Patents

Literature

603results about How to "Avoid bouncing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

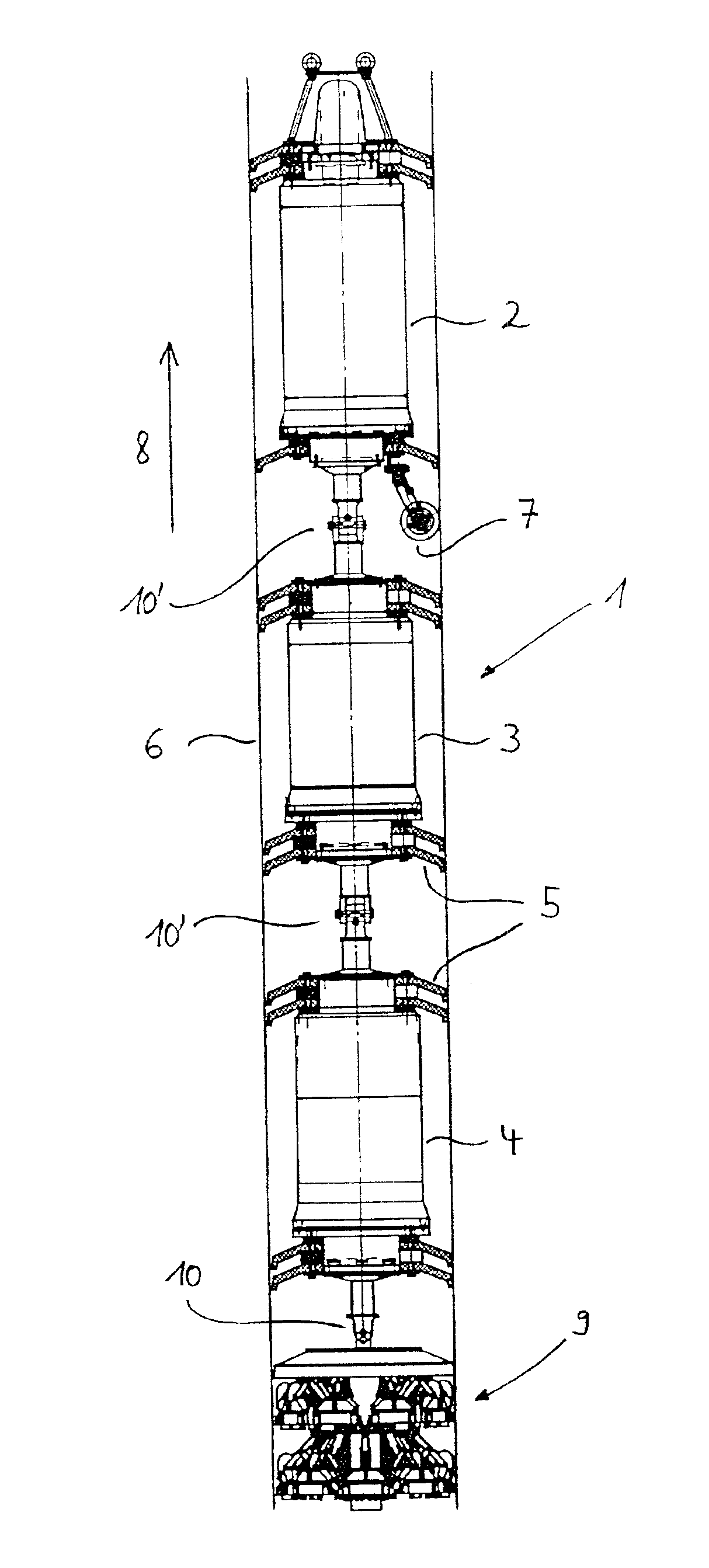

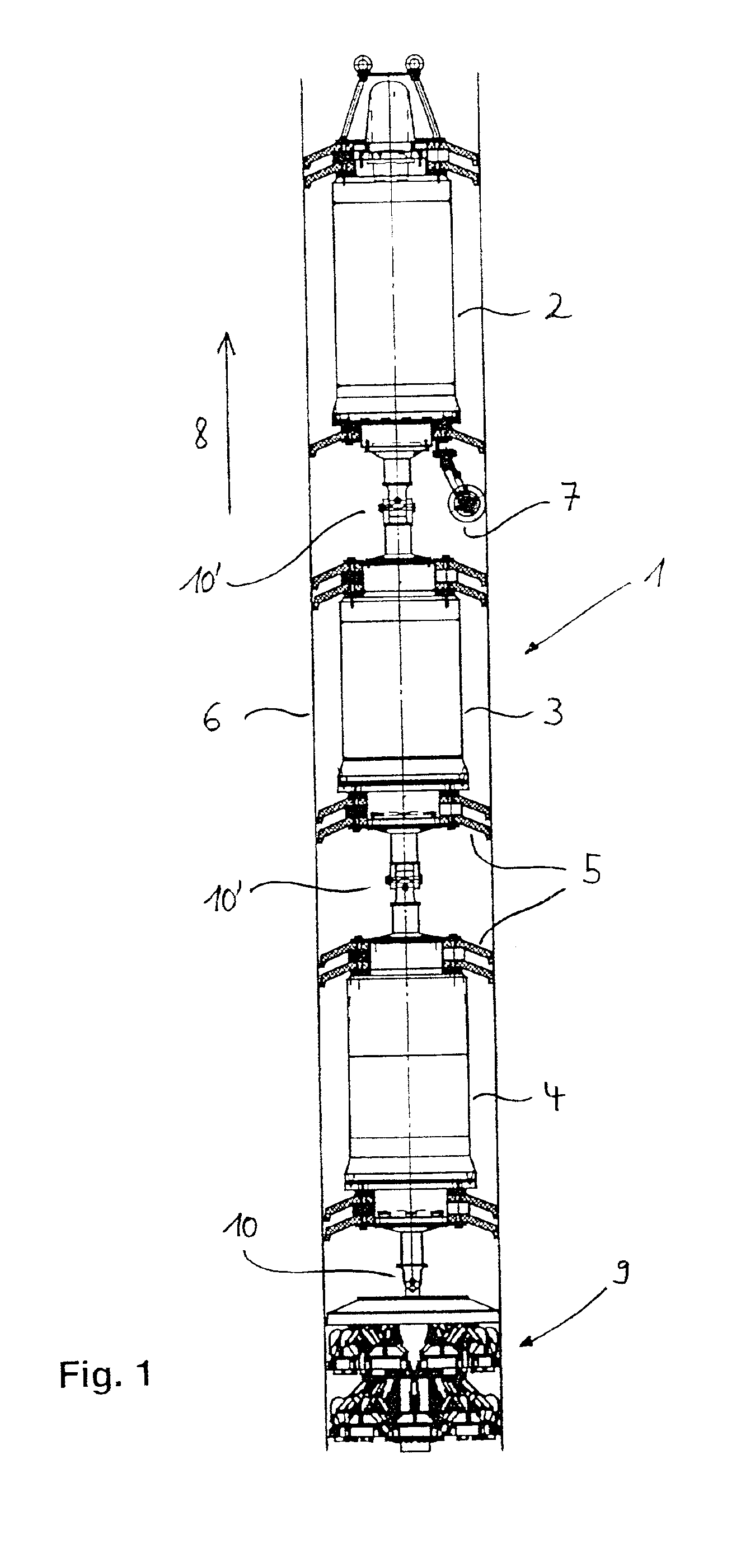

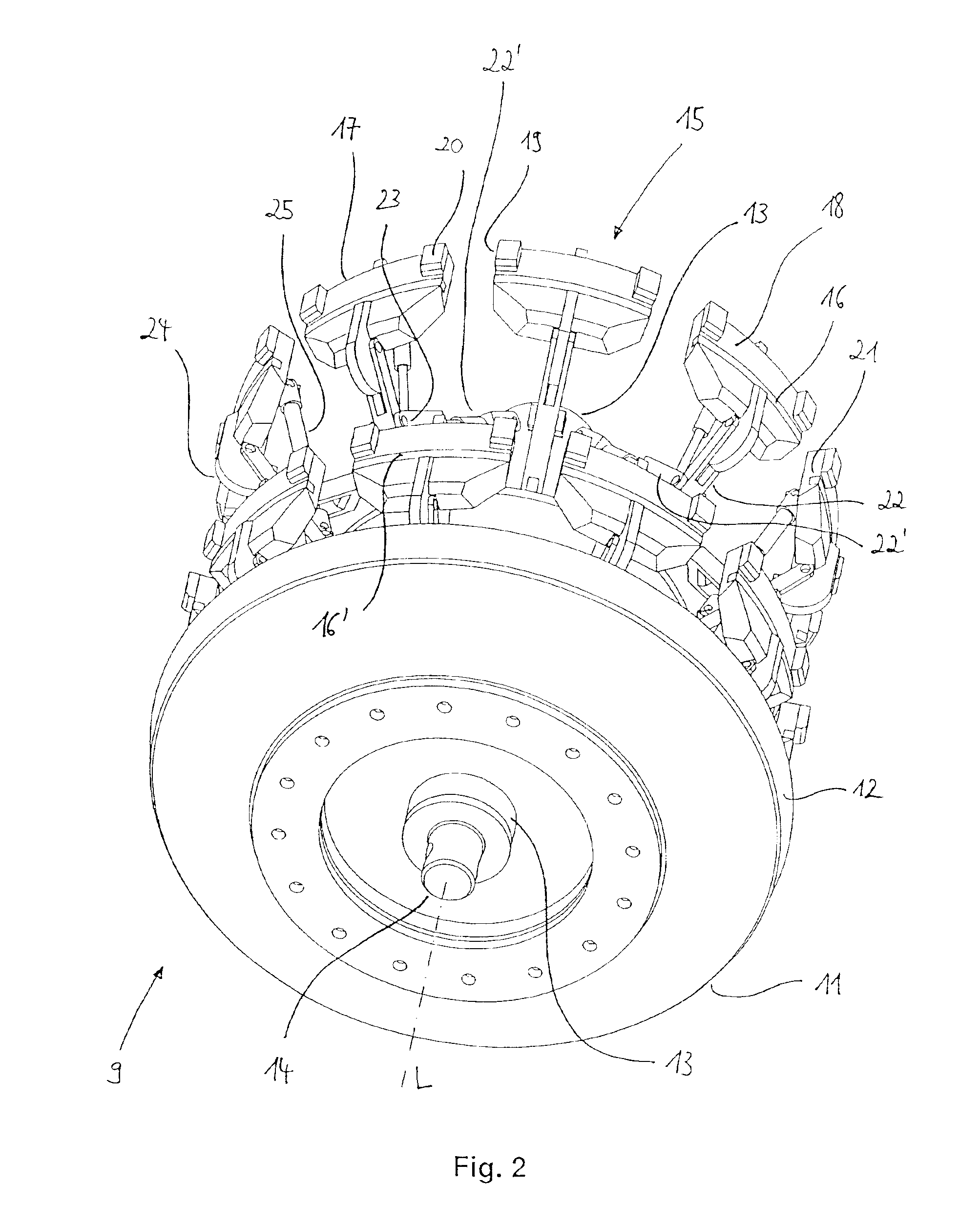

Method and device for inspecting pipelines

InactiveUS6848313B2Avoid bouncingImprove resilientAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEngineeringBoundary region

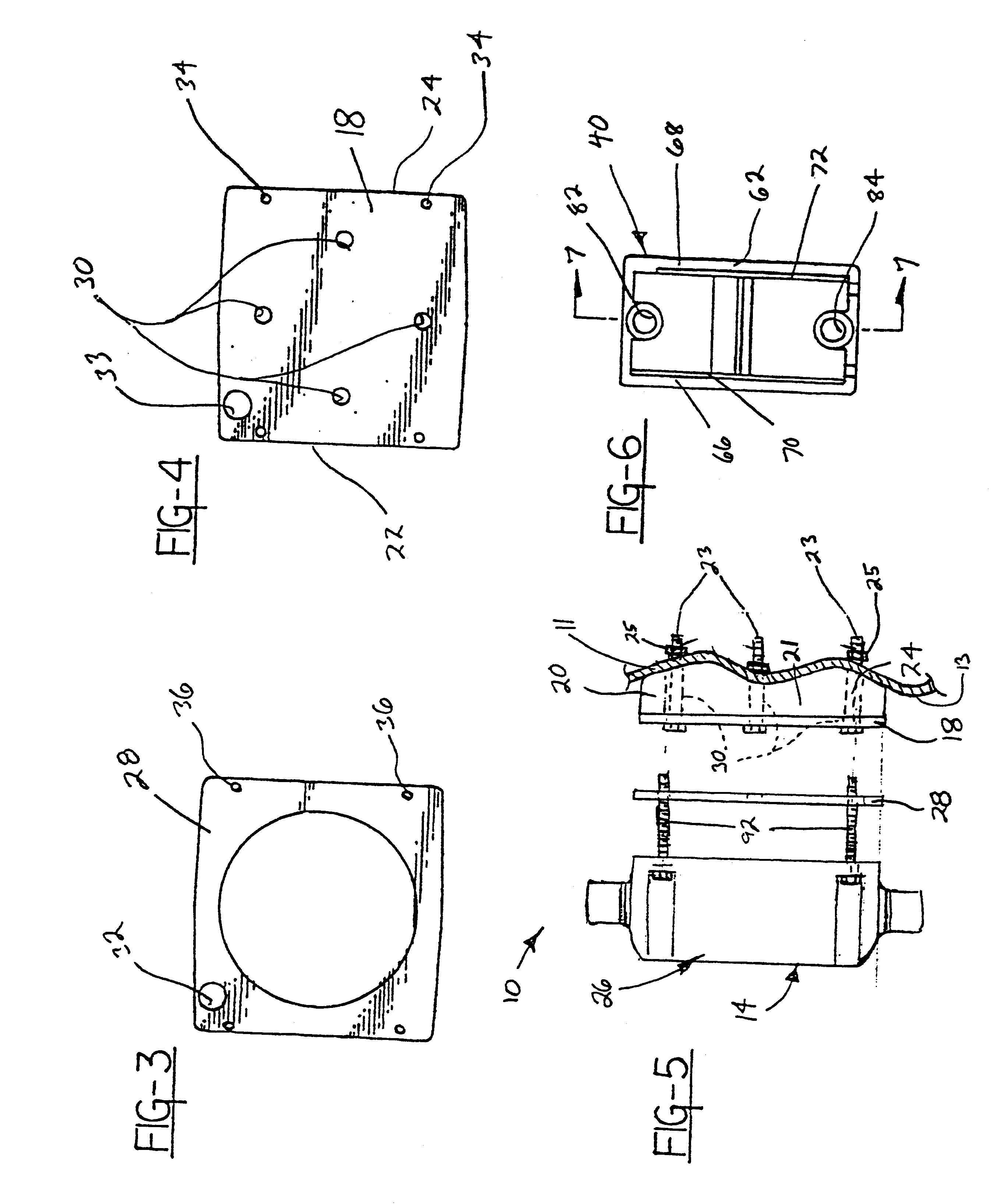

The invention concerns a method and a device for inspecting pipelines, in particular for detecting defects in pipelines by means of ultrasound. Towards this end, measuring sensors transmit ultrasound signals during passage through a pipeline. The signals reflected on boundary regions of a pipeline wall, e.g. surfaces or defects, are then measured and evaluated. The invention is characterized in that partial regions of the measuring sensors (virtual sensors) formed of a plurality of neighboring sensor elements irradiate ultrasound signals into the pipe wall at at least one radiation angle which is inclined with respect to the normal to the pipe wall and the signals reflected at boundary regions of the pipe wall are received by same and / or other partial regions of the respective measuring sensors, wherein defects in the pipe wall are determined by evaluation of the acoustical signals reflected by different boundary regions.

Owner:PII PIPETRONIX

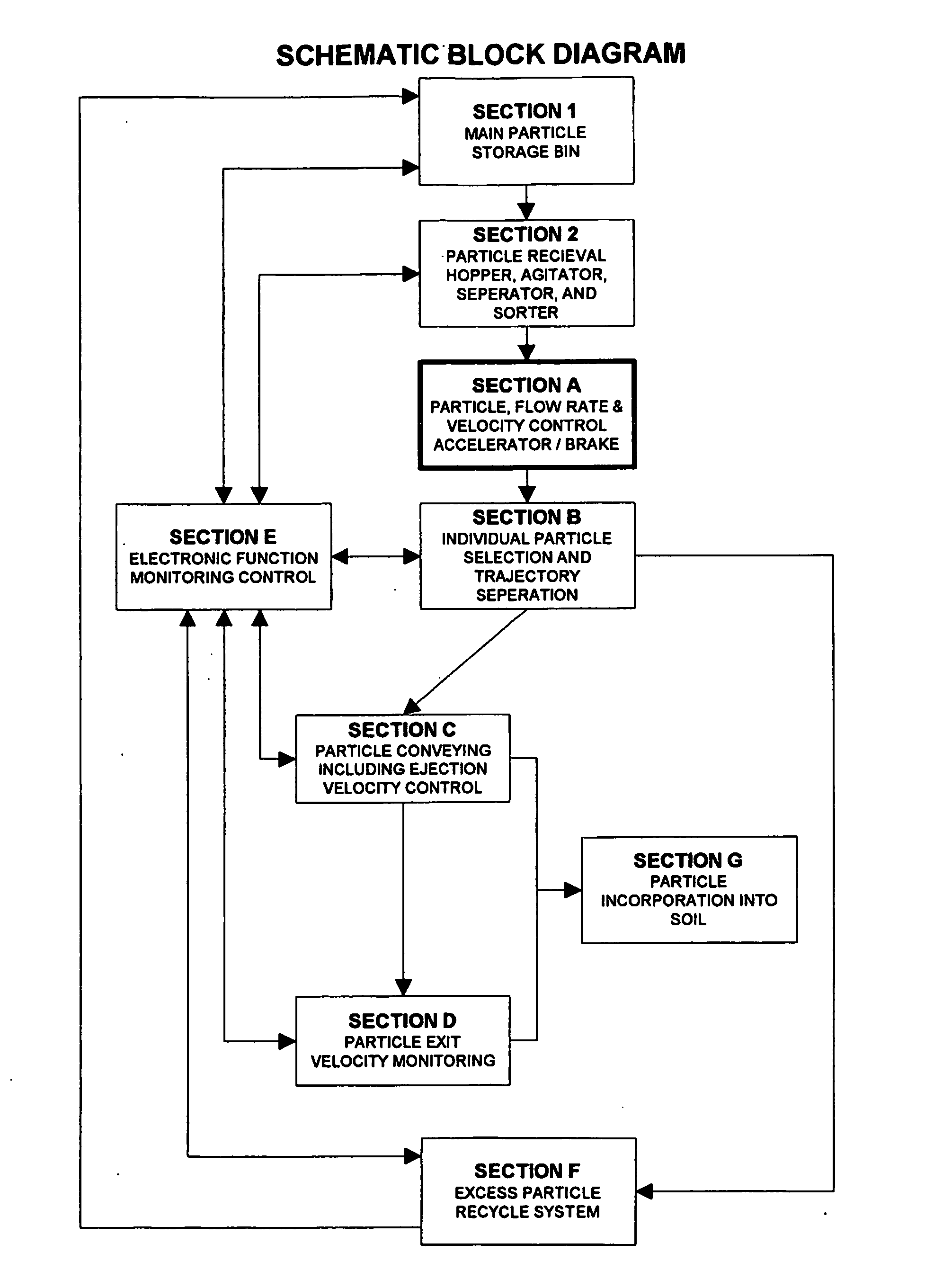

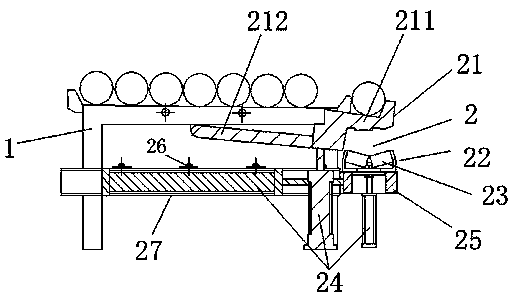

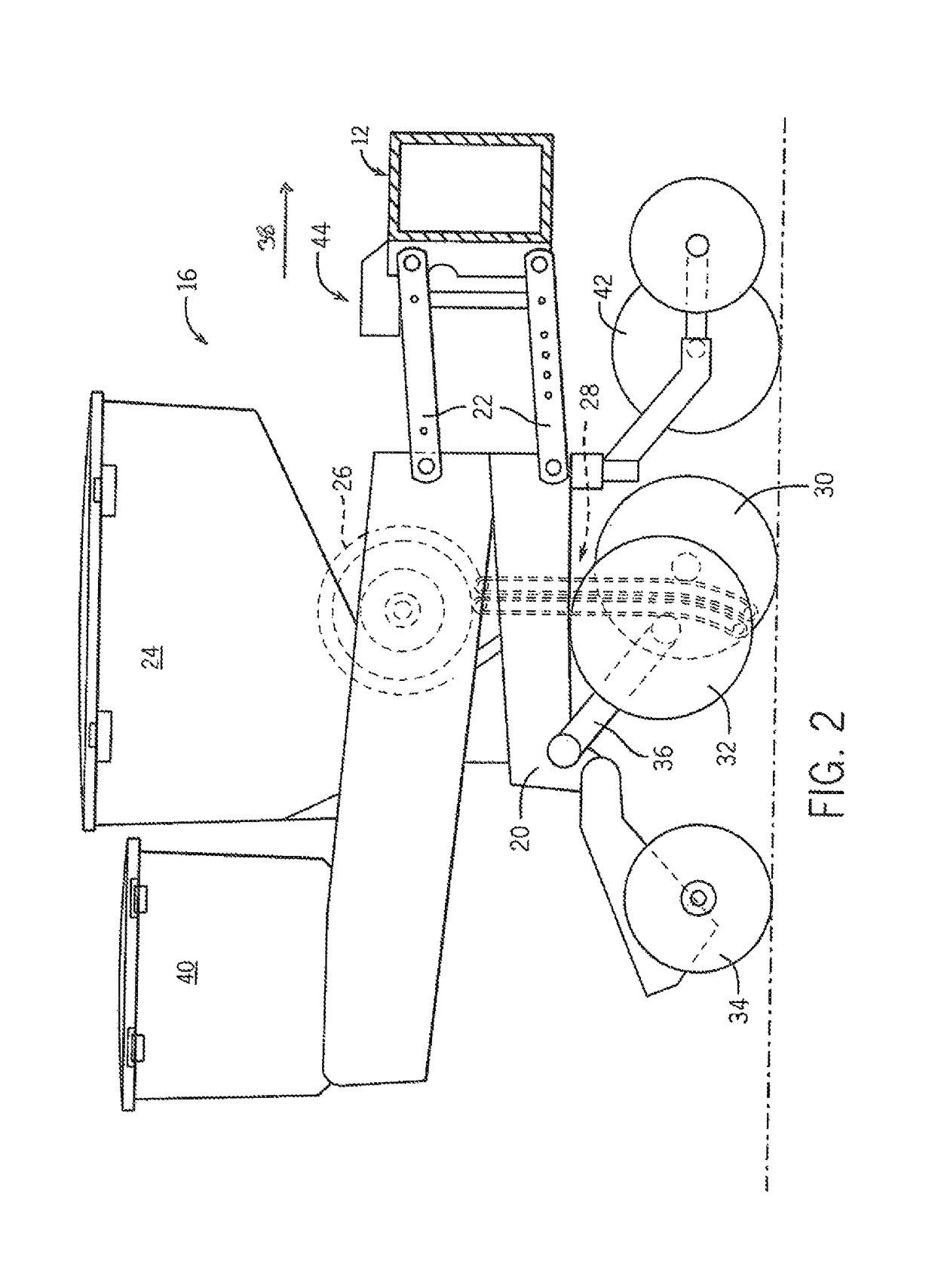

Seed distribution method and apparatus

InactiveUS20060278726A1Accurate faster seedingImprove abilitiesSelf-acting watering devicesWatering devicesDistribution methodEngineering

