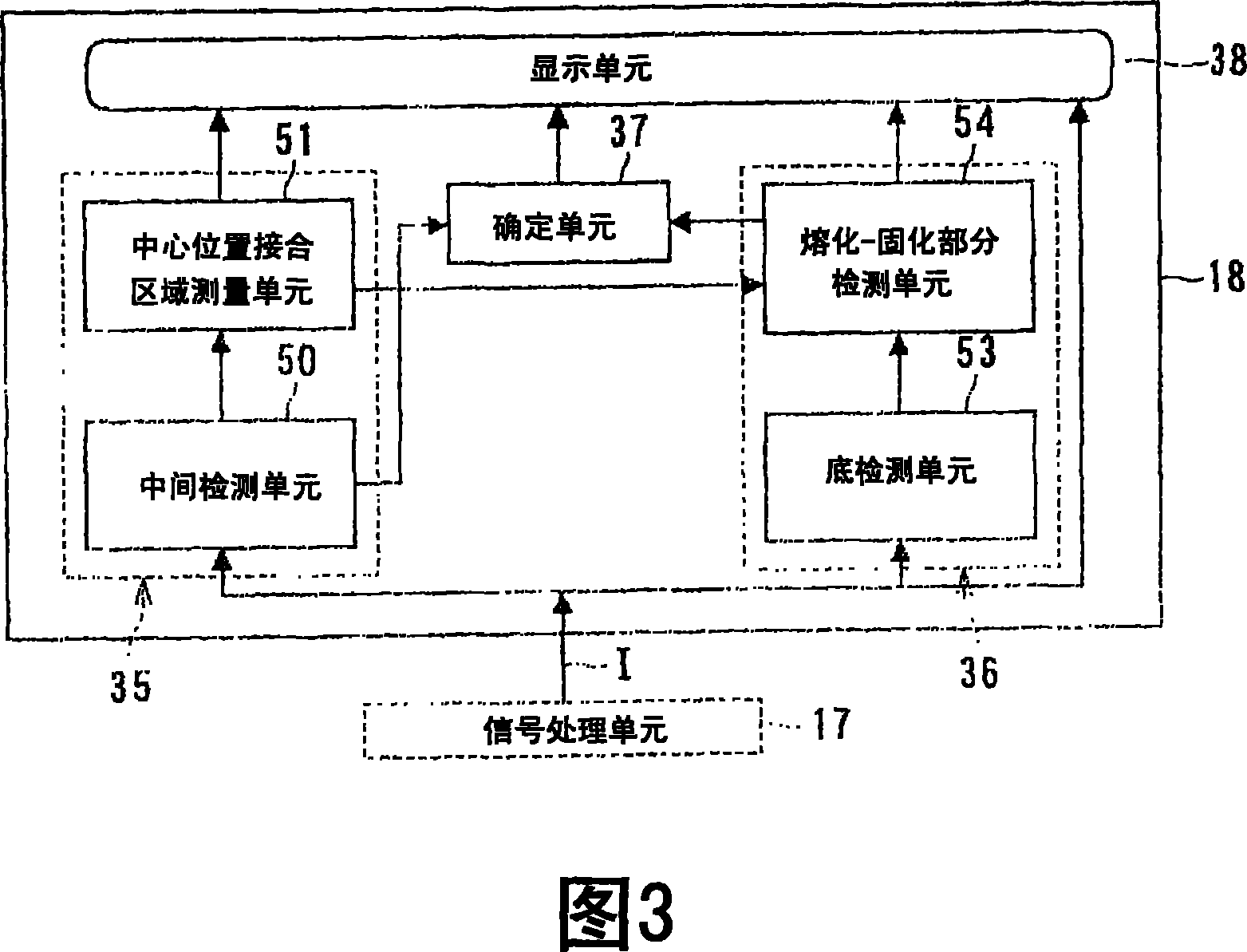

A three-dimensional ultrasonic inspection apparatus includes: a sensing device for ultrasonic inspection including an ultrasonic sensor as a transducer, in which a plurality of piezoelectric vibrators are disposed in a matrix or an array; a drive element selecting unit for selecting and driving a piezoelectric vibrator for producing an ultrasonic wave among the ultrasonic transducer; a signal detecting circuit for detecting the electric signal of the reflected echo by receiving the reflected echo from the joined area; a signal processing unit for subjecting the electric signal to signal processing and generating three-dimensional imaging data by causing the electric signals to correspond to mesh elements in a three-dimensional imaging region of the object to be inspected; and a display processing device for displaying the detection results and three-dimensional image data from the signal processing unit, while detecting the size and the position of the molten-solidified portion, and the size and the position of the weld defect of the joined area, from the intensity distribution of the three-dimensional imaging data generated by the signal processing unit.

Owner:KK TOSHIBA

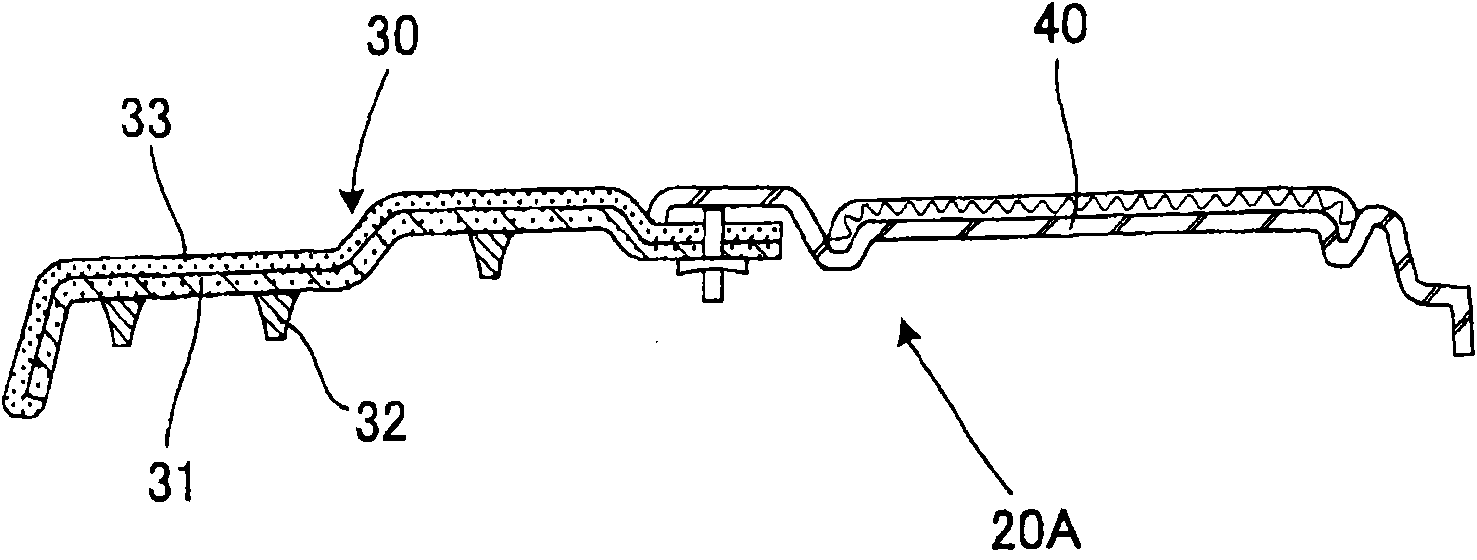

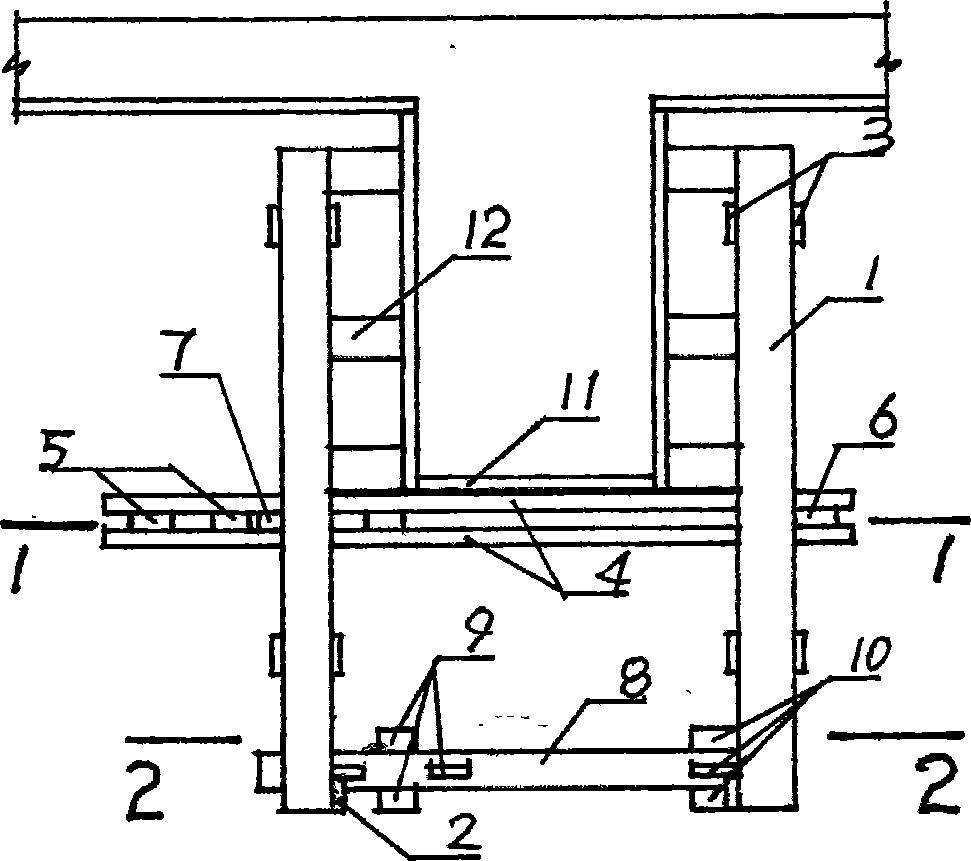

Inner-decoration component for automobile and method for the production thereof

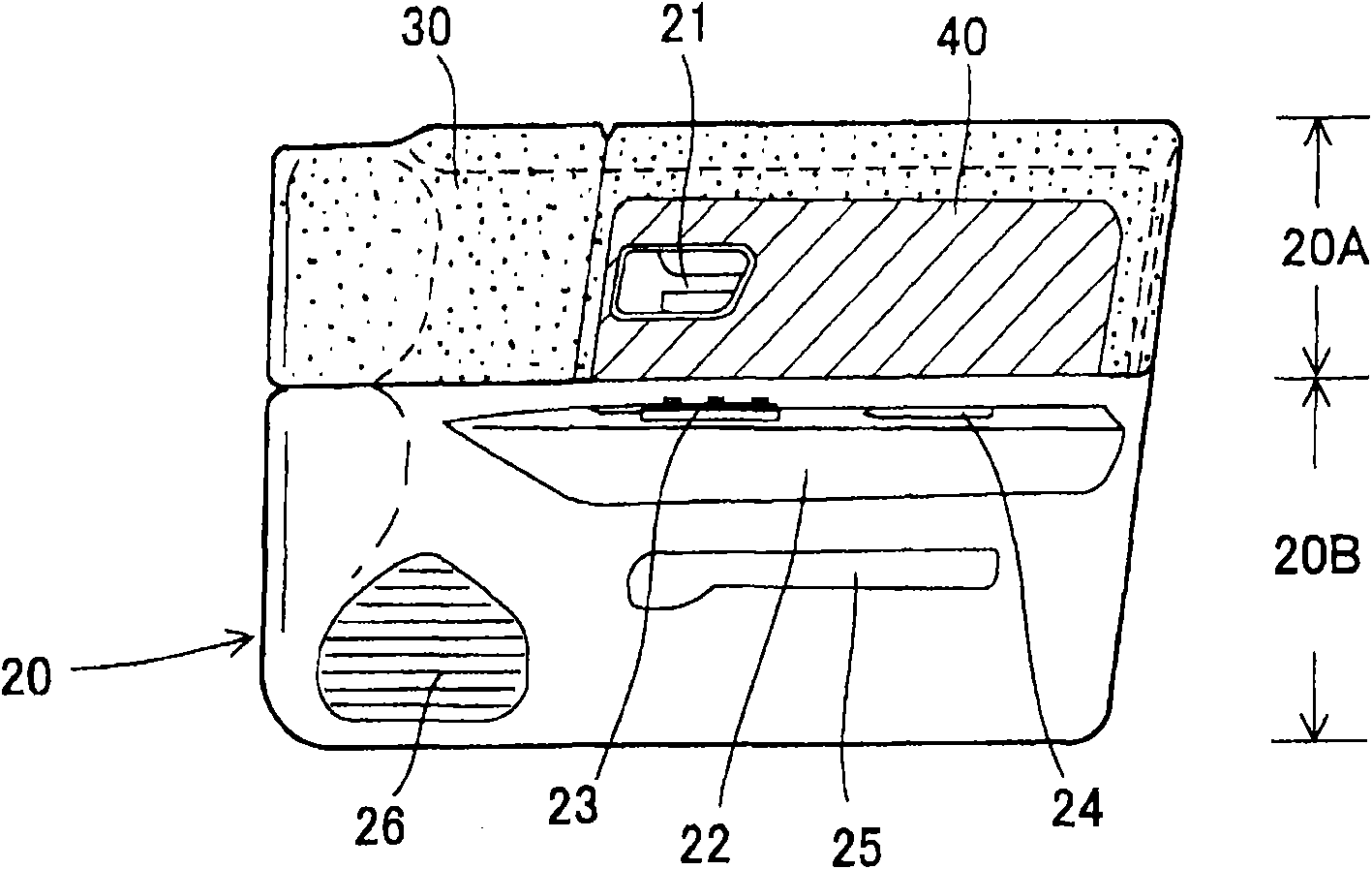

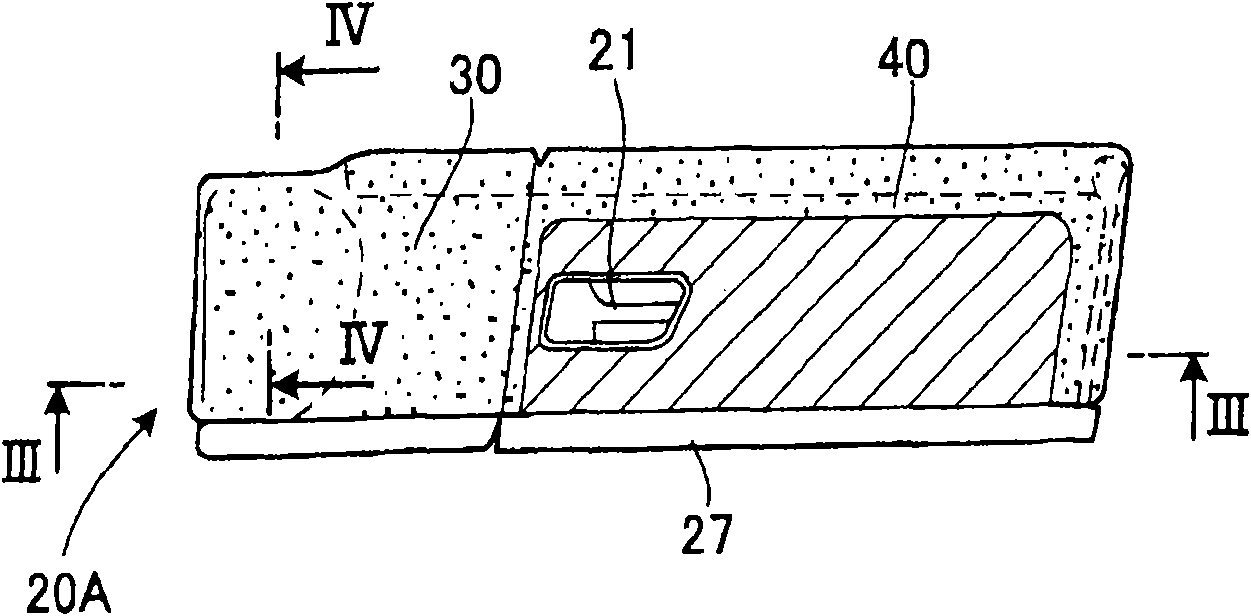

InactiveCN101659238AImprove aestheticsLow costSuperstructure subunitsDomestic articlesEngineeringFusion splicing

Provided are an installation structure on a light decorated back face, used for simply and cheaply installing other parts to the whole or a part of inner-decoration component for automobile and an installation method. A door decoration upper portion-forepart (a laminating structure) (30) of a door decoration (20) is formed by a light laminating body with a foamex substrate (31) with the conformality and a rigid resin rib (31) which is integrated with the substrate and arranged on the back face, and is taken as a structure for installing a waist ornament (other components) (50) on the back side, a part of waist ornament is fused to be integrated by a hump (34) used for fusion splicing and integrated on the resin rib (32), and the part of the waist ornament, corresponding to the end edge portion of the door decoration upper portion-forepart uses the coiling process by means of the coiling material (35) at the circumference of the foamex substrate, the upper terminal (50a) of the waist ornament is kept by the coiling of the coiling material, thus simplifying the conformality shape of the waist ornament.

