Patents

Literature

253results about How to "No downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

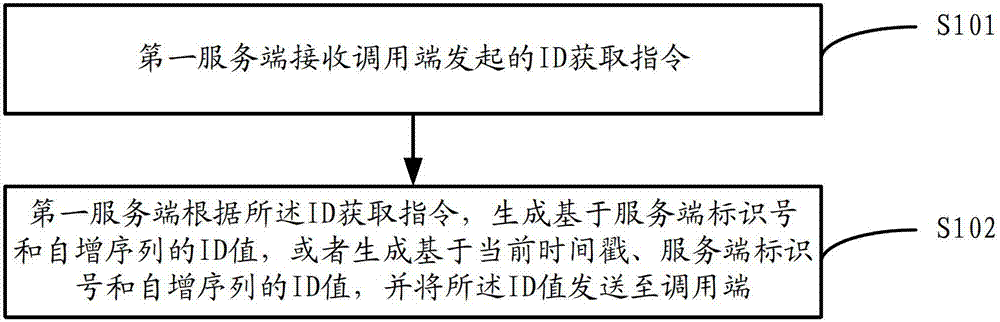

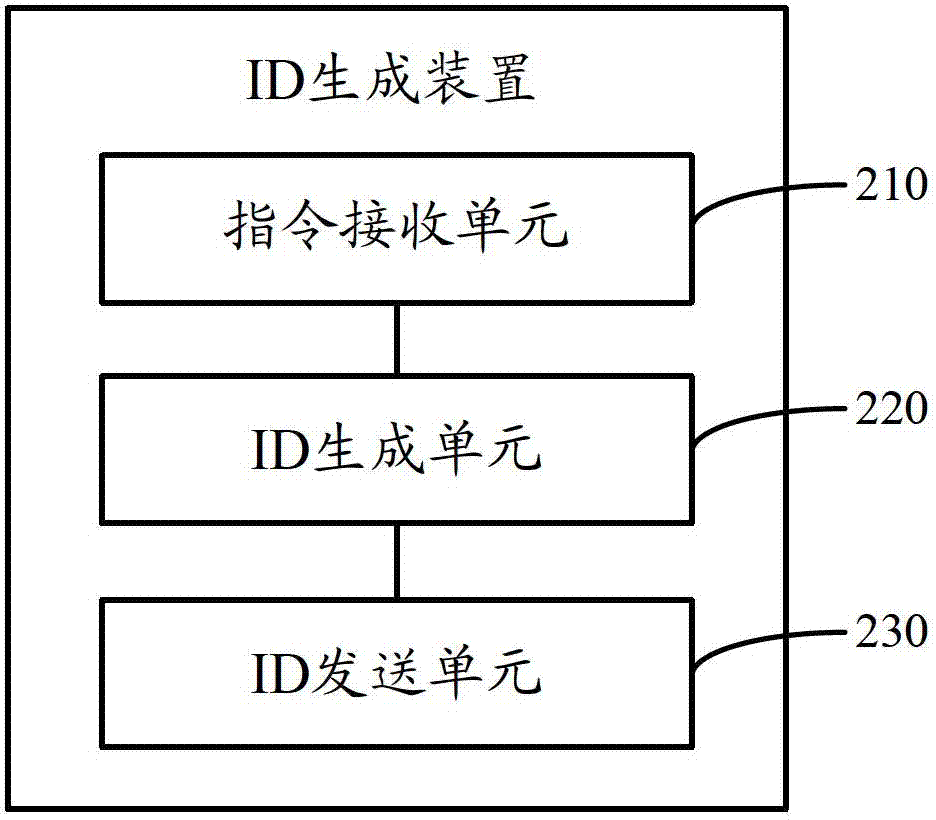

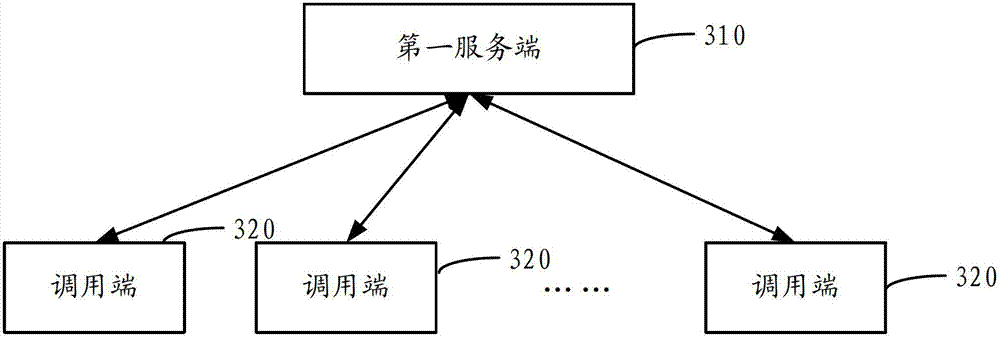

Method, equipment and system for generating ID

ActiveCN102769667AImprove performanceImprove reliabilityTransmissionExtensibilityUniversally unique identifier

The invention discloses a method, equipment and a system for generating an ID. The method comprises the following steps: a first service terminal receives an ID acquisition instruction initiated by calling terminals; according to the ID acquisition instruction, generating an ID value based on a service end identification number and a self-increasing sequence, or generating an ID value based on the current time stamp, a service end identification number and a self-increasing sequence; and transmitting the generated ID value to the calling terminals. According to the technical scheme provided by the invention, an overall unique ID is generated in a service-oriented manner, which is good in extendibility and high in serviceability and reliability; and besides, generated IDs are ensured to be sequential and incremental, the IDs are smaller than a UUID (Universally Unique Identifier) in occupied space, and the application is convenient and quick.

Owner:北京鸿享技术服务有限公司

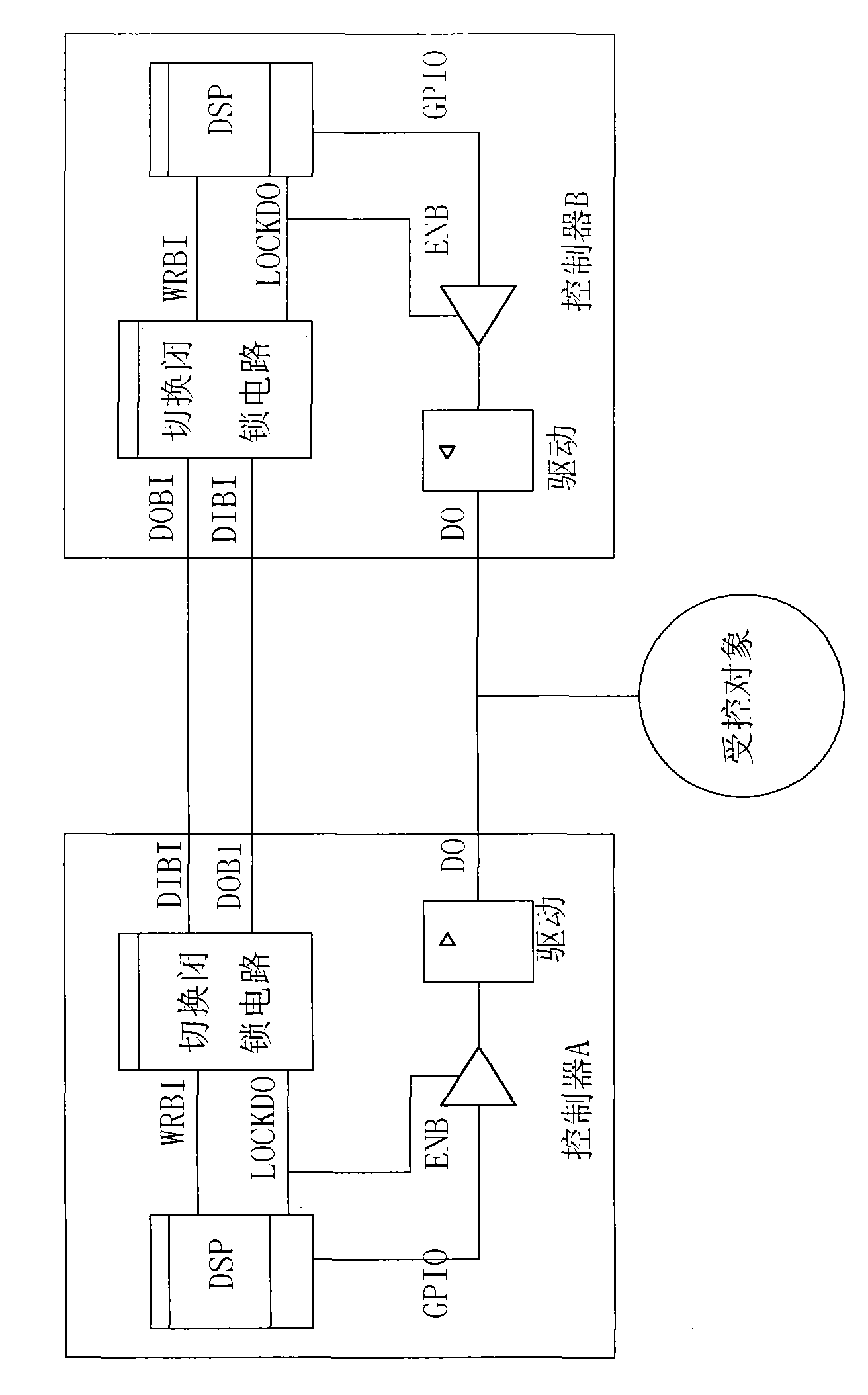

Dual-computer redundancy control method and control device thereof

InactiveCN101794142ANo downtimeRealize redundant configuration control modeTotal factory controlProgramme total factory controlMaster controllerControl mode

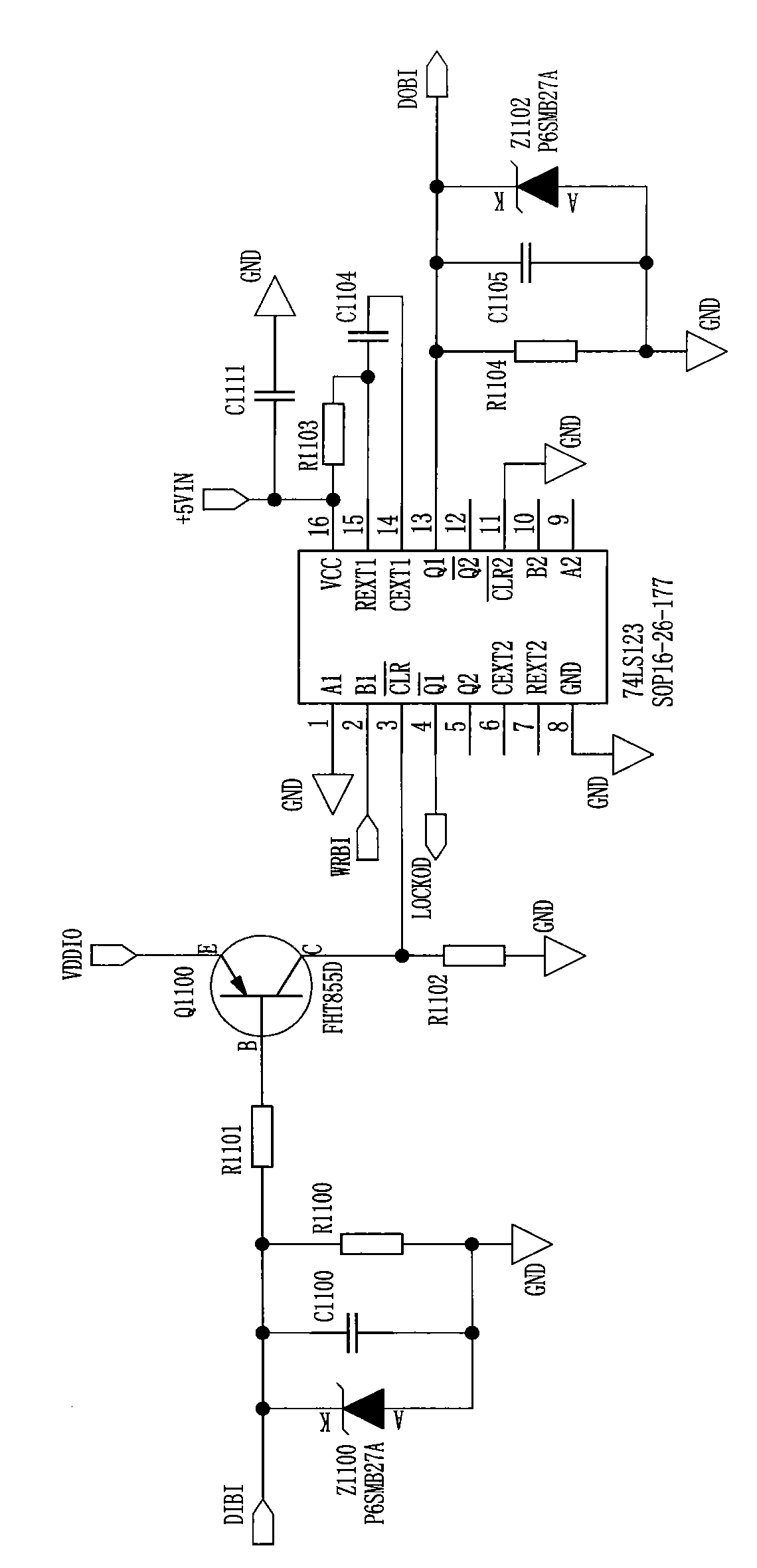

The invention discloses a dual-computer redundancy control method and a control device thereof. The control device is characterized by comprising a control unit A and a control unit B which are of the same structure, wherein each control unit comprises a switch latching circuit, a DSP microprocessor and an output blocking circuit, the input interlocking signal ends and the output interlocking signal ends of the switch latching circuits of the two control units are respectively crosswise connected, and the outputs of the two control units are connected in parallel to an actuating mechanism. The method comprises the following steps: after being electrified, the control unit A and the control unit B compete for conduction, the first started control unit is the main controller, and the other control unit is the backup controller; and when failure occurs, the interlocking signal outputs of the main controller and the backup controller are mutually converted, and the states of the main controller and the backup controller are switched. By connecting the two control units with the same structure with the actuating mechanism in parallel with one operative and other hot standby, the invention switches the main controller and the backup controller when failure occurs, thereby realizing the dual-computer redundancy control mode.

Owner:SHANGHAI HUAXING DIGITAL TECH

APP and server interaction system and method

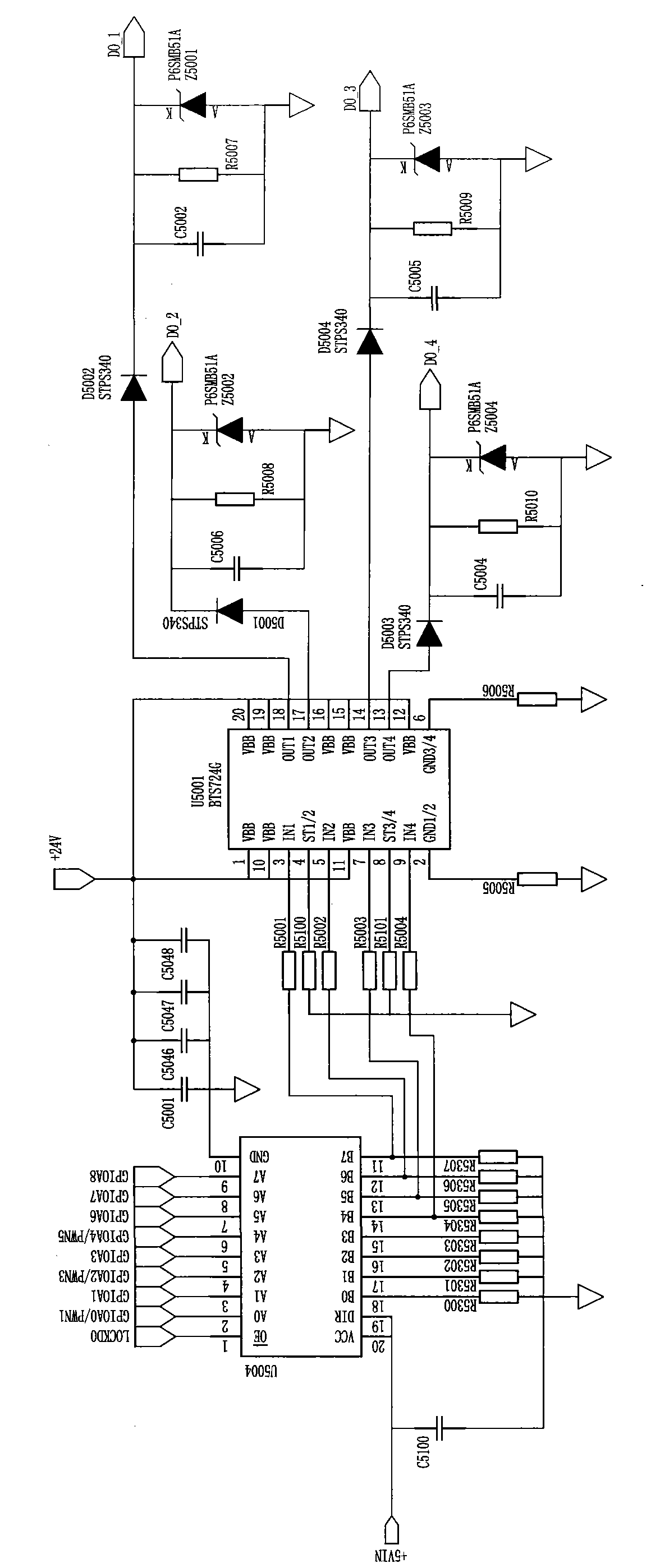

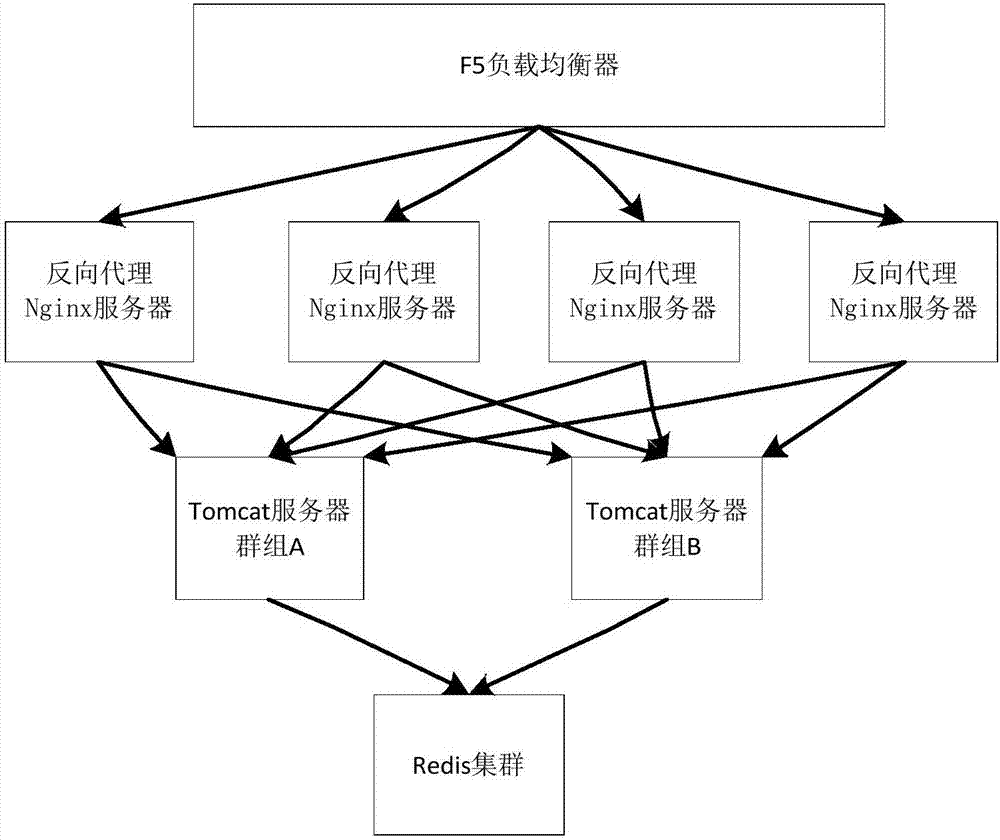

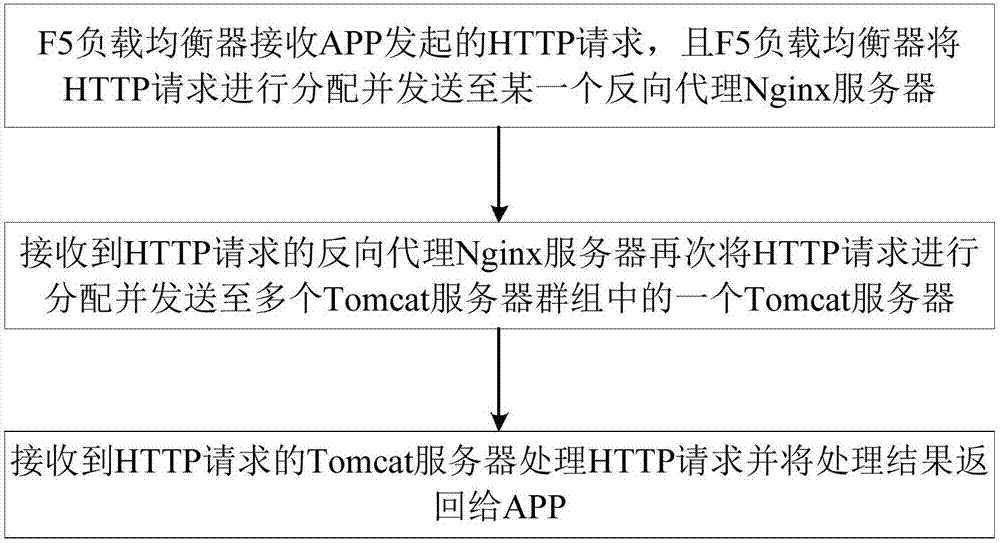

The invention discloses an APP and server interaction system and method. The APP and server interaction system comprises an F5 load balancer, at least one reverse proxy Nginx server and at least one Tomcat server group. The F5 load balancer is used for receiving HTTP requests initiated by an APP. The F5 load balancer is used for allocating the HTTP requests and sending the HTTP requests to a certain reverse proxy Nginx server. The reverse proxy Nginx server is used for allocating the HTTP requests again and sending the HTTP requests to a Tomcat server in the at least one Tomcat server group. The Tomcat server is used for processing the HTTP requests and returning processing results to the APP. According to the APP and server interaction system, as APP users are increased, excessive user demands can be satisfied, and crash does not occurs in the server.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +2

Soil heavy metal biological fixing agent and application method thereof

ActiveCN103275728ALow costReduce environmental risksAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsNutrient

The invention relates to the technical field of soil conditioners and particularly relates to a soil heavy metal biological fixing agent and an application method thereof. The formula of the soil heavy metal biological fixing agent is that every one kilogram of an organic fertilizer is added with 2-10 g (109 CFU / g) of B. natto solid leavening agent, 2-10 g (109 CFU / g) of B.mucilaginosus solid leavening agent, 2-6 g (109 CFU / g) of B.megaterium solid leavening agent and 4-10 g (1010 CFU / g) of Trichoderma koningii solid leavening agent, wherein the main ingredients of the biological organic fertilizer contain more than 40% of organic matter, more than 20 million / g of effective viable count, and more than 5% of total nutrient. The soil heavy metal biological fixing agent is low in cost, has few environmental risks, remarkably reduces the absorption of the heavy metals of the crops, improves the soil fertility, effectively prevents and cures the soil-borne diseases and increases the economic benefit of the crops.

