Paper feeding device and image forming apparatus

A technology of a paper feeding device and a paper feeding box, which is applied in the direction of the electric recording process using the charge pattern, the equipment and the object supply of the electric recording process using the charge pattern, and can solve the problem that the loading plate pushing on the opposite side of the measuring head cannot be changed. Problems such as volume and pressure, inability to make universal patterns for cartons, rising costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

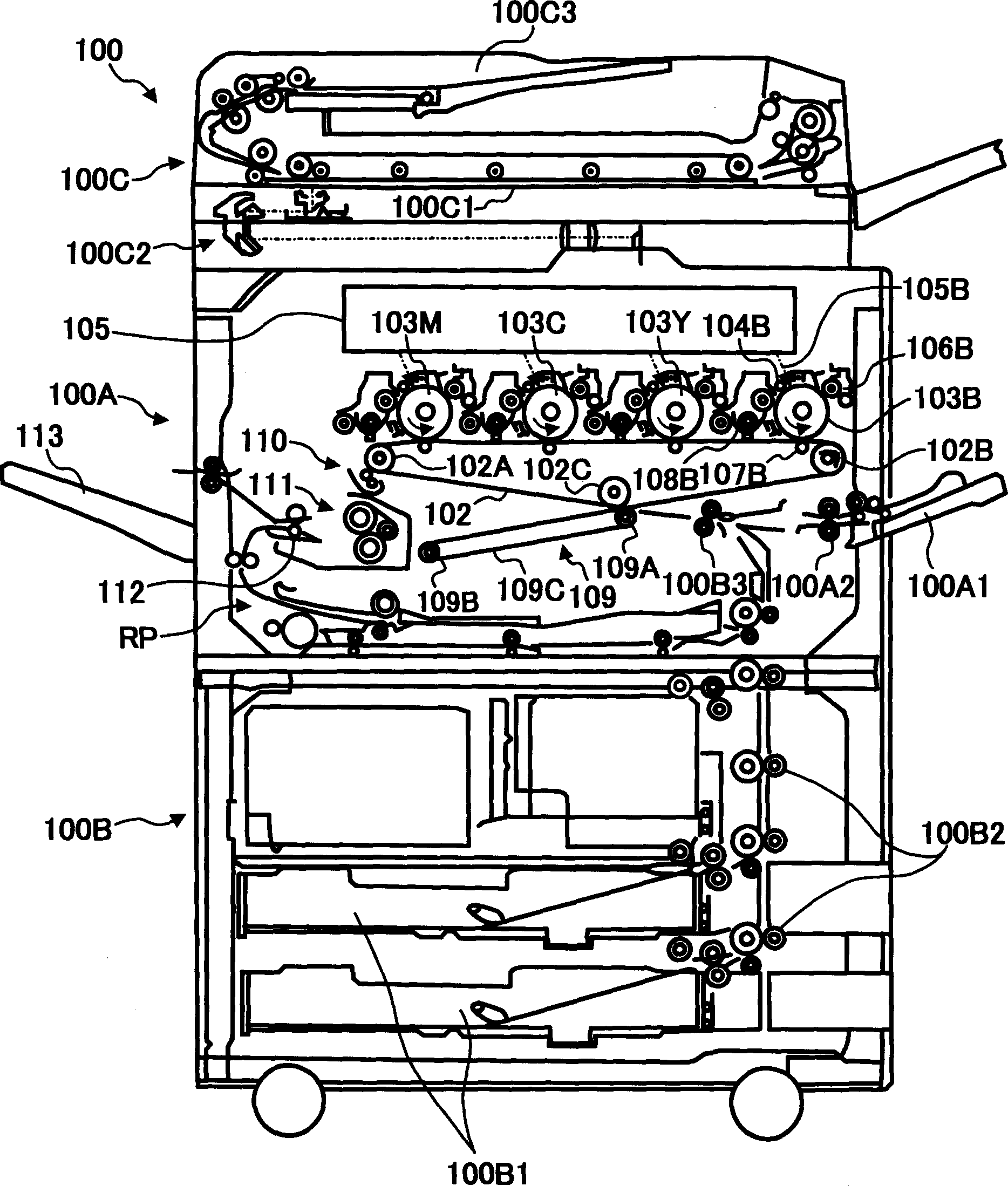

[0094] figure 1 It schematically shows an example of an image forming device equipped with a paper feeding device according to an embodiment of the present invention. The image forming device shown in the figure adopts a tandem type, and is a color printer capable of forming multicolor images. Several photoreceptors are arranged in parallel as latent image carriers on which an image of the color corresponding to the color decomposition can be formed, and the toner images formed on each photoreceptor are superimposed and transferred on the intermediate transfer body, and then the superimposed image is transferred to the recording paper at once. Or transfer paper and other media. In the present invention, the image forming apparatus is not limited to figure 1 The illustrated printer is, needless to say, also applicable to image forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com