Owner:KASAI KOGYO CO LTD

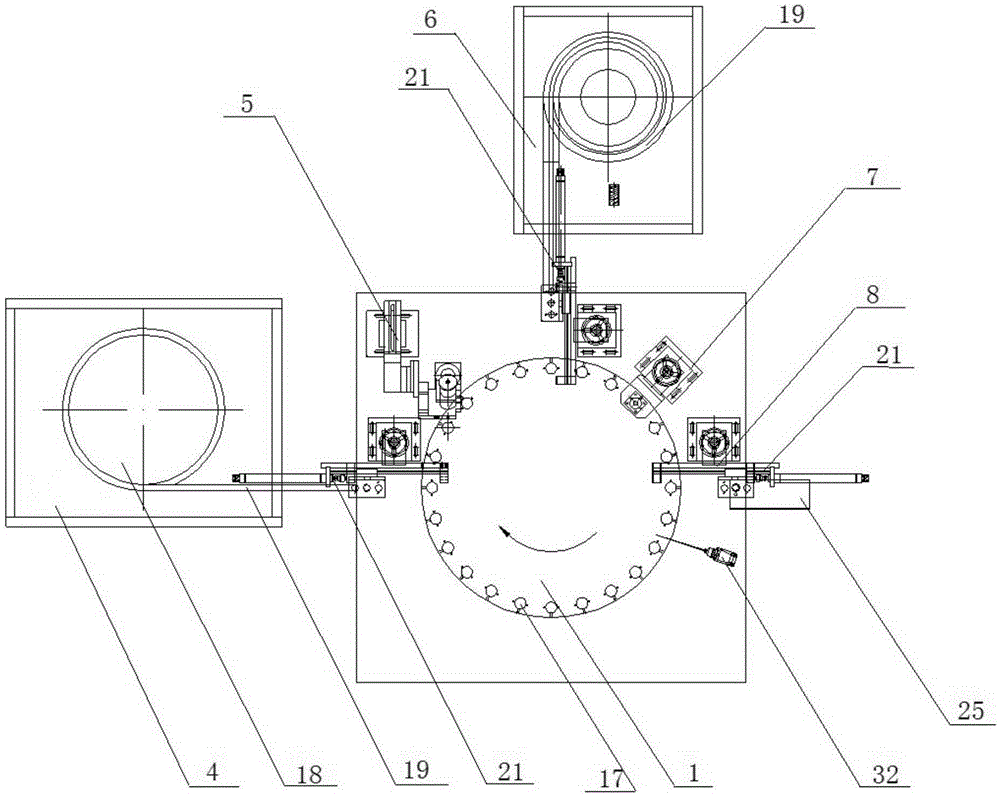

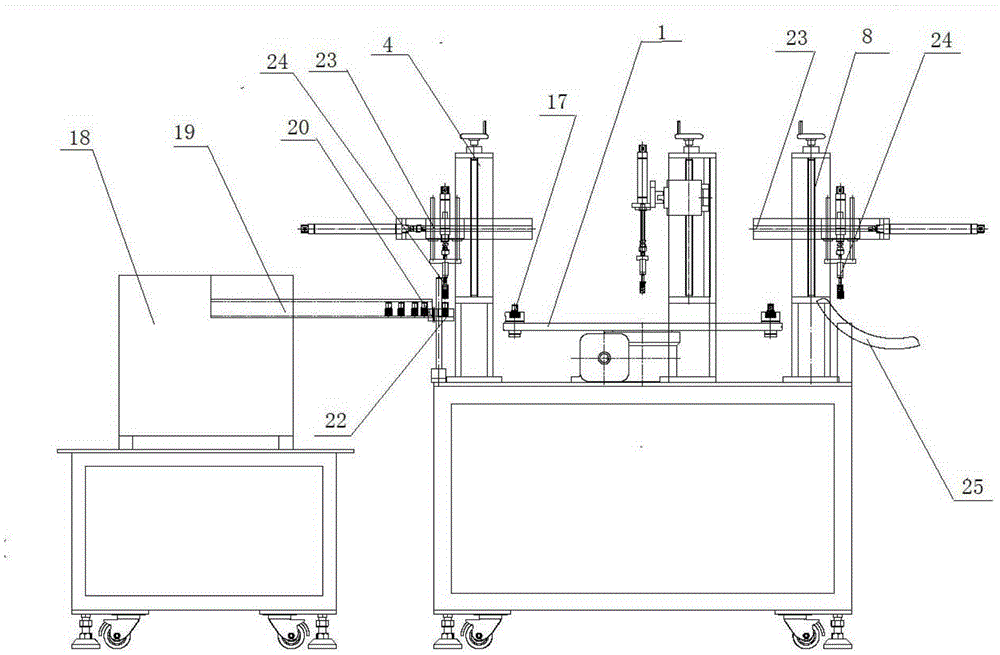

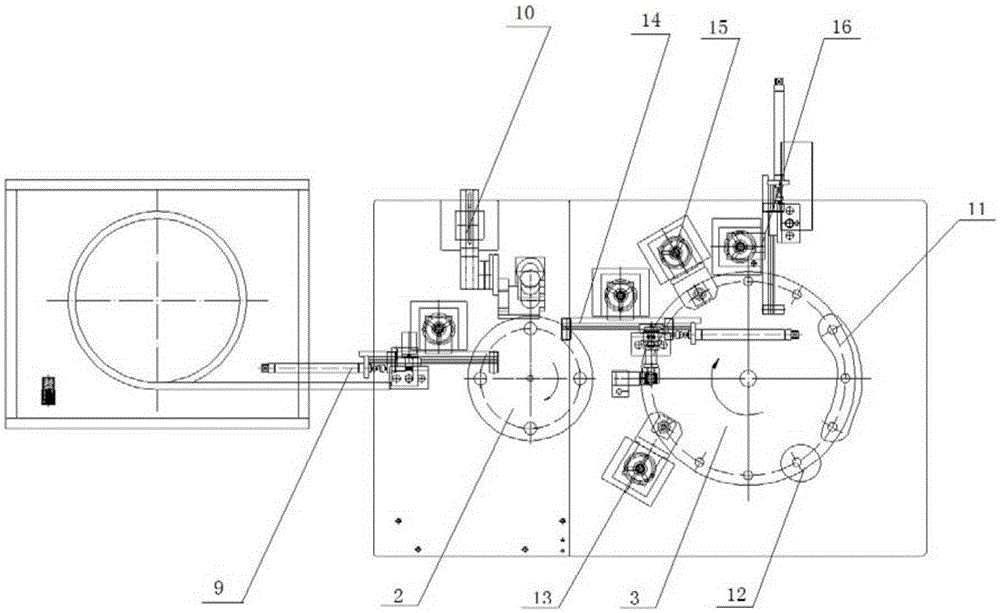

Tubular lipstick plastic shell assembling machine

The invention discloses a tubular lipstick plastic shell assembling machine. A base material feeding mechanism, a base glue feeding mechanism, a spiral tube material feeding mechanism, a press fitting mechanism and a semi-finished product discharging mechanism are sequentially arranged in the peripheral direction of a first assembling machine table rotary disc. A primary base spiral tube combination feeding mechanism and an oiling mechanism are sequentially arranged in the peripheral direction of a second assembling machine table rotary disc. A middle beam tube feeding mechanism, a storage body feeding mechanism, a storage body pressing-down mechanism, a secondary base spiral tube combination feeding mechanism, a base spiral tube press fitting mechanism and a finished product discharging mechanism are sequentially arranged in the peripheral direction of a third assembling machine table rotary disc. The primary base spiral tube combination feeding mechanism conveys semi-finished products discharged from the semi-finished product discharging mechanism onto the second assembling machine table rotary disc. The secondary base spiral tube combination feeding mechanism conveys the semi-finished products from the oiling mechanism onto the third assembling machine table rotary disc. The tubular lipstick plastic shell assembling machine can achieve full-automatic and streamline operation of assembling of lipstick plastic shells, lower the cost and improve the industrial competitiveness.

Owner:COPOLYMER & COSMETICS TECH KUNSHAN

Casting method

InactiveCN101262968APouring pass rate is lowPouring pass rate increasedFoundry mouldsFoundry coresCasting moldCastner process

To provide a casting method based on gravity casting with an air-permeable mold, wherein a melt is charged into only a desired part of the mold cavity and solidified. [MEANS FOR SOLVING PROBLEMS] A melt in a volume approximately equal to the volume of a cavity part which is desired to be filled with the melt is poured. Thereafter, a compressed gas is supplied through the melt-inlet part to fill the desired cavity part with the melt. The melt is then solidified. According to need, the cavity is evacuated before and after the casting.

Owner:五家 政人

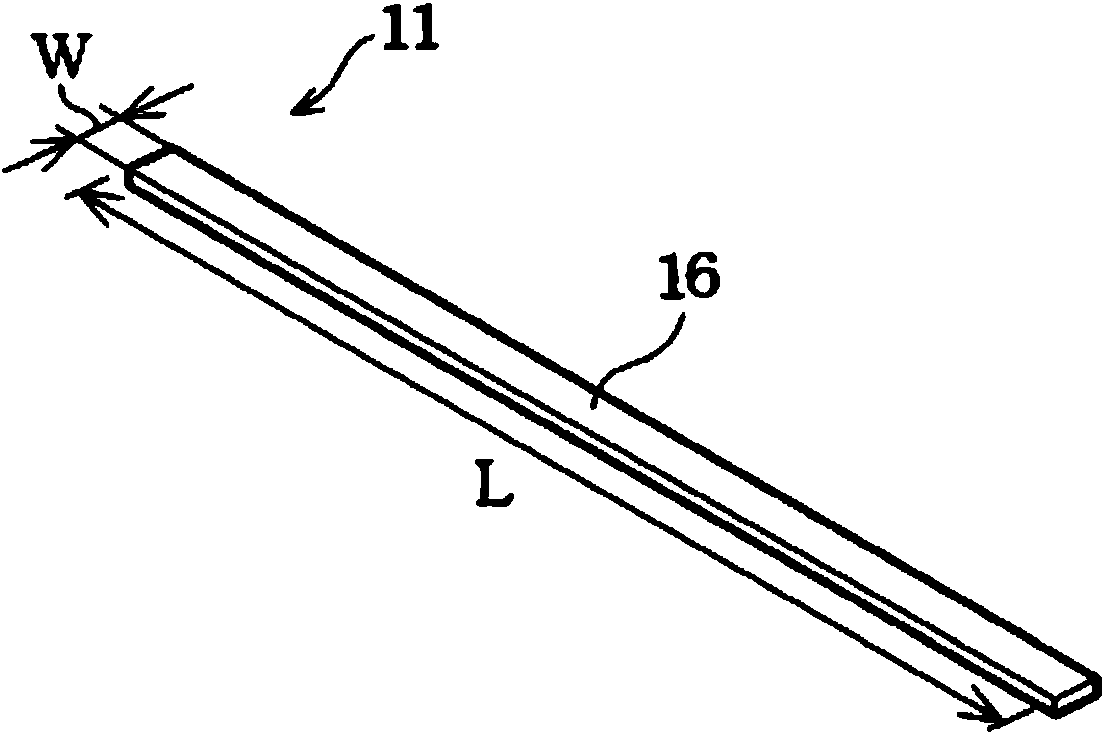

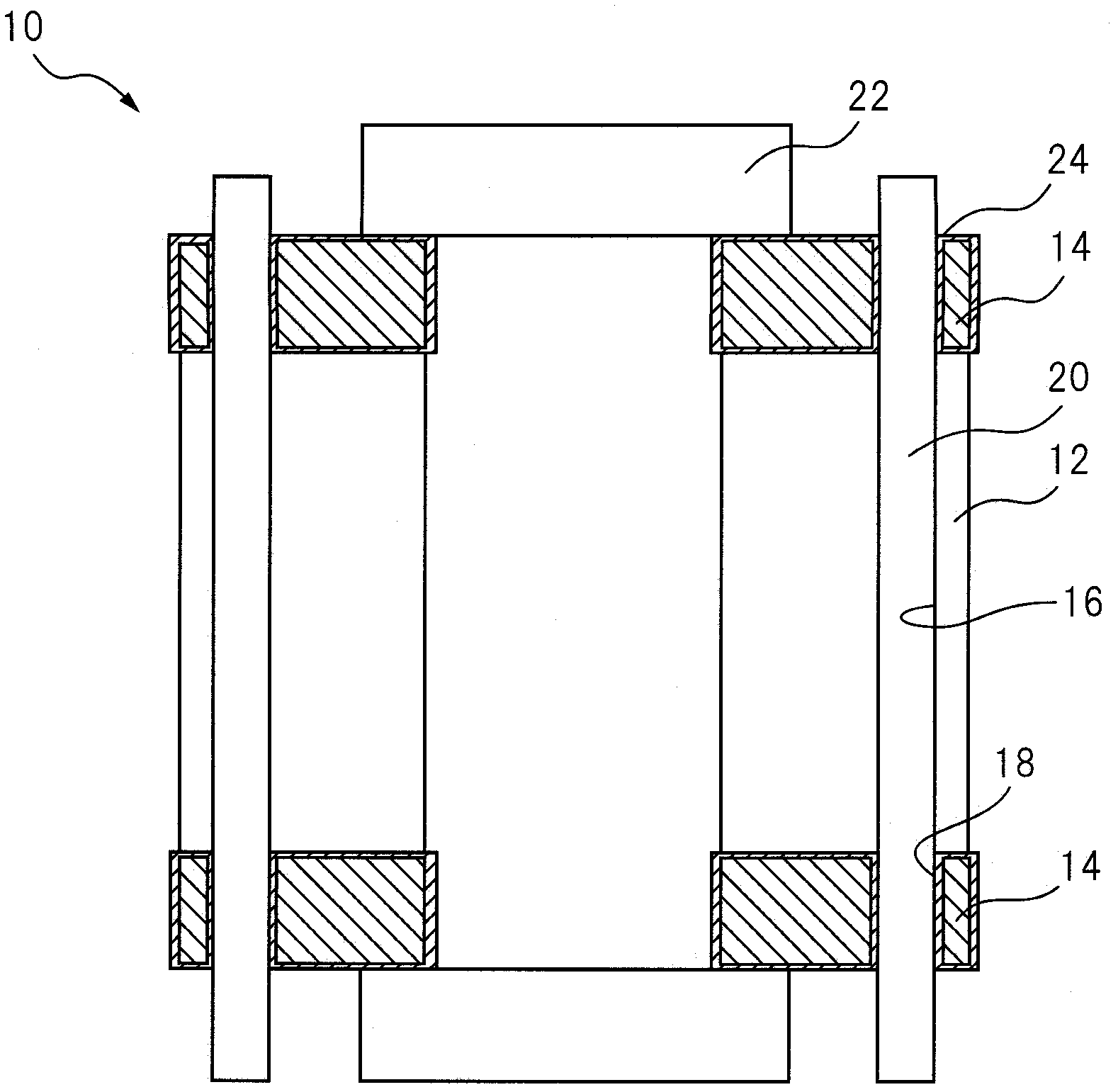

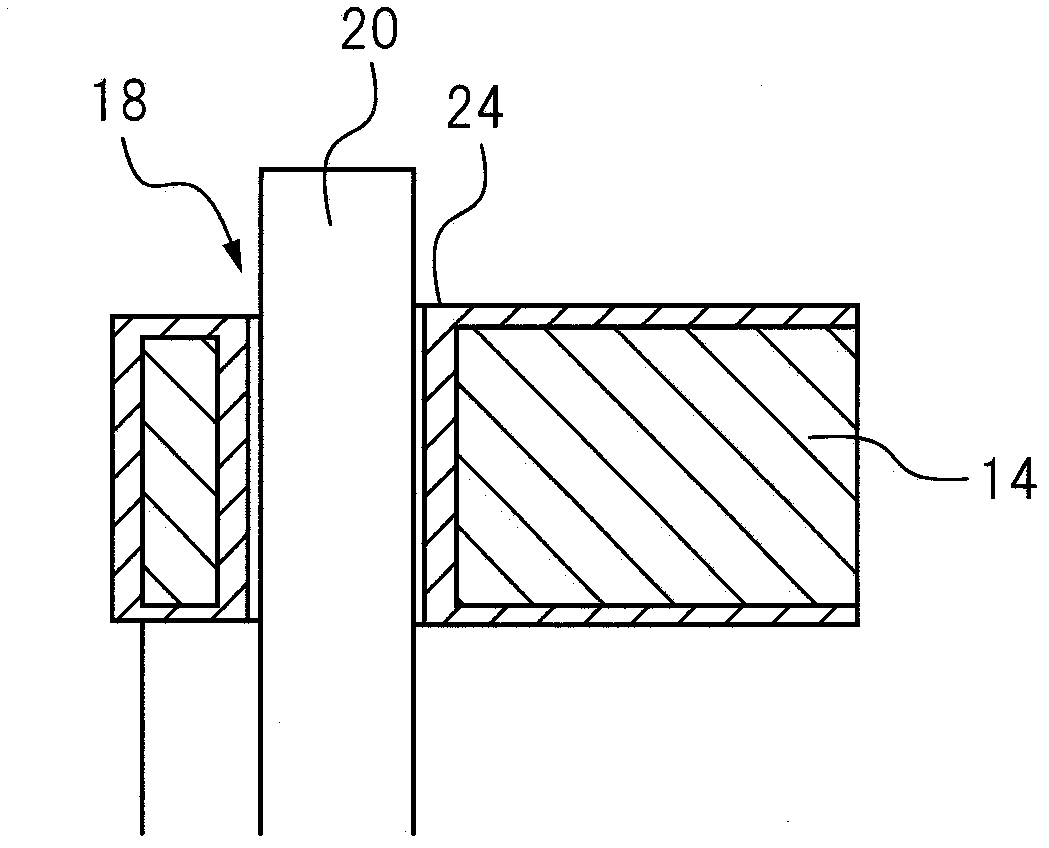

Bus bar and method for manufacturing bus bar

InactiveCN103392281ASuppresses the phenomenon of boundary heatingReduced conductive cross-sectional areaCoupling device connectionsBus-bar/wiring layoutsHardnessMechanical engineering

A bus bar includes a body having at least one bent portion and a plate-shaped or bar-like terminal located on at least one end of the body and formed of a material identical with a material of the body integrally with the body in a seamless manner. The terminal has a higher hardness than the bent portion.