Owner:DONGGUAN BAODE BIOLOGICAL ENG

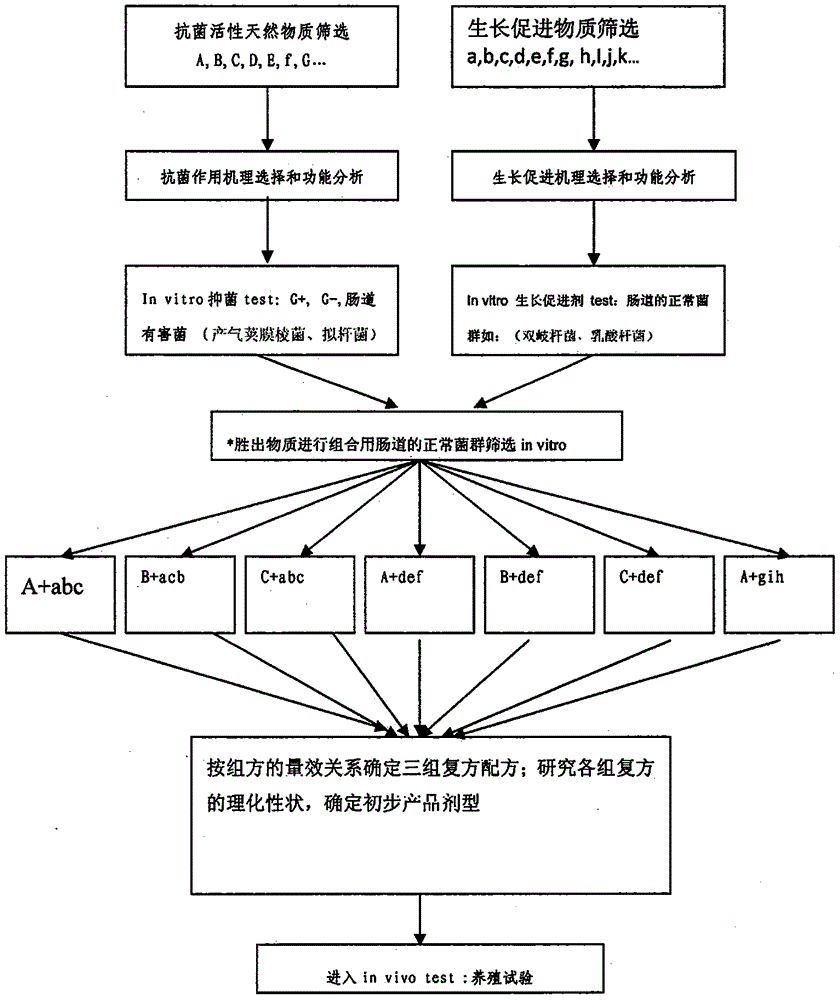

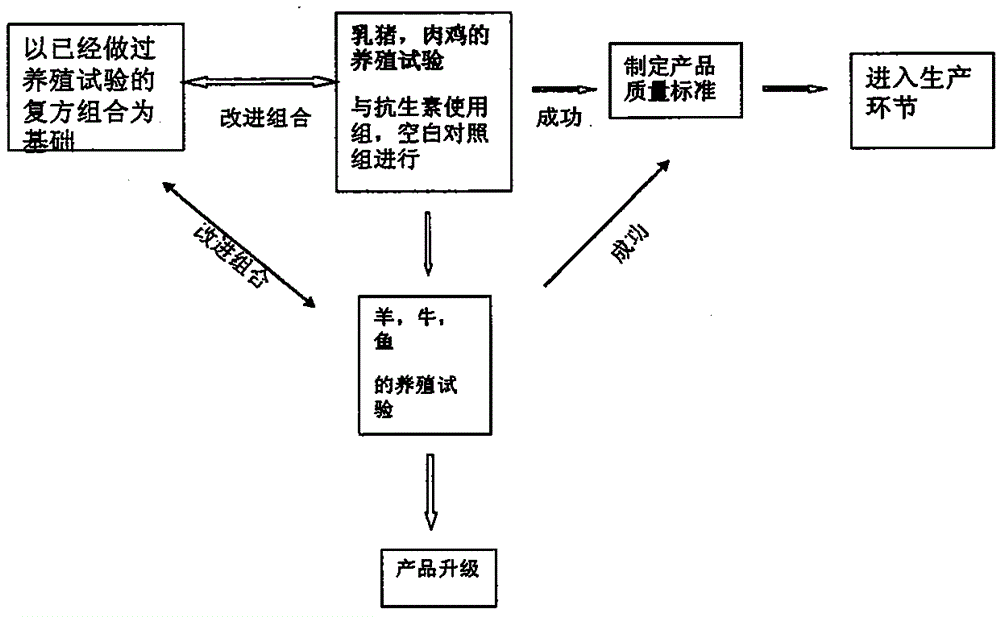

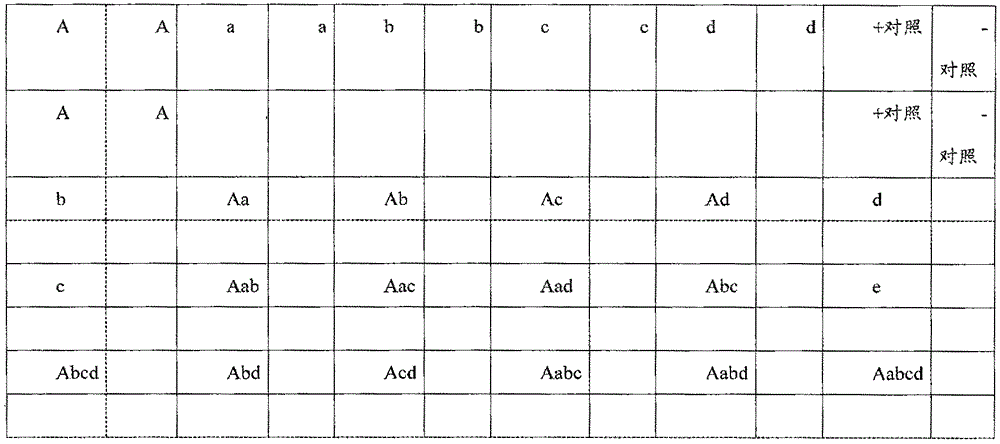

Antibiotic substitute feed additive, its formula, feed with antibiotic substitute feed additive and production method of feed with antibiotic substitute feed additive

InactiveCN105901305AWide range of functionsAdaptableAntibacterial agentsOrganic active ingredientsBiotechnologyTrace element

The invention relates to an antibiotic substitute feed additive, a formula of the antibiotic substitute feed additive, feed with the antibiotic substitute feed additive and a production method of the feed with the antibiotic substitute feed additive. The antibiotic substitute feed additive is a natural antibiotic component. The formula of the antibiotic substitute feed additive comprises a natural antibiotic component, trace elements, a compound enzyme, probiotics, prebiotics and an acid preparation. The invention also relates to the production method of the feed with the antibiotic substitute feed additive.

Owner:张兴龙 +1

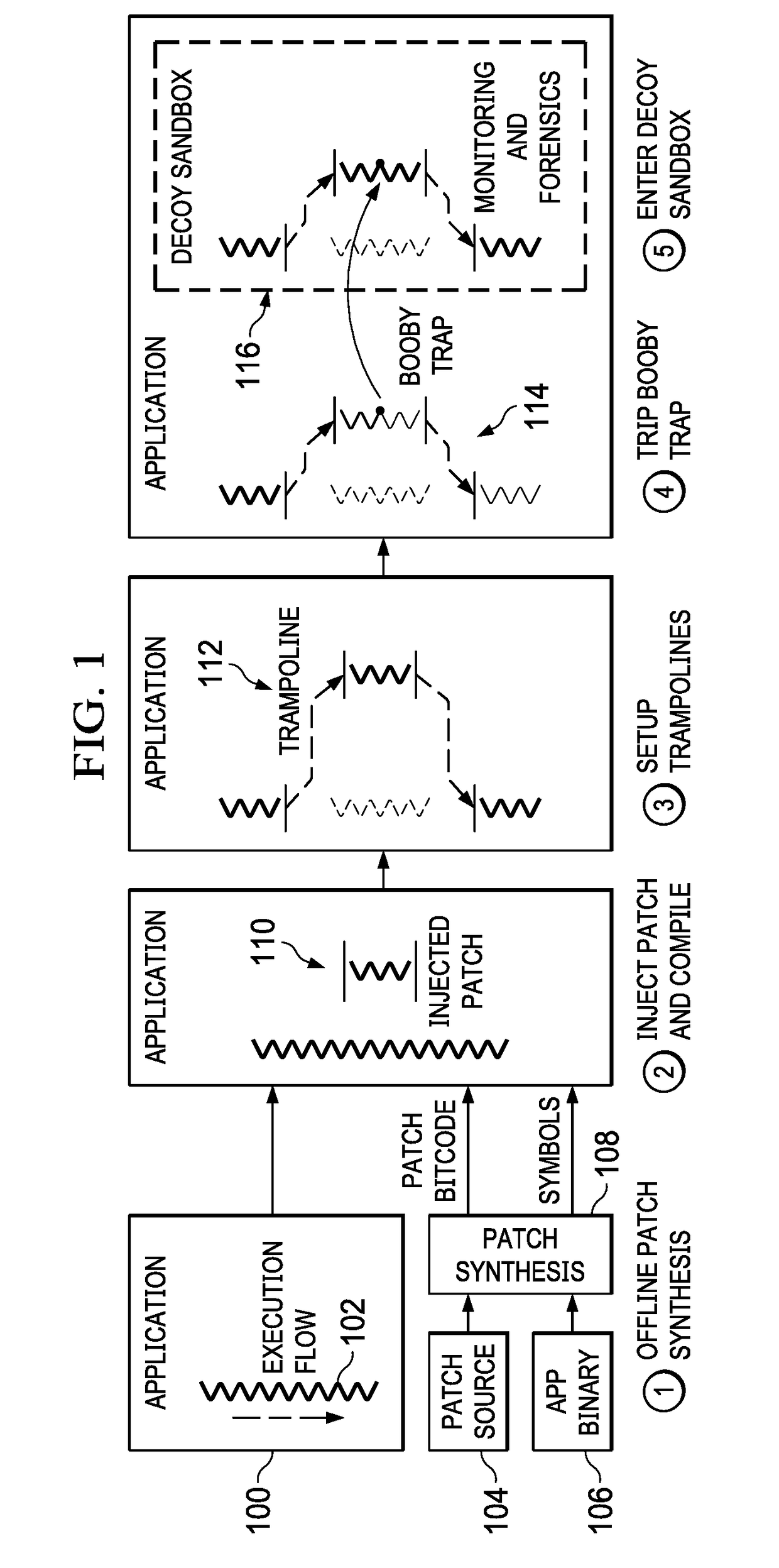

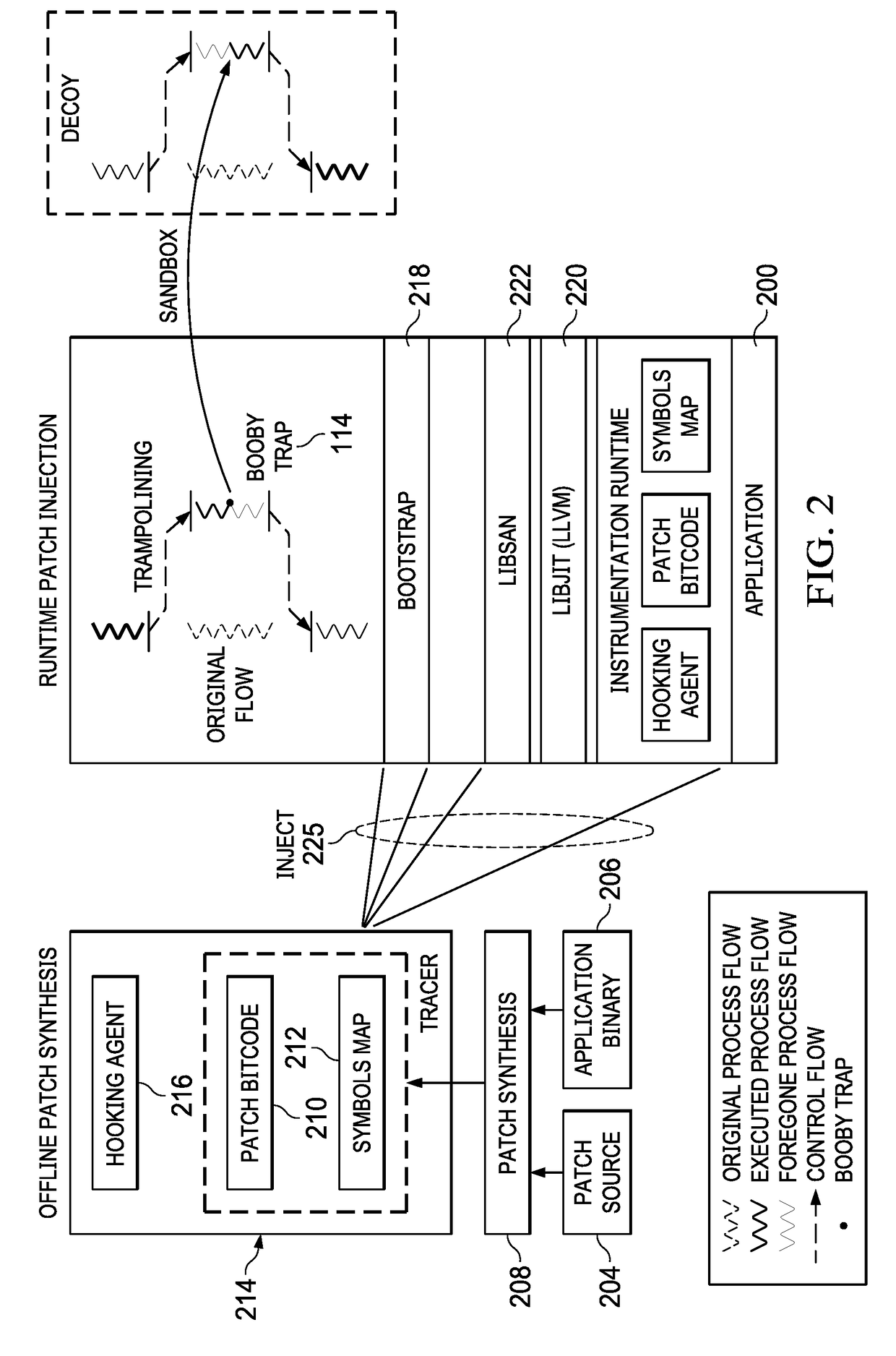

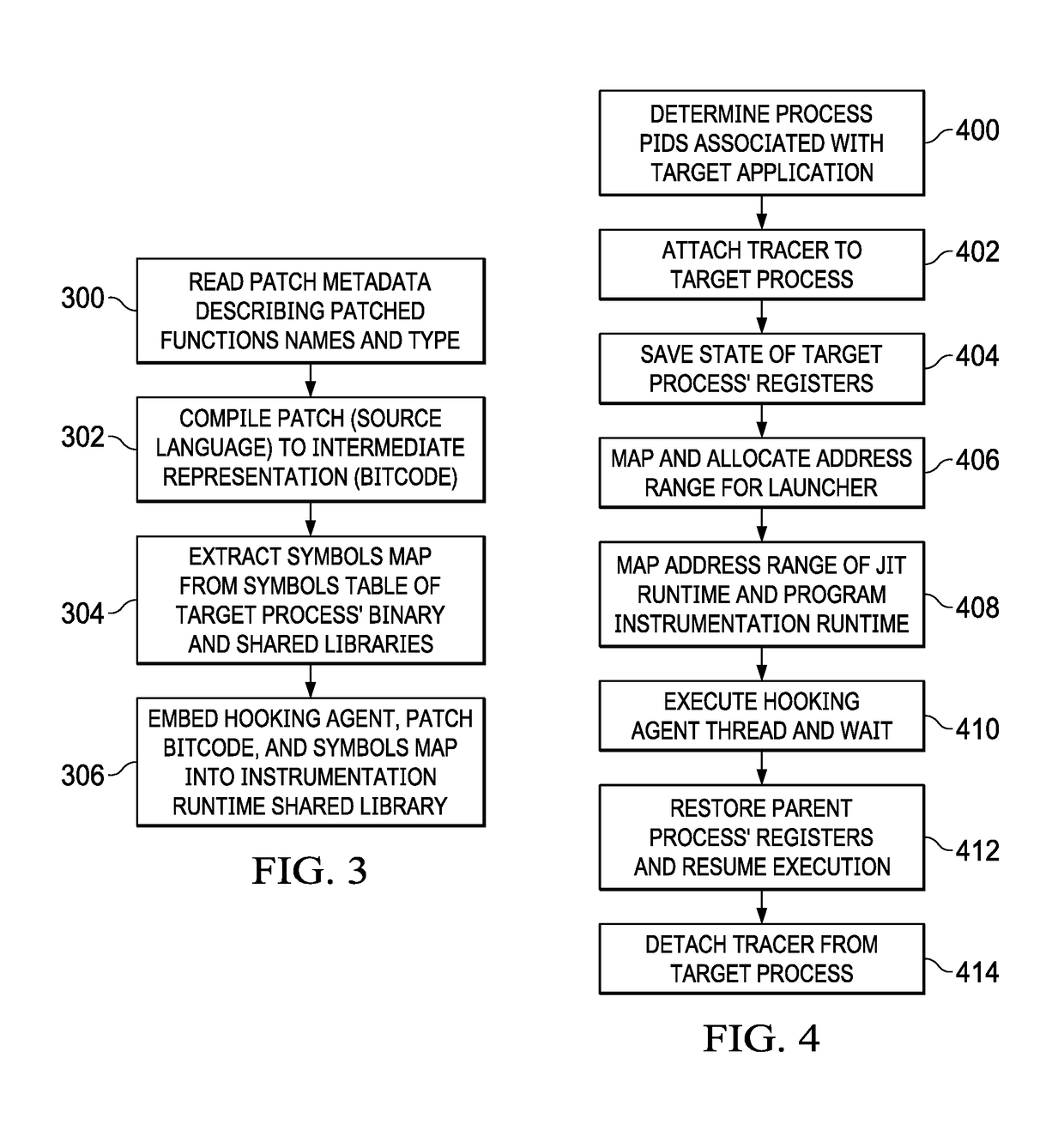

On-demand injection of software booby traps in live processes

ActiveUS20190068640A1Minimal performance overheadRapid deploymentTransformation of program codePlatform integrity maintainanceDecoyDowntime

This disclosure provides for rapid deployments of application-level deceptions (i.e., booby traps) to implant cyber deceptions into running legacy applications both on production and decoy systems, with no downtime and minimal performance overhead compared with the original application. An application-level booby trap is a piece of code injected into an application, and which provides an active defense or deception in response to an attack. A booby trap does not influence program execution under normal operation, and preferably elicits a response that can be defined by a security analyst. In operation, a booby trap is compiled into a bitcode using a patch synthesis process, and it is then injected into a running application, where it is compiled further into machine code, and linked directly with the existing application constructs. The original function also is modified with a function trampoline, and subsequent calls to the original function are then directed to the new function. As easily as a deception (provided by the booby trap) can be deployed, it can be removed easily, thereby leaving no trace in the application.