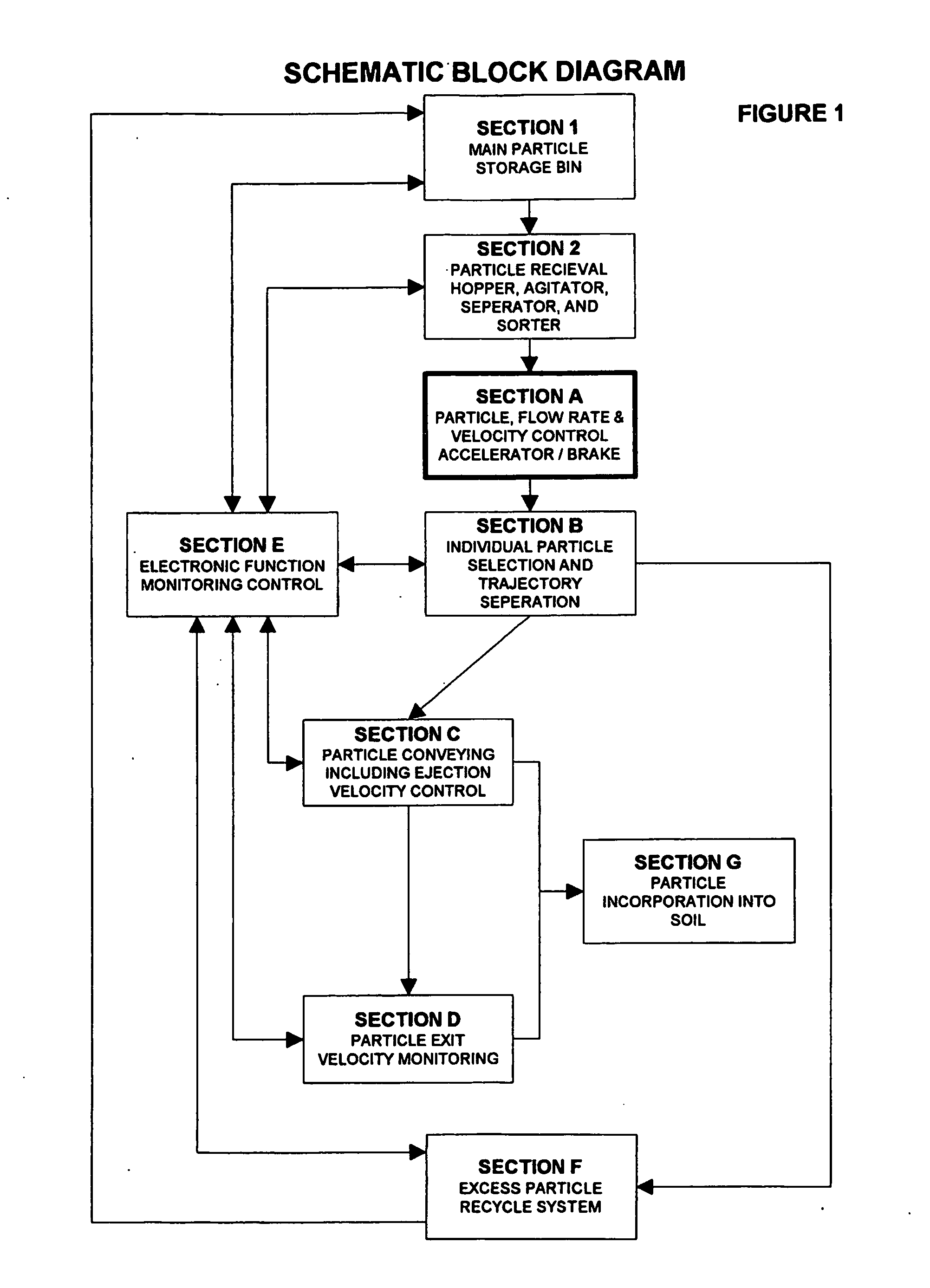

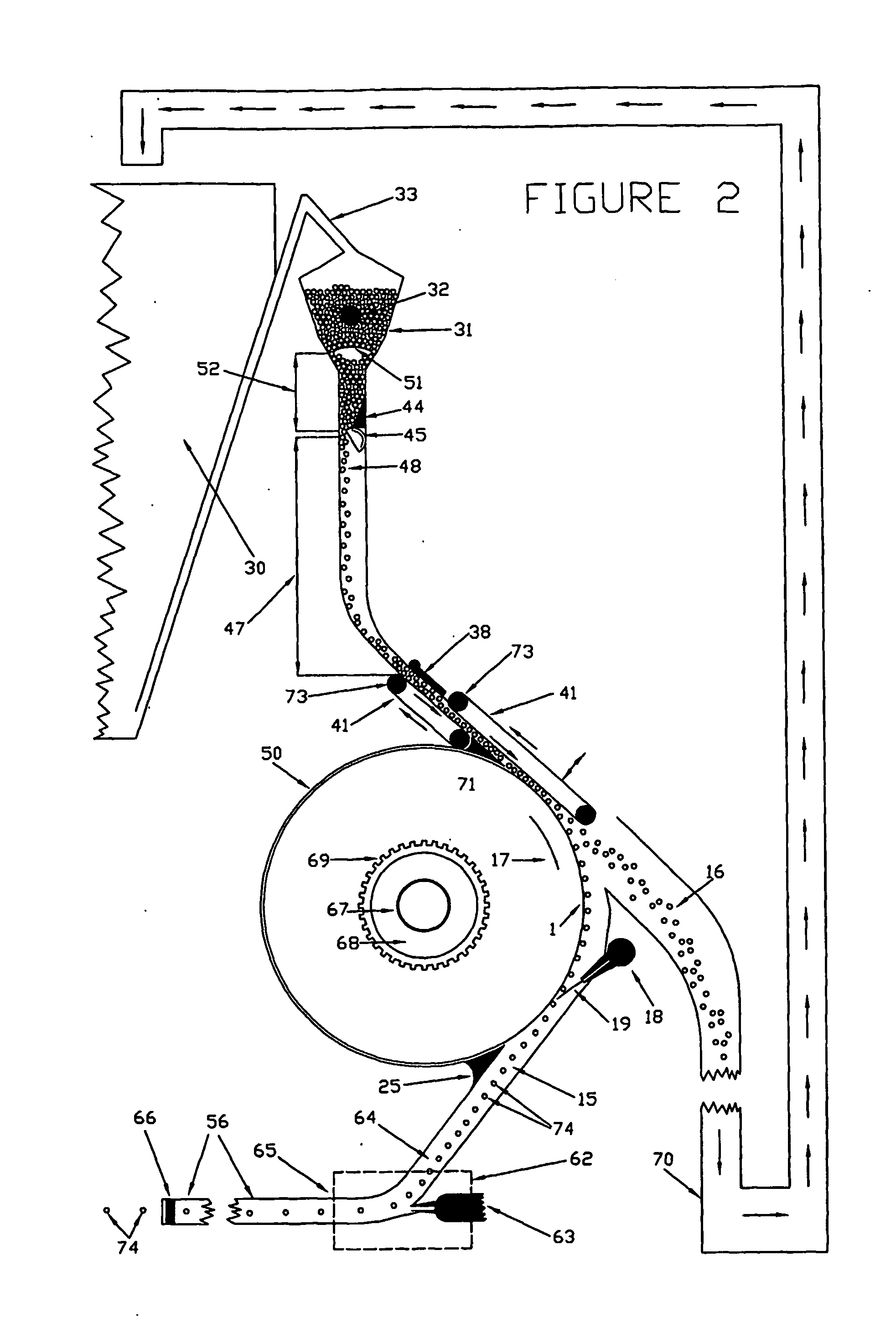

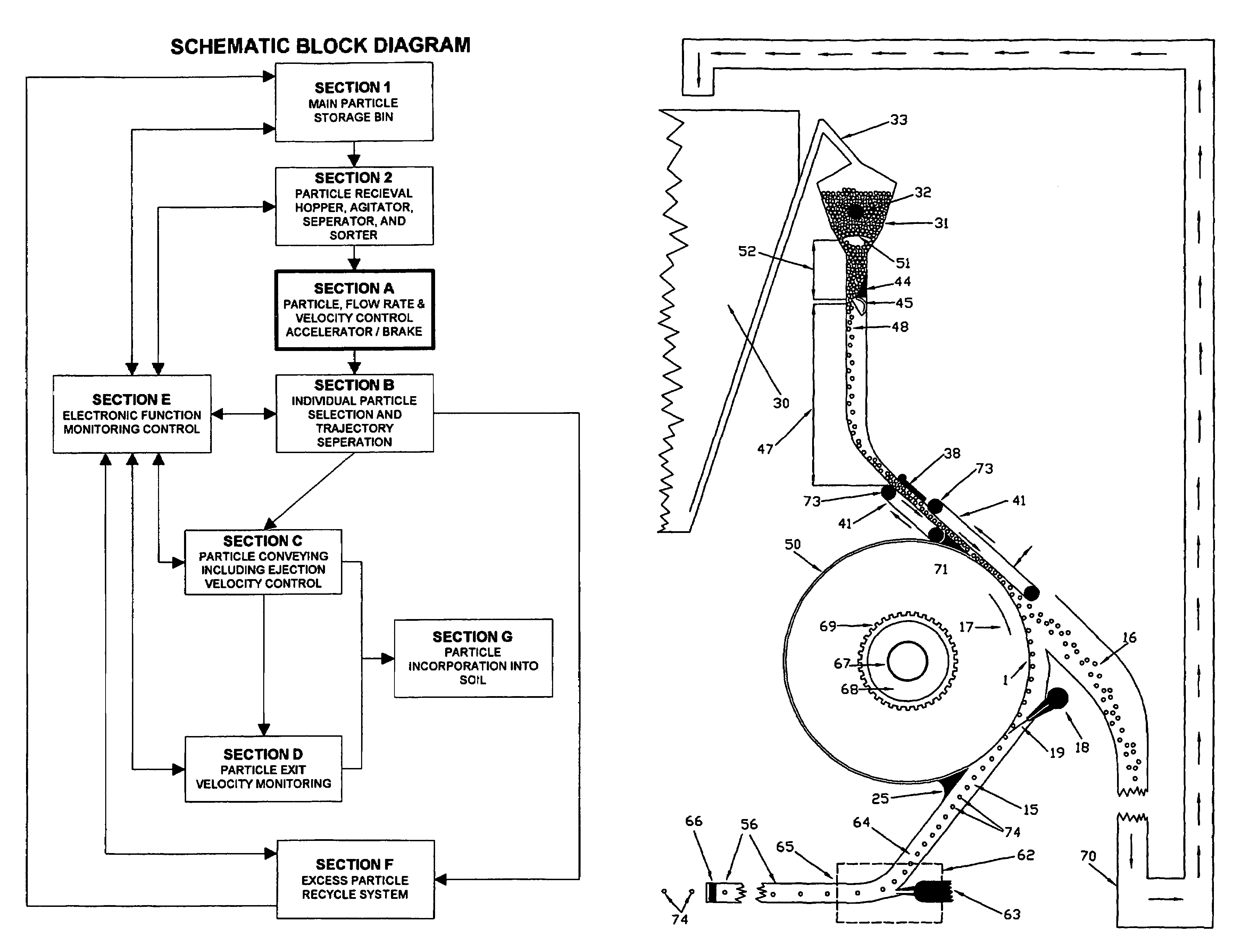

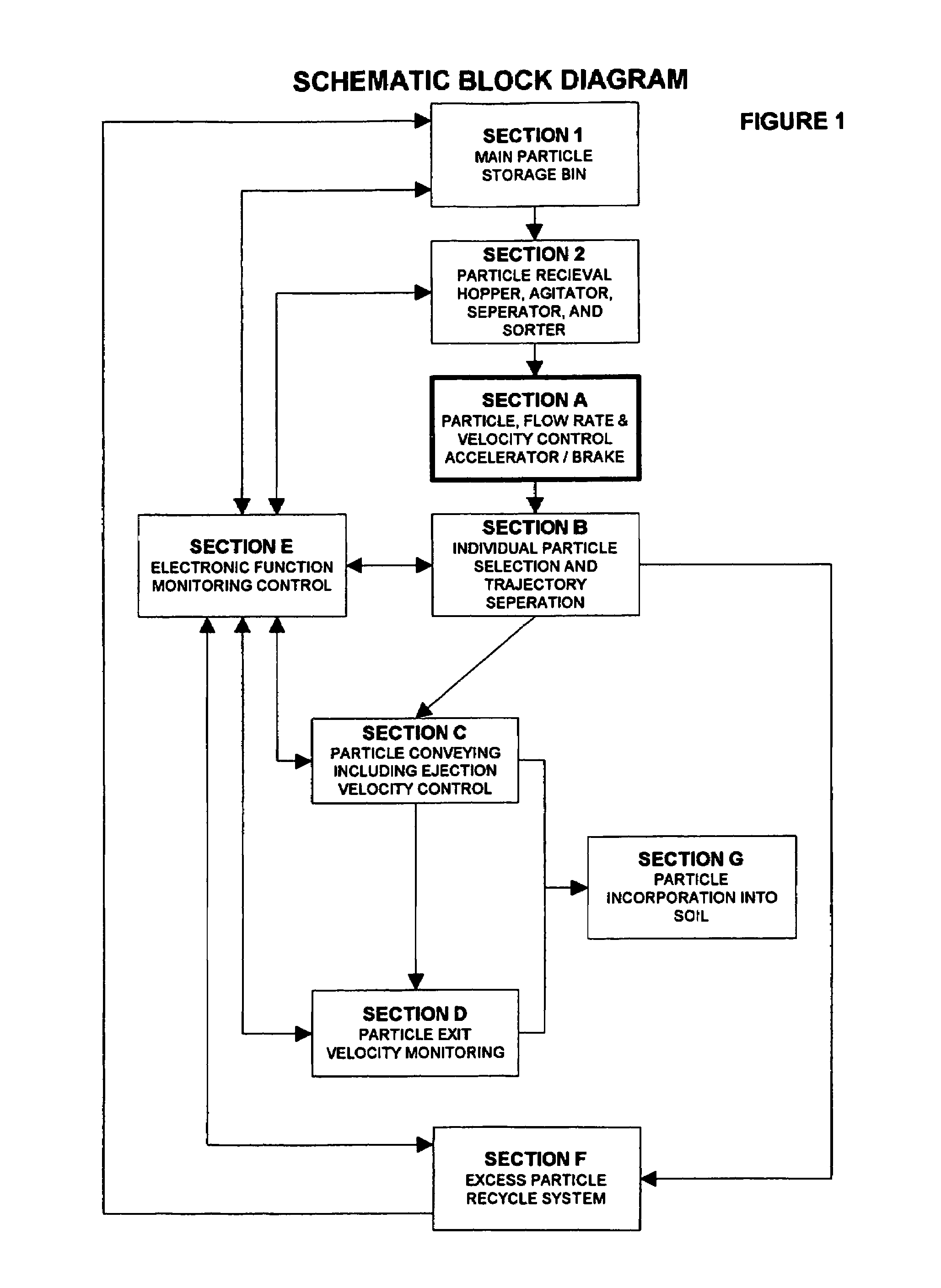

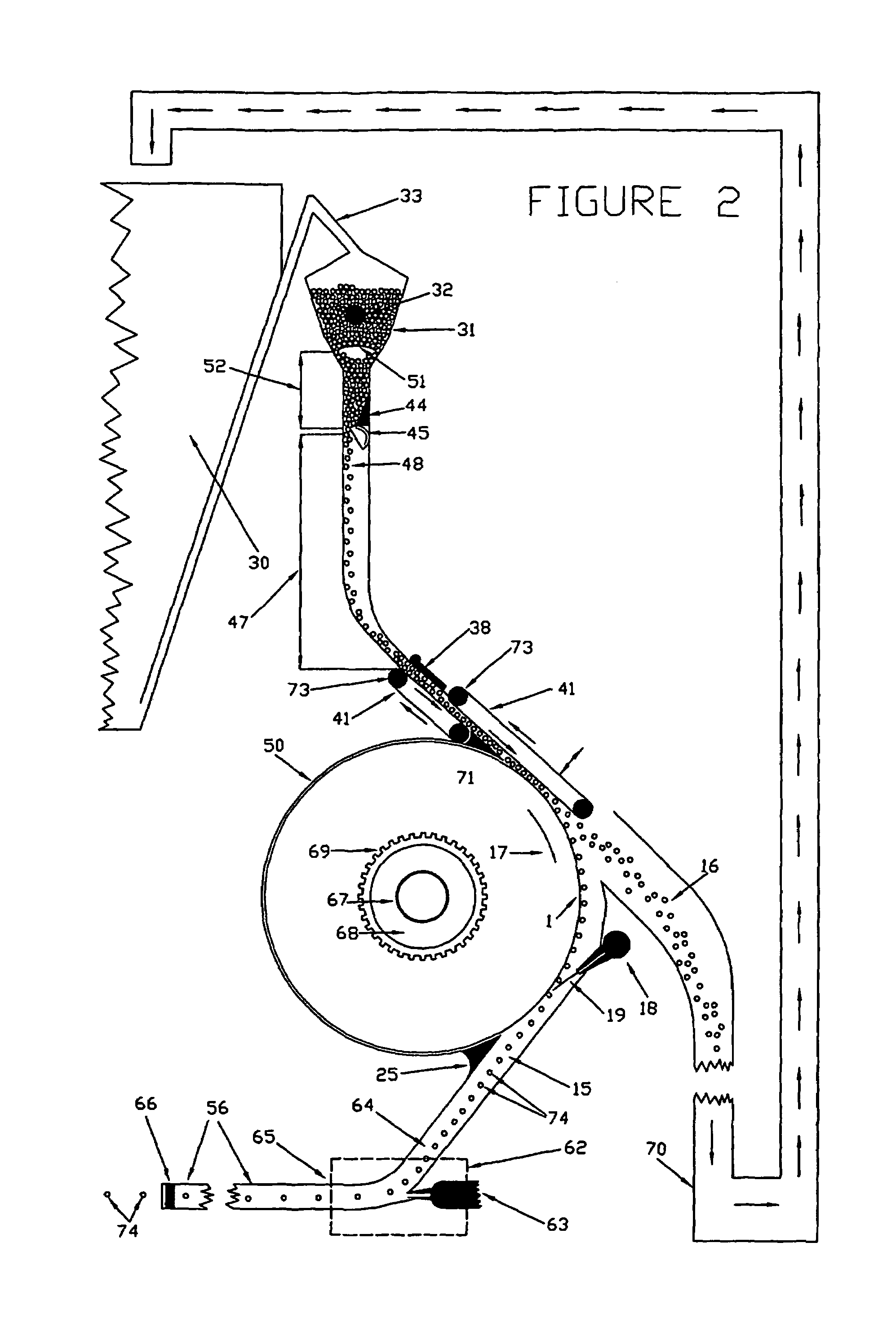

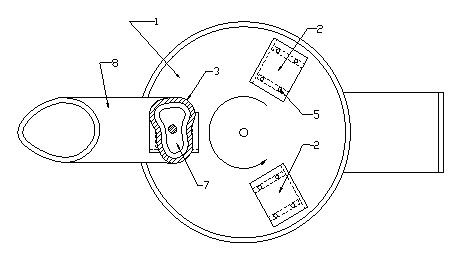

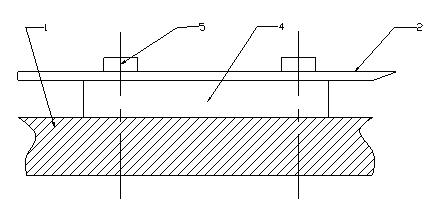

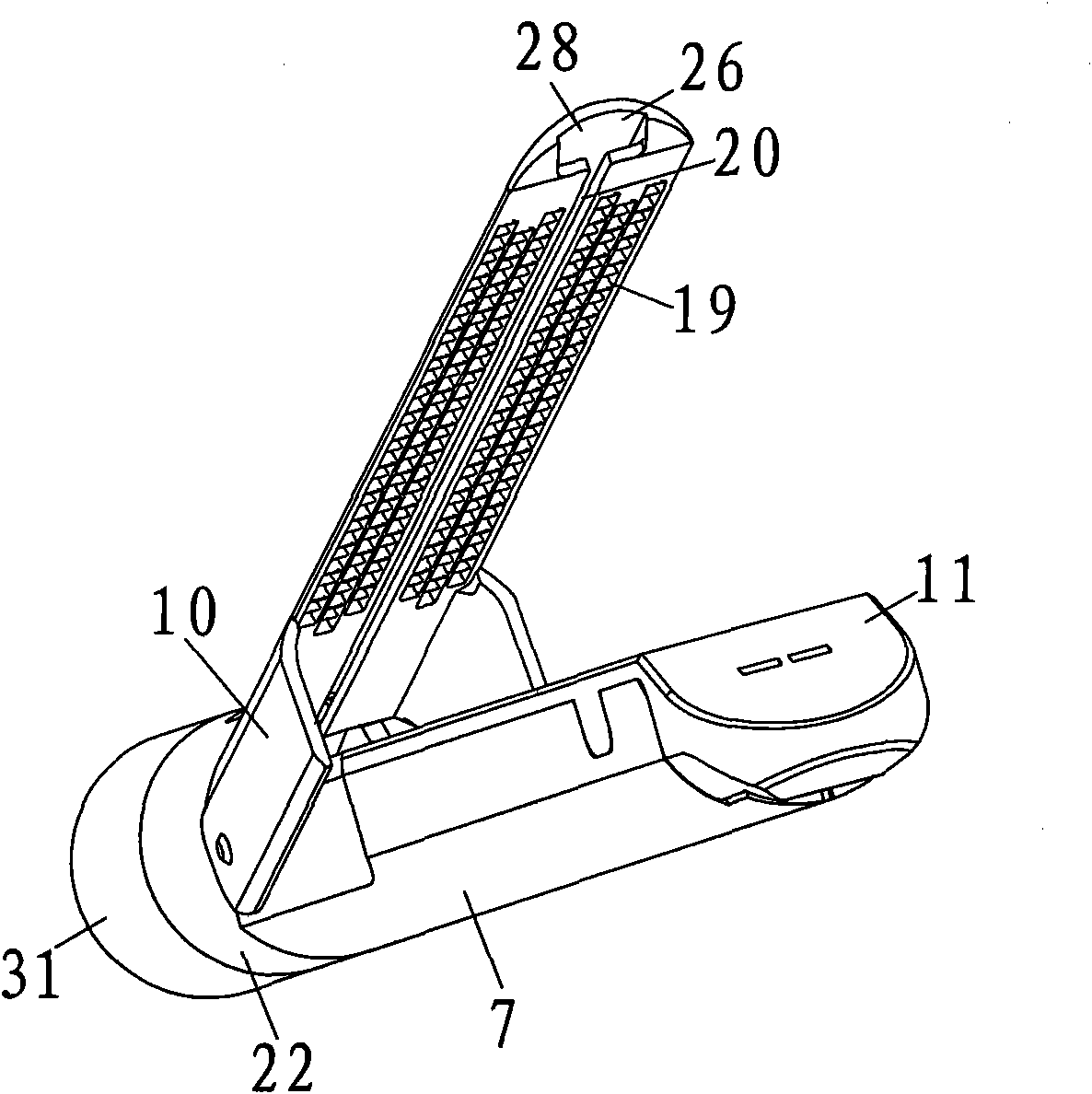

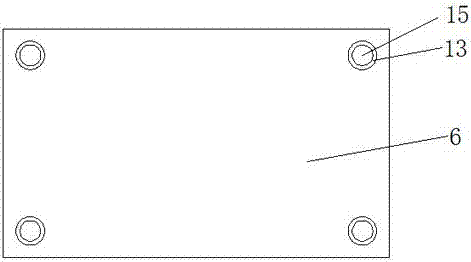

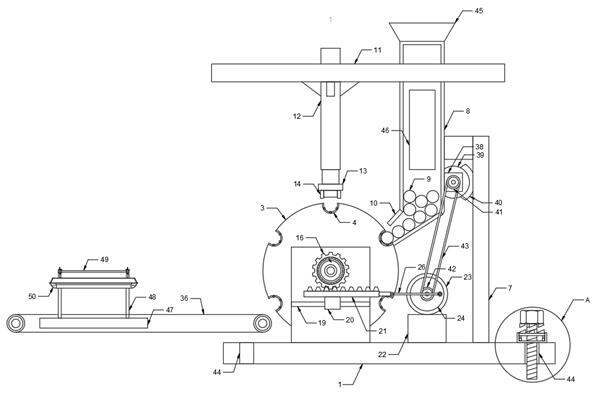

A seeding apparatus comprising: (a) seed distribution metering means including a rotating drum (1) with apertures on its periphery and a vacuum generator for generating a suction pressure inside the drum (1) so that seeds are attracted to the apertures; (b) feeding system including a hopper (31), gravitational acceleration chamber (47), velocity controlling elements such as a flap (38) and continuous belts (41) for feeding seeds at a required amount and speed to the drum (1); (c) release mechanisms including an airjet (19) for releasing metered seeds from the drum (1) along a selected trajectory (15) while unselected seeds follow another trajectory (16). (d) delivery means including an adjustable flow venturi (62) and electronic sensor (66) for controlling delivery of metered seeds.

Owner:HOLLY JOHN

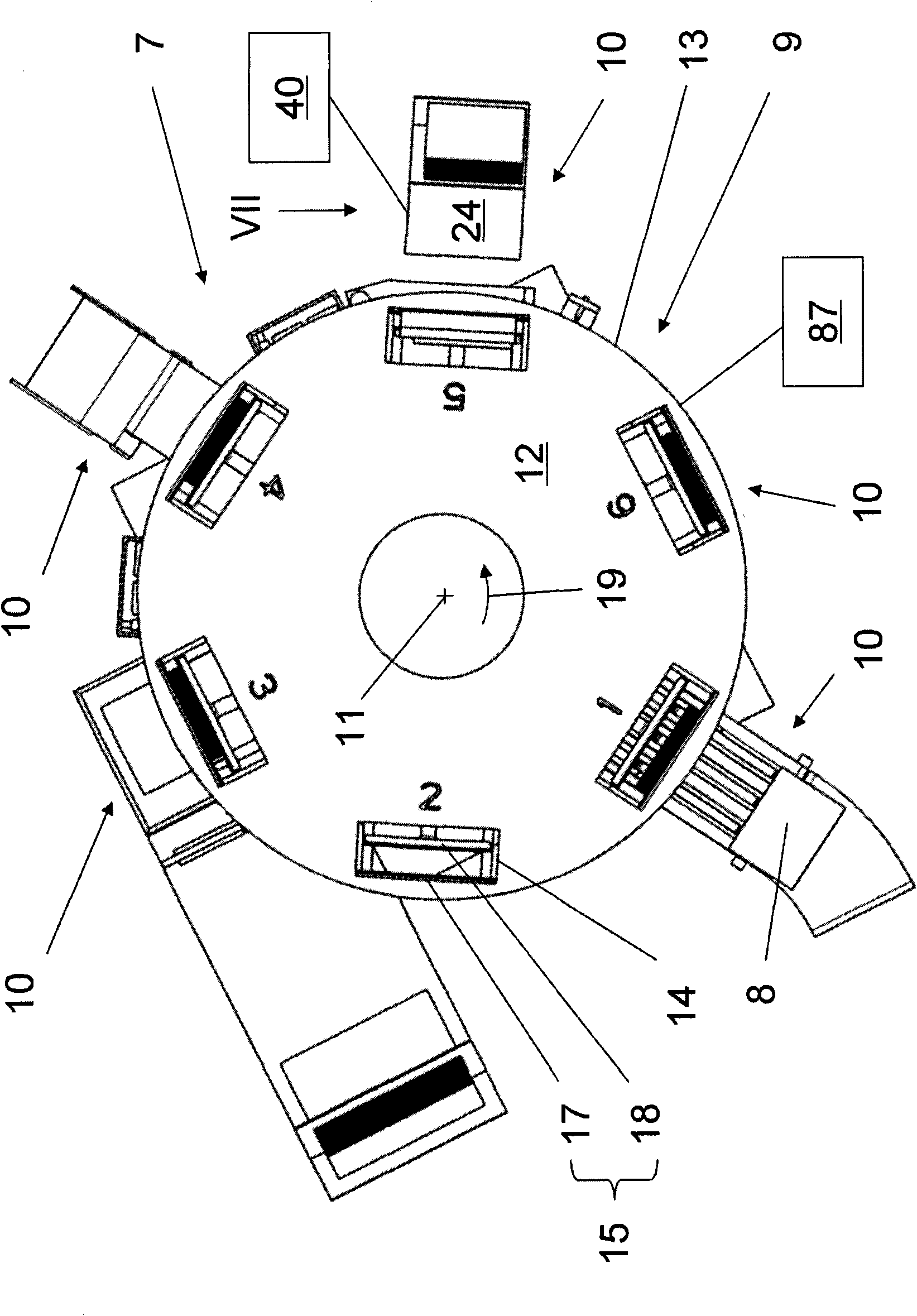

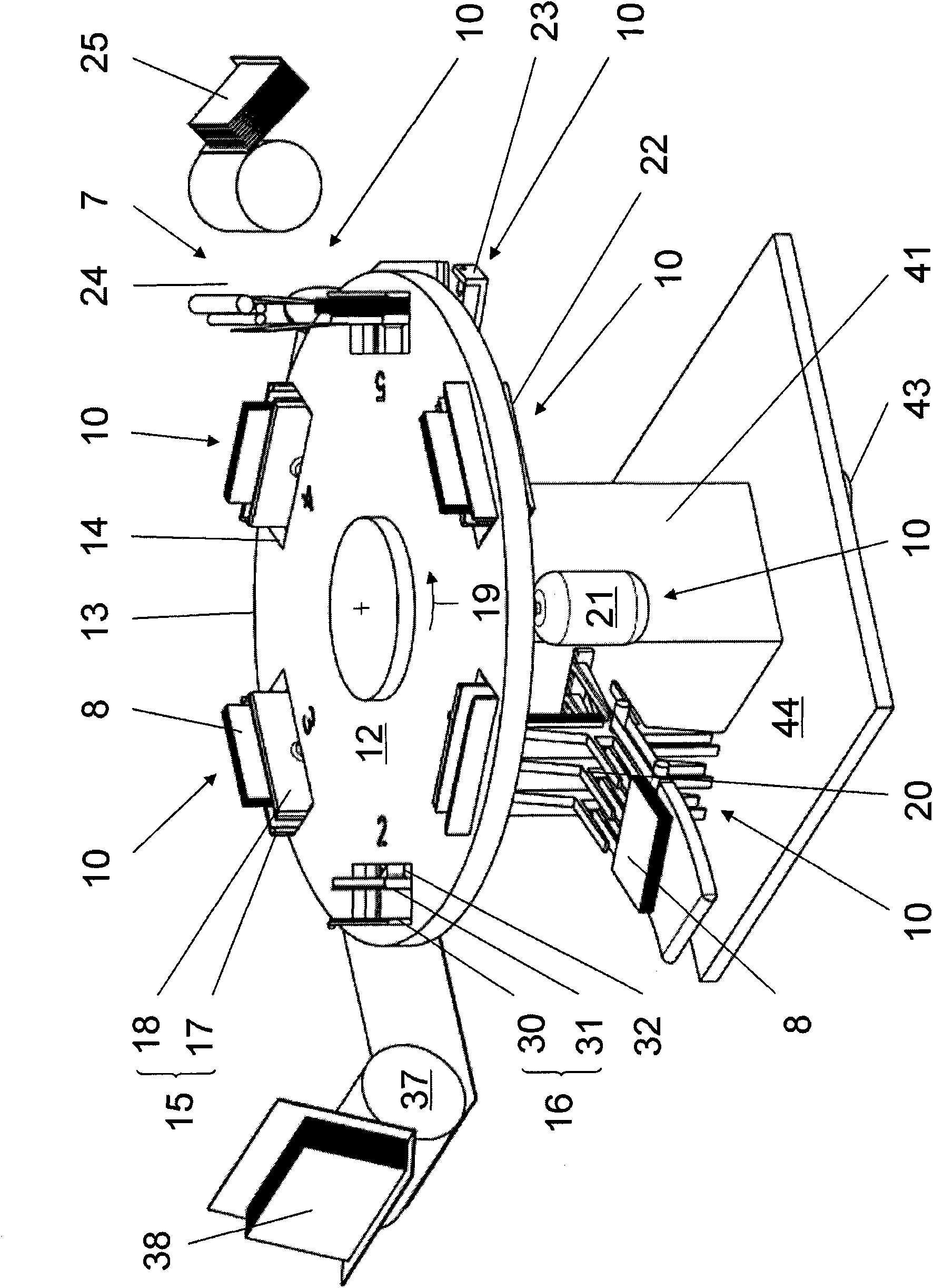

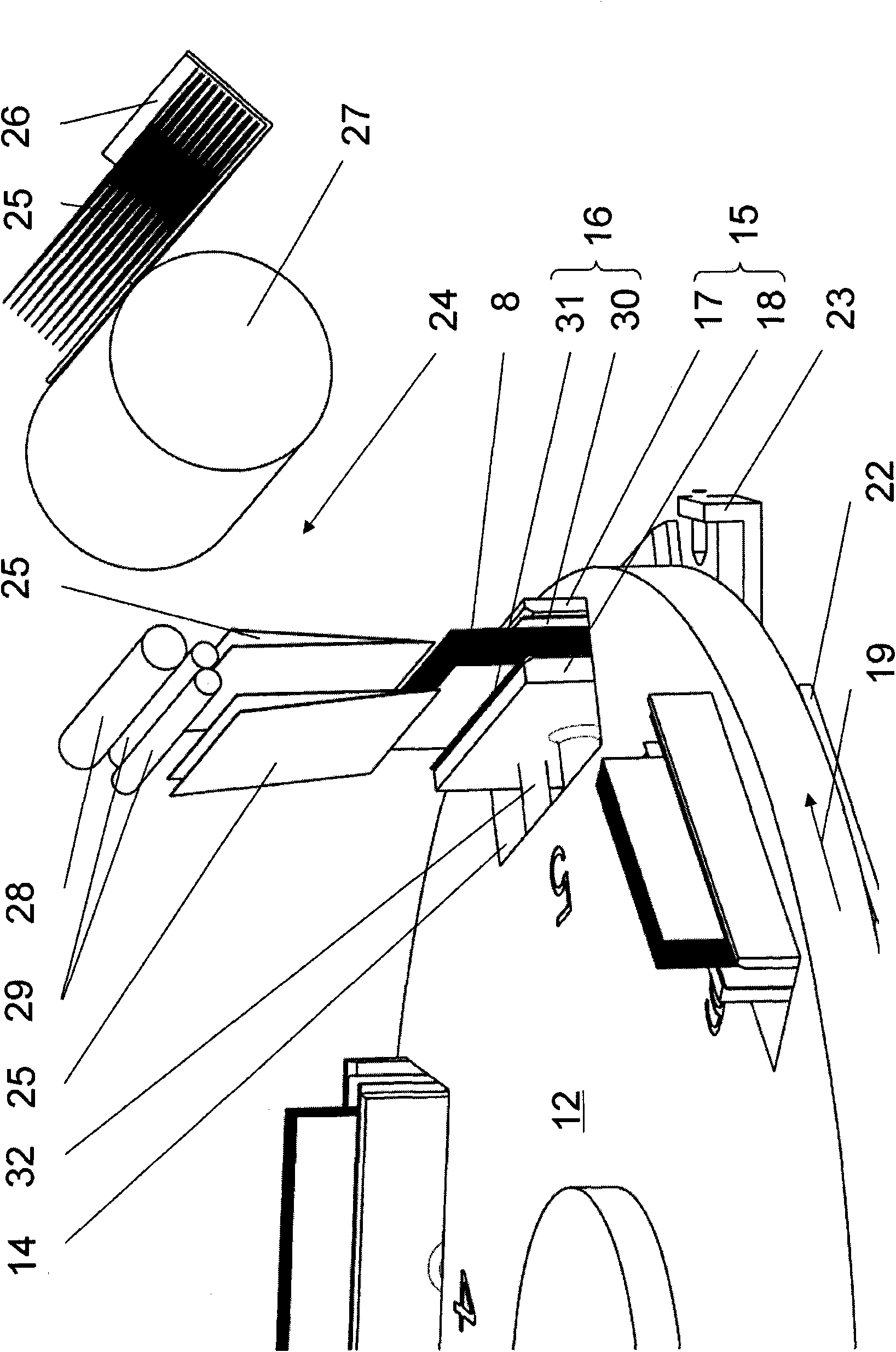

Seed distribution method and apparatus

InactiveUS7490565B2Improve abilitiesAvoid bouncingSelf-acting watering devicesWatering devicesDistribution methodMechanical engineering

A seeding apparatus comprising: (a seed distribution metering means including a rotating d drum with apertures on its periphery and a vacuum generator for generating a suction pressure inside the drum so that seeds are attracted to the apertures; (b) feeding system including a hopper, gravitational acceleration chamber, velocity controlling elements such as a flap and continuous belts for feeding seeds at a required amount and speed to the drum; (c) release mechanisms including an air-jet for releasing metered seeds from the drum along a selected trajectory while unselected seeds follow another trajectory, delivery device including an adjustable flow venturi and electronic sensor for controlling delivery of metered seeds.

Owner:HOLLY JOHN

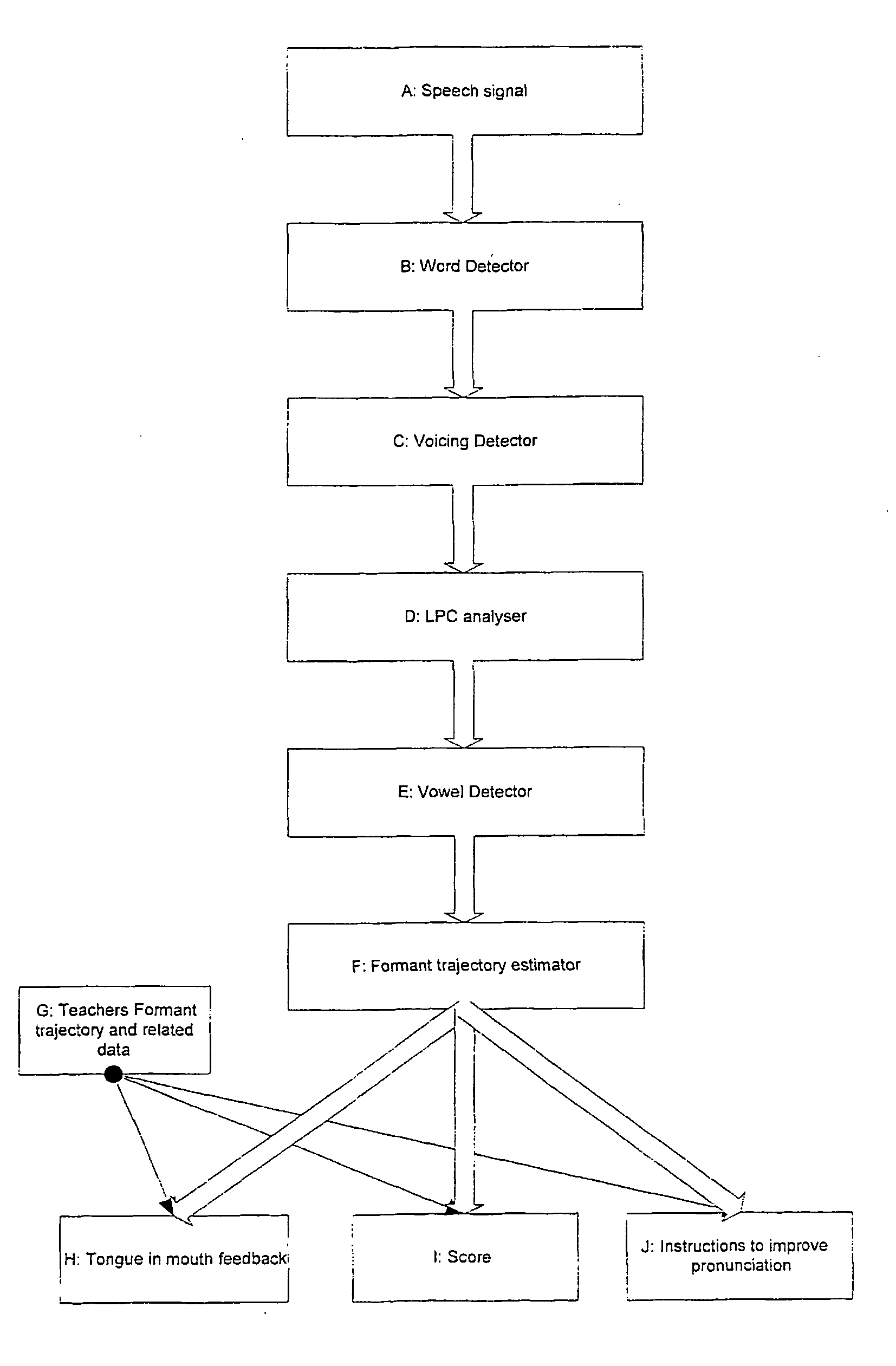

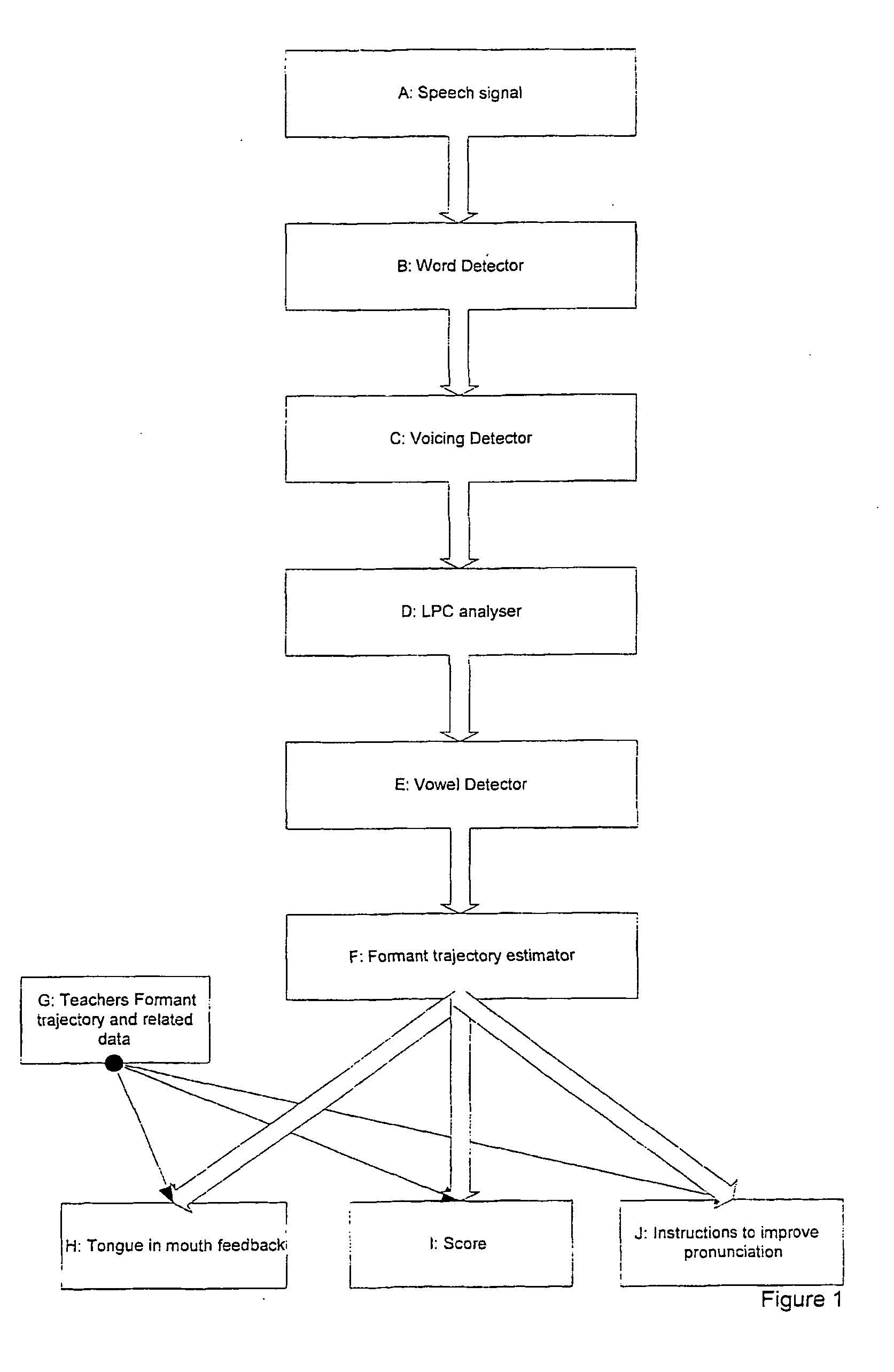

Method, system and software for teaching pronunciation

The present invention relates to a method for teaching pronunciation. More particularly, but not exclusively, the present invention relates to a method for teaching pronunciation using formant trajectories and for teaching pronunciation by splitting speech into phonemes. (A) A speech signal is received from a user; (B) word(s) is / are detected within the signal; (C) voice / unvoiced segments are detected within the word(s); (D) formants of the voiced segments are calculated; (E) vowel phonemes are detected with the voiced segments; the vowel phonemes may be detected using a weighted sum of a Fourier transform measure of frequency energy and a measure based on the formants; and (F) a formant trajectory may be calculated for the vowel phonemes using the detected formants.

