Patents

Literature

161results about How to "No manual processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trading platform data processing method and system

ActiveCN103093378ANo manual processingIncrease flexibilityFinancePayment architectureData processing systemPayment

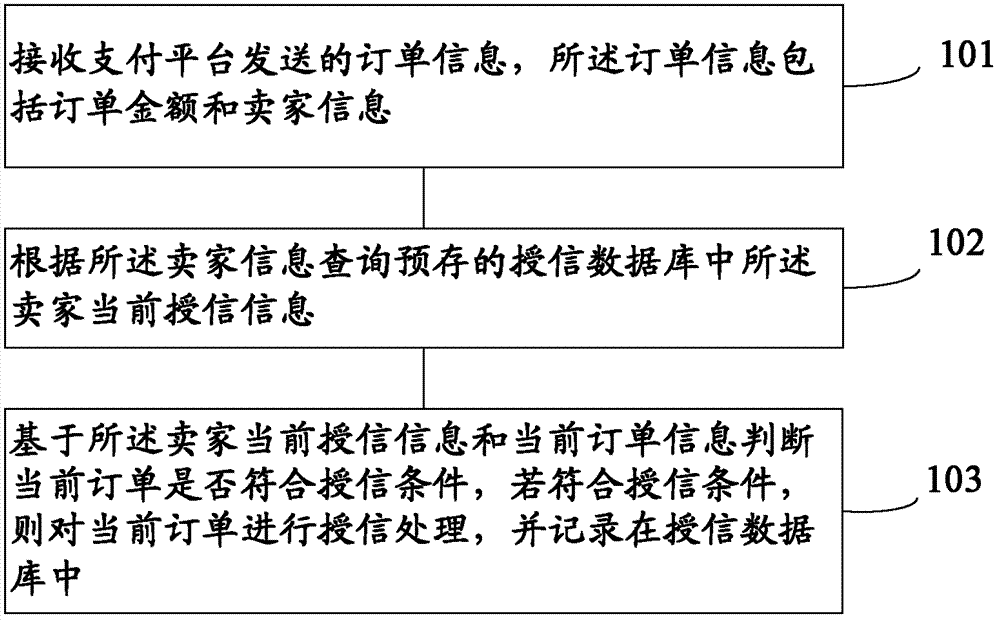

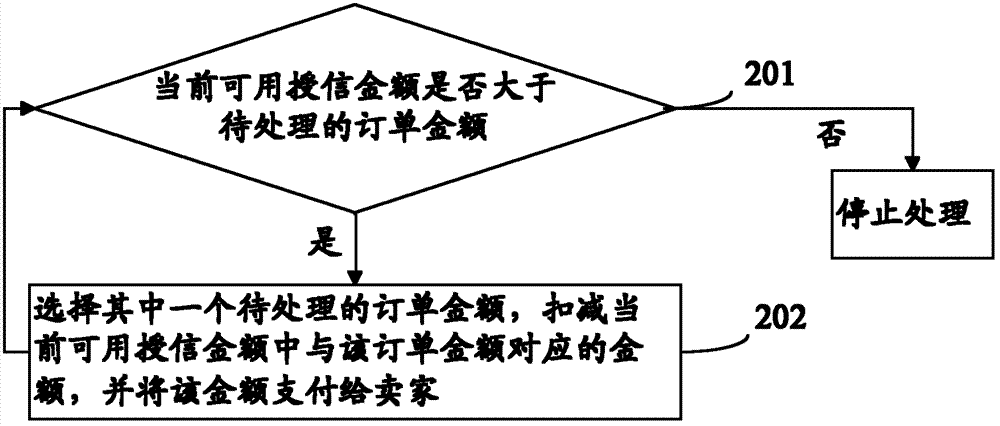

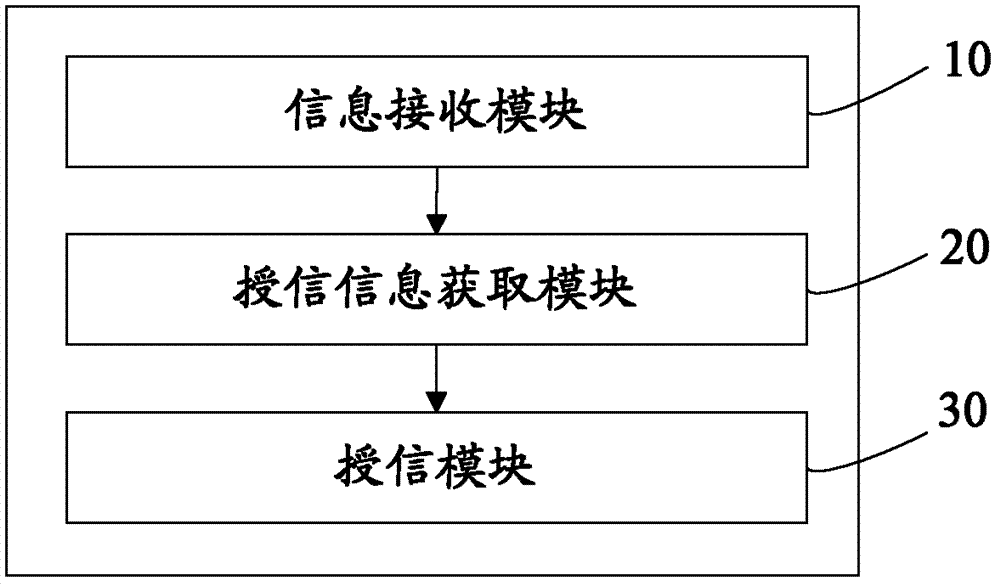

The invention provides a trading platform data processing method, and the trading platform data processing method includes the following steps: (1) receiving order information sent by a payment platform, wherein the order information including order amount and seller information, (2) searching the pre-saved current credit extension information of the seller in the pre-saved credit extension database according to the information of the seller, (3) judging whether the current order information is corresponding to conditions of the credit information or not on the basis of the current credit extension information of the seller and the current order information, and carrying out the credit extension for the current order and recording the credit extension in the credit extension database if the current order corresponds to the conditions of the credit information. The invention further provides a trading platform data processing system used for achieving the method. The trading platform data processing method and the system can achieve automatic credit extension, and improve flexibility of the credit extension and data processing efficiency.