Owner:IBM CORP

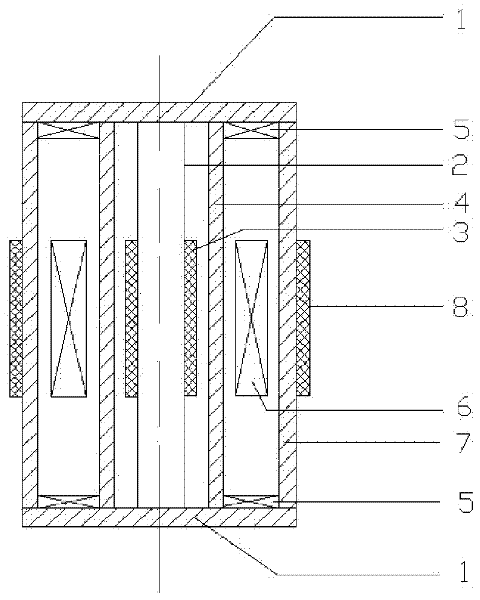

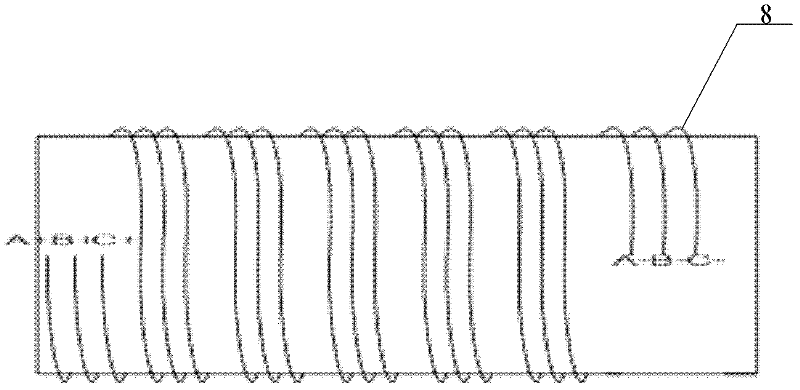

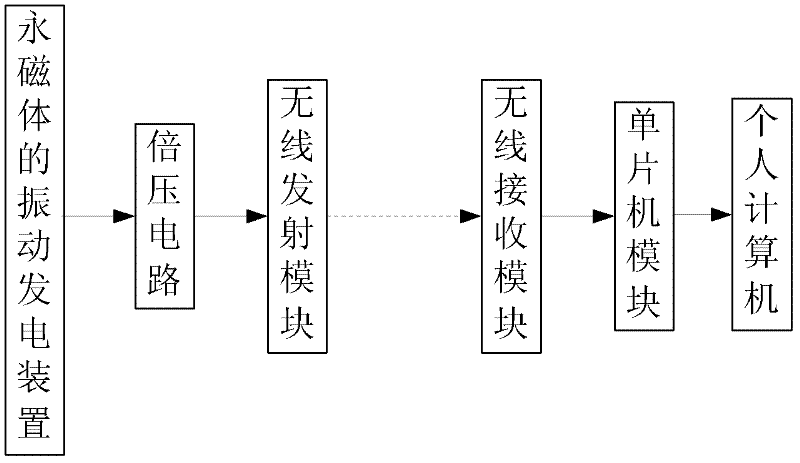

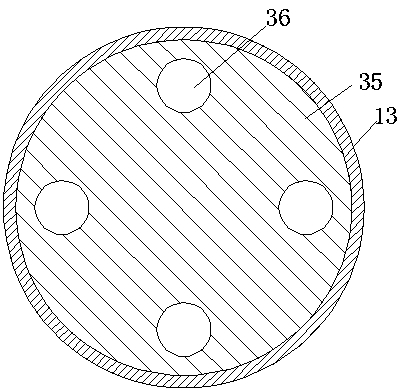

Electromagnetic vibration generating device of permanent magnet and application thereof in vibration detection system

InactiveCN102497133ASlow downSignificant progressElectromagnetic wave systemPiezoelectric/electrostriction/magnetostriction machinesPersonal computerSingle chip

The invention discloses an electromagnetic vibration generating device of a permanent magnet and application thereof in a vibration detection system, and relates to a device for recycling energy from mechanical vibration to realize energy utilization. The electromagnetic vibration generating device of the permanent magnet is composed of two outer cylinder end covers, a columnar hollow shaft, an inner side coil, a columnar inner cylinder, two fixed annular permanent magnets, a moving annular permanent magnet, a columnar outer cylinder and an outer side coil. According to the invention, the shortcomings that the existing vibration generating device only can collect the vibration energy in the vertical direction and the energy conversion efficiency from the vibration energy to electric energy is relatively low are overcome; the electromagnetic vibration generating device of the permanent magnet is used as a unique power supply of the vibration detection system so that the vibration detection system becomes a self-powered vibration detection system; and the self-powered vibration detection system is combined with a voltage doubling circuit, a wireless transmitting module, a wireless receiving module, a single-chip module and a personal computer, thus the inconvenience of arranging a power supply and a lead outside the traditional vibration detection device is overcome, and a worker can master the vibration conditions without arriving at the site.

Owner:HEBEI UNIV OF TECH

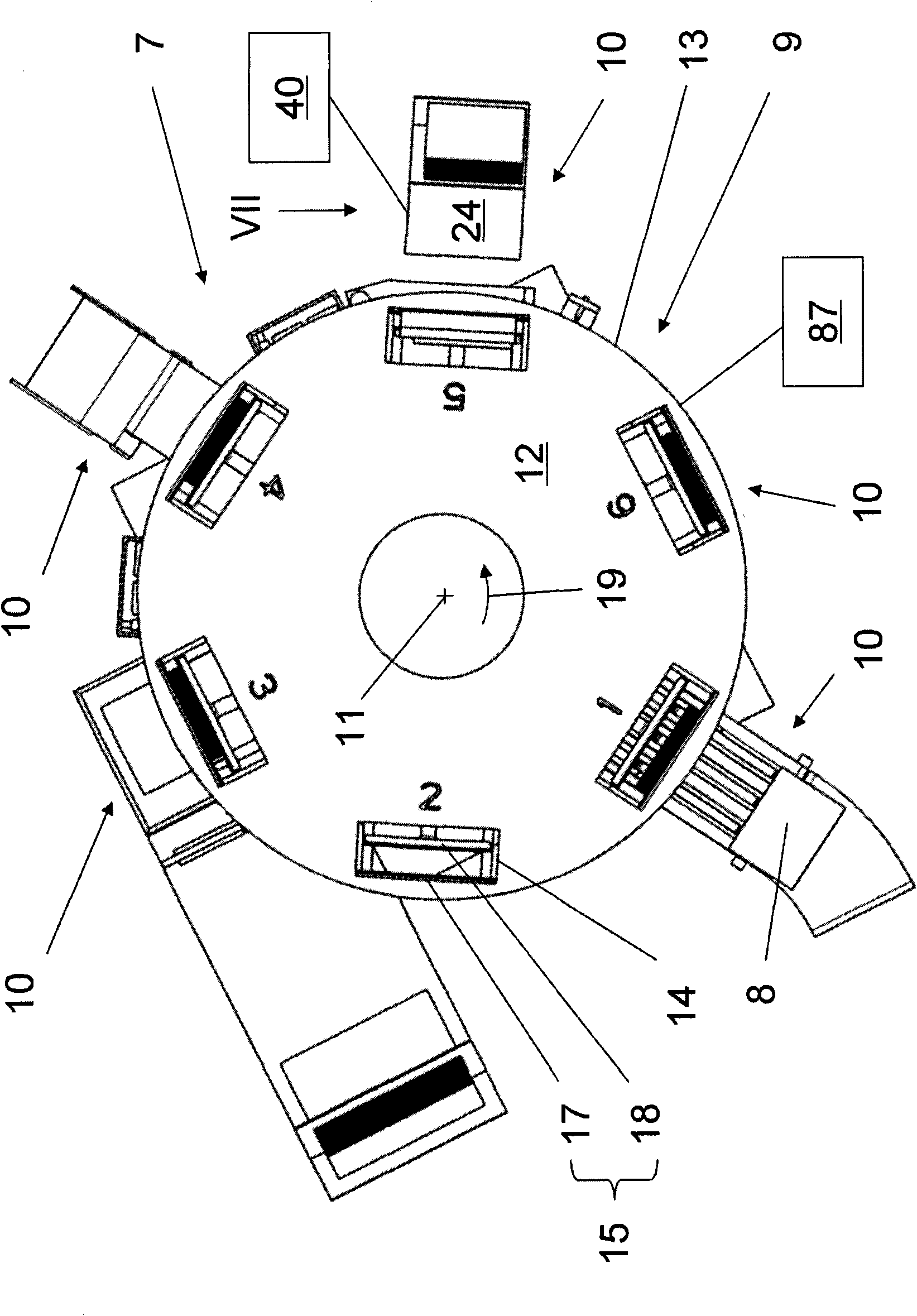

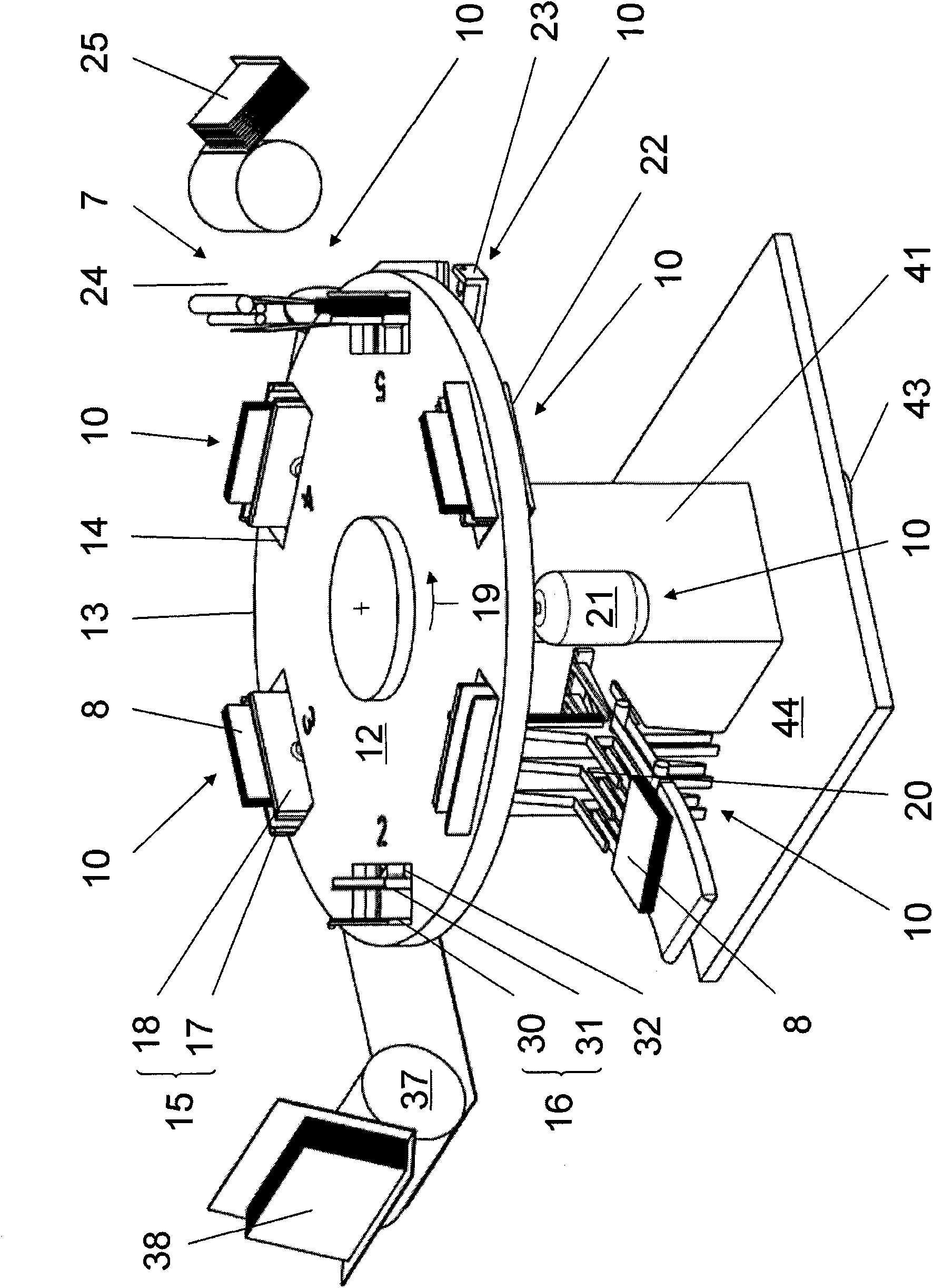

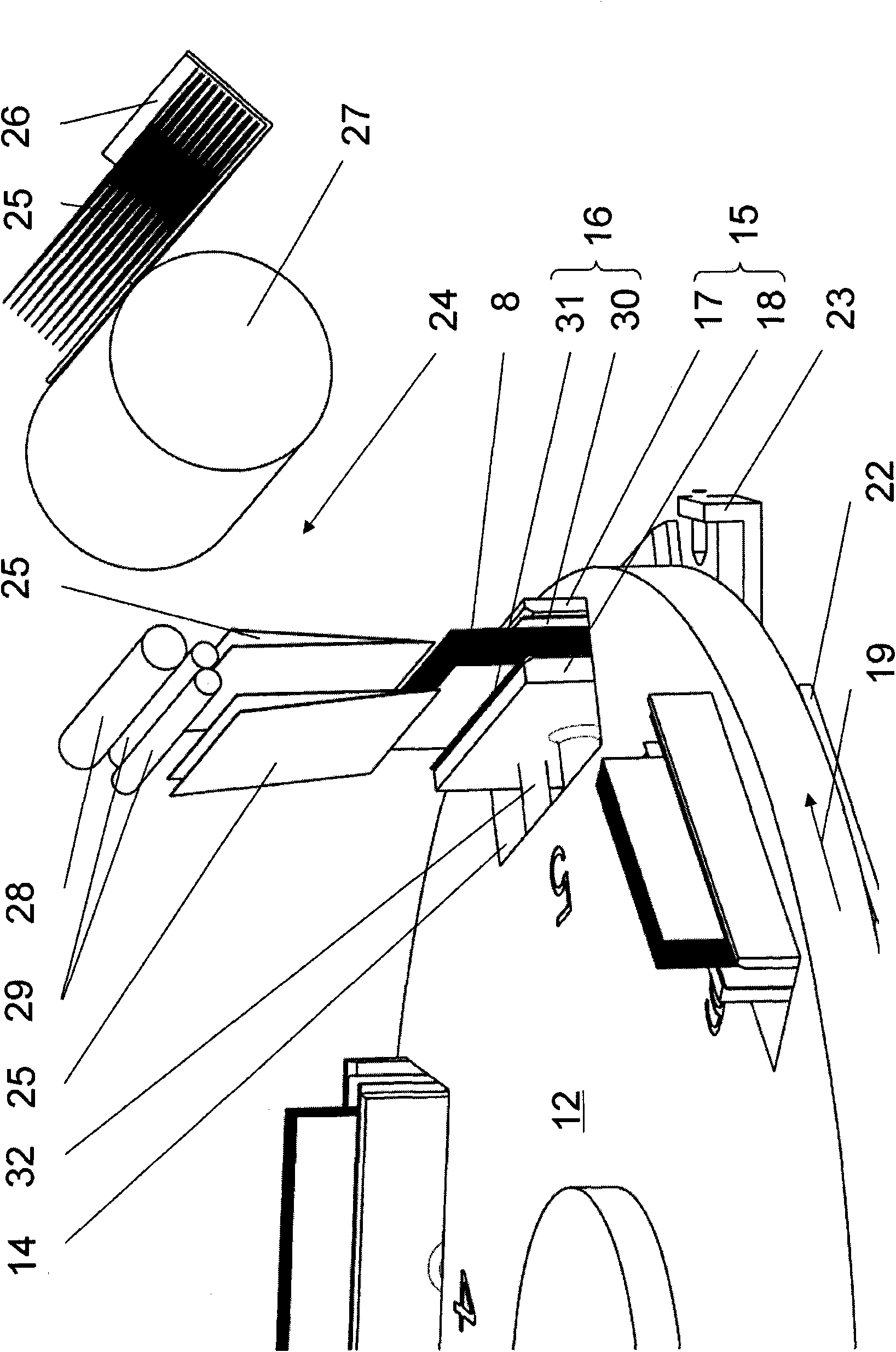

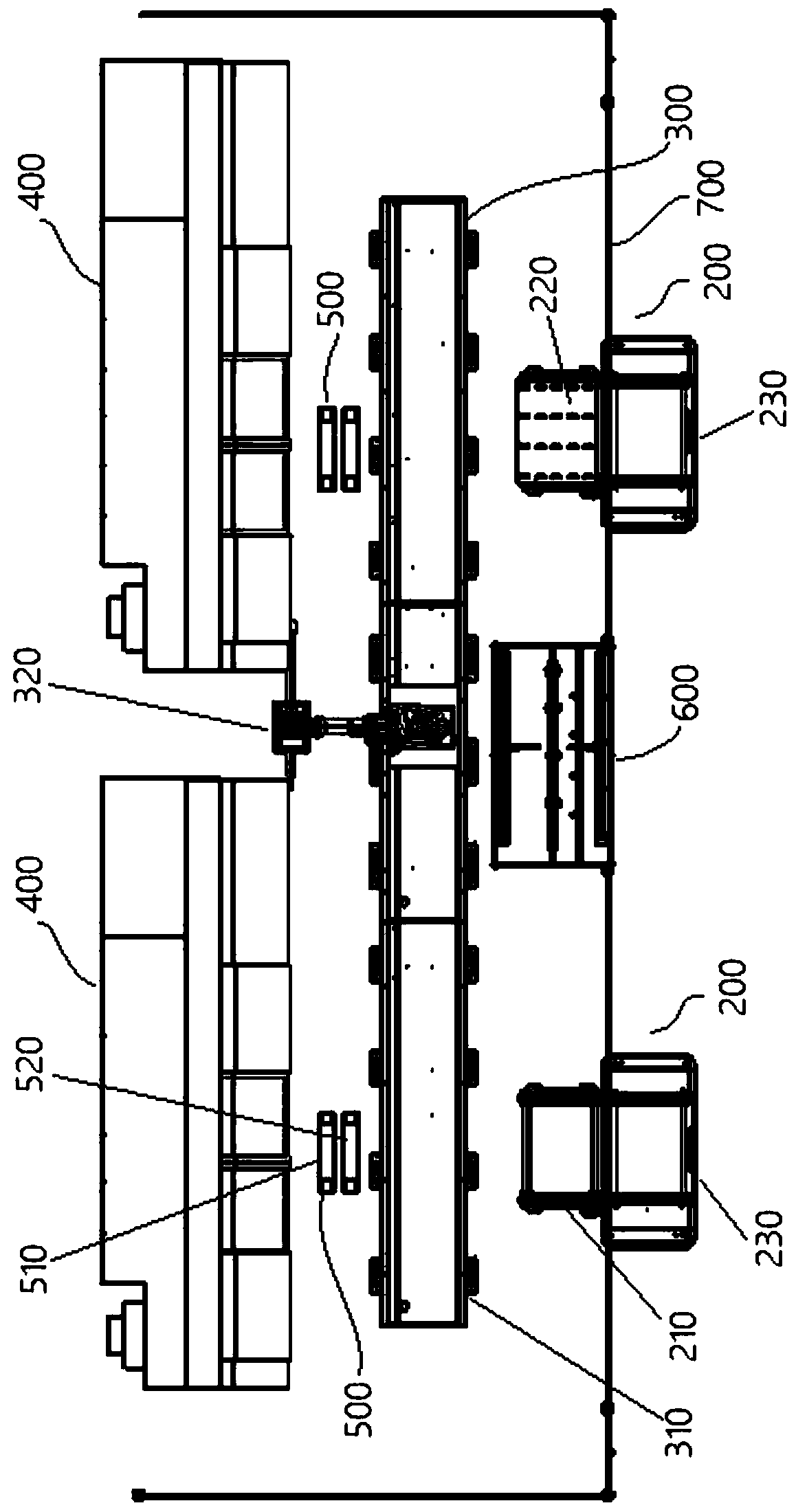

Binder to process book blocks and method of binding

A perfect binder for processing book blocks, including: a conveying device adapted to convey the book blocks along a closed circulating path, the conveying device including a plurality of clamping devices each adapted to convey a book block; and a plurality of processing stations arranged successively along the closed circulating path. One of the processing stations includes a spine-processing station, and another one of the processing stations includes an end sheet feed station following the spine-processing station. According to another aspect of the invention there is provided a method forthe perfect binding of book blocks, comprising: conveying the book blocks around a closed circulating path with each book block clamped in a clamping device of a conveying device, wherein a pluralityof processing stations are arranged successively along the closed circulating path; milling the spine of each book block at one of the processing stations; and subsequently, inserting at least one endsheet into the clamping device at a downstream end sheet feed station.

