Inspection system for rolled products and method for assessing the surface of rolled products of a rolling installation

A technology for inspection systems and rolling equipment, which is applied in the field of inspection systems, can solve problems such as noisy operation and achieve low operating costs, good environmental protection effects, and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

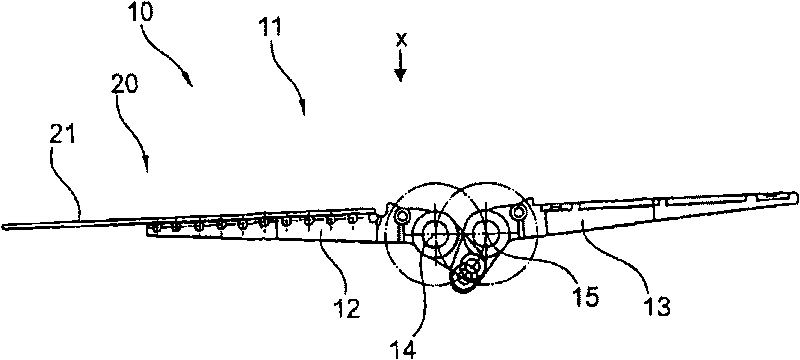

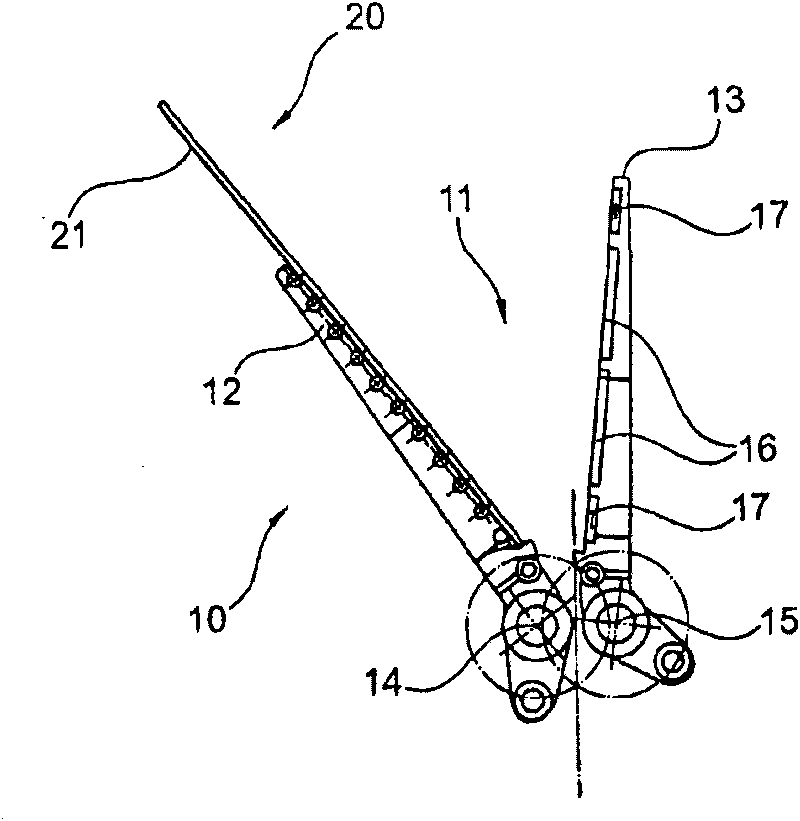

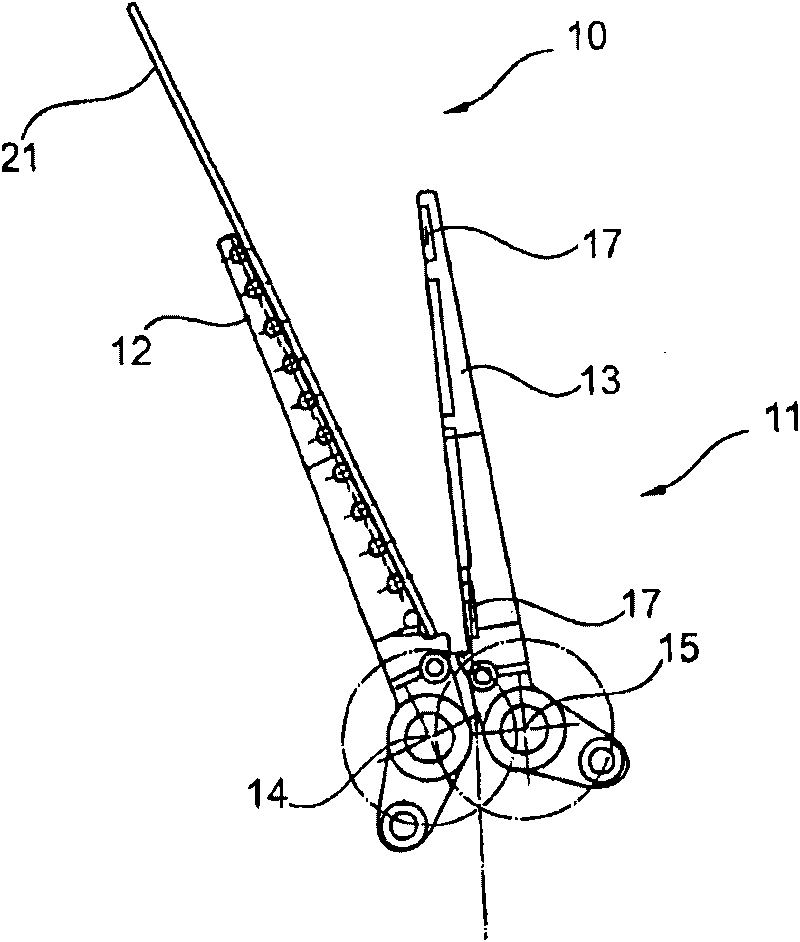

[0024] The inspection system according to the invention is indicated overall at 10 and is provided for rolling products, indicated here at 20 , in a rolling plant. For this purpose, the drawing shows the flipper 11 of the inspection system 10 according to the invention in different functional positions. The inspection system 10 according to the invention comprises at least one turning machine 11 , which has a turning arm 12 for transfer on the turning shaft 14 and a turning arm 12 on the turning shaft 15 . The device formed by the receiving flap arm 13 on the figure 1 with 2 . For the inspection system 10 according to the invention it is provided here that the turning shaft 15 of the receiving turning arm 13 is arranged offset with respect to the turning shaft 14 of the transferring turning arm 12 . The receiving turning arm 13 is thus arranged offset with respect to the turning axis 14 of the transferring turning arm 12 . As a result, the sheet metal 21 does not impinge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com