Owner:VISUAL PRONUNCIATION SOFTWARE

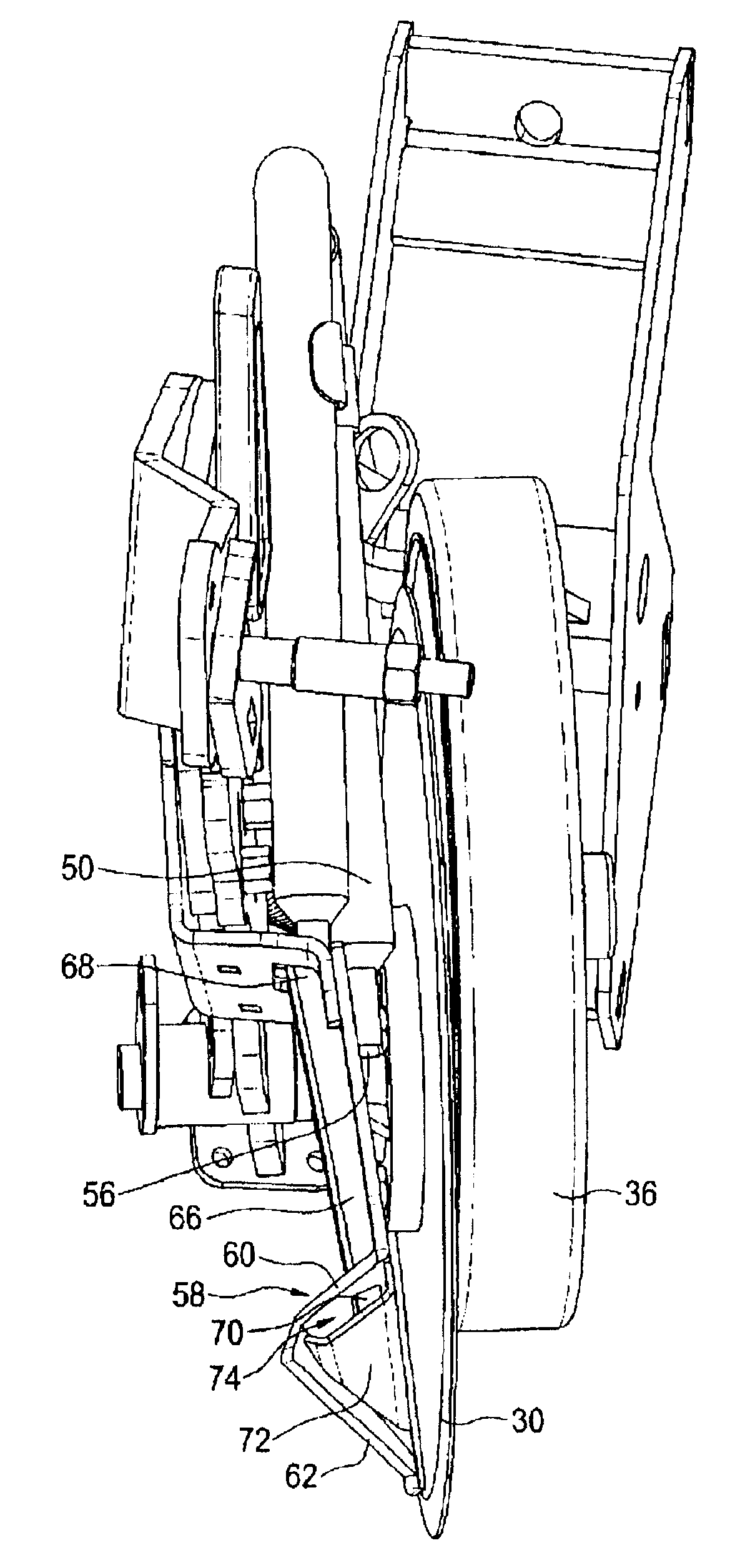

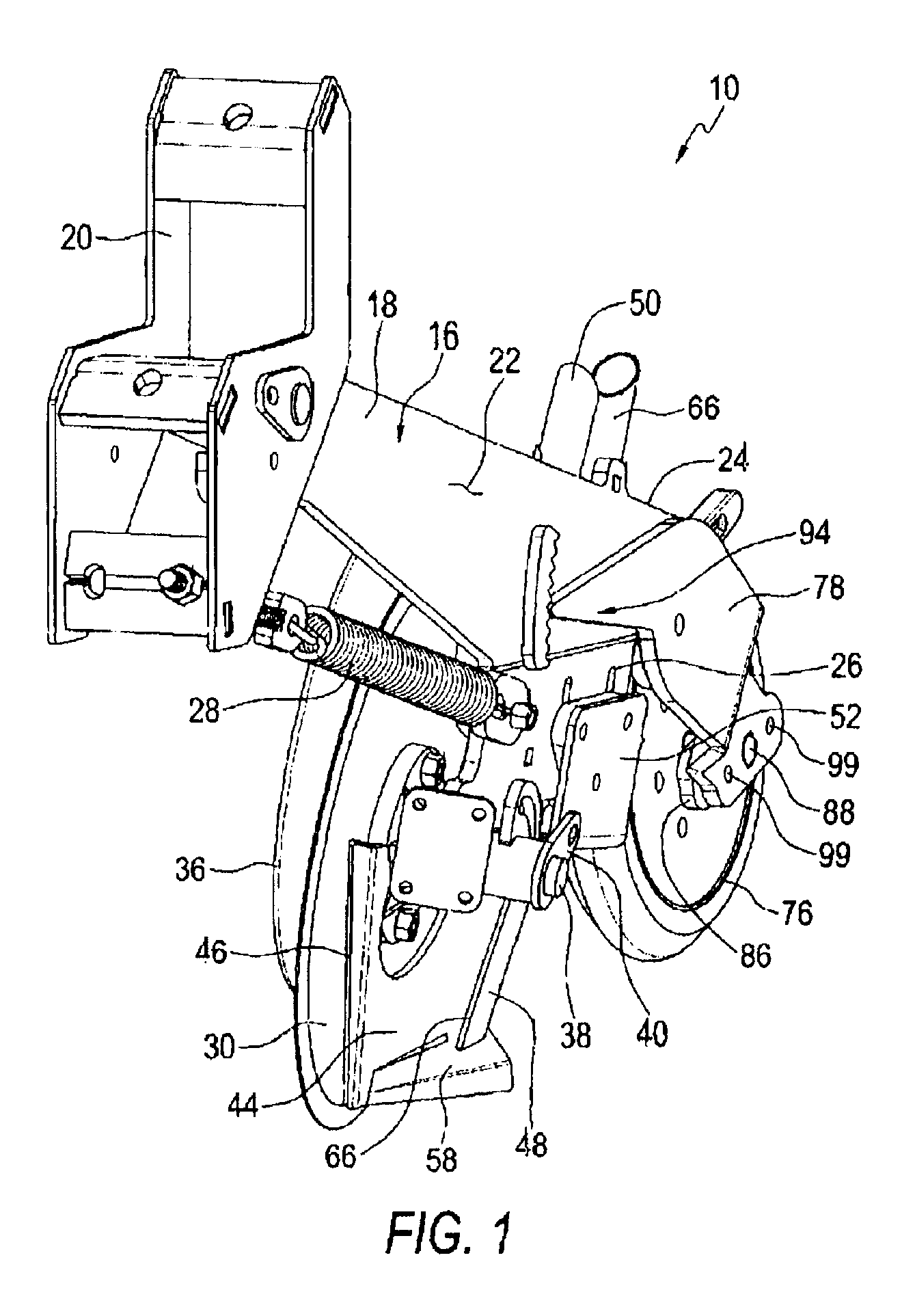

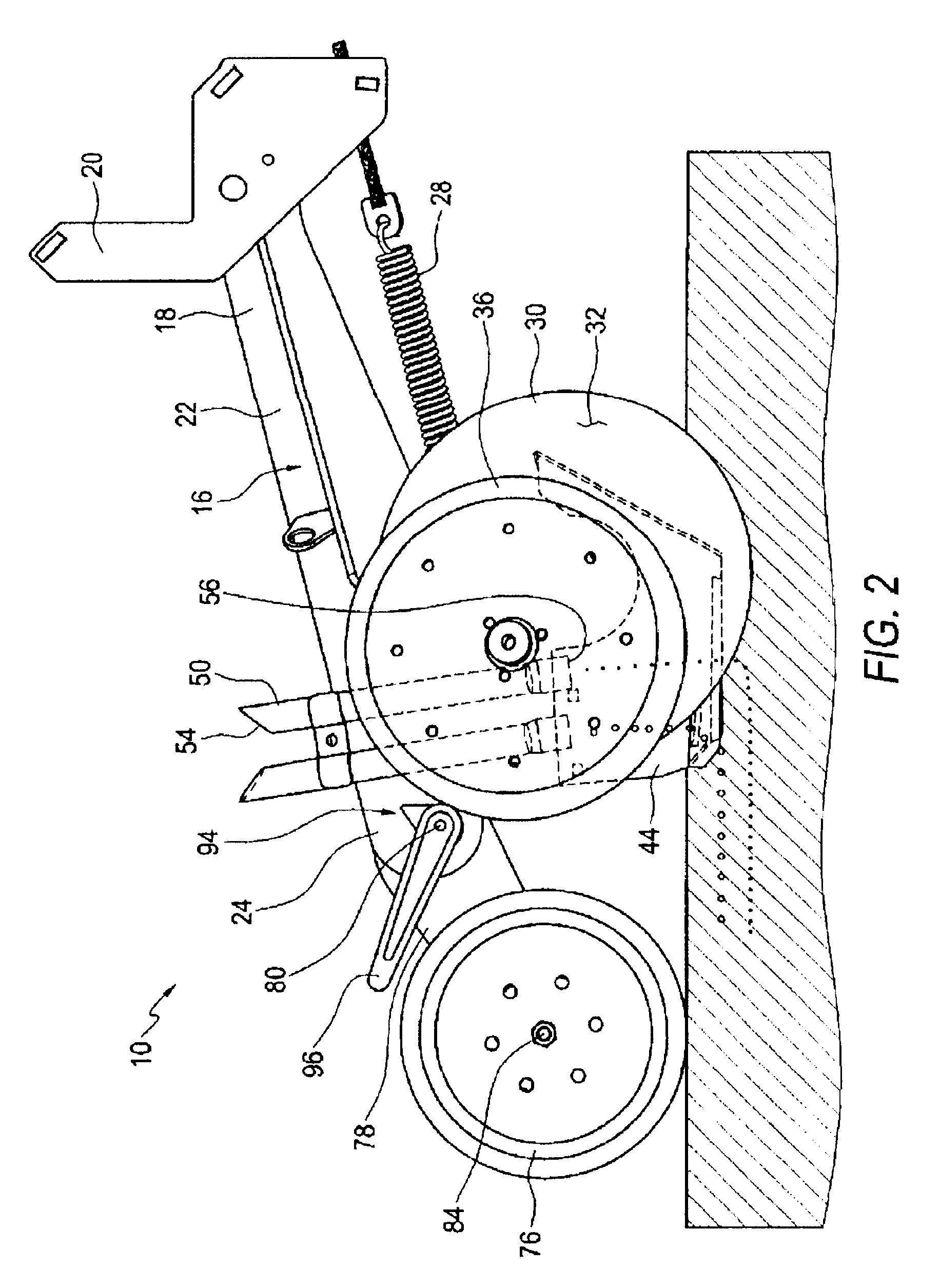

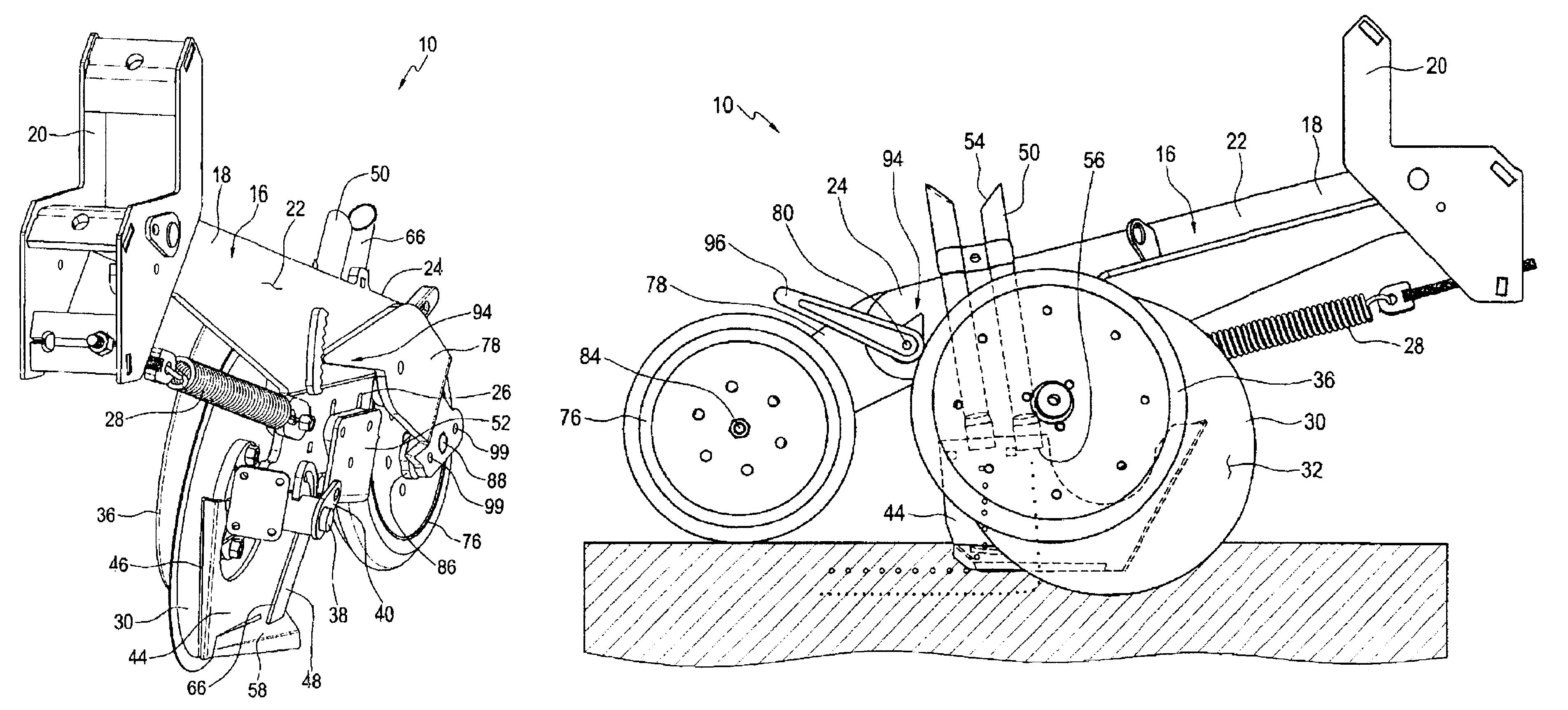

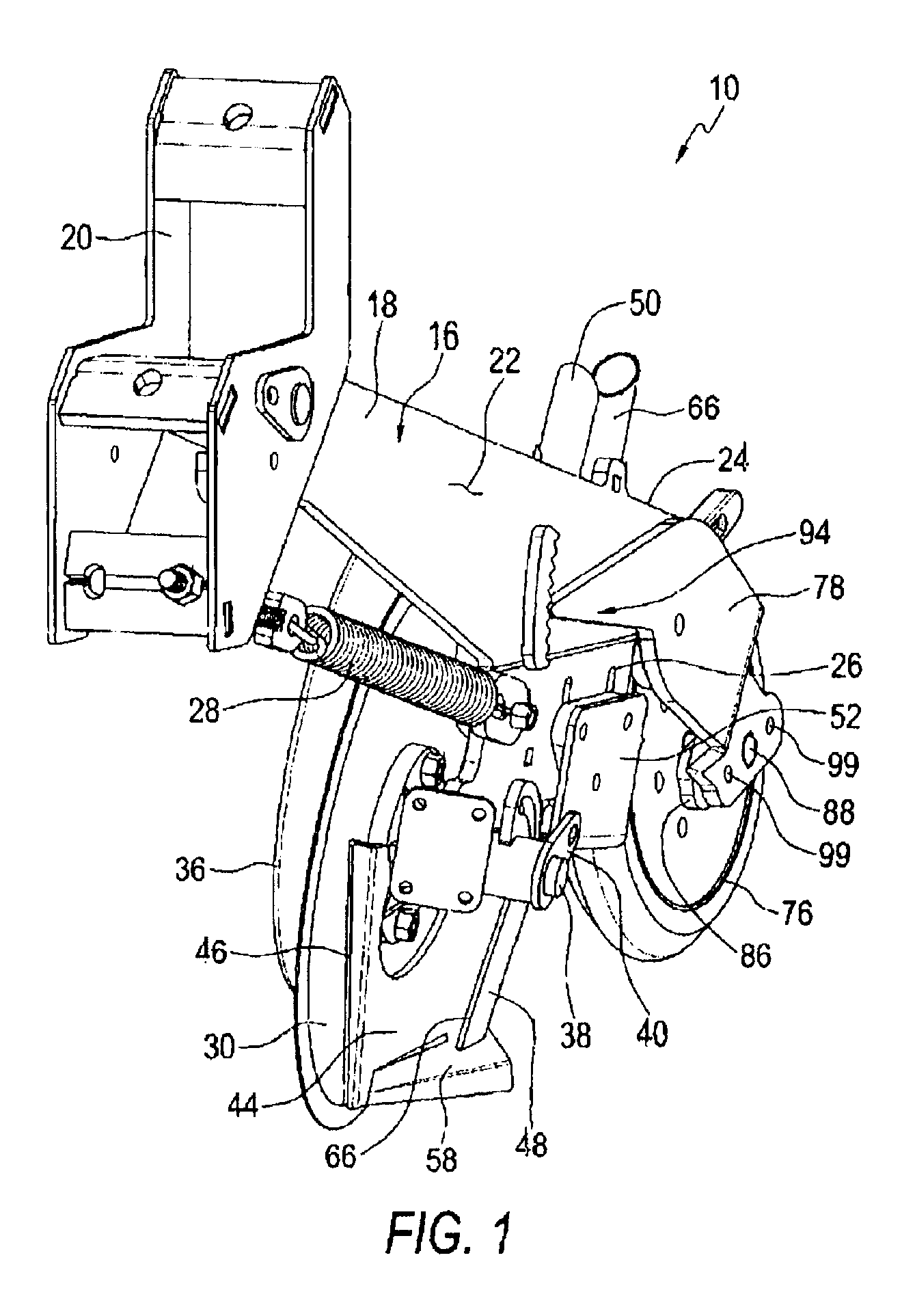

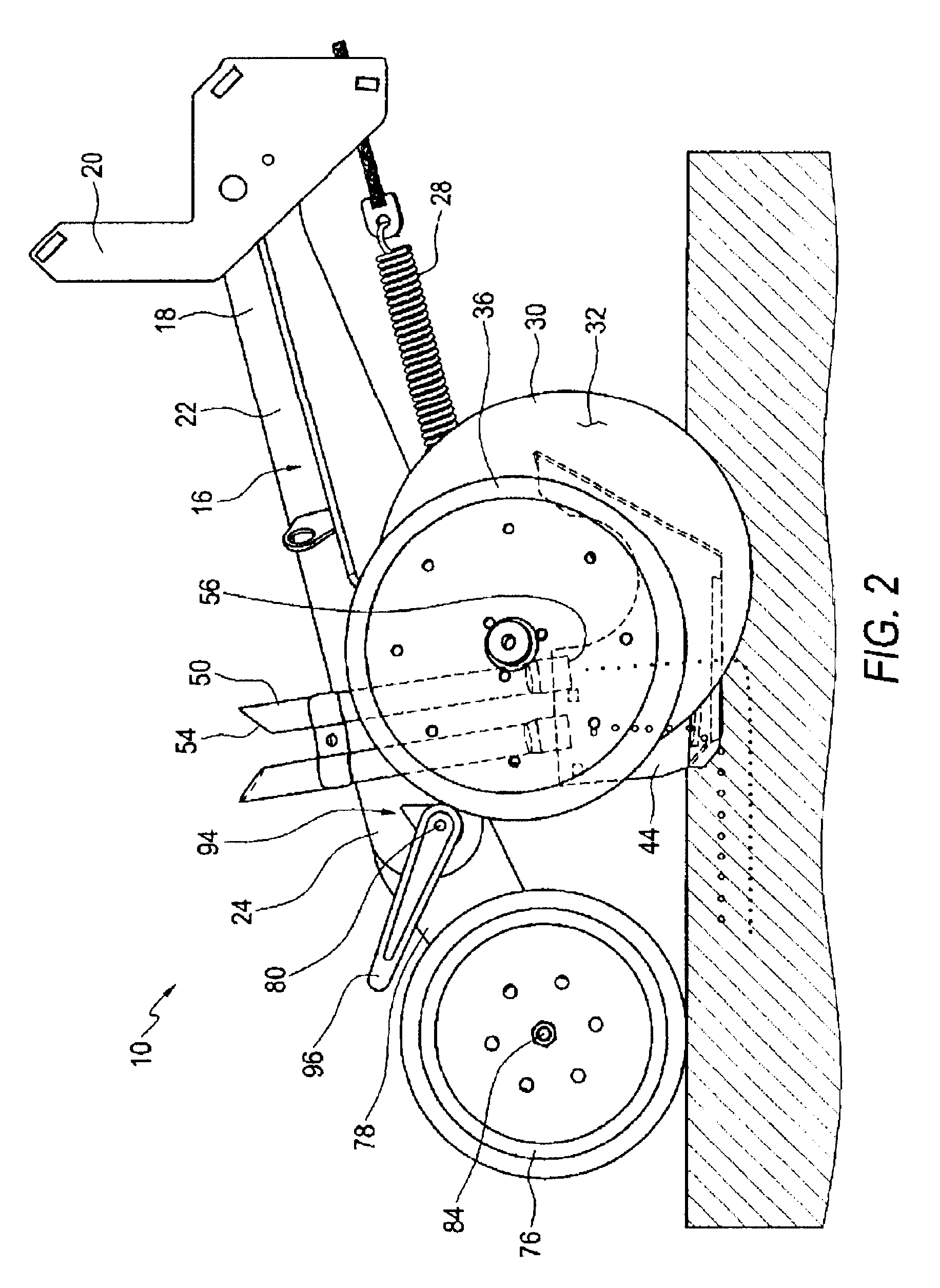

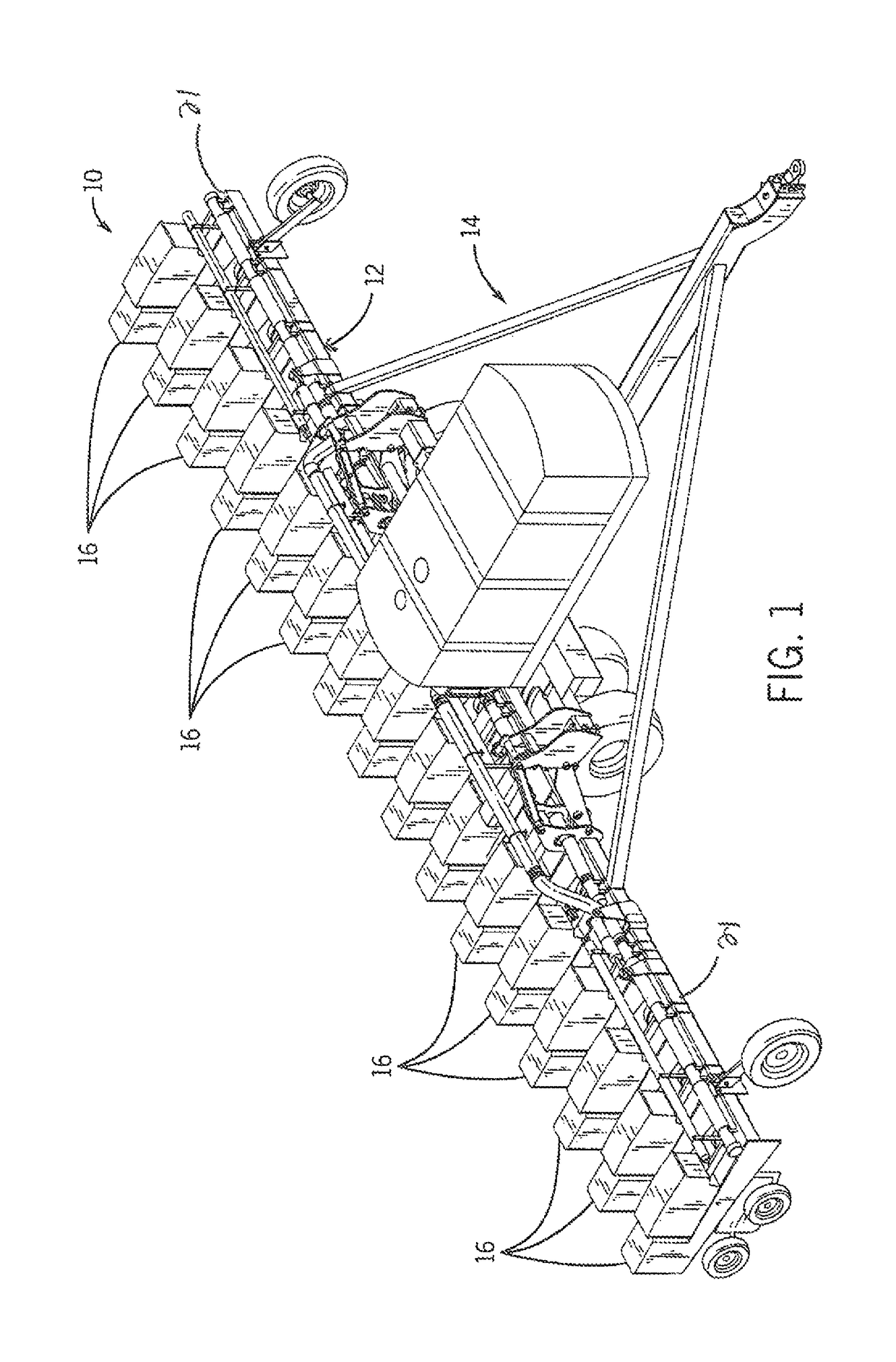

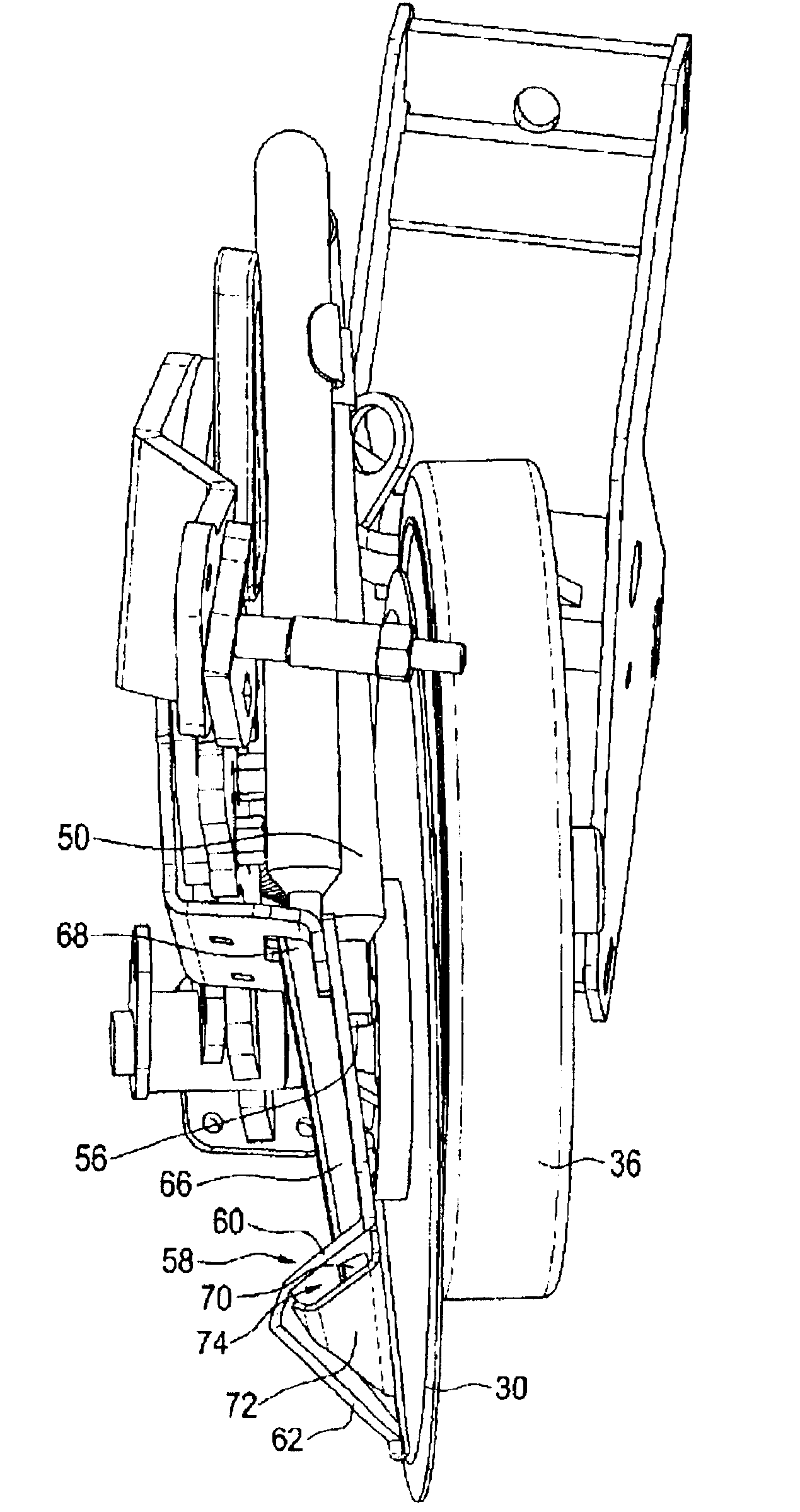

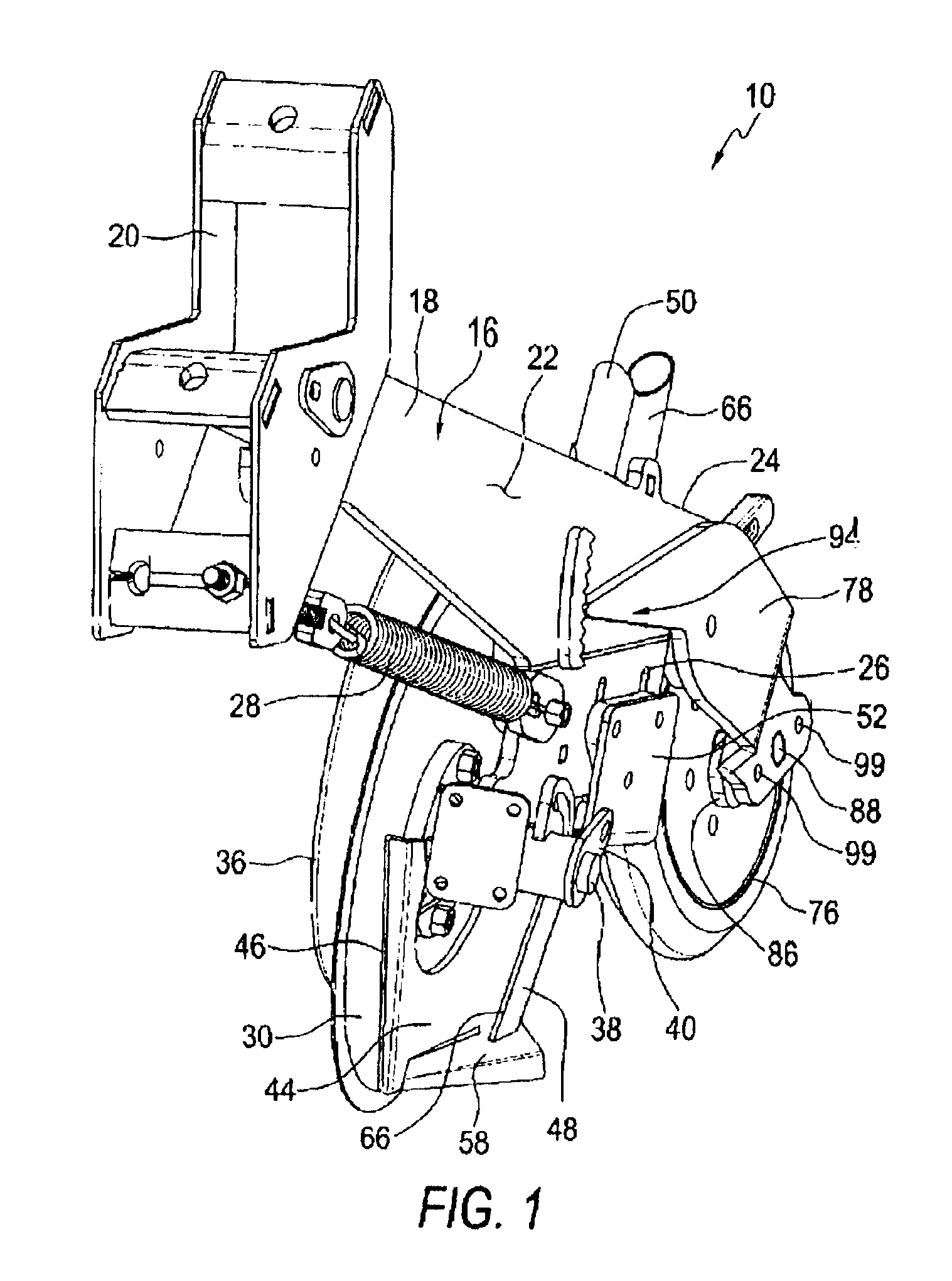

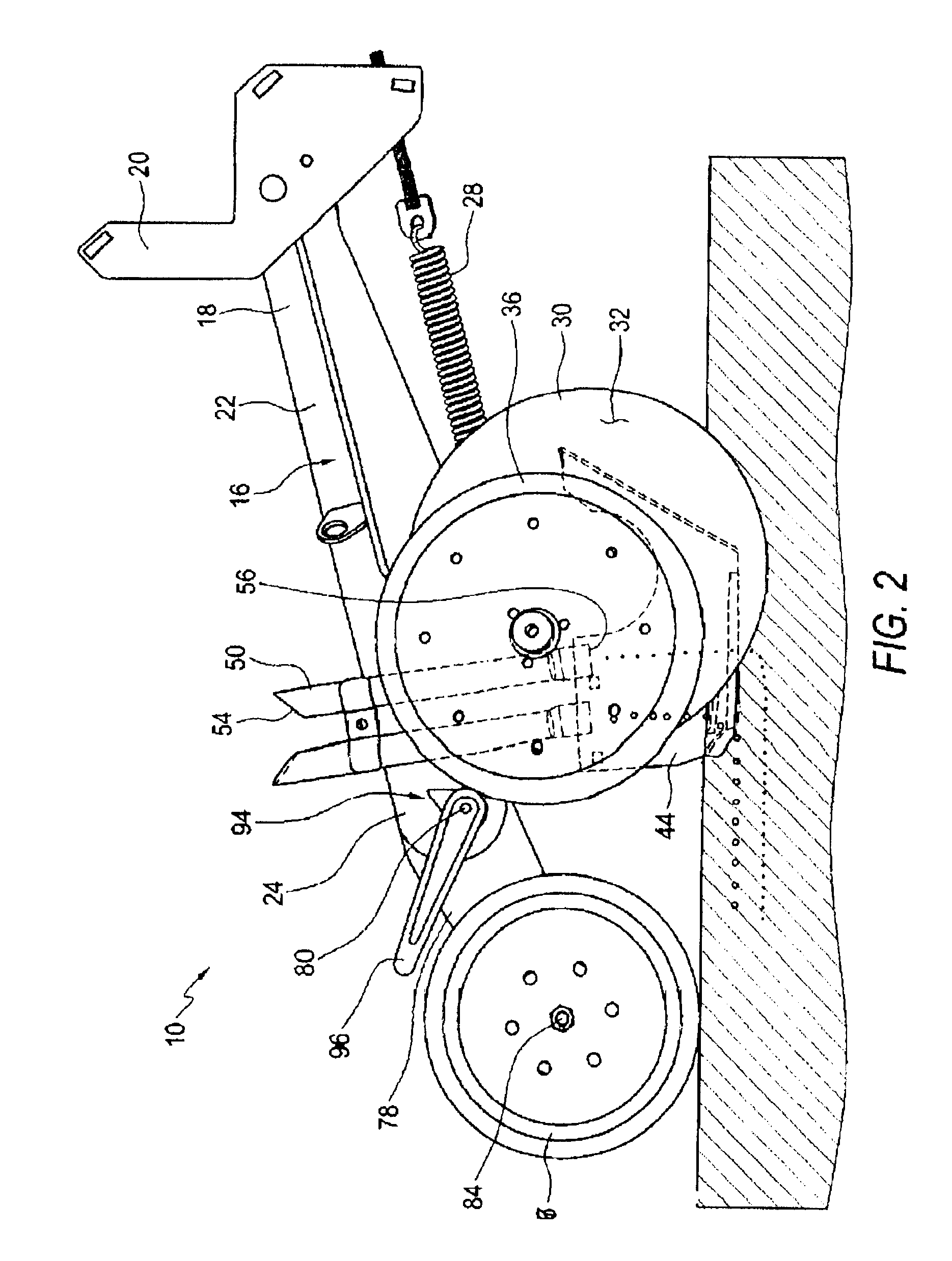

Furrow opener

ActiveUS20080257237A1Avoid bouncingSoil-working equipmentsPotato plantersMechanical engineeringEngineering

