Wood plastic aluminum door and window composite profile and manufacturing method thereof

A technology for door and window profiles and composite profiles, which is applied in the direction of the wing frame and other directions, can solve the problems of easy aging and easy deformation of metal plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

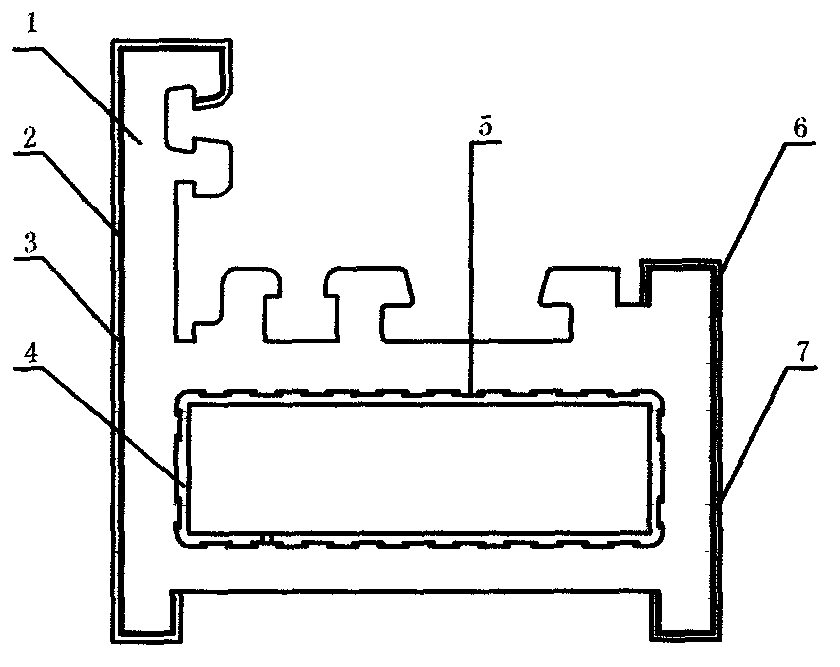

[0021] The end face structure diagram of wood-plastic-aluminum door and window composite window frame profile clad with copper plate on the outdoor side is as follows figure 1 As shown, among them: 1 is the wood-plastic window frame profile, 2 is the glue, 3 is the copper plate, 4 is the aluminum alloy inner core, 5 is the dovetail groove, 6 is the decorative film glue, and 7 is the decorative film.

[0022] The manufacturing method is as follows: 1. Co-extrude the aluminum alloy inner core 4 with the dovetail groove 5 and the wood-plastic window frame profile 1 to produce an inner aluminum outer wood-plastic door and window profile; 2. The outdoor surface of the wood-plastic window frame profile 1 or The inner surface of the copper plate 3 is coated with glue, and the rolled or bent copper plate 3 is laminated on the outer surface of the wood-plastic door and window profile 1 with a rolling machine; The inner surface.

