Electric motor

A motor and insulating resin technology, applied in electric components, electrical components, electromechanical devices, etc., can solve problems such as insulation damage, and achieve the effects of high insulation endurance, reduced usage, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

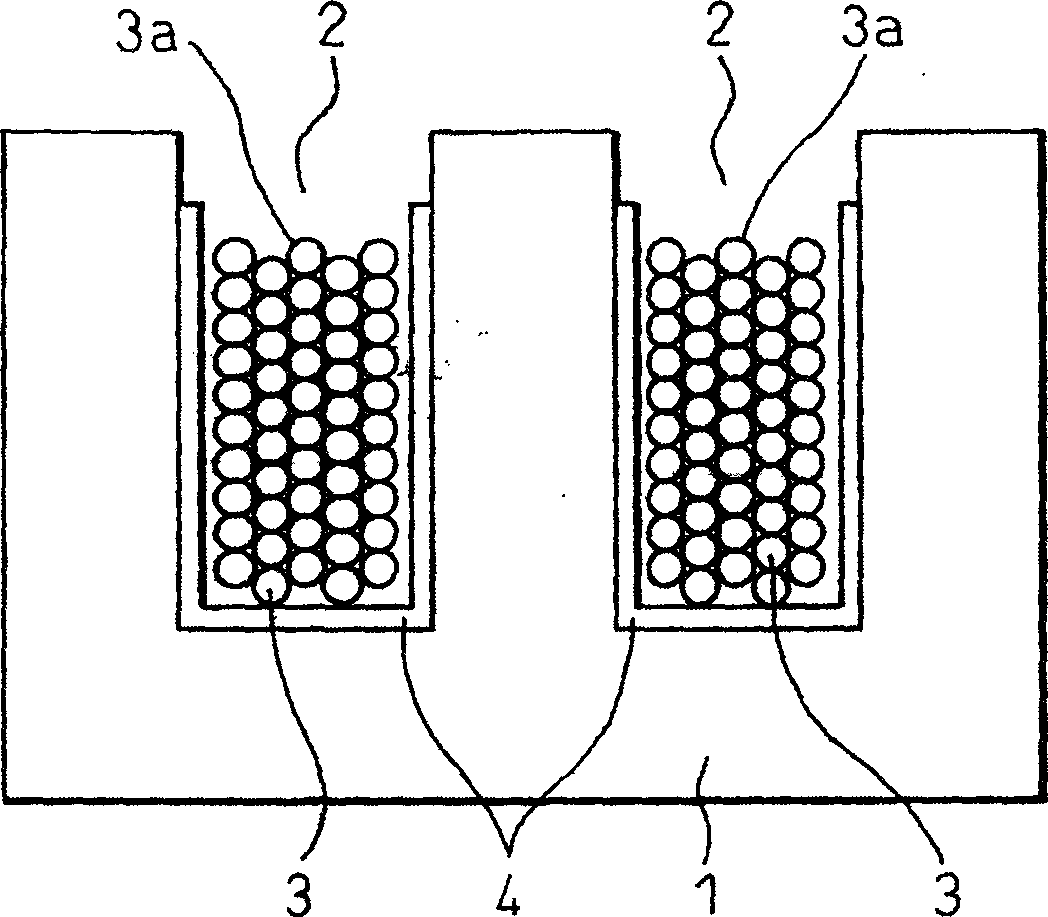

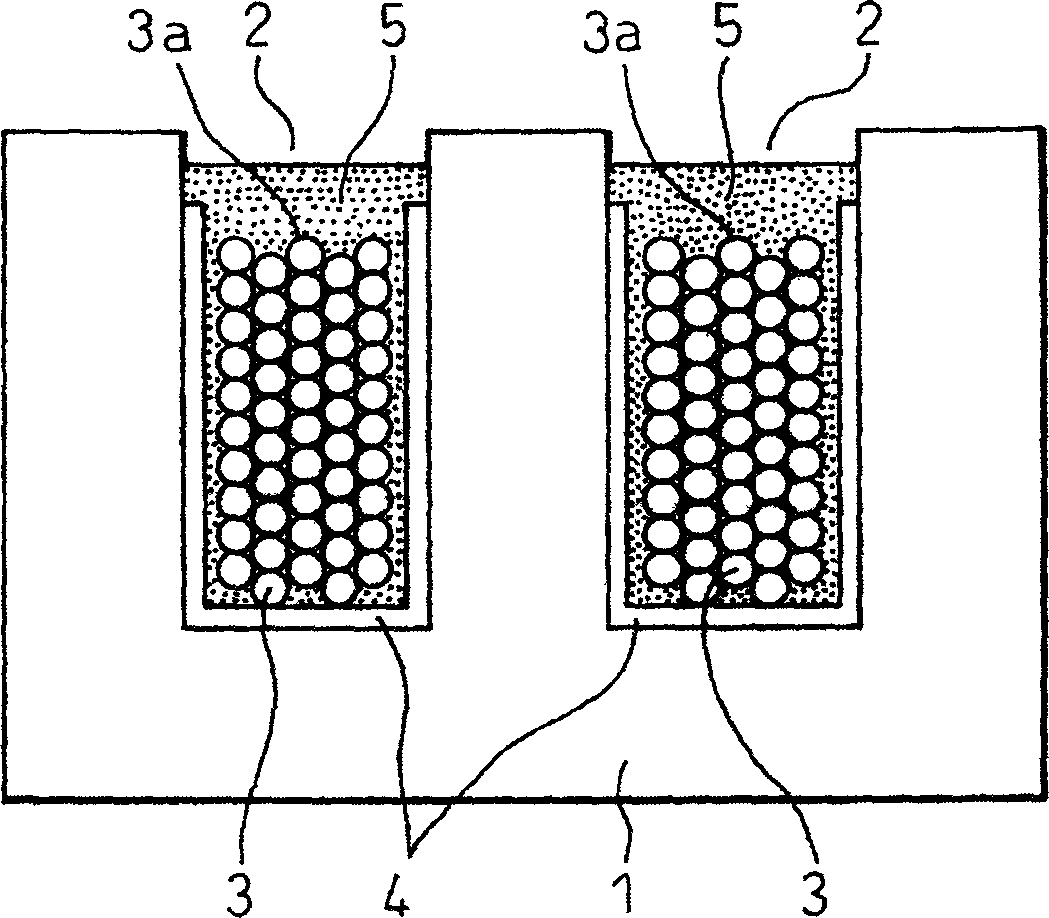

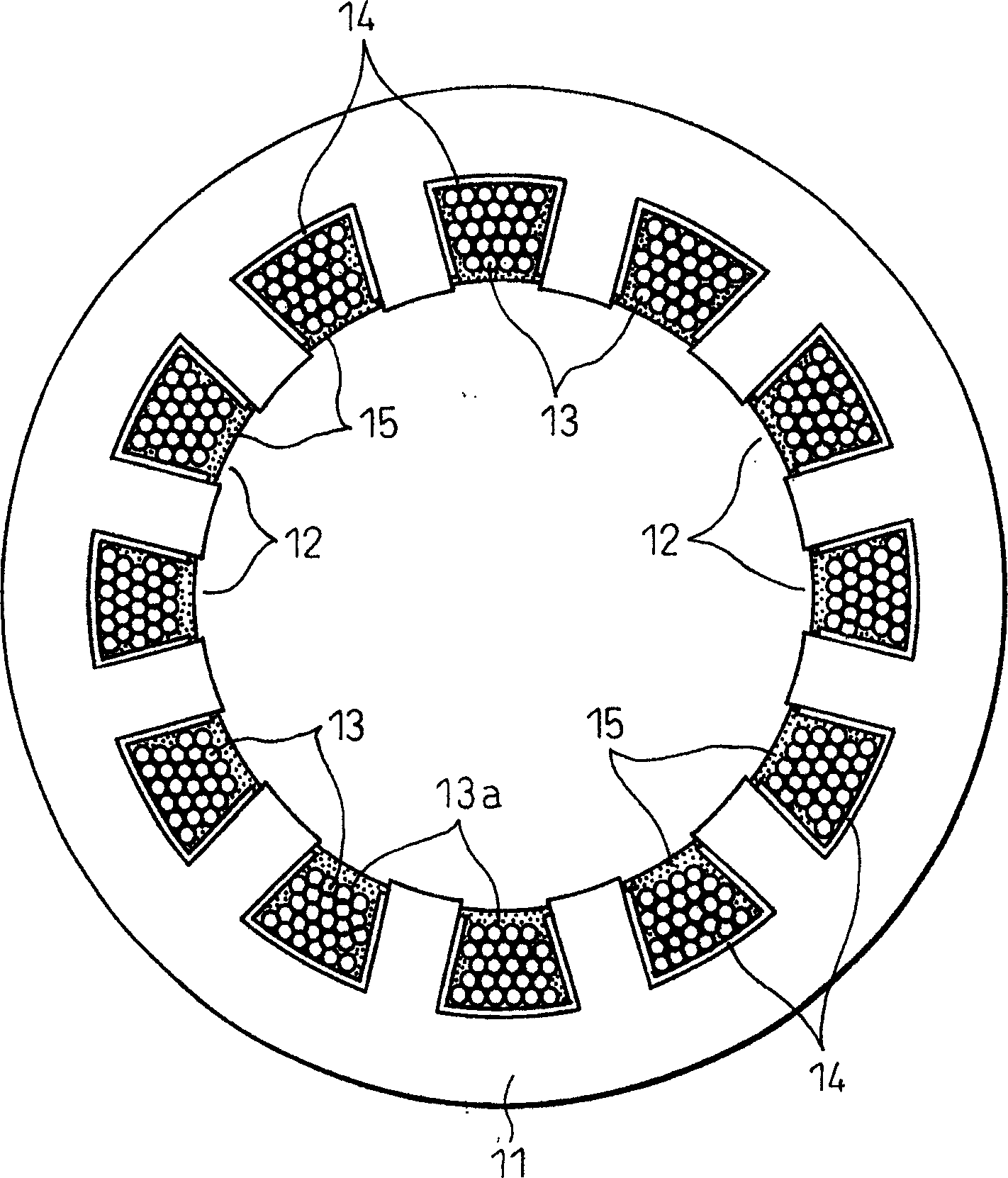

[0019] Figure 1a and Figure 1b It is an explanatory diagram of main parts of the first embodiment in which the present invention is applied to a linear motor. Figure 1a Indicates the state before molding with insulating resin, Figure 1b It shows the state after molding with insulating resin. Reference numeral 1 denotes a stator core, and reference numeral 2 denotes slots provided on the stator core 1 . In addition, reference numeral 3 represents a coil, and reference numeral 4 represents insulating paper. Additionally, for image 3 and Figure 4 The same components in the shown prior art examples are given the same symbols.

[0020] In each slot 2 of the stator core 1, the opening side of the slot 2 is reserved, and the coil 3 covered with the insulating paper 4 arranged along the inner surface shape of the slot is inserted into the slot 2 to form Figure 1a status shown in . Such as Figure 1b As shown, the coil 3 is not covered with insulating paper 4 on the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com