Process for preparing calcium sulfate whisker

A calcium sulfate whisker and raw material preparation technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve problems such as difficult industrialized large-scale production, high process production costs, and serious equipment corrosion , to achieve the effects of easy industrial production, low production cost and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

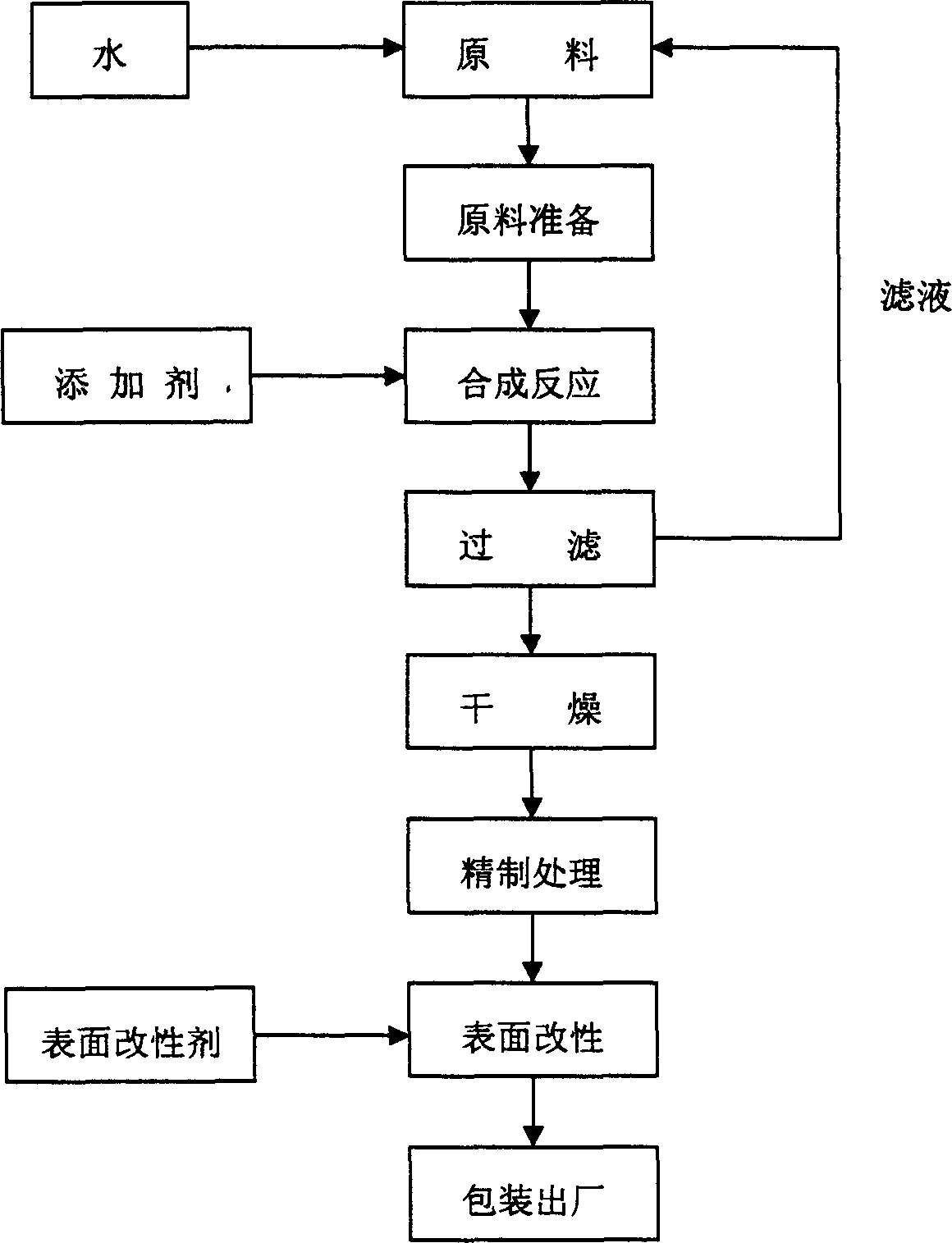

Method used

Image

Examples

example 1

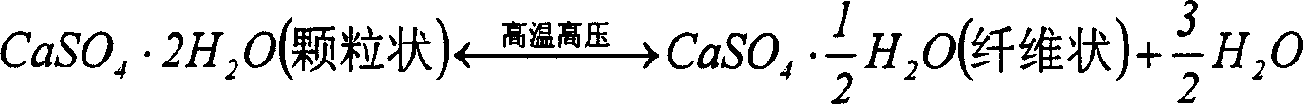

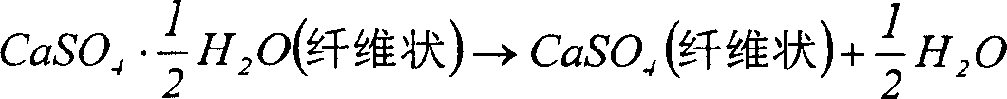

[0053] The raw materials are selected from Hubei Province. The main elements of the raw materials are Ca and S, and the impurities are Mg, Si, Al, Fe, etc. The raw gypsum (CaSO 4 2H 2 The content of O) was 98%. Prepare raw gypsum powder and water to form a slurry with a weight concentration of 4-14%. After being emulsified by an emulsifier, put it into a high-pressure reactor, seal it, start stirring at a stirring speed of 400-1000rpm, and start heating. During the synthesis of calcium sulfate whiskers, a temperature sensor is used to measure the solution temperature in the reactor, and a pressure sensor is used to measure the pressure in the reactor. When the reaction temperature and pressure reach a certain value (100-200° C., 1-3 atm), the preparation reaction ends. The solution is filtered, dried at a temperature of 200-400° C., and depolymerized to obtain a calcium sulfate whisker product. Scanning electron microscope or transmission electron microscope is used to test...

example 2

[0055] Add additives in embodiment 1, concrete method is as follows: at the beginning of reaction, adjust the pH value of gypsum emulsion, make it reach 8~12, other conditions are the same as example 1, obtain calcium sulfate whisker product. The test results of the product show that the crystal form is calcium sulfate fiber, the fiber diameter is below 100nm, and the aspect ratio is 50-1000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com