Inner-decoration component for automobile and method for the production thereof

A technology for automotive interiors and manufacturing methods, applied to vehicle parts, household components, applications, etc., can solve problems such as time-consuming work, restricted design freedom, unoptimized working environment, etc., and achieve improved appearance , The effect of improving position accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Hereinafter, preferred embodiments of the automotive interior component and its manufacturing method according to the present invention will be described in detail with reference to the drawings. In addition, it should be noted that the gist of the present invention is described in the claims, and the contents of the embodiments described below are merely examples of the present invention.

[0102] 【Example】

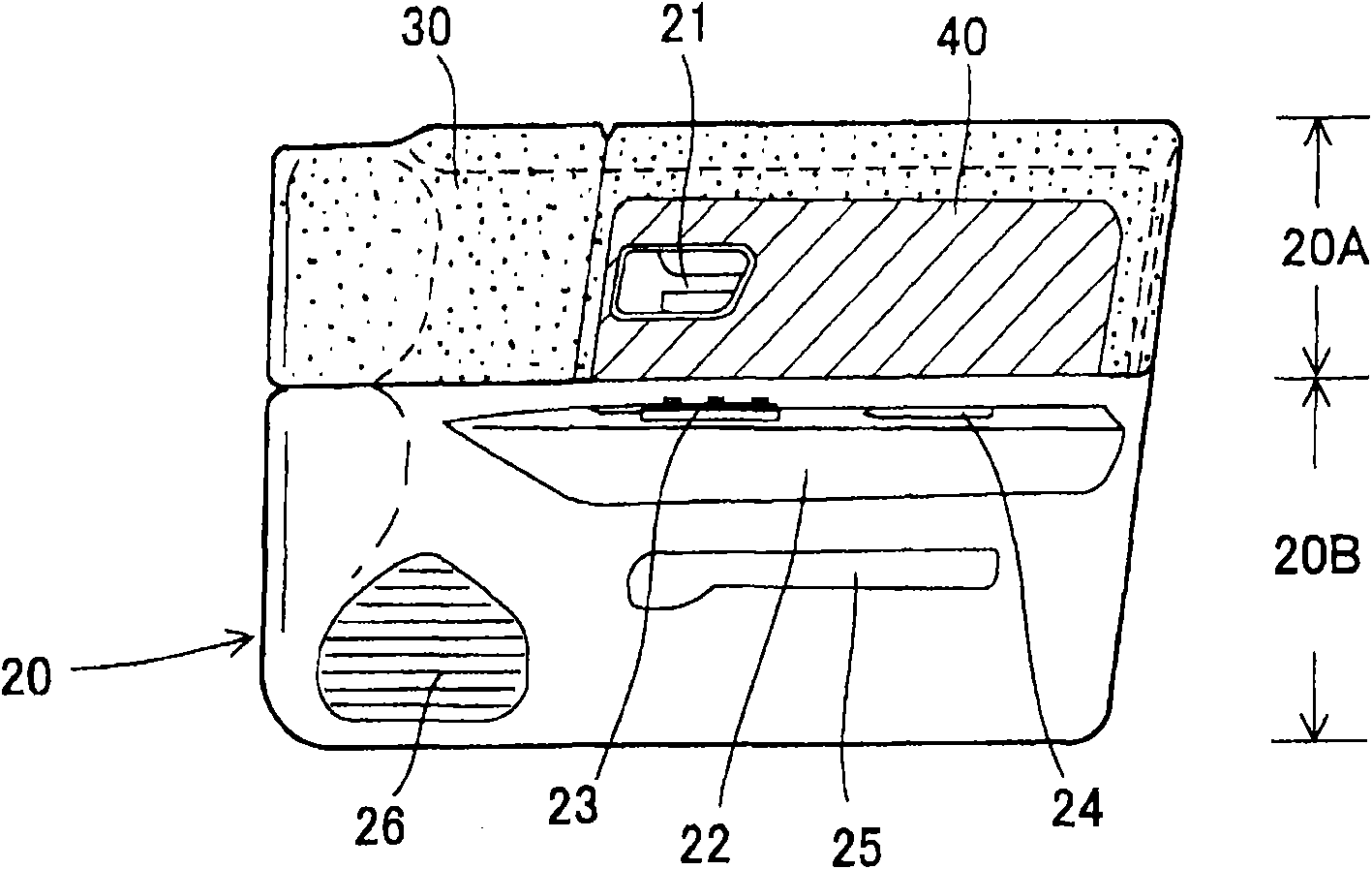

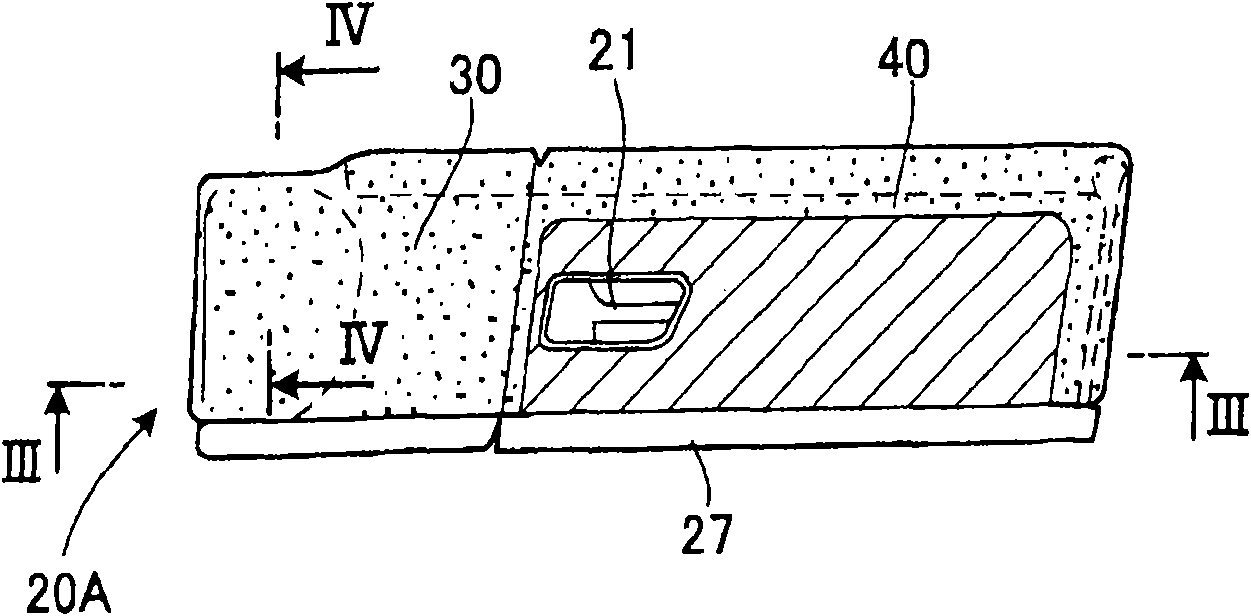

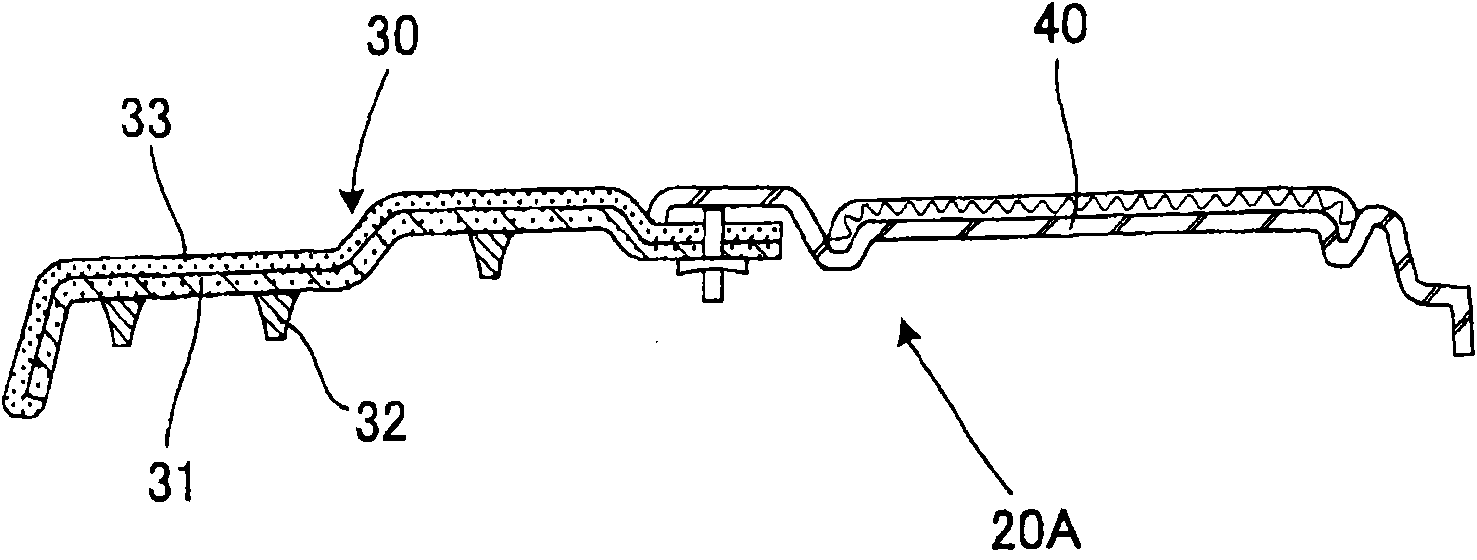

[0103] Figure 1 to Figure 20 It is a figure which shows an Example of this invention. figure 1 It is a front view showing a door trim for a car, figure 2 It is a front view showing the upper part of the door decoration of the door decoration, image 3 is a sectional view showing the structure of the upper part of the door decoration, Figure 4 It is a cross-sectional view showing the structure of the door decoration upper part-front part of the door decoration upper part, Figure 5 It is an overall view showing the structure of the molding die used in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com