Owner:TOGO SEISAKUSYO CORP

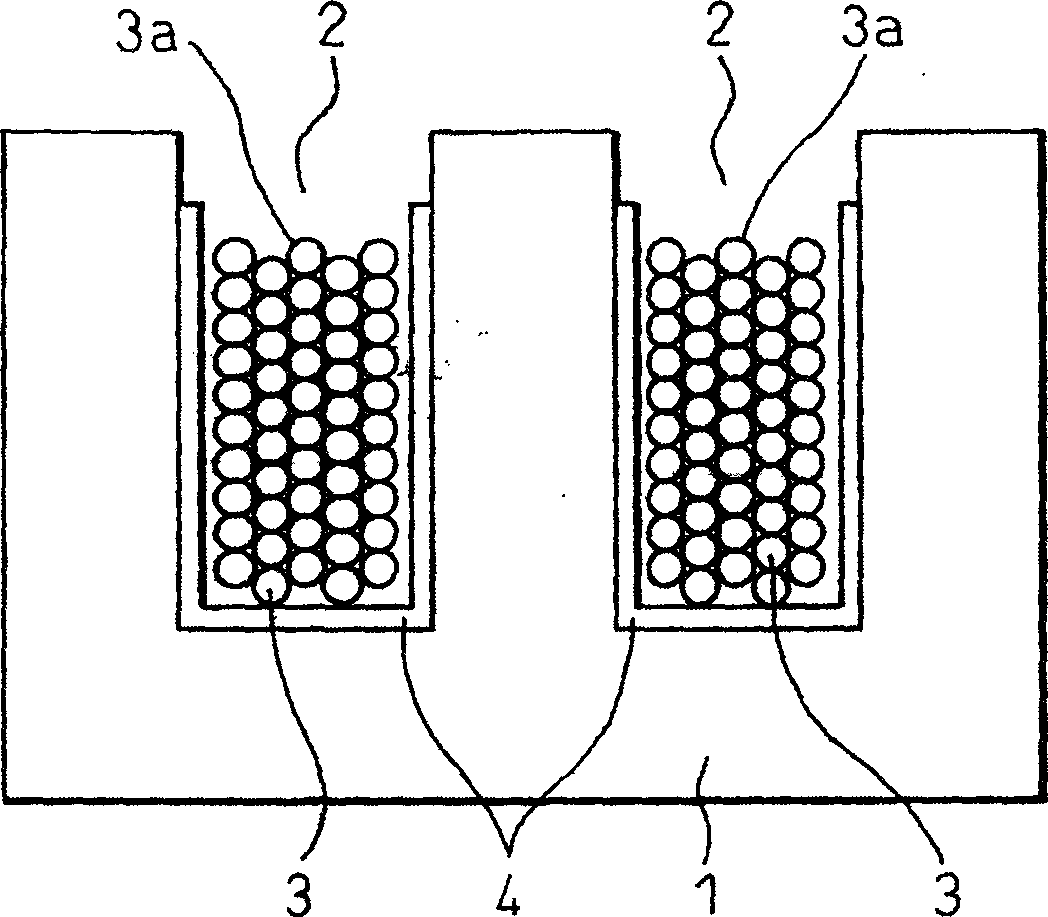

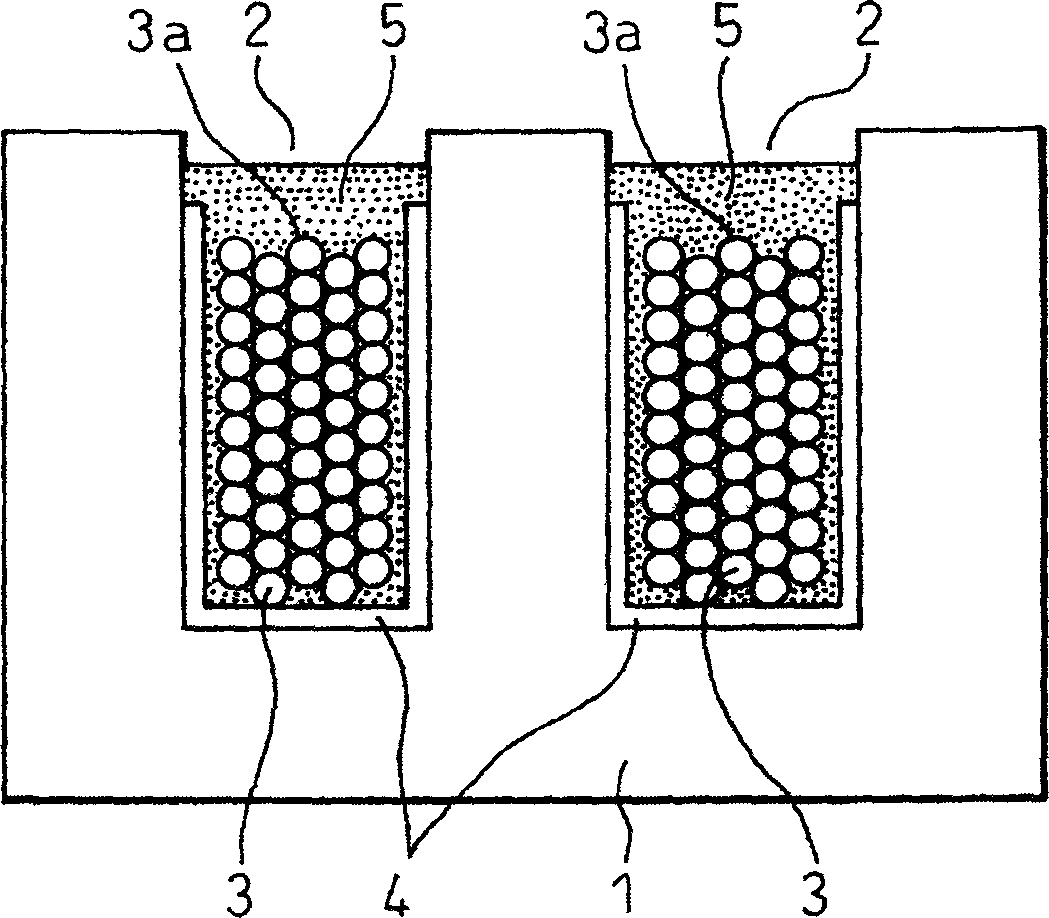

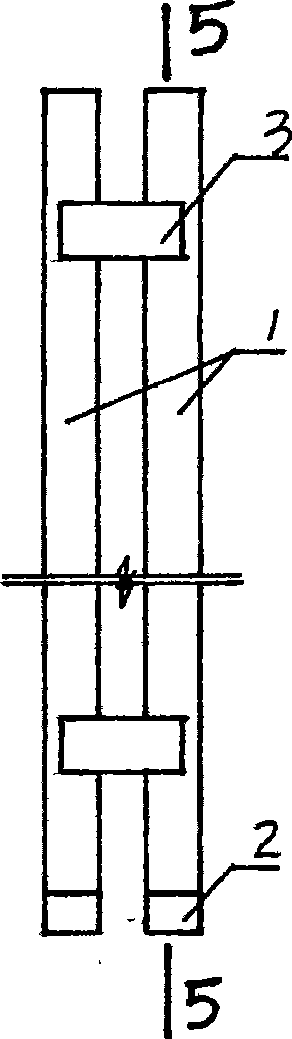

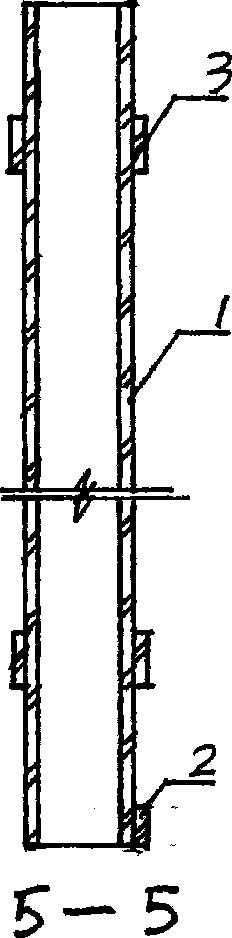

Squirrel-cage rotor of induction motor and production method thereof wherein end ring is brazed with bar

ActiveCN102684435AReduce working hoursMagnetic circuit rotating partsAsynchronous induction motorsSilver plateElectrical conductor

The present invention relates to a squirrel-cage rotor of an induction motor and a production method thereof, wherein an end ring is brazed with a bar. An object of the present invention is to provide a squirrel-cage rotor of an induction motor and a production method thereof, wherein locating of the brazing material is not necessary in order to reduce manhours for brazing, and a bar is easily connected to an end ring. Before assembling a rotor, a silver plated layer is formed on at least one of an end ring and a conductive bar. In order to melt the silver plated layer, the rotor is heated to a temperature which is equal to or larger than the melting point of the silver plated layer. The melted layer functions as a brazing material, whereby the end ring and the conductive bar are connected.

Owner:FANUC LTD

Injection molding mould, preheating device, and method for preheating by using injection molding mould

InactiveCN102114698AReduce wear and tearAchieve uniform temperature effectInduction heating apparatusEngineeringInjection moulding

The invention discloses an injection molding mould having a preheating device, the preheating device thereof, and a method for preheating by using the injection molding mould. The preheating device comprises a high-frequency coil element and a transmission device, wherein the transmission device comprises a Z shaft servo motor device, a Z axis linear sliding rail, an annular transmission belt and a hoisting frame; the annular transmission belt rotates along with the action of the Z shaft servo motor device; the high-frequency coil element is hung on the hoisting frame; and the hoisting frame is moveably connected to the Z axis linear sliding rail, is coupled with the annular transmission belt, and shifts up and down along the Z axis linear sliding rail along with the running of the annular transmission belt, thereby guiding the high-frequency coil element to get in / out of the position between a male mold and a female mold.