Owner:MULLER MARTINI HLDG

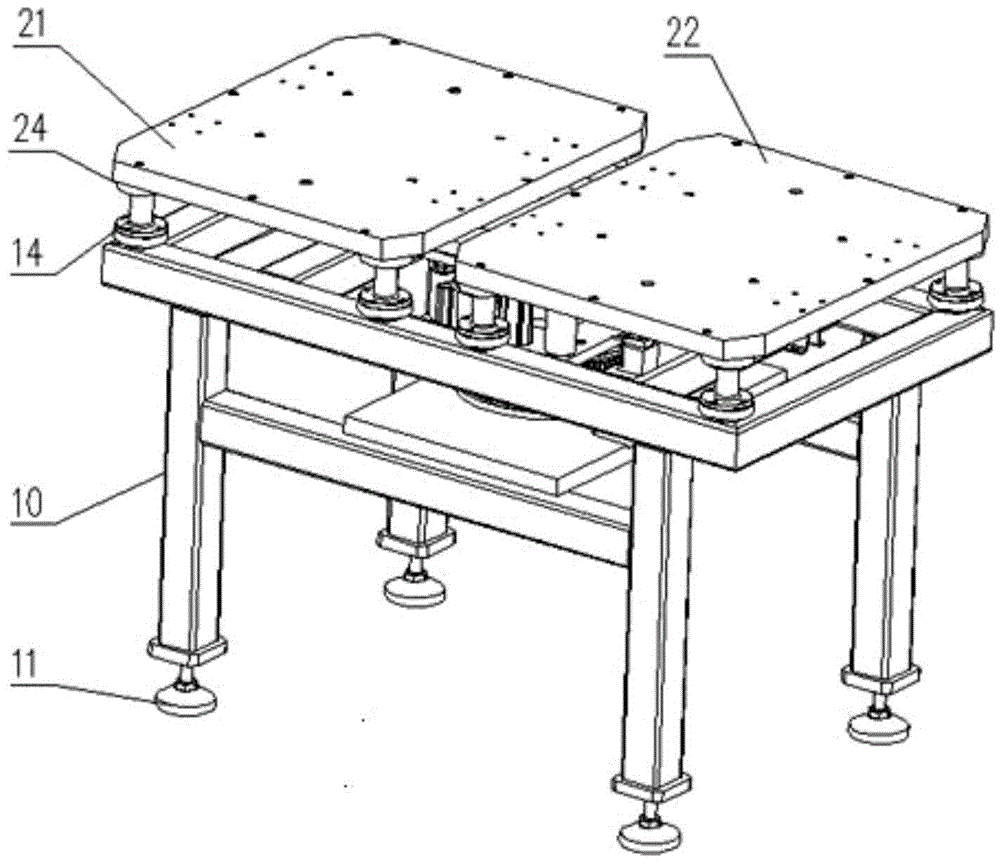

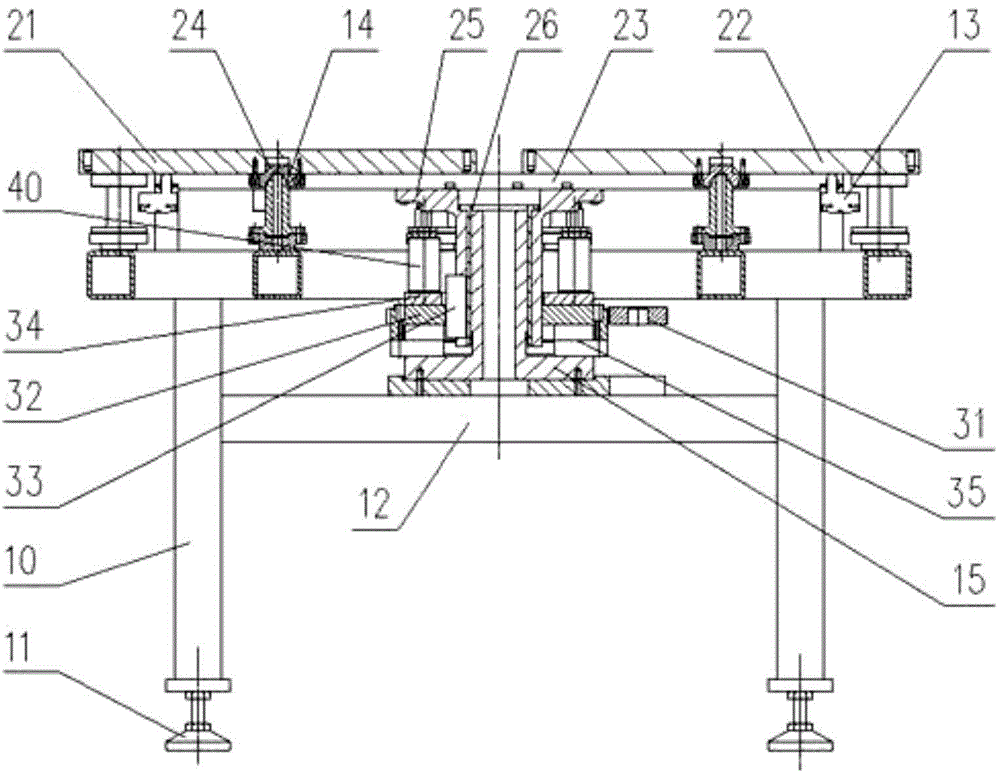

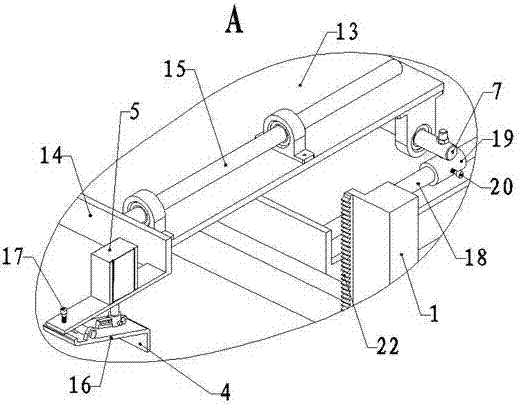

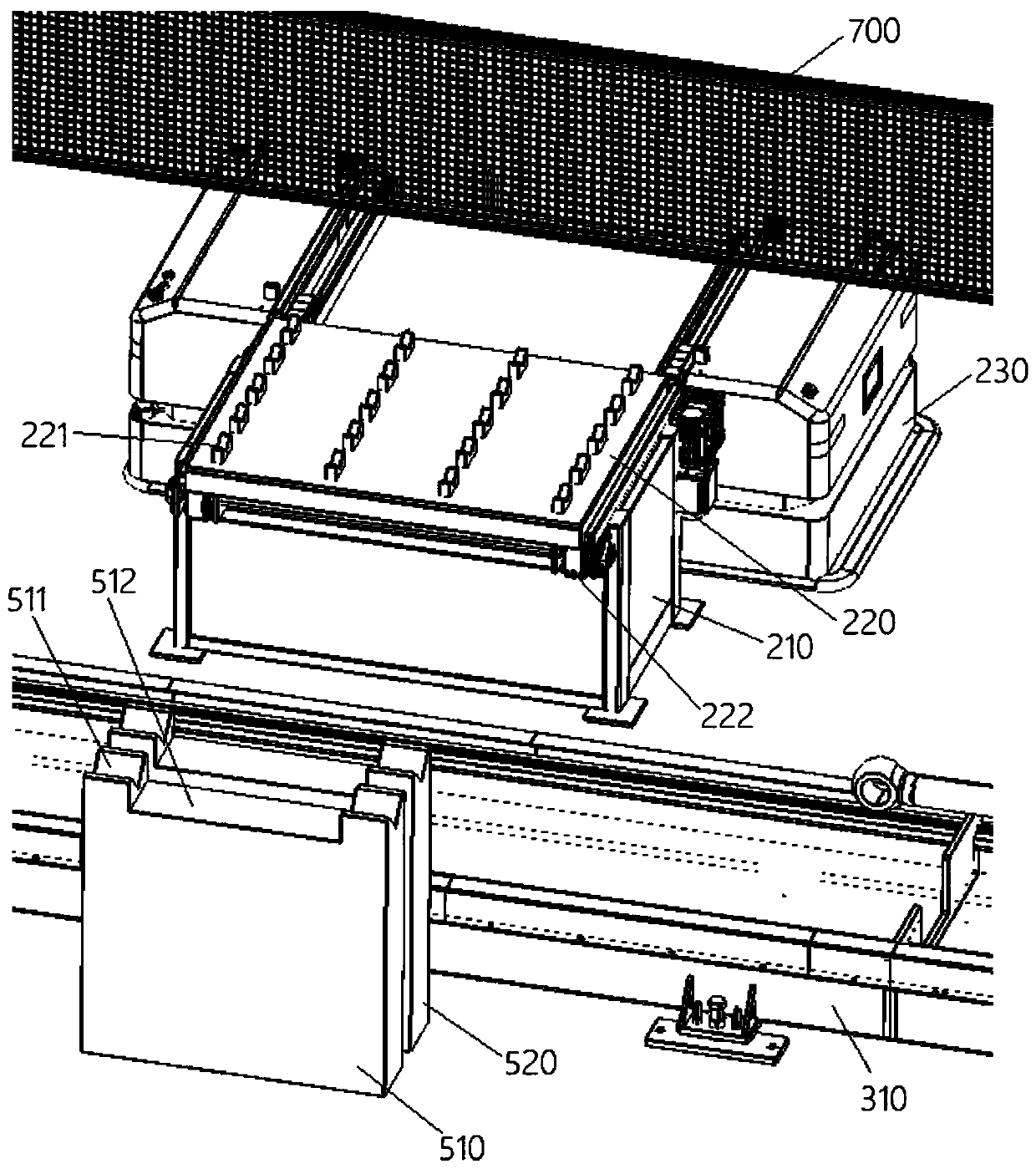

Double-exchange workbench

The invention belongs to the technical field of automation equipment, and in particular relates to a double-exchange workbench. The double-exchange workbench comprises a support and a workbench, wherein the workbench is arranged at the top of the support; a rotary standard shaft vertical to the workbench is fixedly arranged on the support, the support is provided with a transmission mechanism and a supporting mechanism, the transmission mechanism can drive the workbench to rotate around the rotary standard shaft, the supporting mechanism can drive the workbench to slide along the rotary standard shaft up and down, the support is provided with a sensing switch capable of detecting the rotation position of the workbench, and a locating device is arranged between the workbench and the support. According to the double-exchange workbench disclosed by the invention, a motor drives gears to do transmission, and a lifting air cylinder, a locating tapered hole and a locating tapered shaft are matched, so that the exchange and the location of the workbench are realized; the structure is compact, the location precision is high, the manufacturing cost is low, and the application range is wide.

Owner:WUHAN FINGU ELECTRONICS TECH

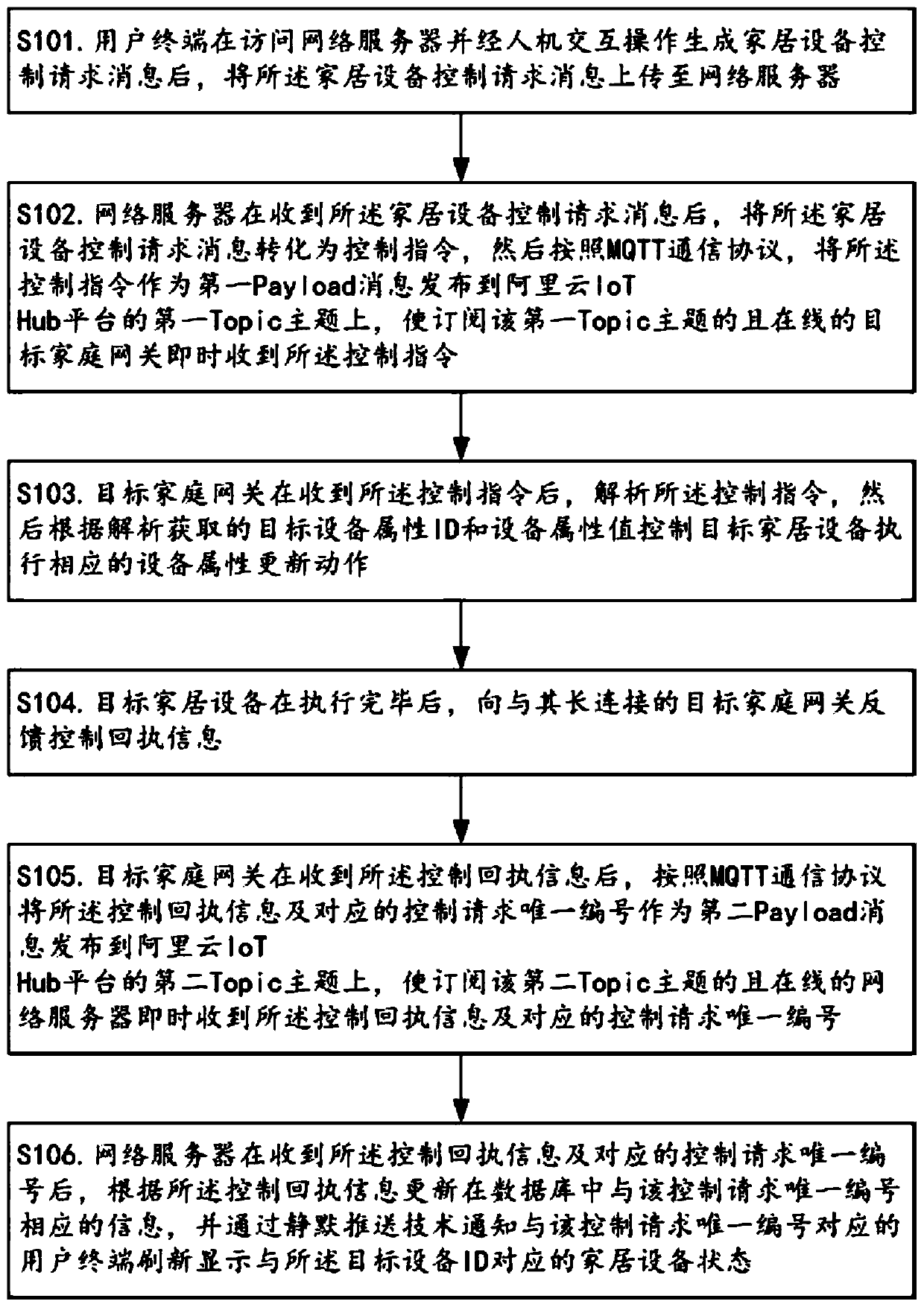

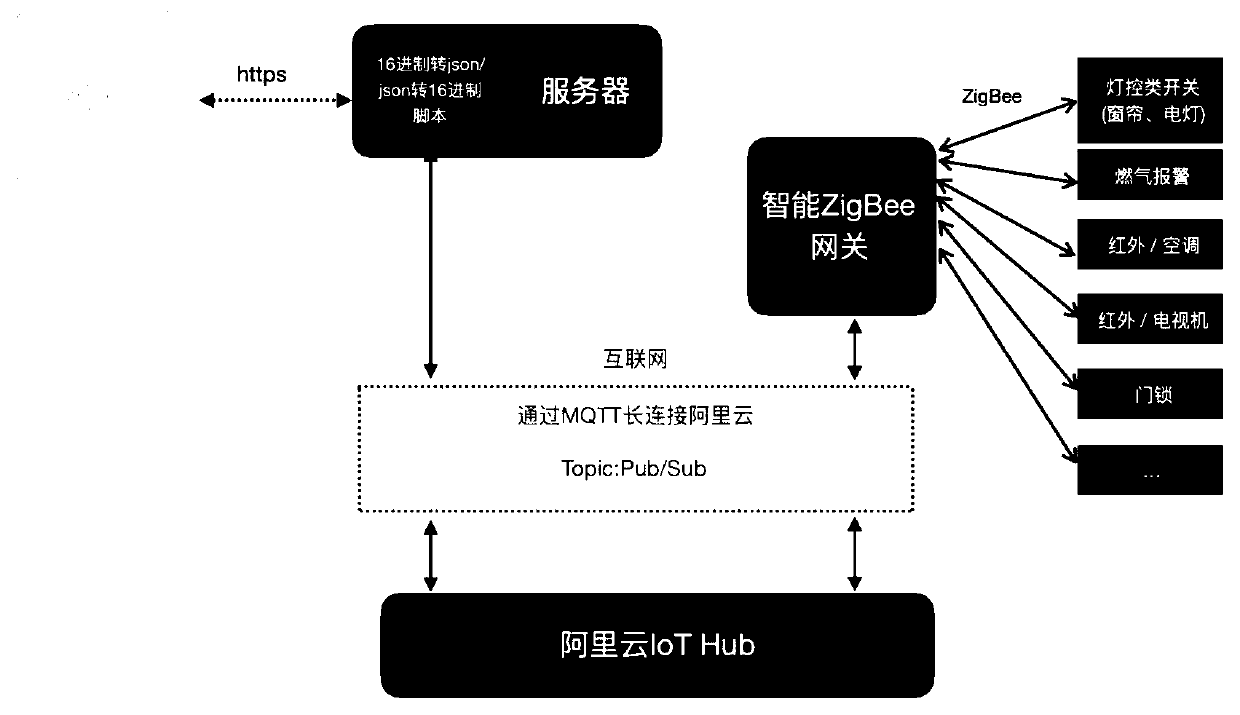

Smart home Internet of Things communication method based on AliCloud IoT Hub platform

ActiveCN110912789AMeet timeliness needsTimeliness demand guaranteeIndividual entry/exit registersSecurity arrangementTelecommunicationsInformation transmission

The invention relates to the technical field of smart home and discloses a smart home Internet of Things communication method based on an AliCloud IoT Hub platform. On one hand, subscription message transmission between a network server and a home gateway is realized on an AliCloud IoT Hub platform by adopting an MQTT communication protocol. The timeliness of information transmission can be guaranteed by using the communication characteristics of the MQTT communication protocol, so that after a user terminal sends out the control request, target household equipment can execute and respond mostquickly, the receipt receiving time is shortened to the greatest extent, the use state of the household equipment can be updated quickly, and the timeliness requirement of a user is met; and on the other hand, the home gateway only needs to subscribe to one publish theme and one subscribe theme to complete the operation of a plurality of devices in the room, so that the purposes of economy, practicability and easiness in popularization can be achieved. In addition, the invention has the characteristics of gateway activation automation, convenience in equipment addition, easiness in multi-house management and the like, can provide a simple operation interface, and is convenient to operate.

