Injection molding mould, preheating device, and method for preheating by using injection molding mould

A technology of injection molding and preheating device, applied in induction heating device, induction heating and other directions, can solve the problems of high risk, insufficient mold temperature control stability, inability to meet the requirements of energy saving and carbon reduction, and reduce the consumption of high frequency energy. Chance, cooldown reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the technology taught in the present invention, which does not depart from the present invention. spirit and scope.

[0039] The invention discloses an injection mold with a preheating device, the preheating device, and a method for preheating the injection mold.

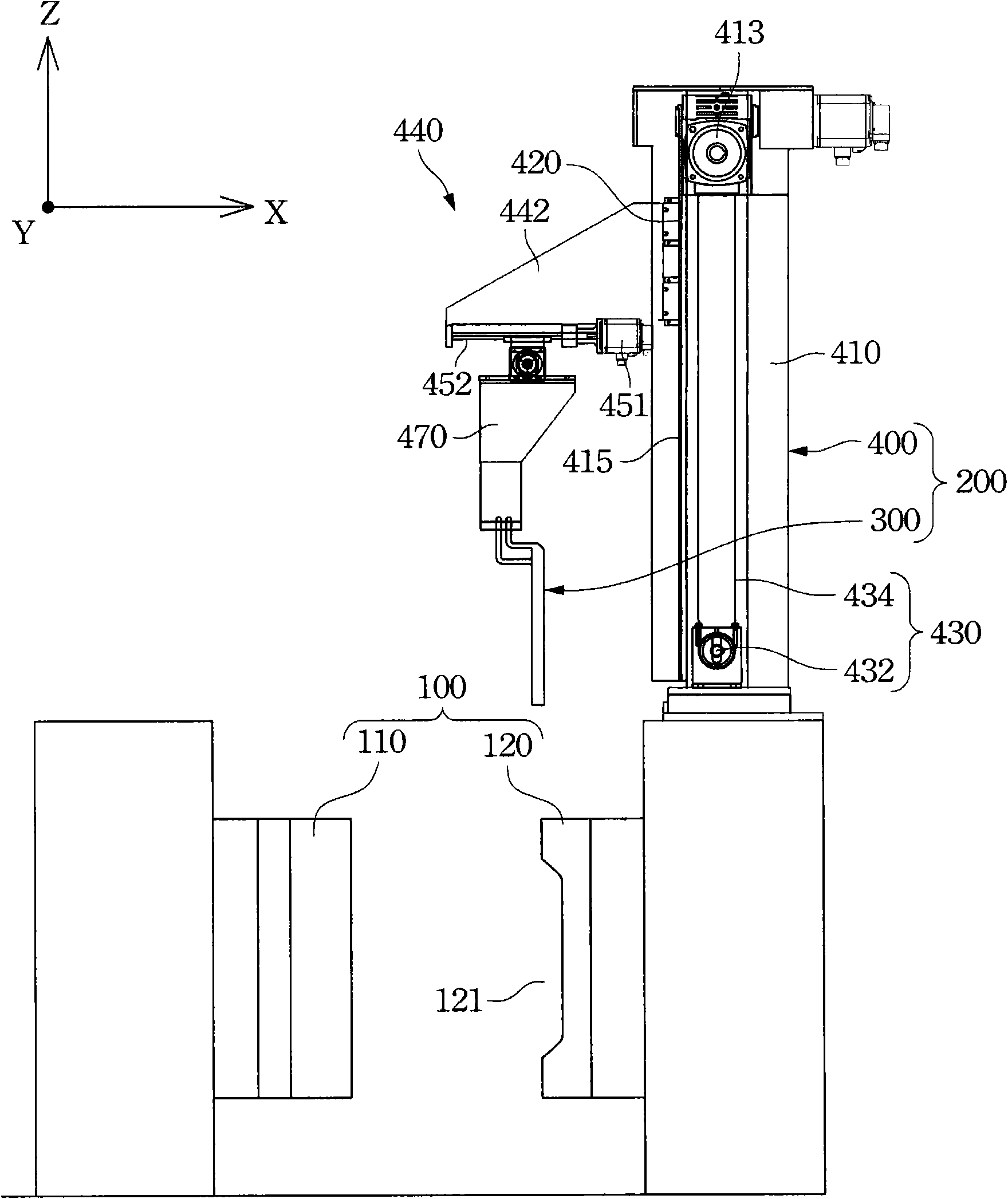

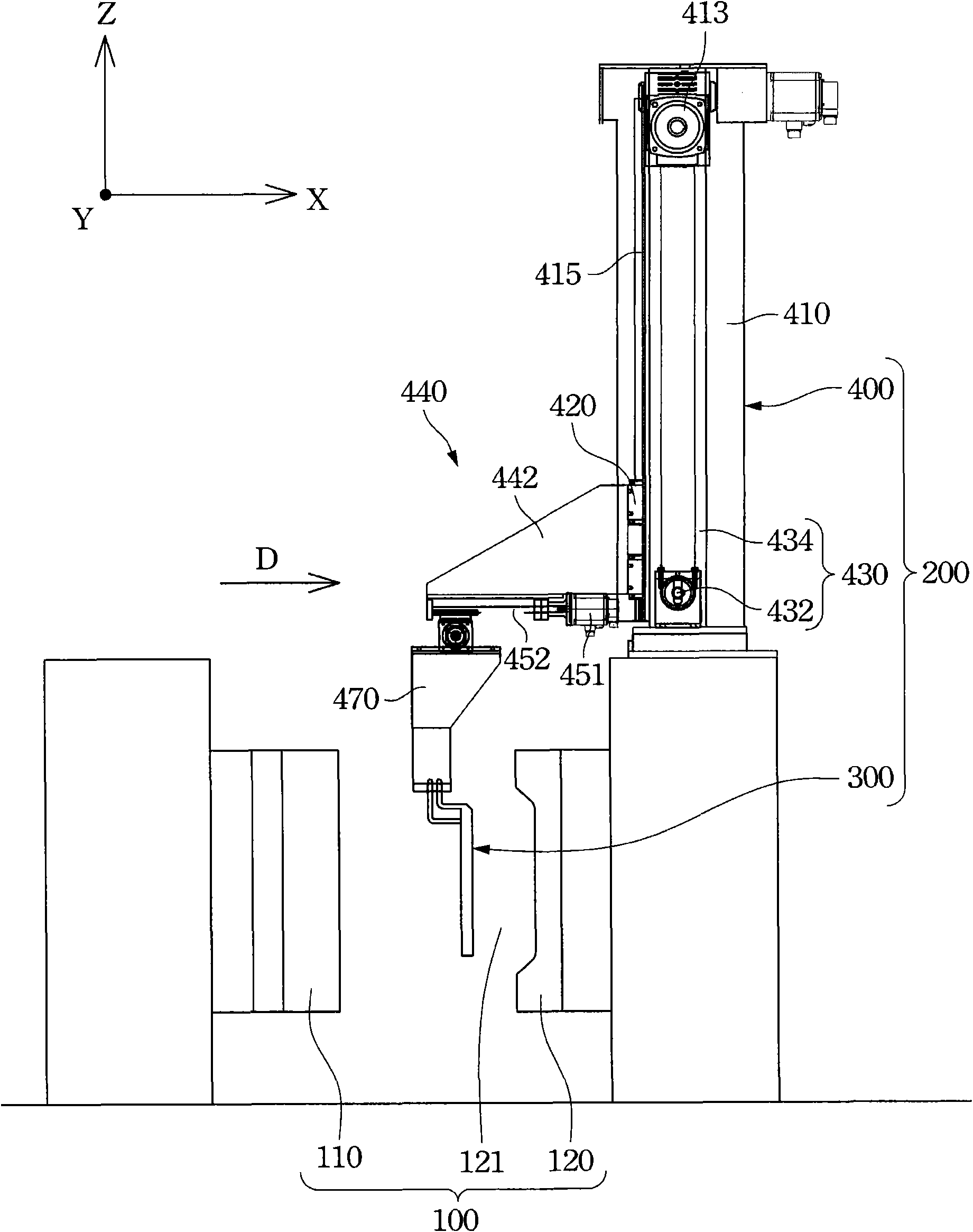

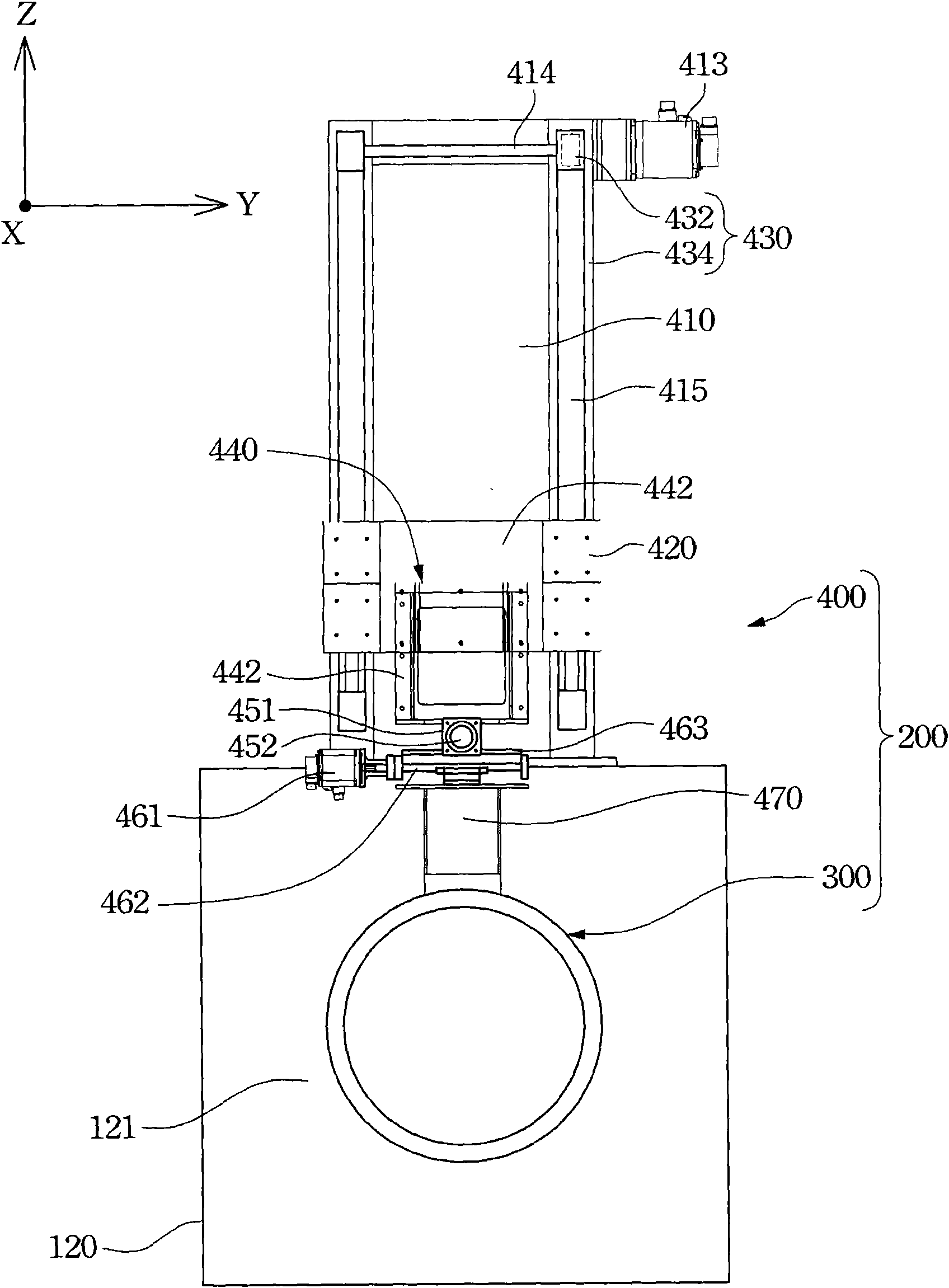

[0040] see Figure 1 to Figure 3 shown. figure 1 A schematic structural view of an embodiment of an injection mold with a preheating device according to the present invention is shown. figure 2 A schematic diagram of the operation of the injection molding mold with the preheating device moving along the Z-axis linear slide rail in this embodiment of the present invention is shown. image 3 Showing looking in a direction D figure 2 Schematic diagram of the preheating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com