Owner:ALIBABA GRP HLDG LTD

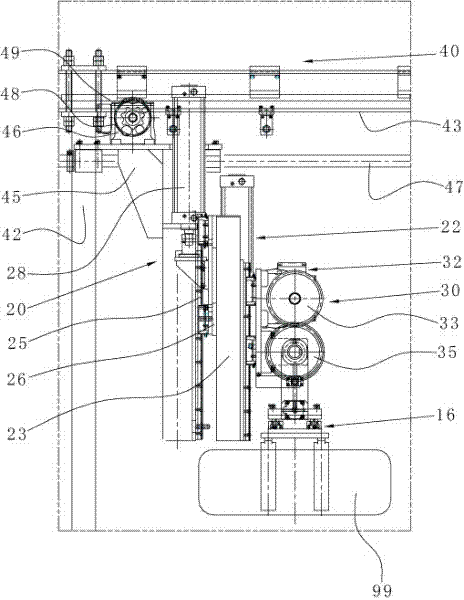

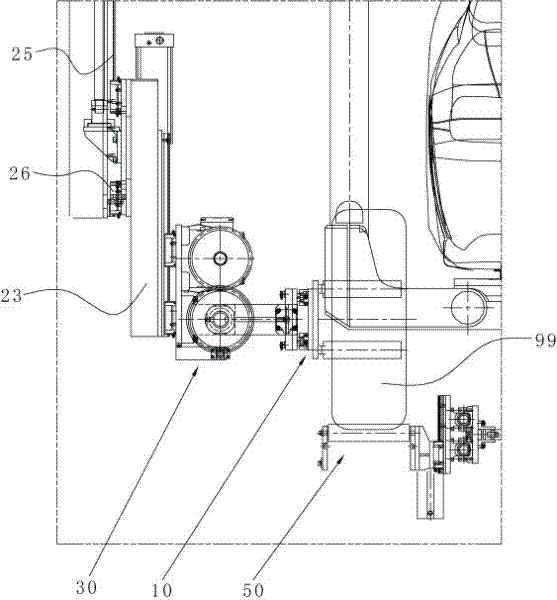

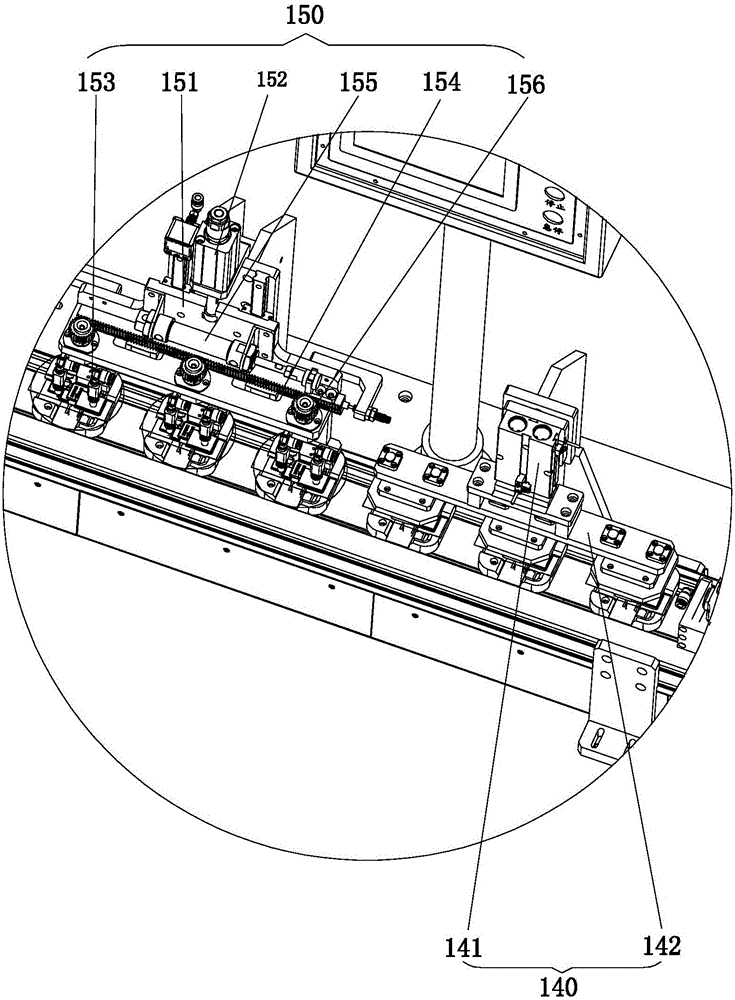

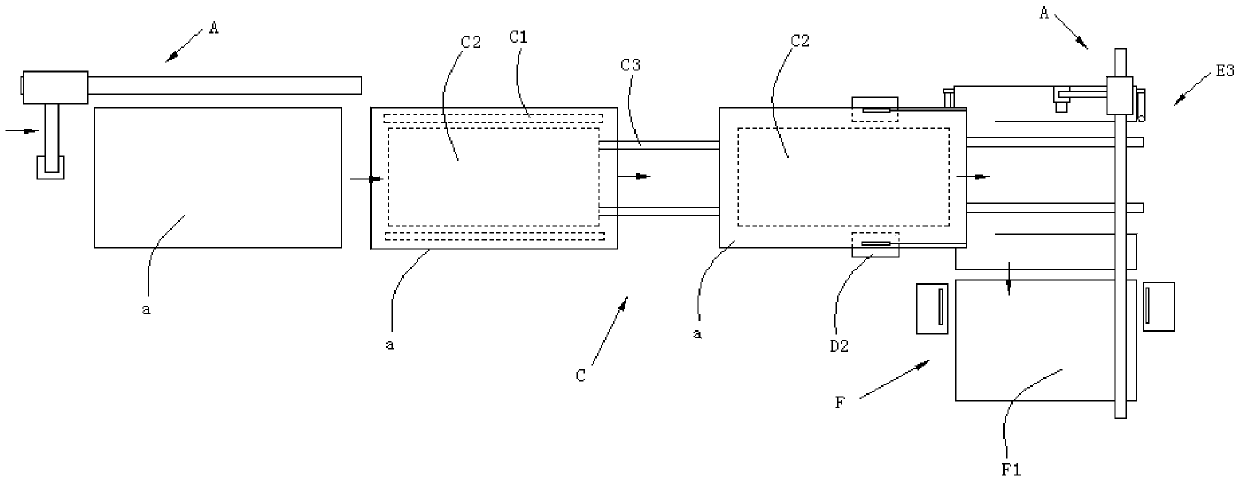

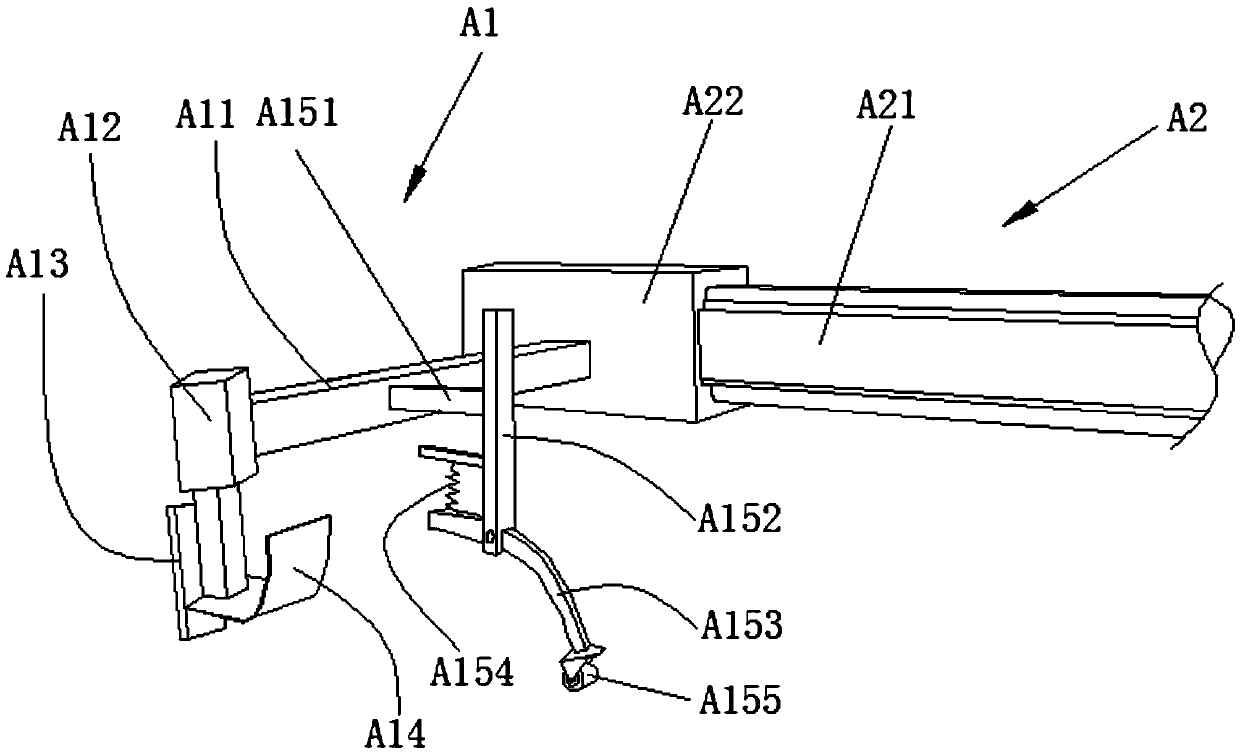

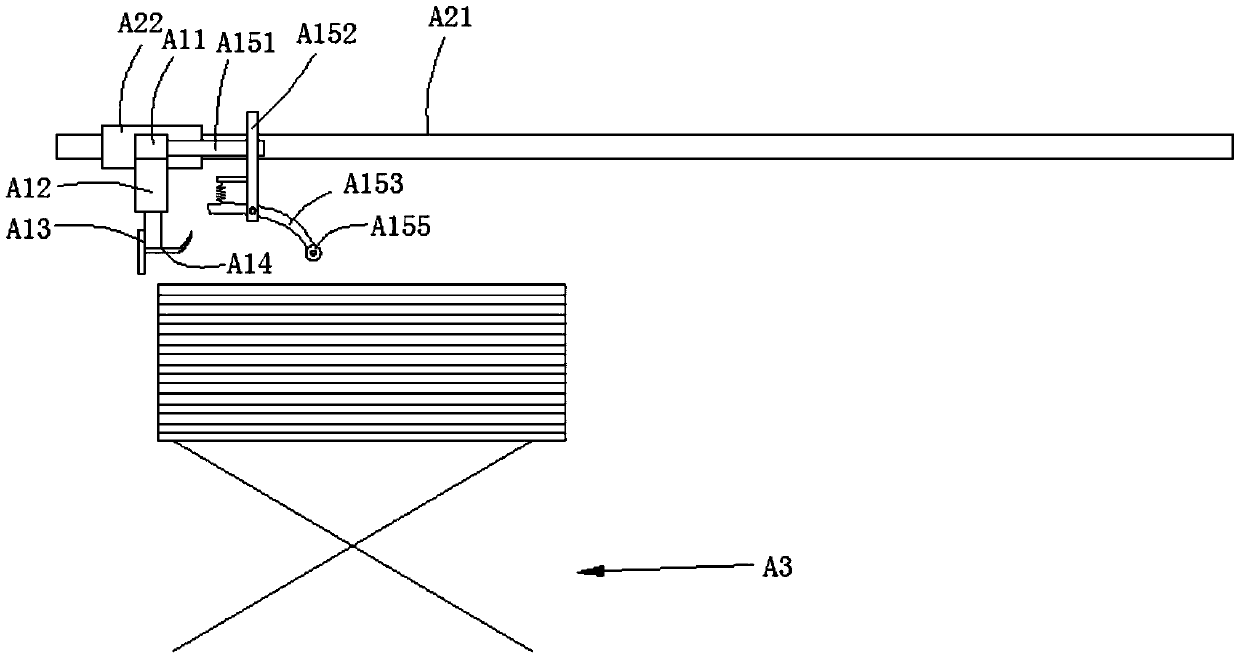

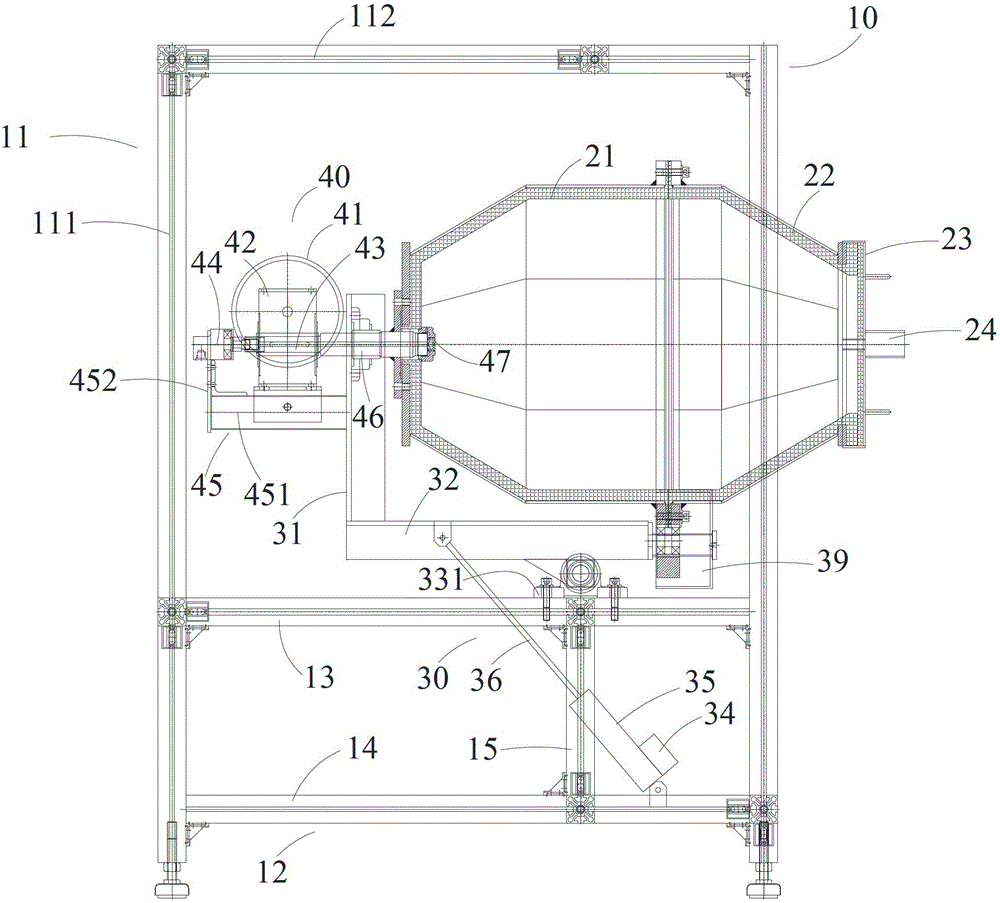

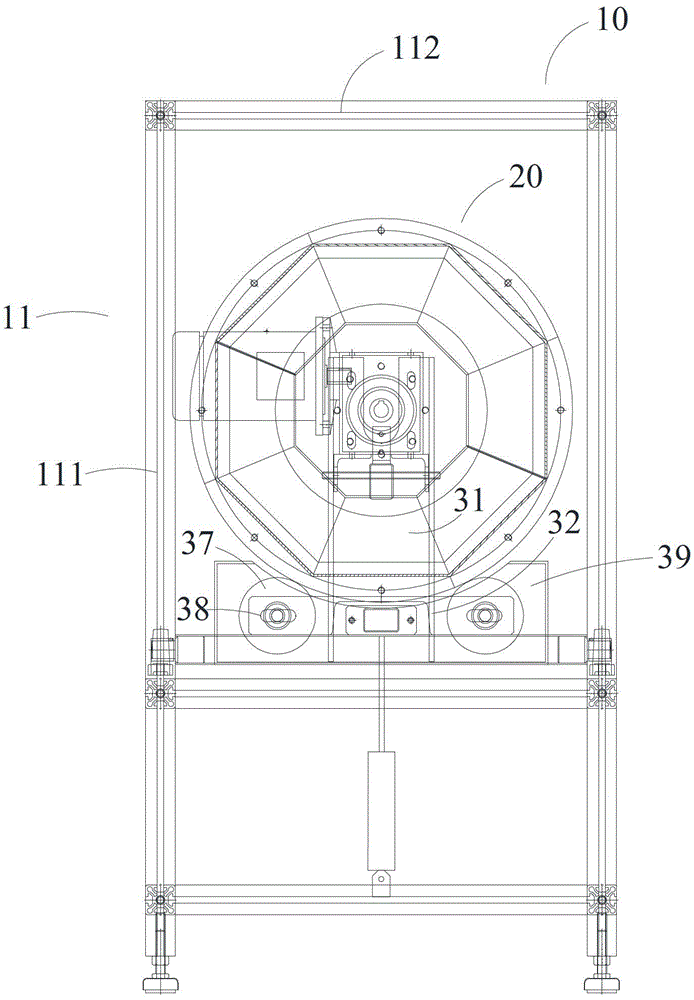

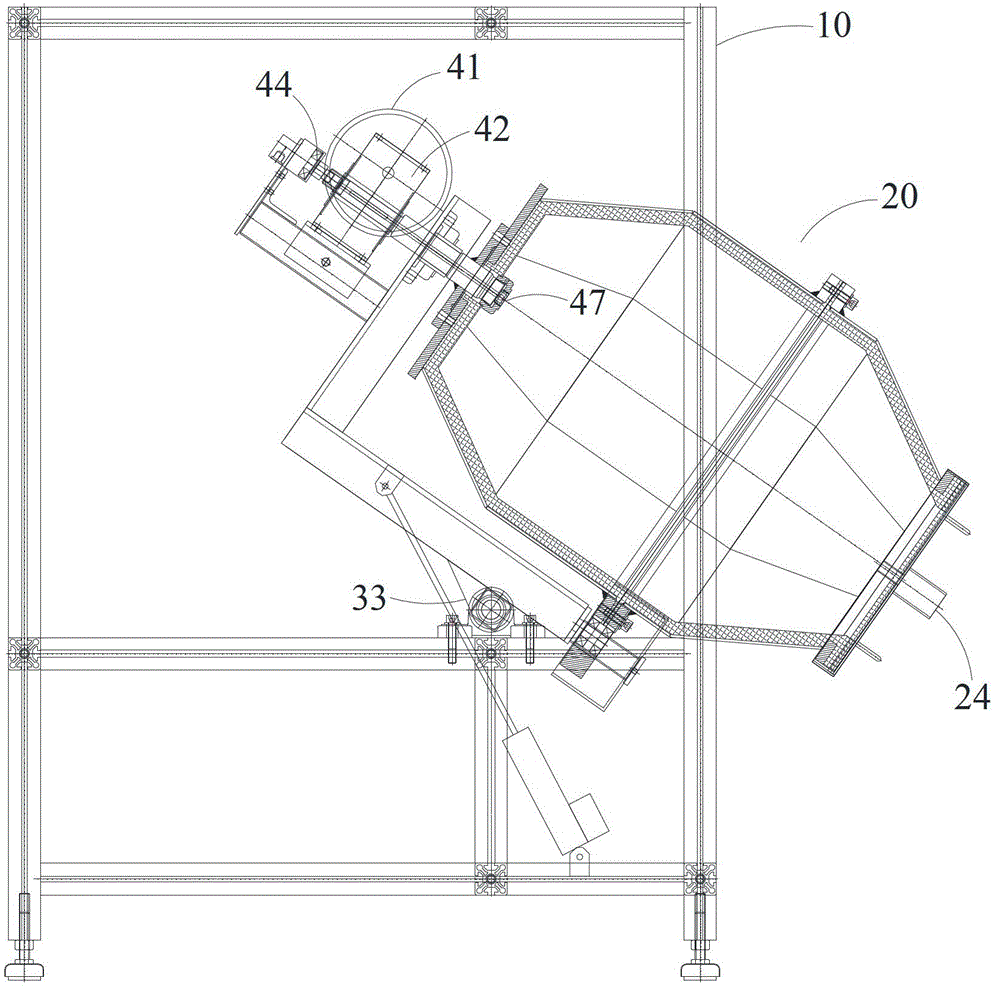

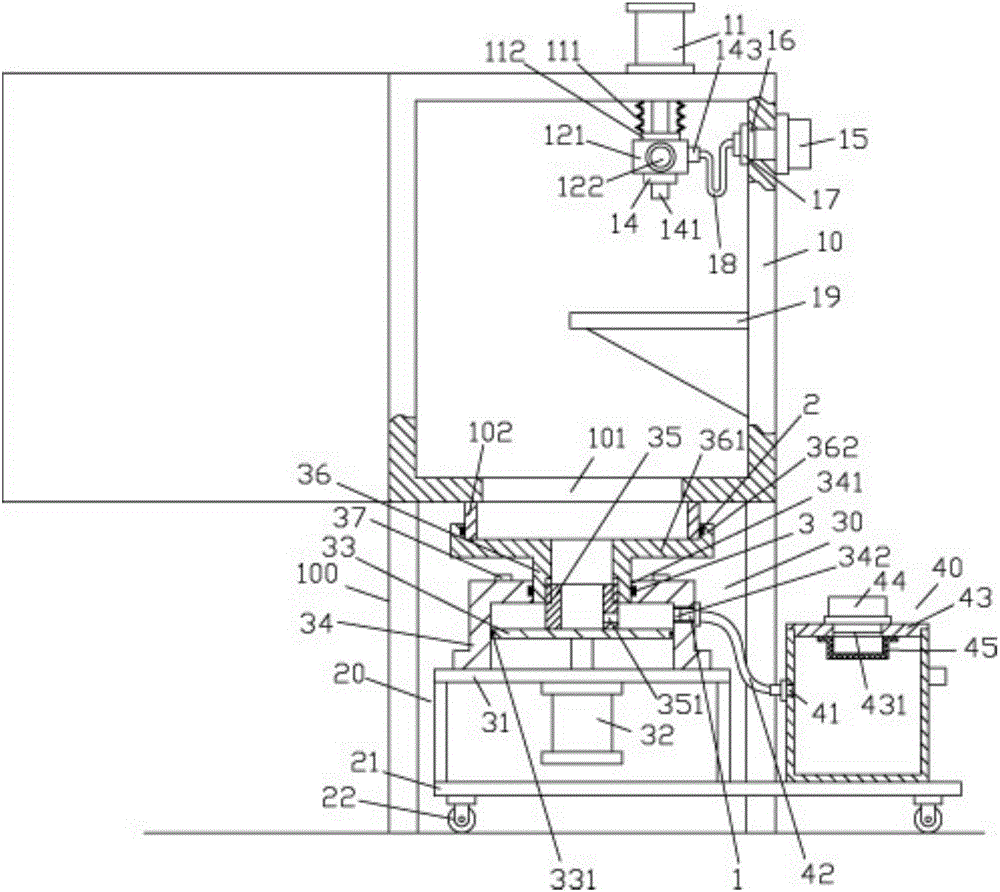

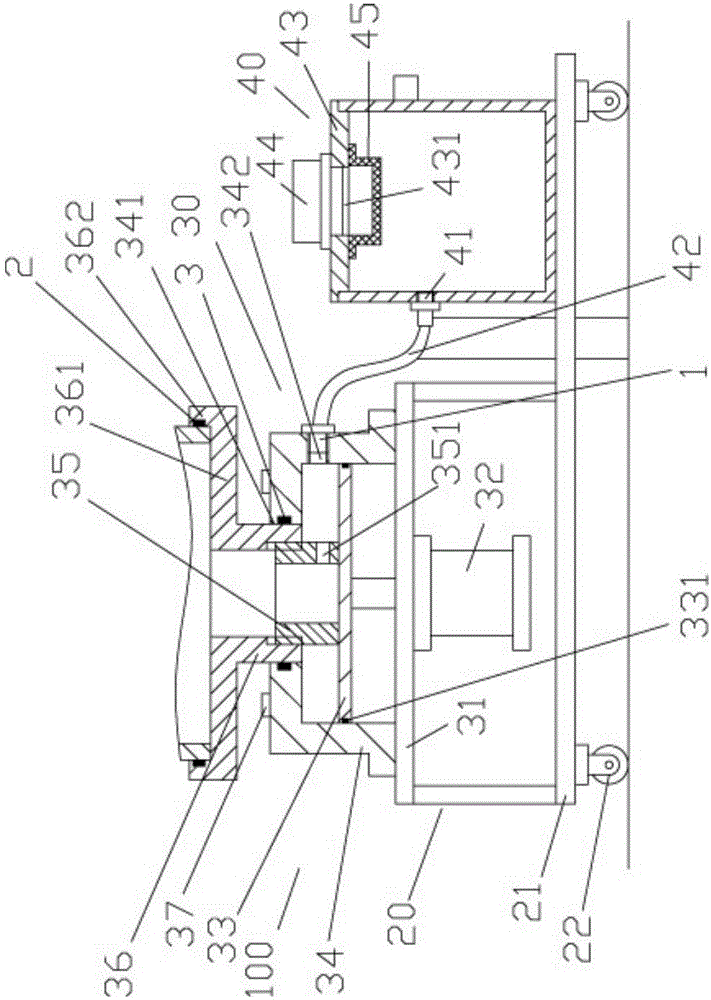

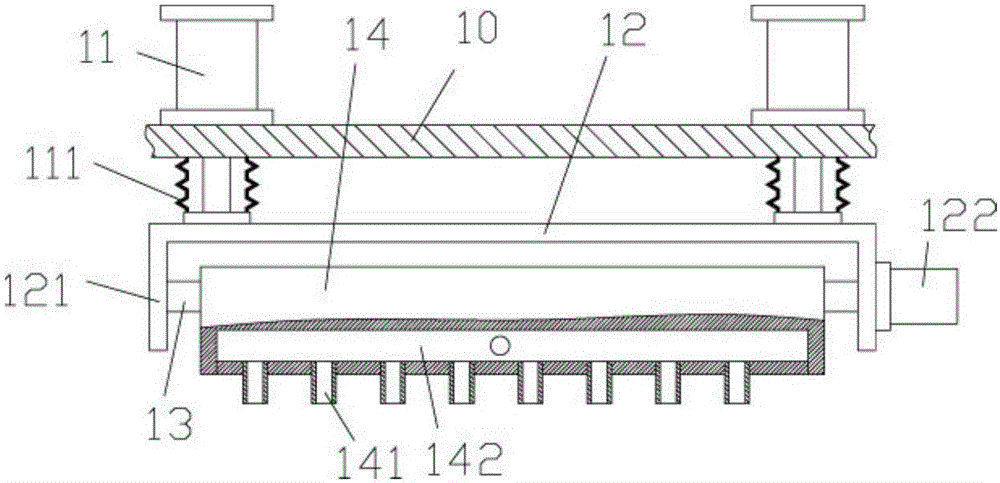

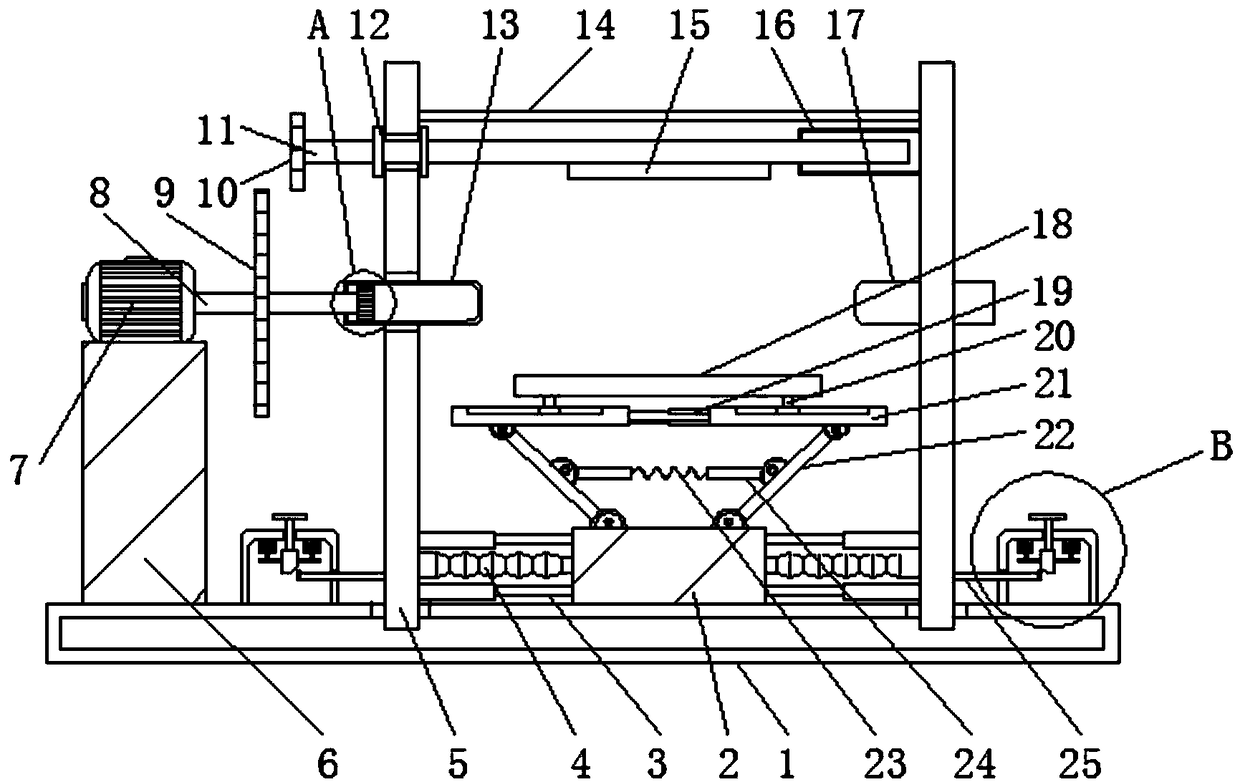

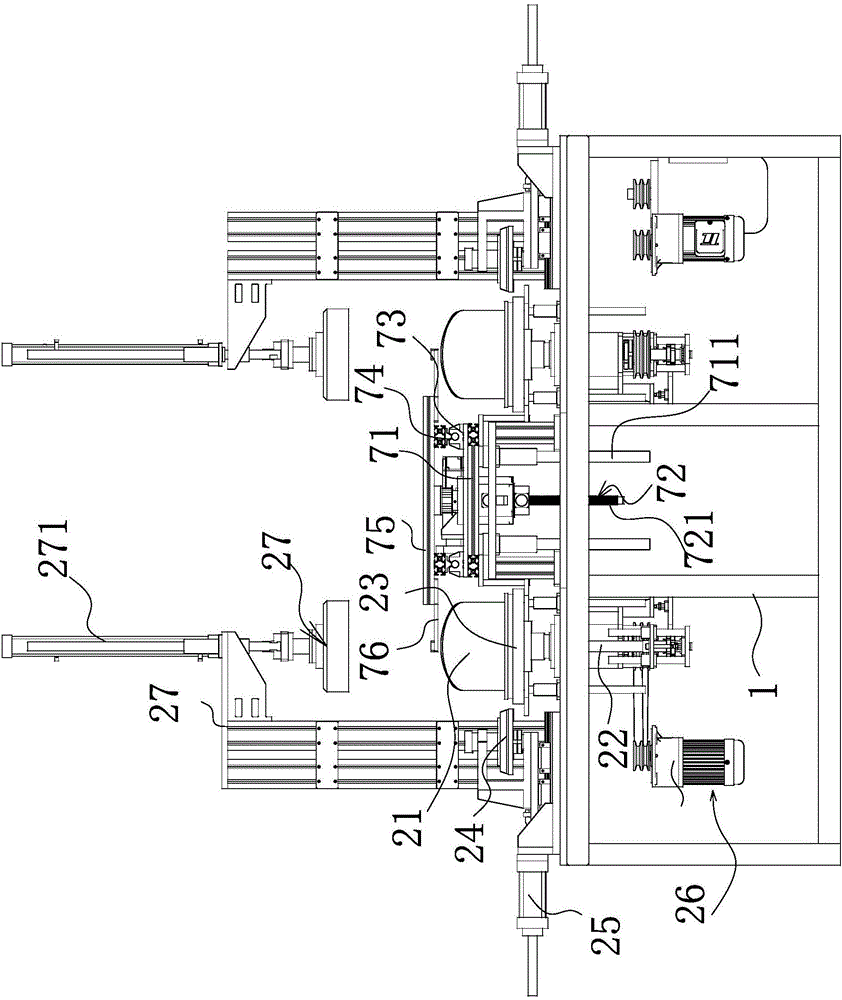

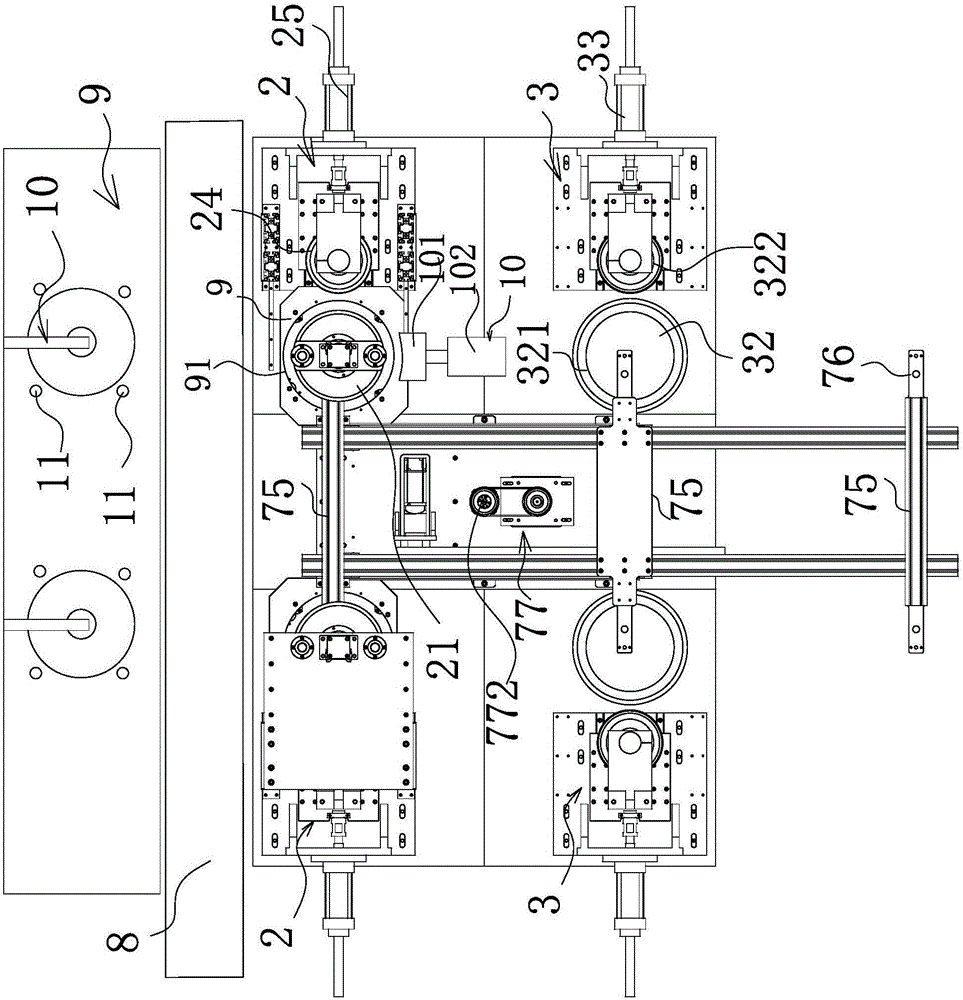

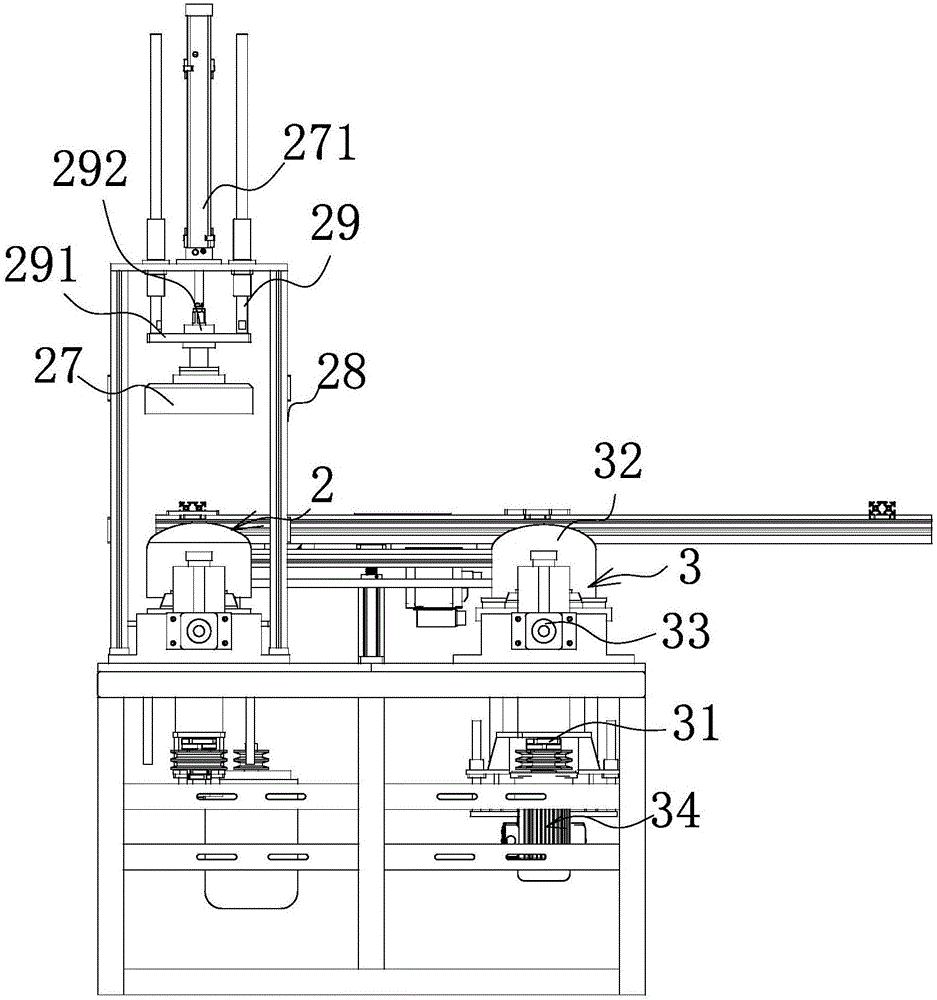

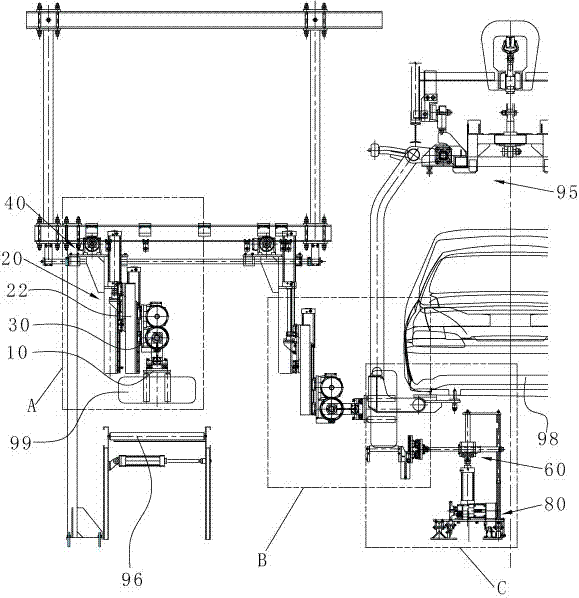

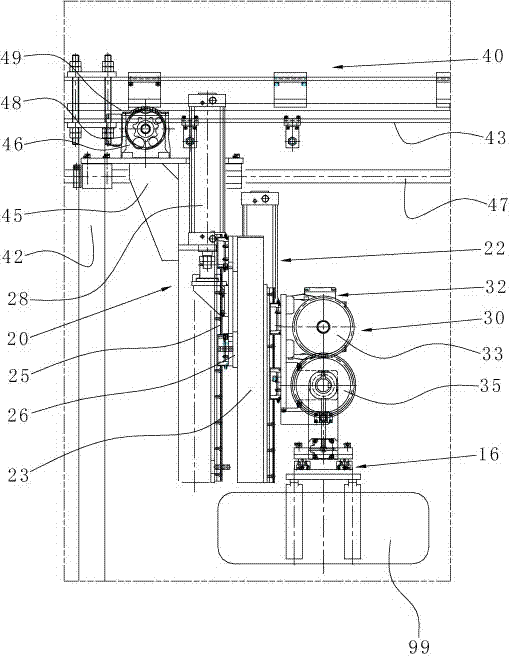

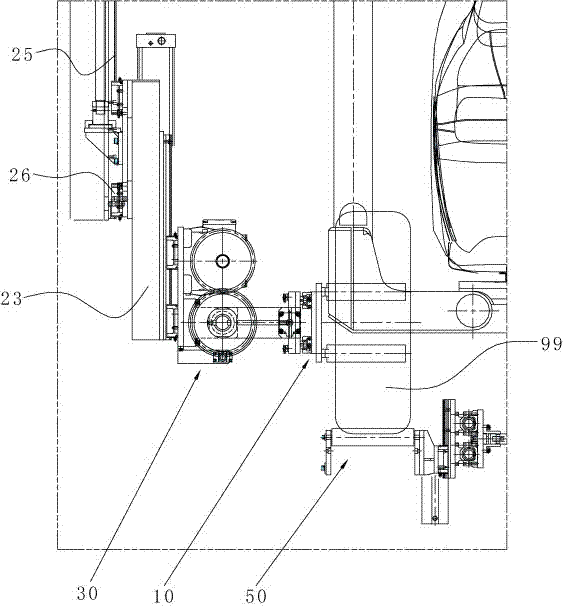

Automatic tire-supplying system

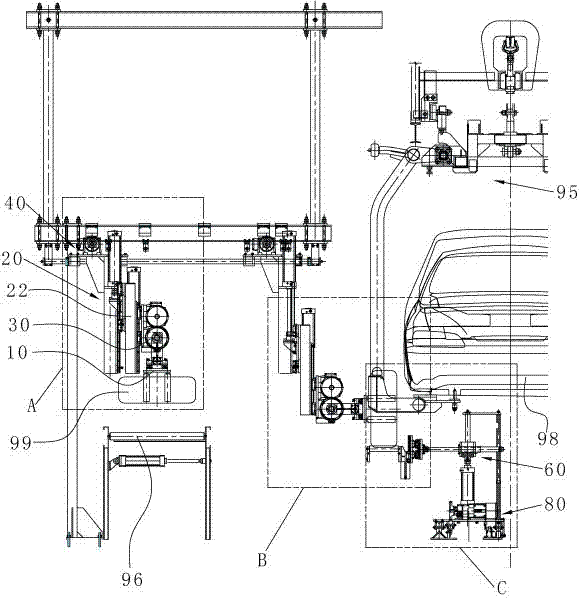

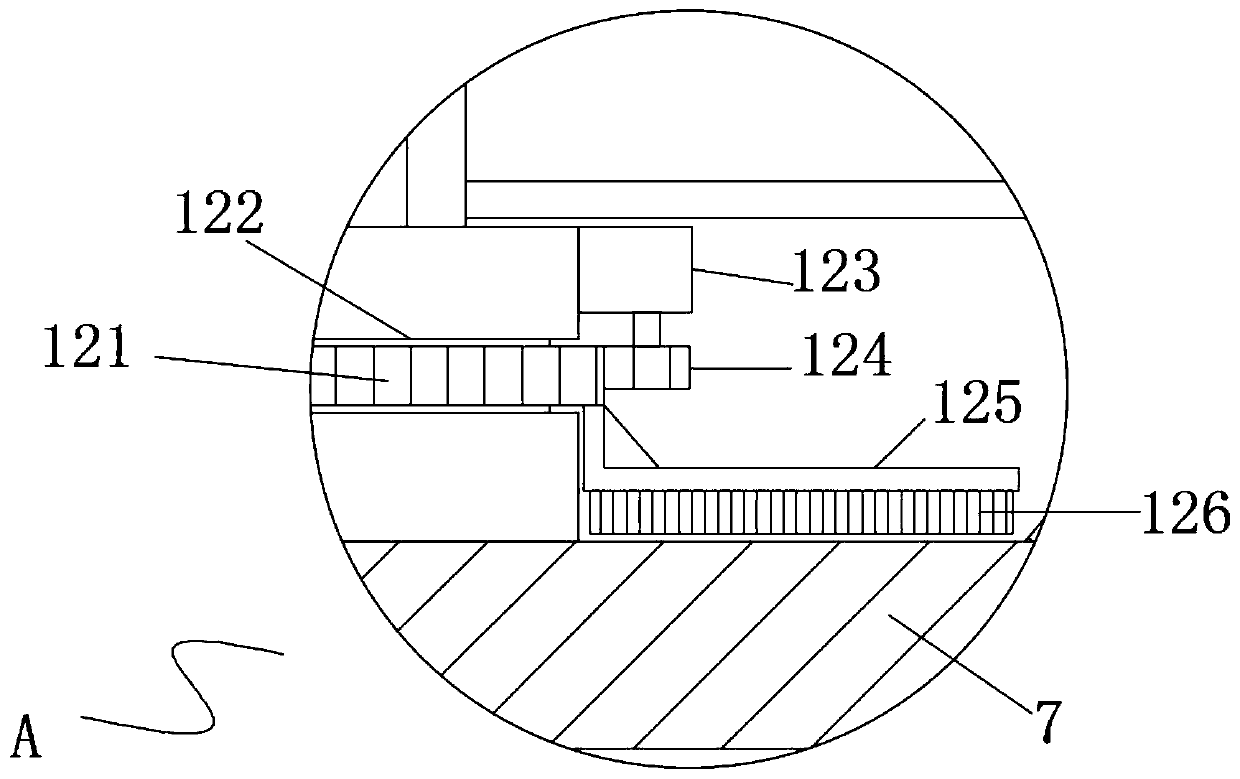

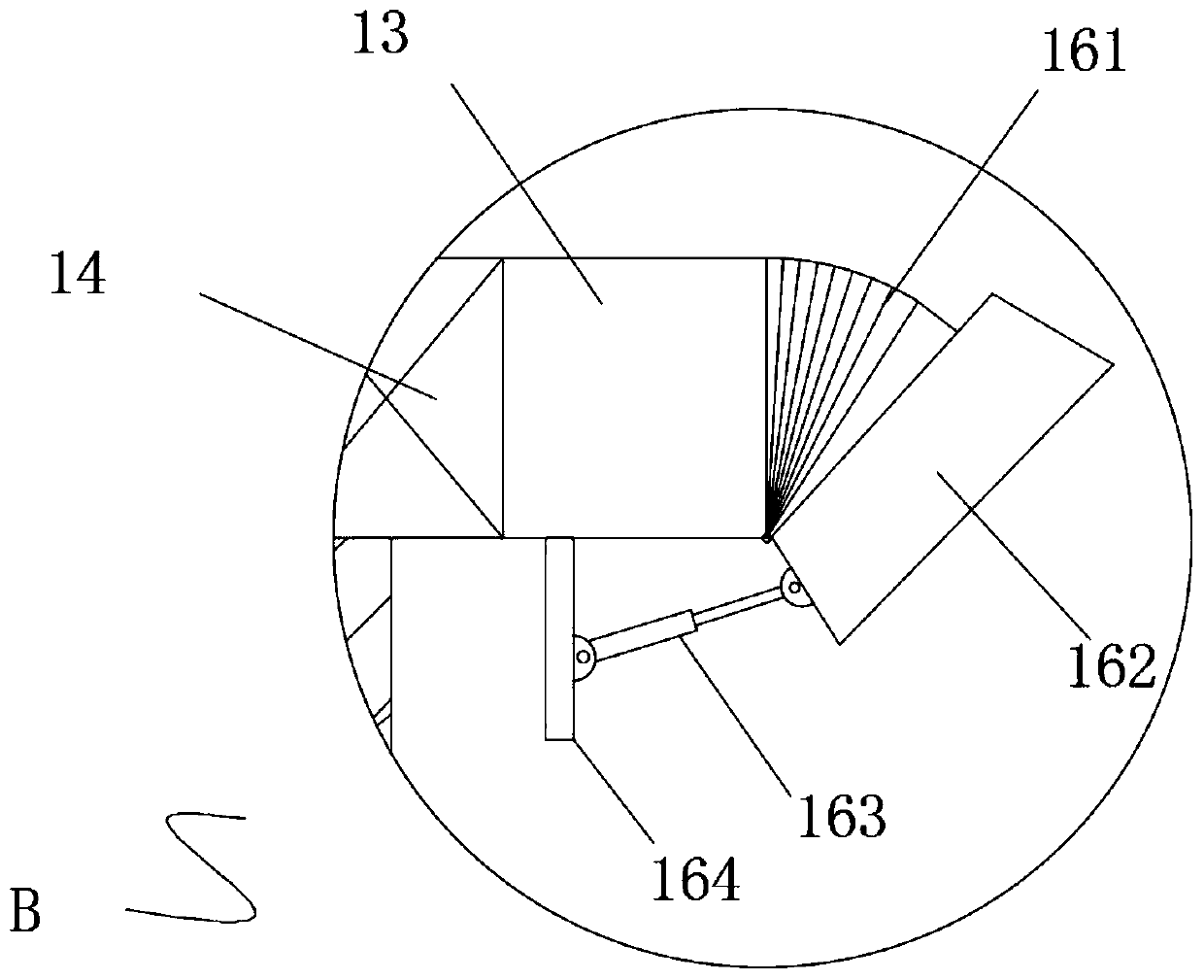

The invention discloses an automatic tire-supplying system, which is used for automatically transferring tires on a tire conveying raceway to side edges of wheel hubs at an assembly line. The automatic tire-supplying system comprises a clamping device, a lifting and turnover device and a line-shifting device which are sequentially connected, a vehicle-side supporting bracket, a three-way aligning device used for adjusting the position of the vehicle-side supporting bracket, and a following device used for supporting the three-way aligning device to synchronously move along with a vehicle body at the assembly line, wherein the vehicle-side supporting bracket, the three-way aligning device and the following device are sequentially connected and arranged at the lower side part of the assembly line; and a pre-inflated tire is clamped through the clamping device, is then lifted and overturned into a vertical state, is conveyed to the side of the moving trajectory of a wheel hub through the line-shifting device and is placed at the vehicle-side supporting bracket, then the position of the tire is adjusted under the control of the three-way aligning device, and the tire is aligned with the wheel hub and synchronously moves with the vehicle body. According to the automatic tire-supplying system disclosed by the invention, automatic carrying, conveying and aligning of machinery are realized, the assembly of the tire can be completed without manual carrying, conveying and aligning, the labor intensity is reduced, and the automation level is improved.

Owner:GUANGQI HONDA +1

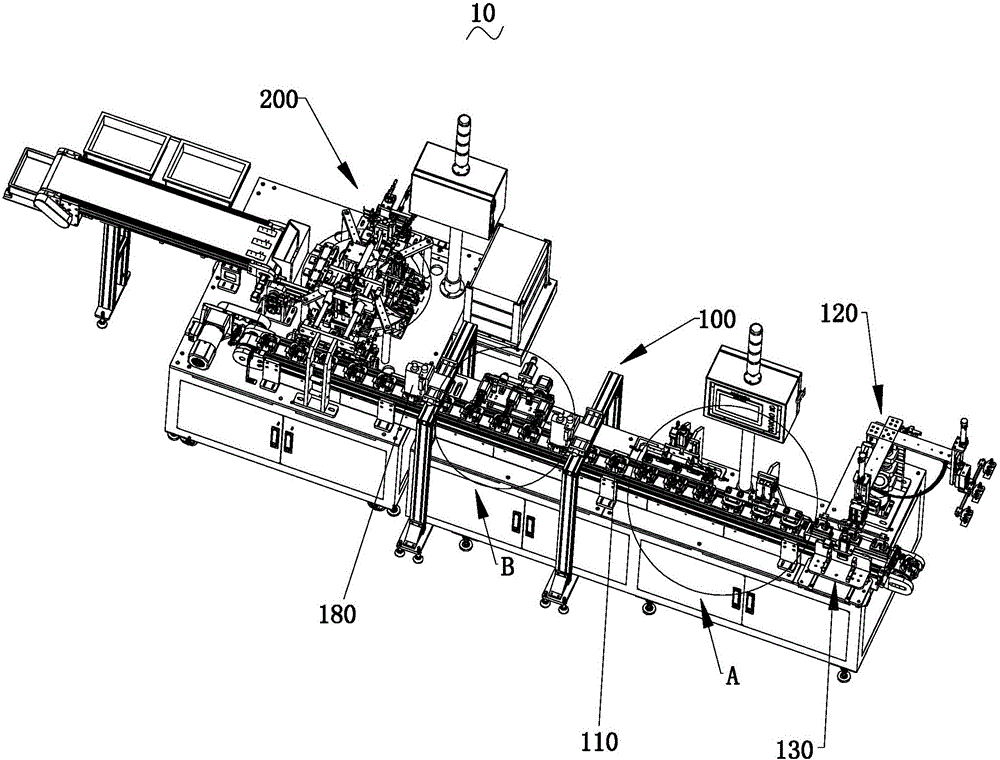

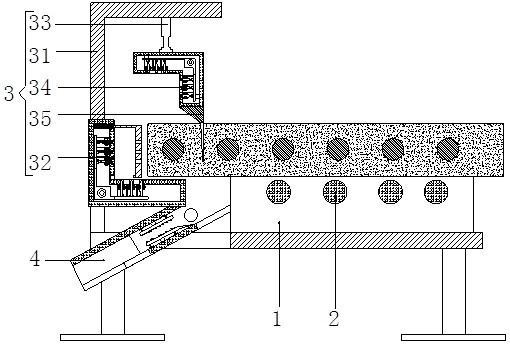

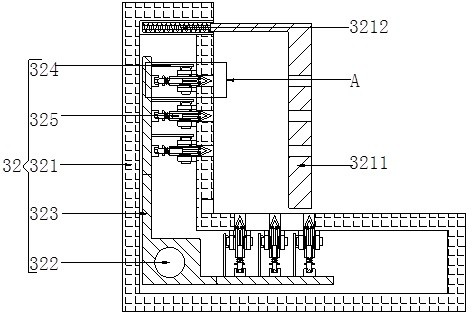

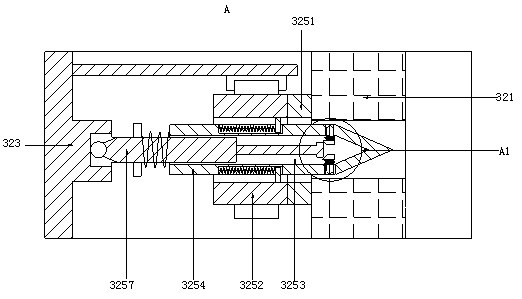

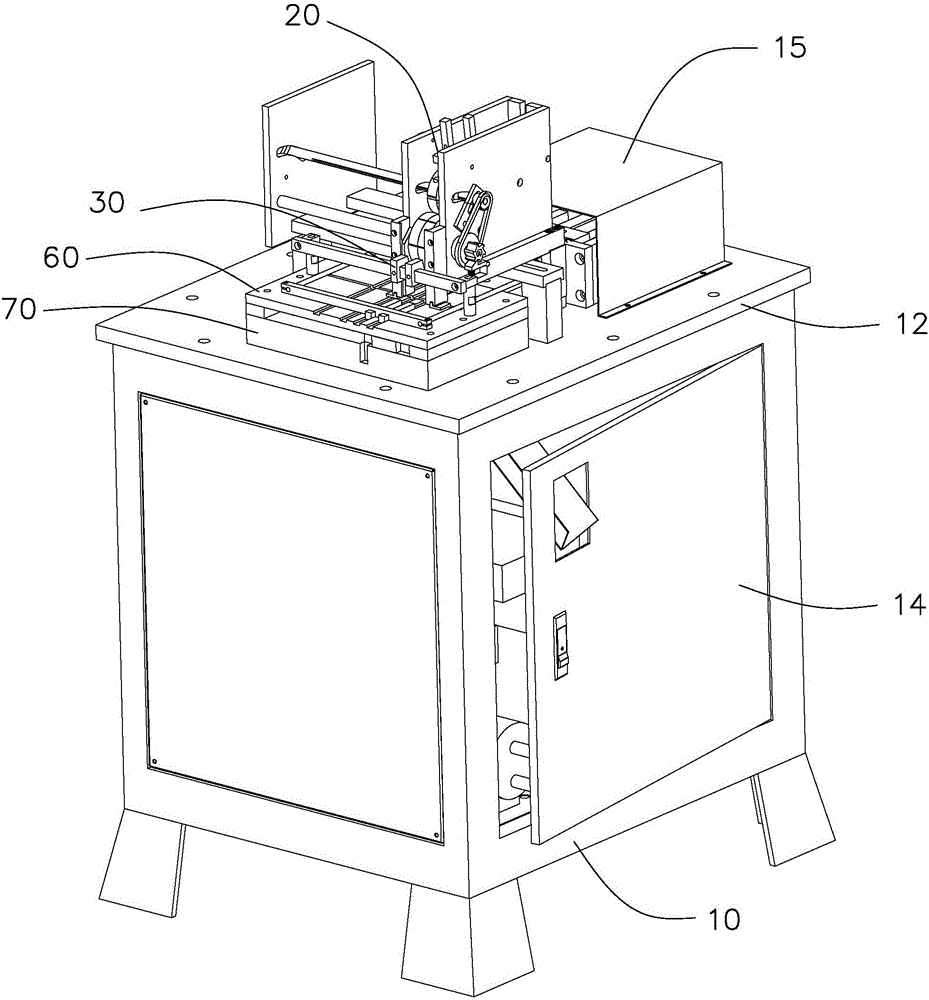