Owner:无锡青起长升智能科技有限公司

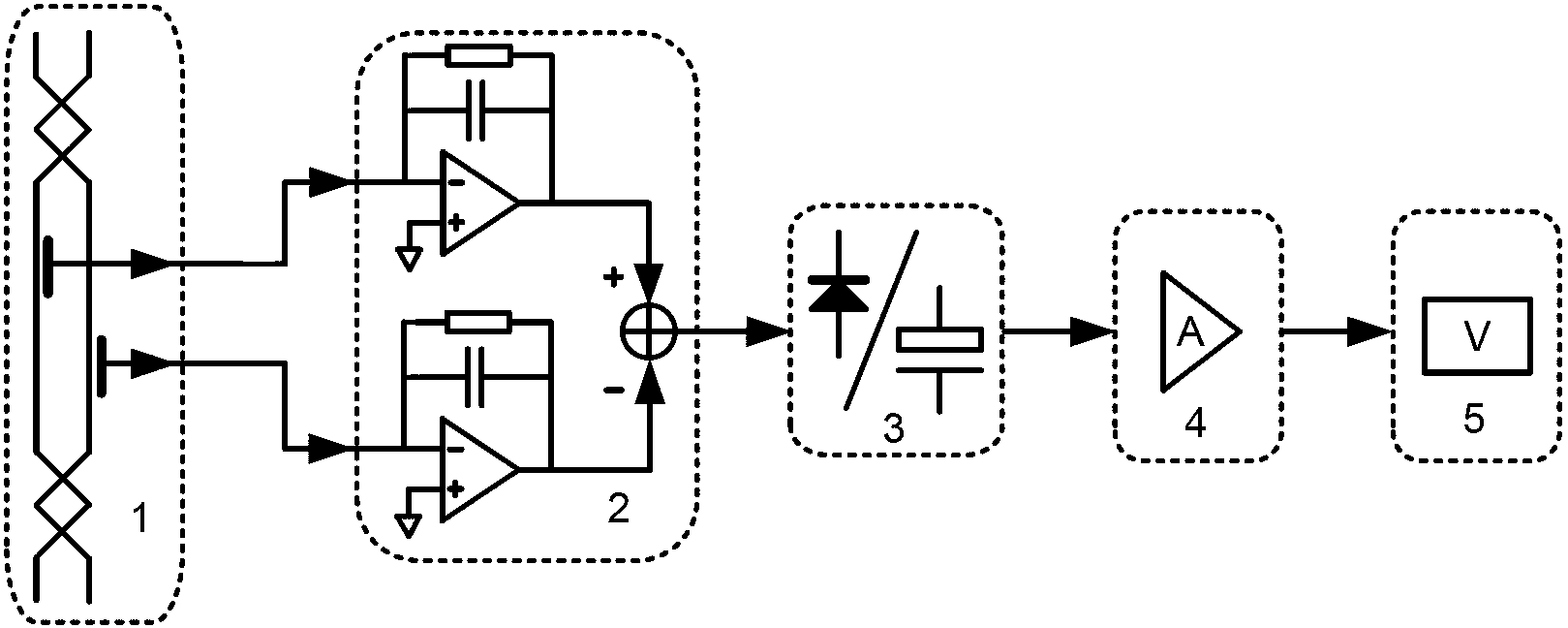

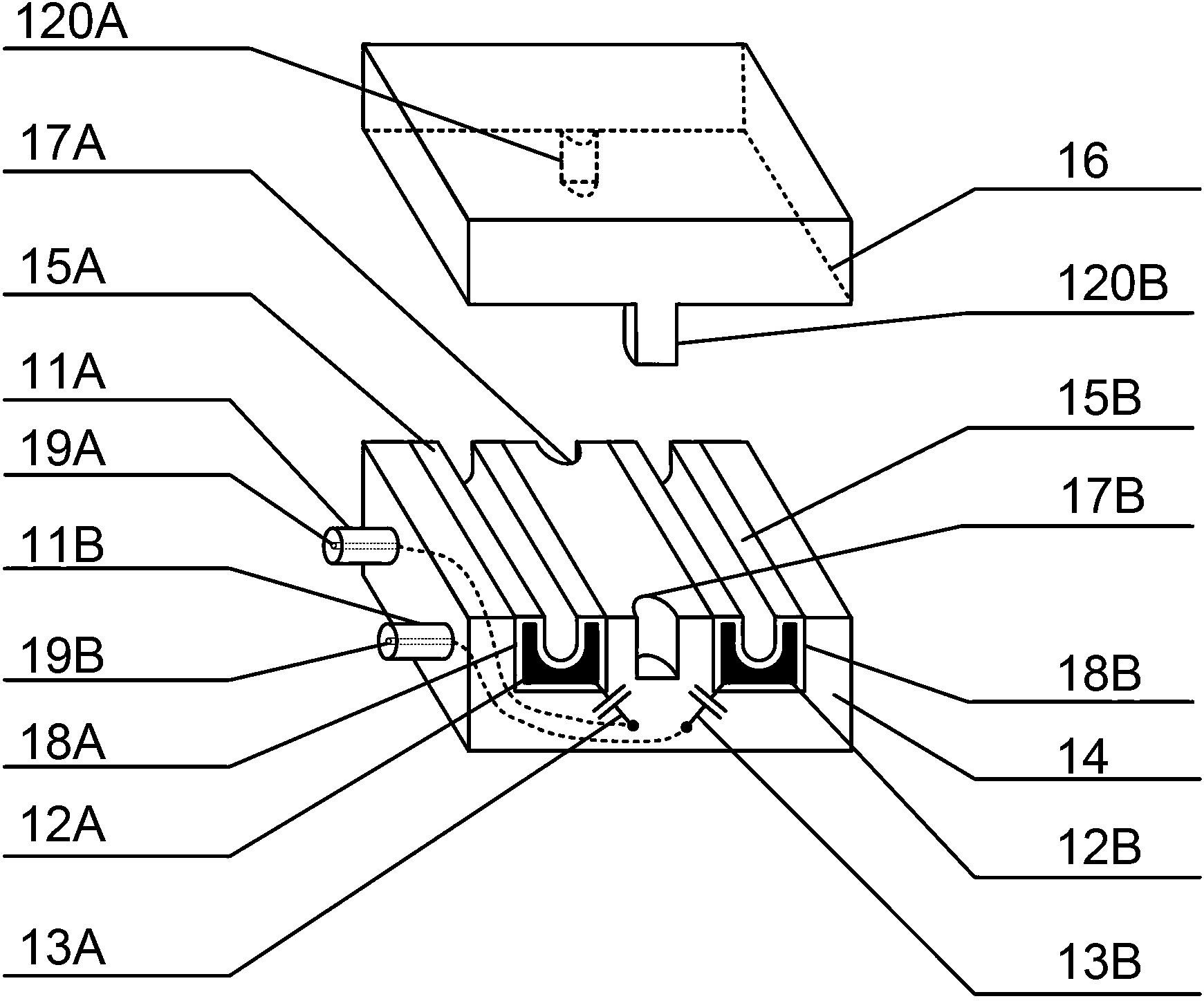

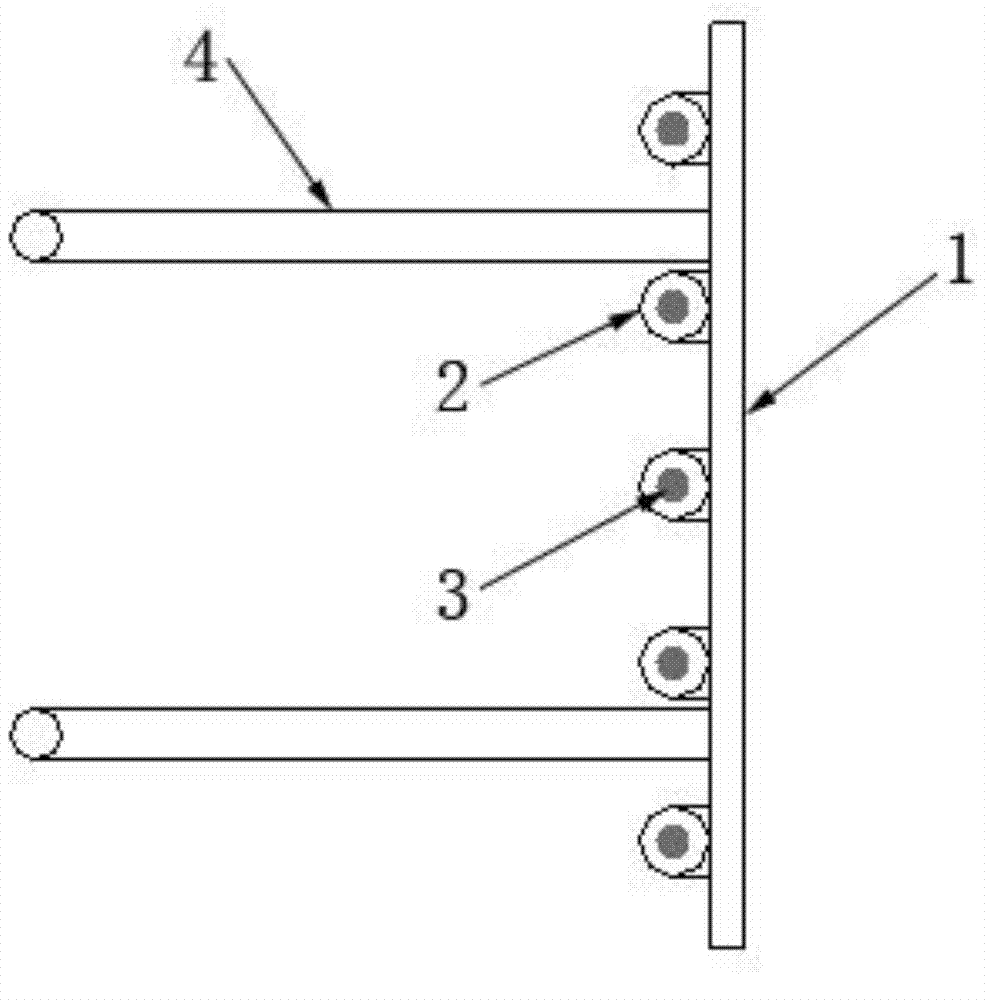

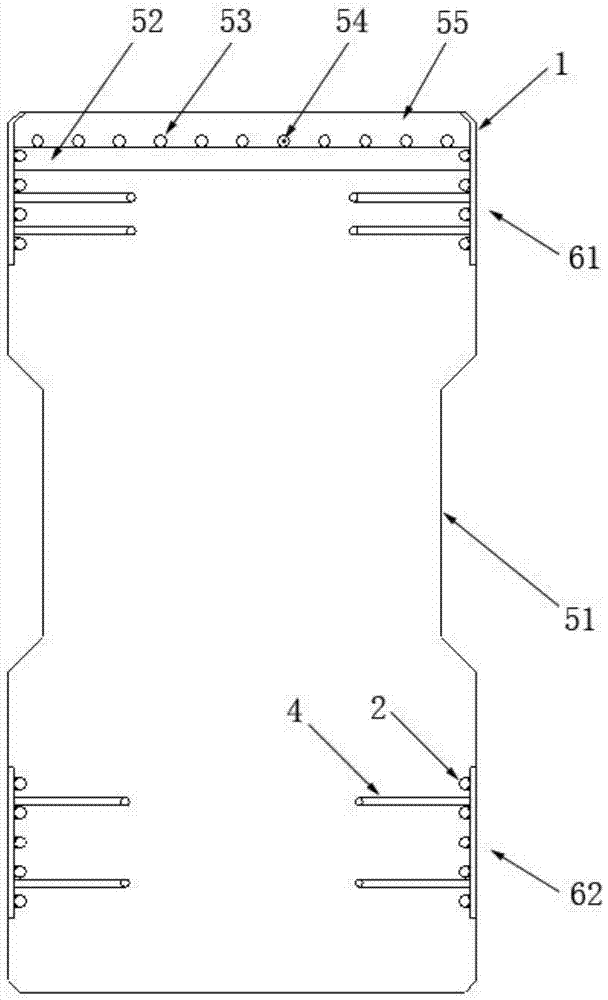

Non-contacting-type power frequency voltage measuring device

InactiveCN103257263AFree from destructionNo downtimeCurrent/voltage measurementMeasurement instrument housingEngineeringElectric cables

The invention discloses a non-contacting-type power frequency voltage measuring device. The problems that an existing measuring device is in electric contact with a tested electric cable, so that operation is not convenient, and potential safety hazards exist are mainly solved. The non-contacting-type power frequency voltage measuring device comprises a non-contacting-type measuring clamp (1), a difference charge amplifier (2), a rectifier filter (3), a gain regulator (4) and a meter head (5). The non-contacting-type measuring clamp (1) is based on the near field radiation principle, a near field radiation signal of the tested electric cable is formed by coupling in an electromagnetic coupling mode, the power frequency voltage effective value of the tested electric cable is measured through a circuit, and a non-contacting-type measuring process is completed. The device is not in electric contact with the tested electric cable and has the advantages of being simple in operation and complete, halting is of no need, the device can be used for system testing, debugging and fault diagnosis in the field of a distributed measuring and controlling system and an electric electronic system.

Owner:XIDIAN UNIV

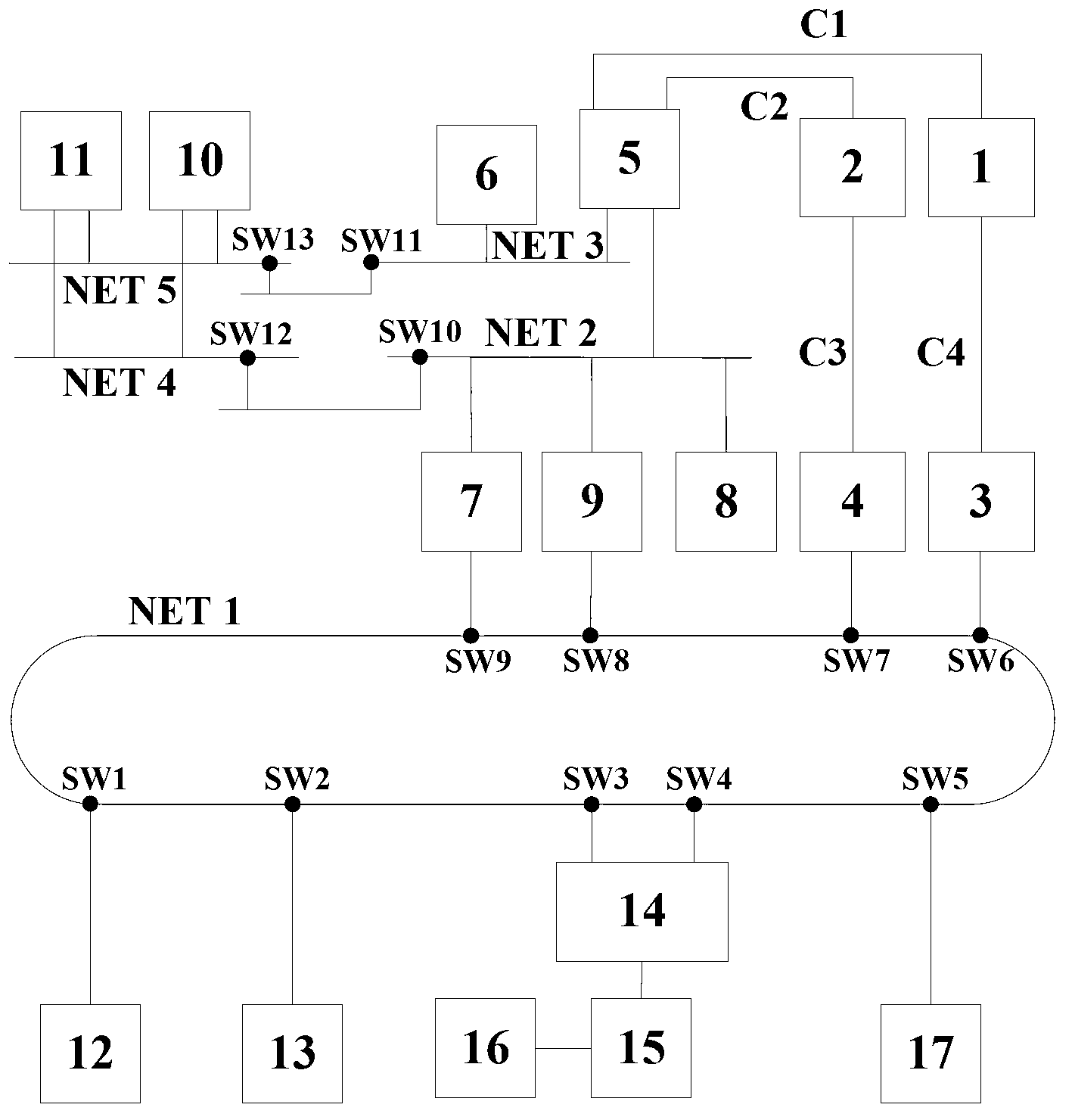

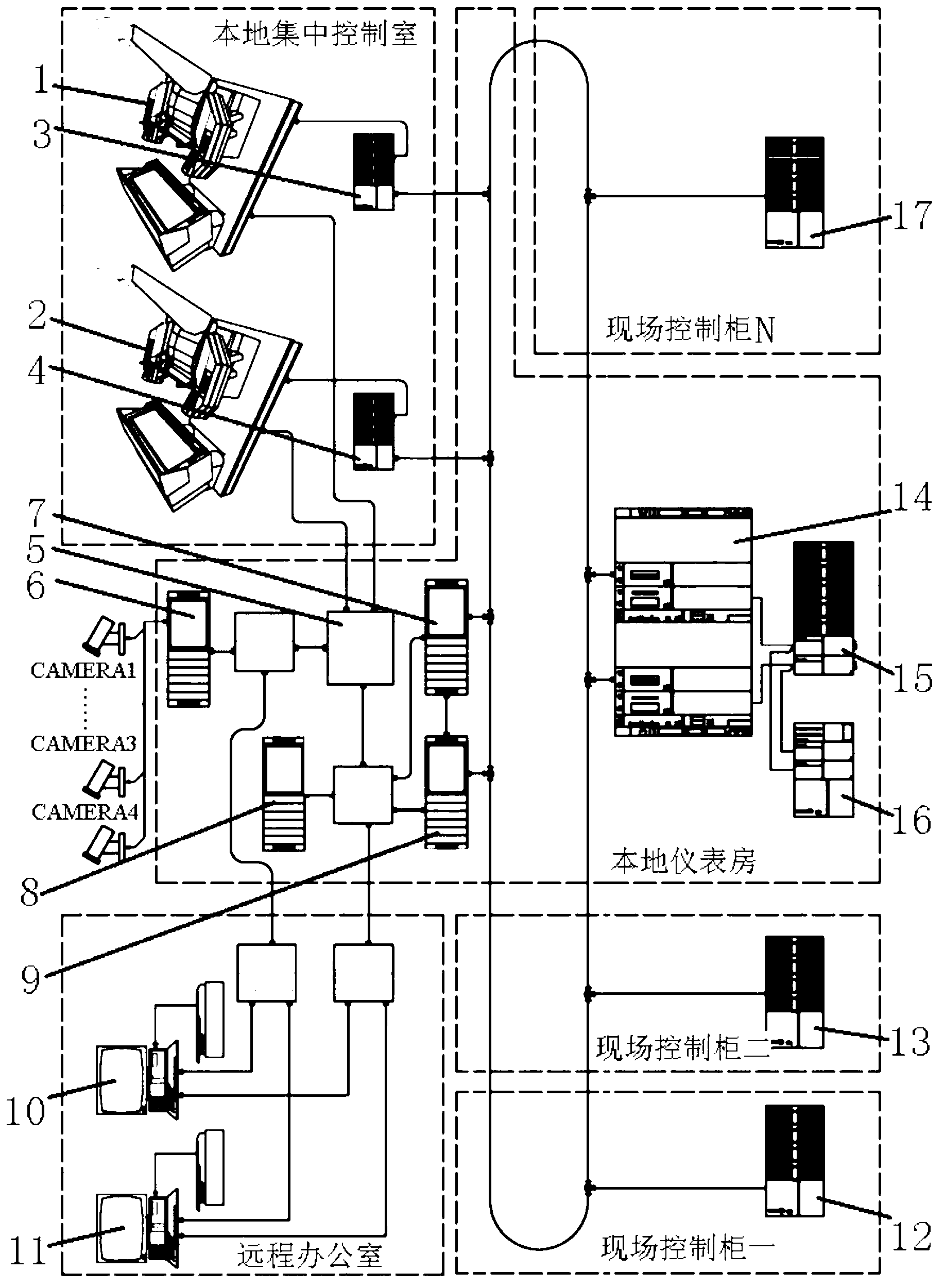

Drilling machine integrated loop network communication control system based on PLC

ActiveCN103324133AMeet the transmissionFully automatedTransmissionProgramme control in sequence/logic controllersControl systemDatabase server

The invention discloses a drilling machine integrated loop network communication control system based on a PLC. The drilling machine integrated loop network communication control system based on the PLC comprises a master operational console, wherein the master operational console is respectively connected with a master operational console PLC station and a client end, the client end is connected with a network NET2 and a network NET3 simultaneously, the network NET3 is connected with a CCTV controller, the network NET2 is connected with an auxiliary server, a database server and a master server, the network NET3 is connected with a network NET5, the network NET5 is connected with a master long-distance monitoring station, the network NET2 is connected with a network NET4, the network NET4 is connected with a master long-distance monitoring station, the master operational console PLC station and the master server are further connected with a network NET1, and the network NET1 is respectively and correspondingly connected with a first PLC control station and a 400H redundancy control station. The drilling machine integrated loop network communication control system based on the PLC achieves automation, intellectualization and networking of the control system, and is good in real-time performance and stable and reliable in communication service.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

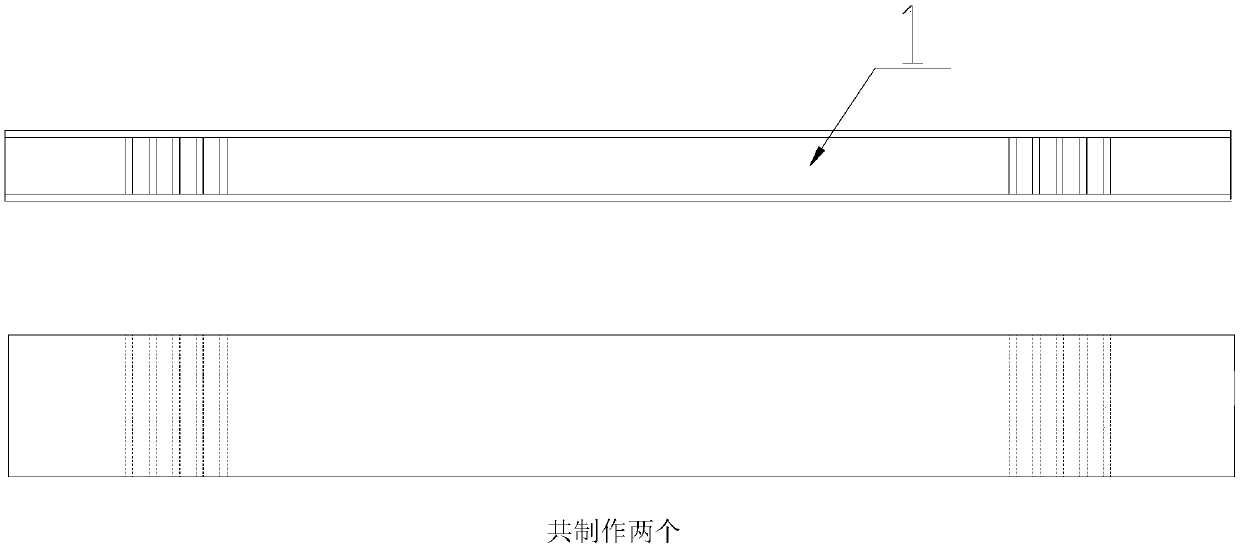

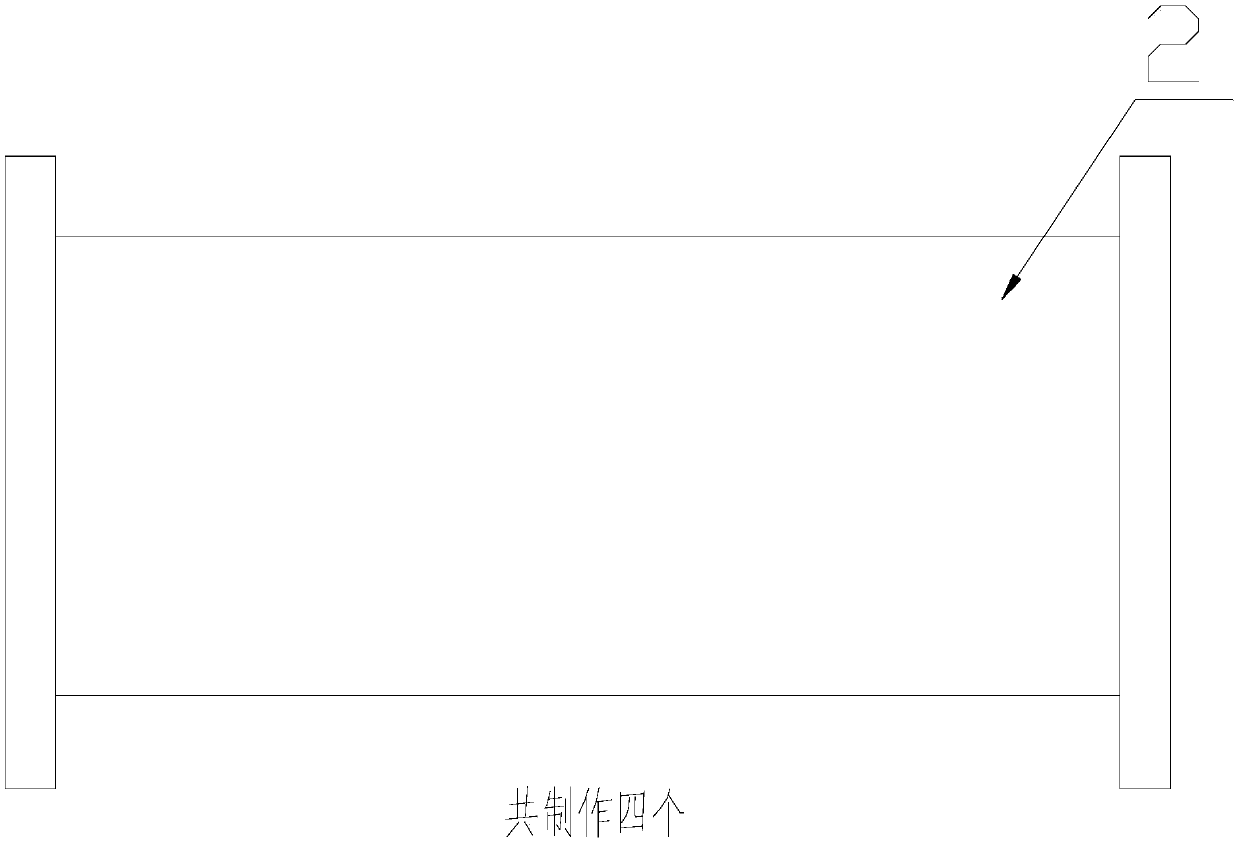

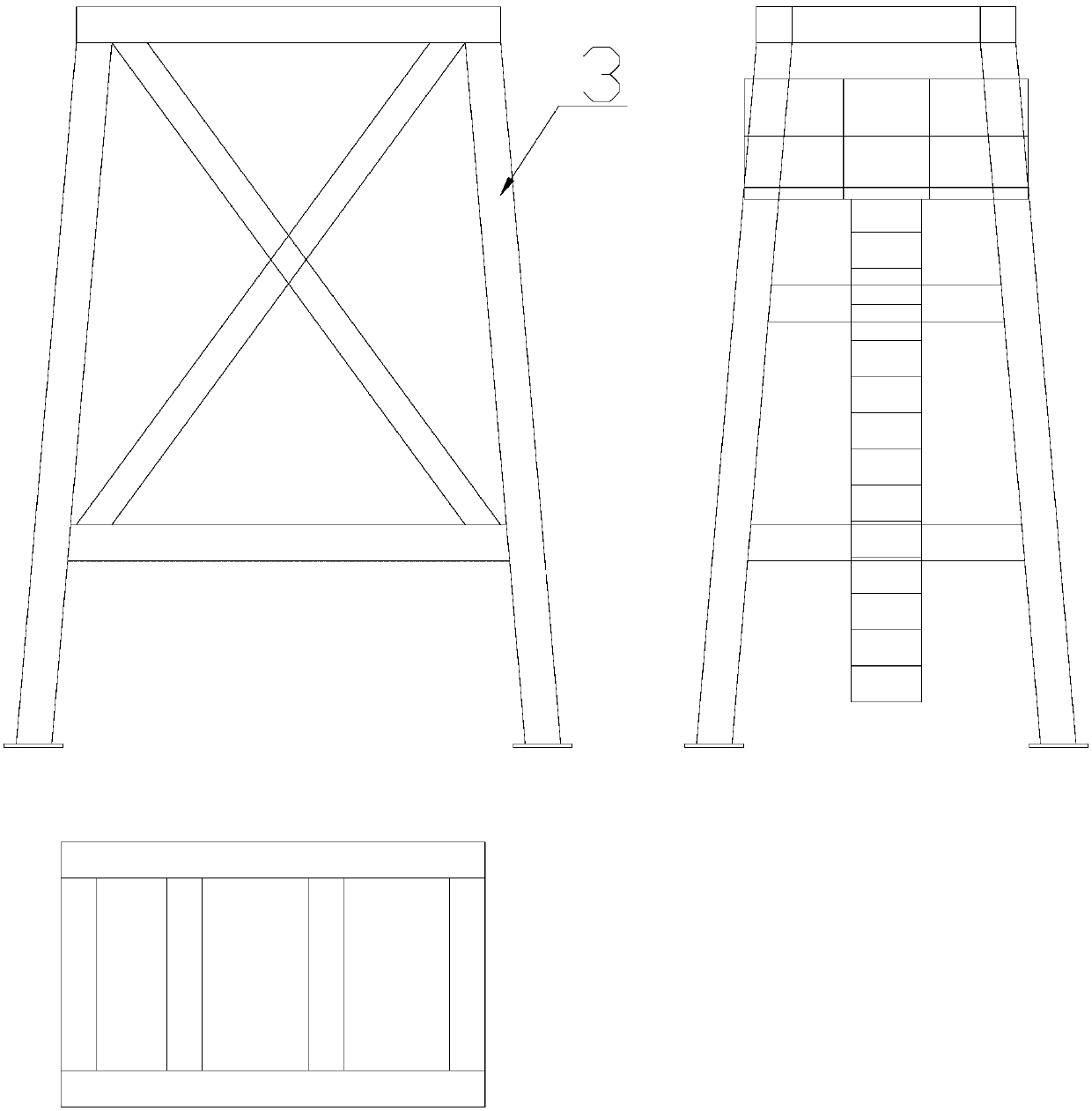

Construction method for sliding and replacing whole body of jacking and revolving bearing of revolved body of stacker-reclaimer

The invention discloses a construction method for sliding and replacing a whole body of a jacking and revolving bearing of a revolved body of a stacker-reclaimer, and belongs to the technical field of replacing components of the stacker-reclaimer in iron-smelting raw material yards. The construction method comprises the following steps: before machine halt construction, firstly manufacturing jack supporting beams, safe piles and a stirrup, mounting the jack supporting beams, and mounting the stirrup; selecting hydraulic jacks, and erecting the selected hydraulic jacks; sealing the whole body of the revolved body of the stacker-reclaimer, manufacturing a sliding device of the revolving bearing, mounting the manufactured sliding device, and dismounting and removing components which have influence on the horizontal sliding of the revolving bearing; sliding the whole body of the jacking and revolving bearing of the revolved body, replacing the slid whole body of the jacking and revolving bearing of the revolved body, and mounting the components which have influence on the horizontal sliding of the revolving bearing. The construction method has the advantages that the problems that a large-scale vehicle type crane needs to be used during replacing the revolving bearing of the stacker-reclaimer in the iron-smelting raw material yards, the construction time is long, the occupied site is large, the construction cost is high and influence on the production is great; the method is simple and easy to operate, and the construction cost is reduced; the construction site is reduced, the whole construction time of jacking and sliding is shortened, and influence on the production is reduced; double safety facilities of the sealed whole body and the safe piles are adopted, so that the safety guarantee is supplied.