Owner:QUANTA COMPUTER INC

Polytrimethylene terephthalate fiber and process for producing the same

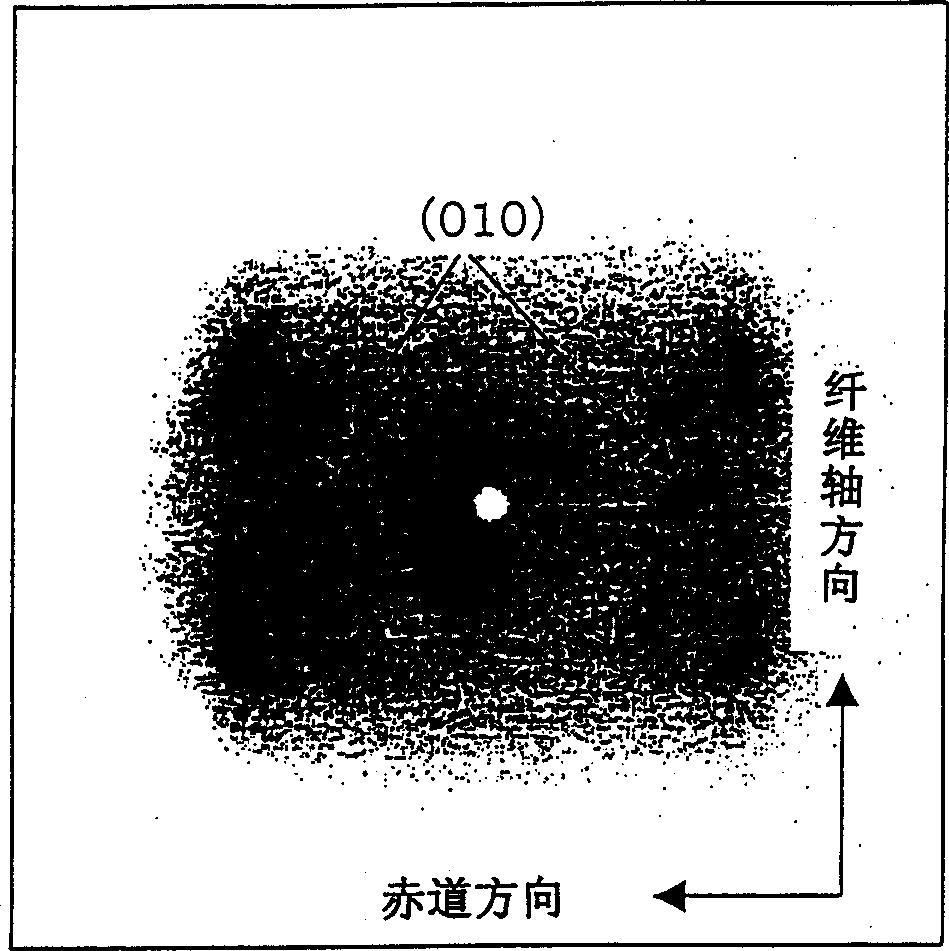

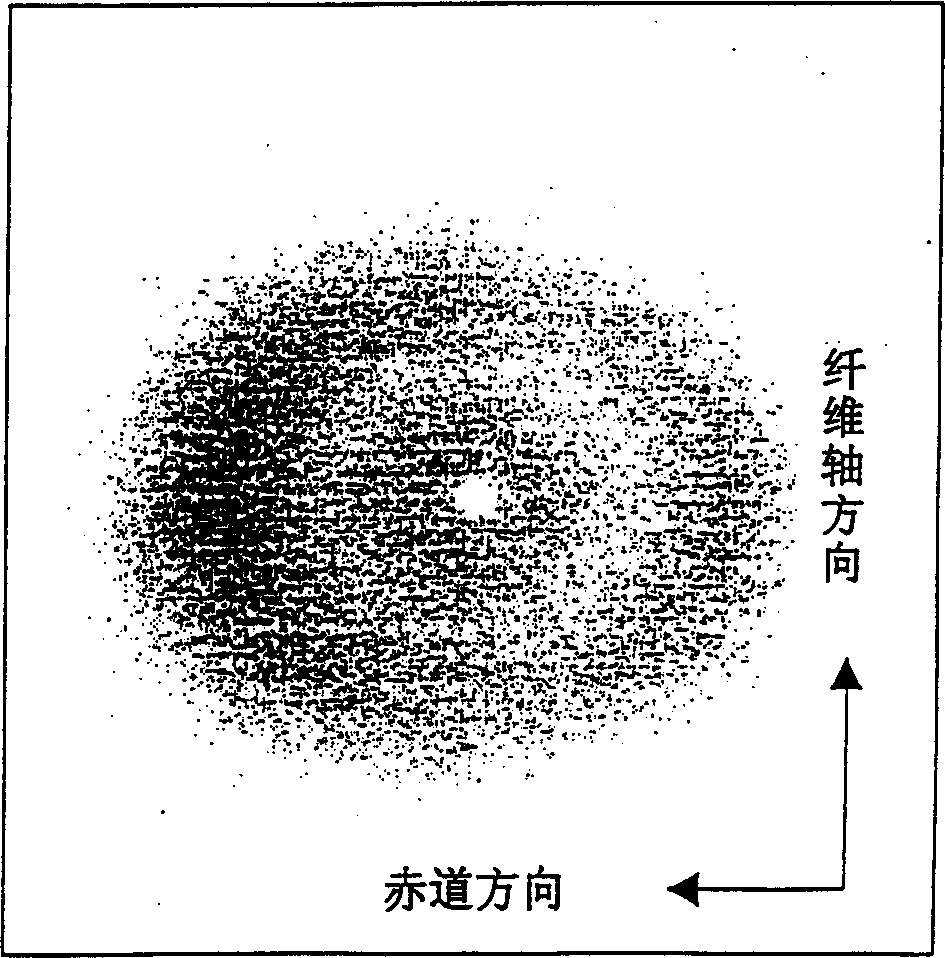

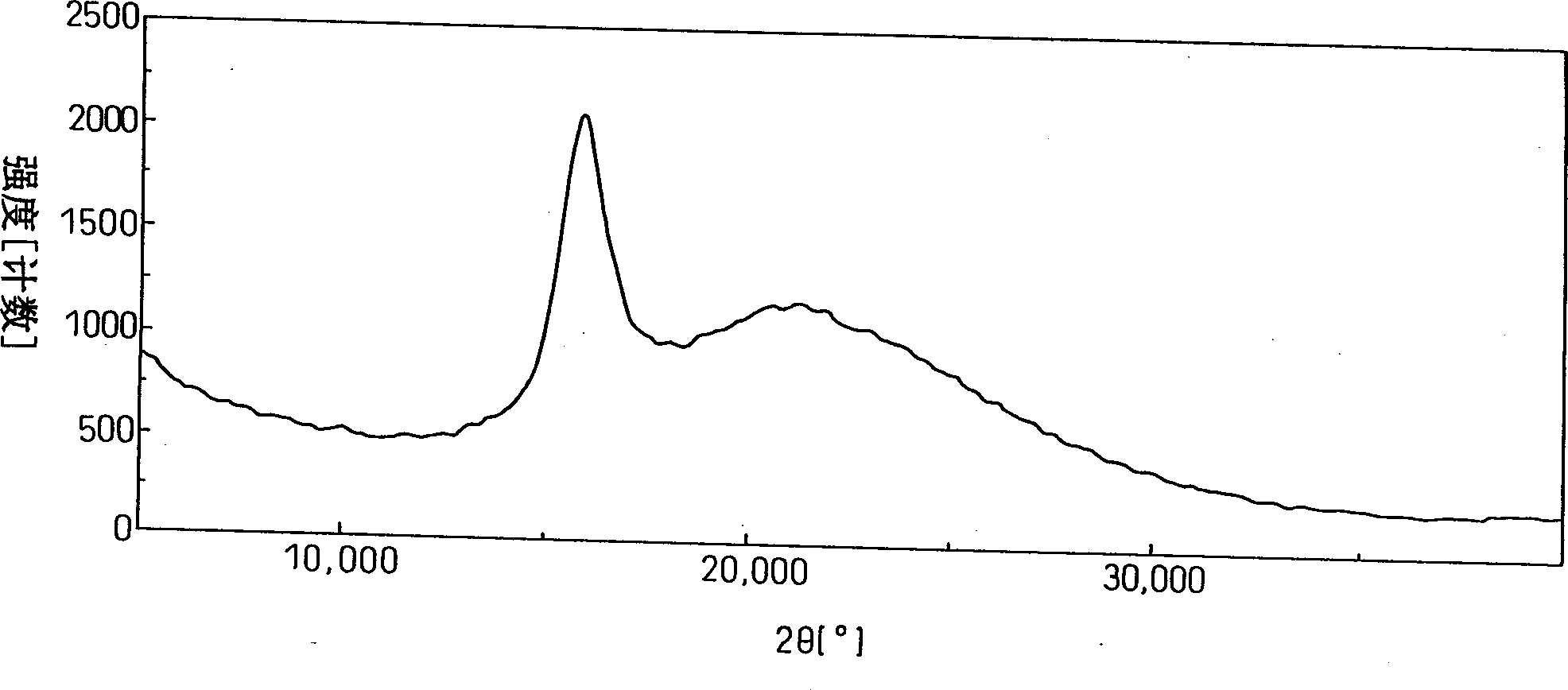

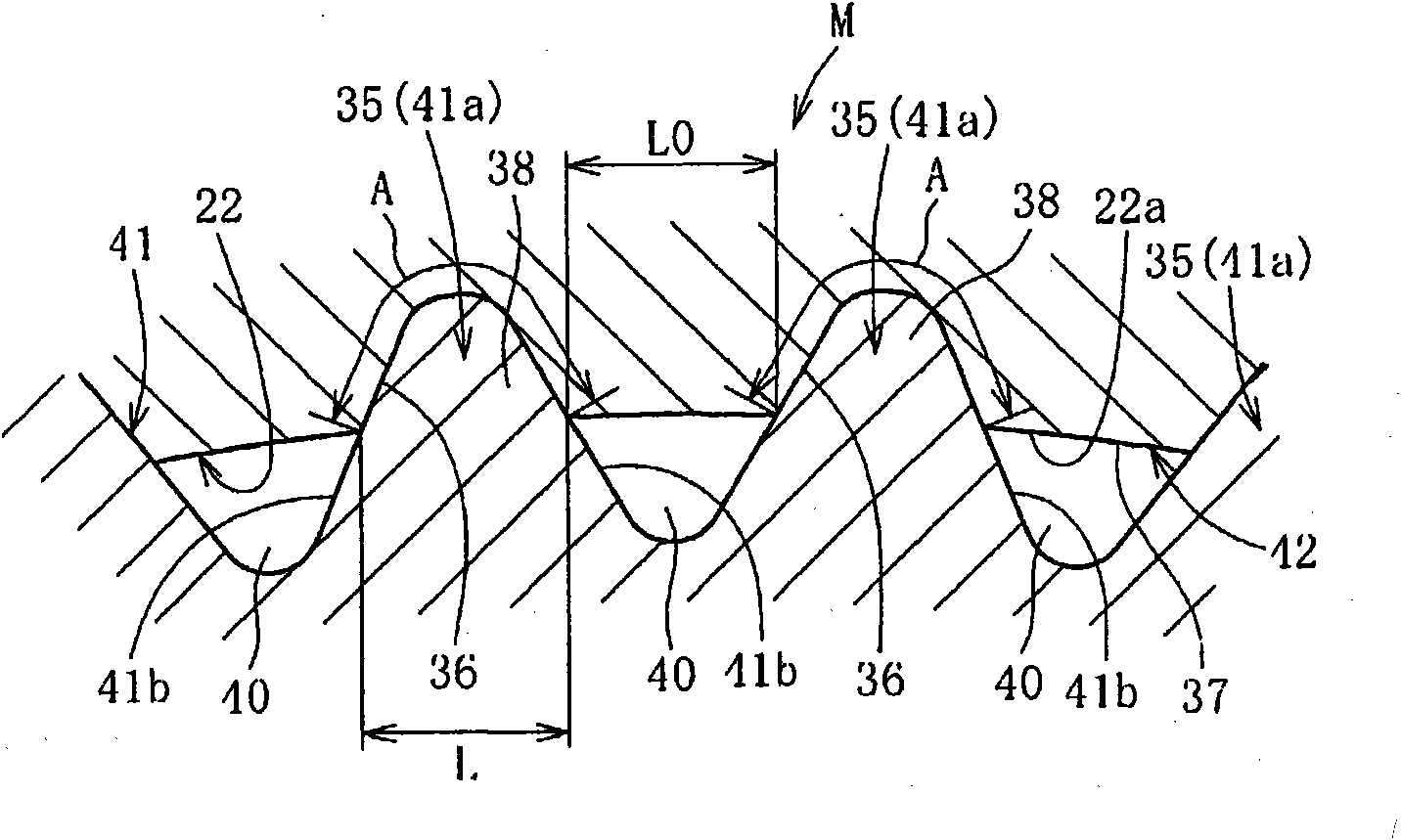

InactiveCN1358242AEasy to curlNot easy to tangleFibre treatmentWoven fabricsYarnPolyethylene terephthalate

A polytrimethylene terephthalate fiber, a method for producing the same, a cheese-shaped package formed thereof, a false-twist textured yarn using the fiber and a fabric using the false-twist textured yarn are provided. The fiber is composed of 90 mol% or more of trimethylene terephthalate repeating units having a density in a range from 1.320 to 1.340 g / cm<3>, a birefringence in a range from 0.030 to 0.070, a peak value of thermal stress in a range from 0.01 to 0.12 cN / dtex, a boiling water shrinkage in a range from 3 to 40%, and an elongation at break in a range from 40 to 140%. The inventive polytrimethylene terephthalate fiber has both of proper crystallinity and orientation and is free from the package tightness due to yarn shrinkage and the bulge. The inventive fiber can be produced on an industrial scale.

Owner:ASAHI KASEI KK

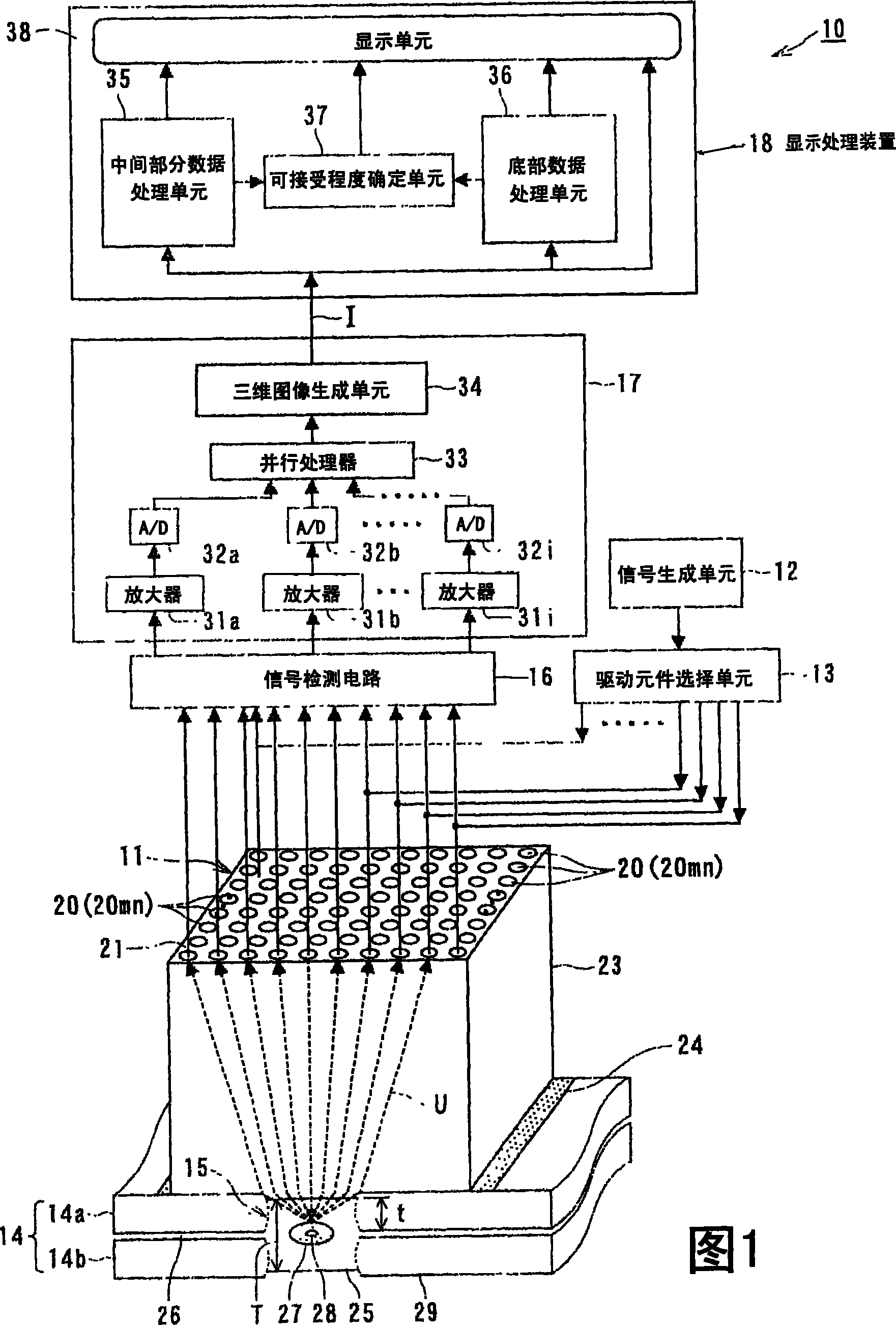

Three-dimensional ultrasonic inspection device

ActiveCN100545650CQuick internal checkAccurate and correct internal inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic sensorSonification

A three-dimensional ultrasonic inspection device includes: a sensing device for ultrasonic inspection, including an ultrasonic transducer as a transducer, wherein a plurality of piezoelectric vibrators are placed in a matrix or an array; a drive element selection unit for The piezoelectric vibrator is selected and driven in the transducer to generate ultrasonic waves; the signal detection circuit is used to detect the electrical signal of the reflected echo by receiving the reflected echo from the bonding area; the signal processing unit is used to process the electrical signal into a signal processing to generate three-dimensional imaging data by making the electric signal correspond to mesh elements within the three-dimensional imaging region of the inspection object; and display processing means for displaying the detection result and the three-dimensional image from the signal processing unit data, while detecting the size and position of the melt-solidified portion, and the size and position of welding defects in the joint region from the intensity distribution of the three-dimensional imaging data generated by the signal processing unit.