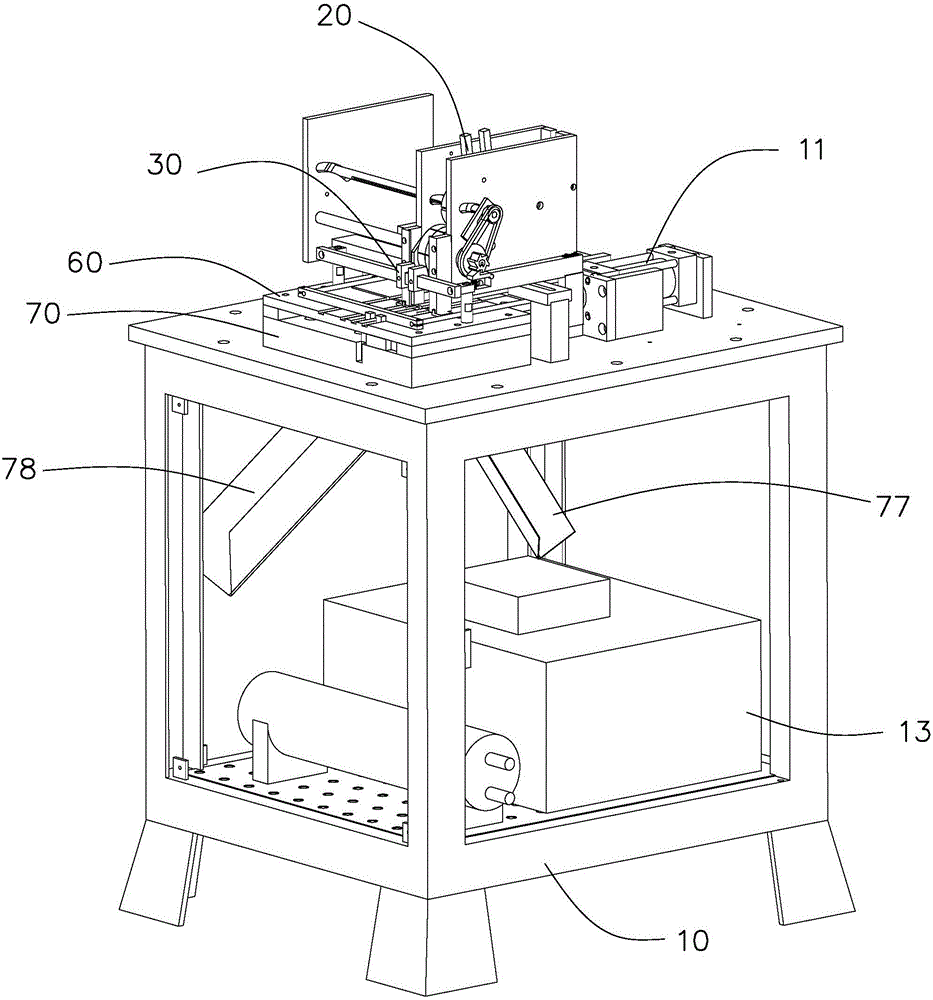

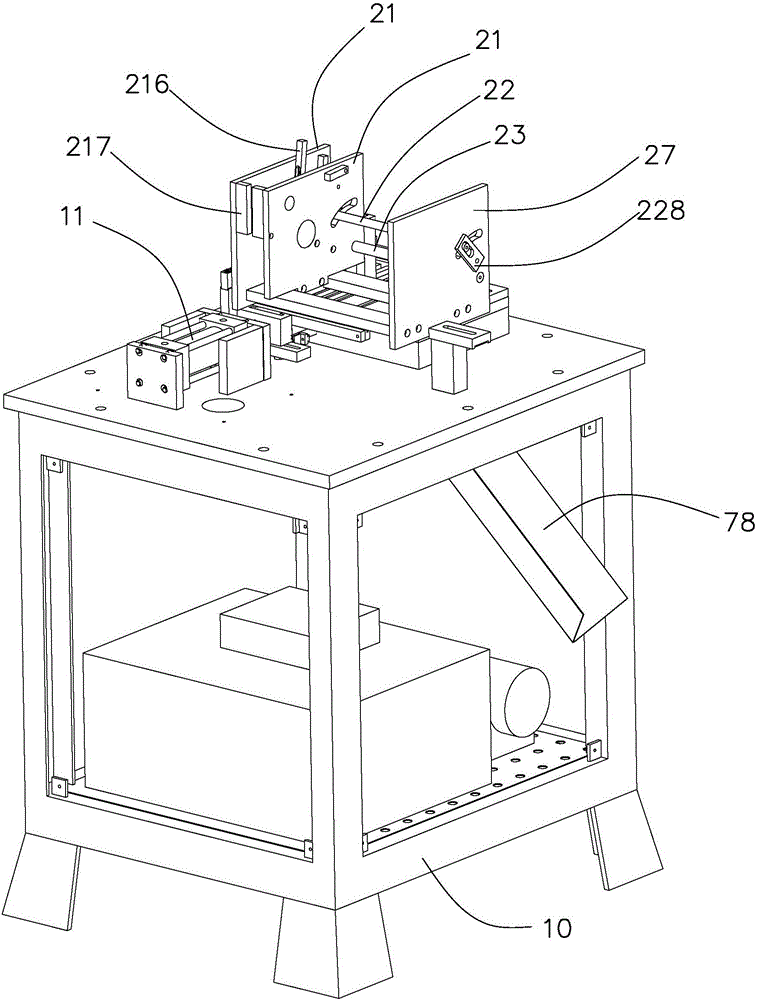

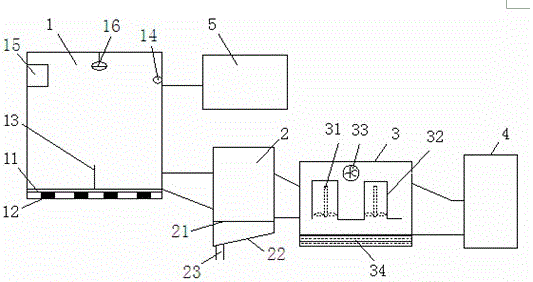

Laminate polymer battery automatic code-spurting rotating disc type flaring detection machine

ActiveCN105946363ANo manual processingIncrease productivityElectrical testingTypewritersProduction lineElectrical battery

The invention discloses a laminate polymer battery automatic code-spurting rotating disc type flaring detection machine, and the machine comprises an automatic code-spurting device which is used for spurting a code on a laminate polymer battery and a rotating disc type flaring detection device which is used for detecting the laminate polymer battery. The automatic code-spurting device comprises a straight-line type production line, battery rotatably feeding manipulators which are arranged on the straight-line type production line in sequence, a first battery overturning part, a battery correcting part, a battery rotating part, a first code-spurting part, a second battery overturning part and a second code-spurting part. The rotating disc type flaring detection device comprises a frame, a rotating disc which is rotatably arranged on the frame, battery detection feeding manipulators which are arranged around the rotating disc in sequence, a piercing short circuit testing part, a battery flaring part and a battery blanking part. According to the invention, the laminate polymer battery automatic code-spurting rotating disc type flaring detection machine is adopted to perform automatic code-spurting and flaring detection on the laminate polymer battery, the automatic production is realized in the whole process, so that the production efficiency can be greatly improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Full-automatic trimming machine

The invention provides a full-automatic trimming machine which comprises a feeding device, a long edge trimming device, a steering device and a short edge trimming device, wherein panels sequentially pass through the feeding device, the long edge trimming device, the steering device and the short edge trimming device; the long edge trimming device and the short edge trimming device are respectively positioned on the two adjacent sides of the steering device; and the horizontal-direction included angle of the long edge trimming device and the short edge trimming device is 90 degrees. Compared with the prior art, the trimming machine provided by the invention has the advantages that the structure is simple, the panel feeding is smooth, all the steps closely cooperate with each other, before the next step is carried out, the next work task is prepared in the precious step, the connection is close, and the working efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

