System for processing base plate conveyance and method

A processing system and processing method technology, applied in the field of substrate transportation systems, can solve the problems of limited substrate processing efficiency, such as limited pick-and-place efficiency, inability to effectively improve, etc., and achieve the effects of shortening key time, reducing working time, and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly illustrate the spirit of the present invention with drawings and detailed descriptions. Anyone with ordinary knowledge in the technical field can change and modify the technology taught by the present invention after understanding the preferred embodiments of the present invention. without departing from the spirit and scope of the present invention.

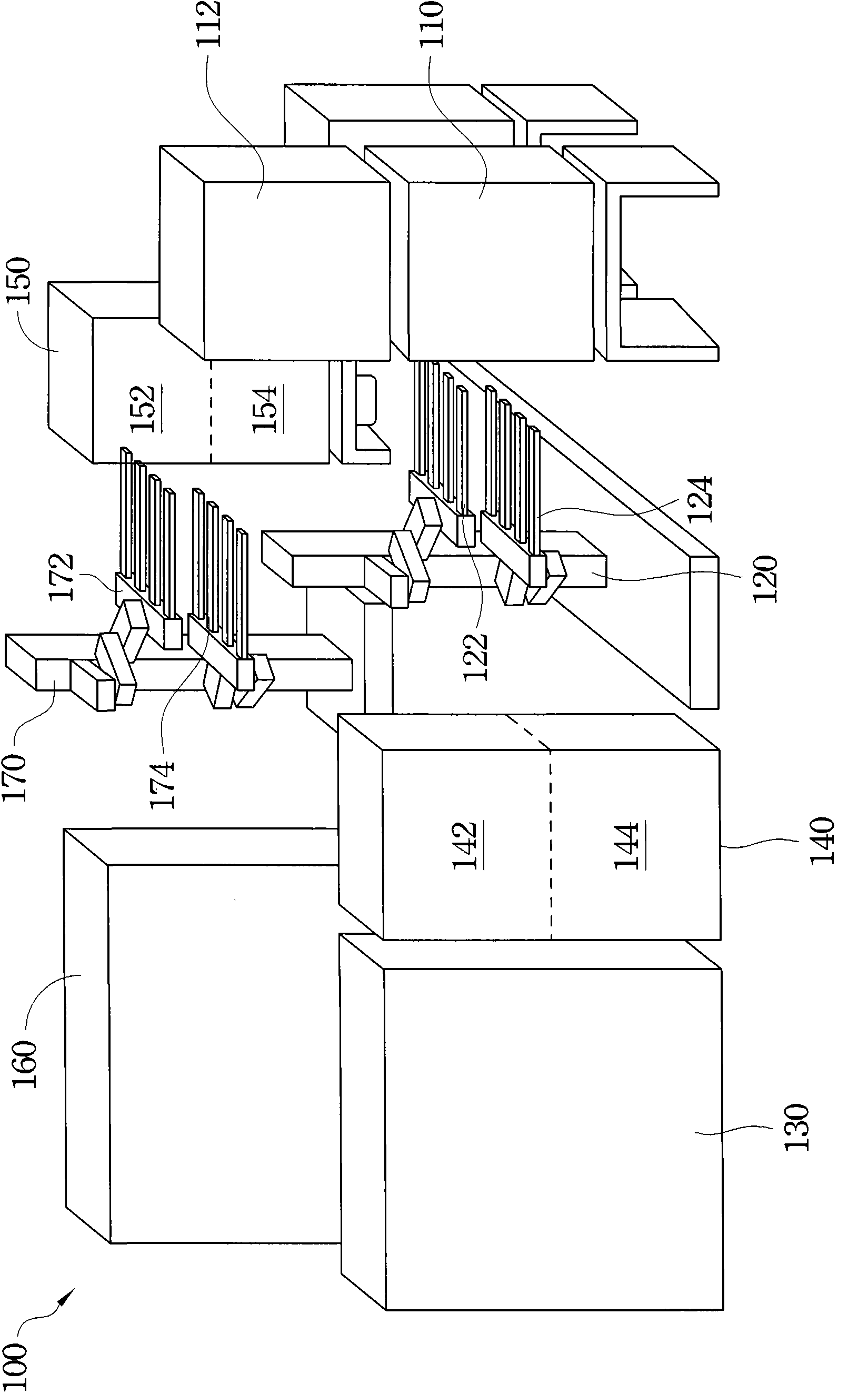

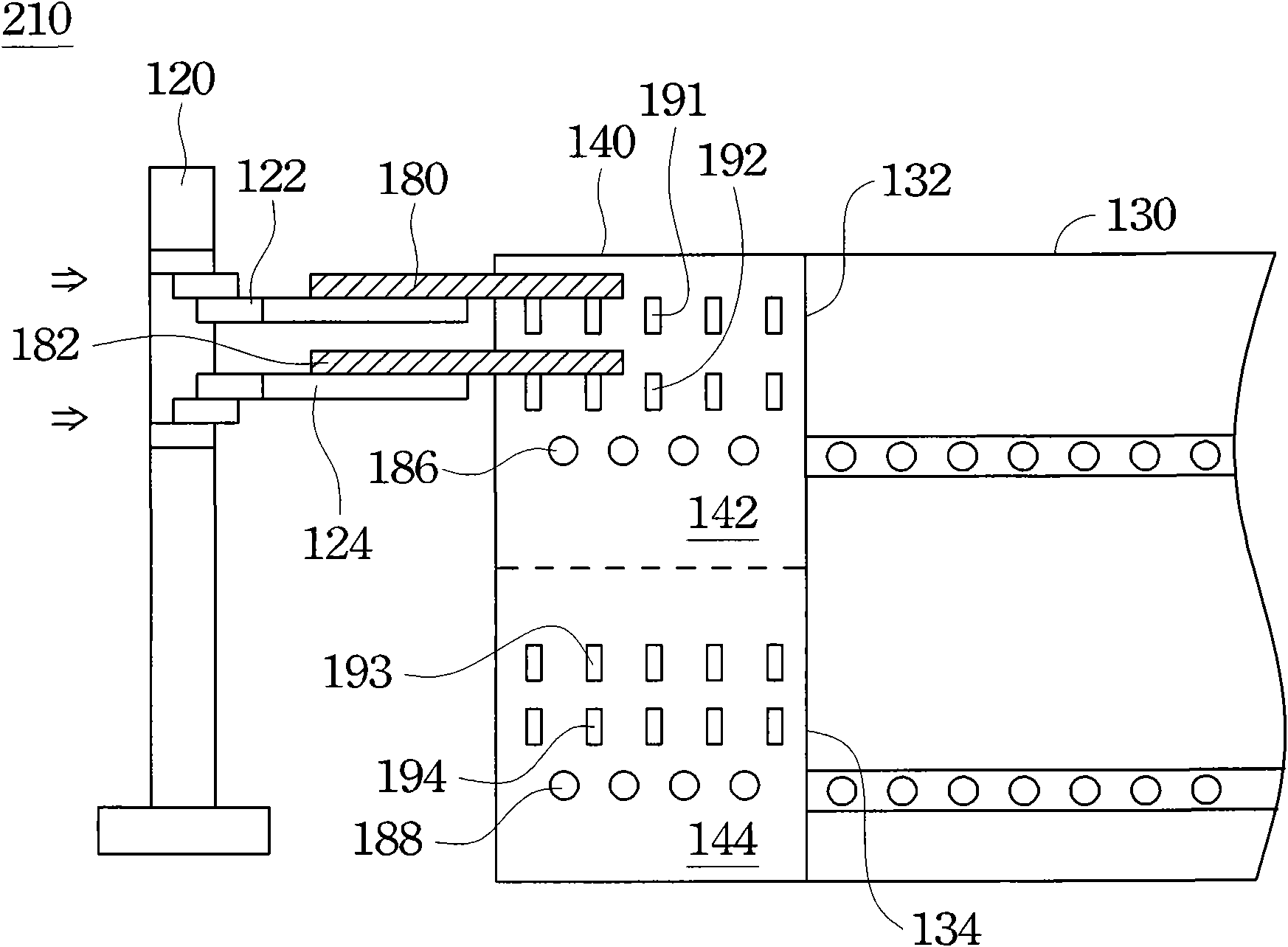

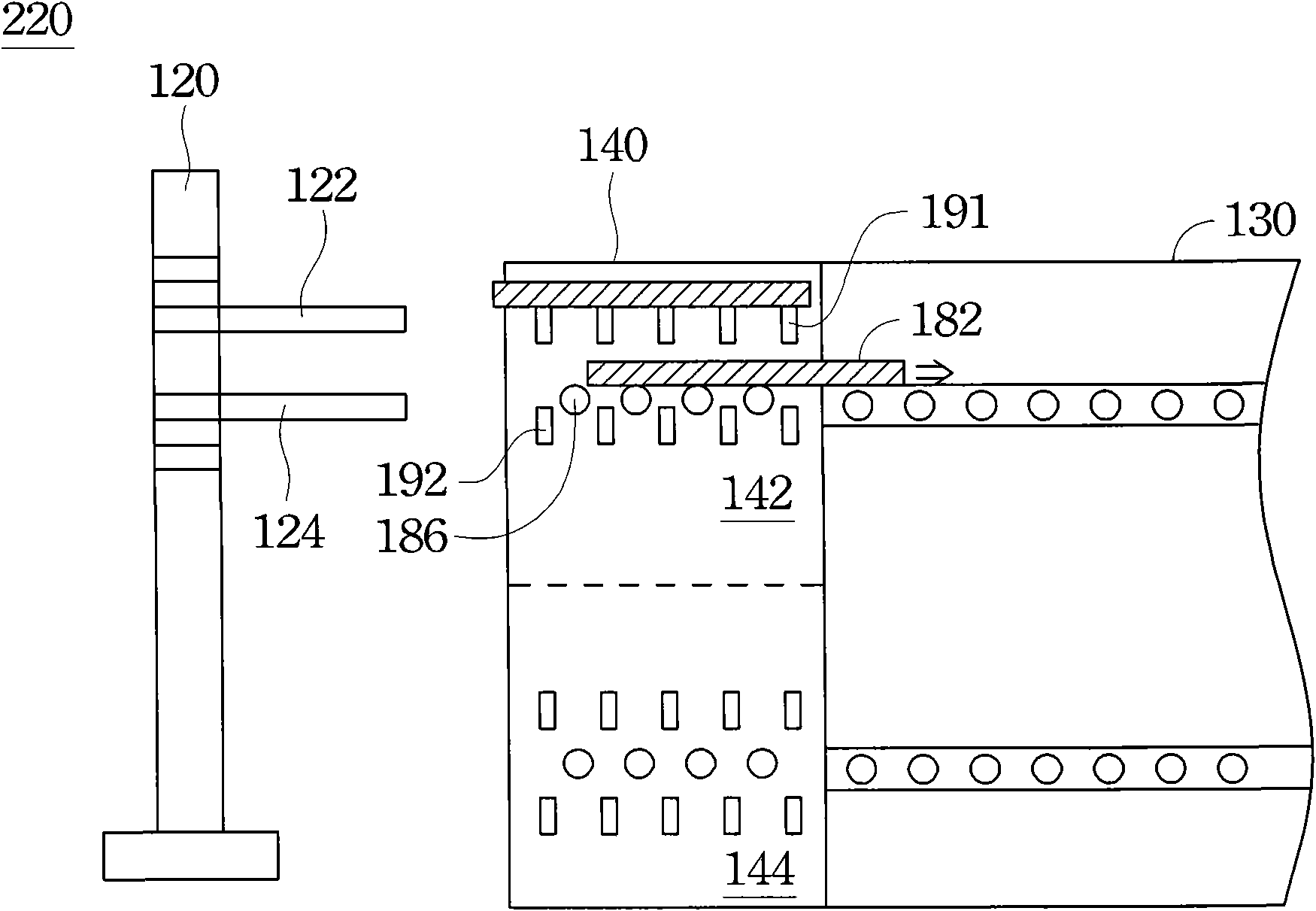

[0033] refer to figure 1 , which shows a schematic diagram of an embodiment of the substrate transportation and processing system of the present invention. The substrate transport processing system 100 includes at least one substrate accommodating cassette 110 and 112, a first robotic arm 120, a substrate cleaning machine 130, a temporary storage machine 140, a rotatable temporary storage machine 150, a A substrate processing machine 160 and a second robotic arm 170 .

[0034] The substrate receiving cassettes 110 and 112 are used to place a plurality of substrates. A plurality of protrusions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com