Owner:BEIJING SHOUGANG CONSTR GROUP

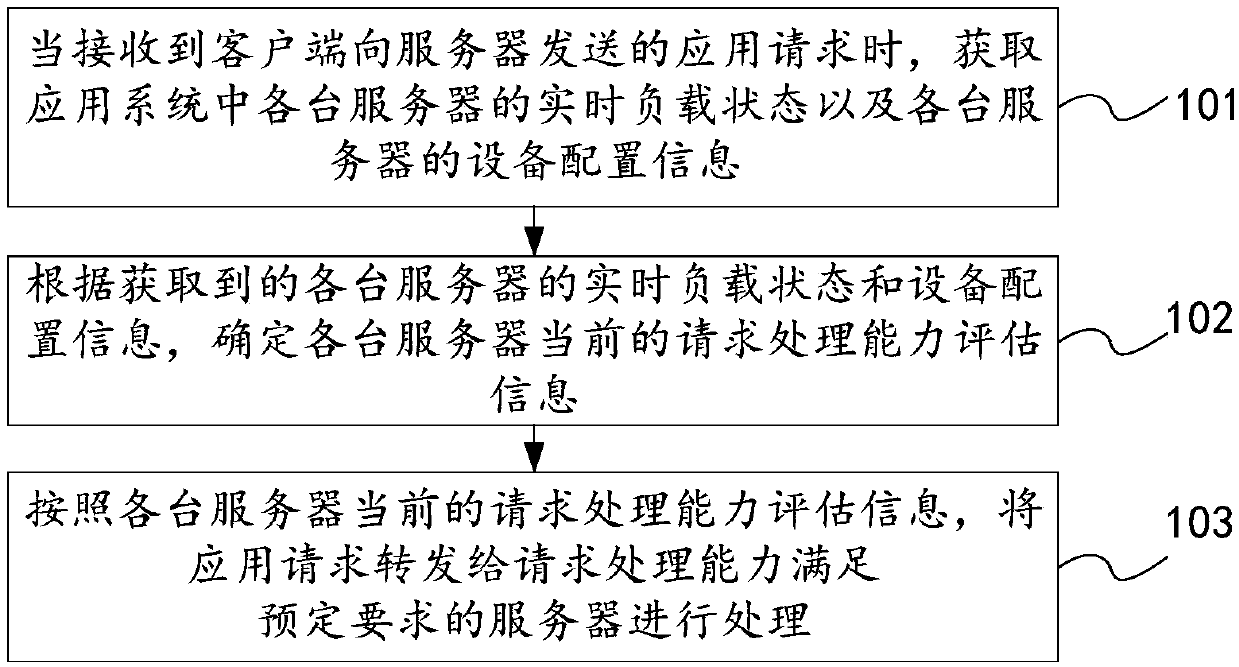

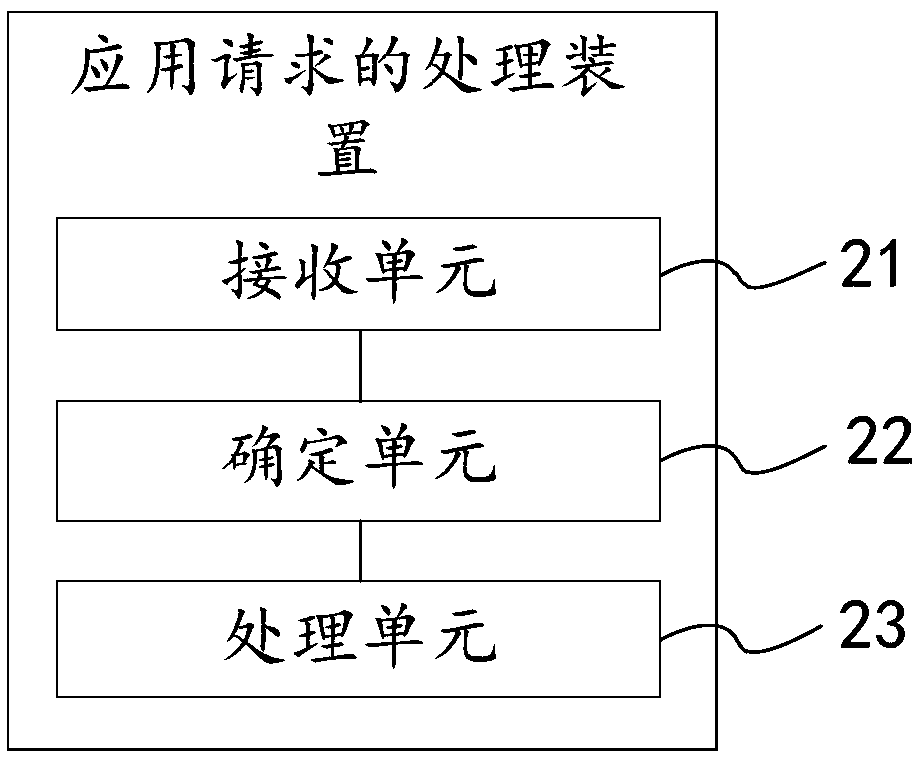

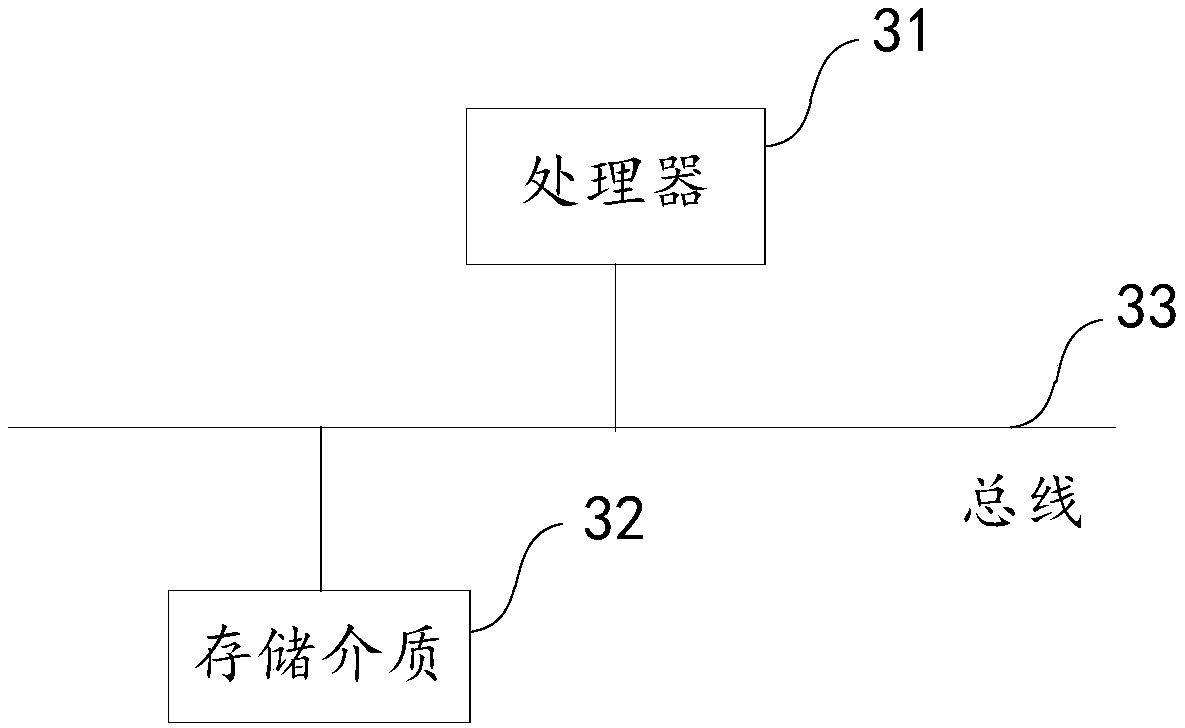

Application request processing method and device and router

ActiveCN109729131AAvoid Unresponsive SituationsWill not affect normal useTransmissionTraffic capacityDowntime

The invention discloses an application request processing method and device and a router, and relates to the technical field of applications, and the method comprises the steps: obtaining the real-time load state of each server and the equipment configuration information of each server in an application system when an application request sent by a client to the server is received; Determining request processing capability assessment information corresponding to each server according to the real-time load state of each server and the equipment configuration information; And according to the current request processing capability assessment information of each server, forwarding the application request to the server with the request processing capability meeting a predetermined requirement for processing. based on automatic flow switching strategy, the application system of the server can be switched to the available server in time without modifying routing configuration parameters or restarting the application system of the server to generate downtime, so that the server can process the application request sent by the client in time, the situation that the application request cannotrespond is avoided, and the normal use of the application of the client cannot be influenced.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

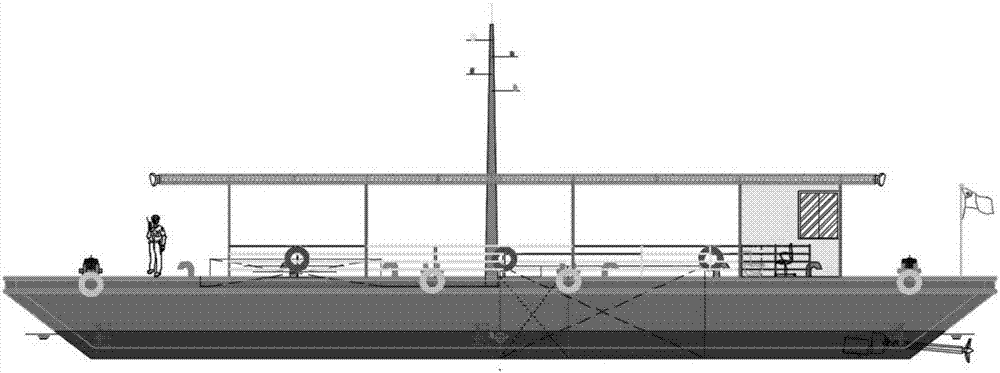

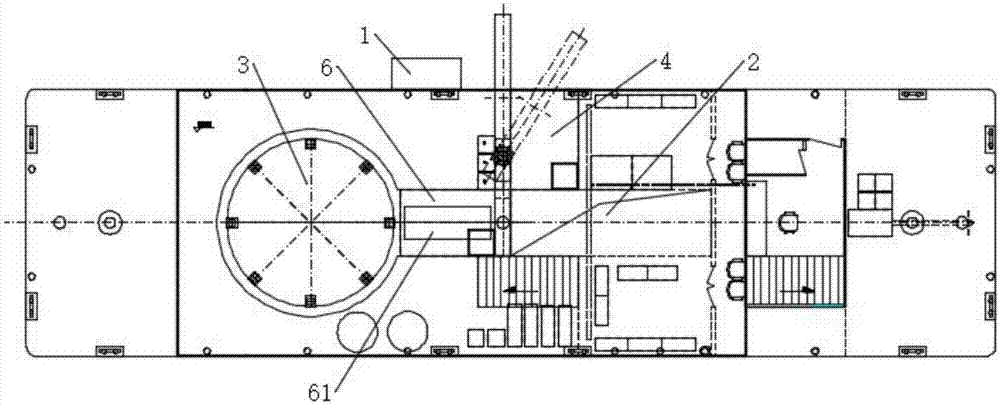

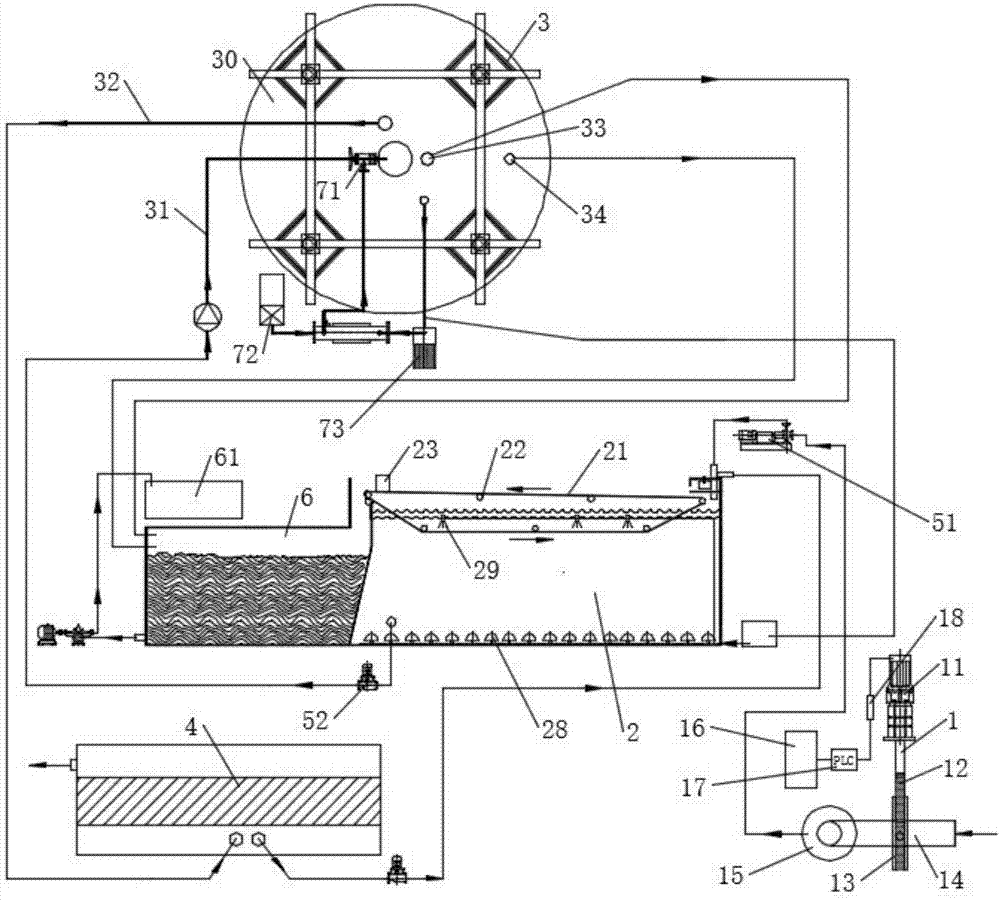

Blue alga and aquatic plant treatment ship and method

PendingCN107445369AEfficient removalImprove work efficiencyWater treatment parameter controlWater cleaningSlurryPre treatment

A blue alga and aquatic plant treatment ship comprises a liftable water feeding system, a pretreatment tank, an ionic gas flotation device and a precipitation accelerating tank which are arranged on a cabin or deck, wherein the liftable water feeding system is communicated with the pretreatment tank through a raw water pump or a pipeline, the pretreatment tank is communicated with the ionic gas flotation device through a secondary pump and a pipeline, and the ionic gas flotation device is communicated with the precipitation accelerating tank through a clear water outlet pipeline. The ship further comprises an alga slurry tank communicated with the pretreatment tank and the ionic gas flotation device, and an alga slurry dewatering system is arranged in the alga slurry tank. According to the glue alga and aquatic plant treatment ship and method, the blue alga and aquatic plant treatment system is arranged on the cabin and the deck of the ship and becomes a mobile blue alga treatment work station. Larger algae in inflow water can be removed through a blue alga pretreatment device comprising the liftable water feeding system, the pretreatment tank, a rotary filter belt and the like, and raw water filtrate with certain concentration enters the efficient ionic gas flotation treatment device to be treated and is discharged after meeting the standard.

Owner:翟葆麟

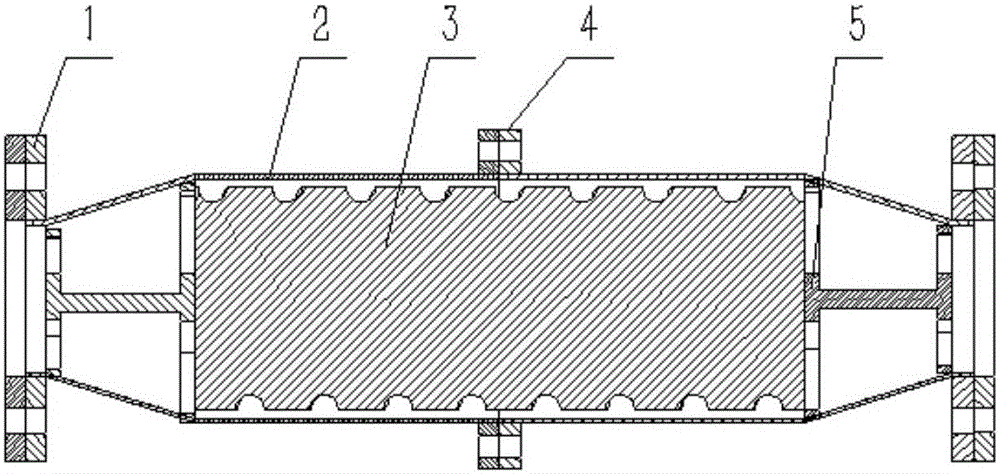

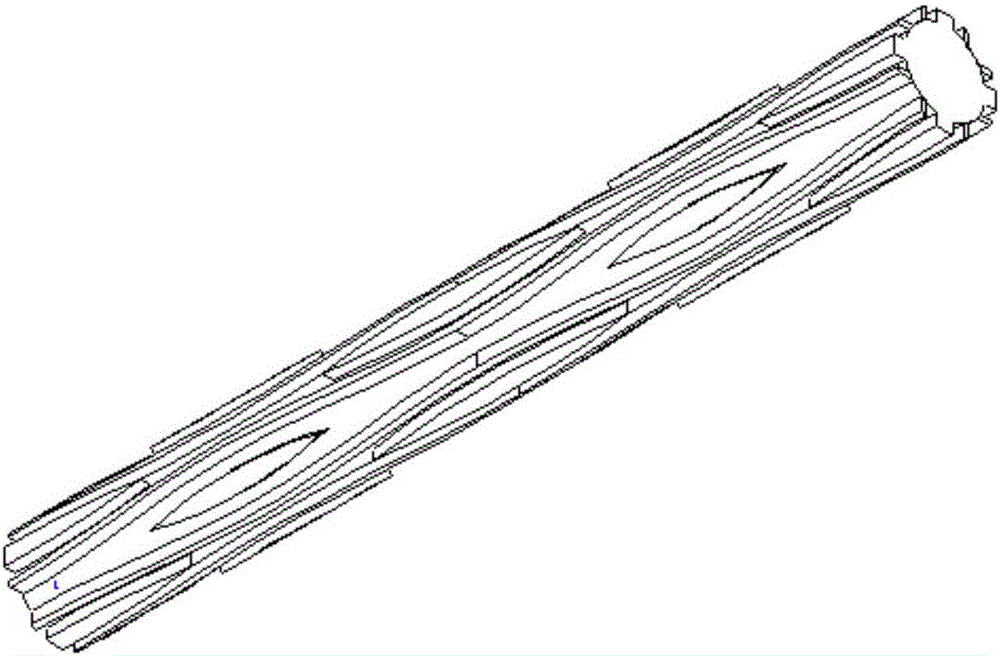

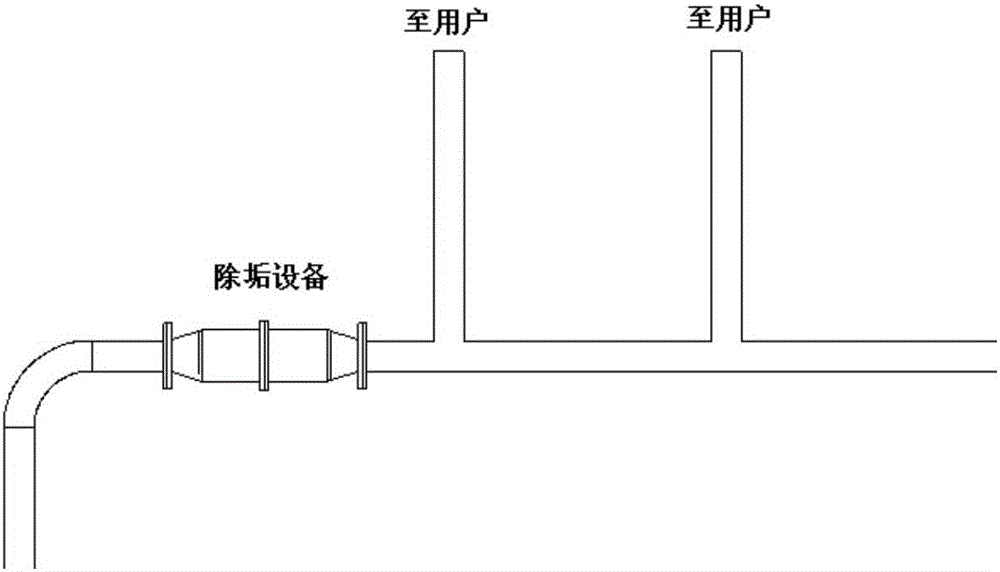

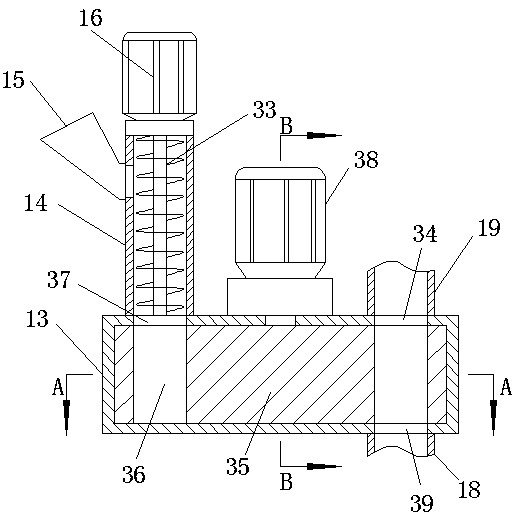

Water body scale removing and preventing apparatus and applications thereof

InactiveCN106477735AUniversalAccurate Quantitative DesignScale removal and water softeningWater flowEngineering

The present invention discloses a water body scale removing and preventing apparatus, which comprises: a cylindrical housing arranged on a water flowing pipeline; and a core coaxially and fixedly arranged in the housing in a sleeved manner, wherein the outer peripheral surface is provided with a concave groove, and the gap formed between the concave groove and the inner wall of the housing is adopted as the water flowing channel. According to the present invention, with the flowing channel structure of the core, the water can be subjected to contact friction with the core and is impacted during the flowing so as to generate the eddy flow, such that the metal electrons in the alloy can be separated and released to adsorb and combine the ions such as calcium and magnesium in the water so as to achieve the water body scale removing and preventing; the invention further discloses applications of the water body scale removing and preventing apparatus in scale removing and preventing of heat exchangers; and with the water body scale removing and preventing apparatus of the present invention, the effective water body scale removing and preventing can be achieved, and the technical problems of low efficiency and poor scale removing and preventing effect of the existing apparatus can be solved.