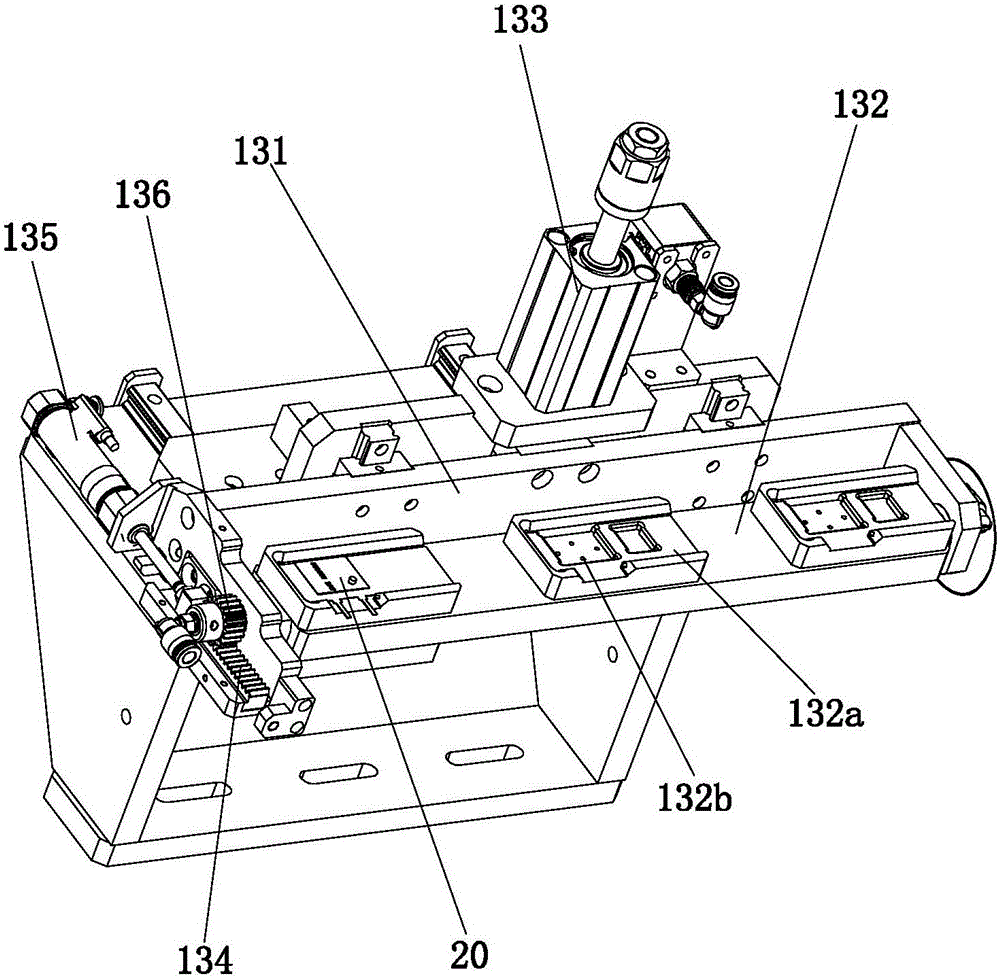

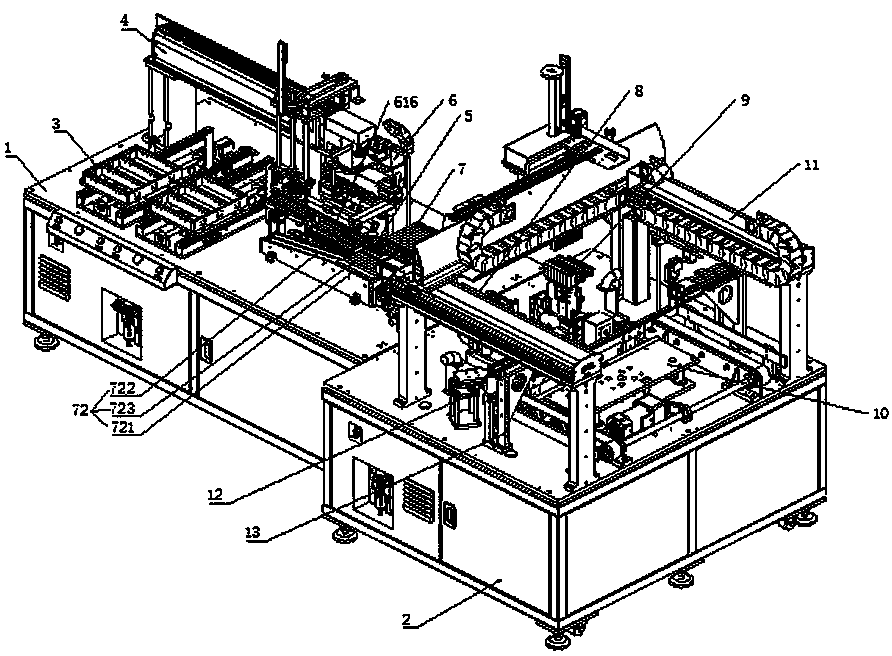

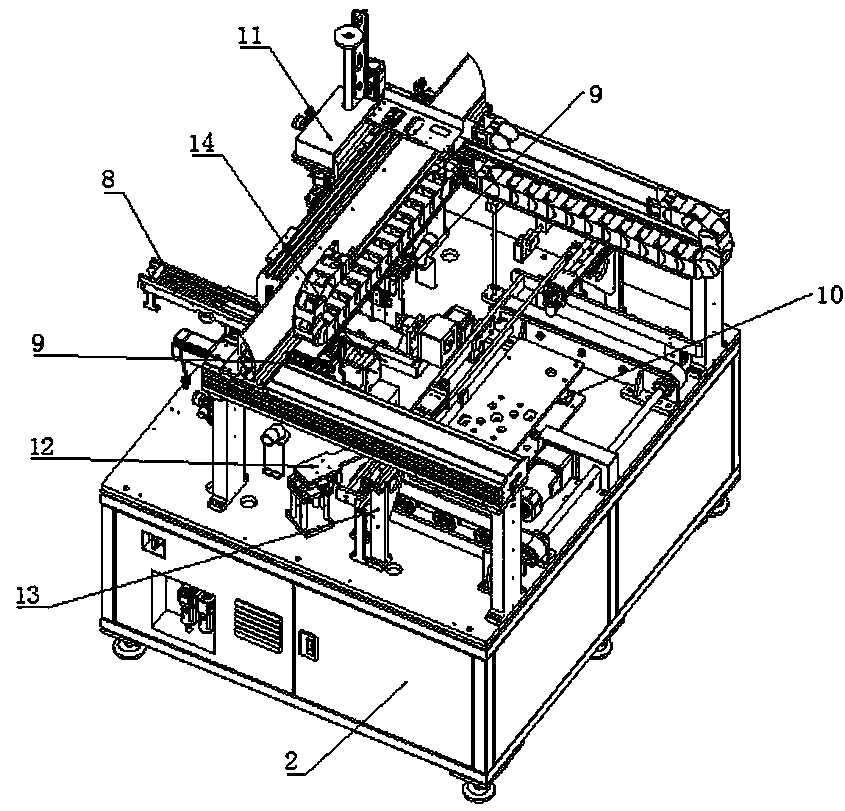

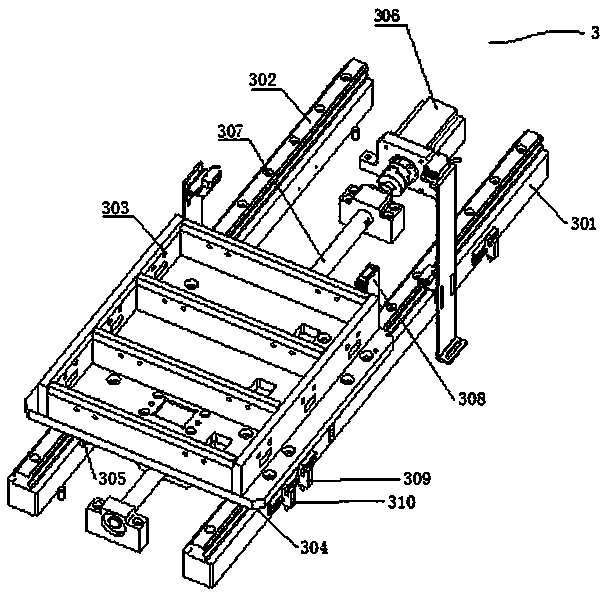

Multi-axis module full-automatic cell-feeding-into-shell machine

PendingCN110560582AImprove work efficiencyIncrease productivityAssembling battery machinesMetal-working feeding devicesEngineeringMulti axis

The invention discloses a multi-axis module full-automatic cell-feeding-into-shell machine. The machine comprises a first machine table and a second machine table, wherein the first machine table andthe second machine table are arranged side by side, a translation loading mechanism is arranged on the first machine table, a feeding mechanism is arranged above the translation loading mechanism, a transferring through groove is formed in the first machine table, the transferring through groove is formed at one side of the translation loading mechanism, a transferring mechanism is arranged in thetransferring through groove, a rotary code scanning mechanism is arranged on one side of the transferring mechanism, code scanning-based unqualified product pushing mechanisms are further arranged atthe rotary code scanning mechanism in sequence, a qualified product flow channel line mechanism connected with the transferring mechanism is arranged on the second machine table, a material storage mechanism is arranged at the tail end of the qualified product flow channel line mechanism, electrode turnover mechanisms are oppositely arranged on the two sides of the material storage mechanism, a tool plate positioning mechanism is arranged at one end of the qualified product flow channel line mechanism, and a cell-feeding-into-shell mechanism is arranged above the tool plate positioning mechanism. According to the machine, unqualified cells can be automatically screened out, the product yield is improved, the cell-feeding-into-shell precision rate is effectively improved, and the working efficiency is improved.

Owner:HUIZHOU LONGHAI TECH

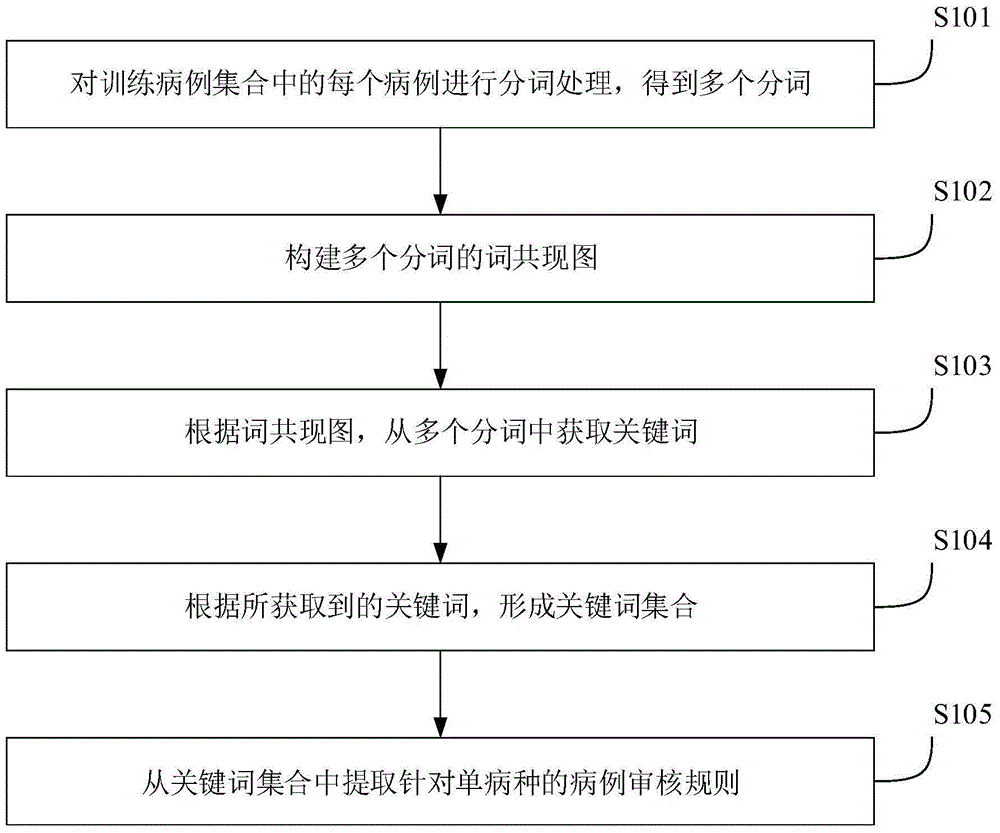

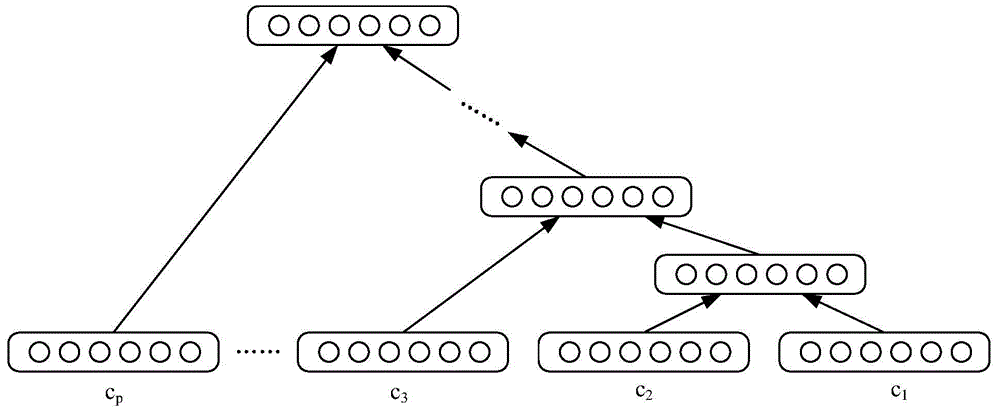

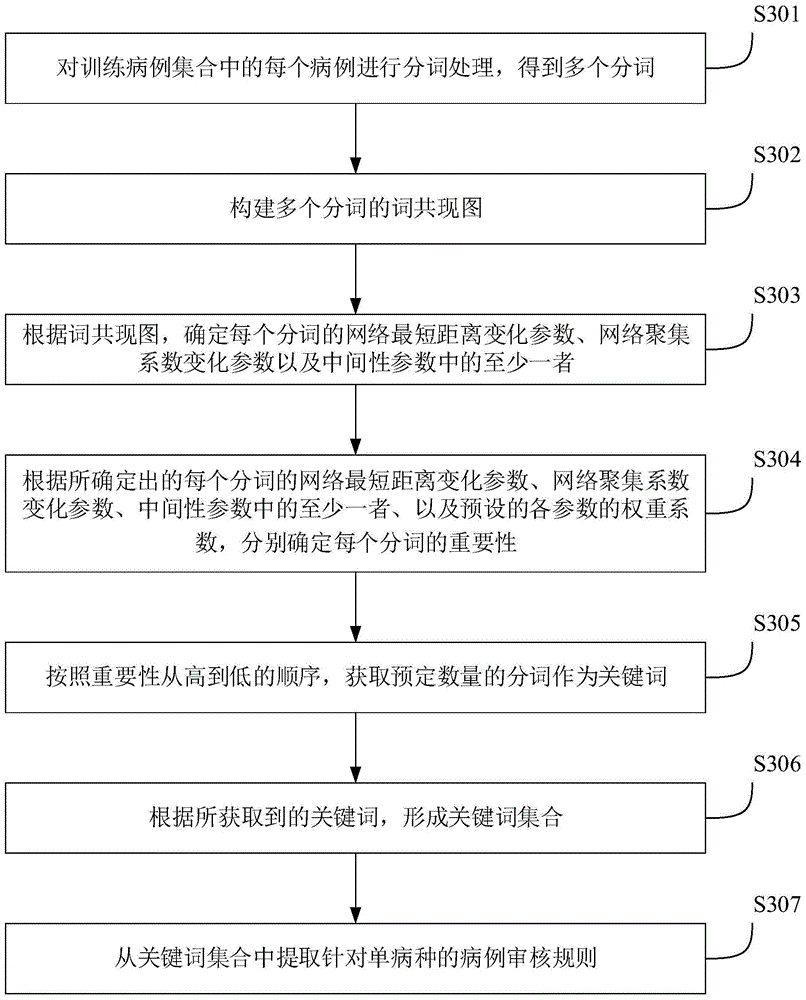

Extracting method and apparatus for case auditing rule, and case auditing method and system

ActiveCN105224807AImprove accuracyEfficient use ofSpecial data processing applicationsMachine learningCo-occurrence

The invention discloses an extracting method and apparatus for a case auditing rule of a single disease, and a case auditing method and system for the single disease. The extracting method comprises the steps of performing word segment processing on each case of a training case set to obtain a plurality of segmented words, wherein the training case set comprises a plurality of cases belonging to preset single disease; establishing a word co-occurrence graph with multiple segmented words, wherein each segmented word is used as a top point of the word co-occurrence graph, and the weight of the side boundary between two top points is the co-occurrence time of the segmented word, corresponding to the two top points, in the training case set; obtaining key words from the multiple segmented words according to the word co-occurrence graph; forming a key word set according to the obtained key words; and extracting the case auditing rule specific to the single disease from the key word set, wherein the case auditing rule is a sequential key word sequence formed by the multiple key words from the key word set. Therefore, the case auditing rule for the single disease can be extracted for realizing the automatic auditing for cases of the single disease.

Owner:NEUSOFT CORP

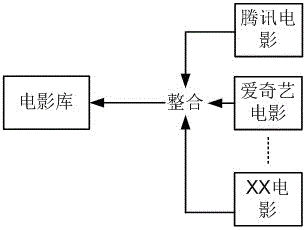

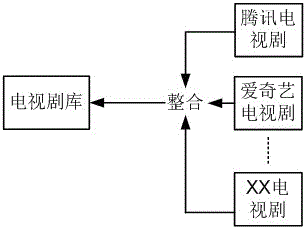

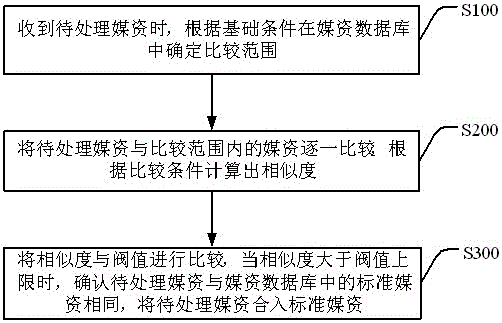

Media asset data integrating method and system

ActiveCN106354827AAutomatic integrationNo manual processingSpecial data processing applicationsWorkloadData science

The invention discloses an automatic media asset data integrating method and system. The automatic media asset data integrating method comprises the following steps: step A, when receiving media assets to be processed, determining a comparing range in a media asset database according to basic conditions; step B, comparing the media assets to be processed to media assets in a comparing range one by one, and calculating similarity according to comparison conditions; and step C, comparing the similarity to a threshold value, when the similarity is greater than upper limit of the threshold value, determining that the media assets to be processed are the same as standard media assets in the media asset database, and integrating the media assets to be processed into the standard media assets. The comparing range of the media assets to be processed is determined at first, the similarity is calculated in the comparing range, whether the media assets to be processed are the same as existing media assets in the media asset database or not is judged according to the similarity, if the media assets to be processed are the same as the existing media assets in the media asset database, the media assets to be processed are integrated into the existing media assets, so that automatic integration of media asset data is realized, manual processing is not required, and the problems that a massive amount of existing media asset data are huge in manual integration workload, time is wasted, and operation is troublesome are solved.

Owner:TCL CORPORATION

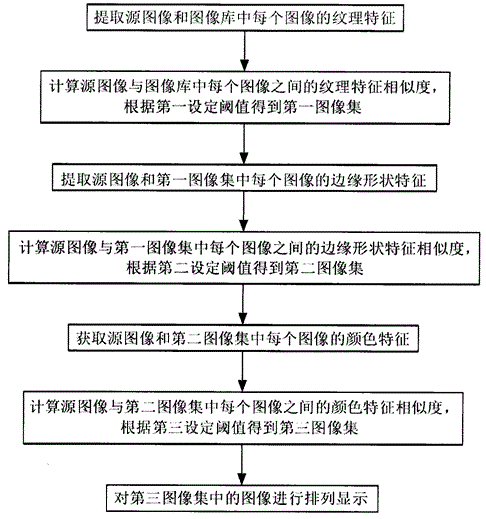

Image retrieval method

InactiveCN104809245ALow dimensionality of eigenvectorsProcessing speedSpecial data processing applicationsImage retrievalSource image

The invention discloses an image retrieval method. On the basis of an image library comprising N comparison images, the method comprises the following steps: extracting the texture features of a source image and each image in the image library; calculating the similarity degree of texture features of the source image and each image in the image library, and obtaining a first image set according to a first set threshold; extracting the shape features of boundary of the source image and each image in the first image set; calculating the similarity degree of shape features of boundary of the source image and each image in the first image set, and obtaining a second image set according to a second set threshold; obtaining the color features of the source image and each image in the second image set; calculating the similarity degree of color features of the source image and each image in the second image set, and obtaining a third image set according to a third set threshold; arranging and showing images in the third image set. The method combines the similarity degree of texture features, the shape features of boundary and color features of the images, so that the degree of accuracy of image retrieval is greatly improved, and the precision of retrieved results is ensured.