Owner:KK TOSHIBA

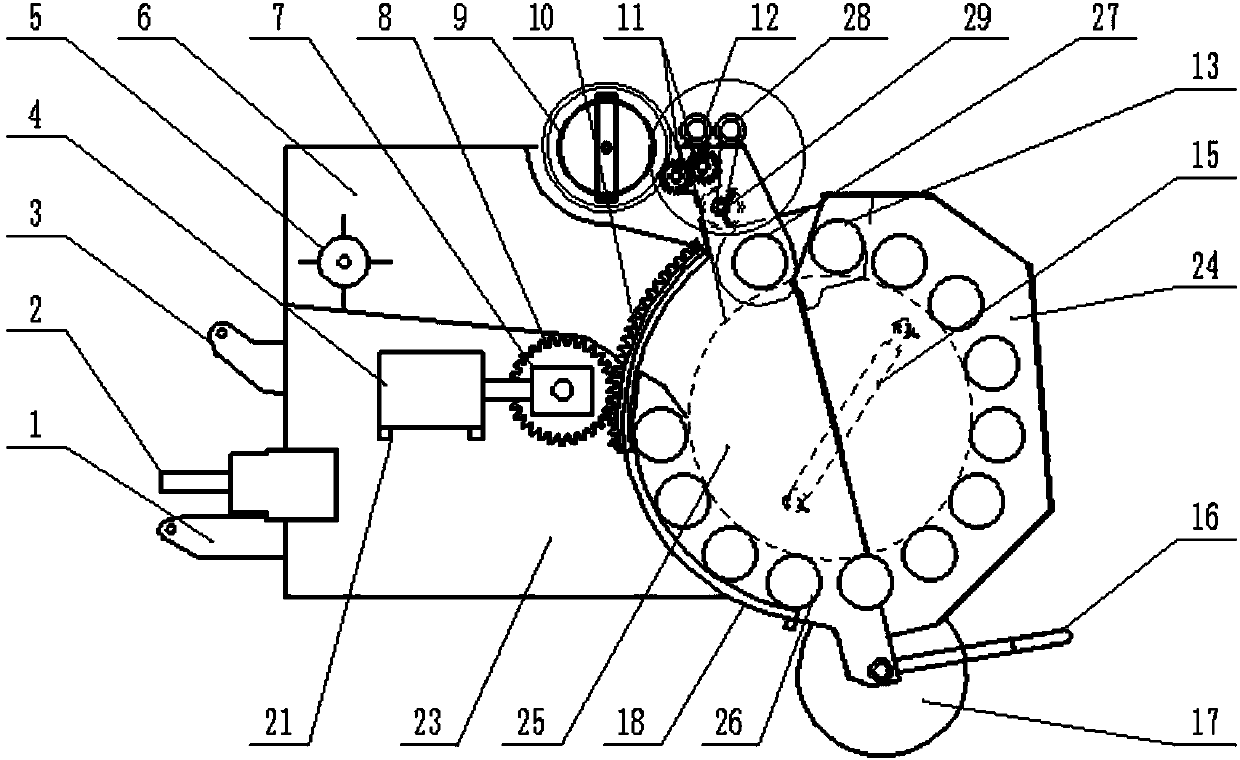

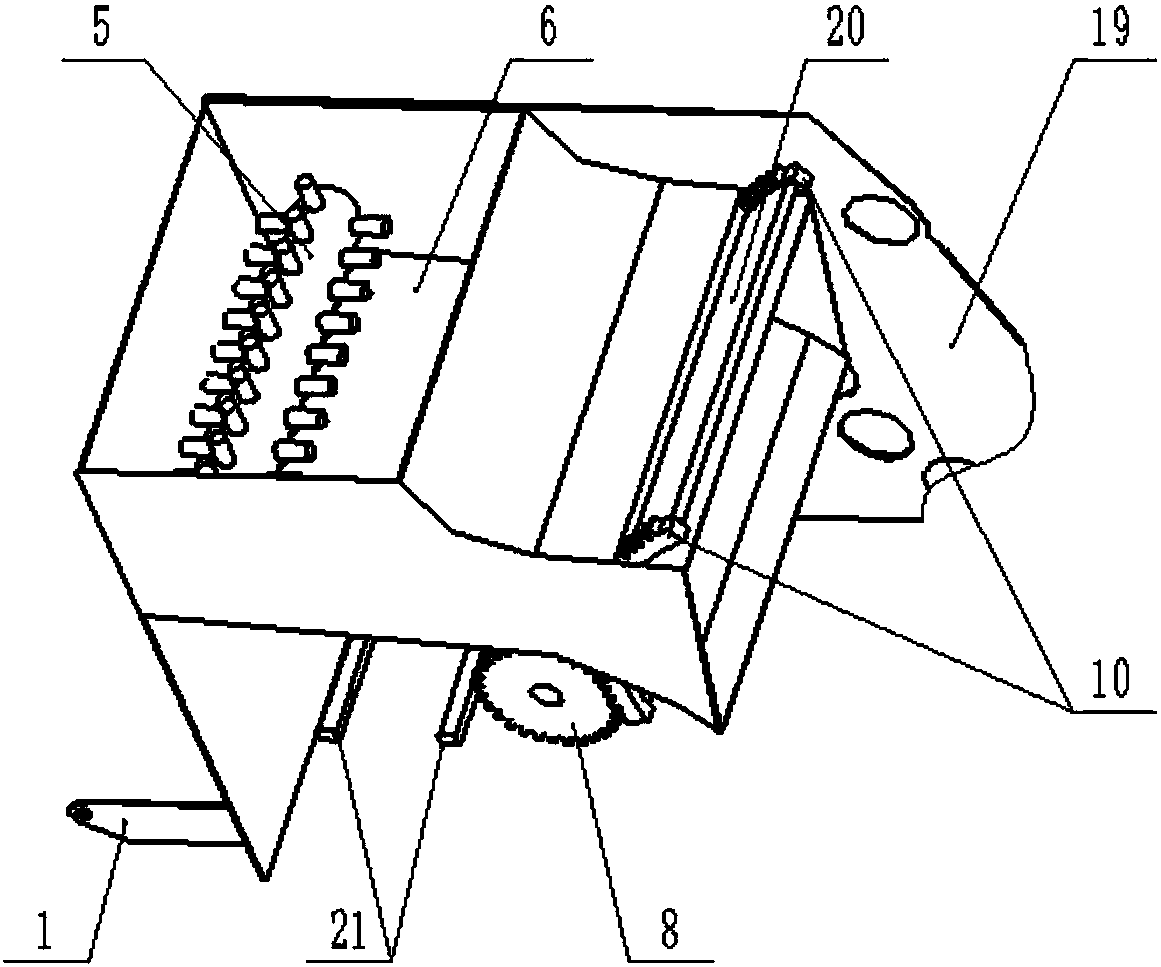

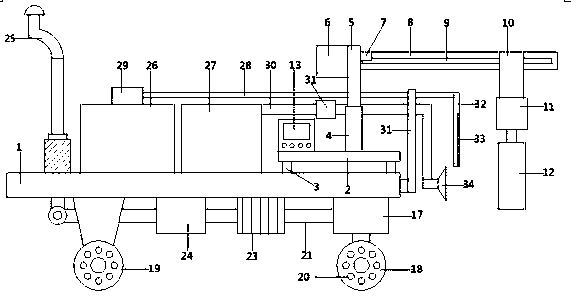

Silage roll bale baler capable of continuous operation and baling method

The invention belongs to the field of animal husbandry machinery, and particularly relates to a silage roll bale baler capable of continuous operation and a baling method. The baler comprises a body structure, a first motor (4), a gearbox (7), a gear (8), a bale unloading mechanism (16), a guide rail (18), a sector rack (10), a bin door (20), a net winding device, a steel-roller rolling and balingdevice and a net cutting device; the body structure comprises a side wall (19), a feed bin (6) and a front bin (23). In a working process of the baler, materials can be stored in two spaces of the feed bin (6) and the steel-roller rolling and baling device alternately, and by means of alternating placement of the materials in the two spaces, it is achieved that the materials can enter continuousoperation of machines and tools continuously during net winding and bale unloading; by means of the baling method, the problem can be solved that in the prior art, a halt is needed in a baling processfor operation; therefore, the production efficiency of the silage roll bale baler is improved, and the production cost is lowered.

Owner:CHINA AGRI UNIV

Drilling machine for highway construction

InactiveCN107724956ANo pollution in the processAvoid pollutionConstructionsDerricks/mastsArchitectural engineeringWater spray

The invention discloses a drilling machine for road construction, which comprises a base, a drilling machine base is arranged at the right end of the upper side of the base, fixing columns are arranged at the four corners of the lower side of the drilling machine base, and the bottom ends of the fixing columns are fixed on the base , there is an electric telescopic rod on the upper side of the base of the drilling machine, the movable end of the upper side of the electric telescopic rod is connected with a support rod, one side of the support rod is provided with a weighing block, the other side is connected with a cross bar, and the cross bar is set With a sliding mechanism, the drilling machine for highway construction of the present invention has a reasonable structural design, can realize precise drilling, has high drilling efficiency, can perform dust suction and water spraying operations, improves the environment, avoids pollution, and prolongs the working life of the drill bit. The service life ensures long-term continuous work. The entire working process is controlled by the control box, which has a high degree of automation and saves time and effort. In addition, it is convenient for quick transfer of drilling machinery, which improves work efficiency and has small vibration during movement.

Owner:陕西天策智汇建筑科技有限公司

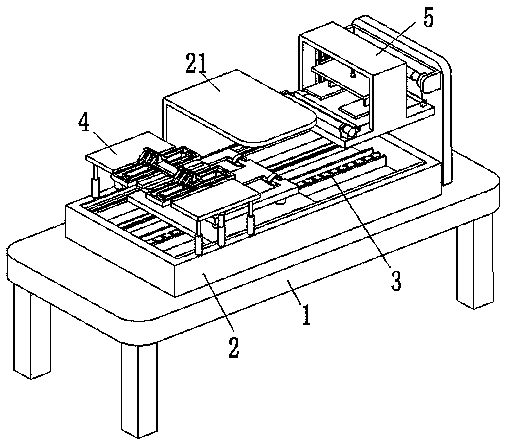

Arm soft fixing splint dressing applying device

InactiveCN109833134AEasy to useReduce working hoursLiquid surface applicatorsFractureEngineeringBandage

The present invention relates to an arm soft fixing splint dressing applying device. The arm soft fixing splint dressing applying device comprises a bottom plate, a mounting frame, a clamping conveying device, a material applying device and a film coating device, an upper end of the bottom plate is provided with the mounting frame, the mounting frame is internally provided with the clamping conveying device, the material applying device is arranged at a left side of the mounting frame, the film coating device is arranged at a right side of an upper end of the bottom plate, and the film coatingdevice is located above a left side of the mounting frame. The arm soft fixing splint dressing applying device can solve problems that during use of existing soft fixing splints, use effects are generally poor and doctors need to apply dressing, leading to long consumption time and affecting work efficiency, besides, the existing soft fixing splints need to be used with bandages and cannot directly adhere to patient's arms, etc., can realize automatic dressing applying and film coating of the soft fixing splints, and has advantages of being good in use effects, shortening time for the doctorsto apply the medical dressing, being capable of directly adhering to the patient's arms, good in use effects, etc.

Owner:JILIN UNIV

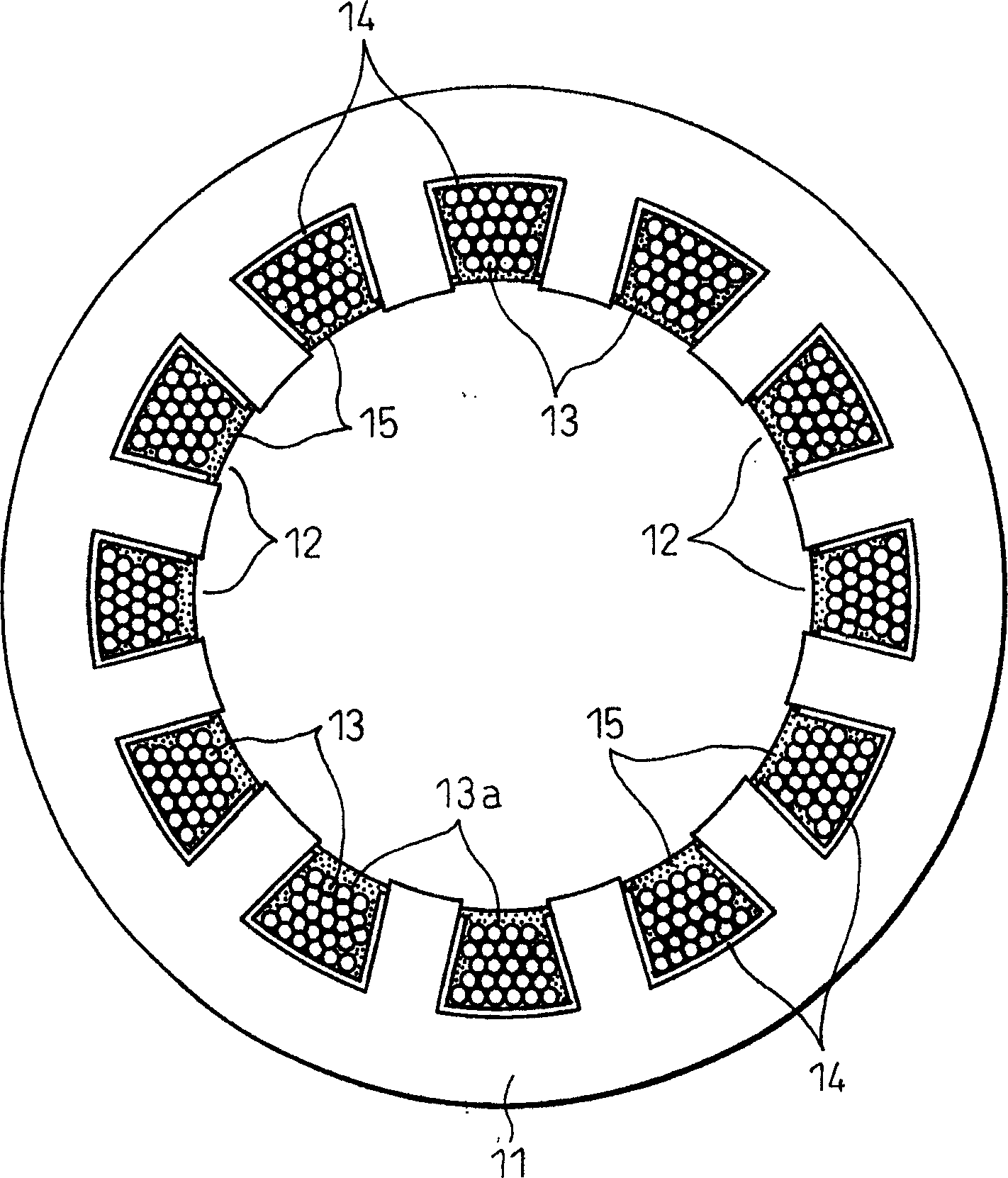

Electric motor

InactiveCN1627603AReduce usageHigh insulation resistanceWindings insulation shape/form/constructionMagnetic circuit characterised by insulating materialsSlot insulationEngineering