Owner:FRIESEN DICK EDWARD +1

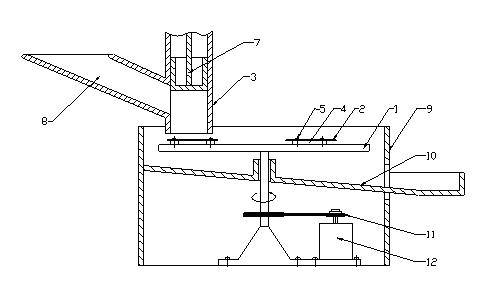

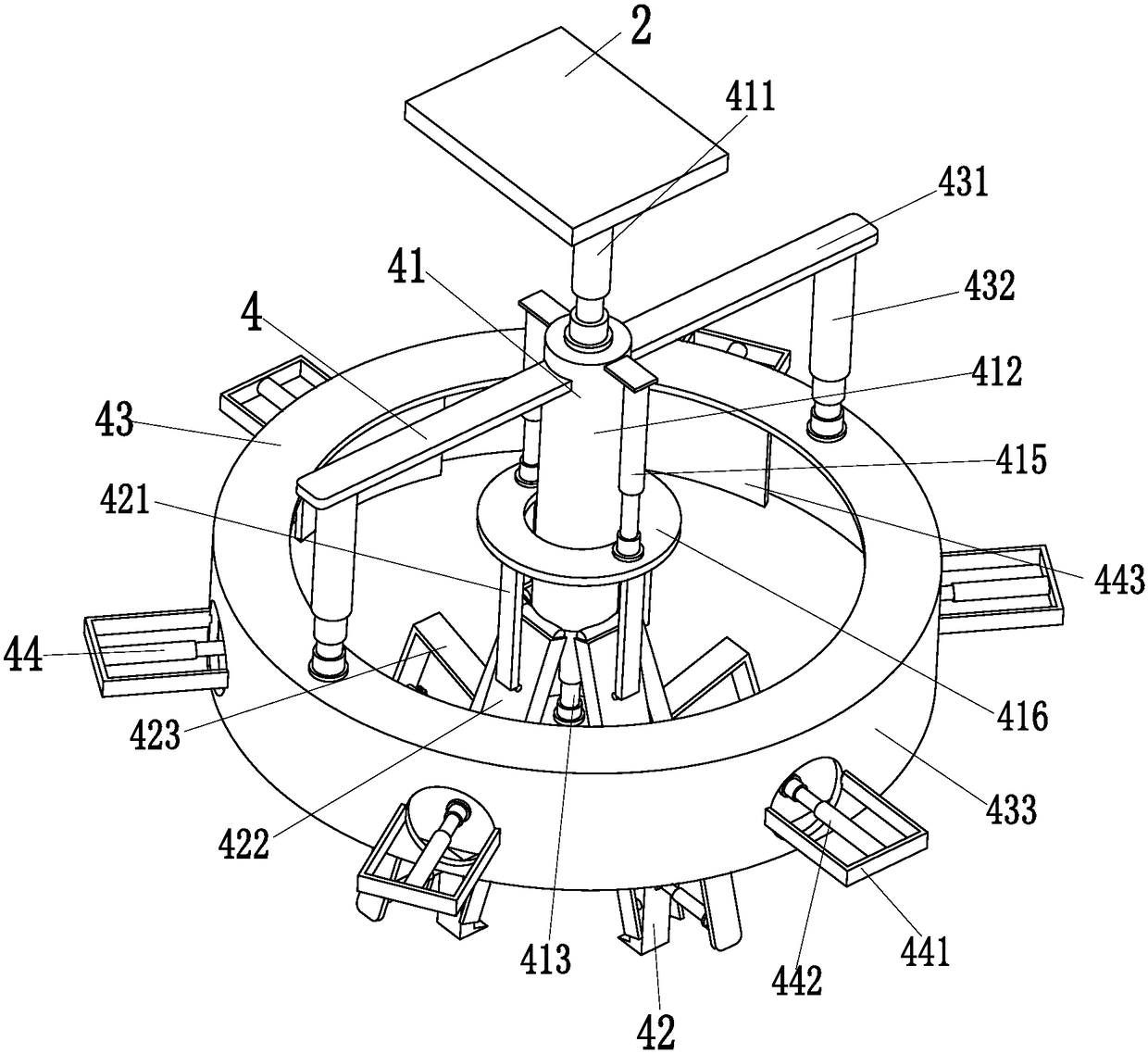

Finger citron slicing machine

InactiveCN101898368AReasonable designEasy to operateMetal working apparatusSlice thicknessSurface mounting

The invention relates to a finger citron slicing machine which comprises a rotary disc. The finger citron slicing machine is characterized in that the upper surface of the rotary disc is provided with a rotary cutting blade, and a feed guide sleeve is arranged above the station of the rotary cutting blade. The slicing machine has simple structure, the continuous slicing of finger citron can be easily realized, the thickness of slices is adjustable, and the uniformity of the thickness of the finger citron slices is ensured, which is beneficial to next processing procedure. In addition, another embodiment of the invention adopts the structural form of an inverted woodworking plane, and the finger citron slices cut by the structural form can meet food processing requirements and can have any thickness, which is beneficial to food processing and development and is also beneficial to the development of new application fields of finger citron besides medicinal application.

Owner:福建承天农林科技发展有限公司

Timed passive air sampler

ActiveCN103033398AGuaranteed tensionAvoid contactWithdrawing sample devicesAutomatic controlEngineering

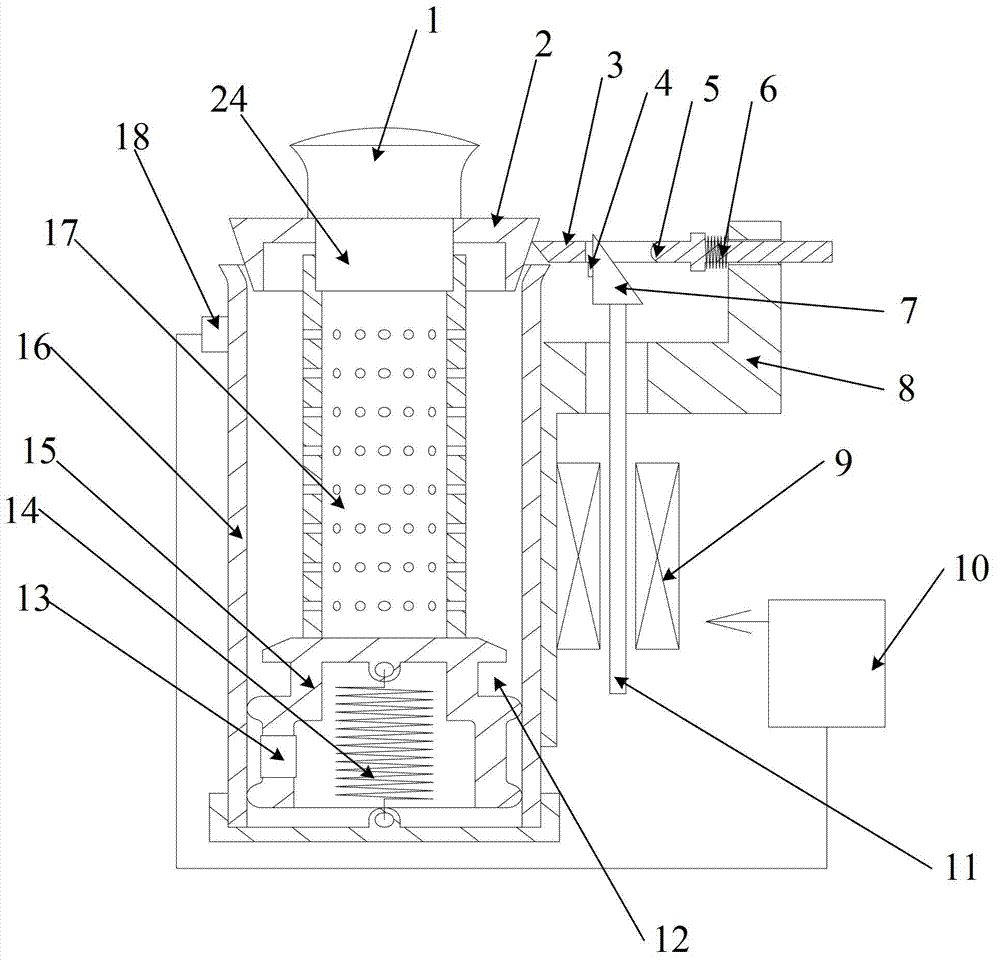

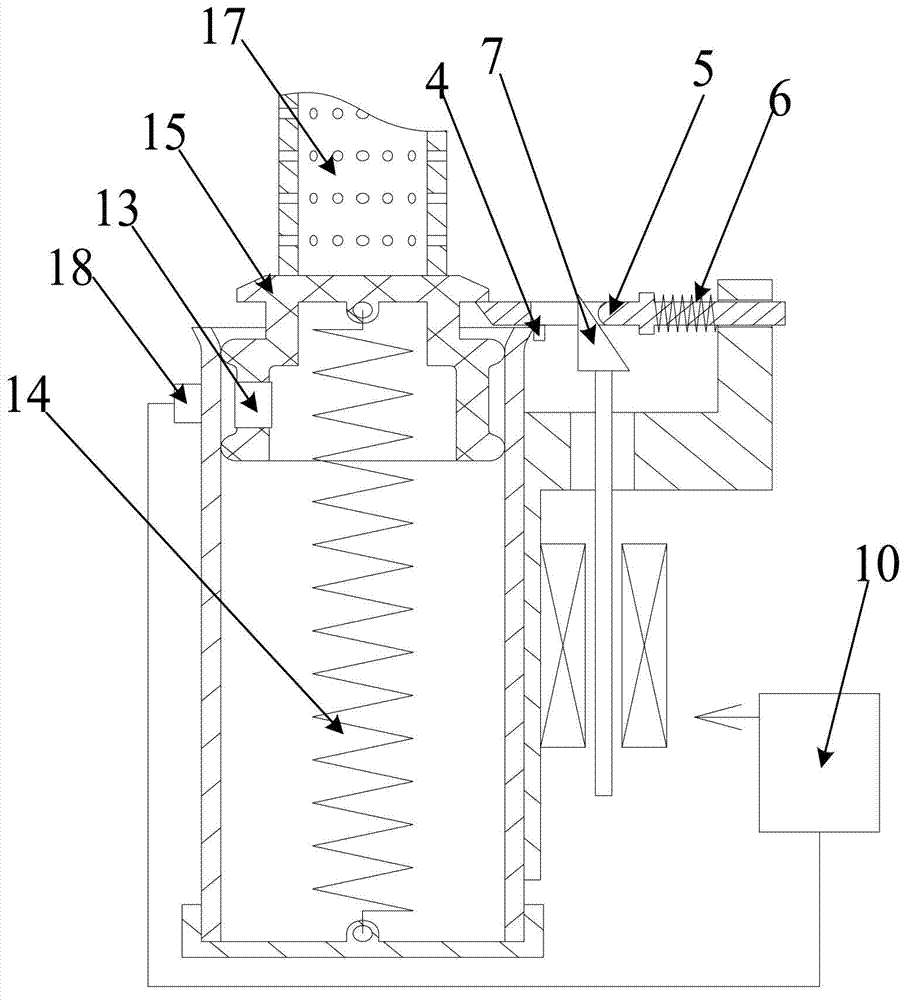

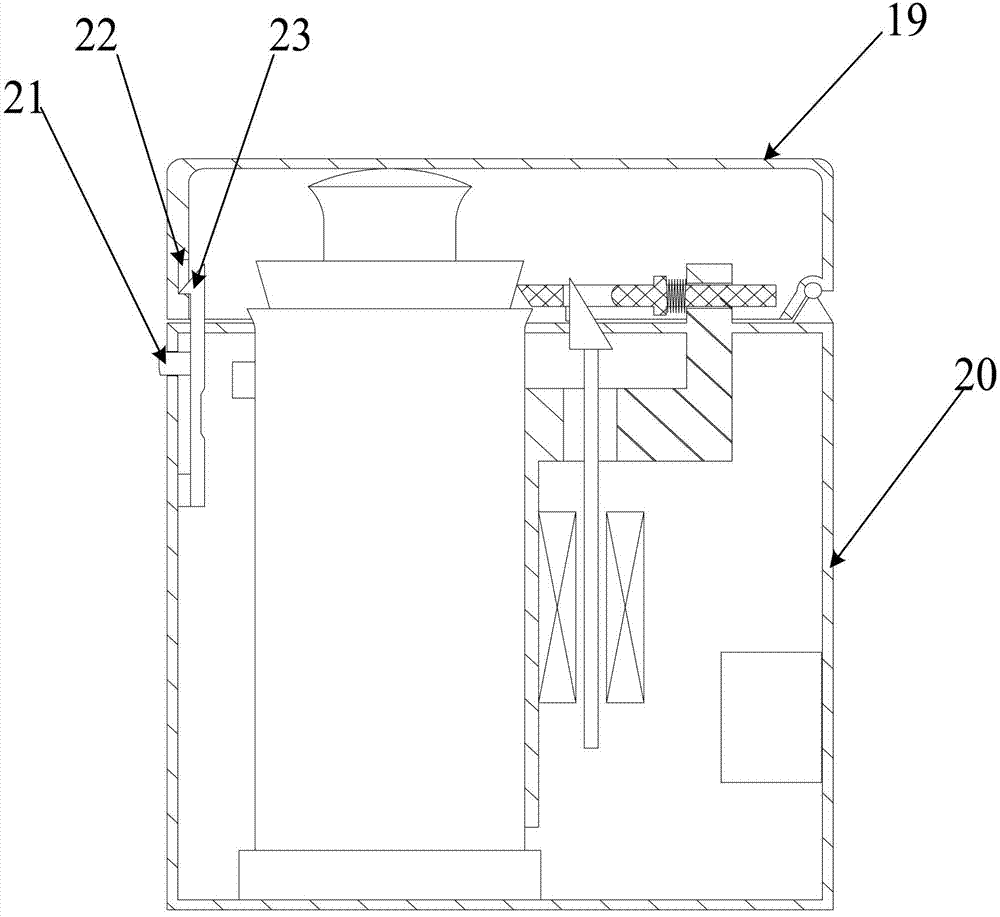

The invention discloses a timed passive air sampler, which comprises an air sampler main body, wherein the air sampler main body comprises a packaging barrel with an opening at the top, an adsorbent cage which is sheathed in the packaging barrel, a blocking pillar, an electromagnet and a timing driving circuit; a timing beginning sensor and a mounting bracket are arranged on the side wall of the packaging barrel; a rubber plug matched with the top of the packaging barrel is arranged at the top end of the adsorbent cage; a return spring is arranged between the bottom of the adsorbent cage and the bottom of the packaging barrel; a bayonet which can be pulled out to expose the packaging barrel and a sensing body corresponding to the timing beginning sensor are arranged on the adsorbent barrel; the blocking pillar is arranged on the mounting bracket and can move in the radial direction of the packaging barrel and be matched with the bayonet; the electromagnet is arranged on the outer wall of the bracket of the packaging barrel and can control the blocking pillar to be departed from the bayonet; and the timing driving circuit is connected with the timing beginning sensor and the electromagnet. The timed passive air sampler can implement the accurate automatic control of the sampling time, automatic packaging, and effectively improve the sampling accuracy of the passive air sampler.

Owner:SHENZHEN INST OF BUILDING RES

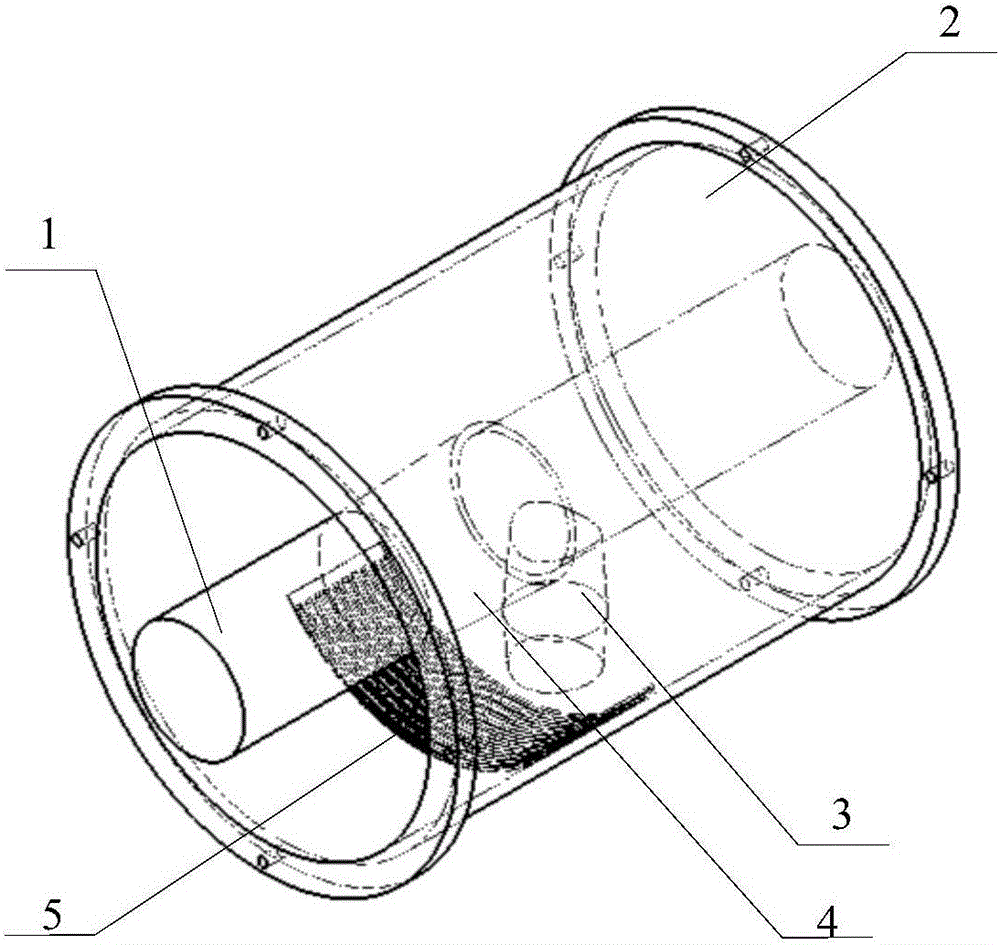

Metal particle trap for direct-current gas-insulated power transmission line

InactiveCN105149096AAging does not occurSolve agingElectric supply techniquesElectrode constructionsEpoxyElectrical conductor

The invention discloses a metal particle trap for a direct-current gas-insulated power transmission line. The metal particle trap is composed of a driving electrode and a metal particle trapping groove. A direct-current GIL aluminum alloy conductor and a pillar insulator for a direct current GIL are arranged inside a direct-current GIL aluminum alloy shell. The driving electrode is installed nearby the pillar insulator for the direct-current GIL on the direct-current GIL aluminum alloy conductor. The metal particle trapping groove is installed inside a direct-current GIL cavity, so that the inclined face of the driving electrode faces the bottom metal particle trapping groove. The metal particle trapping groove comprises three layers which are the inward-concave type metal shielding groove, an epoxy resin insulation pad and the high-viscidity hot melt adhesive coating in sequence from bottom to top. The metal particle trapping groove is used for capturing and limiting particles, the inward-concave type metal shielding groove in the bottommost layer generates a low electric field area, the epoxy resin insulation pad on the middle layer coats the whole bottom of the inward-concave type metal shielding groove, and the high-viscidity hot melt adhesive coating on the uppermost layer can control and trap particles moving at a high speed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

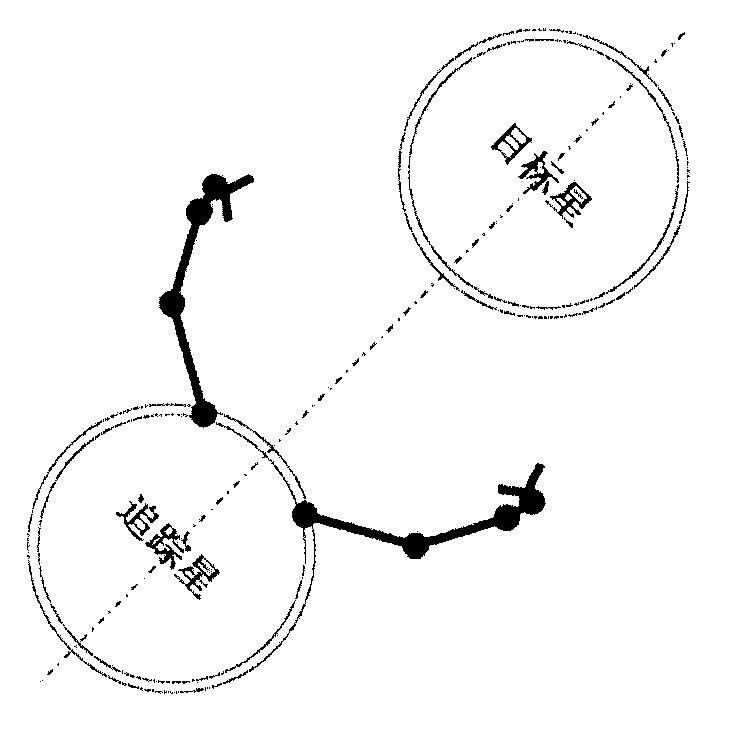

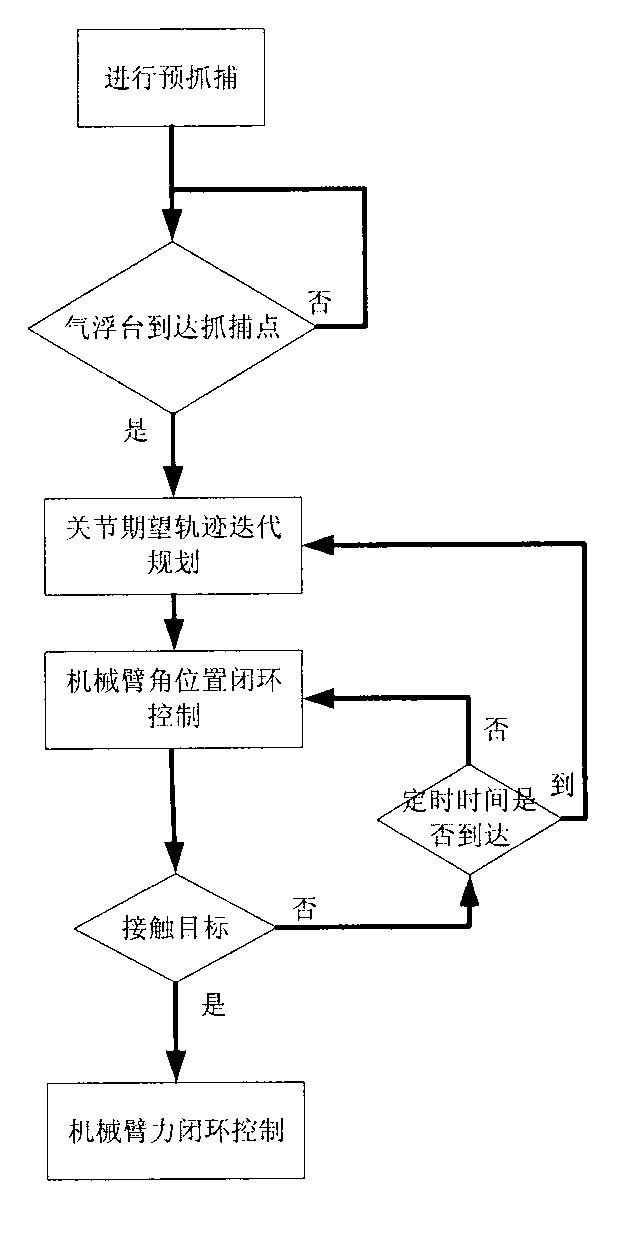

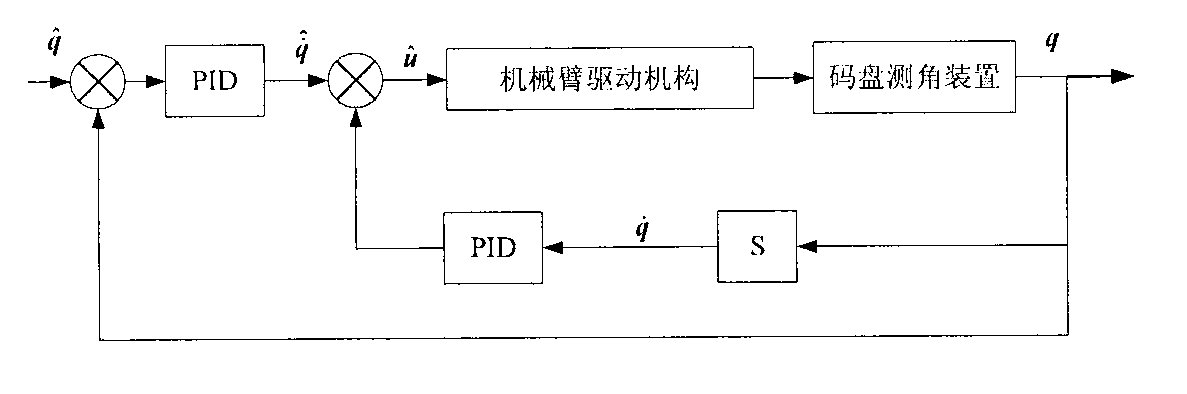

Control method for mechanical arm capture test on air-floating tables

The invention discloses a control method for a mechanical arm capture test on air-floating tables, which comprises a mechanical arm capture process based on an inverse kinematics iteration planning and a force closed-loop capture control process, wherein the mechanical arm capture process based on the inverse kinematics iteration planning can be changed according to the relative distance and the relative posture of the two continuously-updated air-floating tables; all joint target angles of two multi-degree of freedom mechanical arms are iteratively updated; and tracks are planned on line till the tracks are reliably connected, so that the adaptive ability of mechanical arm capture is improved, and the capture redundancy range of a target characteristic part is enlarged; and after an effective signal is detected by a touch sensor, the mechanical arm force closed-loop control process is switched by a joint position and speed closed loop to prevent the hard touch of the mechanical arms to the air-floating tables from causing bouncing. Through the control method, the reliability of mechanical arm capture connection can be ensured.

Owner:BEIJING INST OF CONTROL ENG

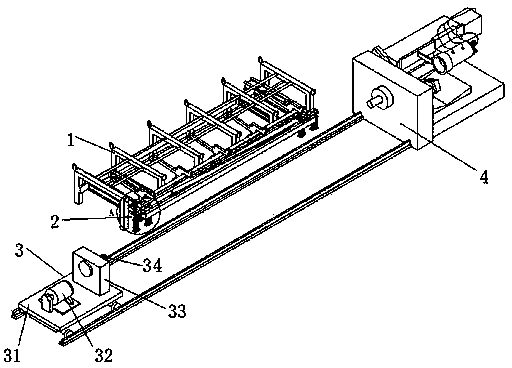

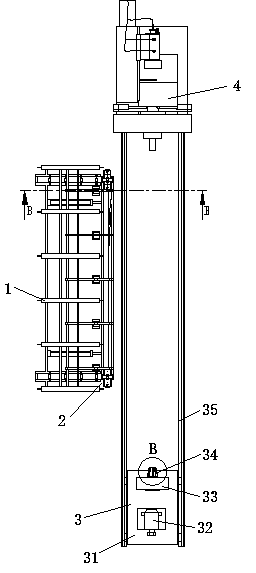

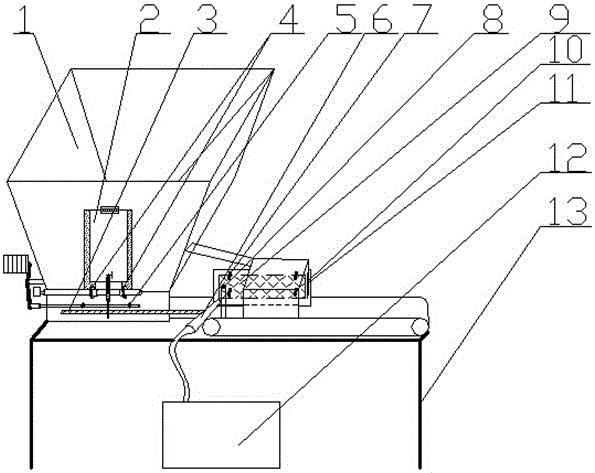

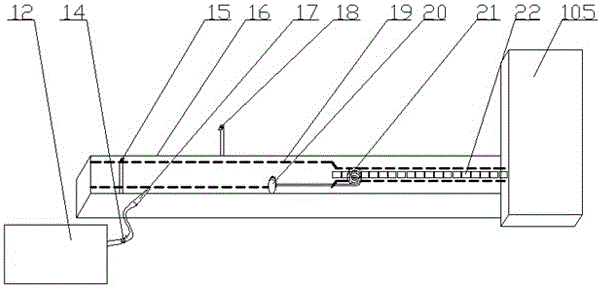

Automatic feeding and cutting assembly line

InactiveCN103447607AControl lengthUniform lengthTube shearing machinesMetal working apparatusEngineeringAssembly line

The invention discloses an automatic feeding and cutting assembly line. The automatic feeding and cutting assembly line comprises a storage rack, a lifting device, a feeding device and a cutting device, wherein the lifting device comprises a get-in device for independently extracting a steel pipe from the storage rack and a get-out device for getting the steel pipe in the get-in device out and conveying to the feeding device; the get-in device comprises an extraction component, a connecting rod and a cylinder; the extraction component is hinged to the storage rack through the connecting rod and is driven by the cylinder to move up and down; the get-out device comprises a bracket frame which is arranged on the lower part of the get-in device and can move horizontally; the bracket frame is provided with a tray which moves up and down. According to the assembly line, the labor cost is greatly saved, the working efficiency is improved, fully automatic operation is realized, and the finally required length of the steel pipe is cut under control. The overall working time for cutting one steel pipe is greatly shortened, and uniform length of each steel pipe can be guaranteed at last.