Owner:XINYANG NORMAL UNIVERSITY

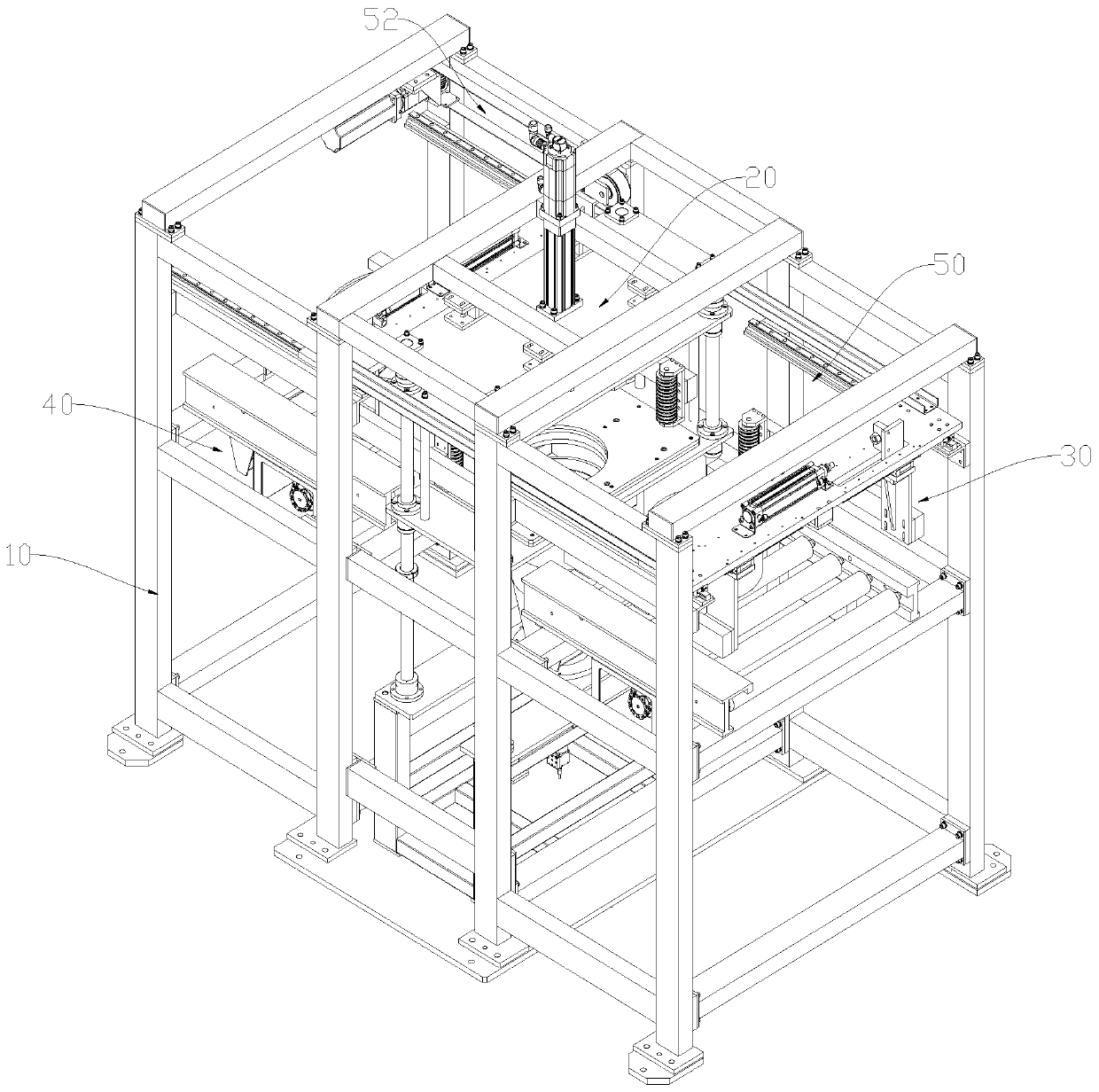

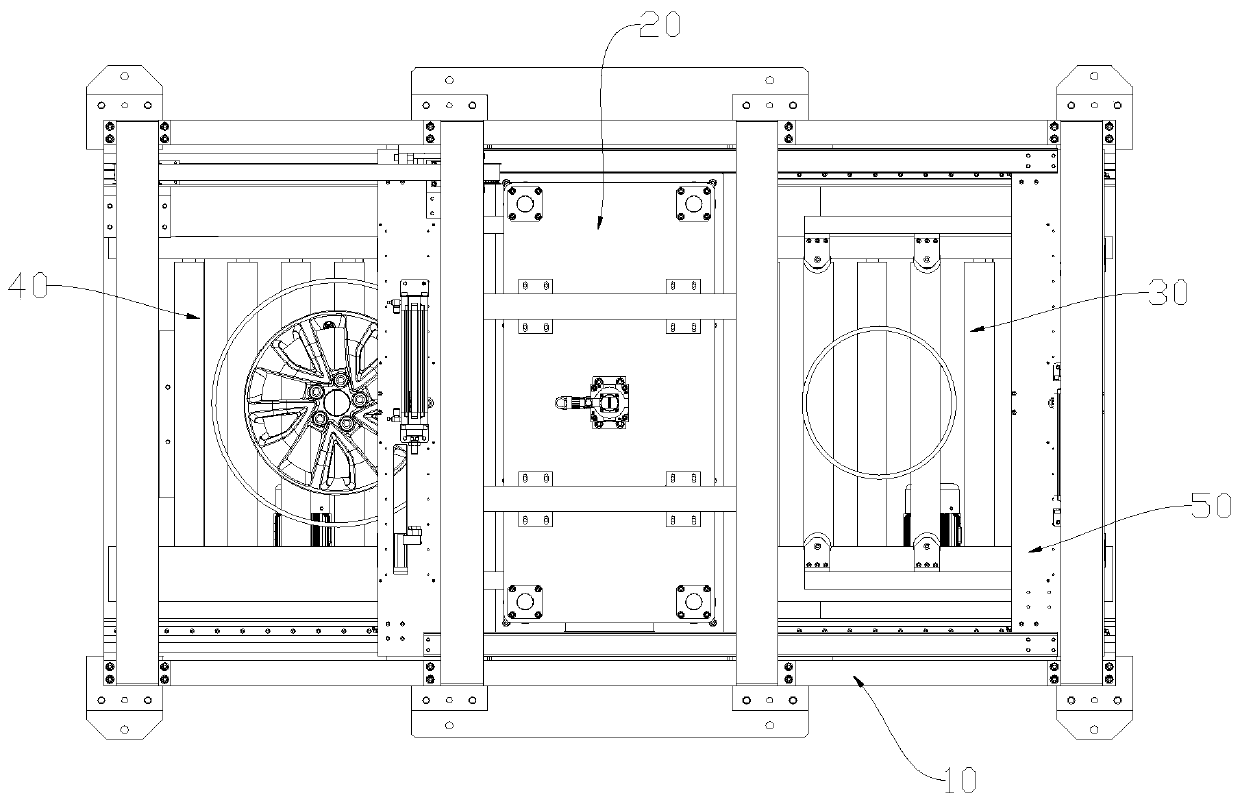

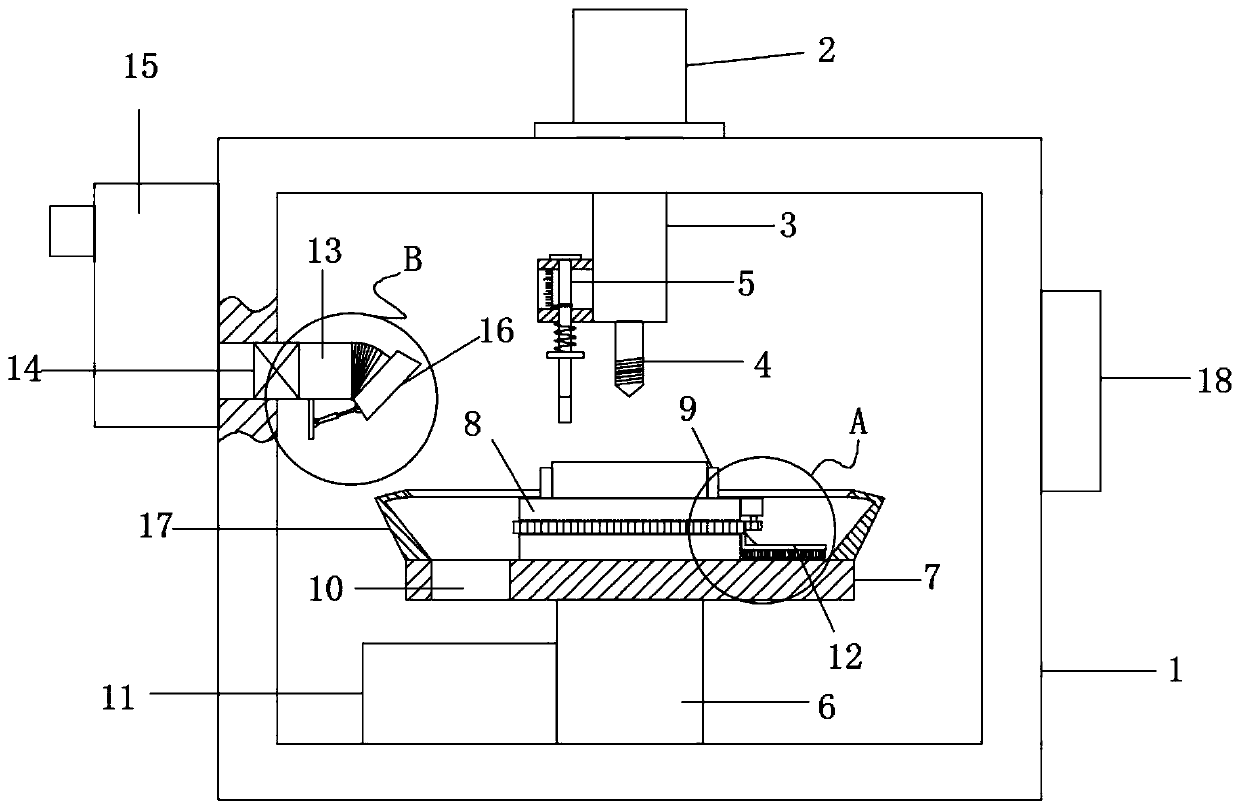

Device for detecting wheel hub and automobile component product

PendingCN110375653ARealize non-contact online detectionThe measurement results are objectiveUsing optical meansControl systemData acquisition

An embodiment of the invention discloses a device for detecting a wheel hub and an automobile component product. The device comprises a frame body, a lifting and lowering detecting device, a first workpiece conveying mechanism, a second workpiece conveying mechanism and a workpiece clamping and moving mechanism. The lifting and lowering detecting device comprises a bracket, a lens fixing plate, alifting and lowering device, a backlight source, a detecting platform, a lens and a camera. The lens is disposed on the lens fixing plate, the camera is disposed under the lens, the detecting platformis disposed above the lens, and the detecting platform is provided with a window penetrating the thickness direction of the detecting platform, a lower surface of the detecting platform is provided with a front light source, and the lifting and lowering device is respectively connected to the lens fixing plate and the detecting platform. Through the cooperation of the camera, the lens and the combined light source, the non-contact online detection is achieved, the automatic data acquisition, processing and automatic identification are completed by a vision system and a control system in the whole process, human subjective factors are reduced, the manual processing is not needed, the detection efficiency and detection accuracy are improved, and the labor cost is reduced.

Owner:长沙精锐智能科技有限公司

Grinding machine

ActiveCN103144018AIncrease exposureNo manual processingEdge grinding machinesPolishing machinesWork in processEngineering

The invention provides a grinding machine, which comprises a support, a rotary drum, a swing mechanism and a rotating mechanism, wherein the rotary drum is arranged on the support, and swings and rotates through the driving of the swing mechanism and the rotating mechanism. Joint lines on semi-finished products, such as glasses frames and the like, can be removed through the grinding machine provided by the invention, and manual treatment is not needed. Moreover, the rotary drum of the grinding machine can swing between different angles of inclination while rotating, and therefore, the contact degree between a workpiece and a grinding material is improved, and a powerful grinding effect is generated.

Owner:XIAMEN JINTAIJIN IND & TRADE

Laser drilling waste collecting mechanism

ActiveCN106392340AImprove cleanlinessReduce the impactLaser beam welding apparatusEngineeringLaser drilling

The invention discloses a laser drilling waste collecting mechanism which comprises a laser drilling rack; a processing box body is arranged on the upper part of the laser drilling rack; at least two telescopic air cylinders are fixedly arranged on the top plate of the processing box body; pushing rods of the telescopic air cylinders downwards pass through the top plate of the processing box body vertically, and are fixedly equipped with a rotary connecting frame; a rotary rod is positioned below the rotary connecting frame; the two ends of the rotary rod are hinged on the vertical plates hinged at the two sides of the rotary connecting frame; a rotary regulating motor is fixedly arranged on the outer side wall of one vertical plate; the output shaft of the rotary regulating motor is a spline shaft; the spline shaft is in plug bush in a spline hole in one end of the rotary rod; an air blowing box is fixedly arranged on the rotary rod; and a plurality of gas jetting tubes are connected on the bottom surface of the air blowing box. The laser drilling waste collecting mechanism disclosed by the invention can be used for automatically collecting waste without manual processing, so that cleanliness of a laser equipment operation environment is guaranteed, and operation of the laser drilling waste collecting mechanism is guaranteed to be normal; and moreover, people do not inhale waste, so that influence on health is reduced.

Owner:郑招才

Drilling machine for numerical control finish machining

InactiveCN110449634ANo problems with drilling errorsImprove drilling efficiencyDrilling/boring measurement devicesMeasurement/indication equipmentsHydraulic cylinderNumerical control

The invention discloses a drilling machine for numerical control finish machining, and belongs to the technical field of drilling machines. The drilling machine for numerical control finish machiningcomprises a machine shell, wherein a hydraulic cylinder is arranged in the middle of the top end of the machine shell, the output end of the hydraulic cylinder penetrates through the top wall of the machine shell and is connected with a telescopic rod, the bottom end of the telescopic rod is provided with a drilling mechanism, a zero setting mechanism is arranged on the left side of the drilling mechanism, and a supporting base is arranged in the middle of the bottom wall of the machine shell in an internally-embedded mode. According to the drilling machine, through arrangement of the zero setting mechanism, a drill bit is replaced with zero setting mechanism to abut against a workpiece drilling surface, so that the problem that drilling errors caused by excessive abutting does not occur;when in use, an input depth instruction is calculated according to a telescopic change value of the zero mechanism, accurate drilling machining is completed, the drilling efficiency effect is greatlyimproved, chippings can be collected through an arranged cover body, chippings in the cover body can be swept and collected through the arranged cleaning mechanism, the chippings in the cover body canbe swept and collected through an arranged sweeping mechanism, manual treatment is not needed, multi-angle negative pressure dust removal can be realized through an arranged fan dust removal mechanism, and raise dust chippings generated in the machining process can be removed.

Owner:HANSHAN QINGXI DESHENG FOUNDRY FACTORY

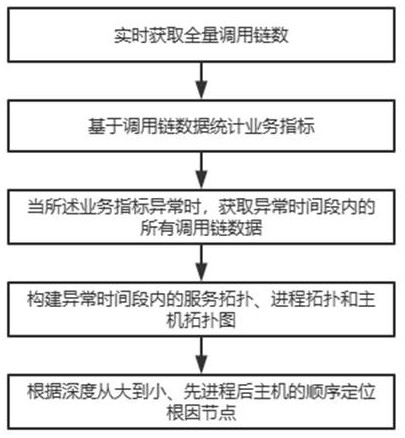

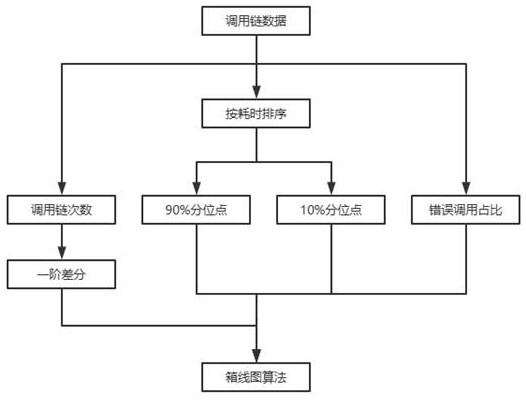

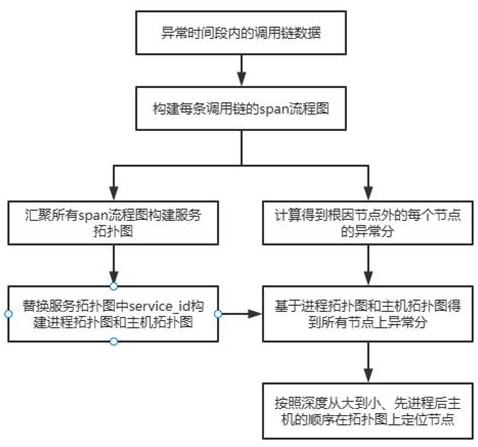

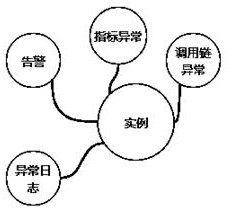

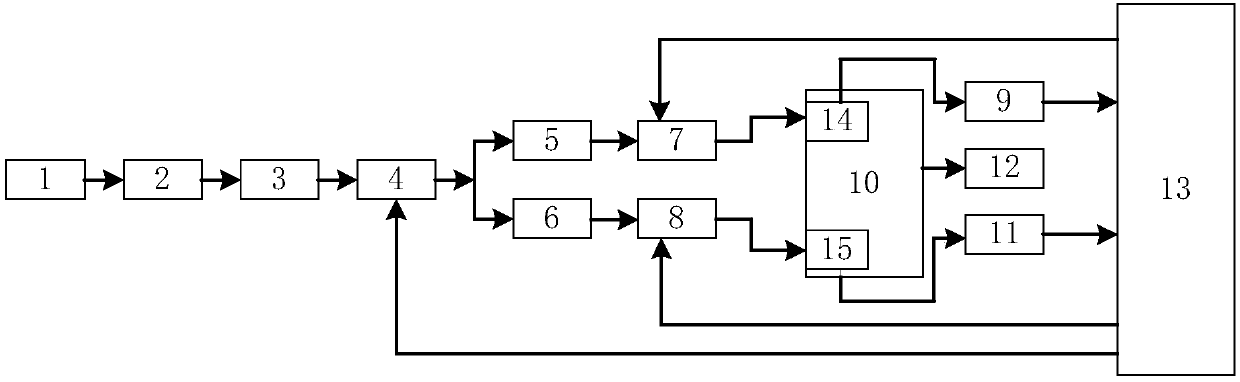

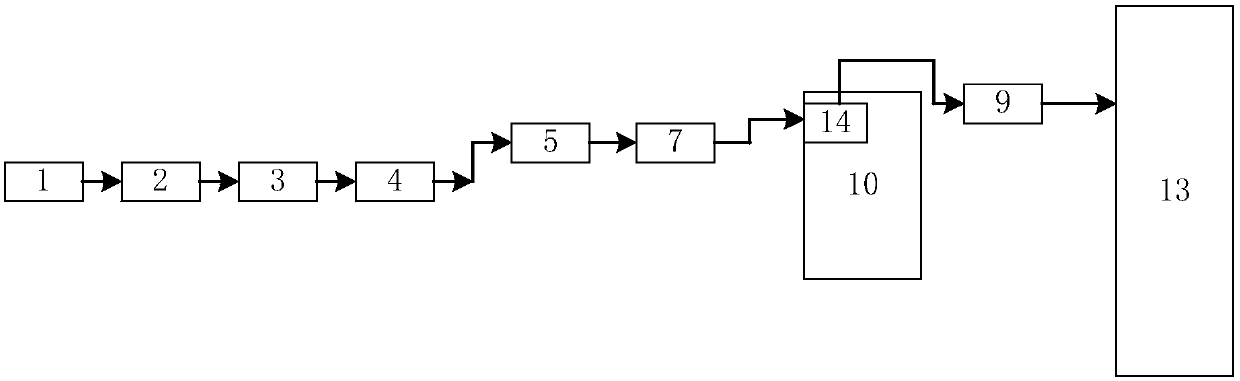

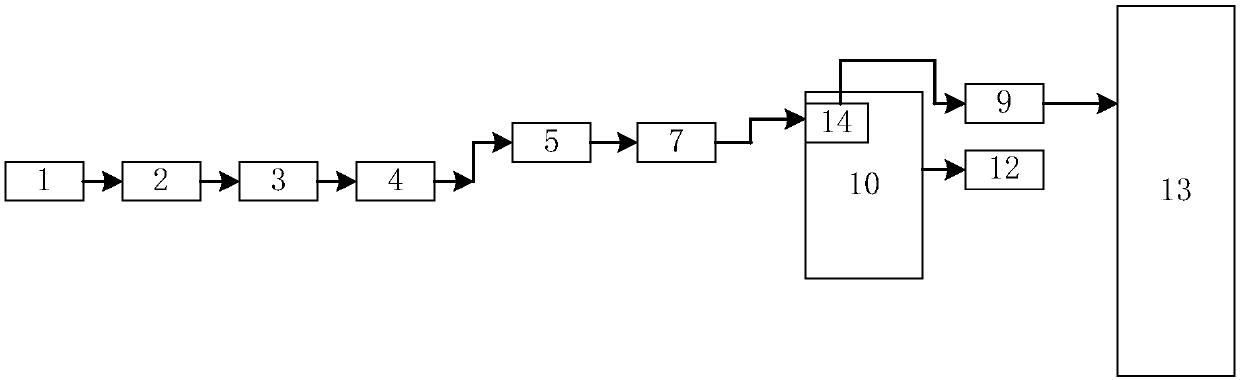

Fault root cause positioning method of micro-service system

ActiveCN114024837ANo manual processingMeet real-time requirementsTransmissionData transformationTopological graph

The invention discloses a fault root cause positioning method for a micro-service system, which comprises the following steps of: acquiring call chain data in the micro-service system in real time, converting the call chain data into four business indexes and monitoring in real time, when an exception is found, constructing a service topological graph, a process topological graph and a host topological graph by using a call chain in an exception time period, calculating an abnormal score of each node on the topological graph, and finally positioning to a root cause node, namely a process node or a host node, according to a sequence from large depth to small depth and from process to host. According to the obtained call chain data, the topological relation of the host level can be dynamically constructed, the topological relation of the process level and the topological relation of the service level can also be dynamically constructed, and data guarantee is provided for more accurate root cause positioning. According to the method, the call chain data in the abnormal time period are analyzed in real time by utilizing an unsupervised algorithm, and training data and labels are not needed.

Owner:杭州乘云数字技术有限公司

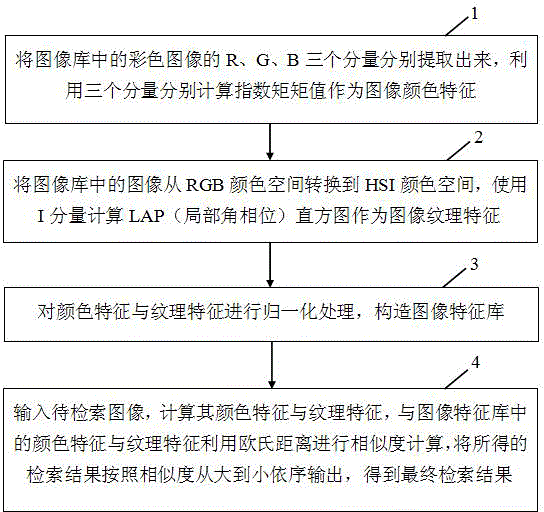

Color image searching method based on multiple features

InactiveCN104484425AGuaranteed accuracyNo manual processingImage analysisCharacter and pattern recognitionColor imageCoupling

The invention discloses a color image searching method based on multiple features. The method comprises the following steps: during a process of searching the color image, extracting R,G, B channels of a to-be-searched color image, respectively calculating an exponential moment value of each channel and taking the exponential moment value as a color feature; converting the color image from an RGB color space into an HIS color space, utilizing an I component to calculate a local corner phase feature and taking the local corner phase feature as a textural feature; comprehensively performing color image searching through the color feature and the textural feature. The color information and the textural information of the image are combined with each other, so that the method provided by the invention can be effectively applied to the color image searching, the precision of the searching result is ensured, the method has the characteristics of simple calculation, no need of manual treatment on to-be-searched image, strong universality, low coupling, and the like, and the practicability for digital image searching is enhanced.

Owner:LIAONING NORMAL UNIVERSITY

Classification recycling treatment equipment for building solid waste garbage and classification recycling treatment method

InactiveCN112044568AReduce labor intensityWill not harmGrain treatmentsStone-like material working toolsRebarProcess engineering

The invention discloses classification recycling treatment equipment for building solid waste garbage and a classification recycling treatment method. The classification recycling treatment equipmentcomprises a mounting bottom frame, rotating rollers, a cutting and crushing device and a cleaning and sorting device, the cutting and crushing device is arranged at the front end of the mounting bottom frame, and the rotating rollers are arranged between the inner walls of the mounting bottom frame and are linearly arranged; and a material falling opening is formed in the front side of the mounting bottom frame, and the cleaning and sorting device is arranged at the material falling opening and located on the lower side of the cutting and crushing device. The problems that in a process of recycling building solid waste garbage at present, prefabricated floor slabs need to be crushed manually by means of tools such as hammers and electric drills, and reinforcing steel bars need to be separated from concrete manually are solved.

Owner:郭亚征

Thread cutting equipment for processing strong polyester long silk thread

The invention discloses thread cutting equipment for processing a strong polyester long silk thread. The thread cutting equipment comprises a supporting base, two supporting rods are arranged at the top of the supporting base in the vertical direction in an embedded mode, a supporting block is welded to the position, located on the vertical center line of the two supporting rods, of the top of thesupporting base, and air bags are boned to the two sides of the supporting blocks along the horizontal center line. In the thread cutting equipment for processing the strong polyester long silk thread, in the winding process of the equipment, two supporting plates push the two supporting rods, a semi-circle block move downwards, and the polyester long silk thread in the winding can be squeezed toprevent the polyester long silk thread from loosing; and when a thread drum does not rotate, the clamping block and a positioning block are further just clamped with each other, when a first limitingrod is separated from a rotating shaft, that is, the moment at which the thread drum stops rotating, a second gear and a third gear can be just connected with each other in a meshing mode, a motor drives a round rod to rotate, and the polyester long silk thread is cut to realize automatic cutting of the polyester long silk thread.

Owner:湖南锦绣新合纤有限公司

Rice screening device with dust removal function for rice production

ActiveCN110238057AImprove cleanlinessImprove screening efficiencySievingGas current separationEngineering

The invention provides a rice screening device with a dust removal function for rice production. The rice screening device with the dust removal function for rice production comprises a screening box, a dust removing mechanism, a box-shaped screening net, supporting mechanisms, a lifting mechanism and a stirring mechanism, the top of the screening box is fixedly provided with a feeding pipe, the side wall of the feeding pipe is fixedly provided with an exhaust fan, the dust removing mechanism is arranged in the feeding pipe, the box-shaped screening net for screening the rice is arranged in the screening box, the four supporting mechanisms are symmetrically arranged on the inner top wall of the screening box correspondingly, the four supporting mechanisms are used for supporting corners of the bottom wall in the box-shaped screening net, the lifting mechanism is arranged in the screening box, and the stirring mechanism is arranged in the screening box. The rice screening device with the dust removal function for rice production has the advantages of dust removal and high rice screening efficiency.

