Binder to process book blocks and method of binding

A technology of adhesives and book blocks, which is applied to binding adhesives, compound continuous process of book processing, book binding, etc., which can solve problems such as product quality problems, problems, and damage to the shape of the milling back.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

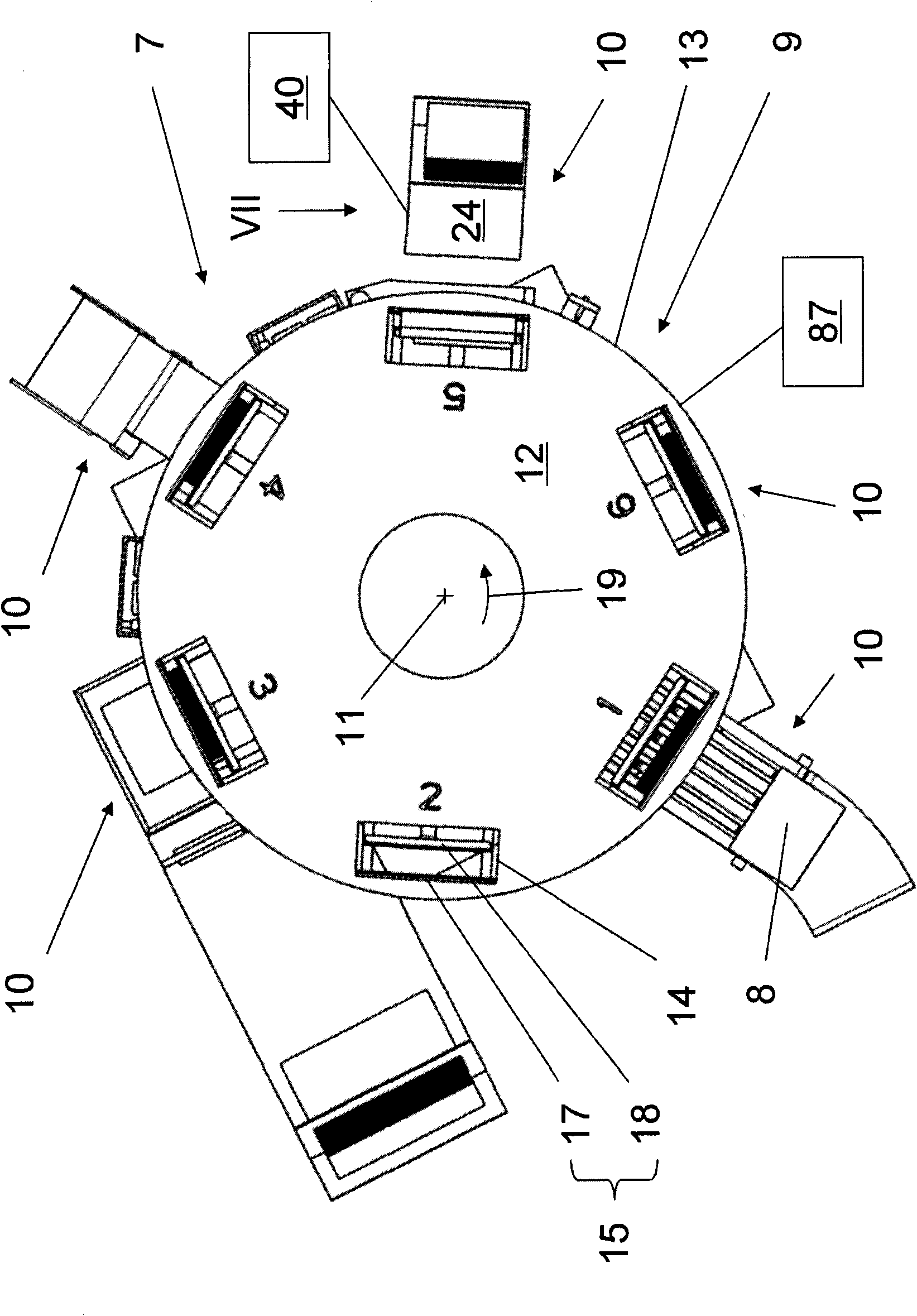

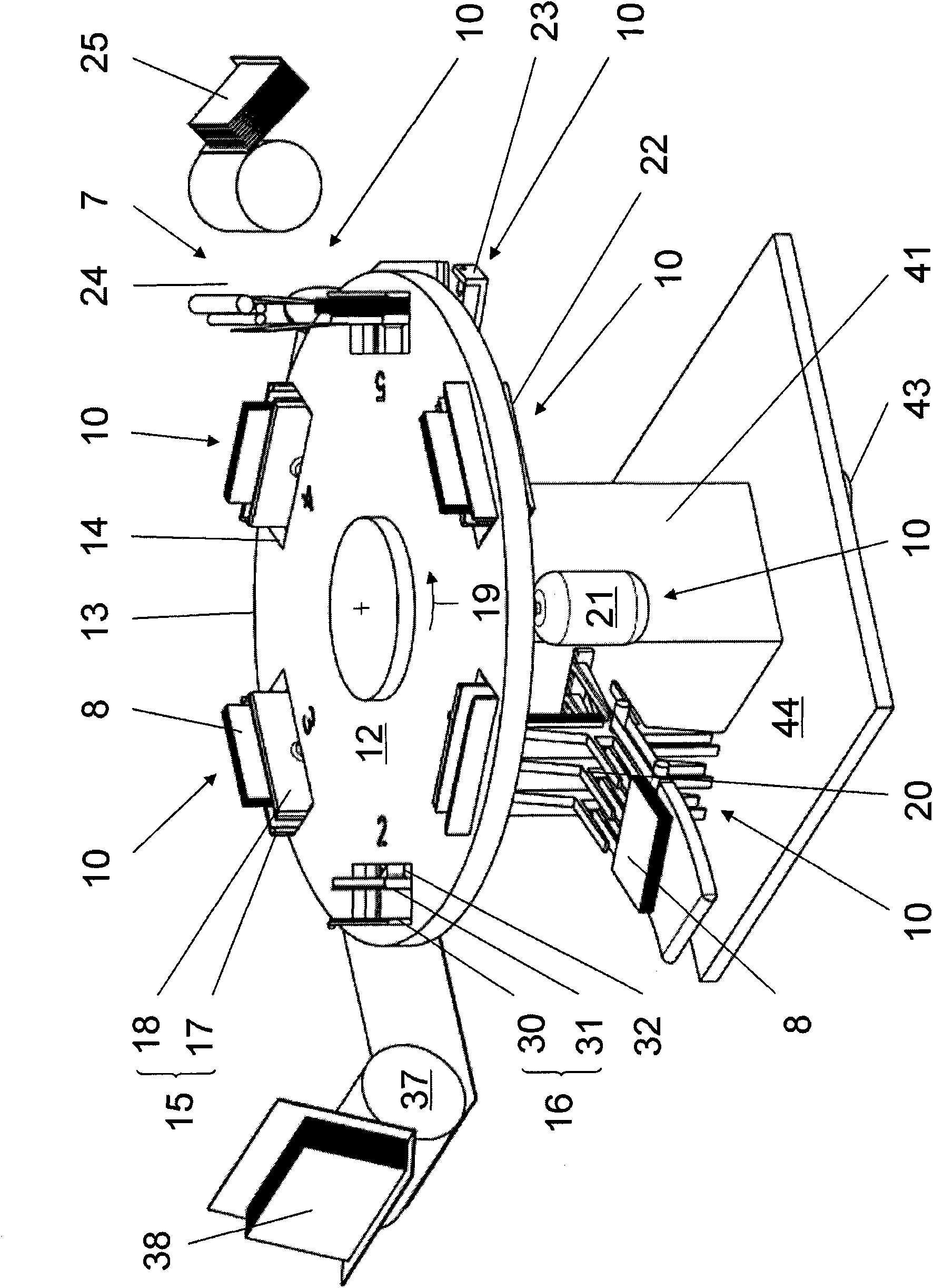

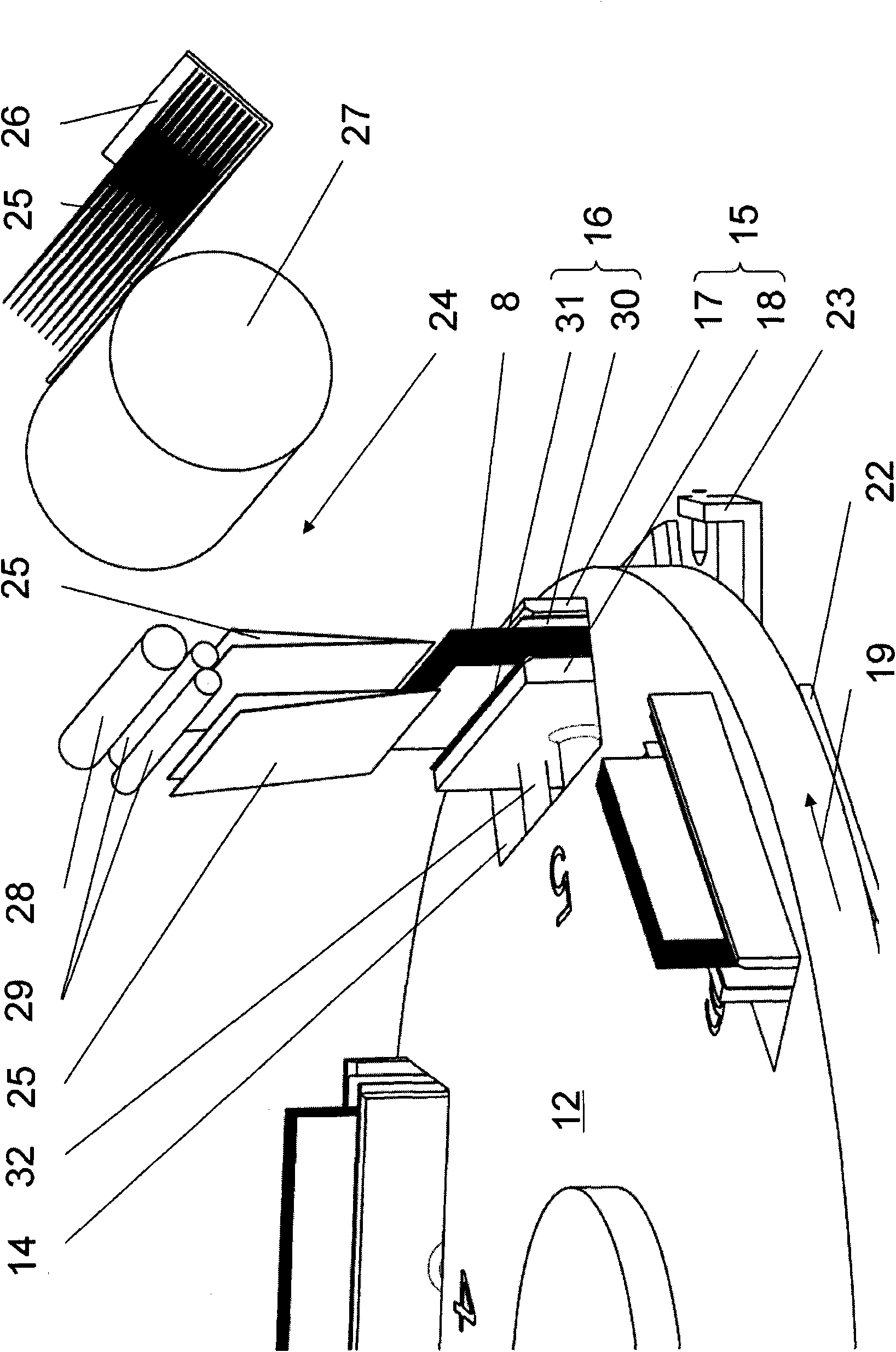

[0039] figure 1 A top view of the bonder 7 used to process the book block 8 into bonded books, which can be made into hardcovers (Hardcover) later in an automatic book production line. The bonder 7 is driven by an unshown drive mechanism designed as a motor. Of course, one or more hydraulic or pneumatic drive mechanisms can also be used. The bonder 7 has a conveying device 9 and a plurality of processing stations 10. The conveying device 9 is a round table 12 rotating around a shaft 11 with a closed circular running track 13. The periphery of the table 12 has six splint accommodating mechanisms 14 arranged at equal intervals with each other, and these splint accommodating mechanisms respectively receive clamping devices 1 to 6 for the book block 8. Clamping devices 1 to 6 are adhesive splints with outer splints and inner splints 15, 16 respectively ( figure 2 ). The outer splints 15 arranged at an interval of 60° respectively have a fixed splint half and a movable splint half 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com