Owner:FANUC LTD

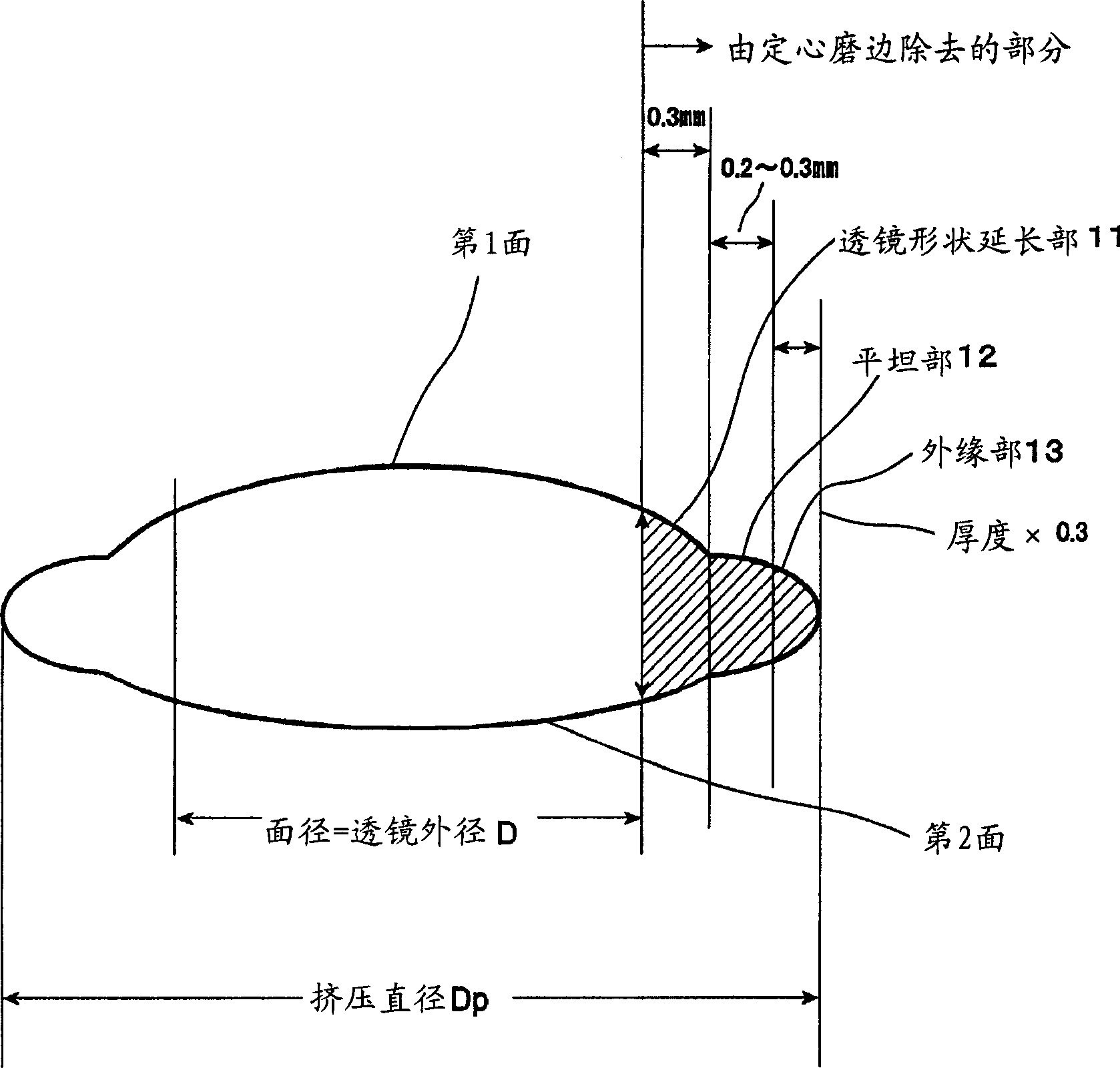

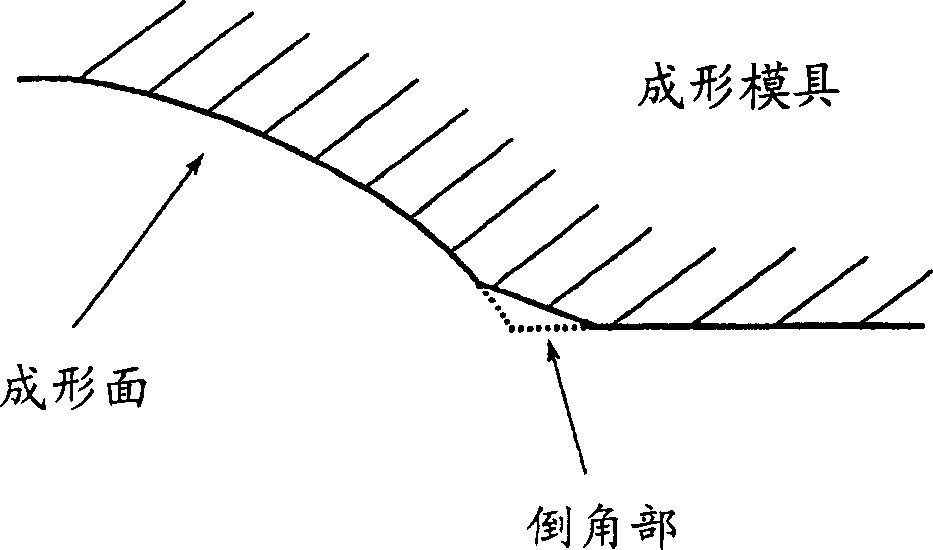

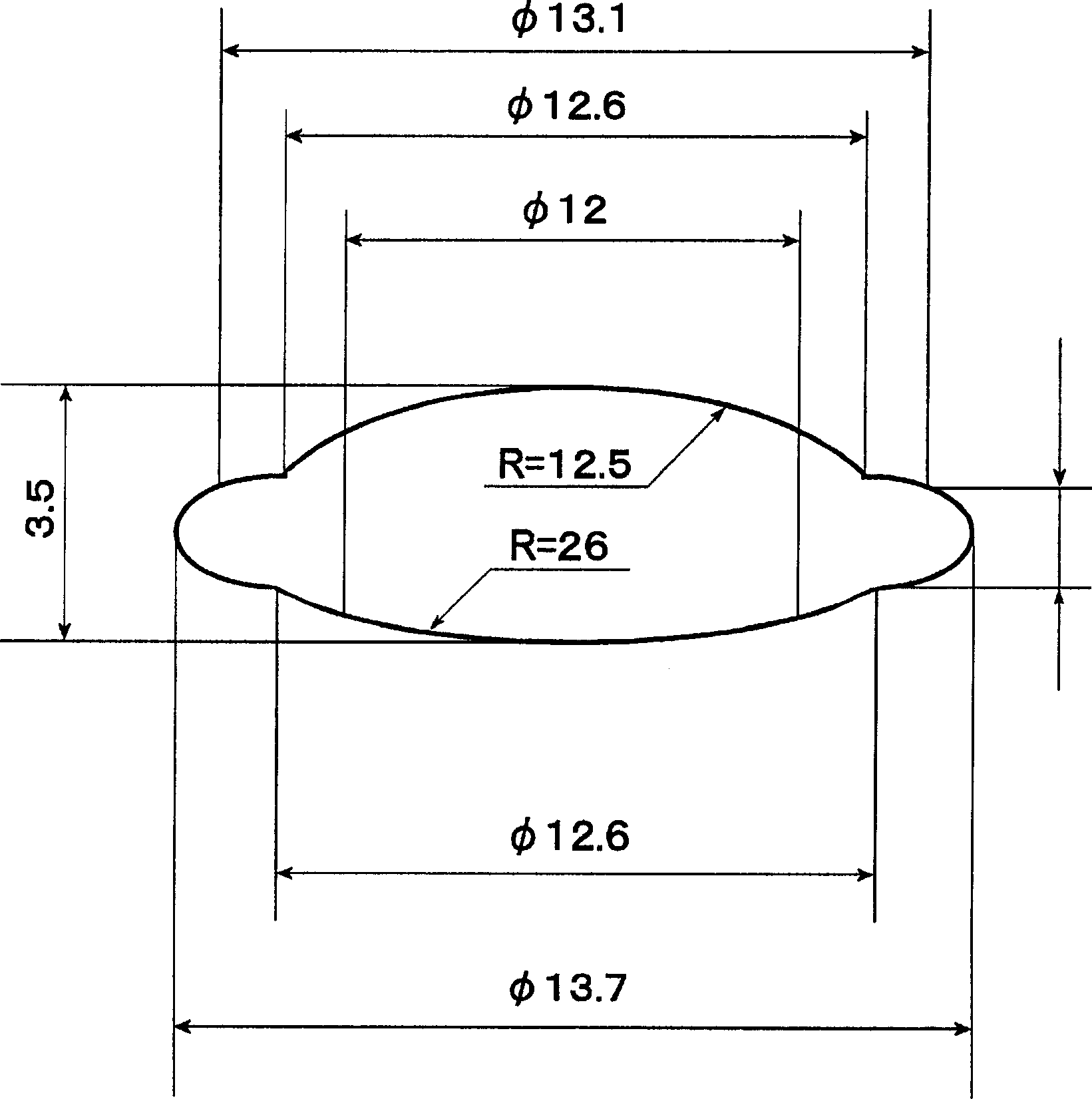

Method for mfg optical elements

ActiveCN1590326AImprove surface accuracyQuality improvementEdge grinding machinesGlass pressing apparatusEngineering

Owner:HOYA CORP

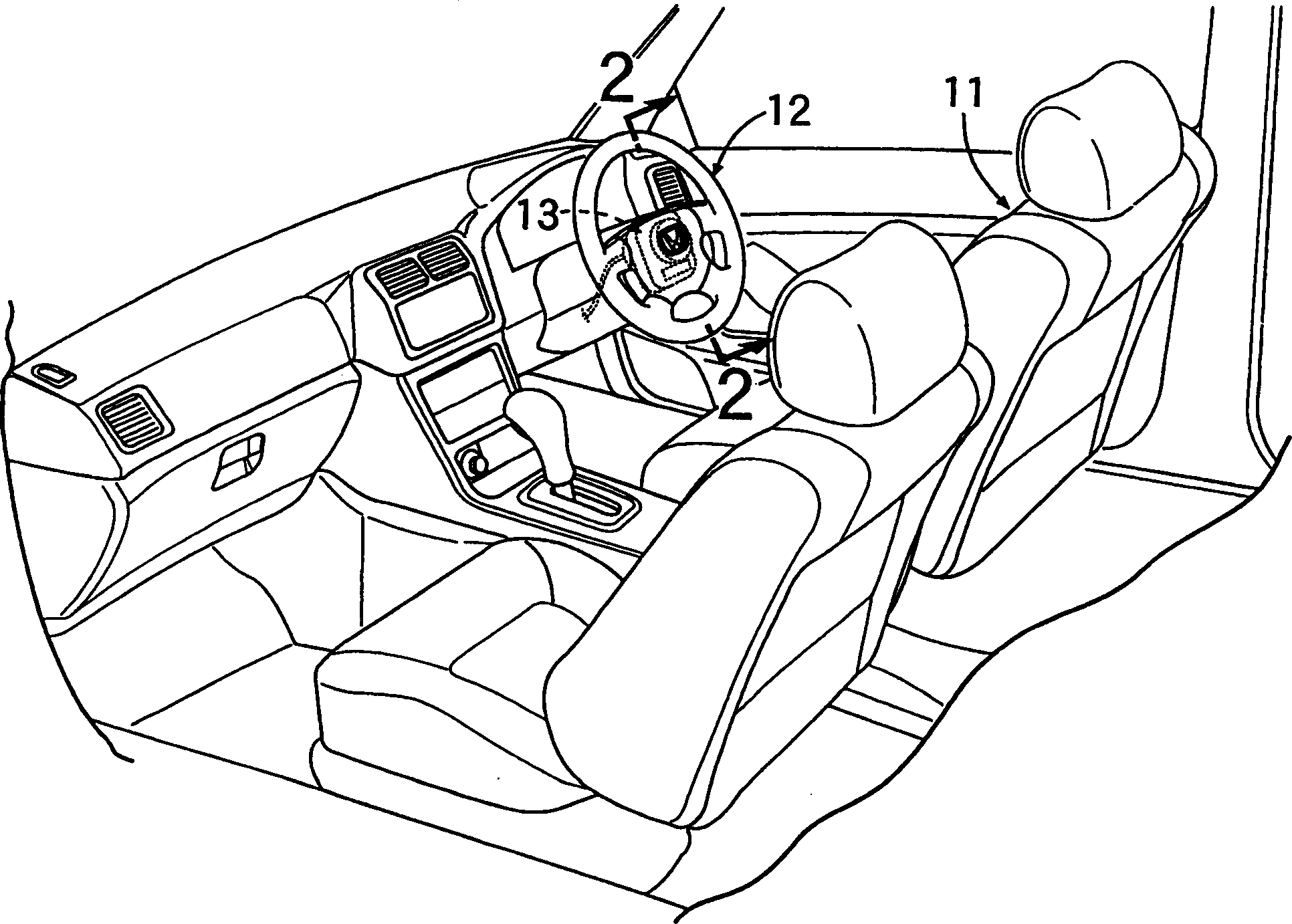

Air bag system

InactiveCN1537753AExpand quicklyPrevent leakagePedestrian/occupant safety arrangementElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

3D ultrasonographic device

InactiveCN101329307AQuick internal checkAccurate and correct internal inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic sensorSonification

A 3D ultrasonographic device includes: an ultrasonographic sensor having an ultrasonic transducer having a plurality of piezoelectric vibrators arranged in a matrix or array shape; a drive element selection unit for selecting an oscillation piezoelectric vibrator from the ultrasonic transducer; a signal detection circuit for receiving a reflection echo from a junction portion of an inspection object by the oscillated ultrasonic wave and detecting electric signal; a signal processing unit for processing the electric signal detected and correlating it to the mesh in the 3D image area of the inspection object, thereby generating 3D image data; and a display processing device for detecting the size / position of the molten hardened portion and the position / size of a welding defect portion from the intensity distribution of the 3D image date generated by the signal processing unit and displaying the detection result and the 3D image data from the signal processing unit.