Owner:东营市垦利区万隆农林经贸有限公司

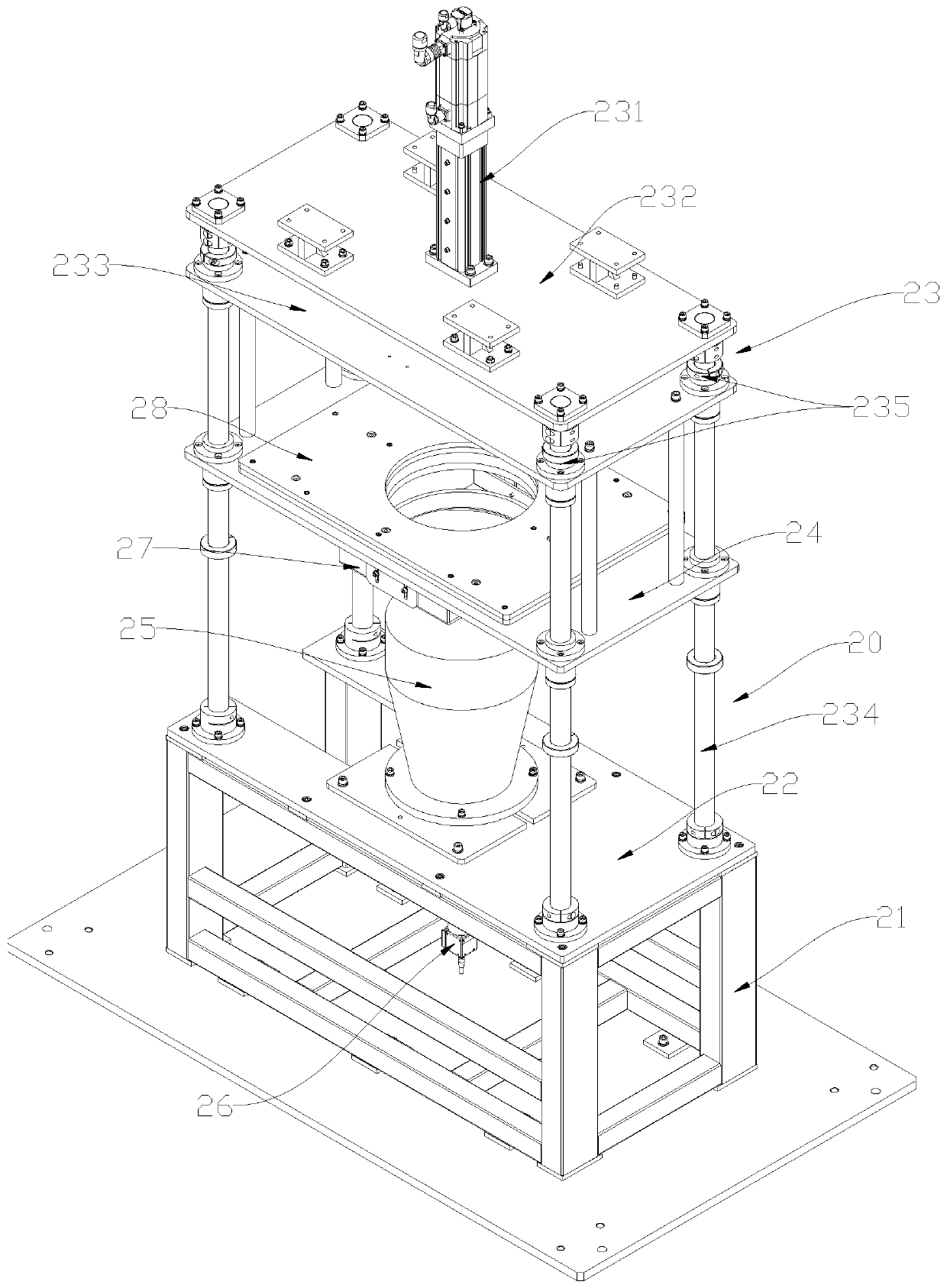

Machining device for lower end enclosure of steel cylinder

ActiveCN106112553AIncrease productivityReasonable designOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The invention belongs to the technical field of steel cylinder machining, in particular to a machining device for a lower end enclosure of a steel cylinder. An end enclosure trimming mechanism and an end enclosure closing mechanism are arranged on two sides of a rack; the end enclosure trimming mechanism is located on one end of the rack; the end enclosure closing mechanism is located on the other end of the rack; the end enclosure trimming mechanism comprises a trimming positioning mould which is arranged on the rack and is used for placing an end enclosure blank; the end enclosure trimming positioning mould is fixed on the upper end of a trimming spindle; a trimming inner tool which sleeves the trimming spindle and can rotate simultaneously with the trimming spindle is arranged below the trimming positioning mould; a trimming outer tool is arranged on the outer side of the trimming inner tool; the trimming outer tool is connected with the rack through a trimming outer tool cylinder which is capable of driving the trimming outer tool to horizontally approach or depart from the trimming inner tool; the trimming spindle is connected with a trimming spindle driving mechanism which can drive the trimming spindle to rotate; and a scrap removing mechanism is also arranged on the end enclosure trimming mechanism. Compared with the prior art, the machining device is advantaged in that 1, design is reasonable; and 2, the automation degree is high.

Owner:深圳市智恩自动化设备有限公司

Full-automatic cutting-off machine

InactiveCN106270717ANo manual processingImprove processing efficiencyMetal-working feeding devicesShearing machinesDrive shaftEngineering

The invention discloses a full-automatic cutting-off machine. The full-automatic cutting-off machine comprises a machine table, a power device, a feeding device, a material receiving device, a head trimming device and a clamping and cutting-off device, the power device, the feeding device, the material receiving device, the head trimming device and the clamping and cutting-off device are installed on the machine table, and the feeding device, the material receiving device, the head trimming device and the clamping and cutting-off device are separately connected with the power device; the feeding device comprises a material tray, a driven shaft, a material trimming wheel installed on the driven shaft, a rotating shaft, a feeding wheel installed on the rotating shaft, a driving belt for connecting the driven shaft with the rotating shaft, a ratchet wheel installed at one end of the rotating shaft, a driving rod connected with the power device and a pawl installed at the free end of the driving rod; the power device drives the driving rod to move in a back and forth reciprocating mode so as to drive the feeding wheel and the material trimming wheel to rotate, and the feeding wheel is used for conveying workpieces in the material tray to the material receiving device. According to the full-automatic cutting-off machine, the feeding device, the material receiving device, the head trimming device and the clamping and cutting-off device are simultaneously driven by the power device to automatically complete all actions, manual processing is not needed, the processing efficiency is high, and the full-automatic cutting-off machine is safe and reliable.

Owner:广东领航精密机械设备科技有限公司

Integrated organic fertilizer treatment system and organic fertilizer preparation method

InactiveCN106045582AEasy to detectRealize automatic clearing deviceClimate change adaptationExcrement fertilisersEngineeringOrganic fertilizer

The invention discloses an integrated organic fertilizer treatment system and an organic fertilizer preparation method. The system comprises a poultry or livestock captive breeding area, a control unit, an excrement discharge detection unit, an excrement scraping and sweeping unit, an excrement liquid filtering unit and a fermentation unit, wherein a plurality of captive breeding units are converged to a first transmission pipeline respectively by a transmission pipeline unit; the first transmission pipeline is connected with the excrement liquid filtering unit; the excrement liquid filtering unit is connected with the fermentation unit by a second transmission pipeline; the excrement discharge detection unit is arranged on the ground of the poultry or livestock captive breeding area; the excrement scraping and sweeping unit is arranged on the opposite wall in the poultry or livestock captive breeding area; the excrement discharge detection unit and the excrement scraping and sweeping unit are separately connected with the control unit. After the system is adopted, not only is the labor intensity lightened in agricultural production, but the ecological balance of the soil is also adjusted, and the permeability of the soil is improved.

Owner:WUXI LEHUA AUTOMATION TECH

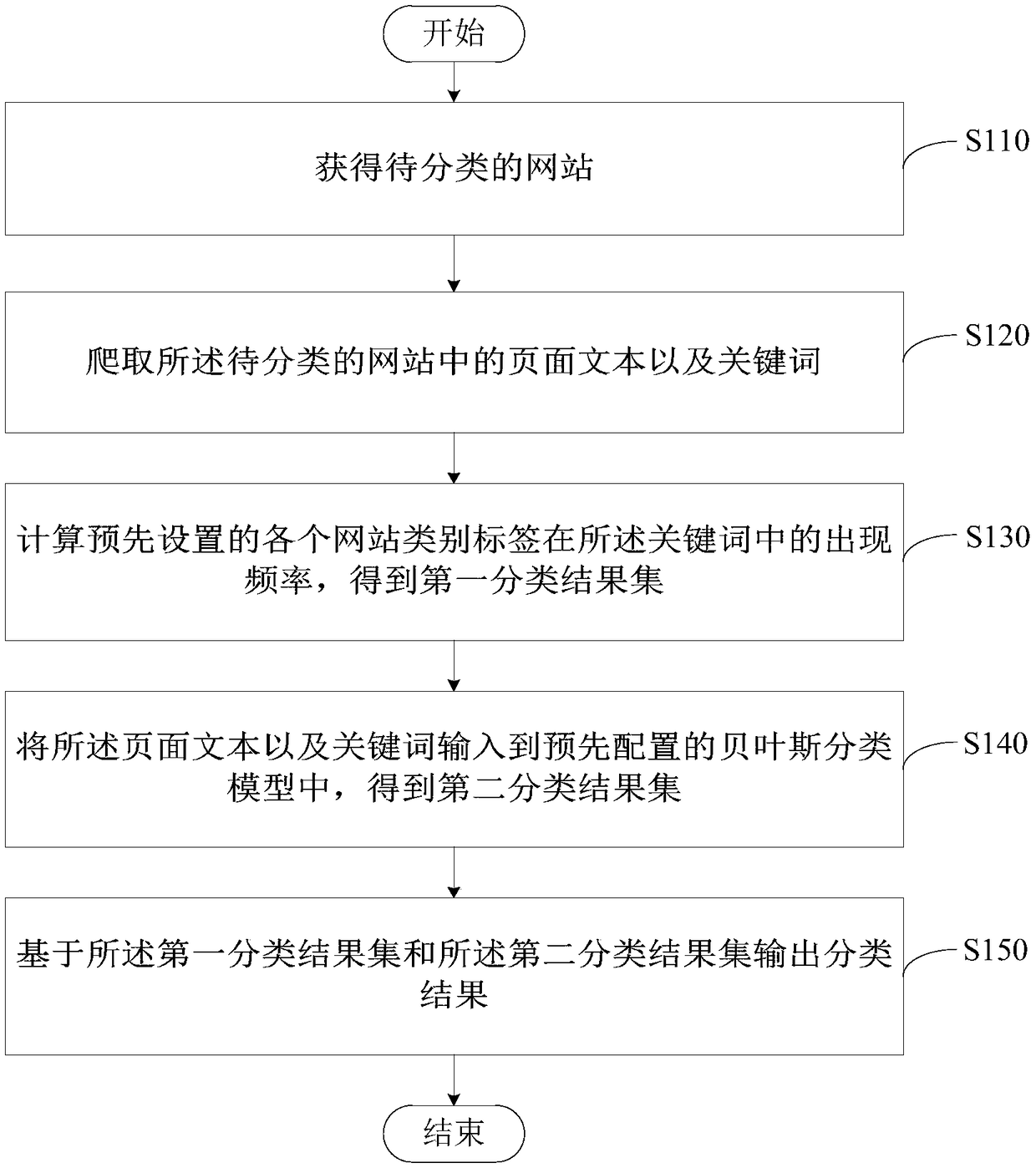

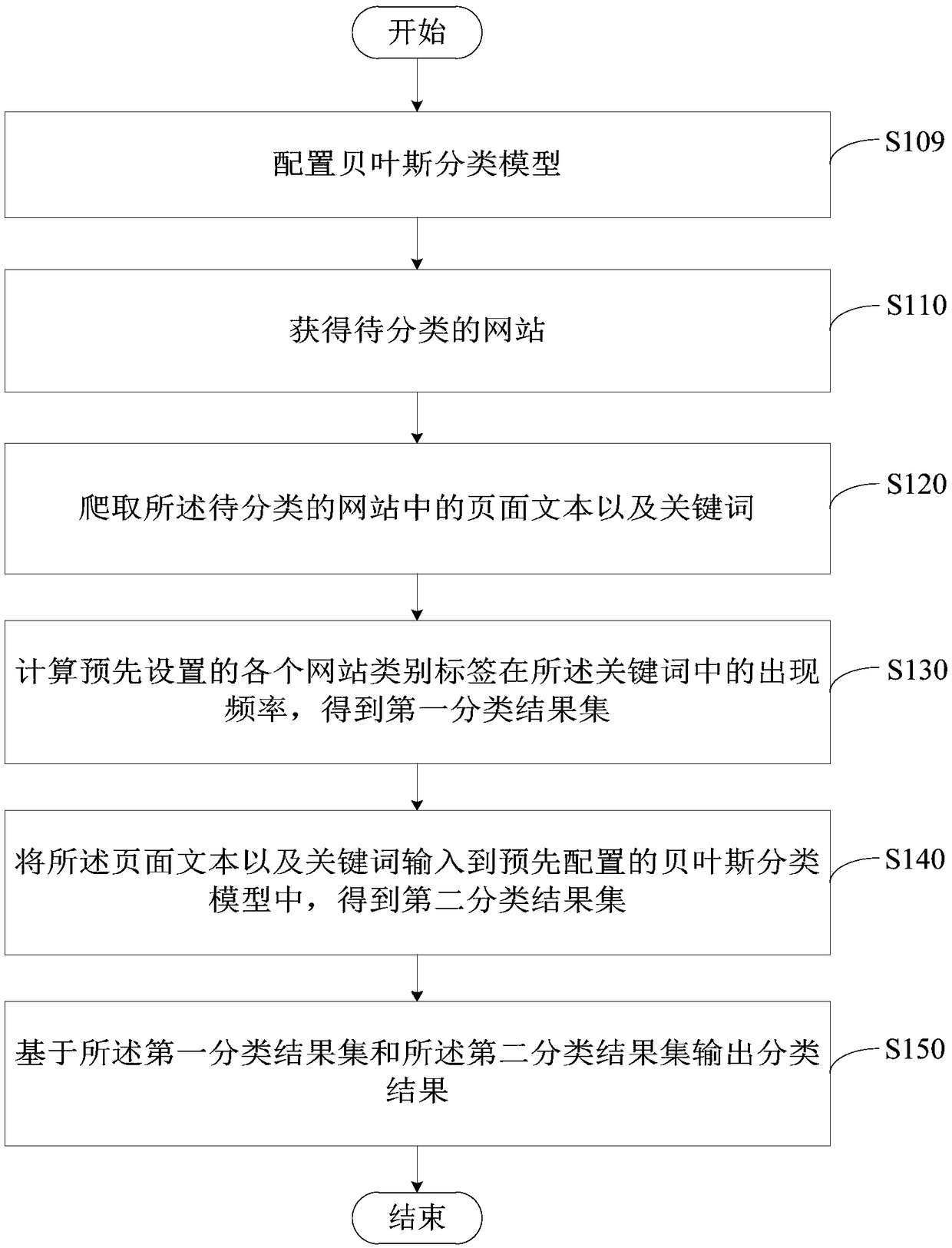

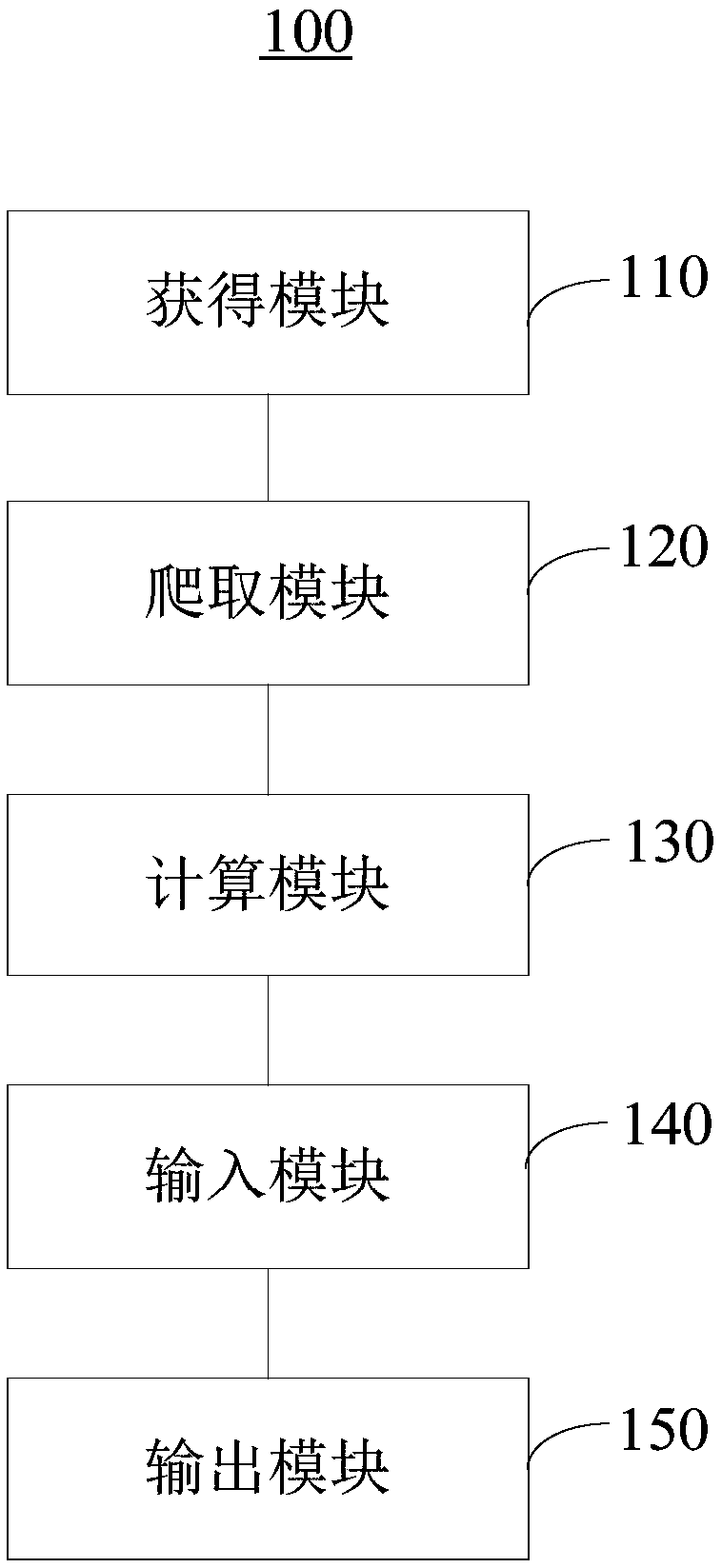

Website classification method and device

ActiveCN108874996AAccurate classificationNo manual processingCharacter and pattern recognitionSpecial data processing applicationsWeb siteClassification methods

Embodiments of the invention provide a website classification method and device. The method comprises the following steps of: obtaining a to-be-classified website; crawling a page text and a keyword in the to-be-classified website; calculating an occurrence frequency, in the keyword, of each preset website category label so as to obtain a first classification result set, wherein each website category label comprises a label name and synonyms thereof; inputting the page text and the keyword into a pre-configured Bayesian classification model so as to obtain a second classification result set, wherein the second classification result set comprises a predicted probability value of each website category label, and training samples of the Bayesian classification model are obtained through website crawling; and outputting a classification result on the basis of the first classification result set and the second classification result set. By adoption of the method and device, manual processing is not needed, the workload is small, and correct website classification can be realized when webpage text data is less.

Owner:BEIJING KNOWNSEC INFORMATION TECH +1

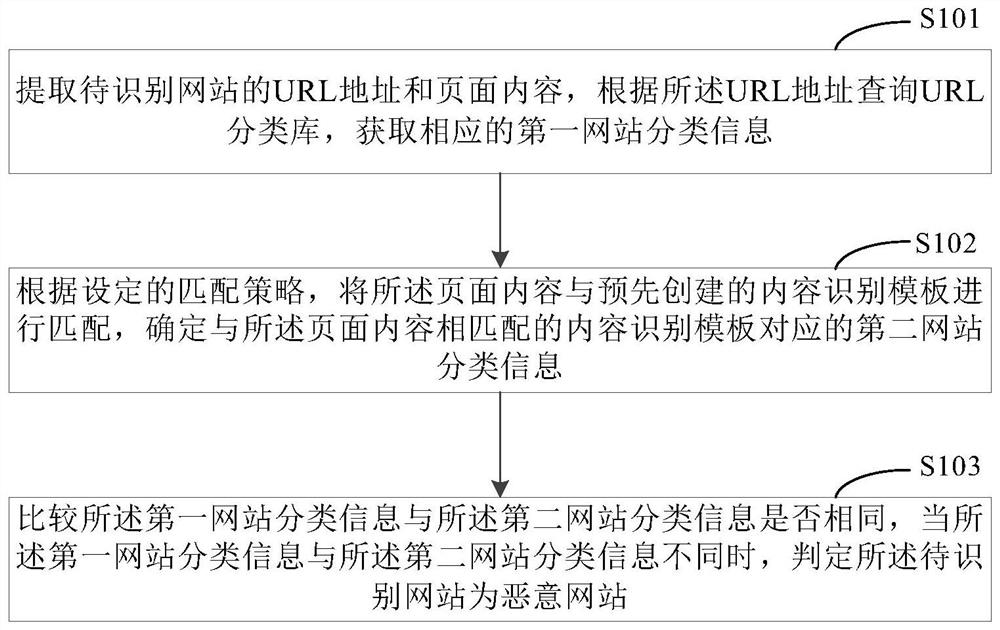

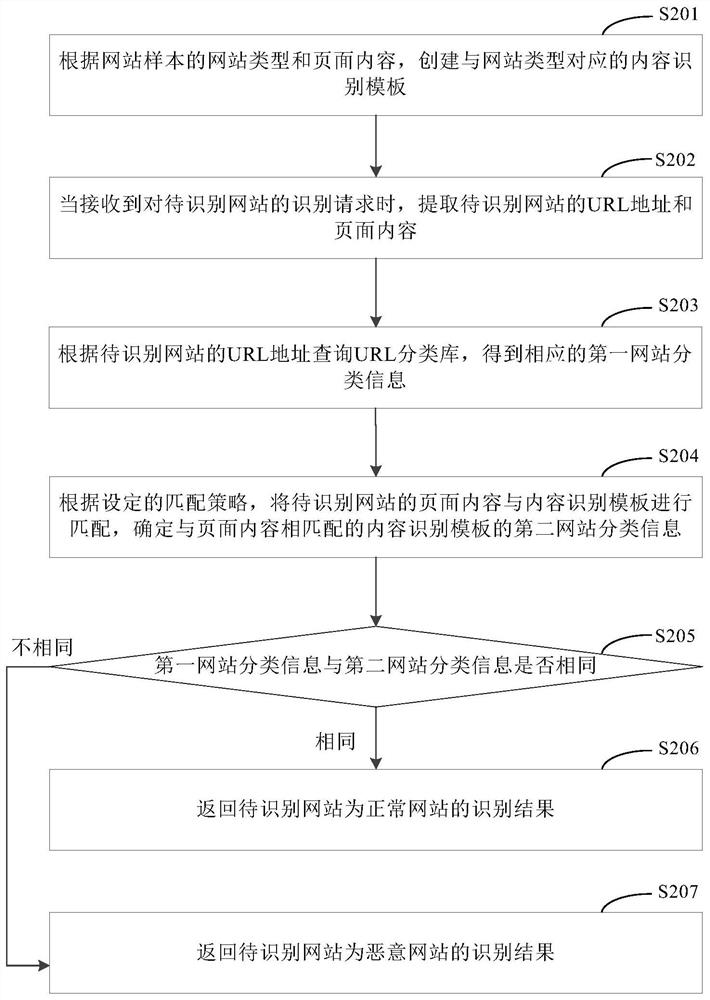

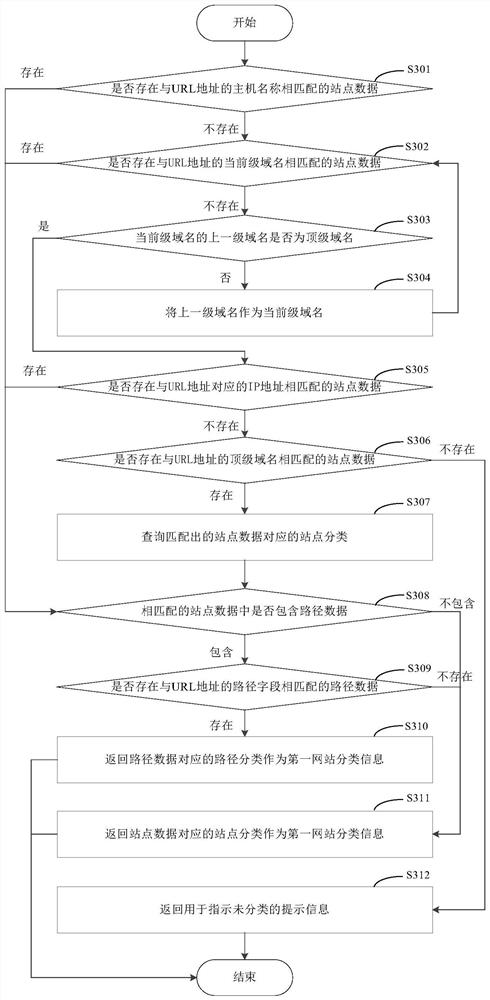

Malicious website identification method and device

PendingCN111753171ARecognition speed is fastEasy to identifyFinanceNatural language data processingWeb siteTemplate match

The invention discloses a malicious website identification method and device, and relates to the technical field of network security. A specific embodiment of the method comprises the steps of extracting a URL address and page content of a to-be-identified website, and querying a URL classification library according to the URL address to obtain corresponding first website classification information; wherein the URL classification library stores a mapping relationship between a URL address sample and website classification information, and the first website classification information is determined from the website classification information; matching the page content with a pre-created content identification template, and determining second website classification information corresponding to the content identification template matched with the page content; and comparing whether the first website classification information is the same as the second website classification information ornot, and when the first website classification information is different from the second website classification information, judging that the to-be-identified website is a malicious website. Accordingto the embodiment, the malicious website can be identified before the URL address of the to-be-identified website is recorded, so that the identification speed and the identification rate of the malicious website are improved.

