Full-automatic trimming machine

An edge sawing machine, a fully automatic technology, applied in circular saws, sawing components, sawing equipment and other directions, can solve the problems of high production cost of automatic edge sawing machines, only one plate can be conveyed at a time, etc., and achieves simple structure and maintenance. Simple and convenient, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

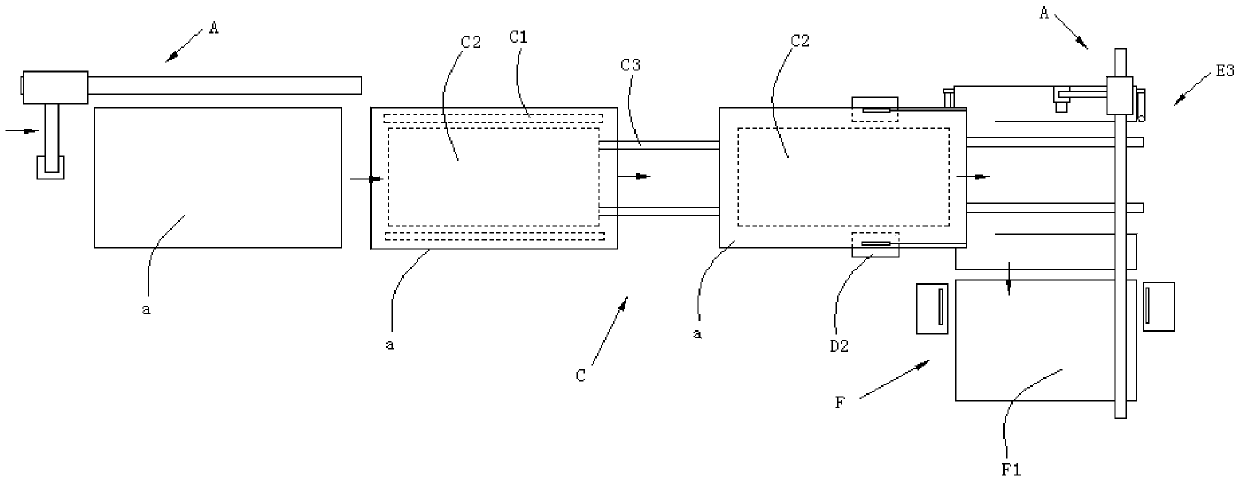

[0042] Such as figure 1 As shown, a fully automatic edge sawing machine includes a feeding device A, a long side sawing device C, a steering device E3, and a short side sawing device F; the board passes through the feeding device A, the long side sawing device C, Turning device E3, short edge sawing device F. The long-side edge sawing device C and the short-side edge sawing device F are respectively located on two sides adjacent to the steering device E3, and the horizontal angle between the long-side edge sawing device C and the short-side edge sawing device F is 90°.