Owner:HUZHOU TIANHE MACHINERY

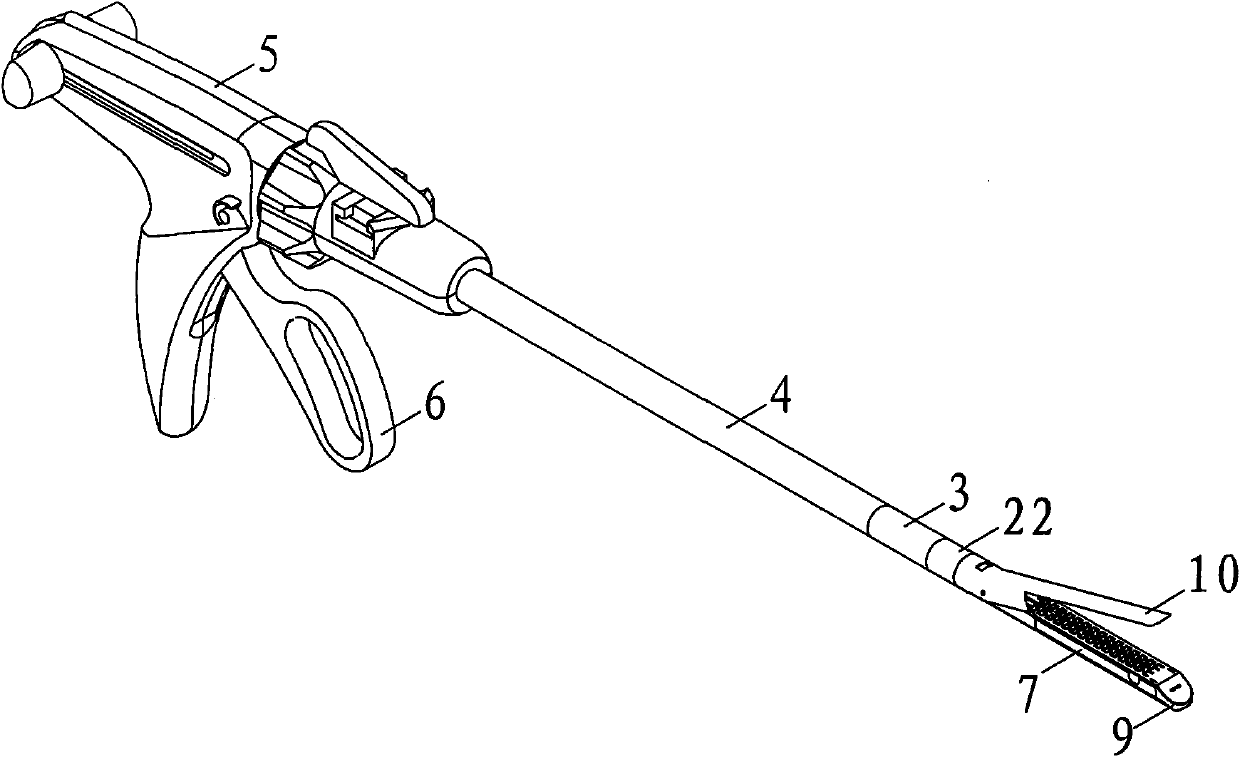

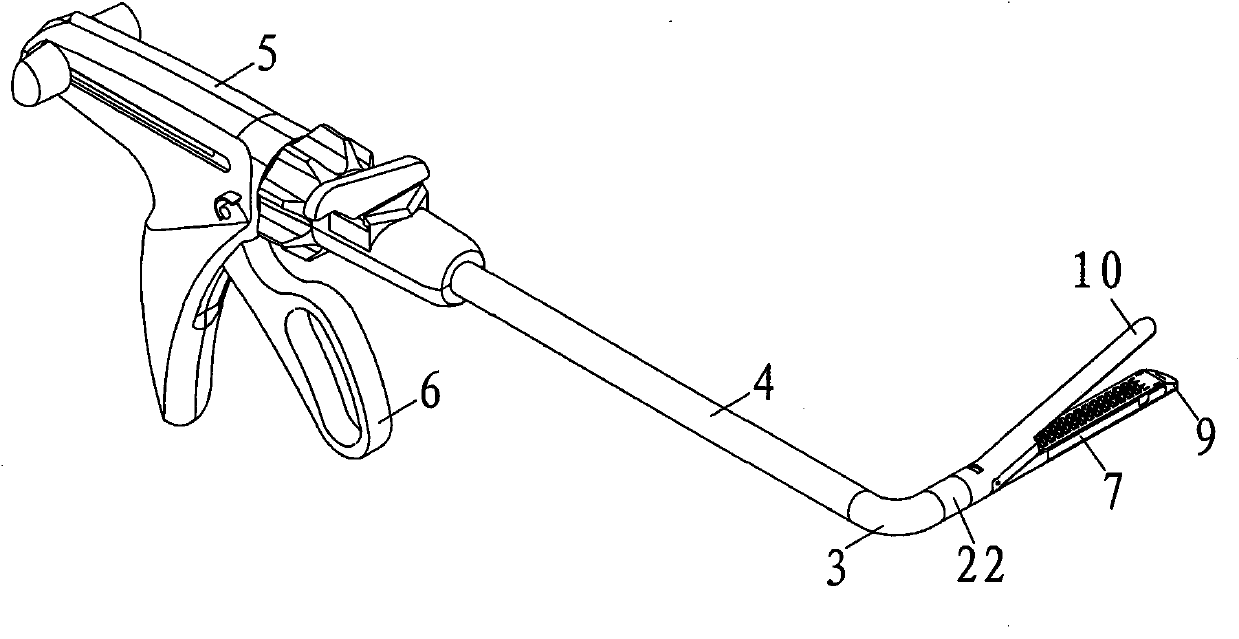

Endoscopic surgery cutting stapler with elastic neck ring

The invention relates to an endoscopic surgery cutting stapler with an elastic neck ring. The cutting stapler comprises a stapler body, an executing head, a connection stapler body, an extension pipe of the executing head and an operating mechanism for controlling the movement of the executing head, wherein the executing head consists of an executing rack, a sliding bar, a nail cartridge and a nail anvil; the sliding bar, the nail cartridge and the nail anvil are arranged on the executing rack; the nail anvil can rotate relatively to the nail cartridge; the periphery of the near end of the executing rack is covered with the elastic neck ring; the edge of the far end of the elastic neck ring closely sticks to the edge of the near end of the nail anvil; when the nail anvil rotates to be in an opening state relative to the nail cartridge, the elastic neck ring is pressed by the nail anvil to perform elastic deformation, the edge of the far end of the elastic neck ring closely sticks to the edge of near end of the nail anvil all the time; and when the nail anvil rotates to be in an closing state relative to the nail cartridge, the edge of the far end of the elastic neck ring return to closely sticks to the edge of near end of the nail anvil. By adopting the invention, the technical effects of reducing the processing and assembling difficulties of each part in the executing head and the product cost can be achieved; and the product is more convenient to use.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

Furrow opener

ActiveUS7540246B2Avoid bouncingSoil-working equipmentsPotato plantersEngineeringMechanical engineering

Owner:FRIESEN DICK EDWARD +1

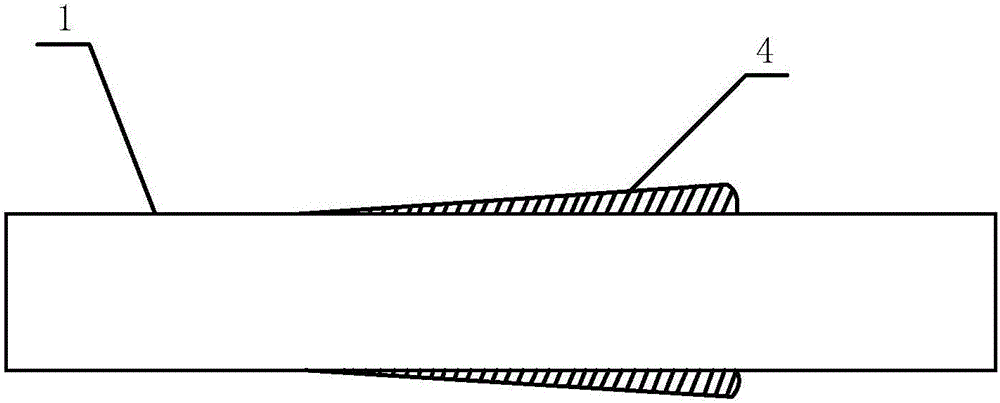

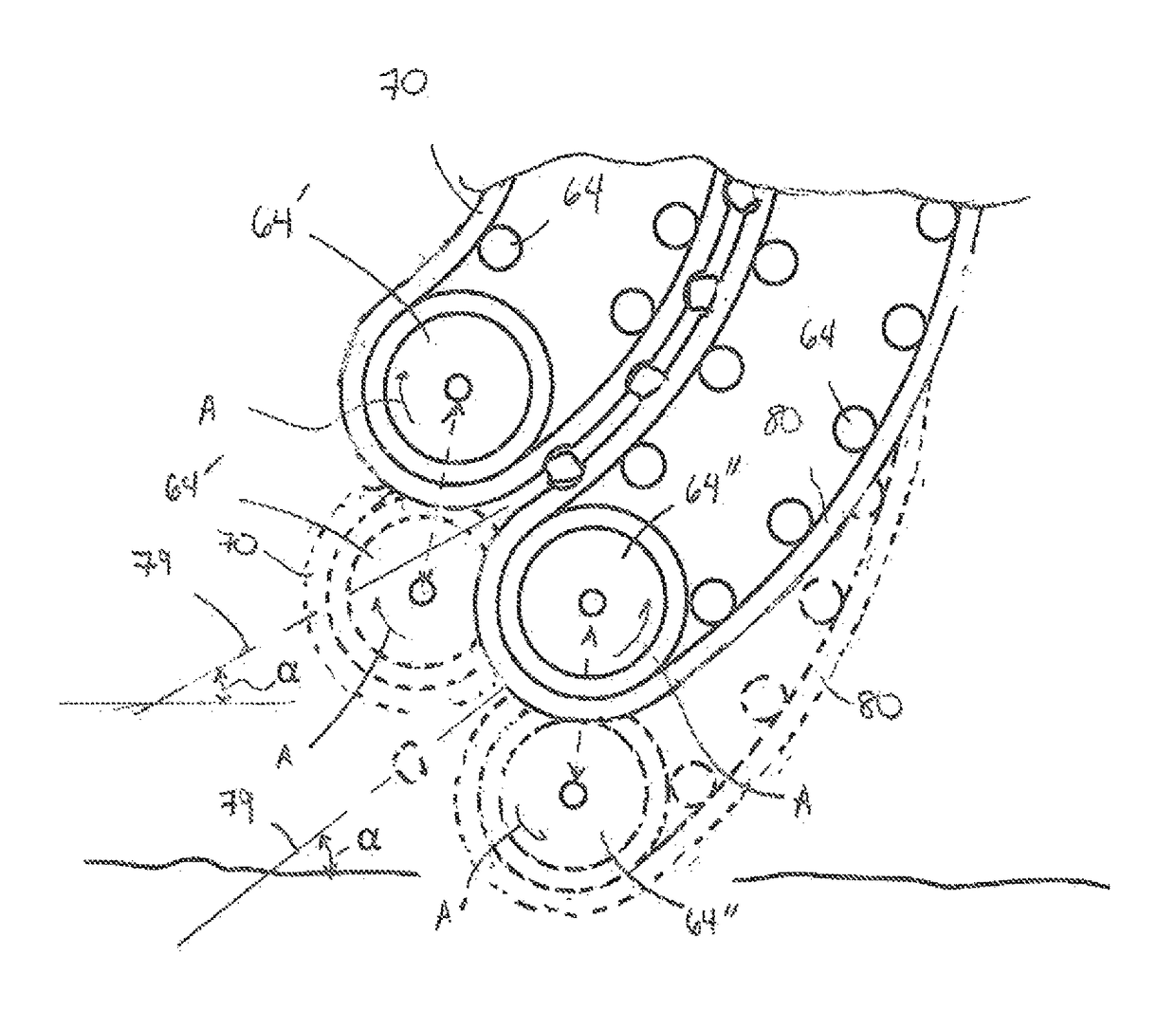

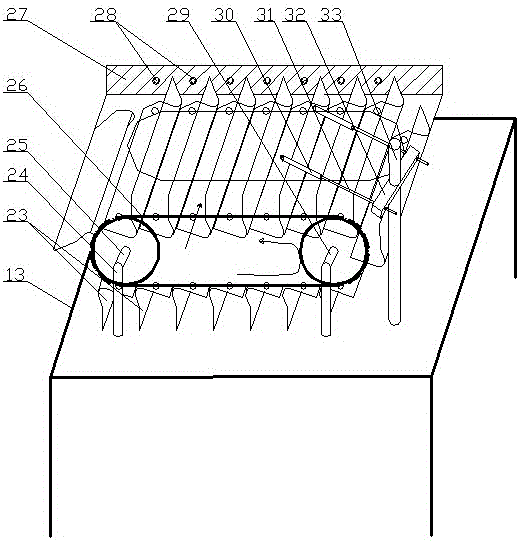

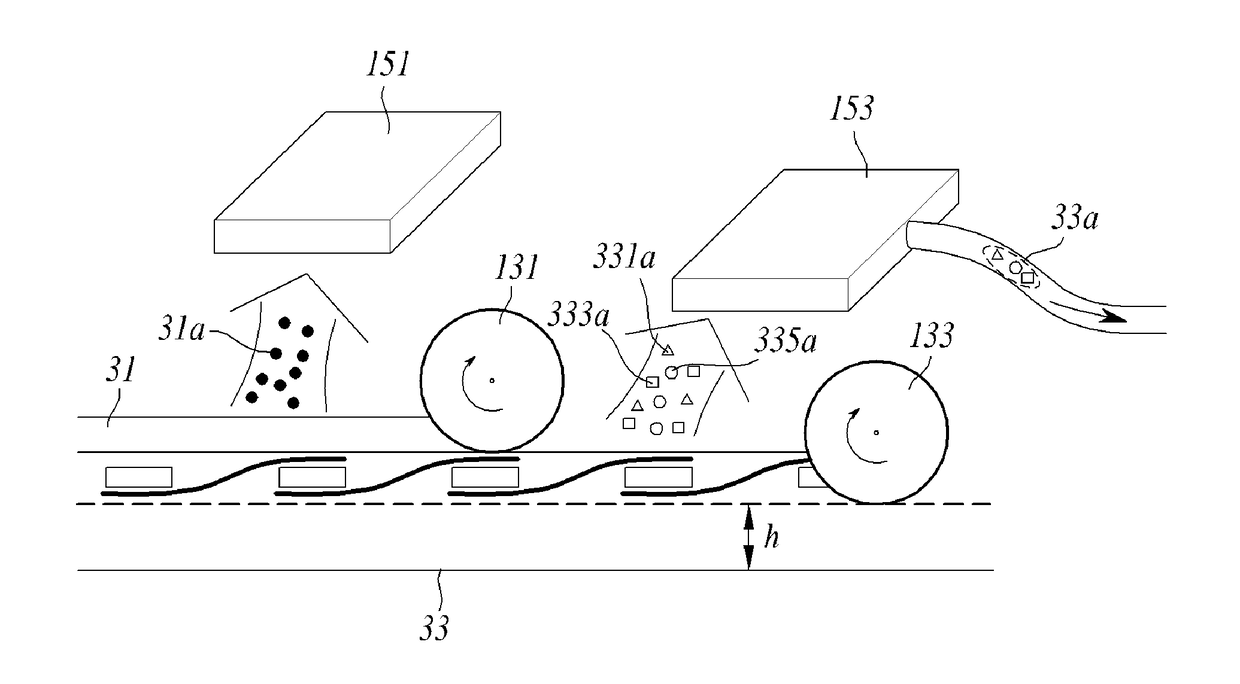

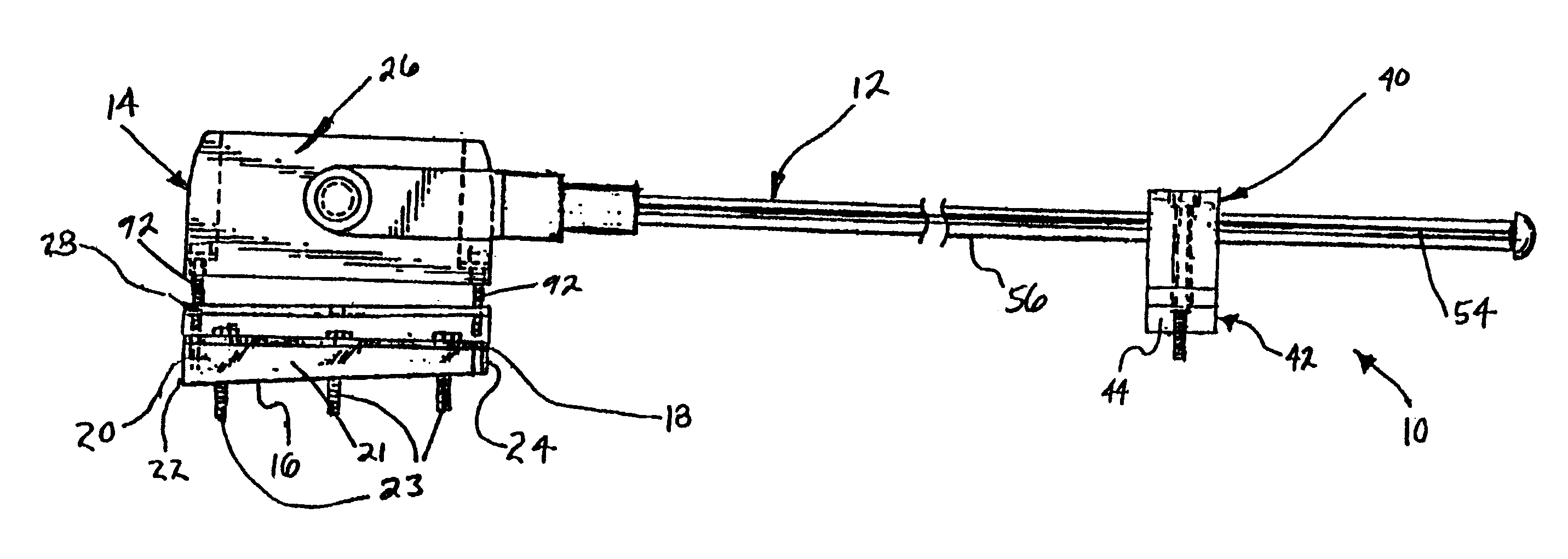

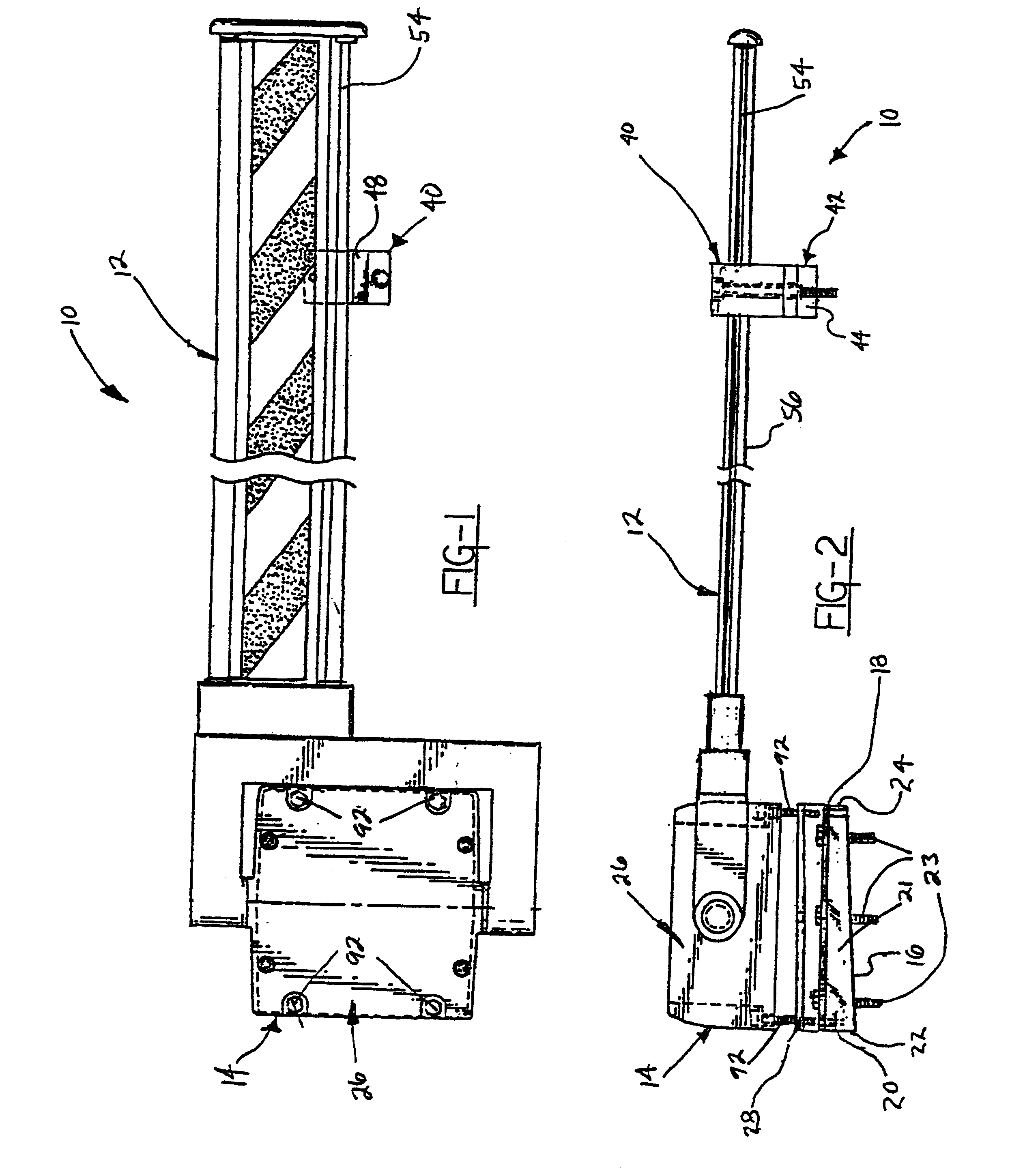

Belted seed transfer mechanism

ActiveUS9814176B2Constant timeAvoid bouncingSeed depositing seeder partsBroadcast seedersTransfer mechanismResidence time

The present invention is directed to a seed discharge system is that employs a pair of rotating belts spaced from one another to receive the seeds from a seed metering device and to direct the seeds into the desired location within a trench over which the discharge system is positioned. The seeds are received within a gap formed between the belts and are clamped and held between the belts as the belts move, consequently moving the seeds from the seed metering device to the discharge opening of the discharge system. The constant engagement of the seeds with the belts through the discharge system prevents the seeds from bouncing, thereby maintaining a constant residence time for the seeds within the discharge system.

Owner:CNH IND CANADA

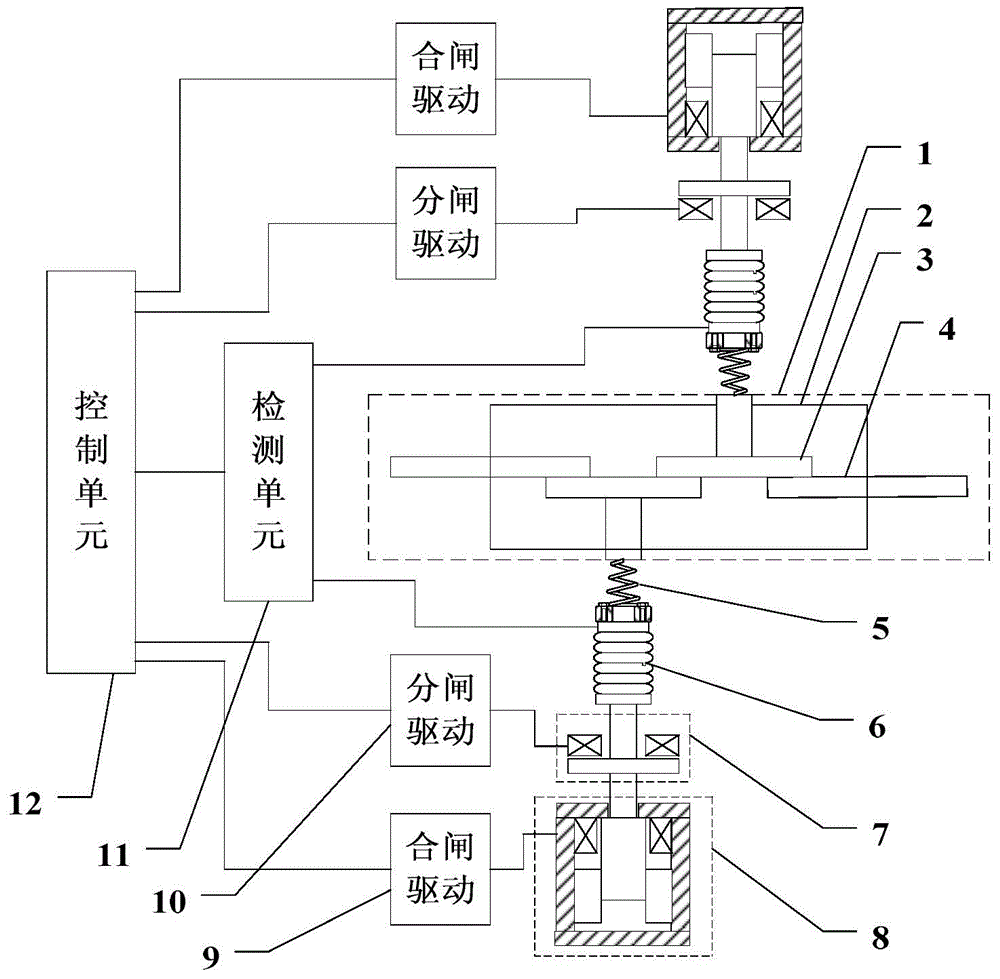

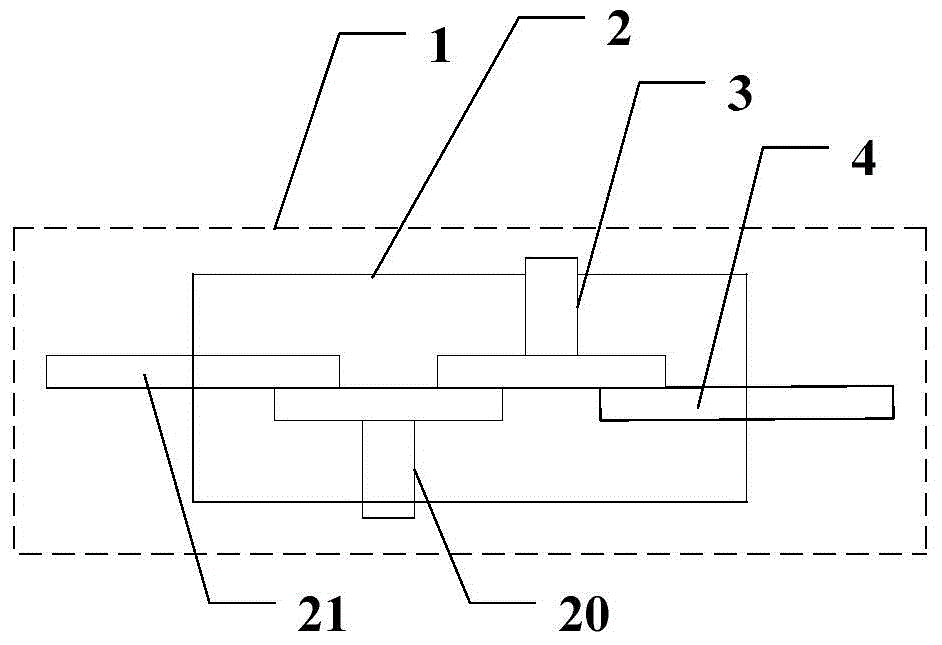

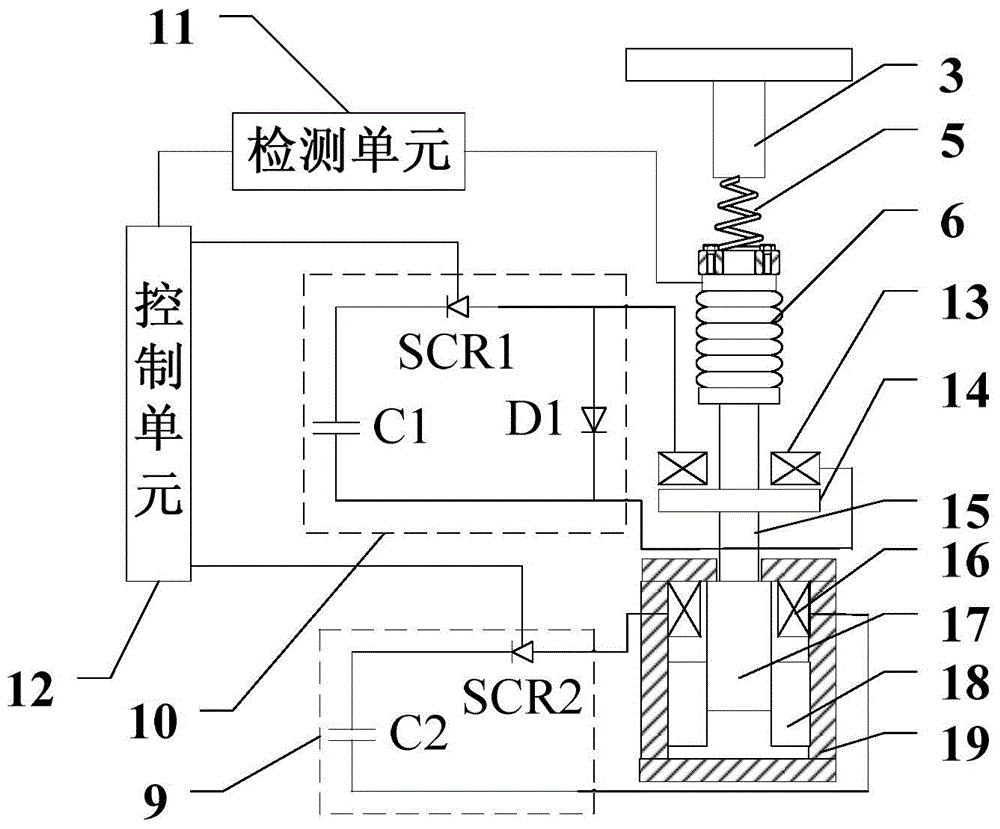

Three-fracture double-acting type high-speed permanent magnet repulsion switch and method thereof

ActiveCN103560023AAvoid bouncingReduce shockContact driving mechanismsSwitch power arrangementsEngineeringDirect current

The invention discloses a three-fracture double-acting type high-speed permanent magnet repulsion switch and a method of the three-fracture double-acting type high-speed permanent magnet repulsion switch and belongs to the field of direct-current switches. The three-fracture double-acting type high-speed permanent magnet repulsion switch comprises a switch body, high-speed electromagnetic repulsion mechanisms, permanent magnetic operating mechanisms, contact springs, insulation pull rods, opening driving circuits, closing driving circuits, a detecting unit and a control unit. Each moving contact is connected to one end of one insulation pull rod through one contact spring, the other end of each insulation pull rod is connected with a driving rod, and each driving rod penetrates through a metal disc in one high-speed electromagnetic repulsion mechanism and is connected with a moving iron core; the control unit is respectively connected with a detecting circuit, the opening driving circuits and the closing driving circuits; each opening driving circuit is connected with an opening coil and each closing driving circuit is connected with a closing coil. According to the three-fracture double-acting type high-speed permanent magnet repulsion switch, a fracture with a large opening distance is formed at a short time and the opening speed of the switch is increased; meanwhile, according to the switch, the two moving contacts and two fixed contacts are in contact in sequence, so that when opening operation is conducted, the problems of movement dispersibility generated when multiple switches are independently driven and the like are solved.