Owner:北京天空卫士网络安全技术有限公司 +1

Fluorescent encoding magnetic bead-based detection method and detection kit

PendingCN110261602AAchieving Simultaneous DetectionQuick checkIndividual particle analysisBiological testingAutomatic controlMicrosphere

The invention belongs to the technical field of biological nano magnetic bead application and medical examination and relates to a fluorescent encoding magnetic bead-based detection method. The method comprises a capture step, a compound formation step, a separation step and an excitation and determination step. According to the capture step, the compound formation step and the separation step, fluorescent encoding microspheres are specifically bound with required target molecules; a magnetic column is adopted as a transport tool for a compound so as to transfer the compound to different reaction environments; automatic control can be realized; and rapid detection is realized. According to the excitation and determination step, a fluorescence spectrophotometric detection method, a flow cell detection method and a liquid phase chip detection method, are adopted to realize the simultaneous detection and high-throughput detection of different target molecules, in particular, the flow cell detection method can realize intelligent automatic detection through storing a fluorescence encoding microsphere spectral waveform database.

Owner:SUZHOU BAIYUAN GENT CO LTD +1

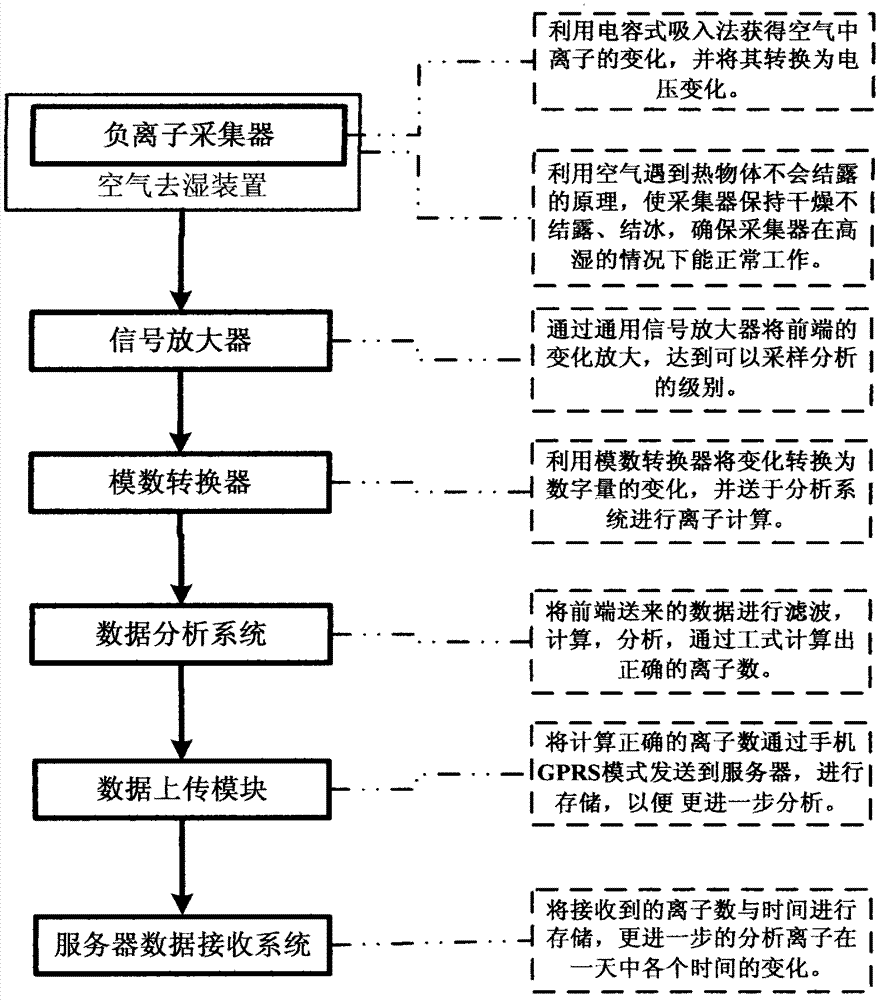

Atmospheric negative oxygen ion monitoring system and monitoring method thereof

InactiveCN103197030AStable detectionAccurate detectionIndividual particle analysisHigh humidityOxygen ions

The invention discloses an atmospheric negative oxygen ion monitoring system and a monitoring method thereof, and relates to the field of measurement of the free electron namely atmospheric negative oxygen ion. The system comprises a negative ion collector, a signal amplifier, an analog to digital converter, a data analysis system, a data upload module and a server data receiving system. The negative ion collector is provided with an air moisture-removal device. The invention solves the problem of measurement of negative ions in air with high humidity, so that the device can conduct all-weather work under high humidity conditions, and has advantages of simple operation and strong practicability.

Owner:谢文斌

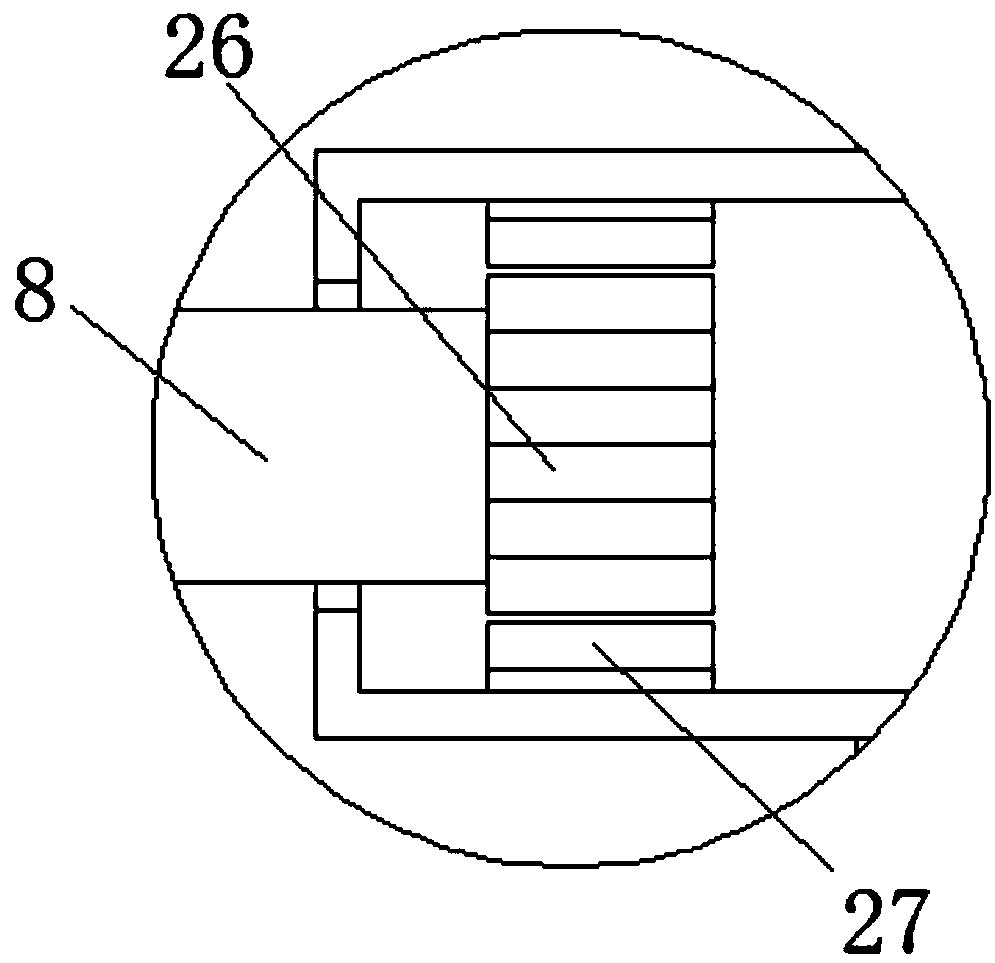

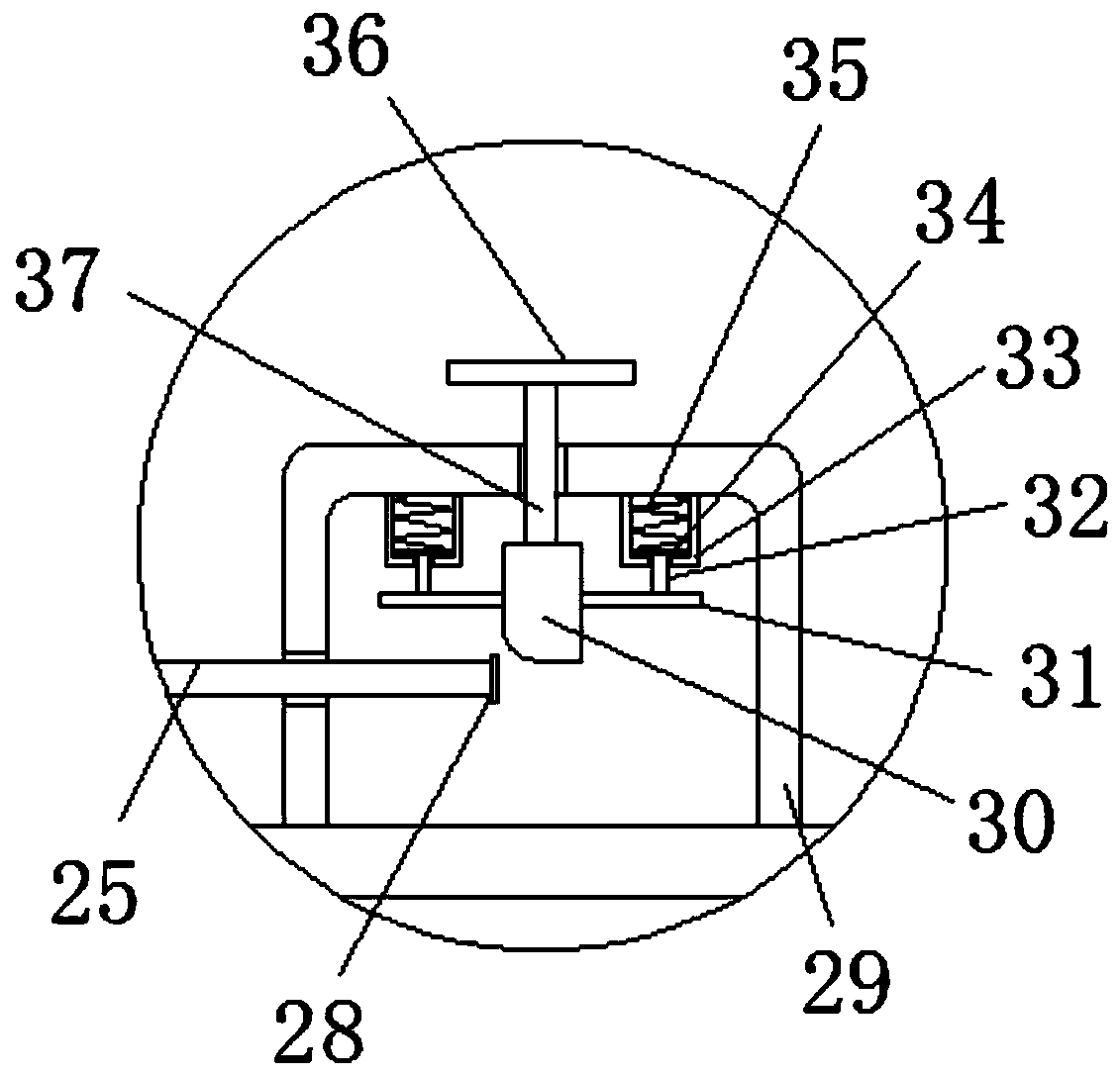

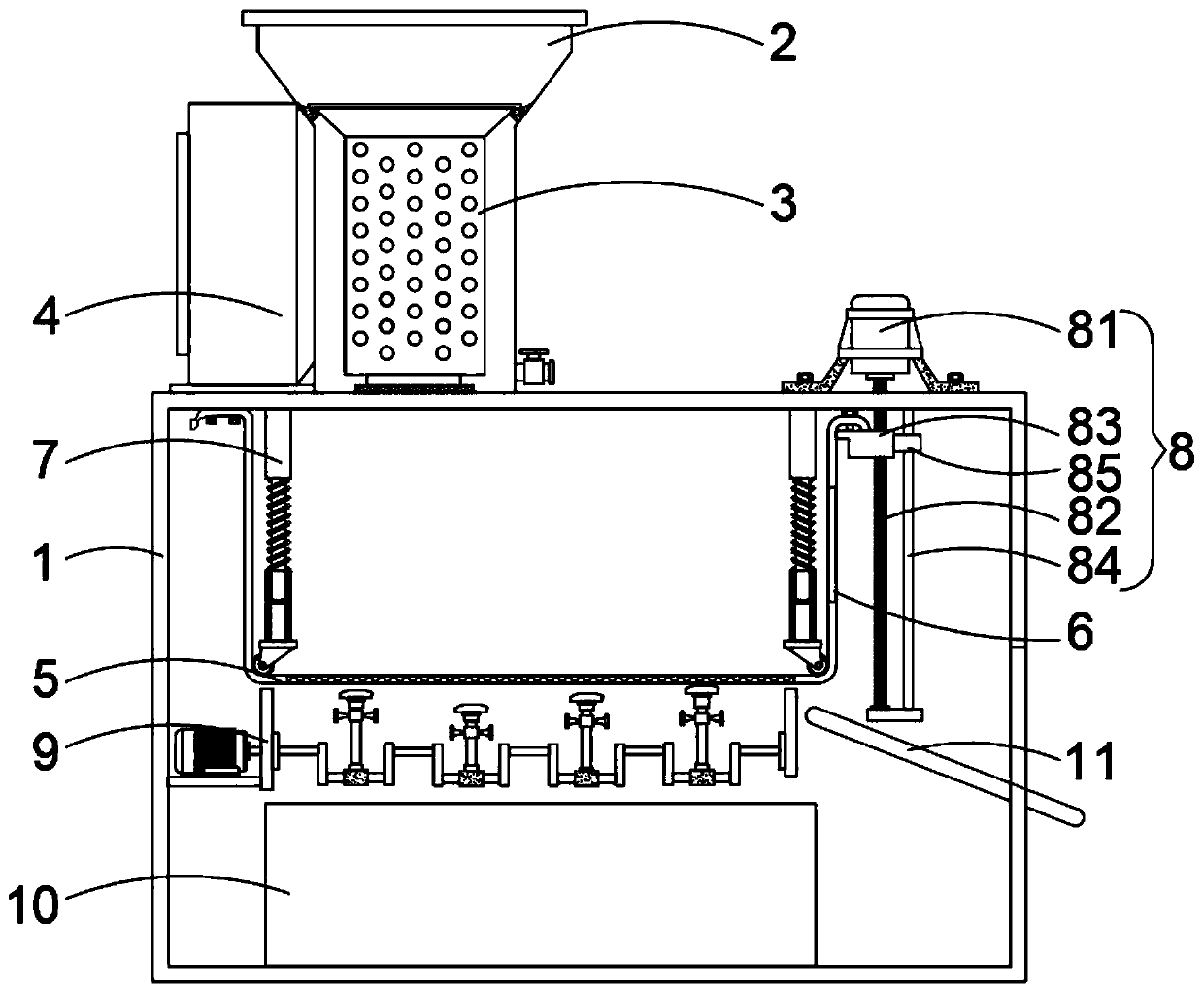

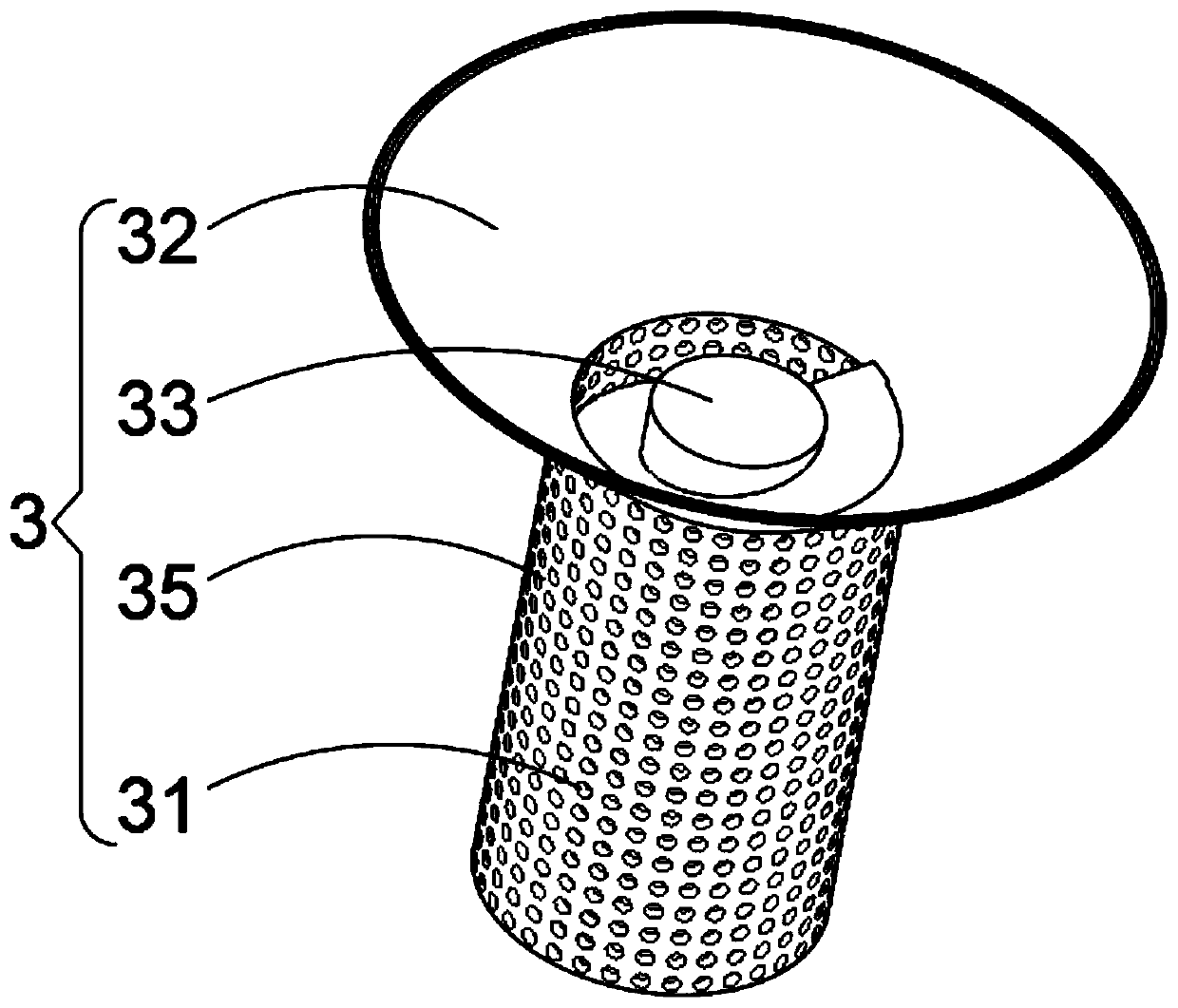

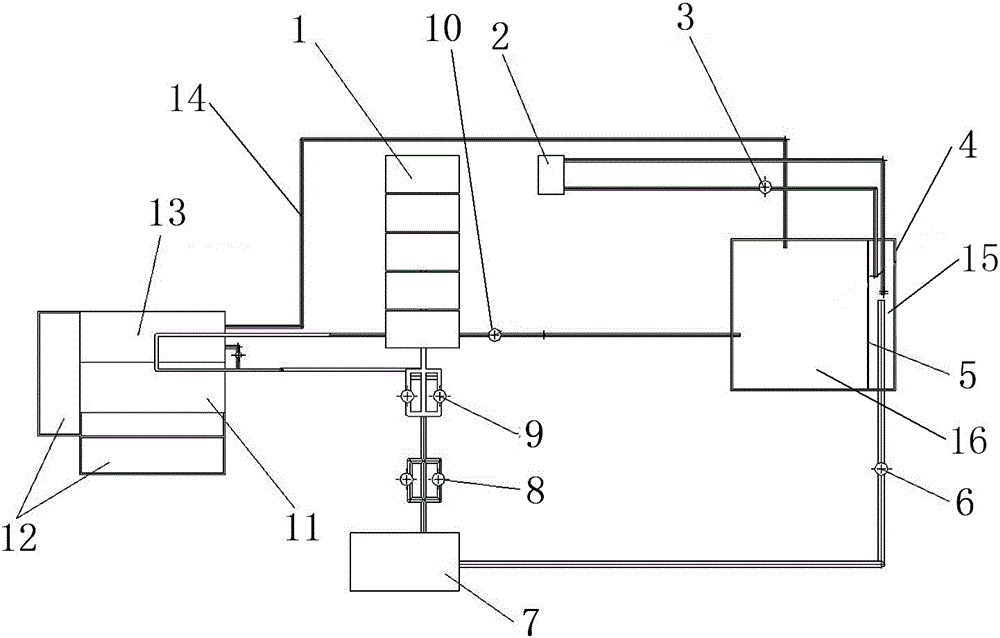

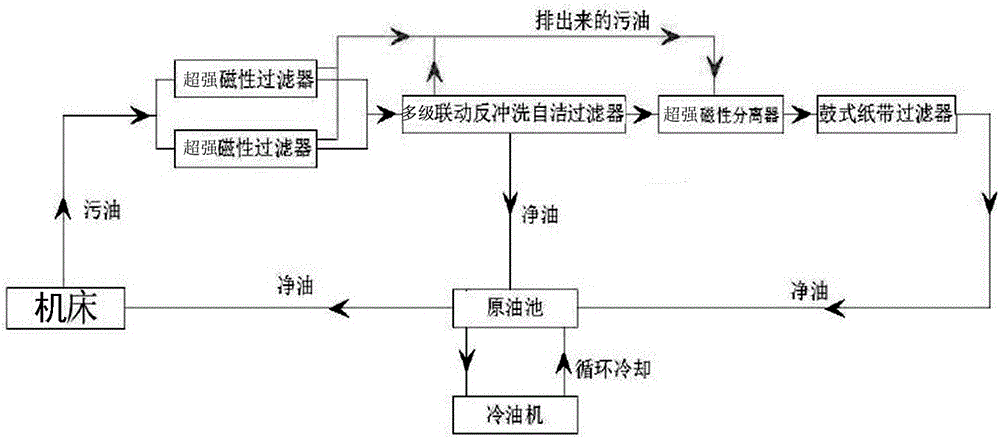

Centralized filtration and oil supply system for machine tool machining

PendingCN106425873AEfficient removalNot easy to stickMagnetic separationGrinding/polishing apparatusFiltrationMagnetic separator

The invention discloses a centralized filtration and oil supply system for machine tool machining. The centralized filtration and oil supply system for machine tool machining comprises a waste oil pipeline connected with the outer portion of a machine tool. The waste oil pipeline is connected with a waste oil pump and a super-strong magnetic filter in sequence. The output end of the super-strong magnetic filter is connected with a multi-stage linkage backwashing self-cleaning filter and a super-strong magnetic separator correspondingly. The output end of the multi-stage linkage backwashing self-cleaning filter is connected with the super-strong magnetic separator and also connected with a crude oil pool. The output end of the super-strong magnetic separator is connected with the crude oil pool through a drum-type paper tape filter. The output end of the crude oil pool is connected with the oil inlet end of the machine tool through an oil scavenging pump. Compared with the prior art, a traditional working manner is changed; equipment investment is reduced through a centralized oil supply method; the occupied workshop area is small; artificial control is not needed; automatic oil supply, filtering and cooling are realized; automation is realized completely, and the centralized filtration and oil supply system is economical and friendly to environment.