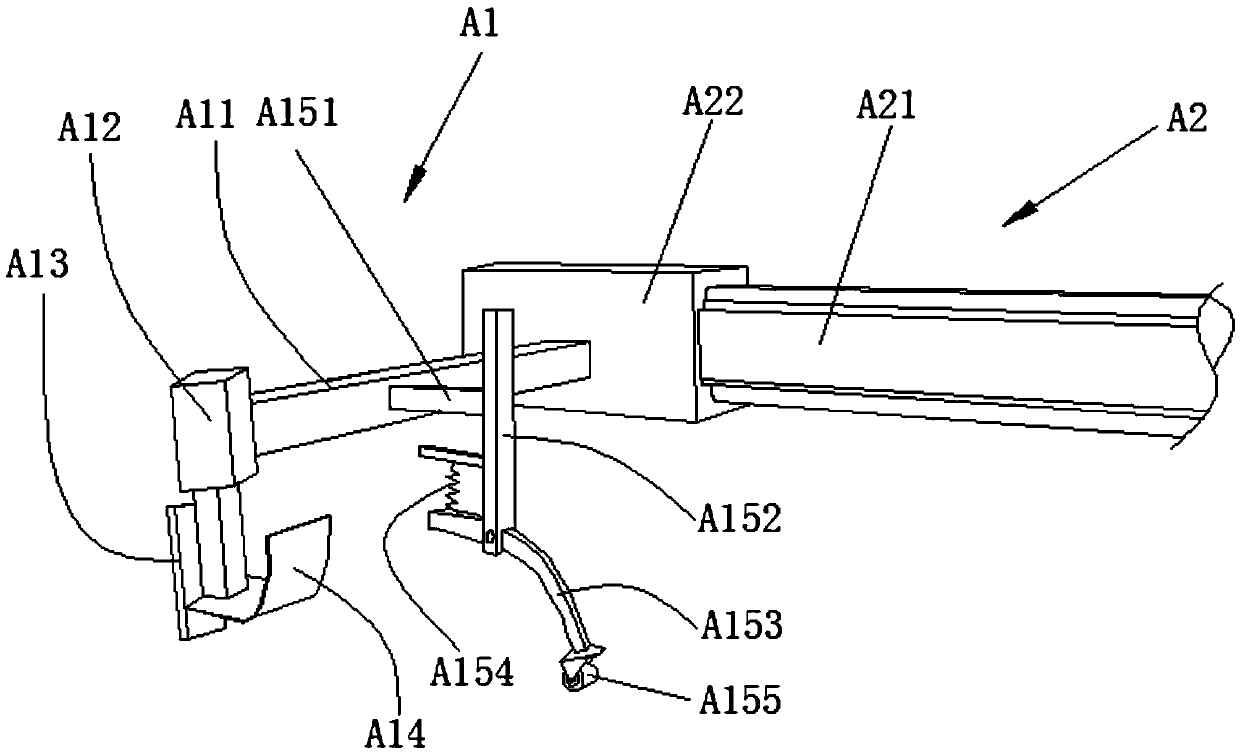

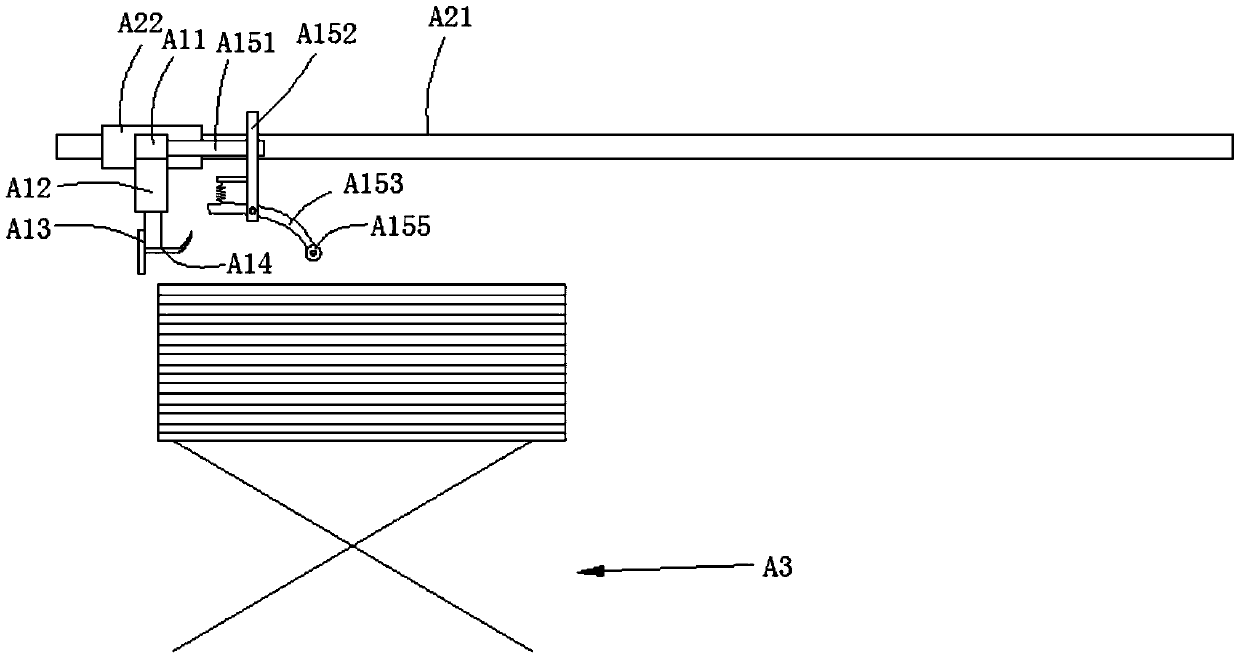

[0043] Such as figure 2 As shown, the feeding device A includes a push plate mechanism A1 and a guide mechanism A2; the push plate mechanism A1 is fixed on the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com