Owner:武汉市嘉扬电气有限责任公司

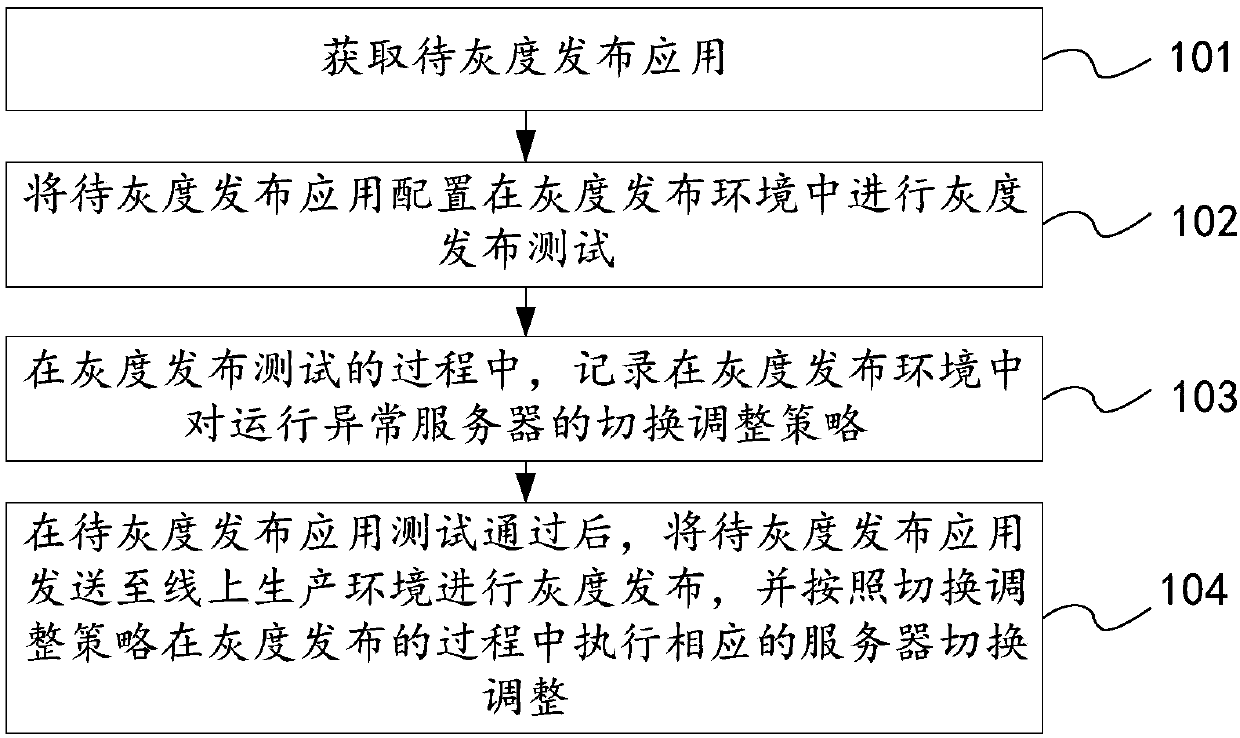

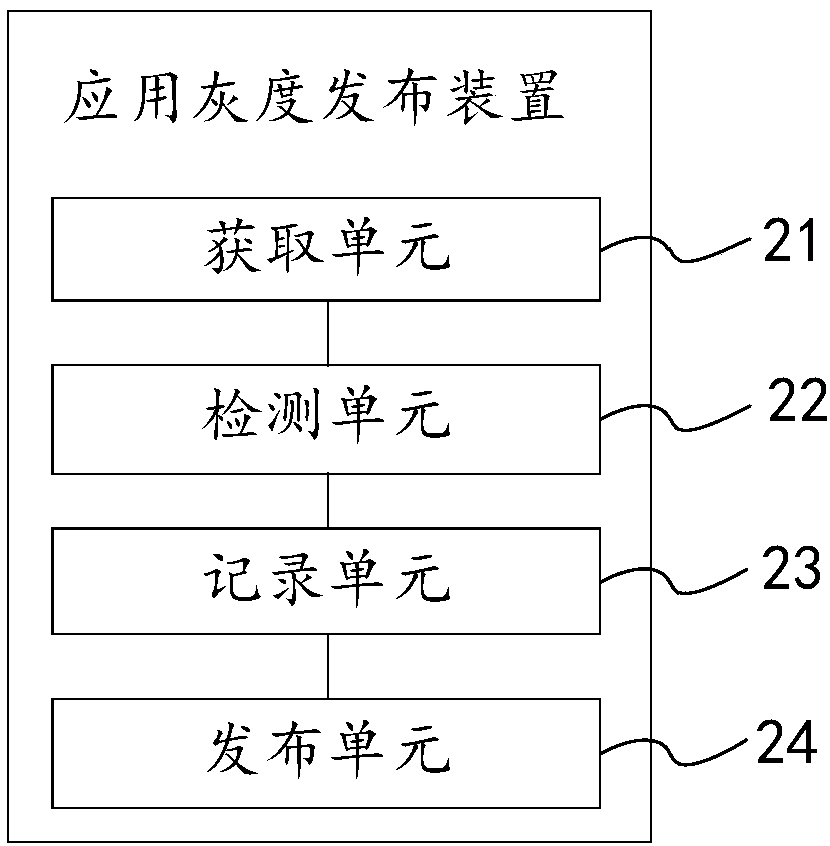

Application gray release method, device and equipment

PendingCN109726099ANo downtimeGuarantee processing qualitySoftware testing/debuggingComputer scienceRelease methods

The invention discloses an application gray release method, device and equipment, and relates to the technical field of application, and the method comprises the steps: obtaining an application to besubjected to gray release; Configuring the application to be subjected to gray release in a gray release environment for gray release test, wherein the gray release environment is an environment created in advance according to the current online production environment; In the gray release test process, recording a switching adjustment strategy of an abnormal operation server in a gray release environment; And after the to-be-gray release application passes the test, sending the to-be-gray release application to an online production environment for gray release, and executing corresponding server switching adjustment in the gray release process according to a switching adjustment strategy. According to the method, the pre-release test process is adopted, the switching adjustment strategy inthe gray release environment is used for guiding server switching adjustment in the formal gray release process of the online production environment, configuration modification and restarting of a server application system are not needed, and the situation that the application system is crashed is avoided.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

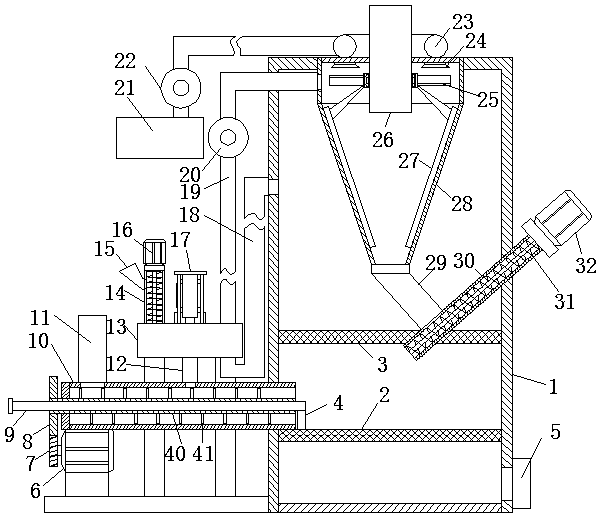

Composite biomass staged gasification furnace

The invention relates to the technical field of gasification furnaces, and in particular to a composite biomass staged gasification furnace. The furnace comprises a furnace body; a fire grate is fixedon the side wall of the lower part in the furnace body; a space below the fire grate is a slag cavity; an ash discharge port is formed in the side wall of the furnace body corresponding to the slag cavity; a filter screen is also fixed on the inner wall of the furnace body; the filter screen is positioned above the fire grate; a fine filter is fixed to the top wall of the interior of the furnacebody, a feeding mechanism is fixed to the outer side of the furnace body, a primary filtering mechanism is fixed to the feeding mechanism and connected with the feeding mechanism through a feeding pipe, and the primary filtering mechanism is connected with the upper portion of the side wall of the furnace body and a fine filtering mechanism through a first air pipe and a second air pipe. Accordingto the composite biomass staged gasification furnace, the content of tar and smoke dust in fuel gas is greatly reduced, the fuel gas quality is improved, equipment is protected, the filtered tar is returned to the furnace again to be subjected to high-temperature cracking to generate small molecular fuel gas, then the fuel gas generation efficiency is improved again, and the tar generation amountis reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING

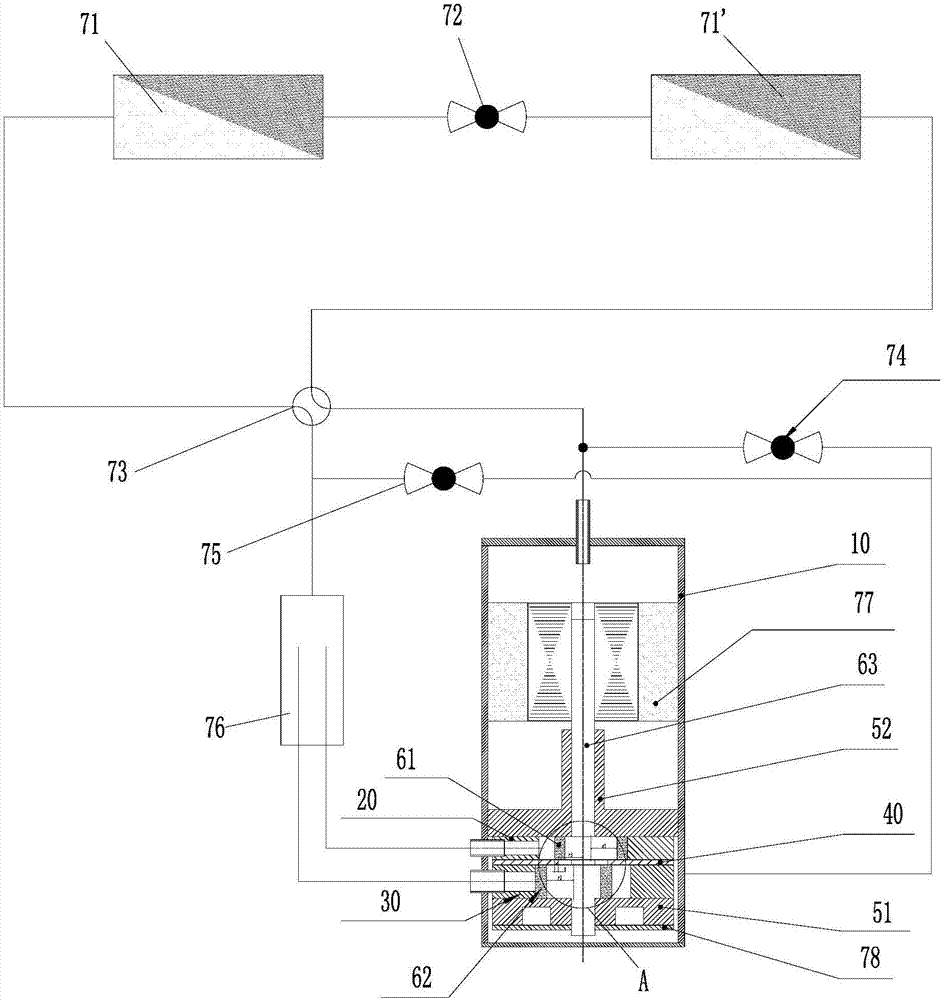

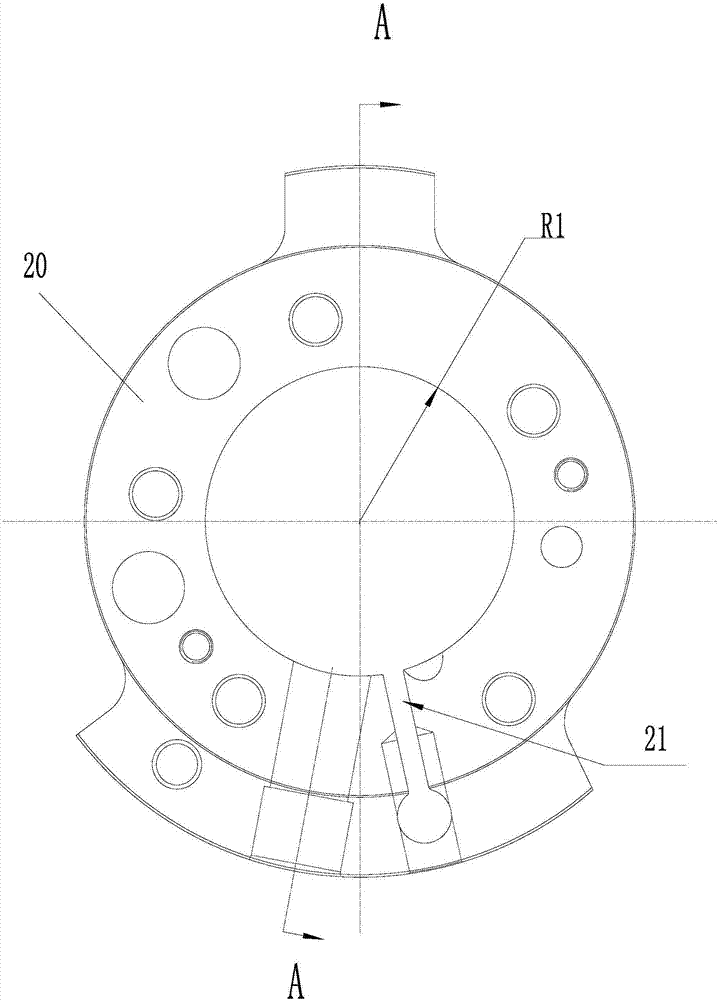

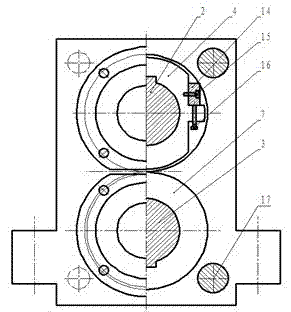

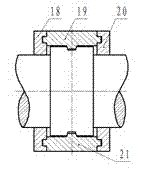

Compressor, air conditioner and assembly method of compressor

PendingCN107476979AImprove availability and reliabilityAvoid downtimeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectrical and Electronics engineering

The invention provides a compressor, an air conditioner and an assembly method of the compressor. The compressor comprises a shell, a first cylinder module and a second cylinder module. The first cylinder module comprises a first cylinder, and is provided with a first exhaust channel; a first end of the first exhaust channel communicates with the first cylinder, and a second end of the first exhaust channel communicates with an accommodating cavity; the second cylinder module comprises a second cylinder; the second cylinder is arranged near the first cylinder; the second cylinder module is provided with a second exhaust channel; the second exhaust channel and the first exhaust channel are arranged in a relatively independent manner; a first end of the second exhaust channel is connected with the second cylinder, and a second end of the second exhaust channel communicates with the accommodating cavity; and when the first cylinder is located in a working state, the second cylinder is located in a working state or an idle state. The performance and the reliability of the compressor are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

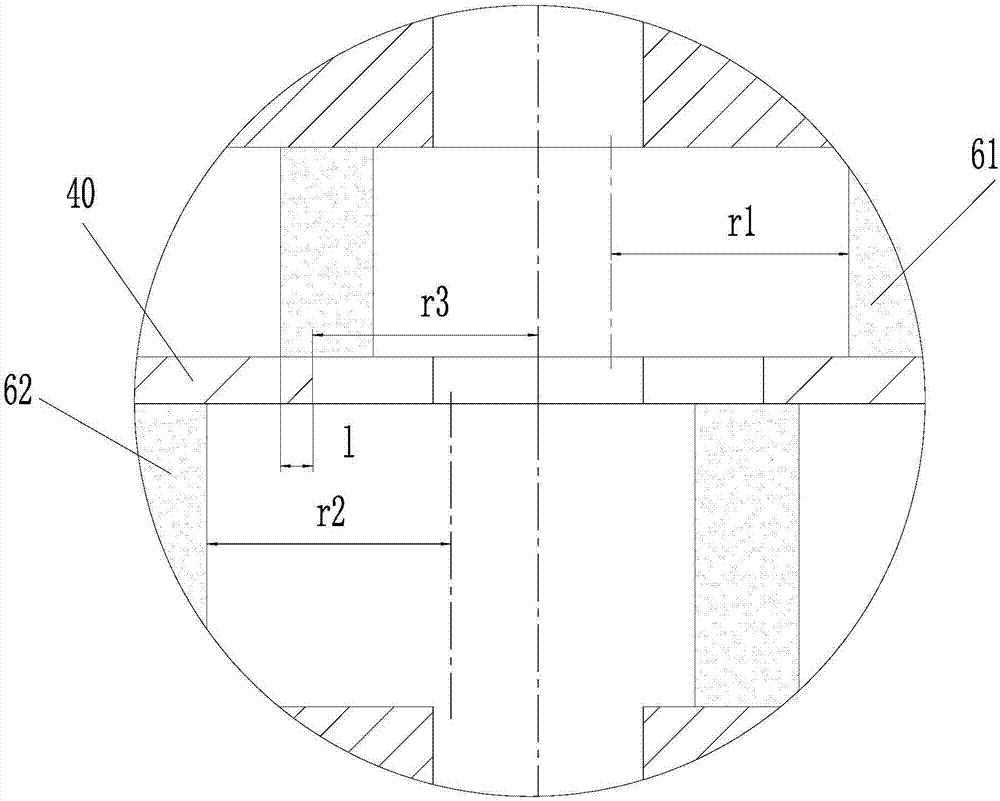

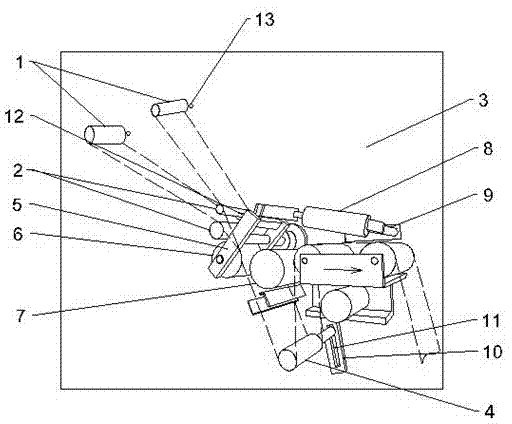

Circle shearing machine capable of determining width and smashing edges of lead belt for storage battery

InactiveCN102513595AEasy axial positioningLess investmentShearing machinesStructural engineeringKnife blades

The invention relates to a circle shearing machine capable of determining the width and smashing the edges of a lead belt for a storage battery. According to the technical scheme, an upper width adjusting component (8) is mounted on an upper knife shaft (2); an upper right blade (9) and a right knife holder (10) are sequentially fixedly mounted by means of being tightly adhered to the right side of the upper width adjusting component (8); 1-4 right edge smashing knifes (14) are mounted on the right knife holder (10); the knife opening of each right edge smashing knife (14) is located on the concentric circumference of the knife shaft (2); an upper left blade (6) and a left knife holder (4) are sequentially fixedly mounted by means of being tightly adhered to the left side of the upper width adjusting component (8); 1-4 left edge smashing knifes (5) are mounted on the left knife holder (4); the knife opening of each left edge smashing knife (5) is located on the concentric circumference of the knife shaft (2); a lower width adjusting component (11) is mounted on a lower knife shaft (3); a lower right blade (12) is fixedly mounted by means of being tightly adhered to the right side of the lower width adjusting component (11); and a lower left blade (7) is fixedly mounted by means of being tightly adhered to the left side of the lower width adjusting component (11). The circle shearing machine disclosed by the invention has the characteristics of less investment, convenience for installation and high shearing efficiency.

