Quilt making automatic scheduling system and method

A technology for manufacturing systems and scheduling subsystems, applied in sewing machines for quilting, program-controlled sewing machines, textiles and papermaking, etc., can solve problems such as failure to achieve work efficiency, and achieve the effect of increasing productivity and eliminating sources of errors and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] best practice

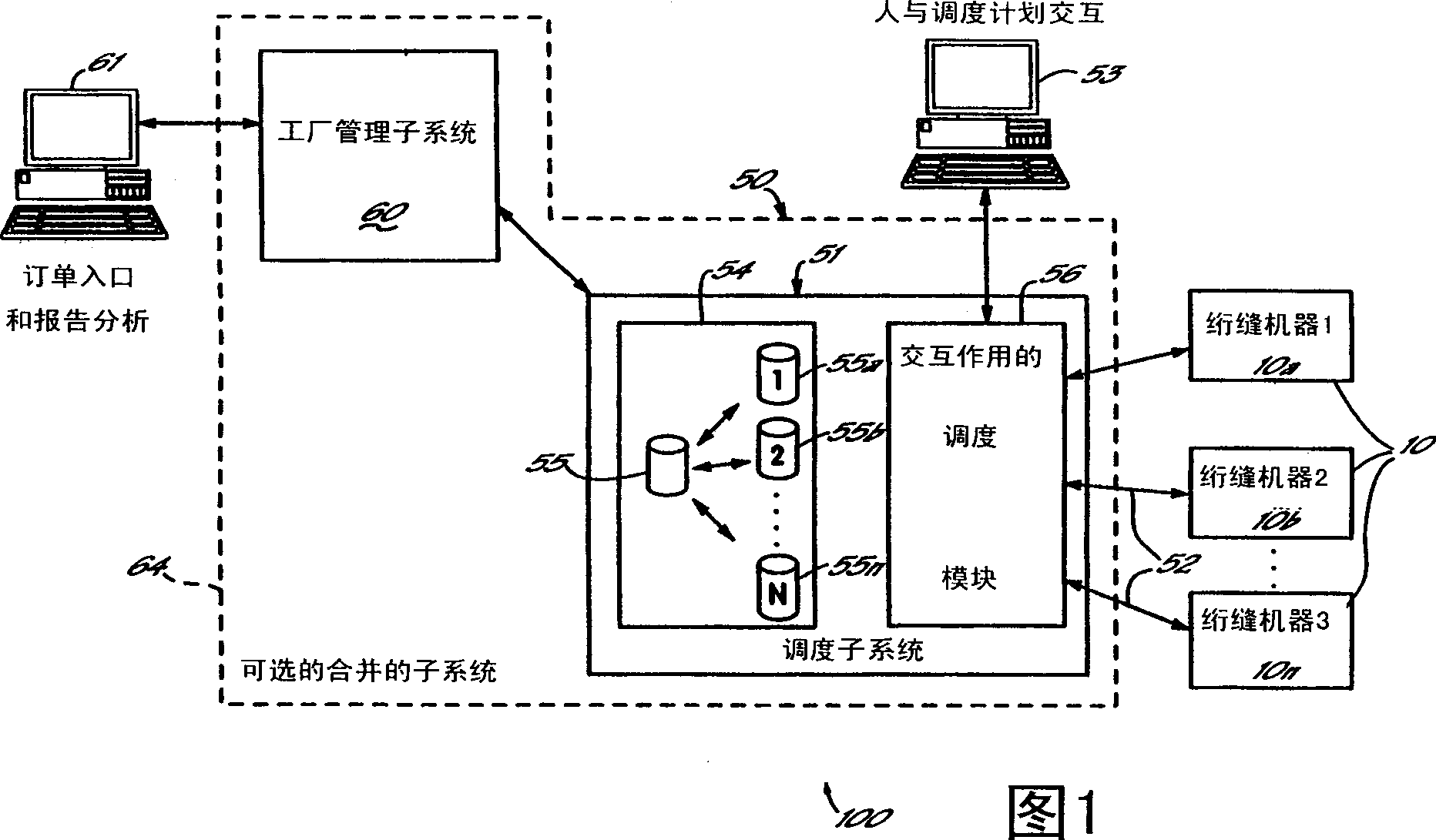

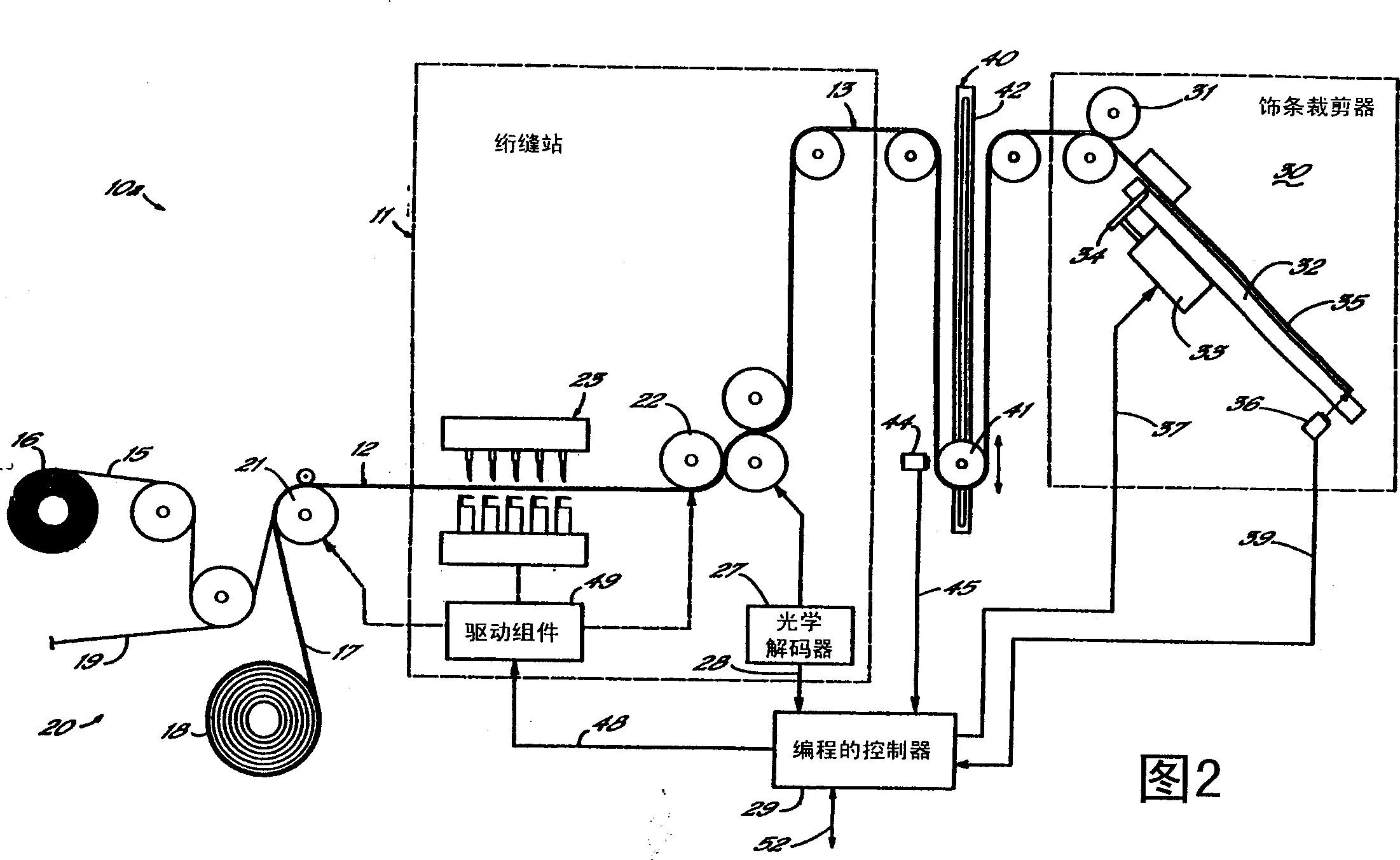

[0025] Figure 1 is a diagram of a plant 100 such as a quilt manufacturing plant comprising a plurality of quilting machines 10, which may be of various types 10n, but which preferably have a programmable controller A quilting machine 10a, 10b of the multi-needle type, the programmable controller is capable of automatically operating the machine to produce various assortments or series of assortments, such as mattress covers of different sizes and types. Quilting machines of this type include, for example, the Paragon 4 modelmachine manufactured by Gribetz international Corporation of Sunrise, Florida (Sunrise Gribetz International Company of Florida). The other quilting machine is that of model 4300,3. One quilting machine 10a of the plurality of quilting machines included in the preferred embodiment of the present invention is diagrammatically illustrated in FIG. Compensating Programmable Quilter and Molding Cutting System) is described in more detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com