Owner:SHENYANG POLYTECHNIC UNIV

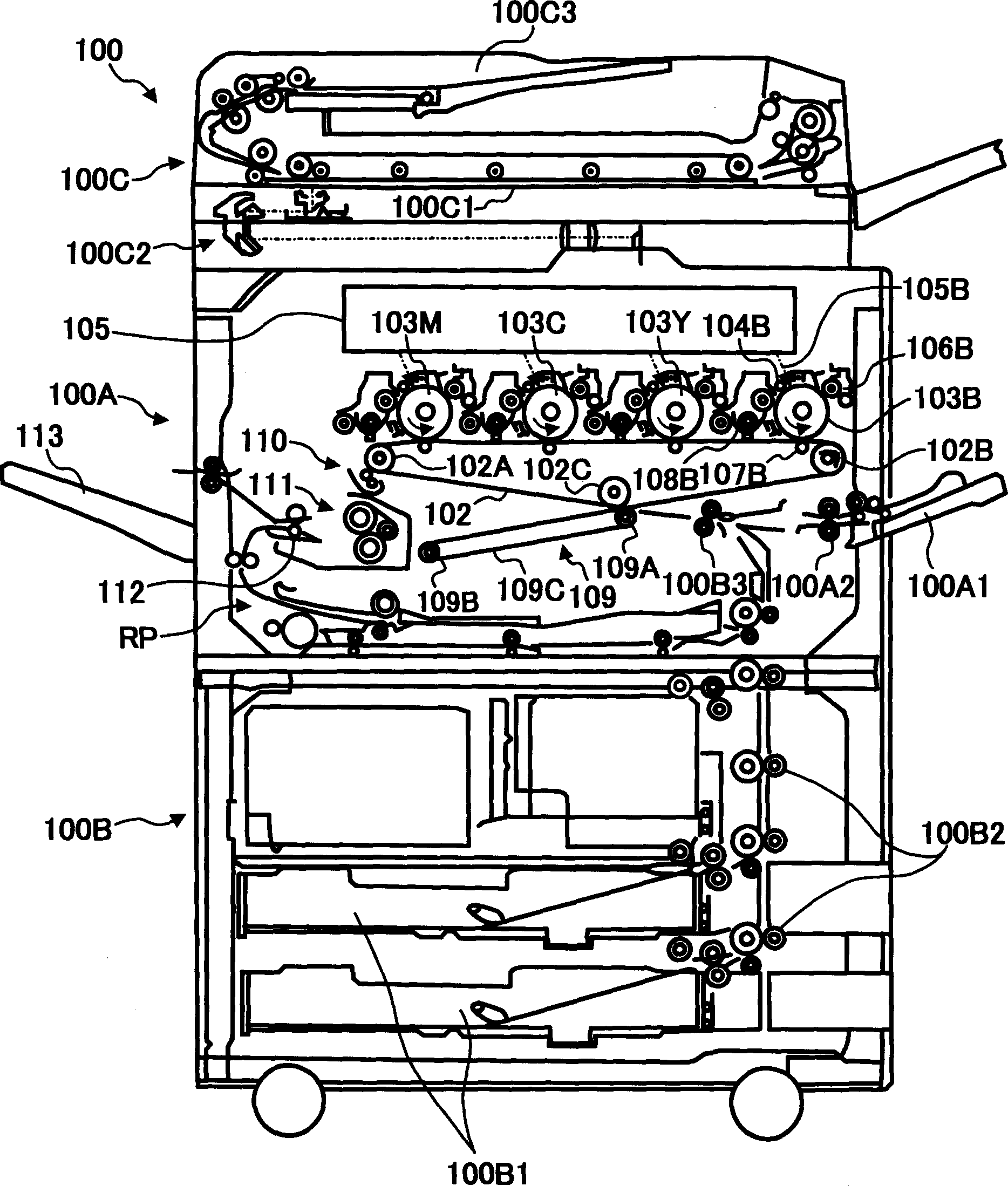

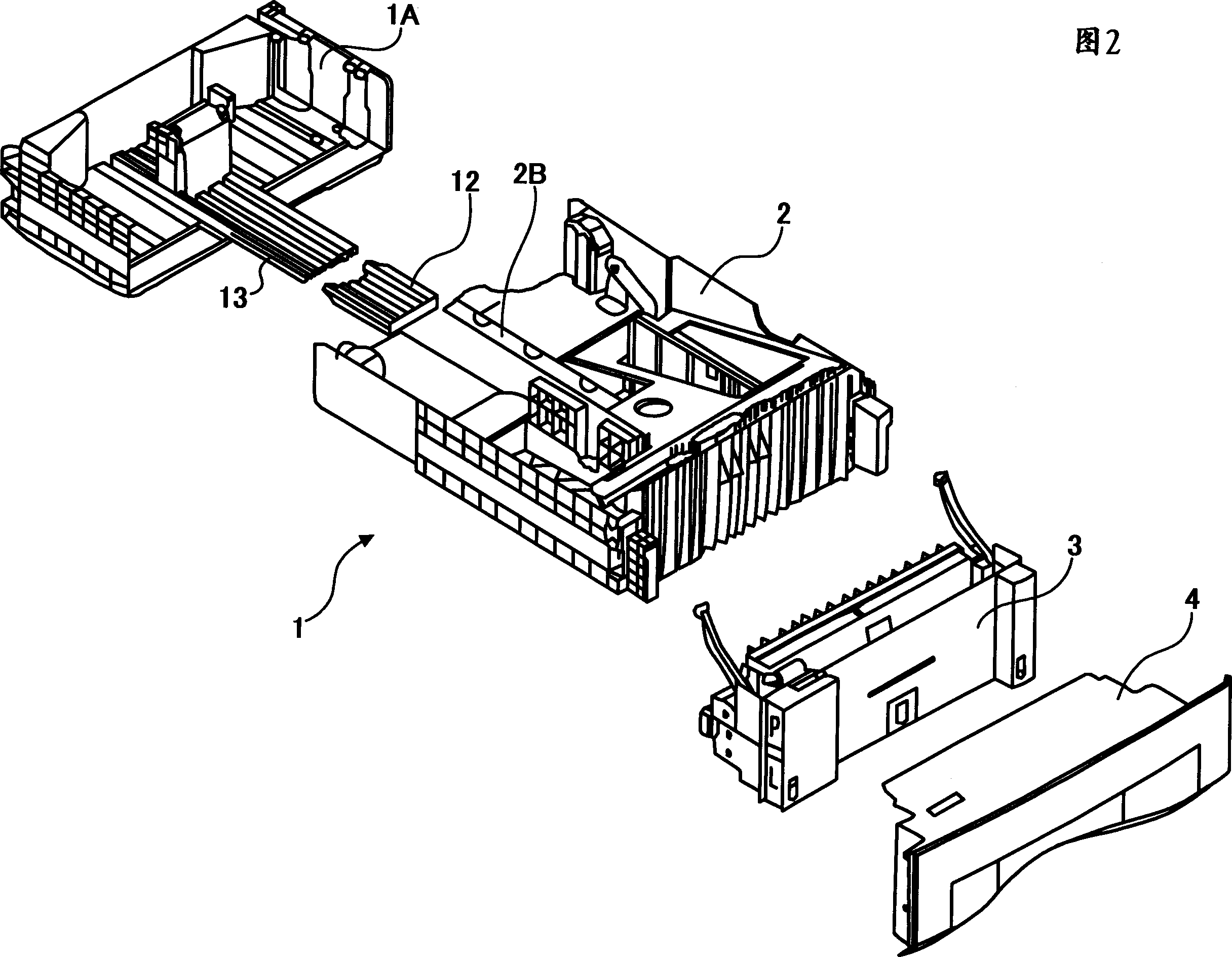

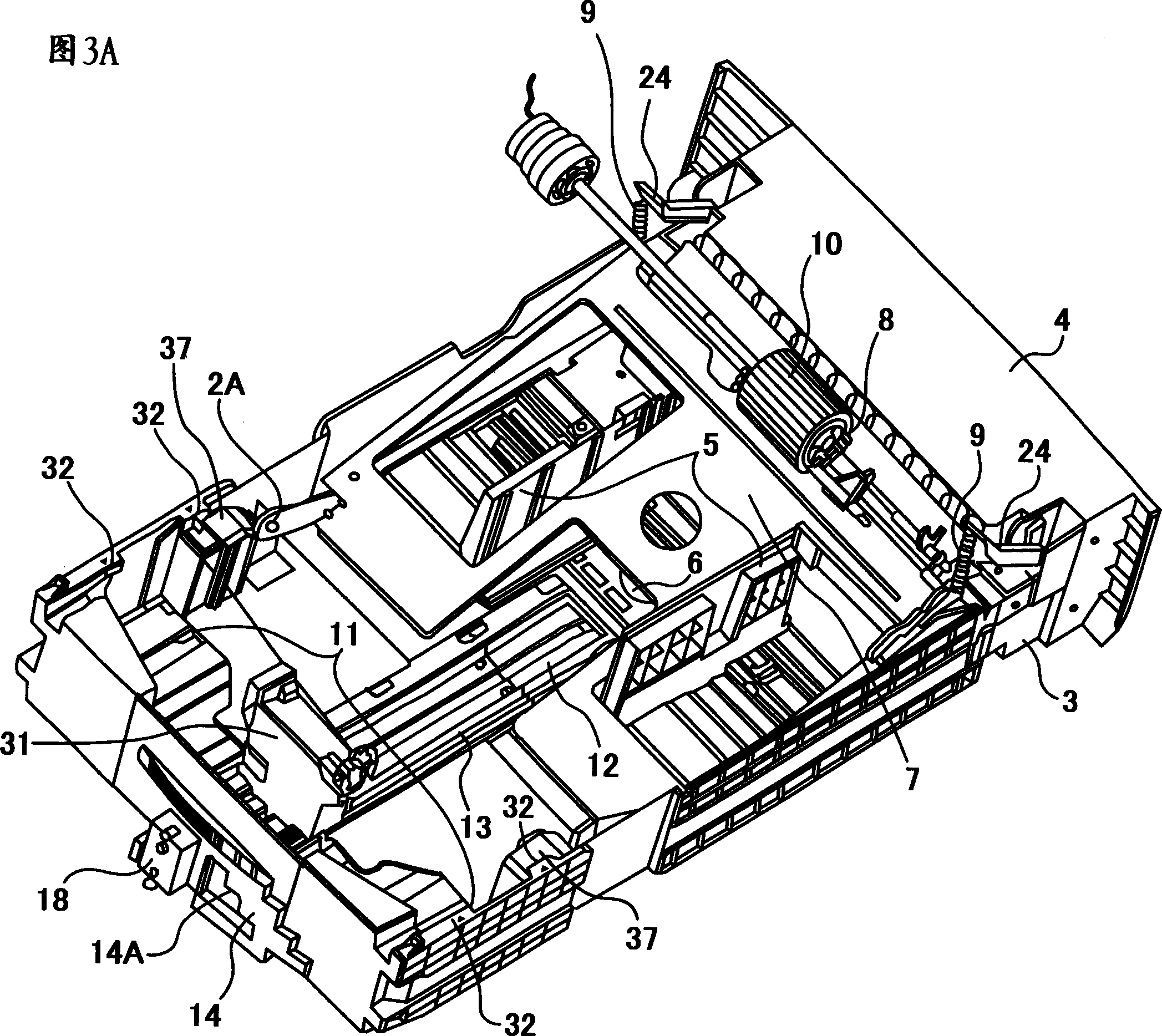

Paper feeding device and image forming apparatus

InactiveCN1534394AIncrease management costsExhaustion status correctly judgedFunction indicatorsShoe lace fasteningsImage formationEngineering

Owner:RICOH KK

Furrow opener apparatus with two way depth control

Owner:FRIESEN DICK EDWARD

Binder to process book blocks and method of binding

A perfect binder for processing book blocks, including: a conveying device adapted to convey the book blocks along a closed circulating path, the conveying device including a plurality of clamping devices each adapted to convey a book block; and a plurality of processing stations arranged successively along the closed circulating path. One of the processing stations includes a spine-processing station, and another one of the processing stations includes an end sheet feed station following the spine-processing station. According to another aspect of the invention there is provided a method forthe perfect binding of book blocks, comprising: conveying the book blocks around a closed circulating path with each book block clamped in a clamping device of a conveying device, wherein a pluralityof processing stations are arranged successively along the closed circulating path; milling the spine of each book block at one of the processing stations; and subsequently, inserting at least one endsheet into the clamping device at a downstream end sheet feed station.

Owner:MULLER MARTINI HLDG

Full-automatic chopsticks packaging machine

ActiveCN105775189AEasy to packSimple structurePackaging automatic controlIndividual articlesPaper sheetPackaging machine

The invention relates to a full-automatic chopsticks packaging machine. The full-automatic chopsticks packaging machine is composed of the following units: a chopsticks supply mechanism, a chopsticks paper sleeve packaging device, a chopsticks inner package detection device, a chopsticks conveying mechanism, a chopsticks outer package packaging device and a control center. A chopsticks arranging device comprises a transmission chain, an arranging rack, a frame and a baffle plate, wherein the arranging rack is fixed on the transmission chain and can rotate along with the transmission chain, and the opening direction of the arranging rack is consistent with the transmission direction of the transmission chain; the baffle plate is arranged at the rear end of the arranging rack; infrared sensors are mounted on the baffle plate; a main driving wheel is arranged on one side of the transmission chain while an auxiliary driving wheel is arranged on the other side of the transmission chain; and the infrared sensors, a servo motor and a control center are connected. The full-automatic chopsticks packaging machine is simple in structure and convenient to use. Arranging plates are driven to move through the transmission chain so as to orderly arrange and put chopsticks dynamically, and therefore, the chopsticks can be conveniently packaged continuously; and paper sleeve packaging and outer package packaging process steps of the chopsticks are full-automatically accomplished.

Owner:CHANGSHA SINOTONG PPC

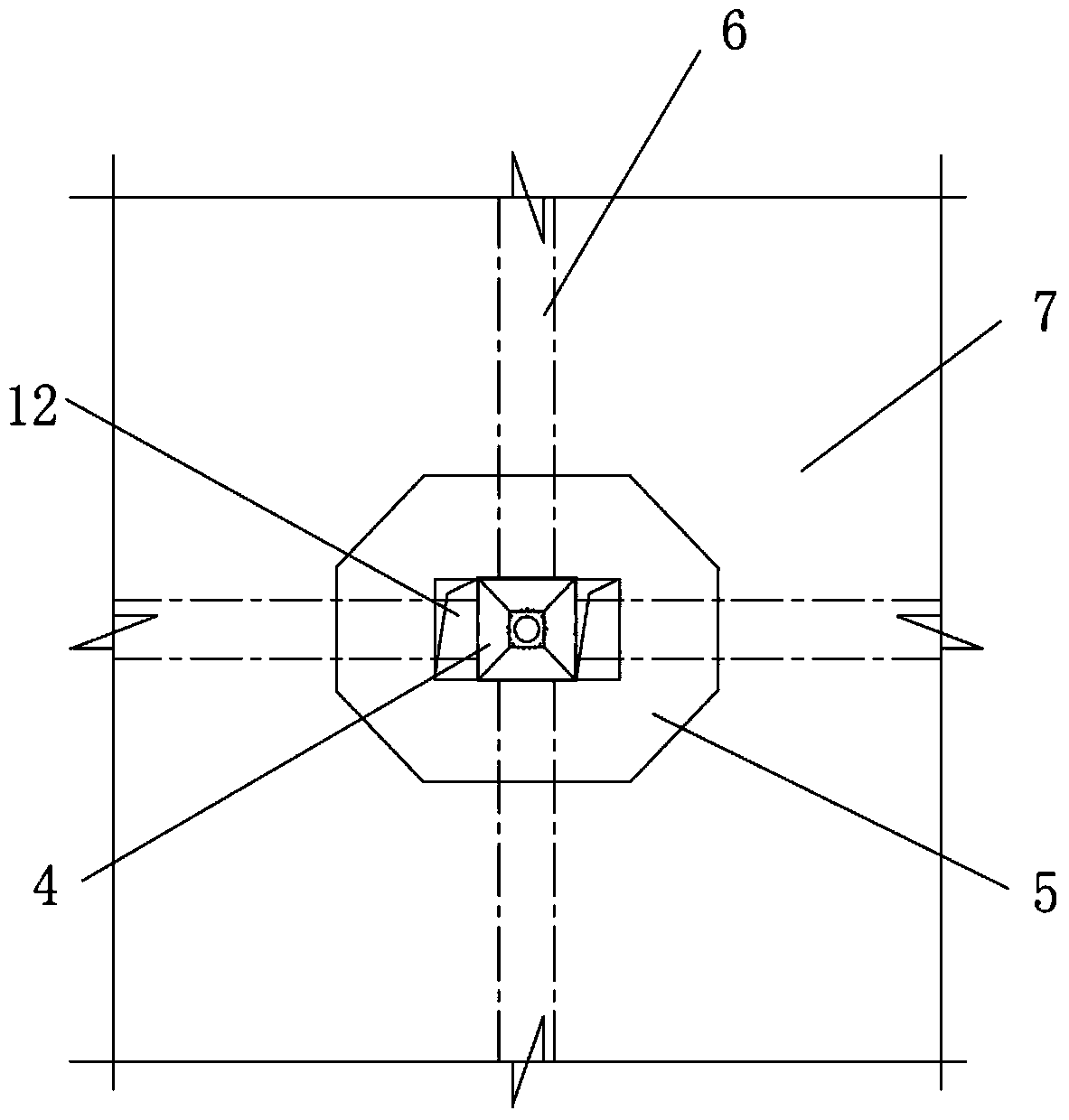

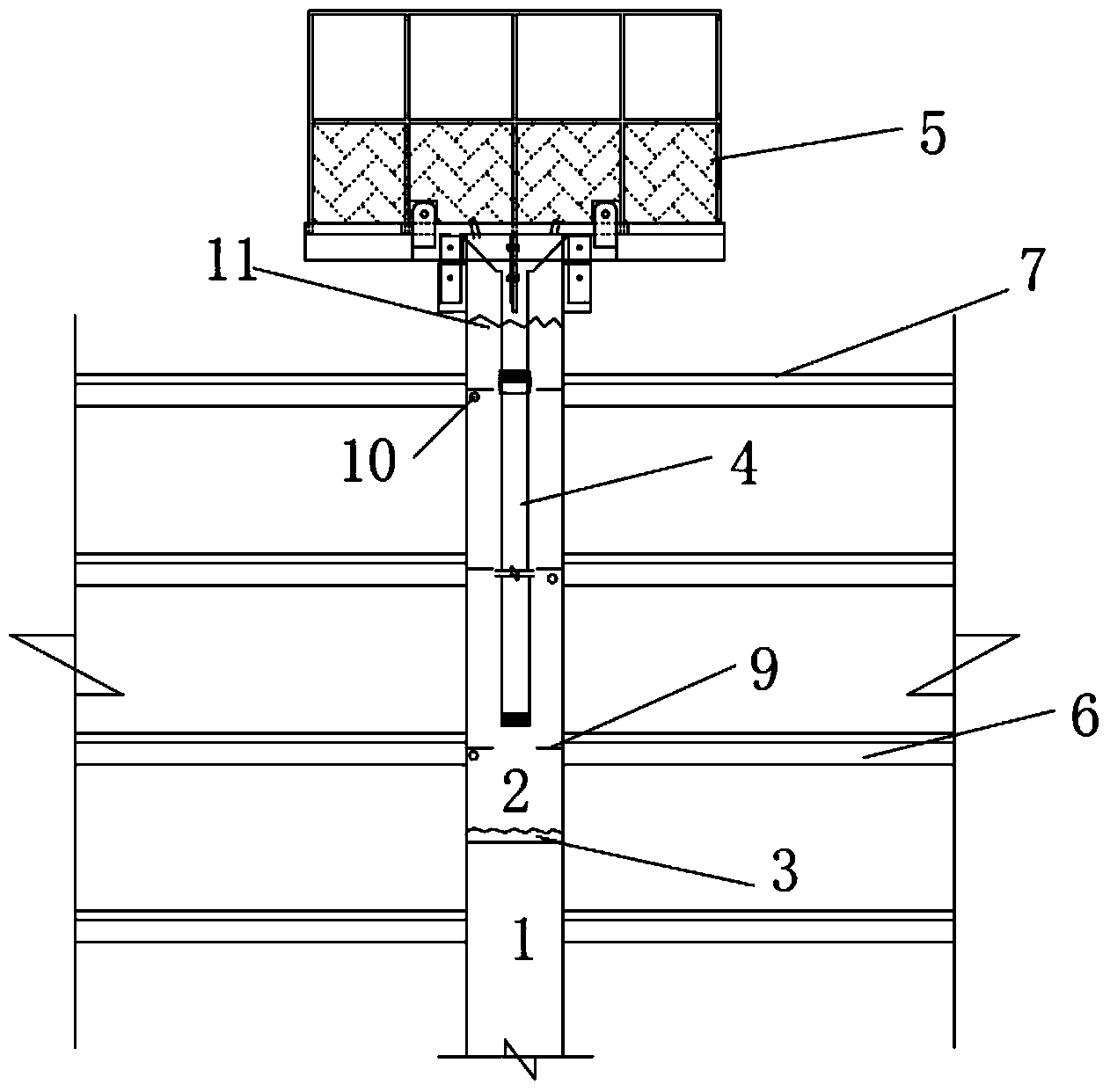

Super high-rise steel pipe column interior concrete pouring construction method

ActiveCN103526929ASimple and safe operationStrong construction applicabilityBuilding material handlingBuilding support scaffoldsSheet steelMaterial consumption

The invention discloses a super high-rise steel pipe column interior concrete pouring construction method. The method mainly comprises the steps of detaching a last section of steel pipe column top sealing hole thin steel plate; hoisting the present section of steel tube column; locating the present section of steel tube column after hoisting a first floor layer steel beam of the present section of steel tube column; arranging a detachable construction steel platform; enabling a sectional connectable serial barrel to extend into the steel pipe column through a locating hole of the construction steel platform; filling same-grade concrete protoplasmic into the steel pipe column; pouring concrete; when the concrete pouring height surpasses the single section serial barrel, detaching one section and continuing concrete pouring construction, and then conducting subsequent pouring; slowing down the speed of concrete discharging and the speed of pouring when a concrete puring face is close to a partition plate in the steel pipe column; pouring the concrete to a certain distance below the top of the steel pipe column and then stopping; adopting a thin steel plate to close the steel pipe column top pouring hole. By the adoption of the construction method, the concrete pouring construction is made to be more convenient, potential safety hazards are eliminated, the construction period is shortened, and manpower and turnover material consumption are reduced.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

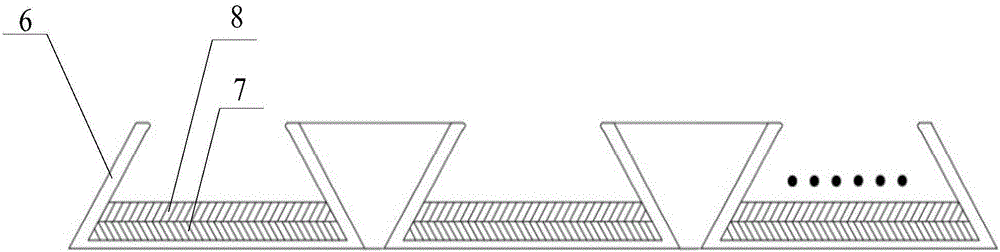

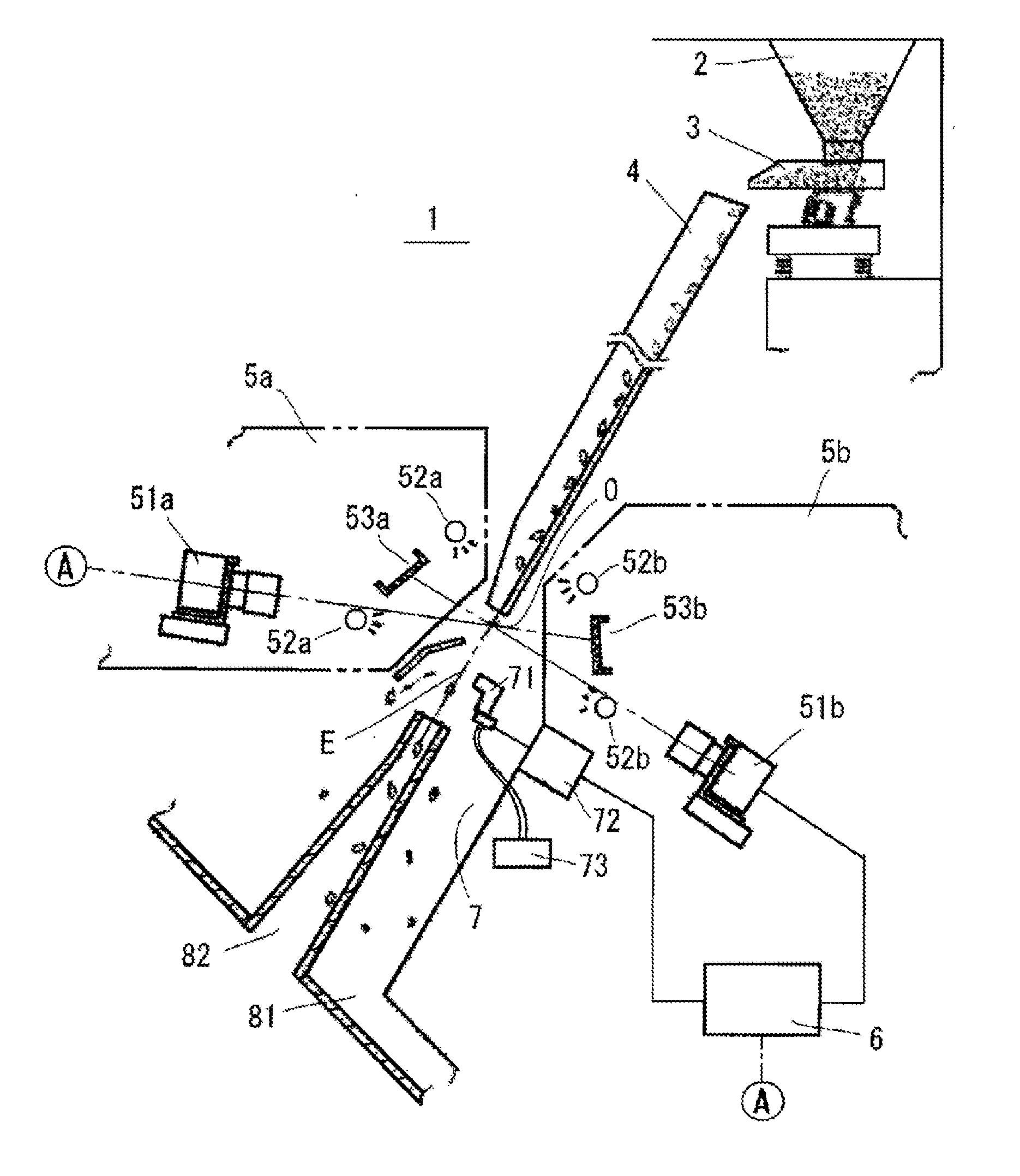

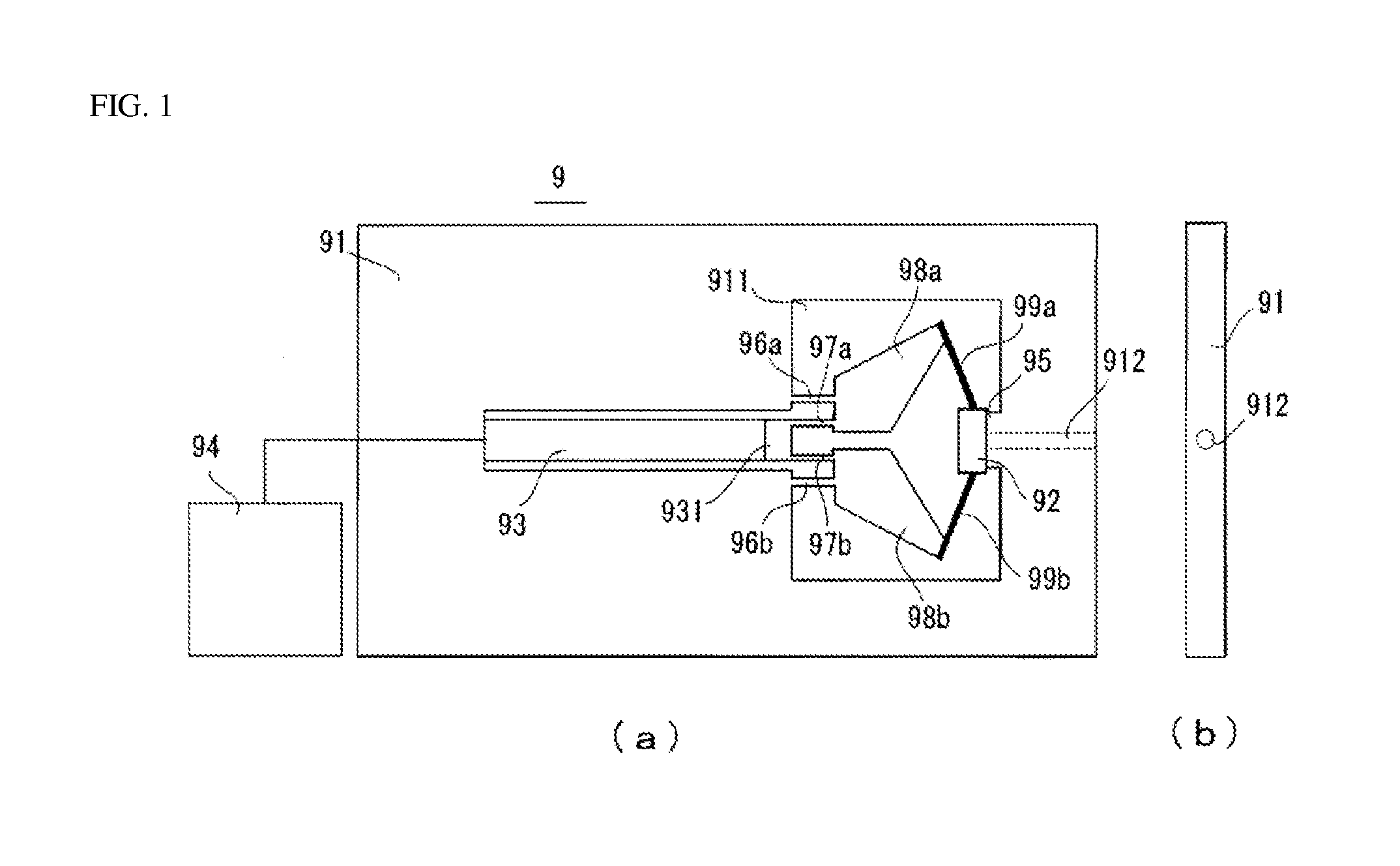

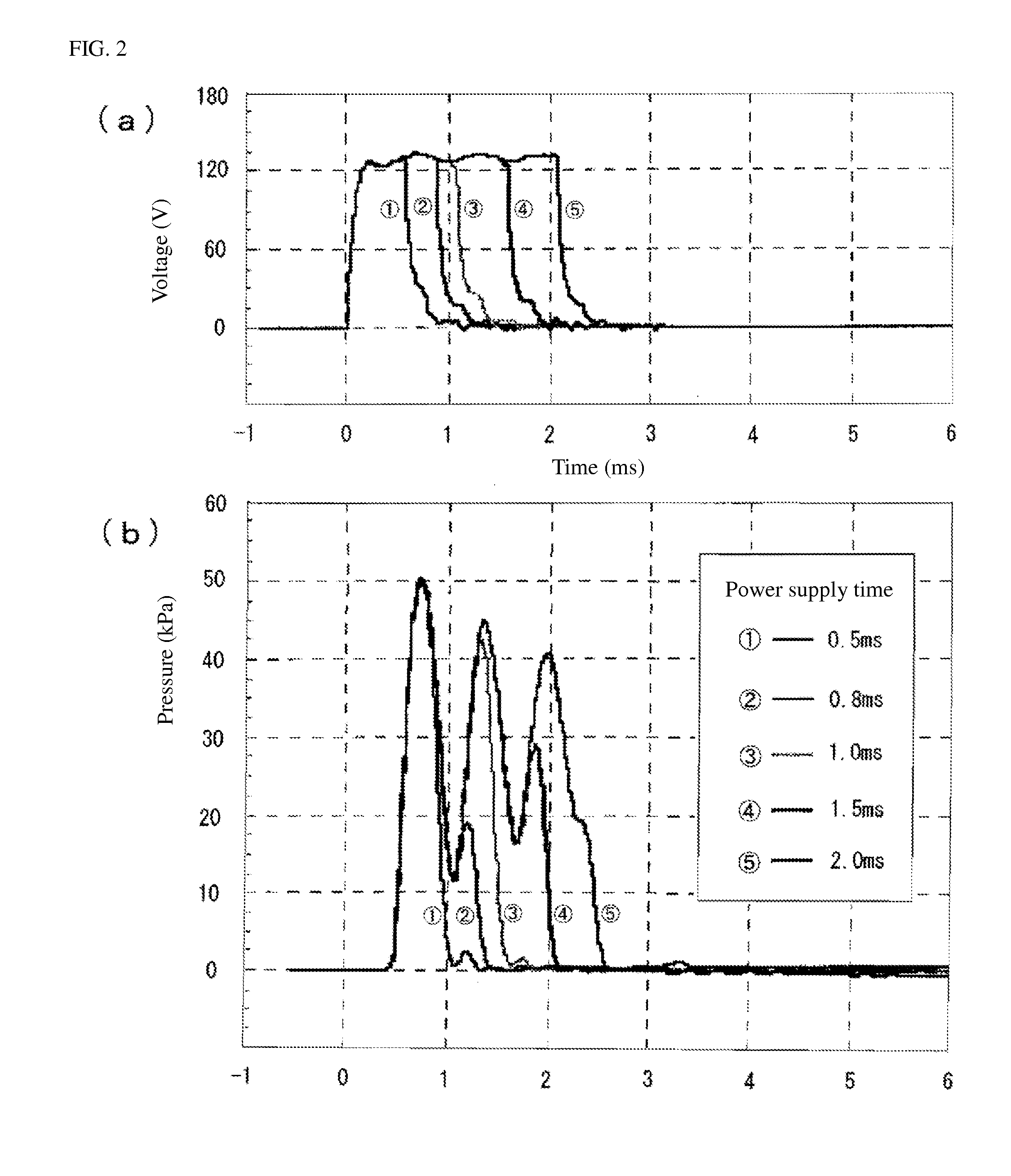

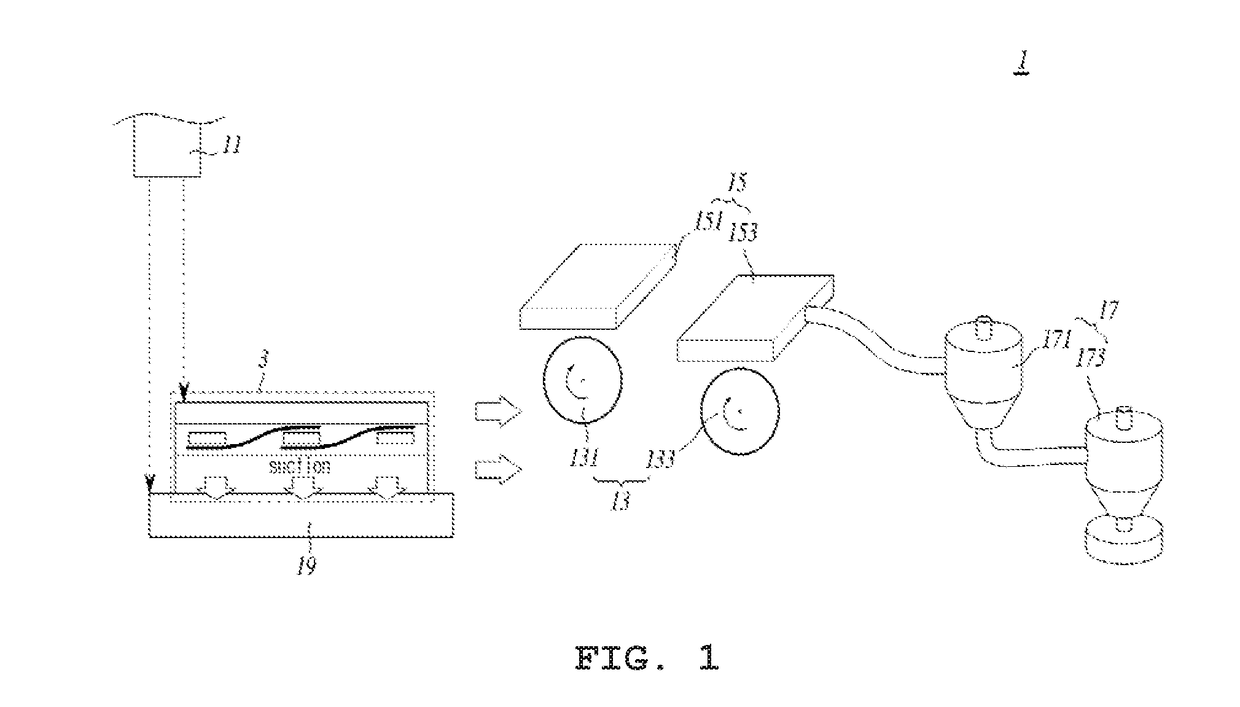

Piezoelectric valve and optical granular material-sorting apparatus utilizing such piezoelectric valve

ActiveUS20110284431A1Suppress fluctuationsReduce vibrationOperating means/releasing devices for valvesGas current separationEngineeringGas release

A piezoelectric valve comprising: a valve main body formed in which are a gas pressure chamber that takes in compressed gas supplied from the outside as well as a gas release channel through which the compressed gas is released from the gas pressure chamber; a valve body placed in the gas pressure chamber to open and close the gas release channel; a piezoelectric element that generates, in the form of displacement, a driving force needed to operate the valve body; at least one displacement amplification mechanism that amplifies a displacement of the piezoelectric element and causes it to act upon the valve body; and a driving means for applying voltage to the piezoelectric element in order to drive the valve body to open the valve and thereby open the gas release channel; wherein such piezoelectric valve is characterized in that the driving means applies voltage to the piezoelectric element in multiple stages so as to suppress fluctuation in the amount of gas ejected from the gas release channel when the valve opens.

