Metal particle trap for direct-current gas-insulated power transmission line

A technology of metal particles and transmission lines, applied in the direction of electrode structure, electrostatic separation, power supply technology, etc., can solve the problems of difficult to control the direction of movement of DC GIL metal particles, difficult to capture metal particles, aging, etc., to solve aging and loss of viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

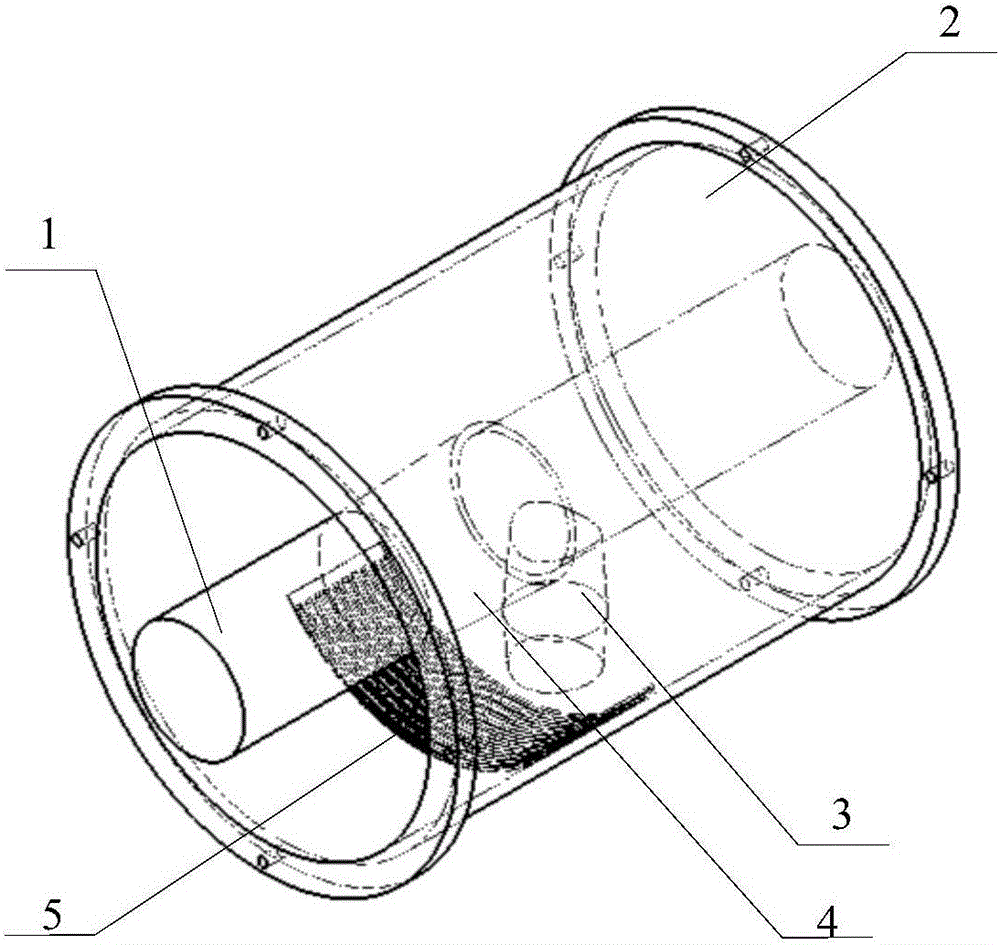

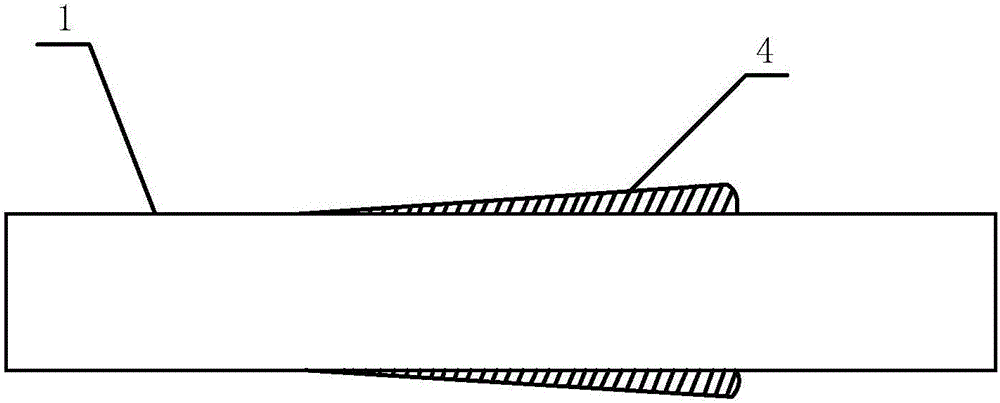

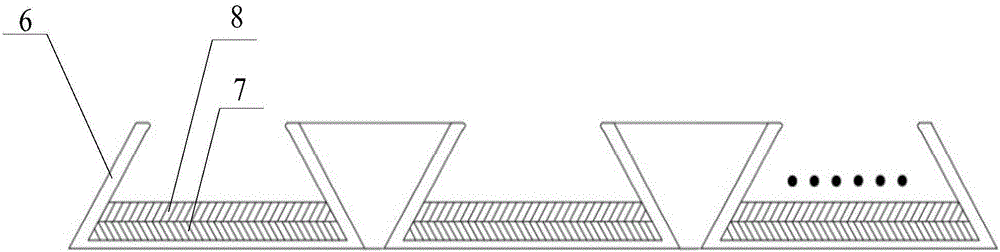

[0023] A metal particle catcher for DC gas insulated transmission lines, characterized in that it consists of two parts: a driving electrode and a metal particle capture tank; a DC GIL aluminum alloy conductor 1 and a DC GIL post insulator 3 Inside the casing 2, the driving electrode 4 is installed on the DC GIL aluminum alloy conductor 1 near the column insulator 3 for the DC GIL, and the metal particle capture groove 5 is installed at the bottom of the DC GIL cavity, so that the inclined surface of the driving electrode 4 faces the metal at the bottom. Particle capture tank 5, metal particle capture tank 5 is divided into 3 layers, from bottom to top are concave metal shielding tank 6, epoxy resin insulation pad 7, strong adhesive hot melt adhesive coating 8; among them, driving electrode 4 Use the electric field gradient and particle collision rebound angle to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com