Tubular lipstick plastic shell assembling machine

A technology of molded case group and assembly machine, which is applied in the field of assembly machines, can solve the problems of reducing industrial competitiveness, excessive manpower and working hours, and relying on manual operations, so as to improve industrial competitiveness, reduce labor and working hours, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

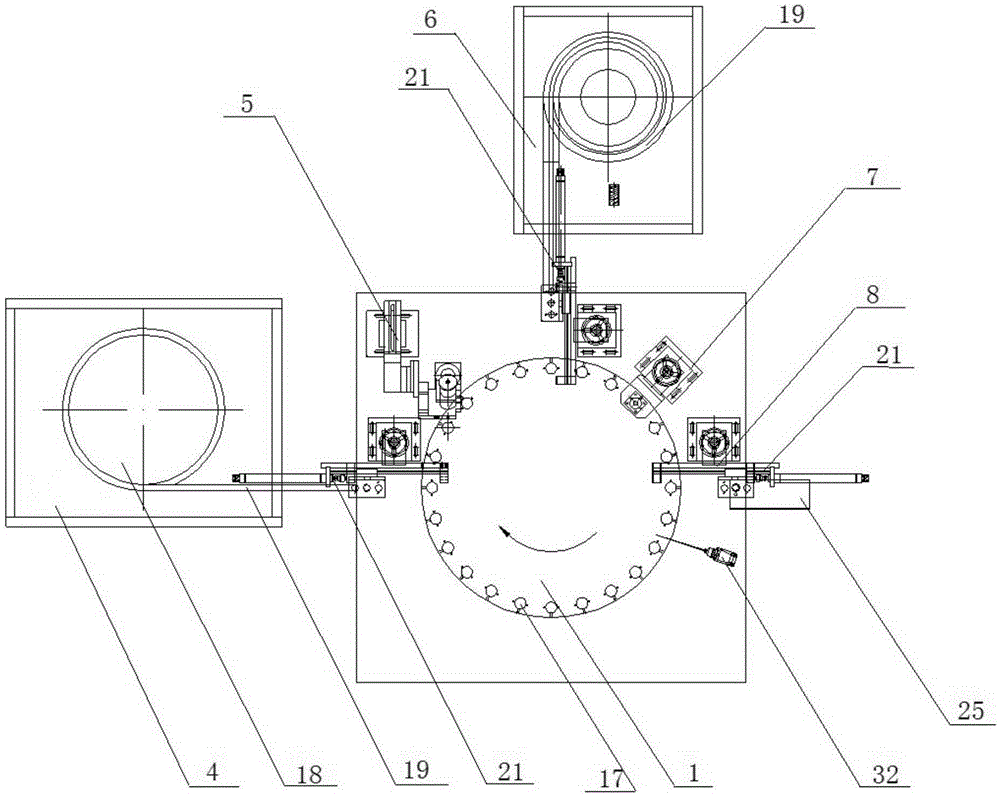

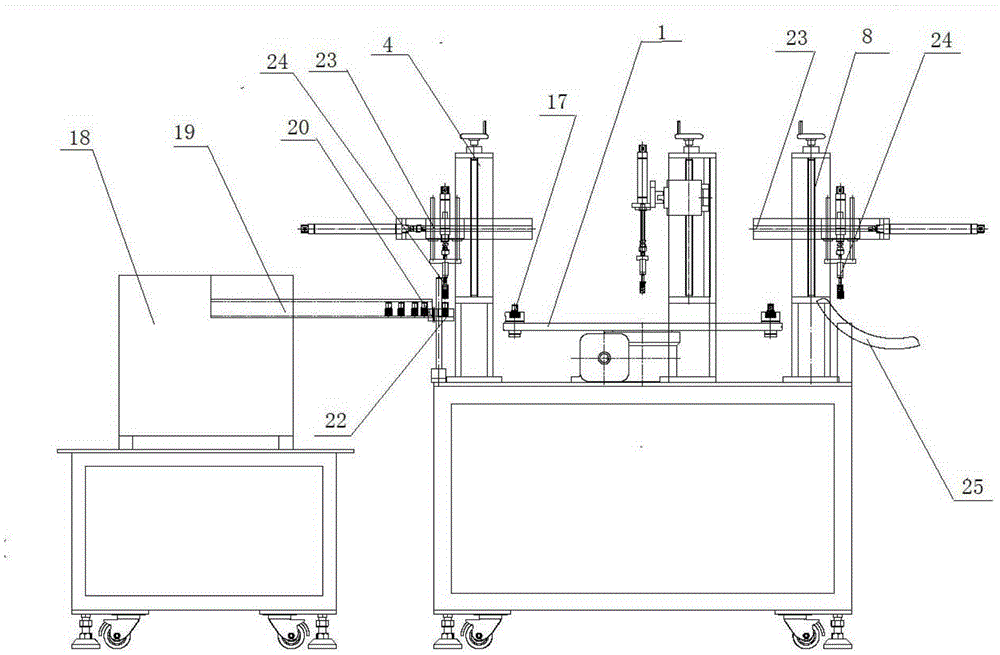

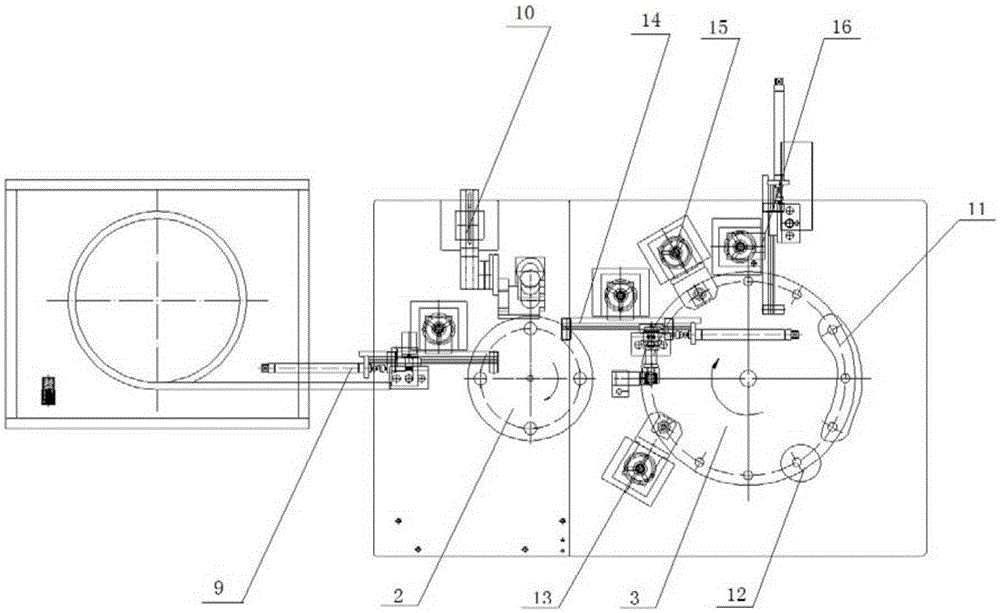

[0043] Below in conjunction with specific embodiment and Figure 1 to Figure 7 The present invention will be described in detail.

[0044] A tubular lipstick plastic case assembly machine, comprising a first assembly machine turntable 1, a second assembly machine turntable 2 and a third assembly machine turntable 3 arranged at intervals and capable of rotating around their central axes respectively. , The turntables of the third assembly machine can be set on a machine base respectively, or the first assembly machine turntable can be set separately on a machine base, and the second and third assembly machine turntables can be set on the same machine base at the same time , the setting method can be arranged according to the assembly procedure of the lipstick case parts, and the second method is adopted in this specific embodiment.

[0045] The radial surfaces of the turntables of the first, second and third assembly machines are provided with a plurality of positioning bases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com