Owner:SATAKE CORP +1

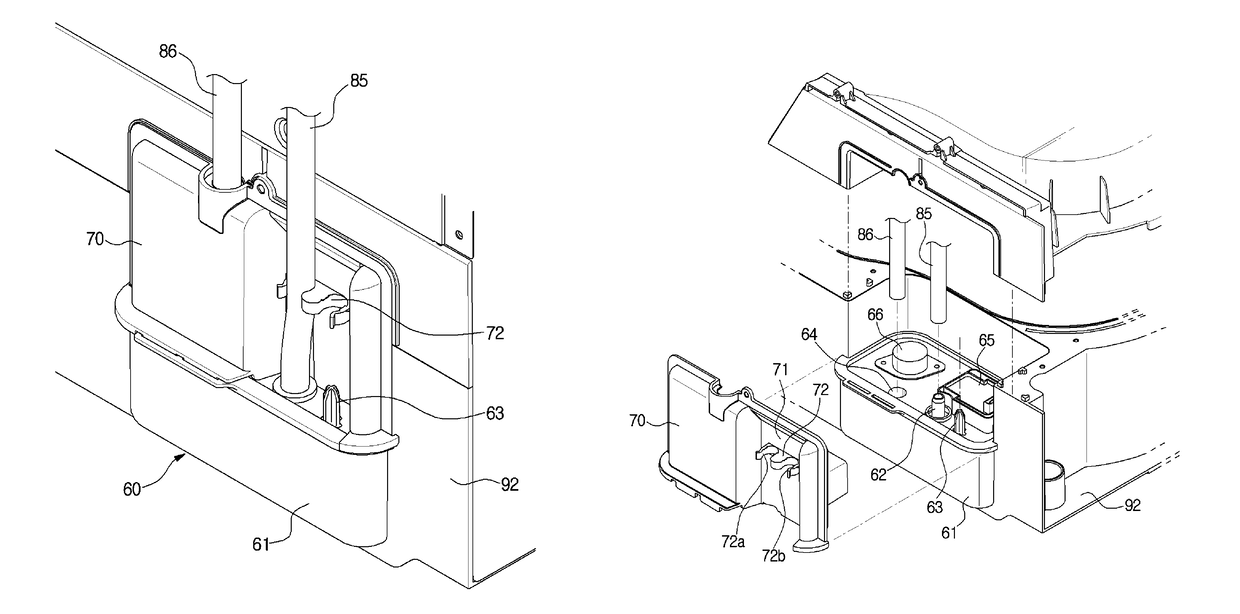

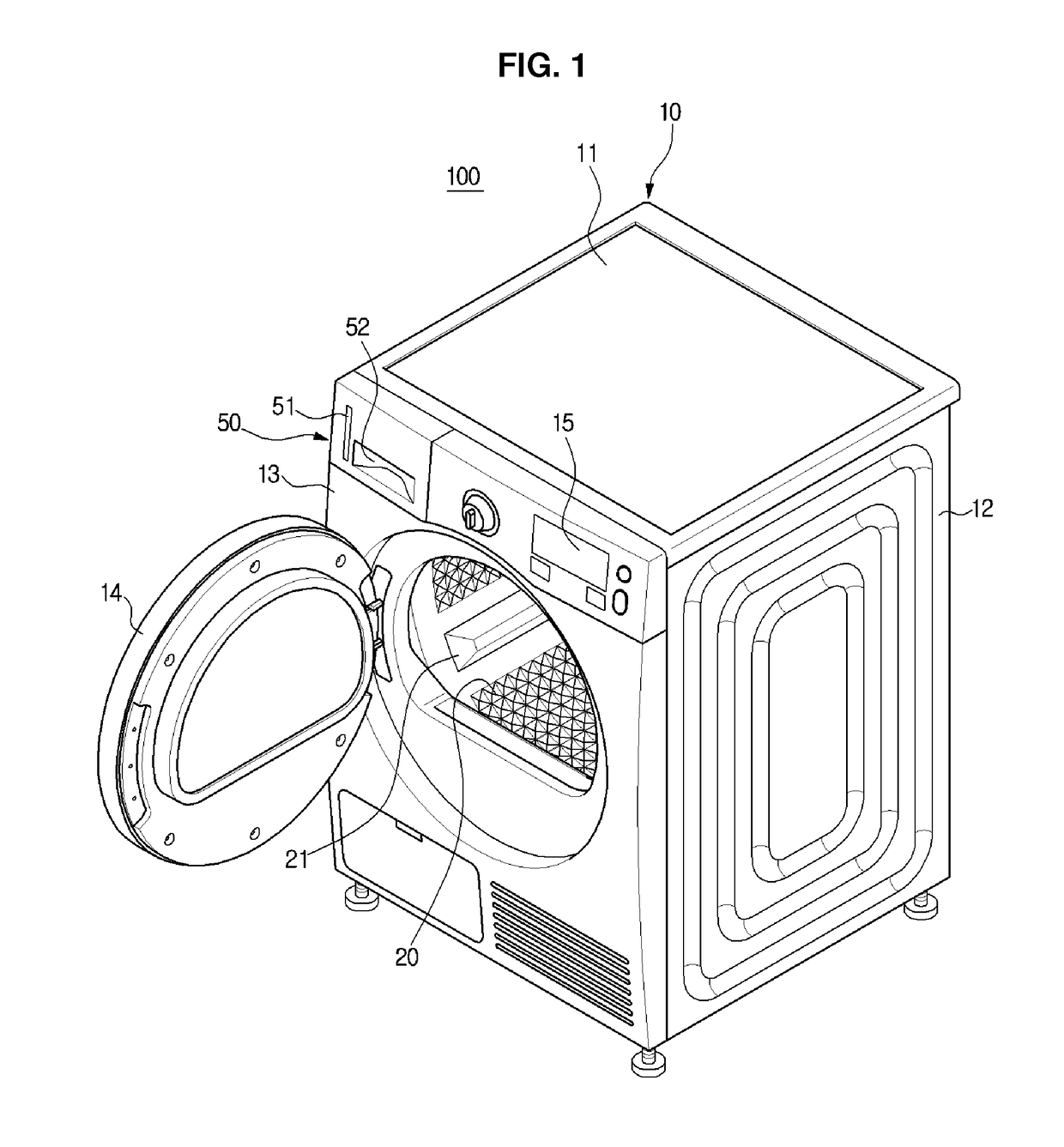

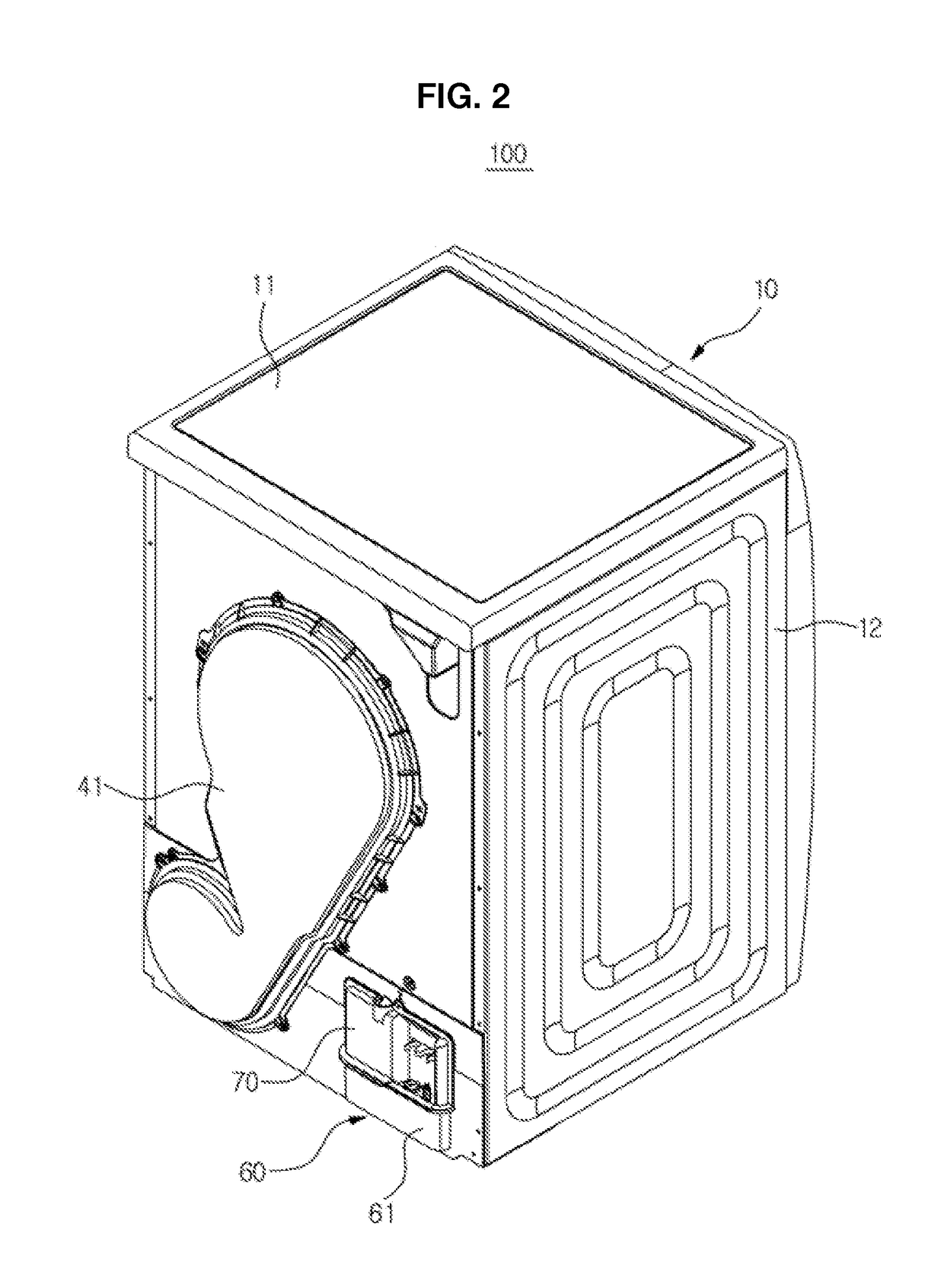

Clothing dryer

ActiveUS9702080B2Simple structureReduce in quantityDrying machines with non-progressive movementsTextiles and paperEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

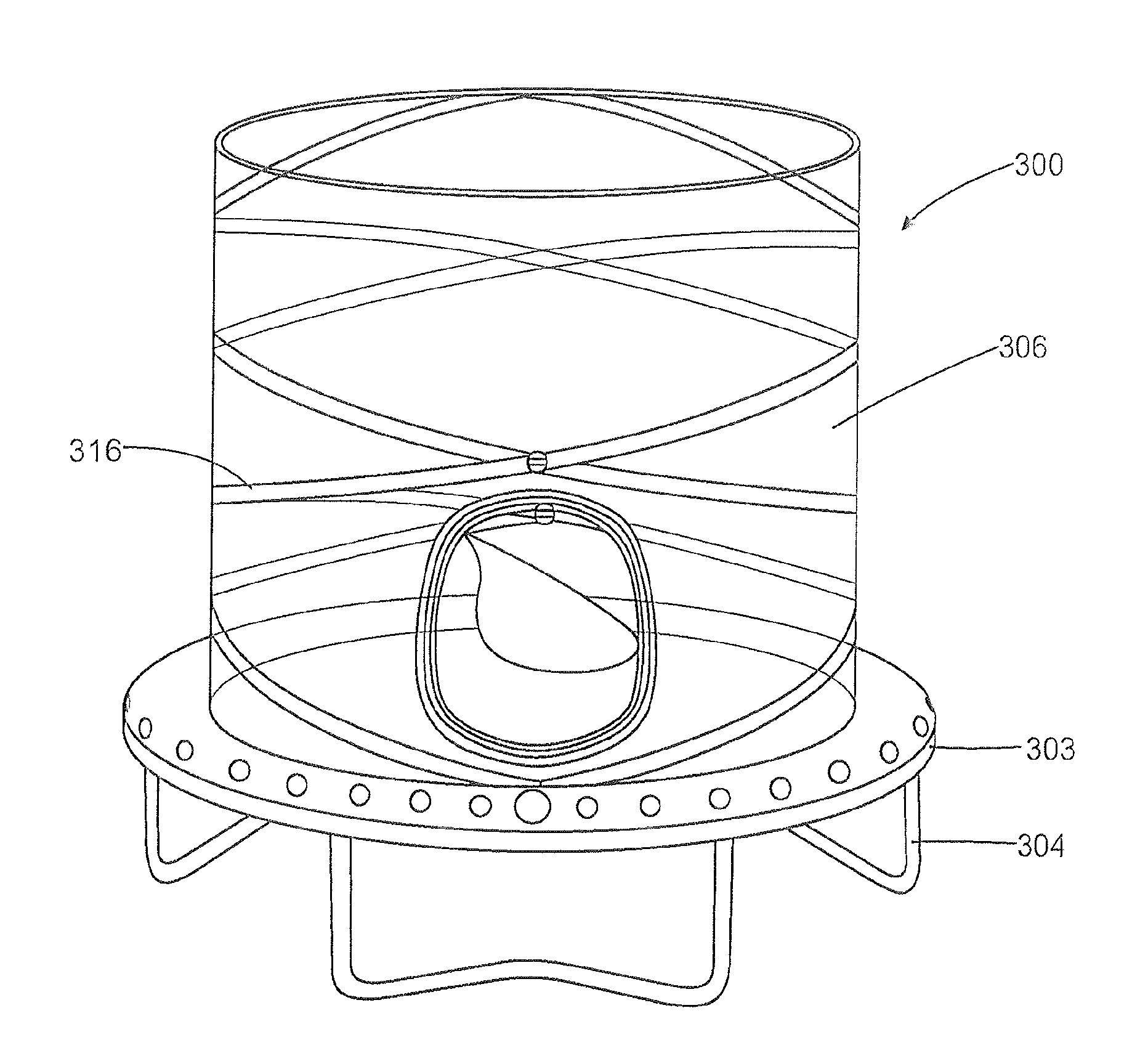

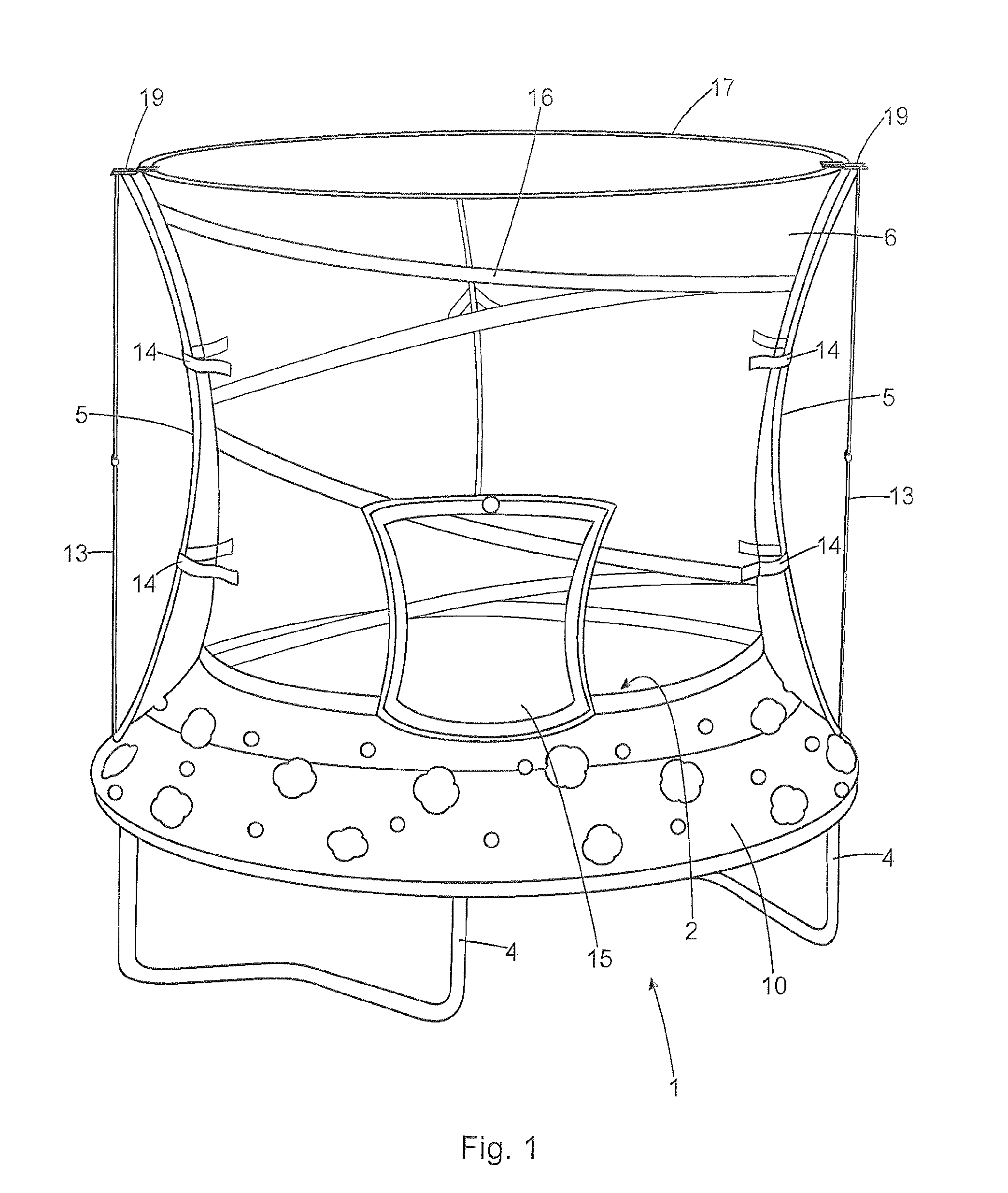

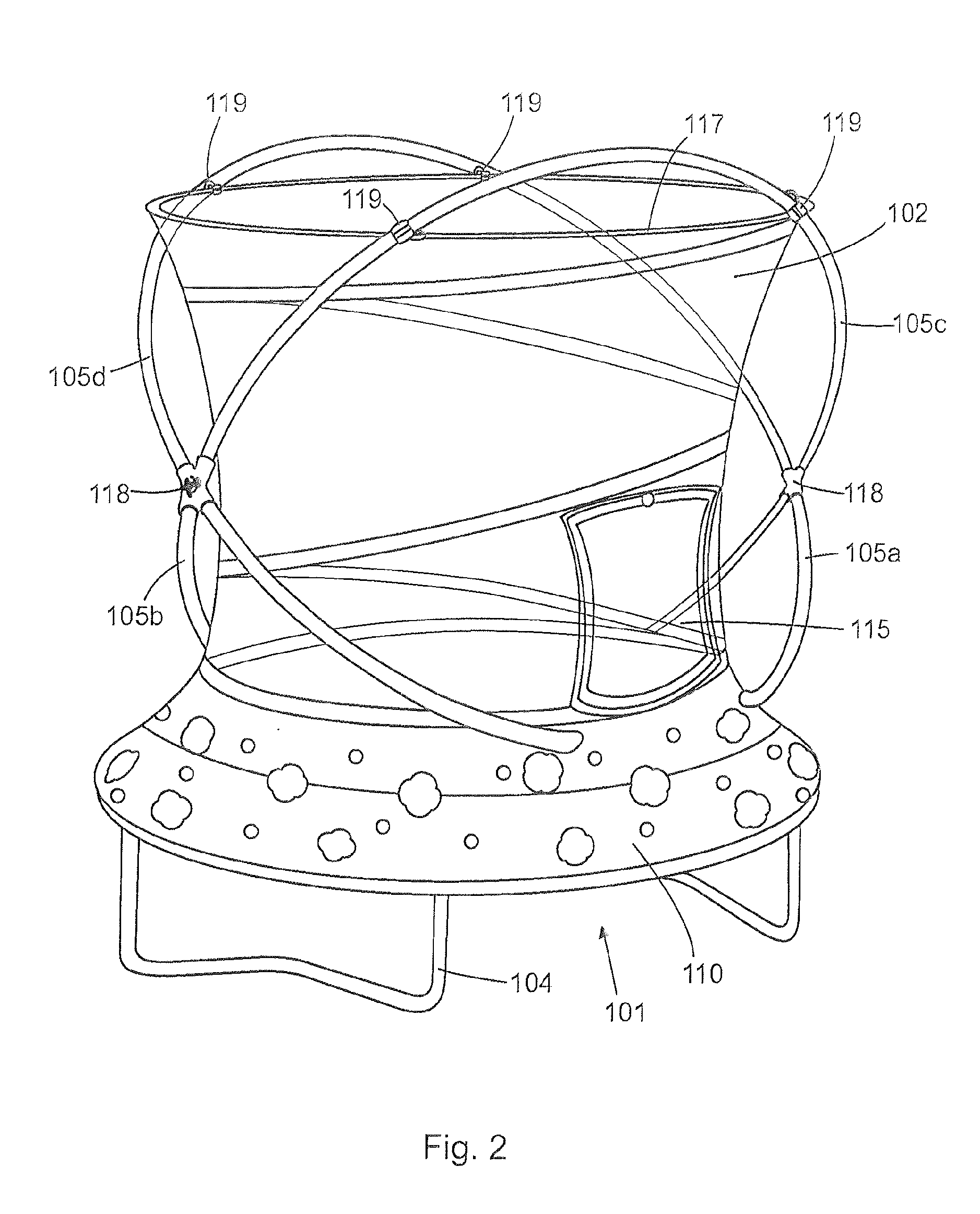

trampolines

InactiveUS20110256985A1Conserve costLimited accessSpring boardsTrampolinesFilling materialsEngineering

Owner:ROBOVISION

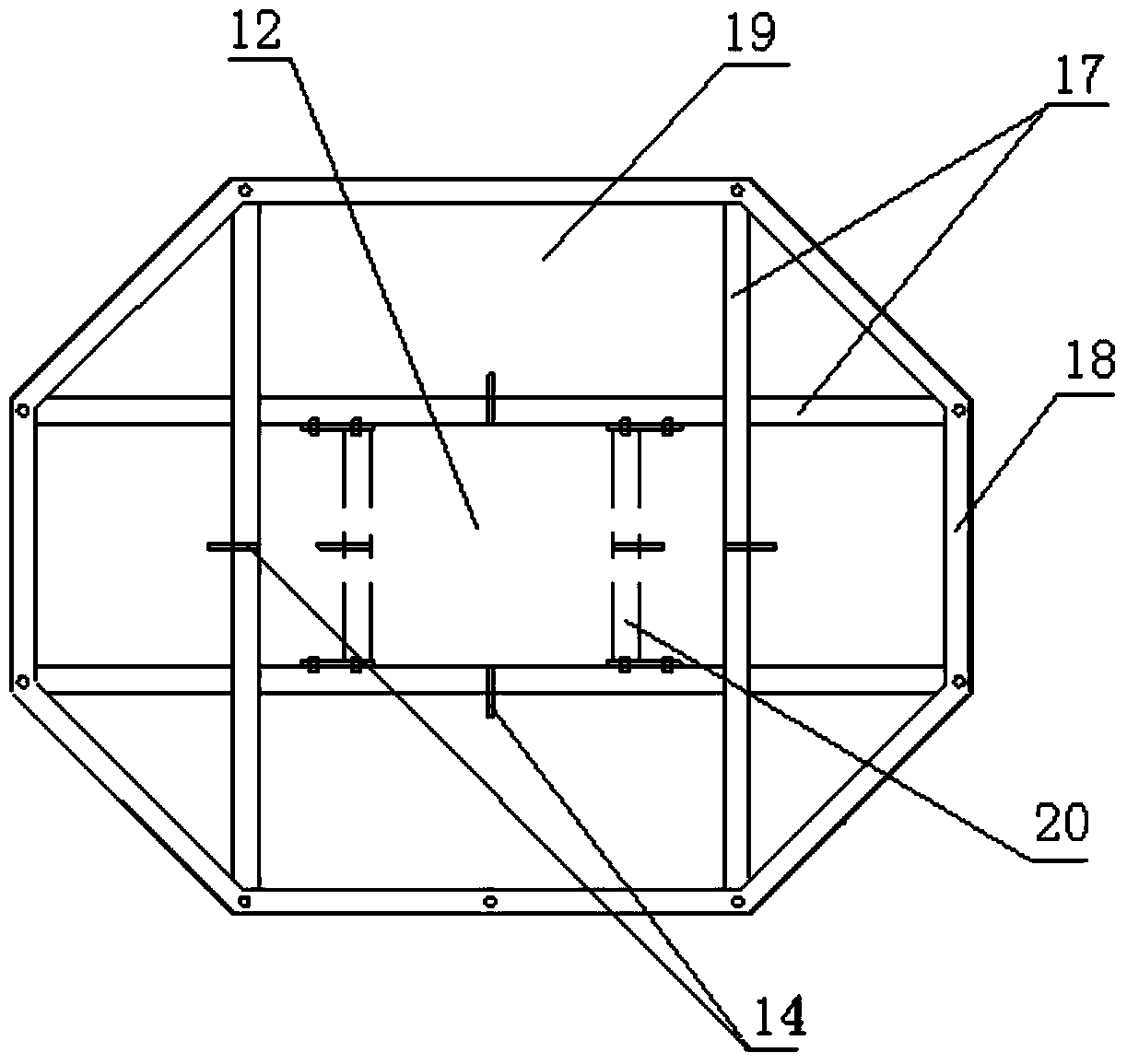

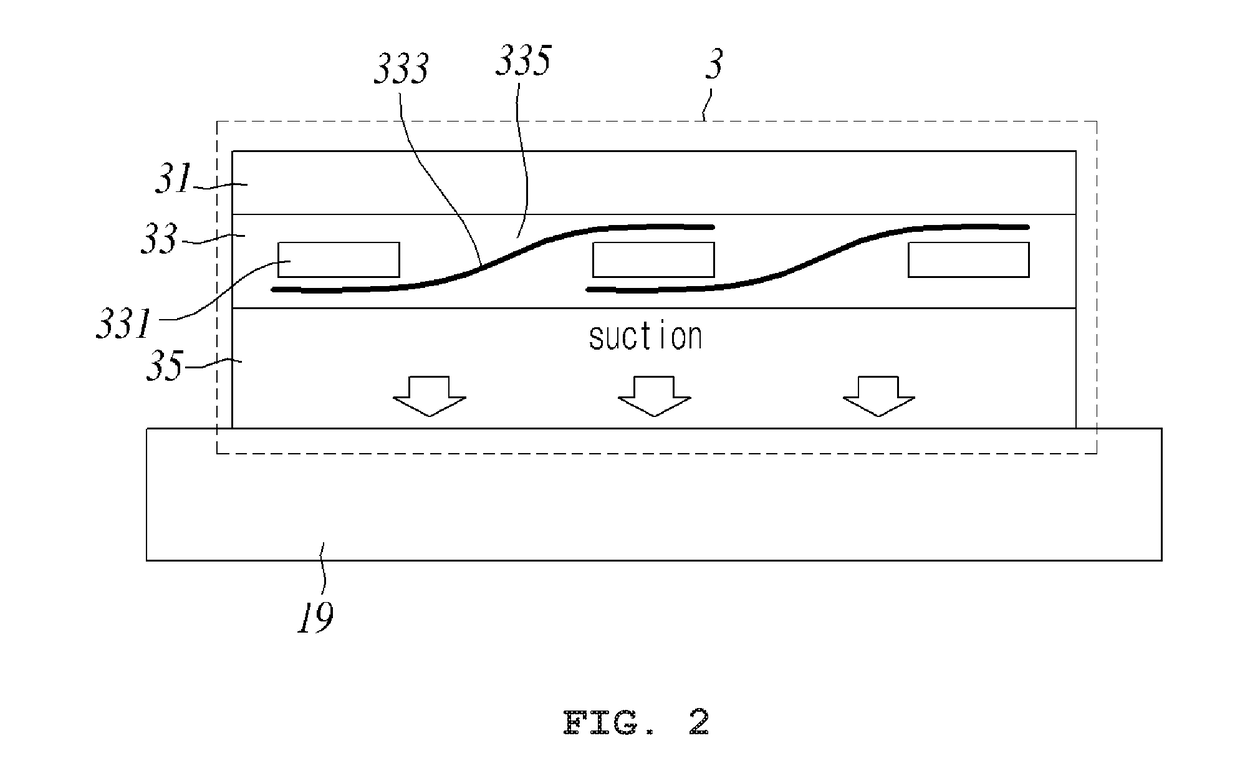

Partial dismantling device of photovoltaic module

ActiveUS20180133720A1Valid choicePrecise definitionReversed direction vortexWaste processingComputer moduleEngineering

Disclosed is a partial dismantling device of a photovoltaic module capable of classifying and collecting the photovoltaic module for recycling the photovoltaic module which includes: a transfer unit for transferring a photovoltaic module; a sensor unit for distinguishing grinding heights of the photovoltaic module arranged on the transfer unit; a grind unit provided with a plurality of grinders in multiple levels, to grind the element layers of a grinding region into particles of collectible forms; and a suction unit provided with a plurality of inhalers respectively corresponding to the plurality of grinders, to classify the particles pulverized by the grind unit and to inhale the same. Thereby, the present invention may improve the efficiency in the subsequent classifying process of the photovoltaic module particles in a classifying unit, with an advantage of applying the partial dismantling device of the photovoltaic module irrespective of damages on a glass substrate.

Owner:KOREA INST OF ENERGY RES

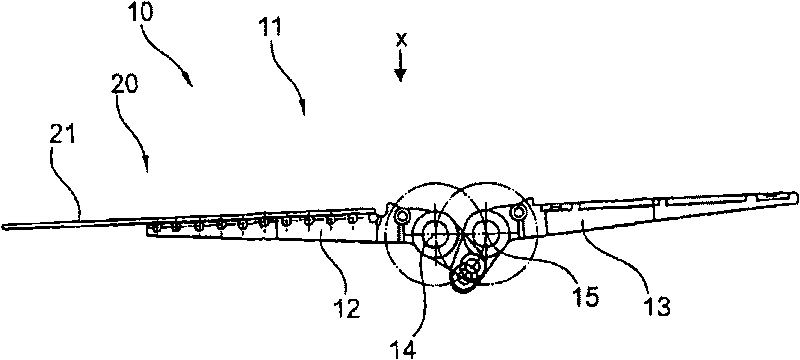

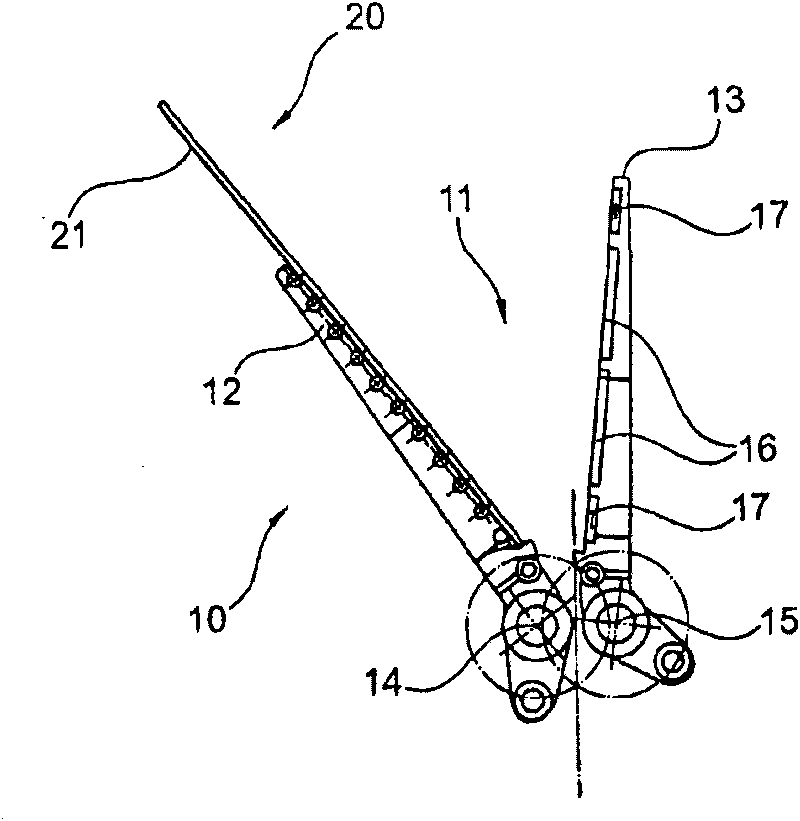

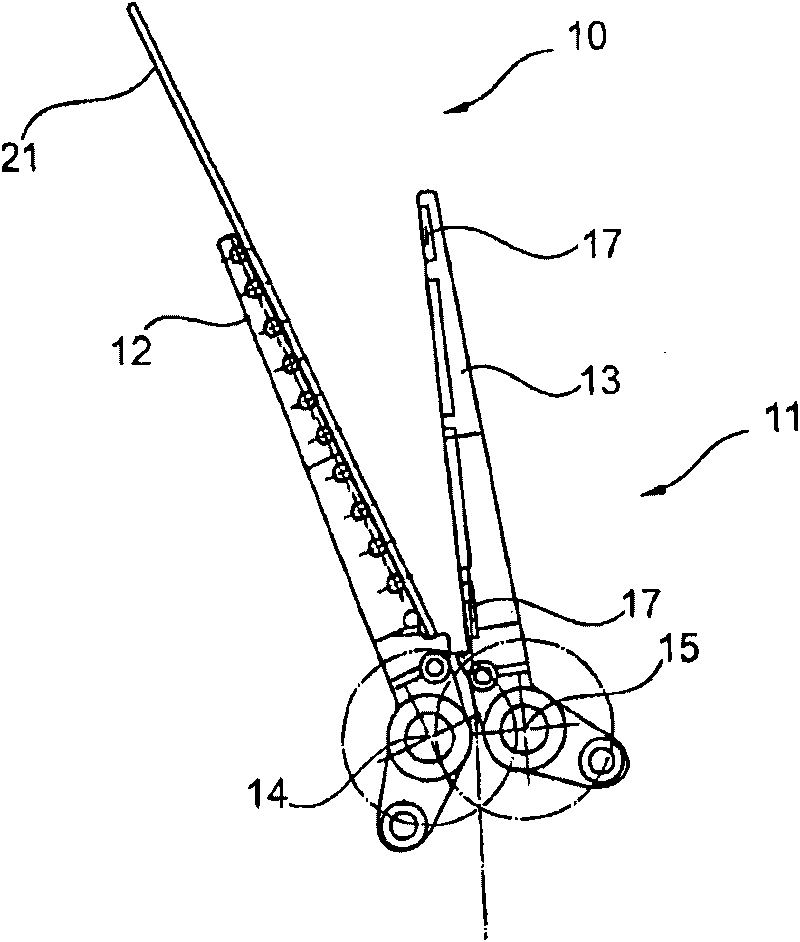

Inspection system for rolled products and method for assessing the surface of rolled products of a rolling installation

ActiveCN101754819AReduce noiseLow running costWork manipulationMeasuring devicesEngineeringMechanical engineering

The invention relates to an inspection system (10) for rolled products (20) of a rolling installation, comprising at least one sheet turner (11) comprising an arrangement of transferring turning arms (12) located on a turner shaft (14) and receiving turning arms (13) located on a turner shaft (15). It is provided according to the invention that the turner shaft (15) of the receiving turning arms (13) is arranged offset with respect to the turner shaft (14) of the transferring turning arms (12). The invention also relates to a method for assessing the surface of rolled products (20) of a rolling installation.