Owner:KK TOSHIBA

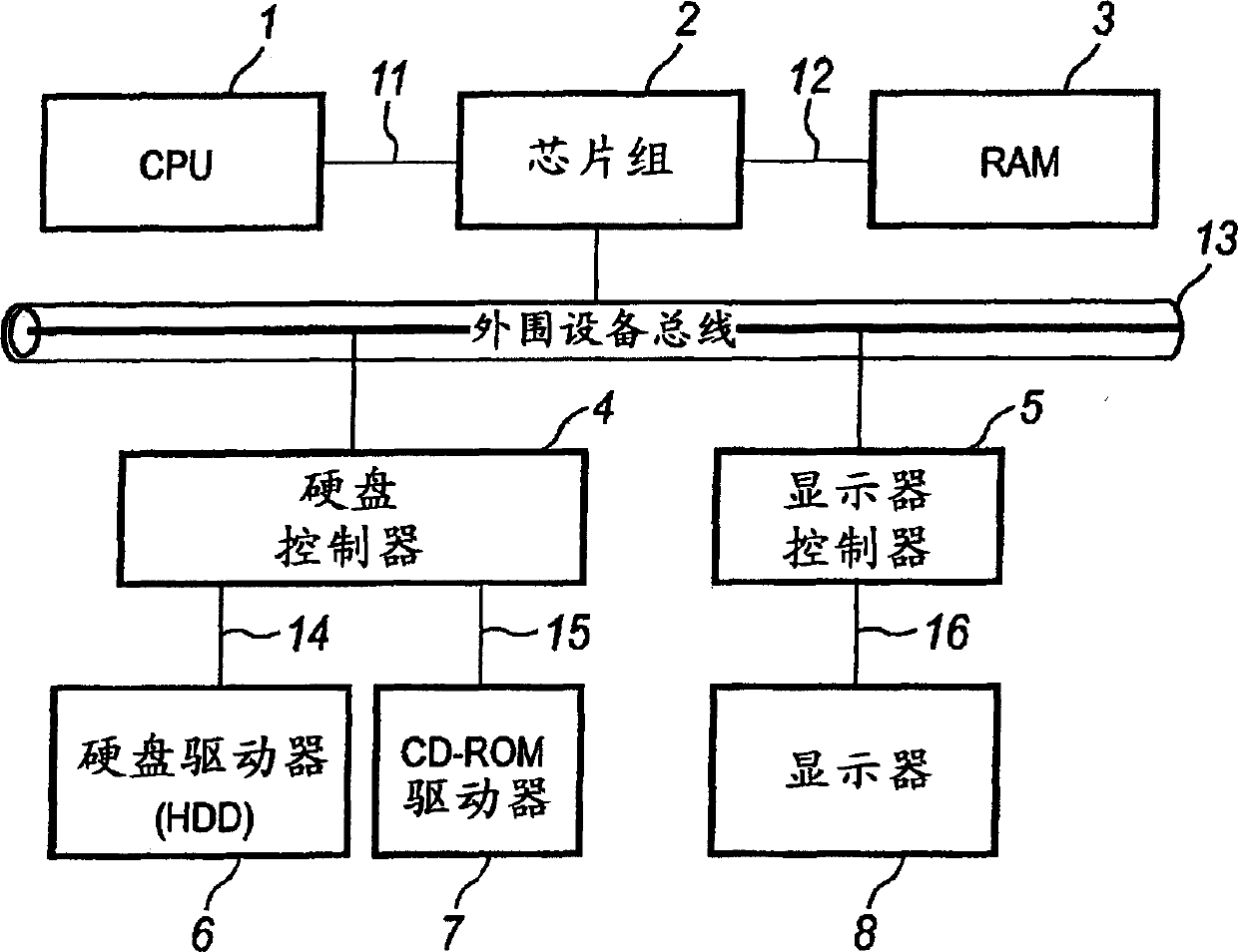

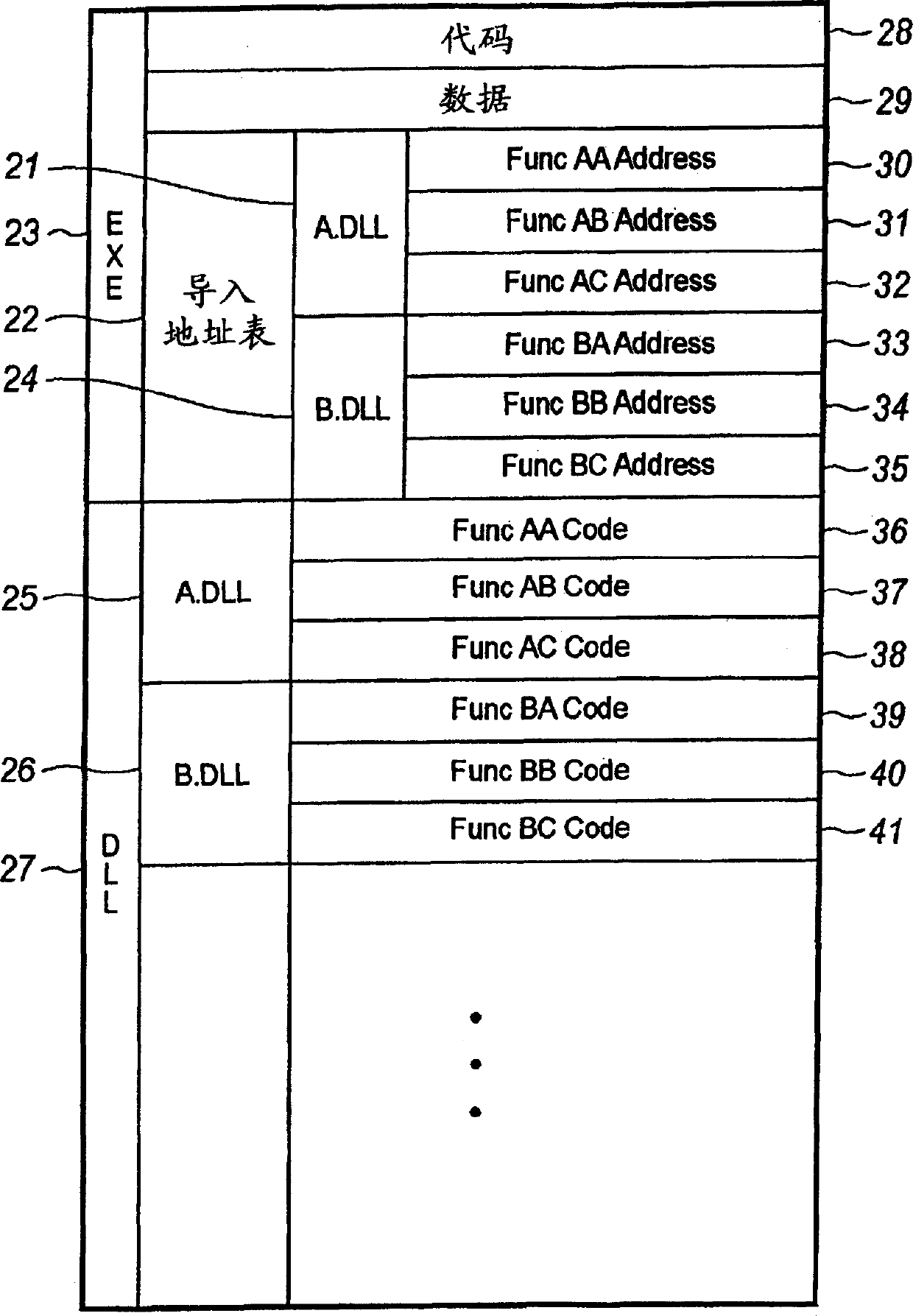

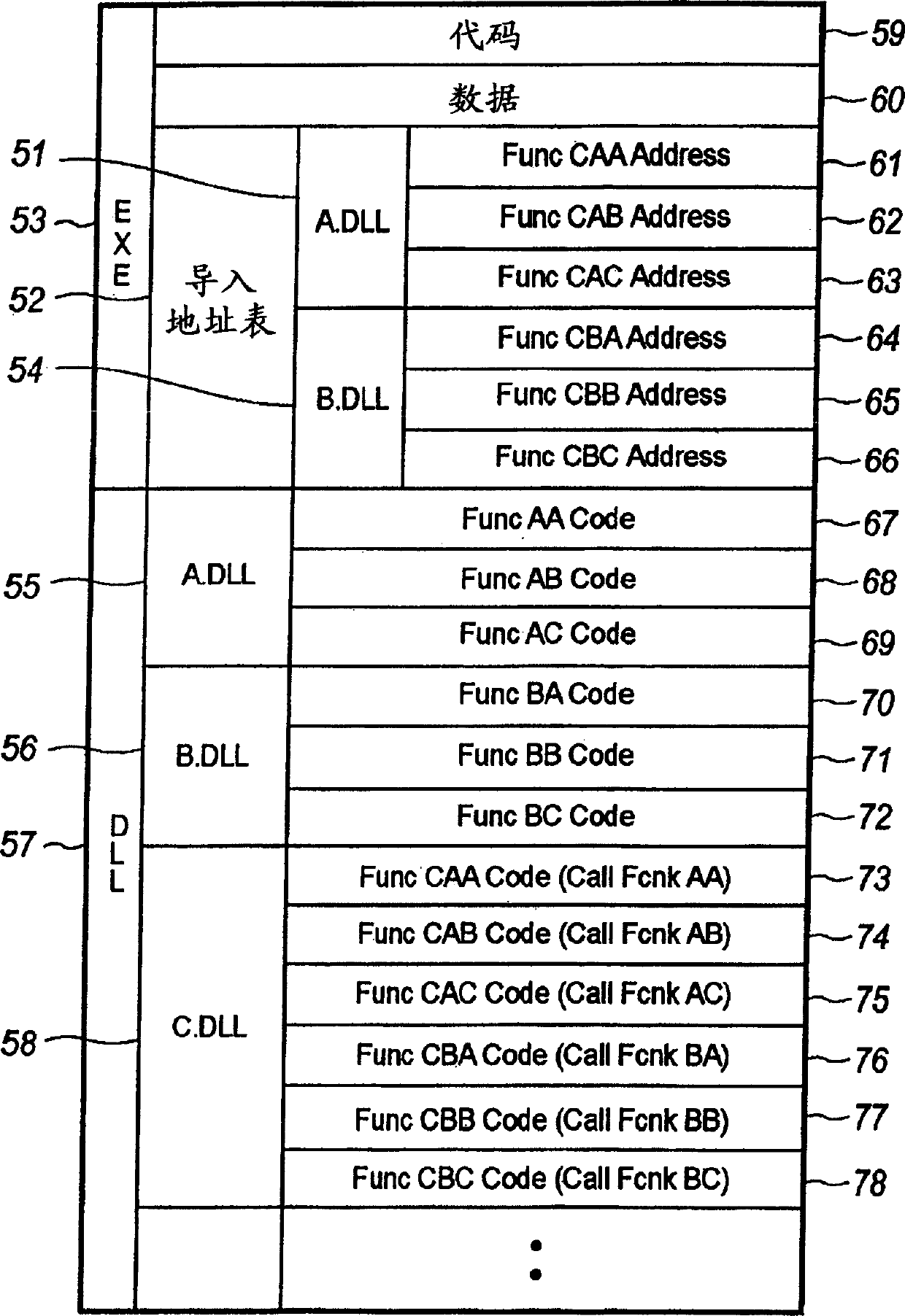

Journal obtaining method and controlling program and storage medium thereof

InactiveCN1534470AReduce working hoursError detection/correctionMultiprogramming arrangementsSoftwareComputer science

Owner:CANON KK

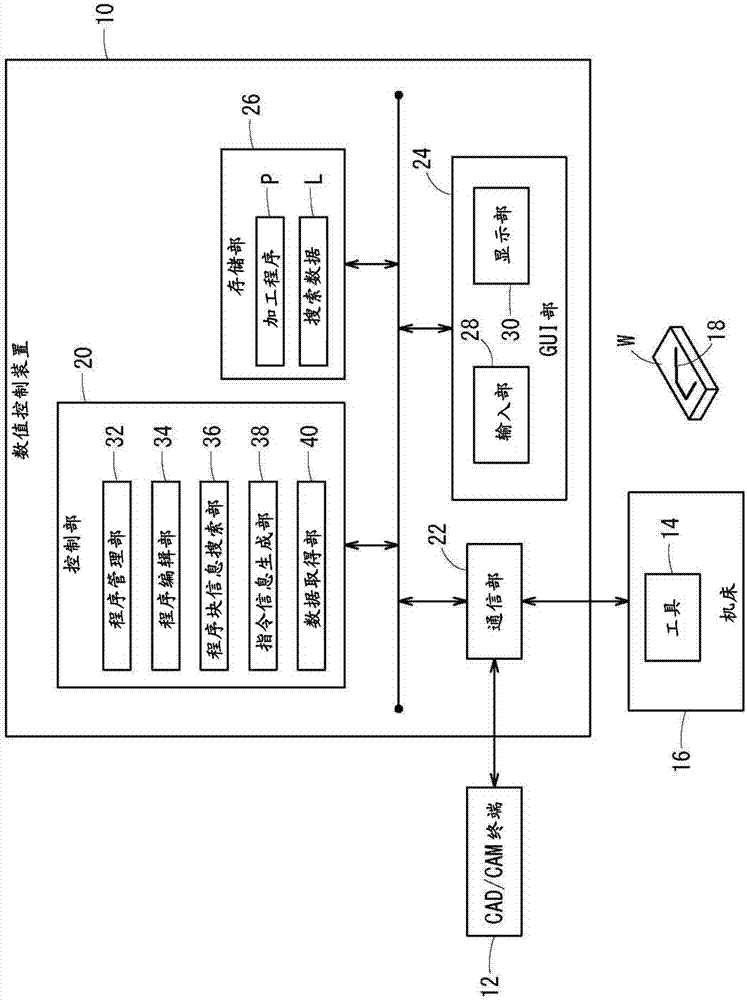

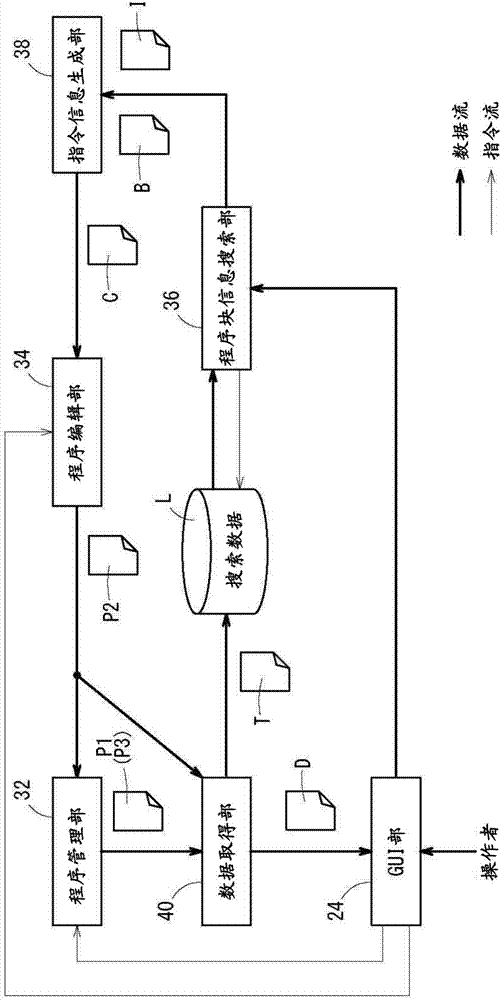

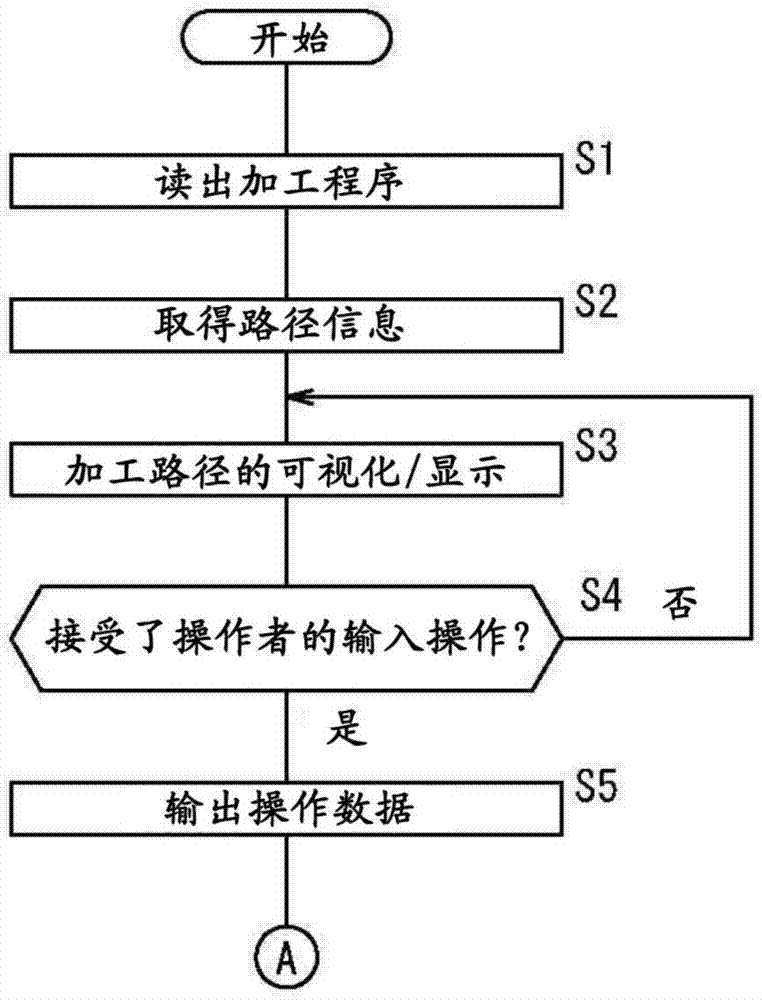

Machining program editing apparatus and method, and storage medium

ActiveCN107544437AReduce working hoursProgramme controlComputer controlComputer graphics (images)Computer science

The invention provides a machining program editing apparatus and method and a storage medium. The machining program editing apparatus (10) includes a GUI unit (24) configured to specify an indicationroute (70) having two points located on an original machining path (52), as a start point (66) and an end point (88), and a program editing unit (34) configured to edit a machining program (P)indicative of the original machining path (52) to thereby form a new machining path (84) by replacing an area from the start point (66) to the end point (68) on the original machining path(52), with the indication route (84) specified through the GUI unit (24).