Owner:新野鼎邦实业有限公司

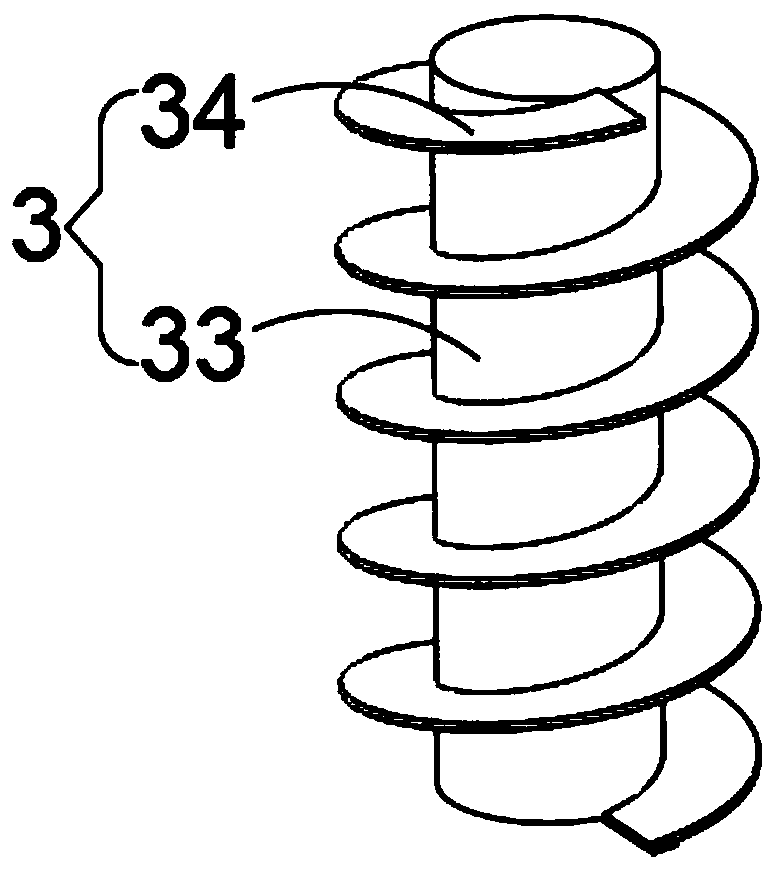

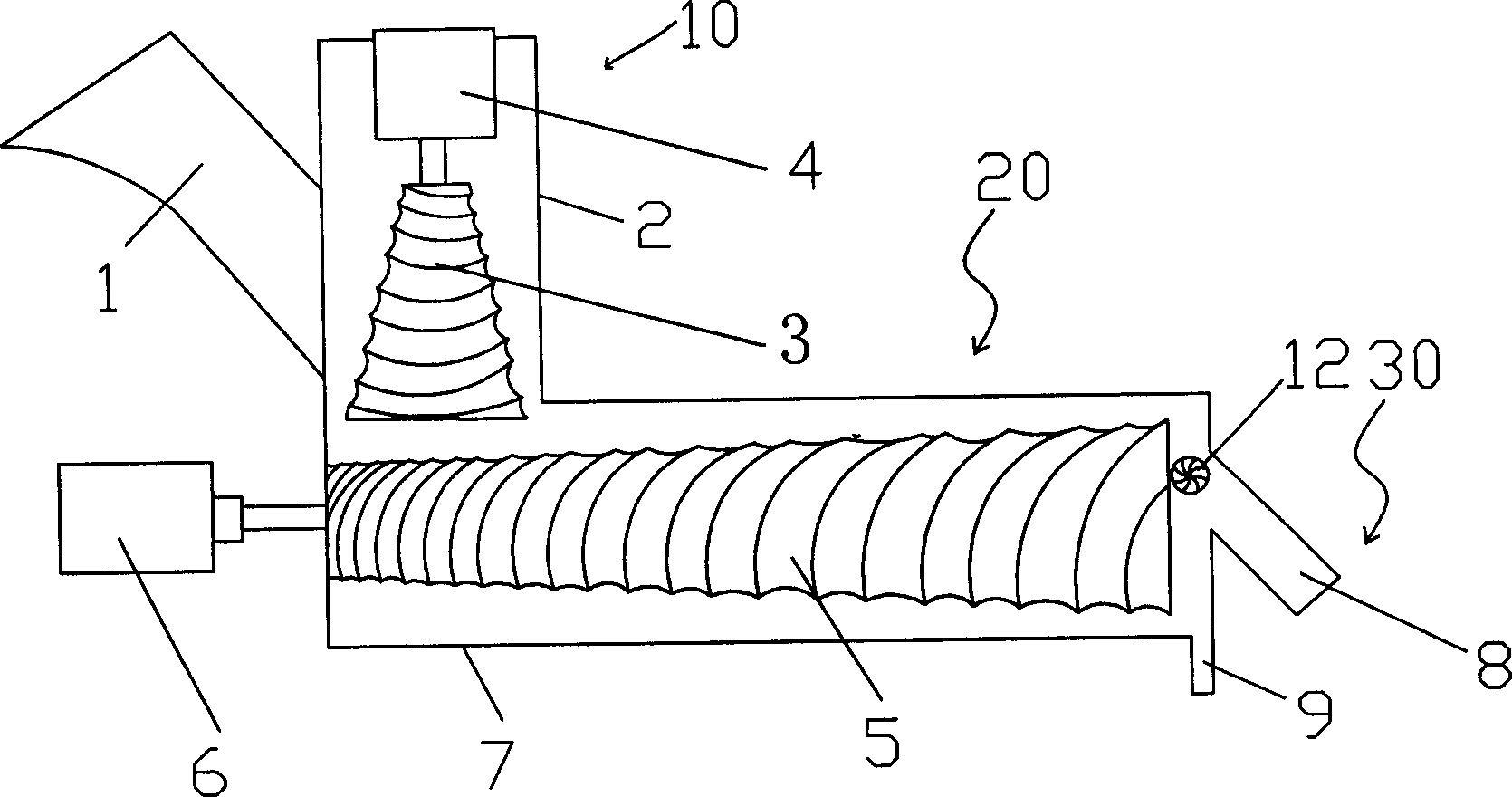

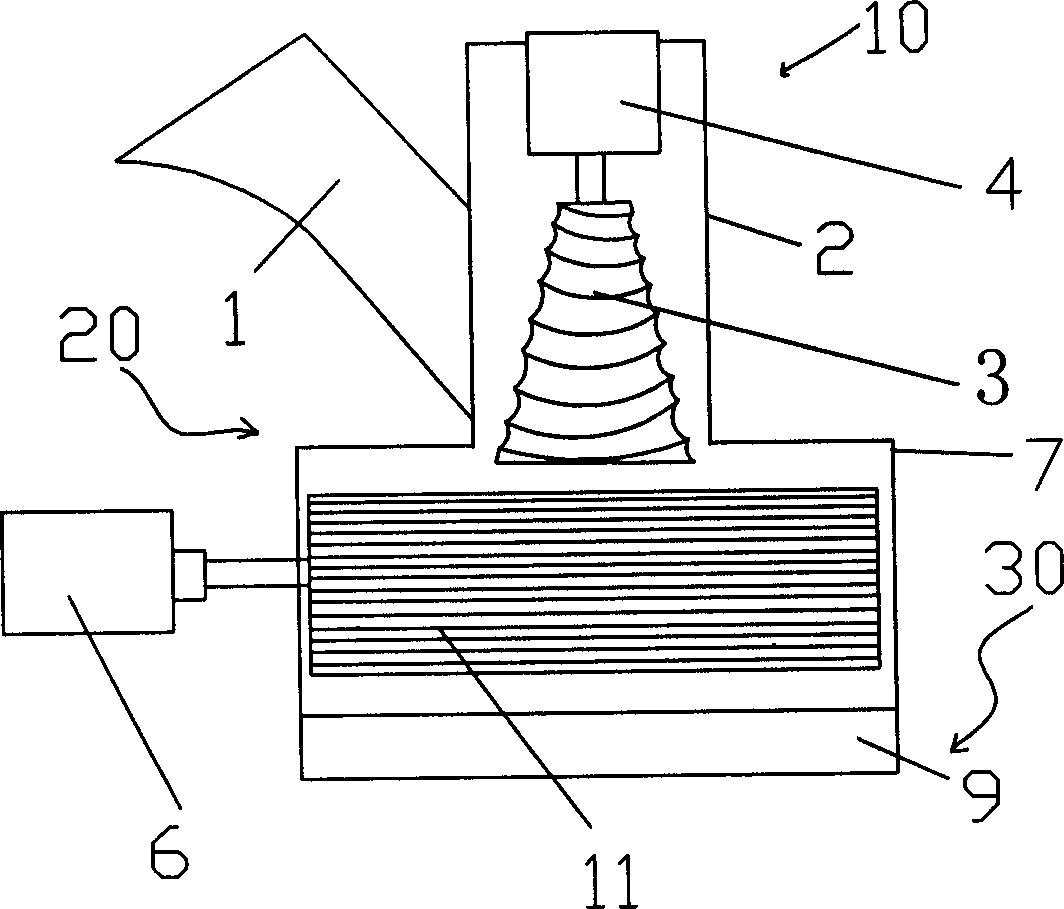

Waste plastic bottle squeezing and label stripping machine

InactiveCN1799804AEasy to transportNo manual processingPlastic recyclingDomestic articlesDrive motorManual handling

The invention relates to a compression label-remove device of waste plastic bottle, which comprises a feeding device (10), a compression device (20), and discharging device (30) while they are connected in sequence. Wherein, the feeding device has a feeding inlet and the discharging device has a discharging outlet; the compression device (20) comprises a compression case (7) inside which a rod (11) with tooth on its surface is arranged; the rod (11) is connected to drive motor; the discharging outlet is under the rod (11); the feeding device comprises a feeding case (2) which has said feeding inlet and inside which a first taper screw (3) is vertically arranged to said rod (11); and said screw is connected to the drive motor while its distance between the inner wall of case (2) can increase along the feeding direction. The invention can compress plastic bottle to apply transmission via the compression device; it can automatically remove the label on the plastic bottle without manual handling; and it has high working efficiency.

Owner:周立荣

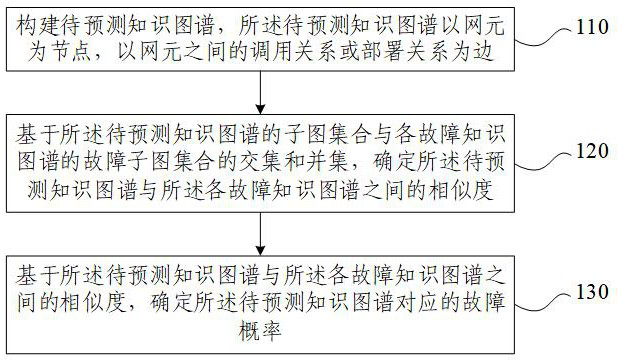

Fault prediction method and device, electronic equipment and storage medium

ActiveCN114465874AImprove accuracyRealize fault warningCharacter and pattern recognitionTransmissionAlgorithmKnowledge graph

The invention provides a fault prediction method and device, electronic equipment and a storage medium, and the method comprises the steps: constructing a to-be-predicted knowledge graph which takes network elements as nodes and takes a calling relation or a deployment relation between the network elements as edges; determining the similarity between the to-be-predicted knowledge graph and each historical fault knowledge graph based on the intersection and union of the sub-graph set of the to-be-predicted knowledge graph and the fault sub-graph set of each historical fault knowledge graph; and determining a fault probability corresponding to the to-be-predicted knowledge graph based on the similarity between the to-be-predicted knowledge graph and each historical fault knowledge graph. According to the method and device, the electronic equipment and the storage medium provided by the invention, the fault prediction accuracy can be improved, fault early warning is realized, the fault occurrence probability is reduced, the influence on enterprises is reduced, manual processing is not needed, a large amount of manpower and material resources are saved, and the fault prediction efficiency is improved.

Owner:北京宝兰德软件股份有限公司

Automatic tire-supplying system

The invention discloses an automatic tire-supplying system, which is used for automatically transferring tires on a tire conveying raceway to side edges of wheel hubs at an assembly line. The automatic tire-supplying system comprises a clamping device, a lifting and turnover device and a line-shifting device which are sequentially connected, a vehicle-side supporting bracket, a three-way aligningdevice used for adjusting the position of the vehicle-side supporting bracket, and a following device used for supporting the three-way aligning device to synchronously move along with a vehicle bodyat the assembly line, wherein the vehicle-side supporting bracket, the three-way aligning device and the following device are sequentially connected and arranged at the lower side part of the assembly line; and a pre-inflated tire is clamped through the clamping device, is then lifted and overturned into a vertical state, is conveyed to the side of the moving trajectory of a wheel hub through theline-shifting device and is placed at the vehicle-side supporting bracket, then the position of the tire is adjusted under the control of the three-way aligning device, and the tire is aligned with the wheel hub and synchronously moves with the vehicle body. According to the automatic tire-supplying system disclosed by the invention, automatic carrying, conveying and aligning of machinery are realized, the assembly of the tire can be completed without manual carrying, conveying and aligning, the labor intensity is reduced, and the automation level is improved.

Owner:GAC HONDA AUTOMOBILE CO LTD +1

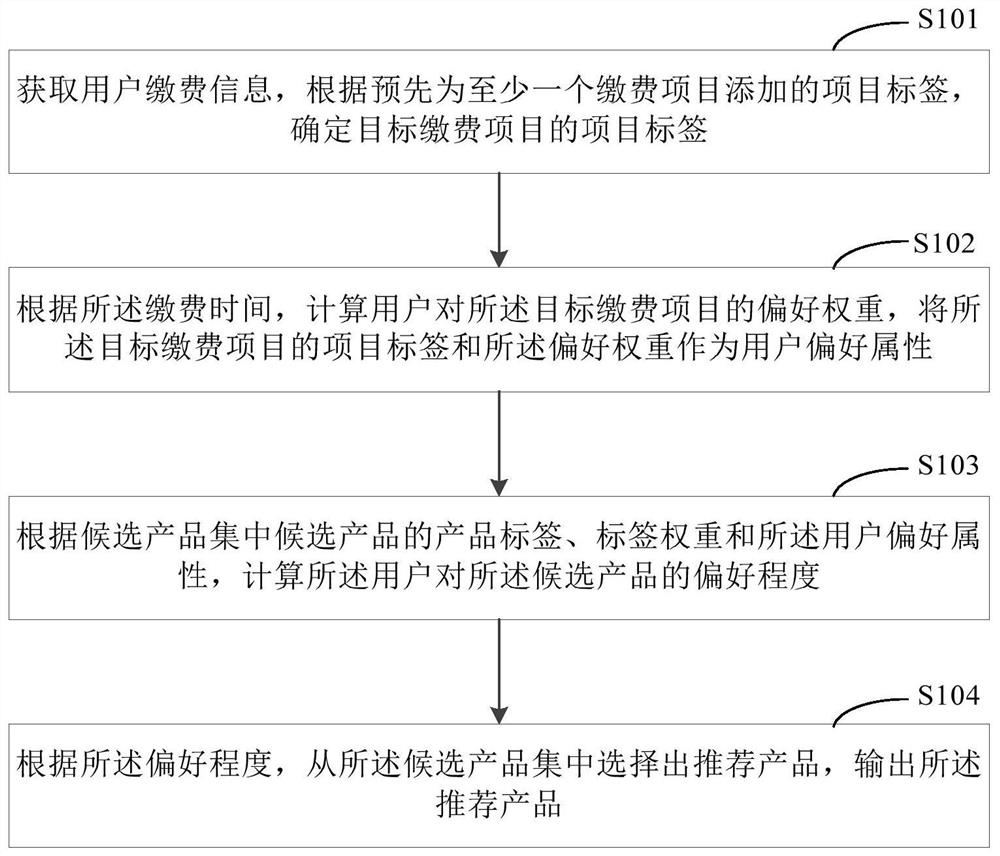

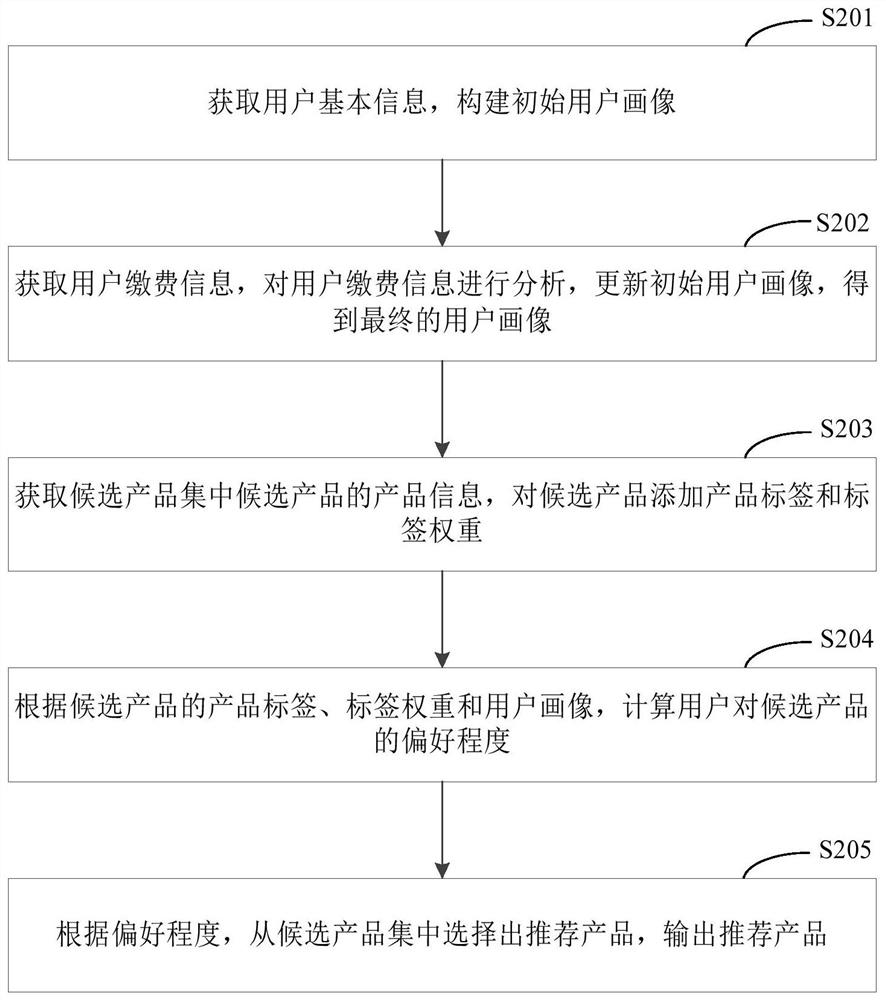

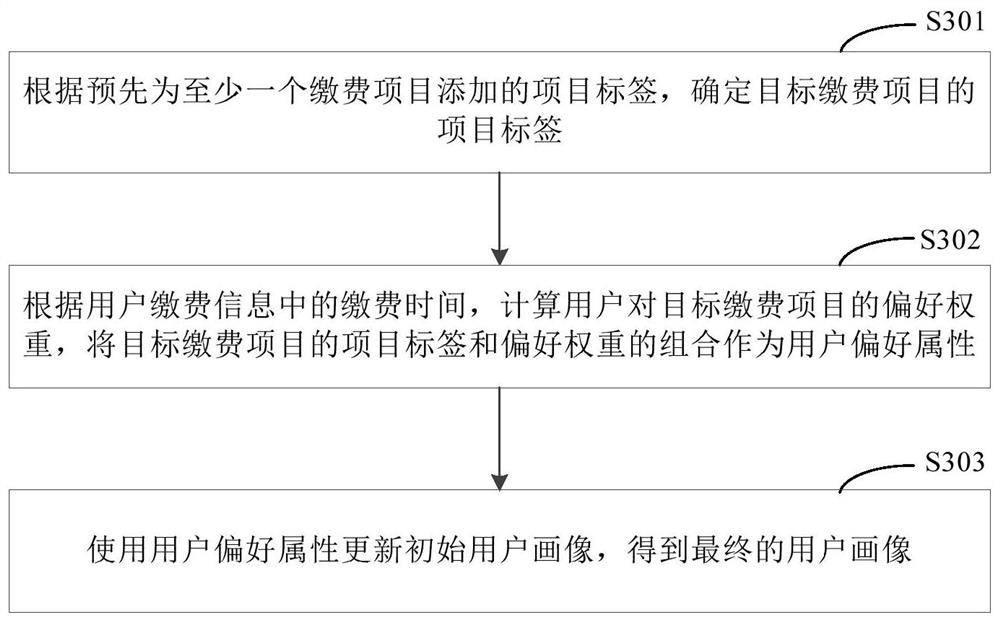

Product recommendation method and device, electronic equipment and computer readable medium

PendingCN113393306ANo manual processingImprove recommendation accuracyBuying/selling/leasing transactionsMarket data gatheringPaymentEngineering

The invention discloses a product recommendation method and device, electronic equipment and a computer readable medium, and relates to the technical field of artificial intelligence. A specific embodiment of the method comprises the steps of obtaining user payment information, and determining a project label of a target payment project according to a project label added for at least one payment project in advance; wherein the user payment information comprises a target payment item and payment time; according to the payment time, calculating the preference weight of the user for the target payment item, and taking the item label and the preference weight of the target payment item as user preference attributes; according to the product labels, the label weights and the user preference attributes of the candidate products in the candidate product set, calculating the preference degree of the user to the candidate products; and selecting a recommended product from the candidate product set according to the preference degree, and outputting the recommended product. According to the method, the recommended product can be automatically matched, manual processing is not needed, and the recommendation accuracy is high.

Owner:CHINA CONSTRUCTION BANK

Device and method for automatically testing polarization extinction ratio of silicon photonic coherent receiver

The invention relates to a testing device and method, belongs to the technical field of photo-communication, and particularly relates to a device and method for automatically testing a polarization extinction ratio of a silicon photonic coherent receiver. By the device and method, full-automated testing on a polarization extinction ratio index in a whole C waveband of the silicon photonic coherentreceiver can be realized, a required testing environment does not need precious instruments, testing steps are speedy, and testing precision is excellent.

Owner:WUHAN TELECOMM DEVICES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com