Automatic feeding and cutting assembly line

An automatic feeding and assembly line technology, applied in shearing devices, pipe shearing devices, shearing machines, etc., can solve the problems of steel pipes crushing workers, consuming physical strength and working time, shortening working hours, improving work efficiency, Achieve the effect of fully automated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

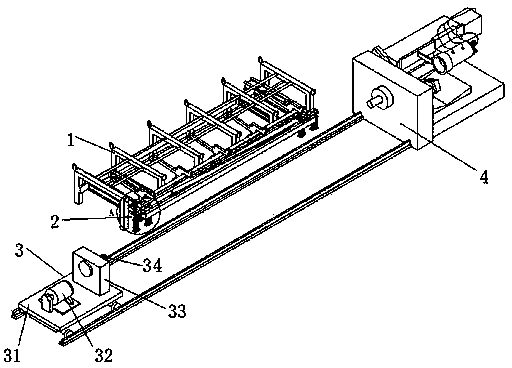

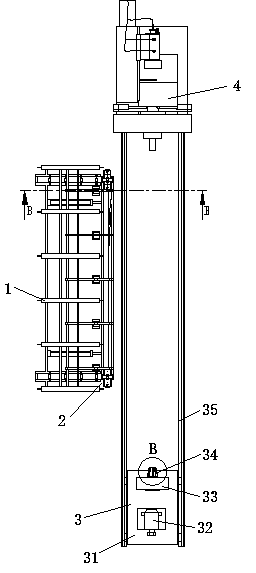

[0026] Example 1, such as Figure 1-2 As shown, a steel pipe automatic feeding and cutting line includes a storage rack 1, a material lifting device 2, a feeding device 3 and a cutting device 4;

[0027] There are 6 material storage racks 1, which are connected to each other by guide rods, and there is a certain distance between each material storage rack 1. The table top of material storage rack 1 is inclined, and the steel pipe placed on it can roll from one end to the other end, but the two ends of material storage rack 1 are all provided with ear protectors that stop the steel pipe from falling. After the material lifting device 2 lifts away a steel pipe, the adjacent second steel pipe will roll down to replace the steel pipe that has been lifted away.

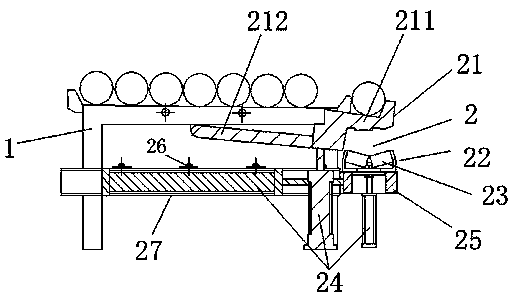

[0028] From Figure 3-5 It can be seen that the feeding device 2 includes a taking-in device 21 for extracting one steel pipe each time from the storage rack 1 and a taking-out device 22 for transporting the steel pipe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com