Owner:SMS DEMAG AG

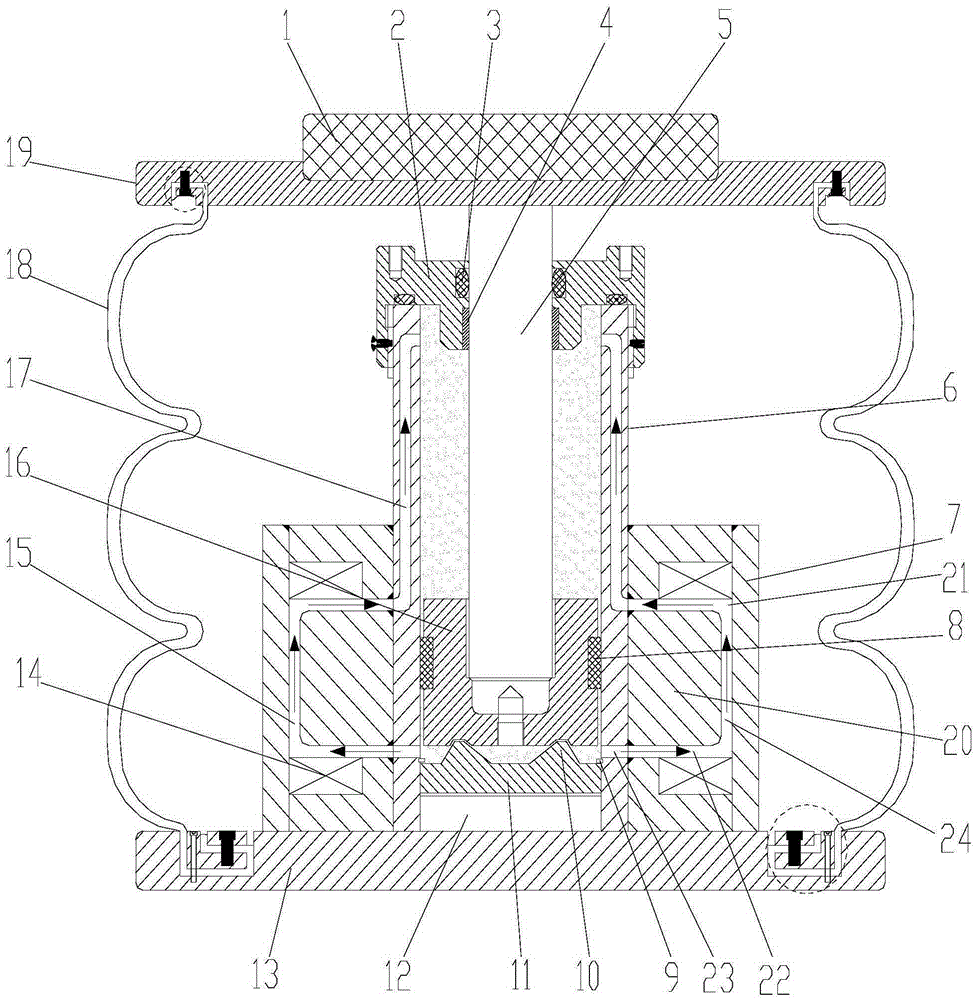

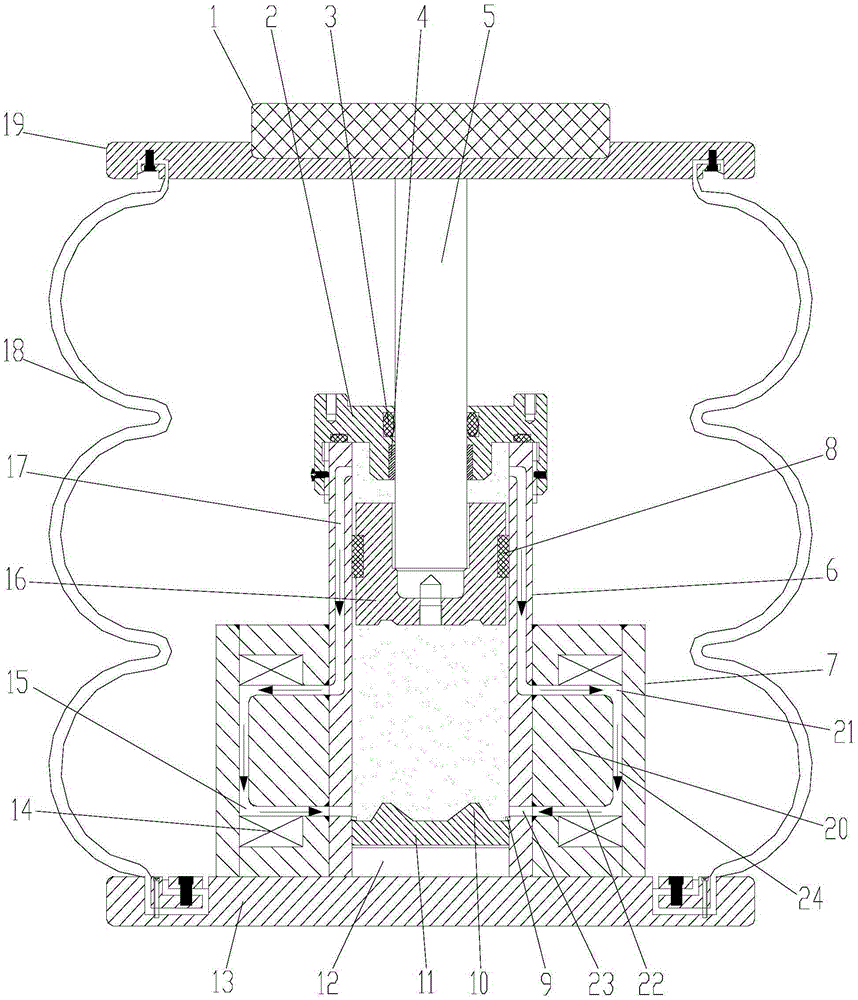

Magnetorheology based elevator drop buffering device

The invention provides a magnetorheology based elevator drop buffering device which comprises an elastic damping part, a magnetorheological damping mechanism and a supporting plate, wherein the elastic damping part and the magnetorheological damping mechanism are fixedly arranged on the lower surface of the supporting plate. The magnetorheology based elevator drop buffering device forms a uniform counter-force and uniform buffering deceleration during elevator drop buffering, it can be ensured that the device is always in an effective state, and accordingly injuries brought to passengers in a car are decreased during elevator drop. In addition, the magnetorheology based elevator drop buffering device can be applied to elevators different in operating speed and is good in adaptability.

Owner:CHONGQING UNIV

Mounting arrangement for crossing arm

InactiveUS6254151B1Avoid crossingAvoid bouncingPedestrian/occupant safety arrangementOptical signallingEngineeringMechanical engineering

A crossing arm assembly that pivotally attaches to a bumper at the front end of a vehicle such as a bus to block pedestrian traffic from crossing immediately in front of the vehicle when the vehicle is stopped. The assembly includes a mounting bracket configured to fixedly mount to the front bumper of a vehicle, the front bumper having a front surface having a profile common to the bumpers of other vehicles of the same make and model. The assembly also includes an elongated beam having an inner end pivotally supported on the mounting bracket. The bracket includes a back surface having a non-planar profile contoured to complement the profile of the front surface of the bumper. The assembly is made by providing a mounting bracket having a back surface profile contoured to complement the non-planar front surface profile of the bumper of the make and model of vehicle the assembly is to be mounted to. The beam is pivotally supported on the mounting bracket either before or after the mounting bracket is fastened to the bumper.

Owner:SPECIALTY MFG CO INC

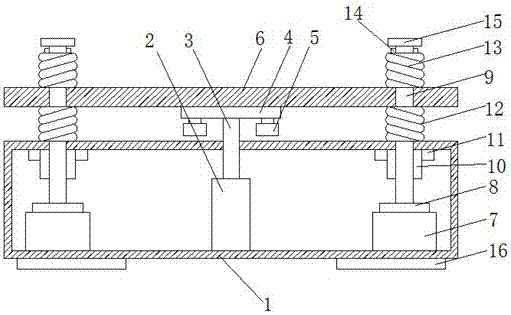

Electromechanical equipment damping device

PendingCN107327665AAvoid bouncingAvoid damageNon-rotating vibration suppressionEngine bedsEngineeringMachine

The invention provides an electromechanical equipment damping device, and relates to the field of equipment damping. The electromechanical equipment damping device comprises a damping base. The bottom of the inner wall of the damping base is fixedly connected with an air pressure barrel. An air pressure rod is movably connected in the air pressure barrel in an inserted manner. The end, away from the air pressure barrel, of the air pressure rod penetrates the damping base and extends to the outer portion of the damping base. A first fixed block is arranged above the damping base. The end, away from the air pressure barrel, of the air pressure rod penetrates the damping base to be fixedly connected with the first fixed block. The top of the first fixed block is fixedly connected with a damping platform. The positions, located on the two sides of the air pressure barrel, of the bottom of the inner wall of the damping base are fixedly connected with rubber damping blocks. According to the electromechanical equipment damping device, first damping springs, second damping springs and the air pressure barrel are arranged, and therefore the function of buffer damping can be effectively achieved when large machines work, and the situation that the ground is damaged due to bouncing of electromechanical equipment is effectively avoided.

Owner:刘兵

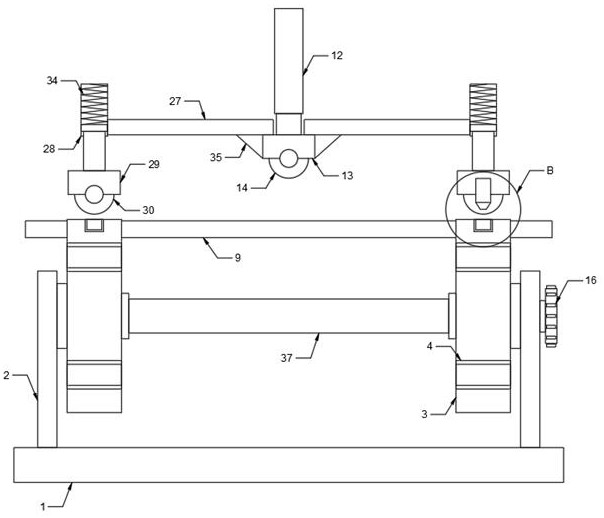

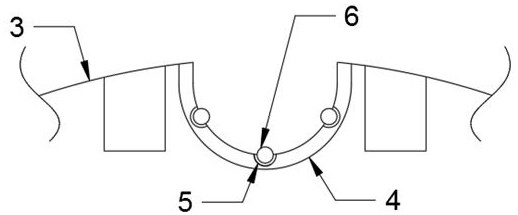

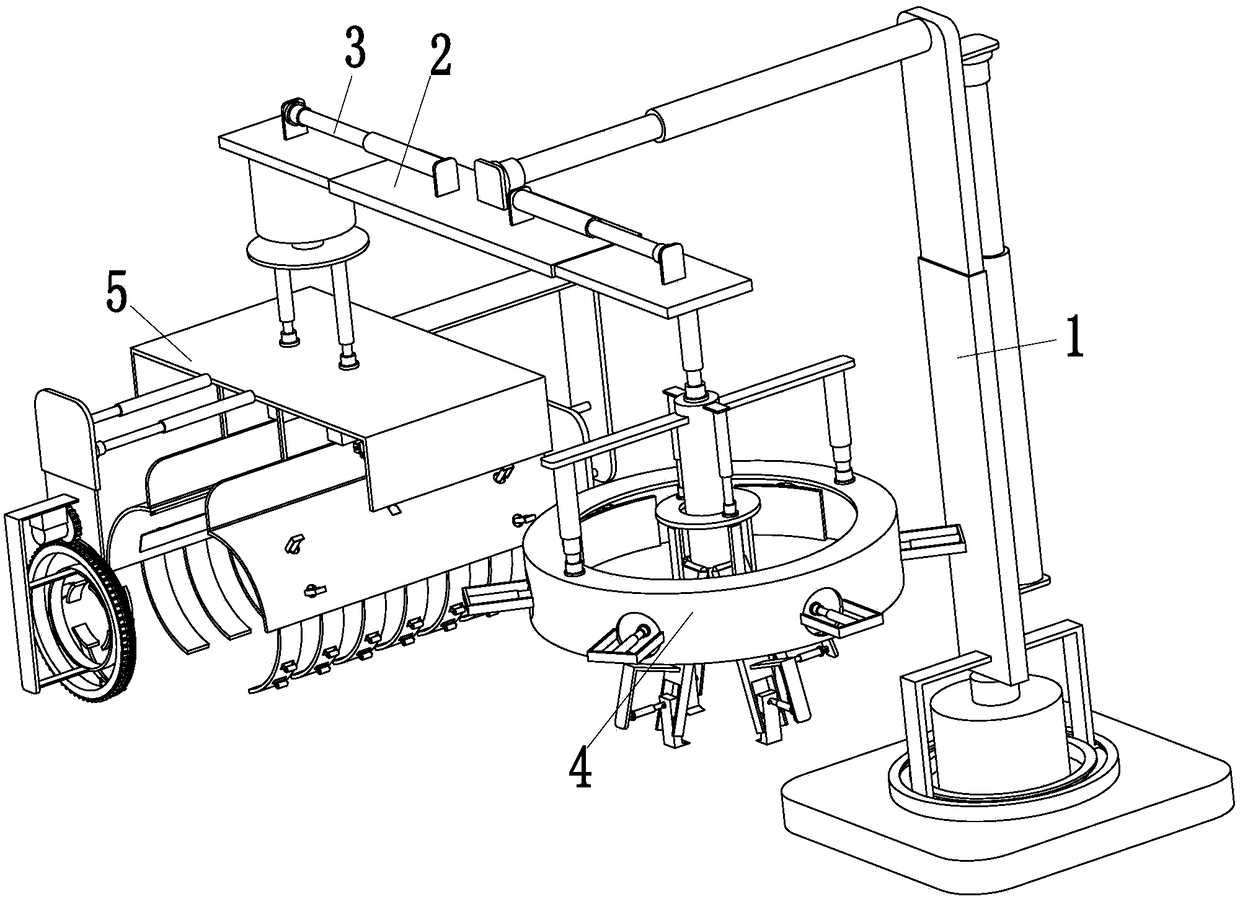

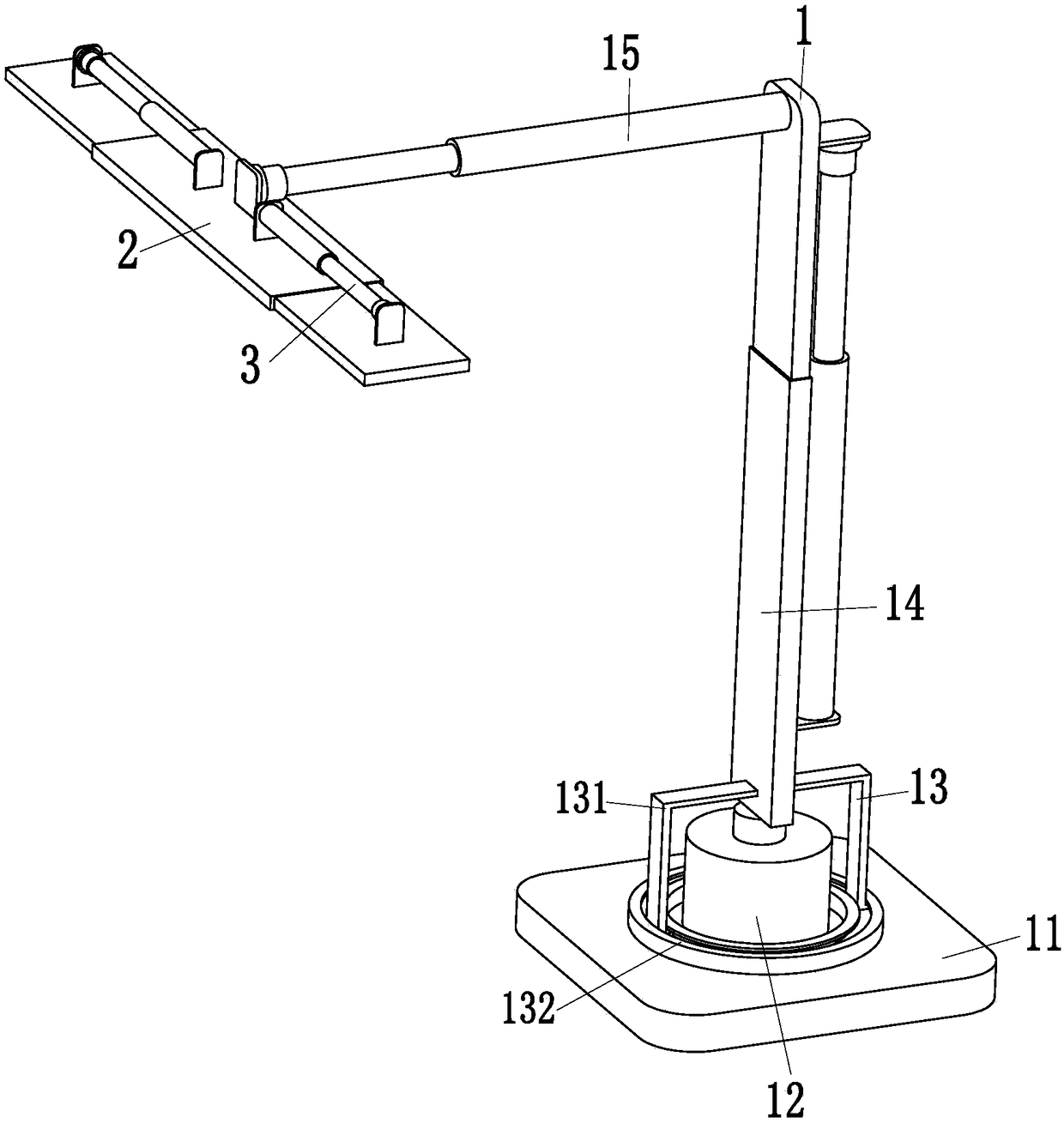

Construction steel pipe machining equipment with fixed-point bending function, and using method thereof

InactiveCN112275859AEasy to bendImprove manual work efficiencyMetal-working feeding devicesPositioning devicesRebarMachining

The invention discloses construction steel pipe machining equipment with a fixed-point bending function, and a using method thereof. The construction steel pipe machining equipment comprises a bottomplate, and supporting plates are fixedly arranged on the two sides of the upper end of the bottom plate; and feeding mechanisms are arranged at the upper ends of the supporting plates, and each feeding mechanism comprises a conveying disc, limiting grooves, clamping grooves and balls. The conveying discs are movably arranged on the outer side surfaces of the supporting plates through rotating shafts, and the multiple limiting grooves are evenly formed in the outer side surfaces of the conveying discs; the multiple clamping grooves are evenly formed in the inner side walls of the limiting grooves, and the balls are movably clamped in the clamping grooves; a first bracket is fixedly arranged on one side of the upper end of the bottom plate; a storage bin is fixedly arranged at the upper endof the first bracket, and a plurality of steel bars are movably arranged in the storage bin; and a guide port is fixedly formed in the lower end of the storage bin. The construction steel pipe machining equipment is good in using effect, and steel pipes needing to be bent can be automatically conveyed to a target position for bending; and manual conveying and placement are not required, and the working efficiency and the safety are higher.

Owner:XIHUA UNIV

Battery machining robot

ActiveCN108466273ANo manual operationEasy to operatePrimary cell manufactureAssembling battery machinesButton batteryBlurred vision

The invention relates to a battery machining robot. The battery machining robot comprises an adjusting device, a two-way telescopic plate, two symmetric air cylinders, a button battery clamping deviceand a cylindrical battery clamping device; the front end of the adjusting device is installed at the upper end of the two-way telescopic plate, the two symmetric air cylinders are installed in the middle of the two-way telescopic plate, and the top ends of the symmetrical air cylinders are installed at the outer ends of the two-way telescopic plate through flanges; and the button battery clampingdevice is installed on the right side of the lower end of the two-way telescopic plate, and the cylindrical battery clamping device is installed on the left side of the lower end of the two-way telescopic plate. According to the battery machining robot, the problems that in the present process of producing batteries, people need to grab the different types of batteries, when the button battery isgrabbed, due to the fact that the button battery is relatively small, jumping and flying of the button battery are prone to occurrence during grabbing by people, and people possibly have blurred vision and then miss grabbing the button battery during long-term grabbing, and in addition, when a cylindrical battery is grabbed, people usually grab the middle part of the cylindrical battery, and thenthe grabbed cylindrical battery possibly falls off due to sweating of hands can be solved.

Owner:JIAXING HENGWEI BATTERY

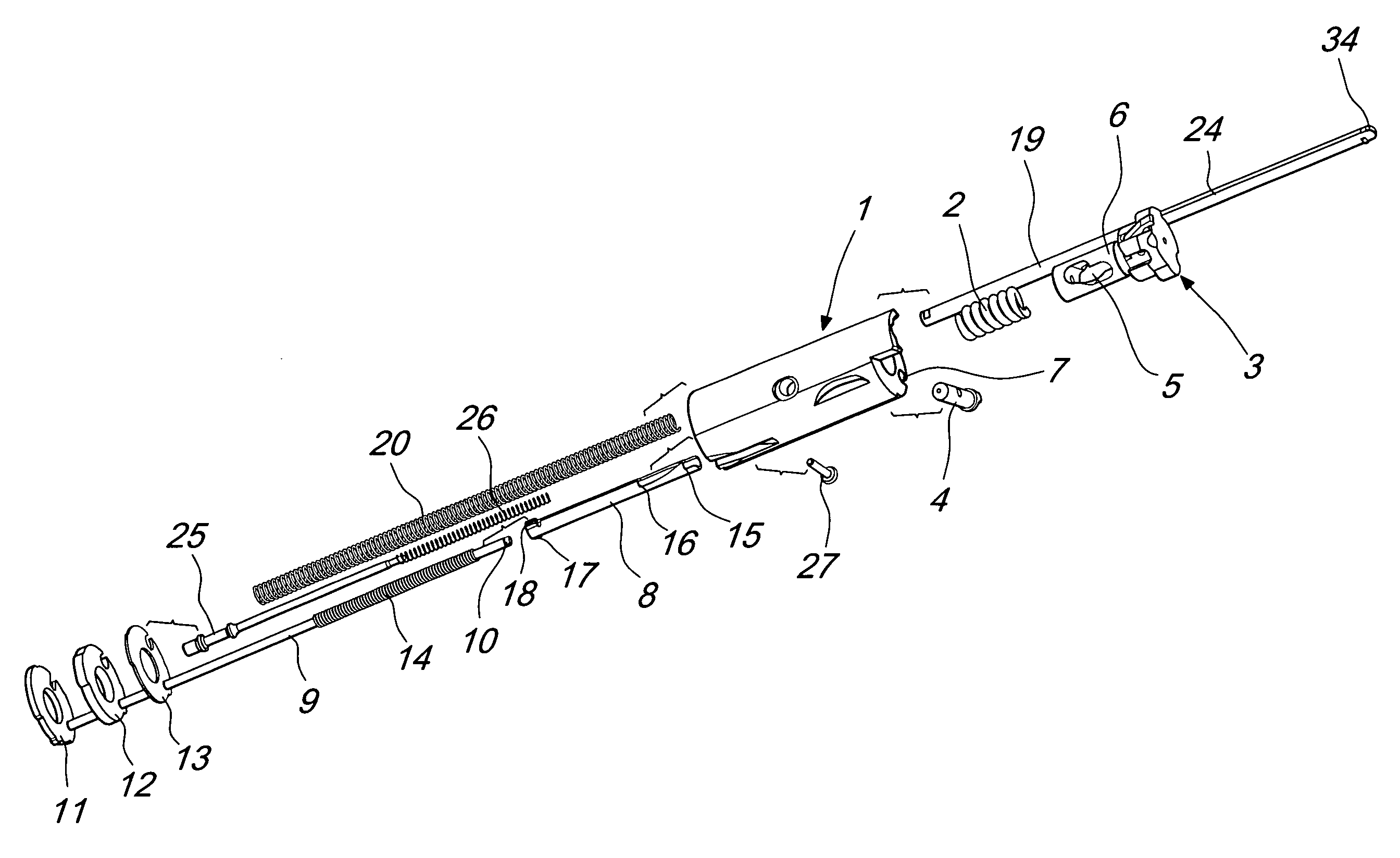

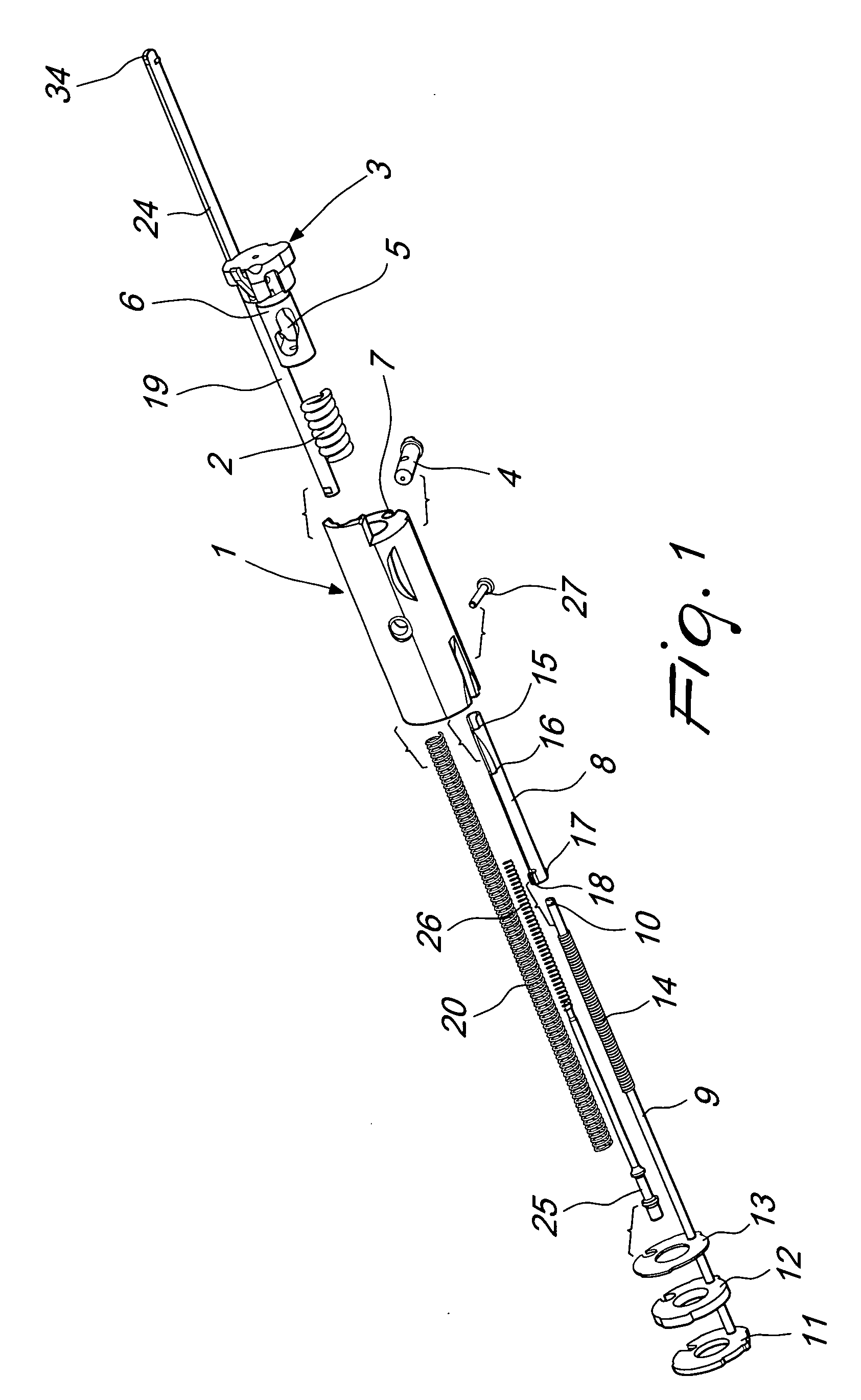

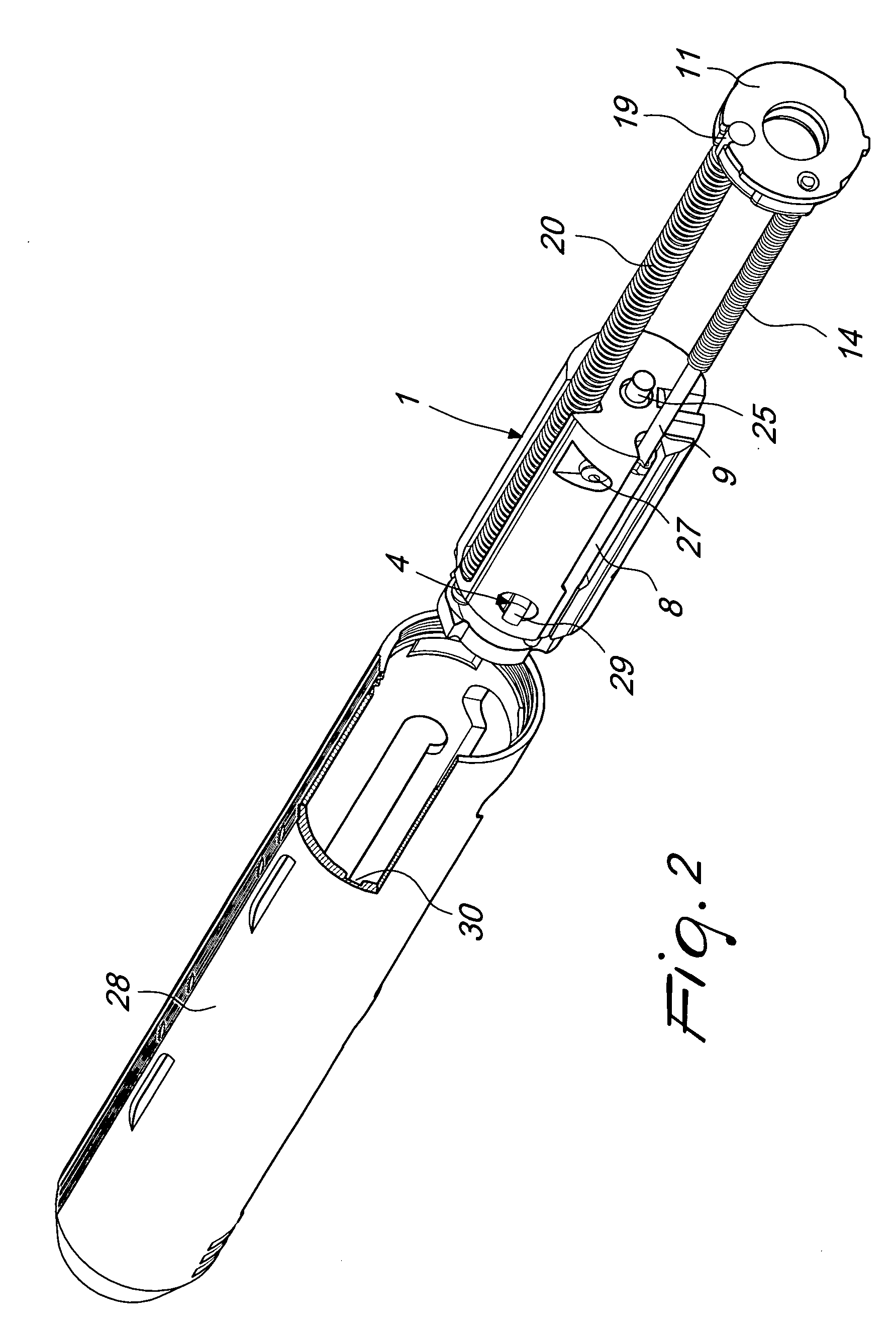

Locking and recocking assembly with swivel breech-lock and rotating locking head, particularly for inertially-actuated weapons using the kinetic energy of recoil

ActiveUS20090019754A1Inhibition effectGood balance and stabilityCartridge extractorsBreech mechanismsEngineeringKinetic energy

A locking and recocking assembly with swivel breech-lock and rotating locking head particularly designed for inertially-actuated weapons, which combines in a single assembly all the functions for locking, opening, case ejection and recocking with locking return, required for correct operation of the weapon; those functions were, until now assigned to various components variously assembled on the weapon. The locking and recocking assembly with swivel breech-lock and rotating locking head has the entire mass, required for inertial operation, concentrated in the swivel breech-lock, which is accommodated completely within the supporting structure of the weapon, such as the sheath or barrel extension or breech of the weapon. All this leads to better balancing and stability of the weapon, higher reliability in operation, greater constructive simplicity and ease of assembly and disassembly.

Owner:BENELLI ARMI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com