Magnetorheology based elevator drop buffering device

A buffer device, magnetorheological technology, applied in transportation and packaging, springs/shock absorbers, shock absorbers, etc. The effect of simplifying the structure, enhancing the adaptability, and reducing the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

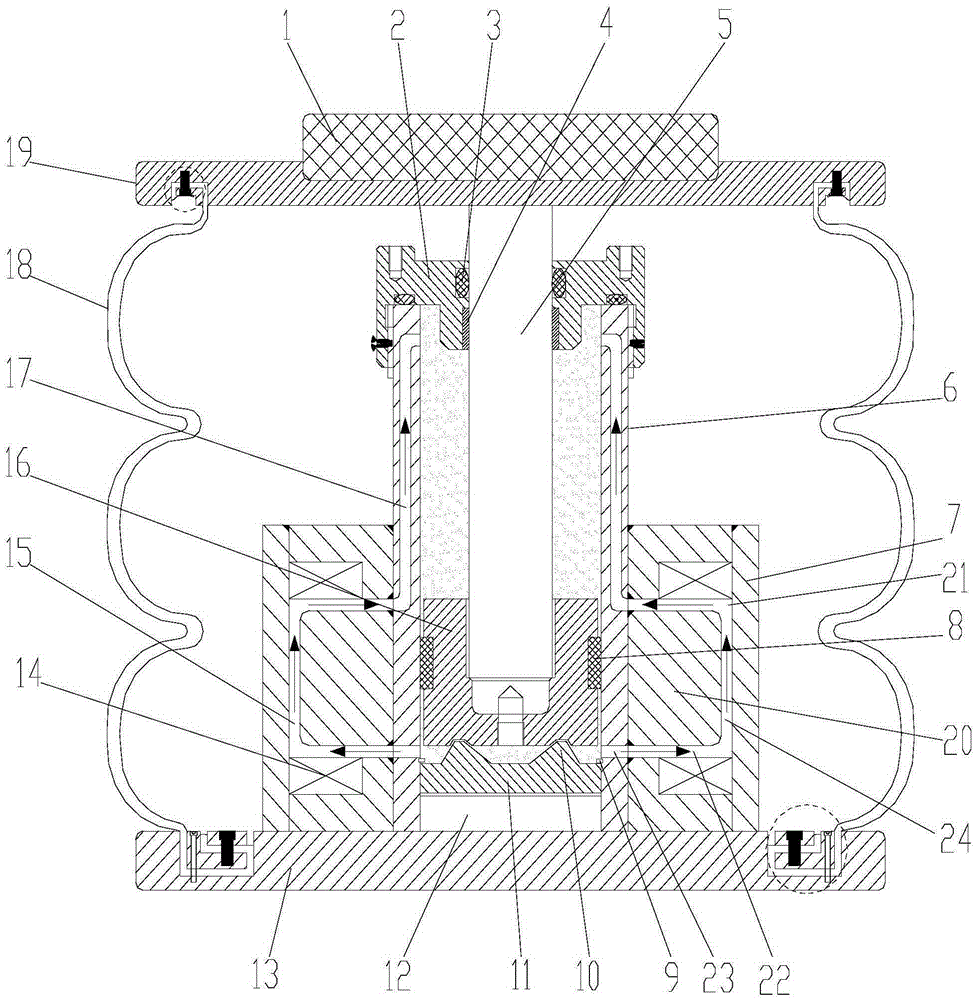

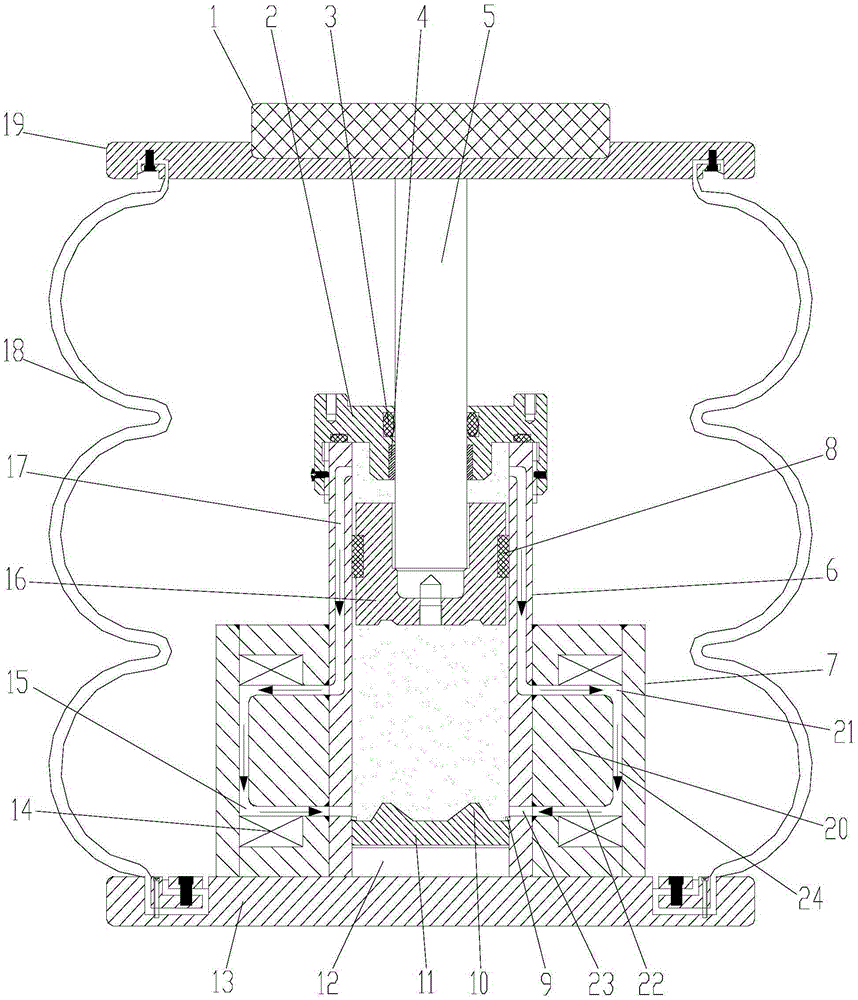

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure after the cushioning of the present invention is completed. As shown in the figure, a magneto-rheological-based elevator fall buffering device provided by the present invention includes an elastic damping member 18, a magnetorheological damping mechanism and a supporting plate 19. The elastic damping The component 18 and the magnetorheological damping mechanism are fixedly arranged on the lower surface of the supporting plate 19, wherein the elastic damping component and the magnetorheological damping mechanism form a juxtaposed structure. When the elevator falls, the elastic damping component and the magnetic The rheological damping mechanism evenly bears the impact force to ensure that the present invention can have a uniform buffer speed, and when the elastic damping member releases the elastic potential energy after the buffering is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com