Owner:FANUC LTD

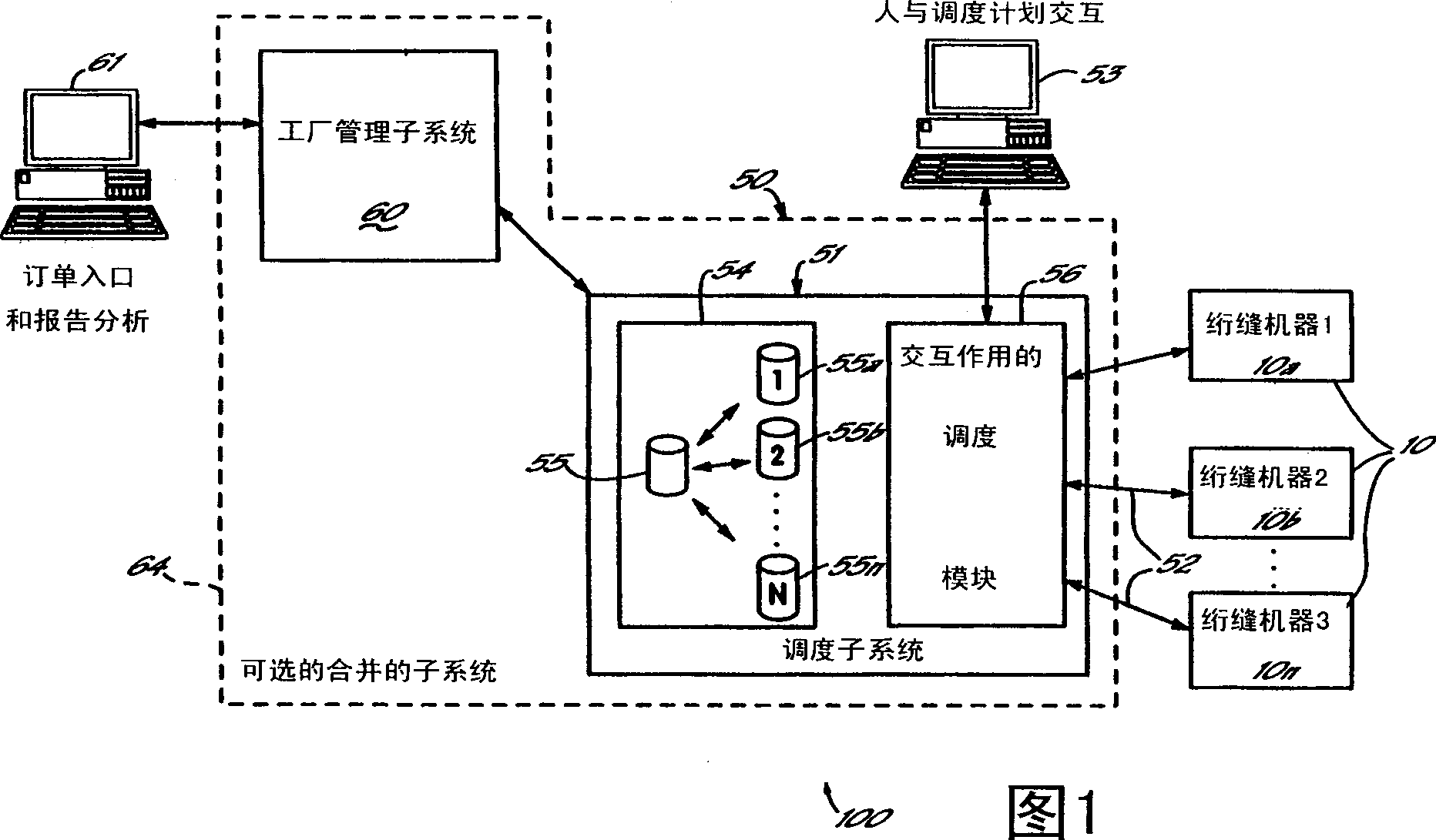

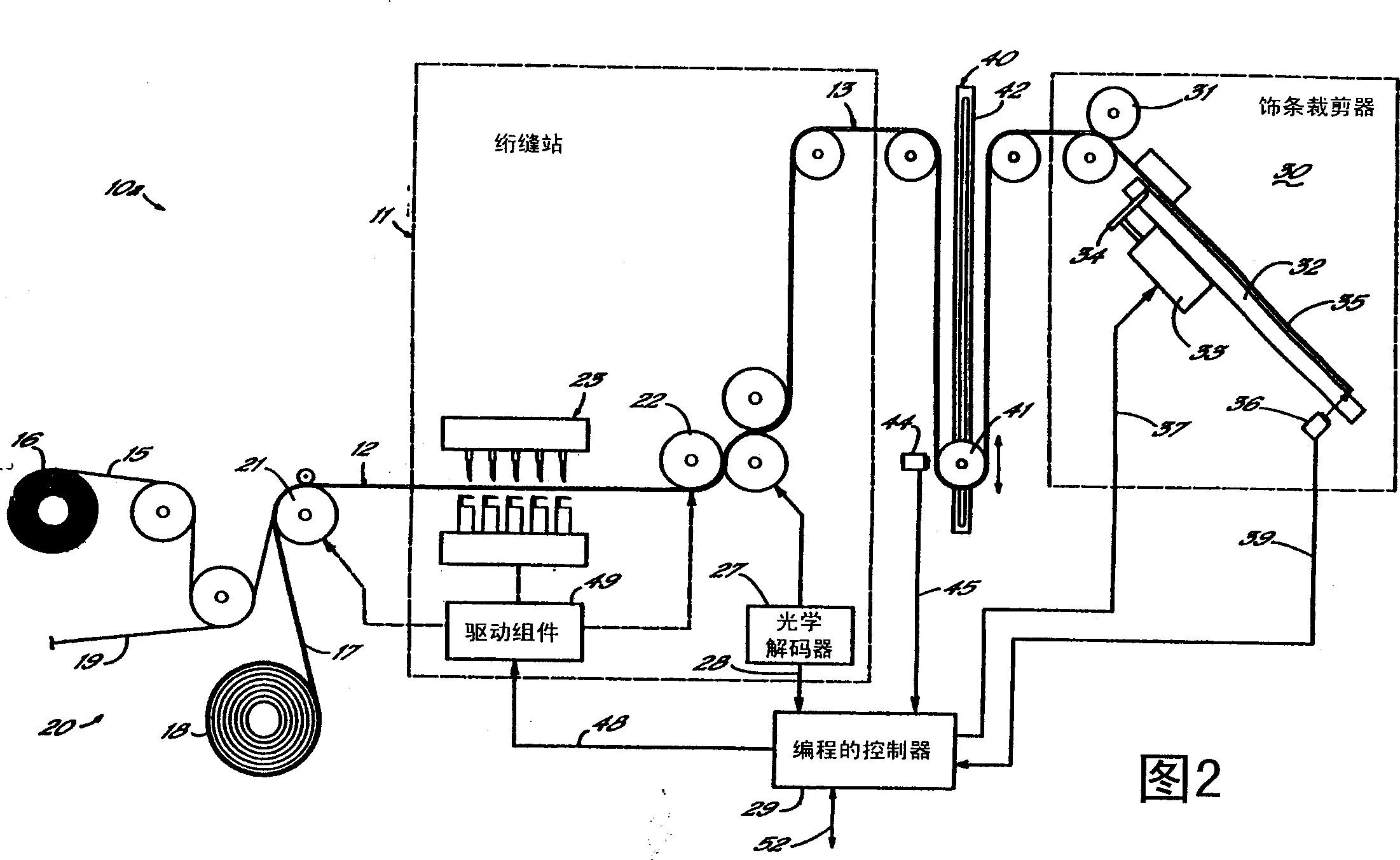

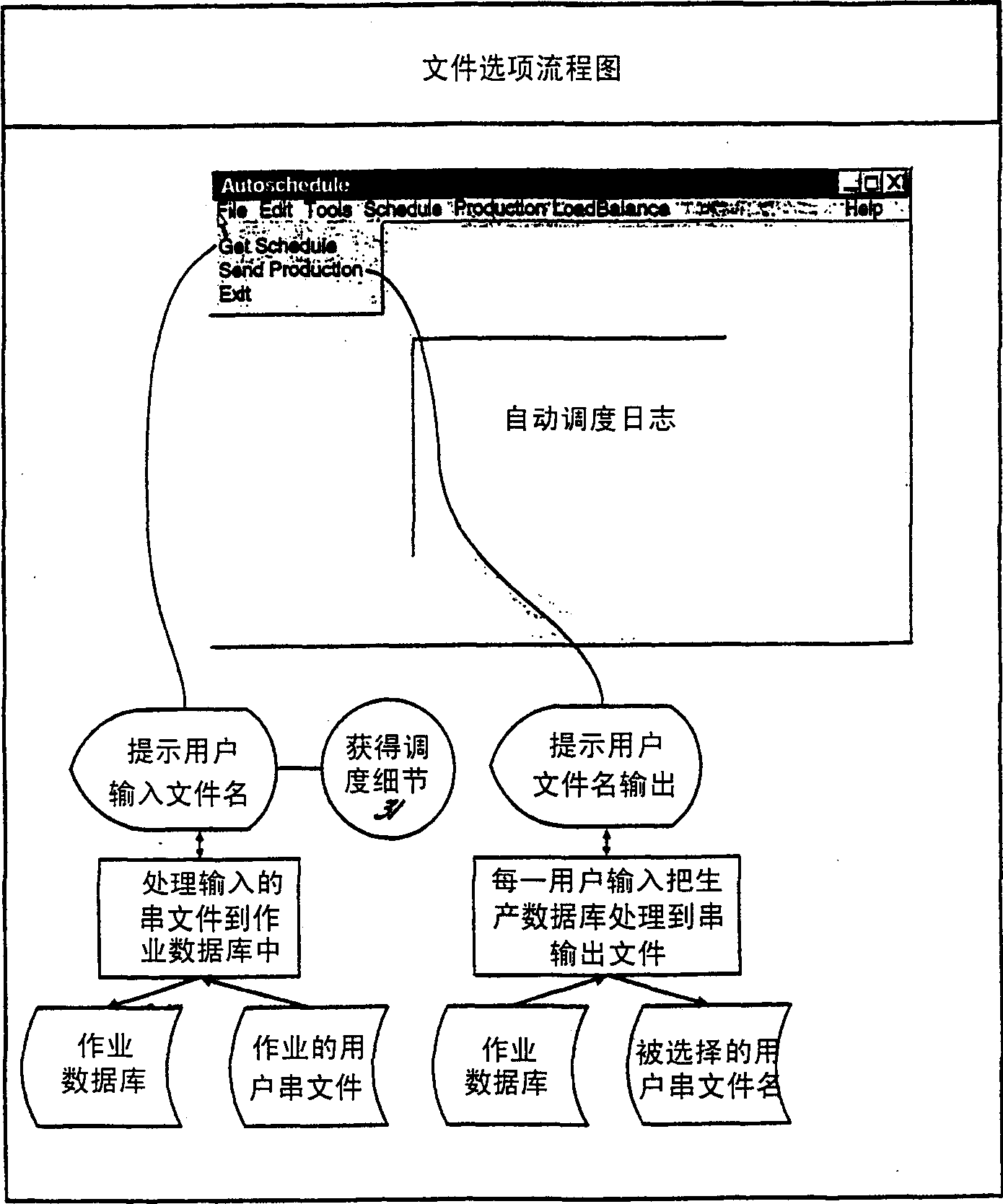

Quilt making automatic scheduling system and method

InactiveCN1341174AIncrease production capacityShorten the timeProgramme-controlled sewing machinesMattress sewingCompletion timeDowntime

A quilt manufacturing facility having a plurality of quilting machines is provided with an automated scheduling system which automatically generates and distributes schedules for the making of quilted products listed in input customer orders. The generated schedules are distributed in the form of computer files downloaded to the controllers of the machines. The generation of schedules is carried out by a programmed central scheduling computer which considers stored data identifying each of the machines and their capabilities, the materials available for production of the products and the product specifications, and determines the machine setting and material requirements for each product on the customer order list as well as the required completion times for each of the ordered products. Schedules for each machine are generated so as to schedule each product with other products having similar machine setting or material requirements in a manner that is consistent with the required completion or delivery times for each product. The scheduling optimizes the use of the quilting machines and operator time by reducing the number of machine setups and material changes. Information is collected from each machine which records all downtime of the machines and the reasons therefor and which records a history of the actual performance of the machines for use by the scheduling computer in more accurately evaluating future schedules.

Owner:L & P PROPERTY MANAGEMENT CO

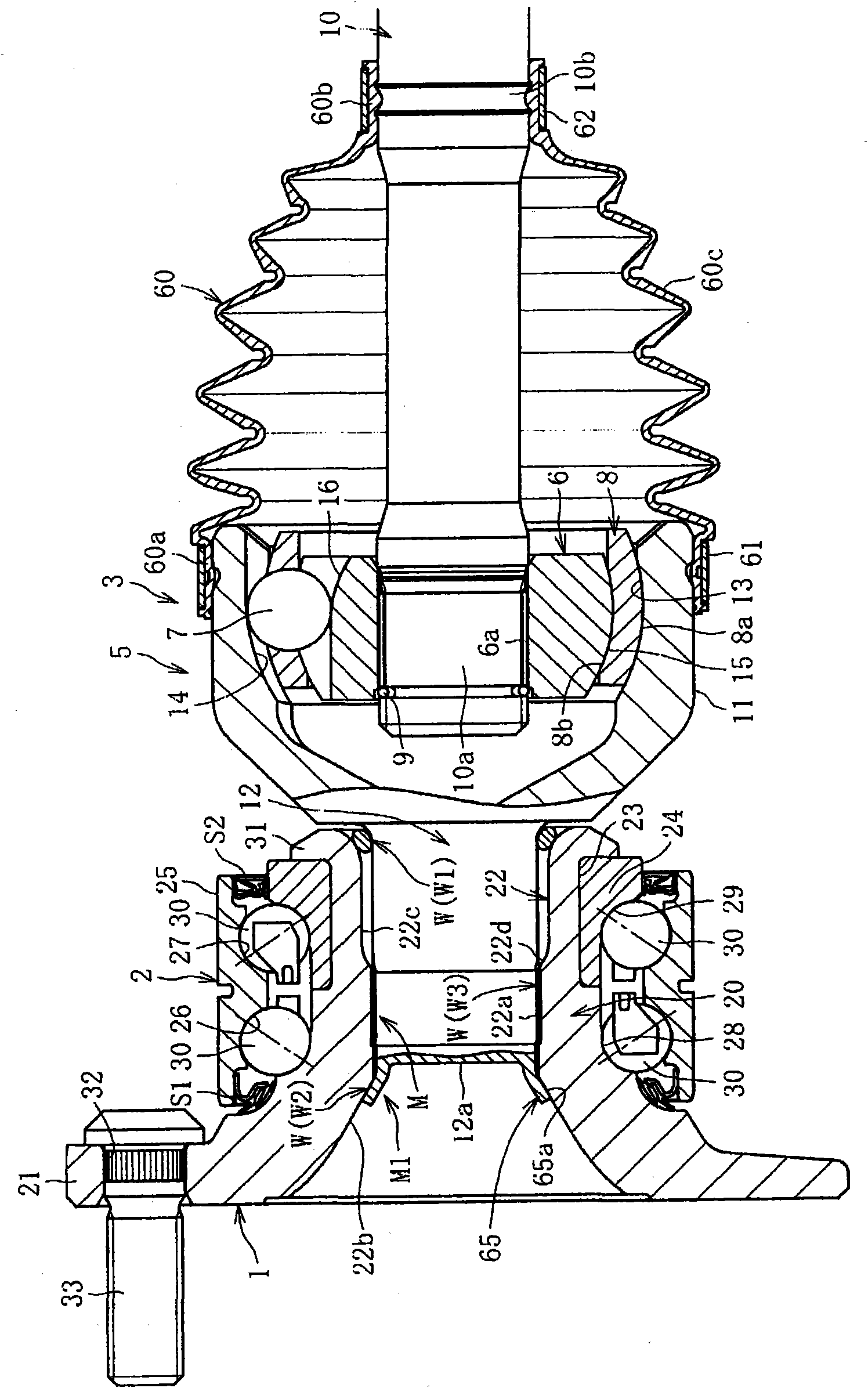

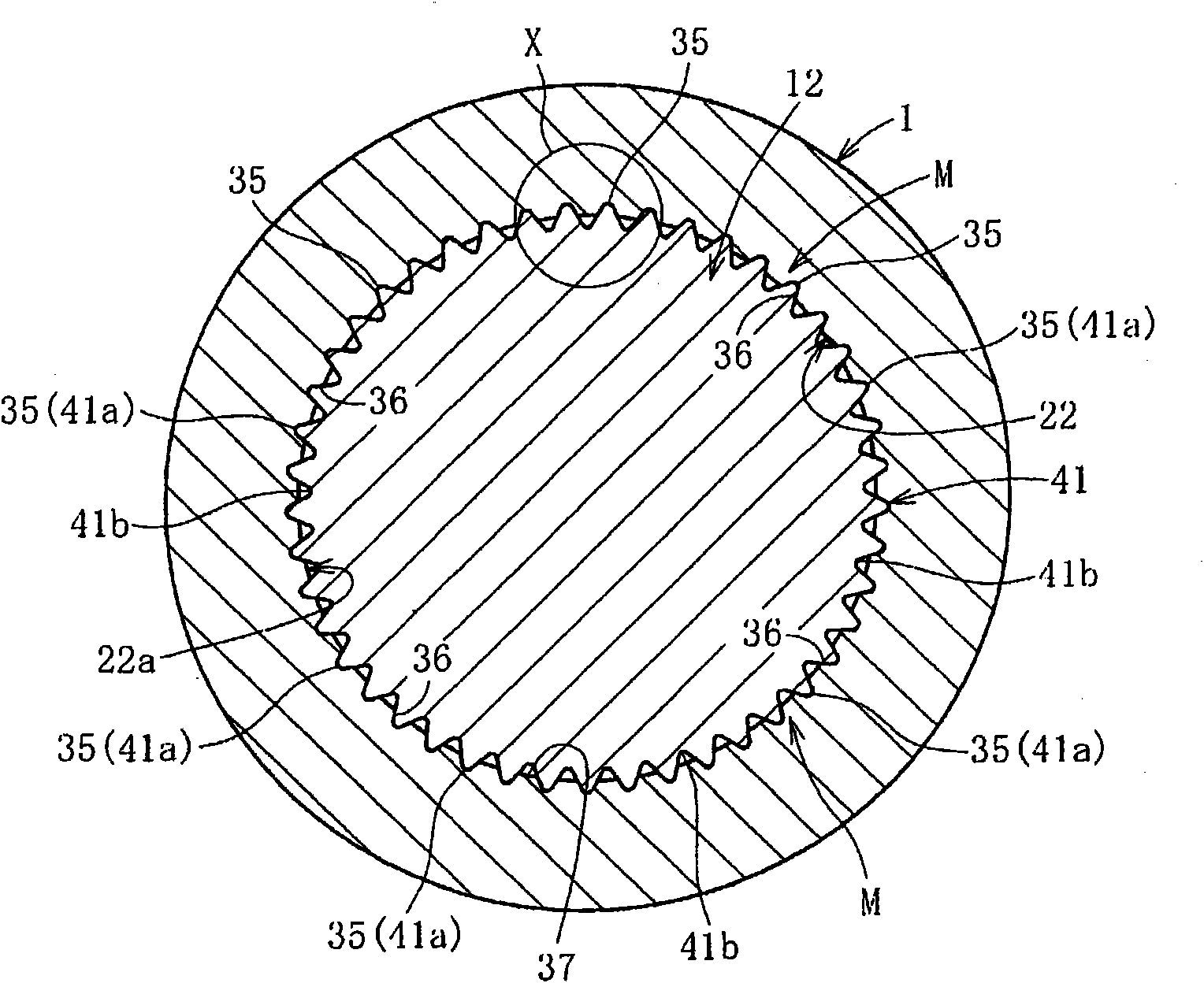

Bearing device for wheel, and axle module

Provided are a bearing device for a wheel, in which circumferential play is reduced, which provides excellent workability in connection between a hub ring and an outer joint member of a constant velocity universal joint, in which fitting between the hub ring and the outer joint member of the constant velocity universal joint is stable, and which has excellent strength, and an axle module using the bearing device. An axially extending projection is formed on either of the outer diameter surface of a shaft section of the outer joint member and the inner diameter surface of a hole of the hub ring. The projection is press-fitted to the other in the axial direction to form a recess in the other by the press-fitting. By this, a recess / projection fit structure is formed, in which the entire regions of those portions of the projection and the recess at which they are fitted to each other are in intimate contact with each other. The hardness of at least that portion of the projection at which the press-fit starts is higher than that of a portion where the recess is formed. The difference in hardness in HRC is 20 or more.

Owner:NTN CORP

Concrete beam formwork support

InactiveCN101413344AChange the force characteristicsSave materialForms/shuttering/falseworksConcrete beamsEngineering

The invention provides a concrete beam formwork support, relates to the engineering of concrete beam formworks, and adopts a cantilever type support to solve the problems of complex bolt-through beams and components, difficult size adjustment and working hour waste in the prior beam formwork support. The support consists of two supporting arms, a pull rod, a wedged plate and a pressure lever, wherein the supporting arms comprise two rod welding plates, the pressure lever is supported on the lower ends of the supporting arms, the pull rod pulls the two supporting arms at a lower rim position of a beam bottom formwork, and the wedged plate is used for connecting and fastening the pull rod and the supporting arms. A force couple formed by inner forces of the pull rod and the pressure lever balances bending moment of the supporting arms to simplify supporting components, therefore, the support achieves the assumption of adjusting working width and height of the beam formwork support flexibly and conveniently according to different sizes of concrete beams, and can be applied to formwork engineering of non-as-cast finish and as-cast finish concrete beams. Because of simplified structure of the support and wedge connection, the support has the advantages that the support expands application range, improves turnover ratio and working quality, and saves materials and working hours.

Owner:胡彦彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com