Embodiment 2

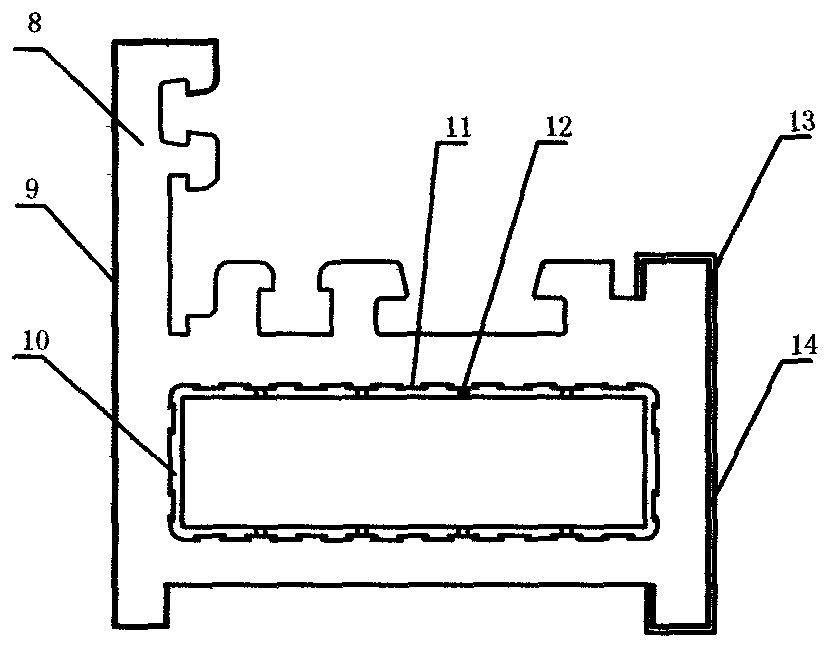

[0024] The end face structure diagram of wood-plastic-aluminum door and window composite window frame profiles coated with metal paint on the outdoor side is as follows figure 2 As shown, wherein: 8 is a wood-plastic window frame profile, 9 is a metallic paint, 10 is an aluminum alloy inner core, 11 is a dovetail groove, 12 is a hole, 13 is a decorative film glue, and 14 is a decorative film.

[0025] The manufacturing method is as follows: 1. Co-extrude the aluminum alloy inner core 10 with the dovetail groove 11 and the hole 12 and the wood-plastic window frame profile 8 to make an inner aluminum outer wood-plastic door and window profile; 2. 8 chambers of the wood-plastic window frame profile The outer surface is coated with metallic paint 9; 3. The interior decorative film 14 with glue is compounded on the inner surface of the wood-plastic door and window profile 8 with decorative film glue 13.

Embodiment 3

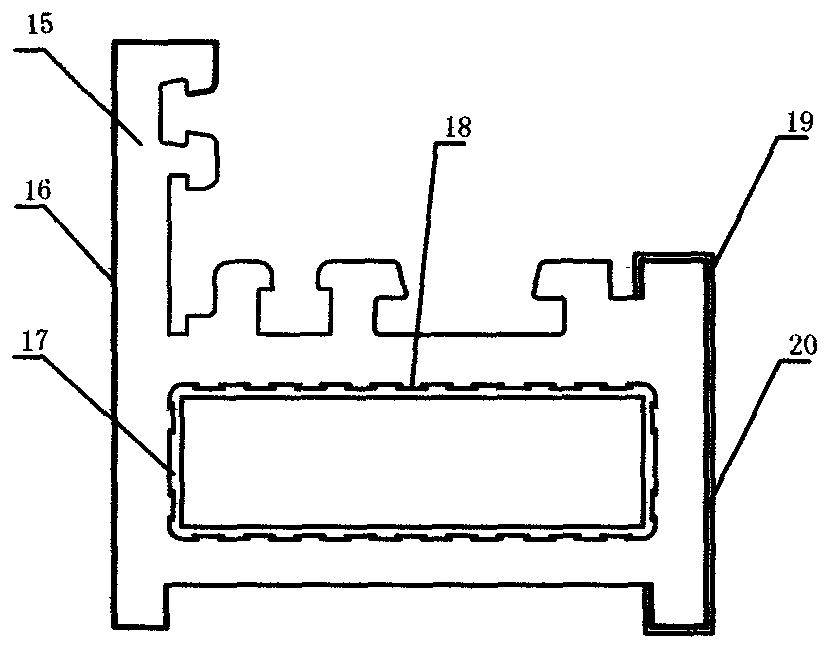

[0027] The end face structure diagram of wood-plastic-aluminum door and window composite window frame profiles co-extruded ASA on the outdoor side is as follows image 3 As shown, among them: 15 is the wood-plastic window frame profile, 16 is ASA, 17 is the aluminum alloy inner core, 18 is the dovetail groove, 19 is the decorative film glue, and 20 is the decorative film.

[0028] The manufacturing method is as follows: 1. Co-extrude the aluminum alloy inner core 17 with the dovetail groove 18, the wood-plastic window frame profile 15 and ASA16 to produce the inner aluminum outer wood-plastic and ASA composite door and window profiles; 2. The inner decorative film with glue 20 compound on the wood-plastic door and window profile 15 inner surfaces with decorative film glue 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com