Owner:WUHAN UNIV OF SCI & TECH

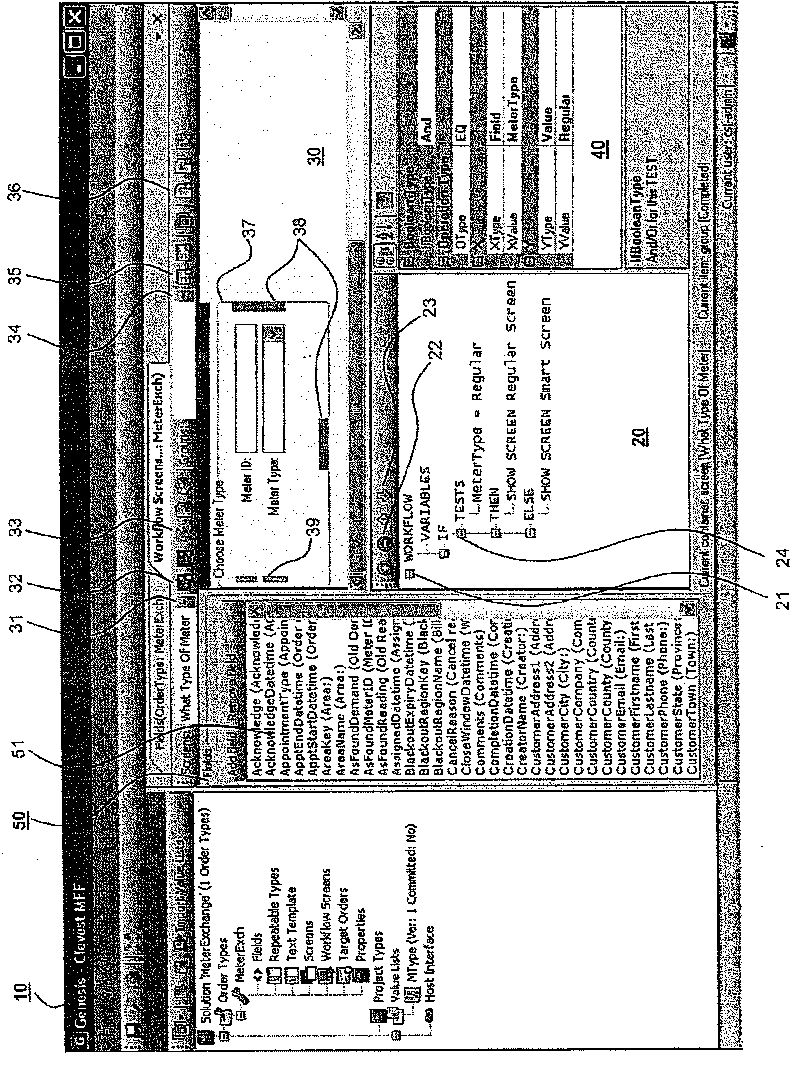

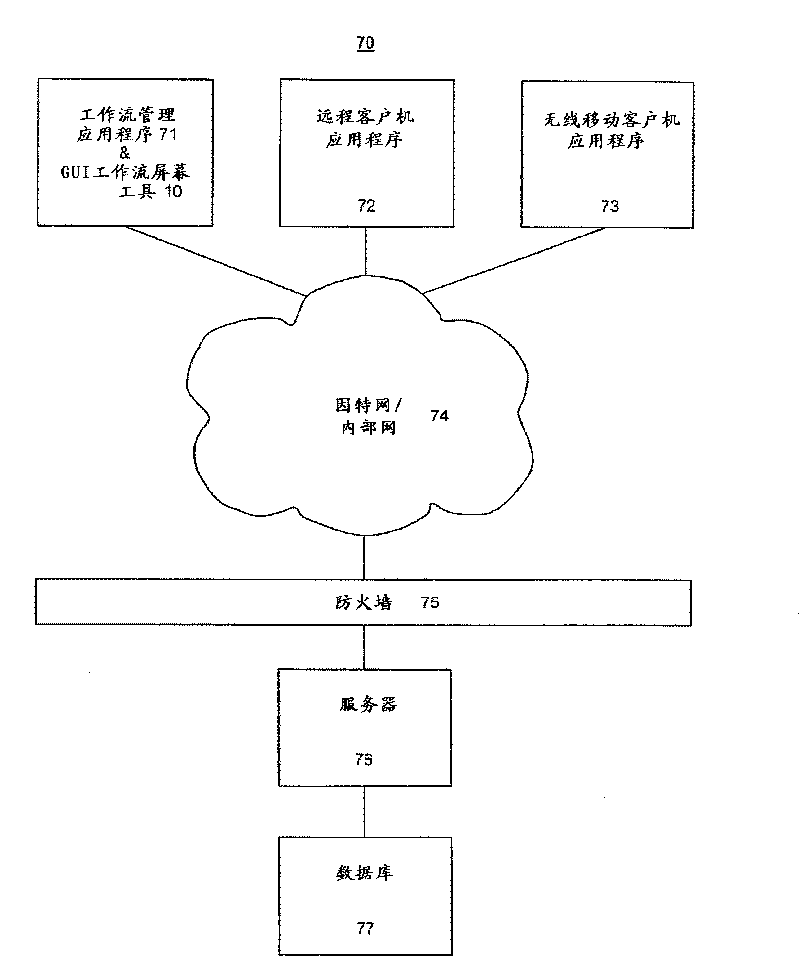

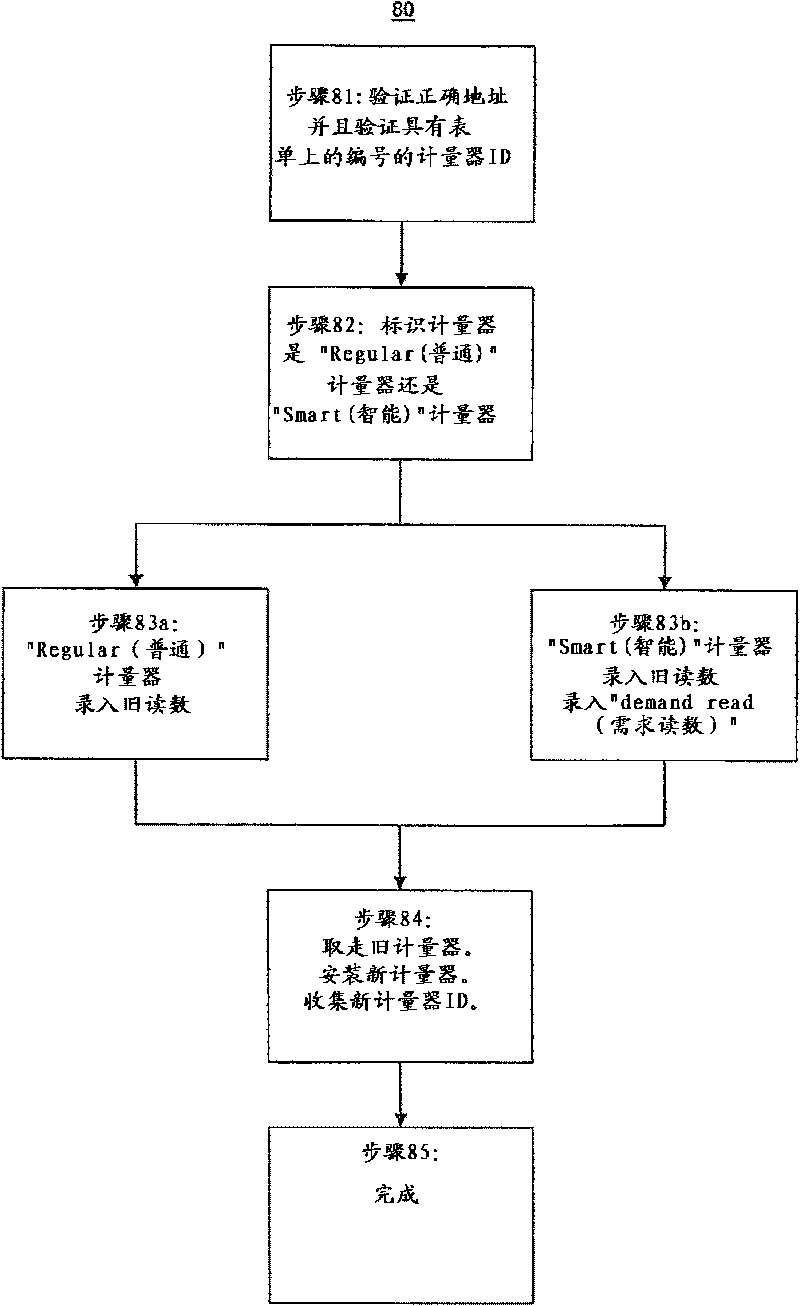

Method and system of editing workflow logic and screens with a gui tool

InactiveCN101710275AAvoid destructionAvoid grammatical errorsSpecific program execution arrangementsWorkflow management systemGraphical user interface

A workflow management system provides a graphical user interface (GUI) tool that allows a user to create and / or edit workflow logic without requiring the re-writing and recompiling of the application software, and without interrupting the operability of the application software at any time. The GUI tool allows the user to simultaneously view and create and / or edit the corresponding application screen where the workflow logic is applied in the application software, while the user creates and / or edits the workflow logic. The user creates and / or edits the workflow logic by selectively combining the available parameters that are provided in spoken language syntax by a context sensitive menu. The workflow logic statements are made available for the application software to call at the appropriate times. The GUI tool works in conjunction with a dynamically configurable database.

Owner:CLEVEST SOLUTIONS

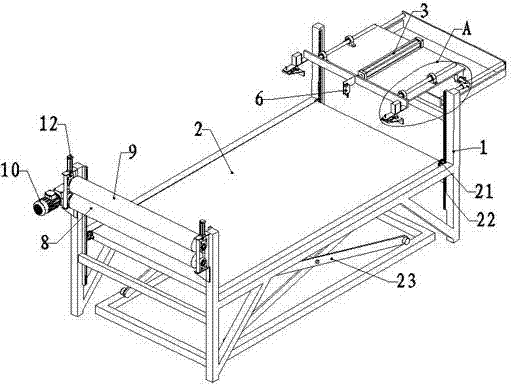

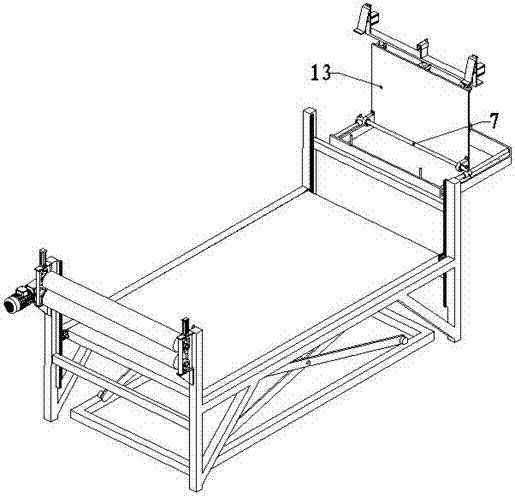

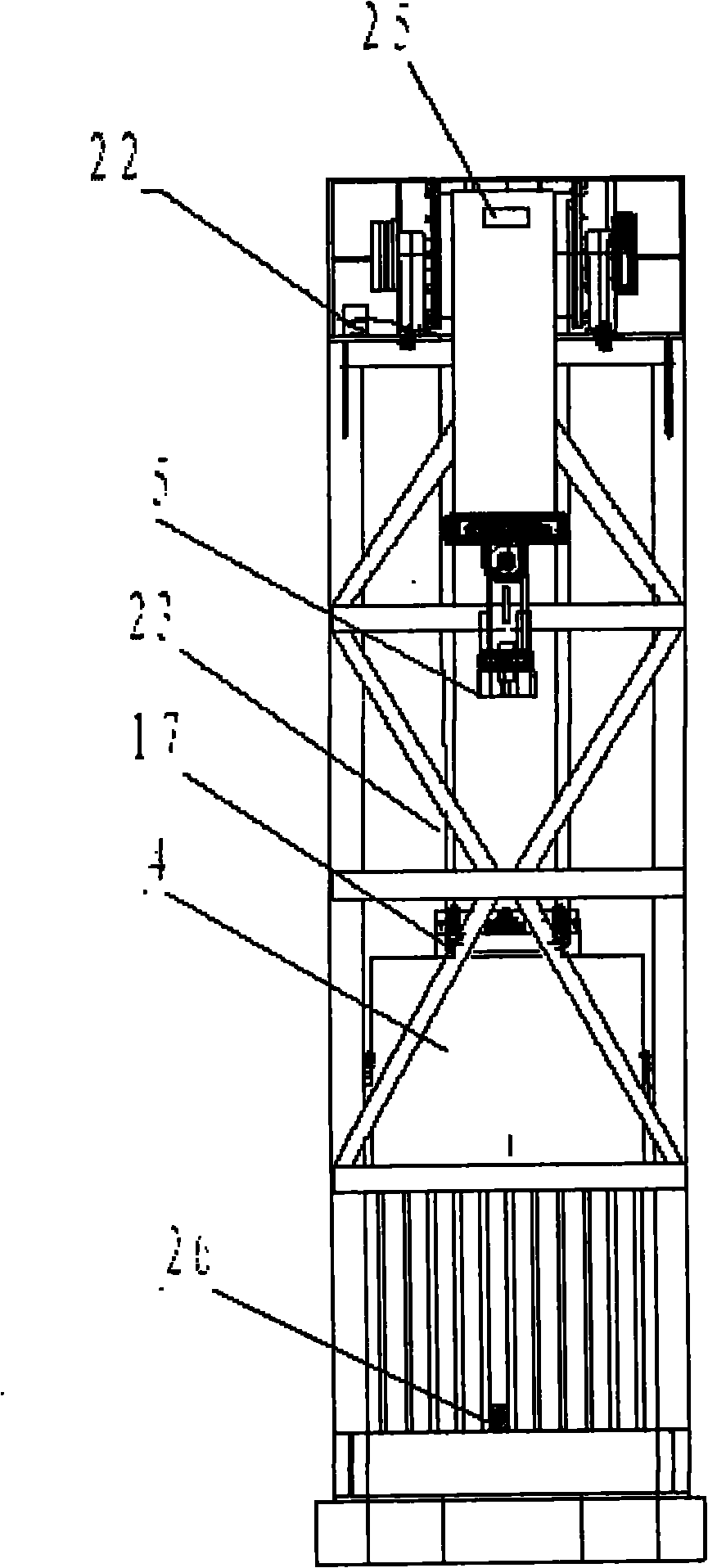

Plate loading machine

ActiveCN106966176AAvoid skewImprove efficiencyConveyorsDe-stacking articlesElectric machineryEngineering

The invention relates to the technical field of plate machining equipment, in particular to a plate loading machine. The plate loading machine comprises a frame body, a support plate, a lifting mechanism, a pushing mechanism and a pulling mechanism; the support plate is arranged in the frame body, and is connected with the lifting mechanism; the pushing mechanism is arranged at the head end of the frame body, and includes a pushing cylinder, a poking piece, a poking piece lifting cylinder and a limiting switch; the pushing cylinder is pivoted to the frame body through a horizontal shaft perpendicular to a loading direction, and can be kept in the horizontal direction; the poking piece lifting cylinder and the limiting switch are both connected with a piston rod of the pushing cylinder; the poking piece is connected with a piston rod of the poking piece lifting cylinder; the pulling mechanism is arranged at the tail end of the frame body; and the pulling mechanism includes a driving roller, a driven roller and a driving motor. The plate loading machine has such advantages as convenience to load materials, high efficiency, low cost and low noise.

Owner:山东同利玻纤制品有限公司

Paper tape splicer

The invention provides a paper tape splicer which comprises two unwinding rollers, two unwinding transition rollers and tension rollers. The two unwinding rollers are mounted above the same side of a roller rack, the two unwinding transition rollers are used with the corresponding unwinding rollers, the tension rollers are assembled on the roller rack below the unwinding transition rollers, and a paper receiving mechanism is arranged on the roller rack among the tension rollers and the unwinding transition rollers. When an infrared sensor senses that an old reel runs short, a control device controls a production line to decelerate and gives an alarm, a worker feeds a new reel on a roller, a paper end is placed between two plastic rollers, and a paper receiving cylinder extends out and drives a movable paper receiving roller to contact with a fixed paper receiving roller, so that two paper tapes are pasted together. The paper tape splicer is simple in structure, convenient to operate and low in labor intensity and does not need stopping.

Owner:浙江好时加卫生用品有限公司

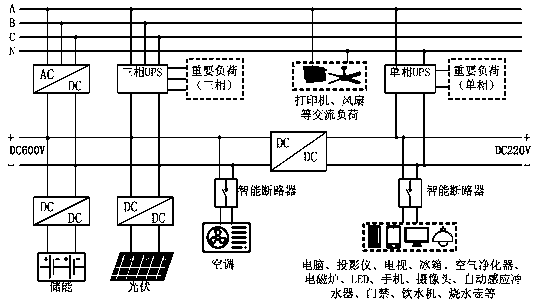

High-compatibility AC/DC hybrid power distribution system

InactiveCN110138075AEfficient use ofMeet power needsSingle network parallel feeding arrangementsPhotovoltaic energy generationFrequency changerData center

The invention discloses a high-compatibility AC / DC hybrid power distribution system characterized in that a rectifier converter, a photovoltaic converter, and an energy storage unit bidirectional converter are connected in parallel to a 600V DC bus; the 600V DC bus is connected to a 220V DC bus through a step-down converter and supplies power to a DC central air conditioner and the like in the system; the 220V DC bus supplies power to a DC load through an isolation converter; a conventional AC load is connected to a 380VAC or 220VAC AC power bus according to an actual situation. A sensitive load similar to a frequency converter or data center computer is powered by a corresponding three-phase or single-phase UPS. The high-compatibility AC / DC hybrid power distribution system works well.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH +1

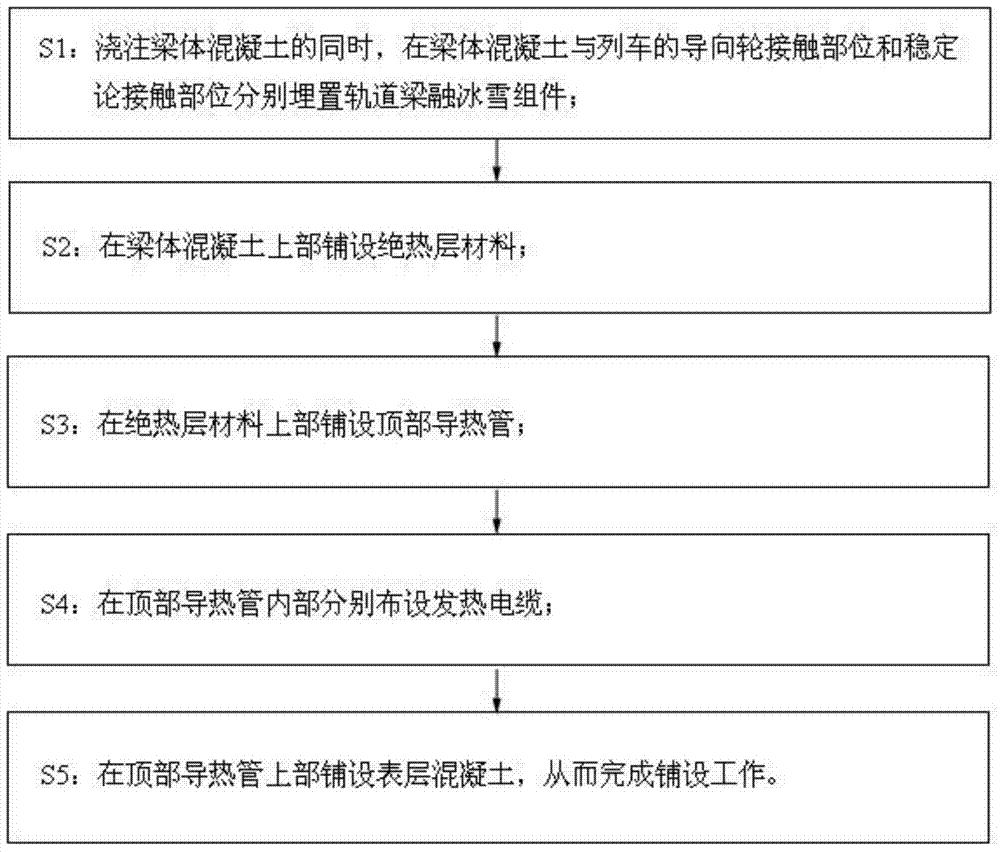

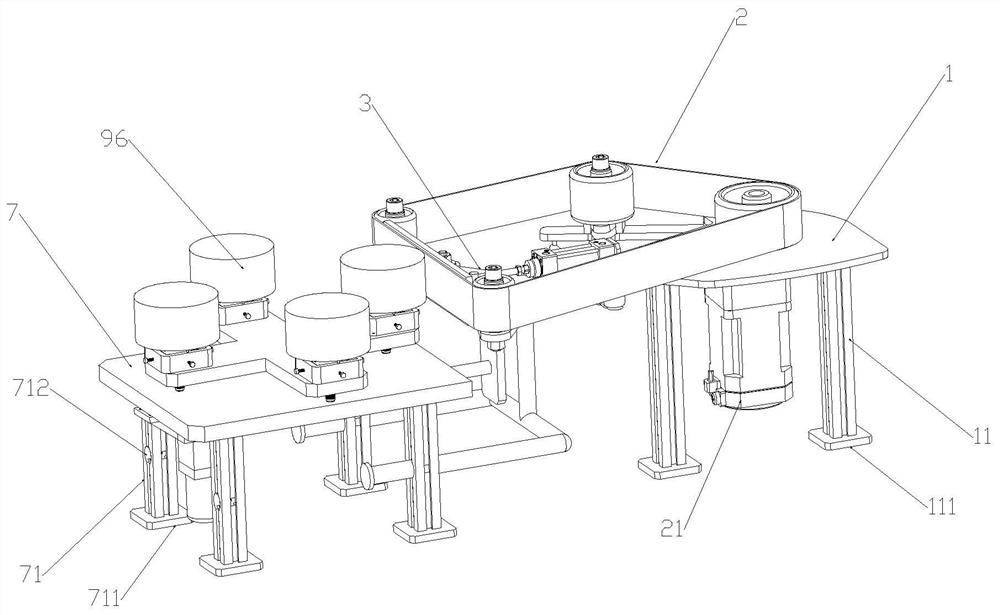

Rail beam ice and snow melting assembly, PC rail beam and laying method of PC rail beam

ActiveCN104711906AAdjustable temperatureHeating fastClimate change adaptationRailway tracksSurface layerSnow melting

The invention discloses a PC rail beam which comprises a rail beam ice and snow melting assembly. The rail beam ice and snow melting assembly comprises a surface layer heat conduction plate, heat conduction pipes which are located at the bottom of the surface layer heat conduction plate and fixedly connected with the surface layer heat conduction plate, heating cables laid in the heat conduction pipes, and a plurality of anchor bars which are fixedly arranged at the bottom of the surface layer heat conduction plate and used for fixedly connecting the surface layer heat conduction plate and beam body concrete. By means of the rail beam ice and snow melting assembly, ice and snow which freeze on the PC rail beam can be rapidly and efficiently processed, and therefore the normal running of trains can be ensured, and obvious social and economical benefits are achieved. In addition, the invention further discloses the rail beam ice and snow melting assembly forming the PC rail beam and a laying method of the PC rail beam.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

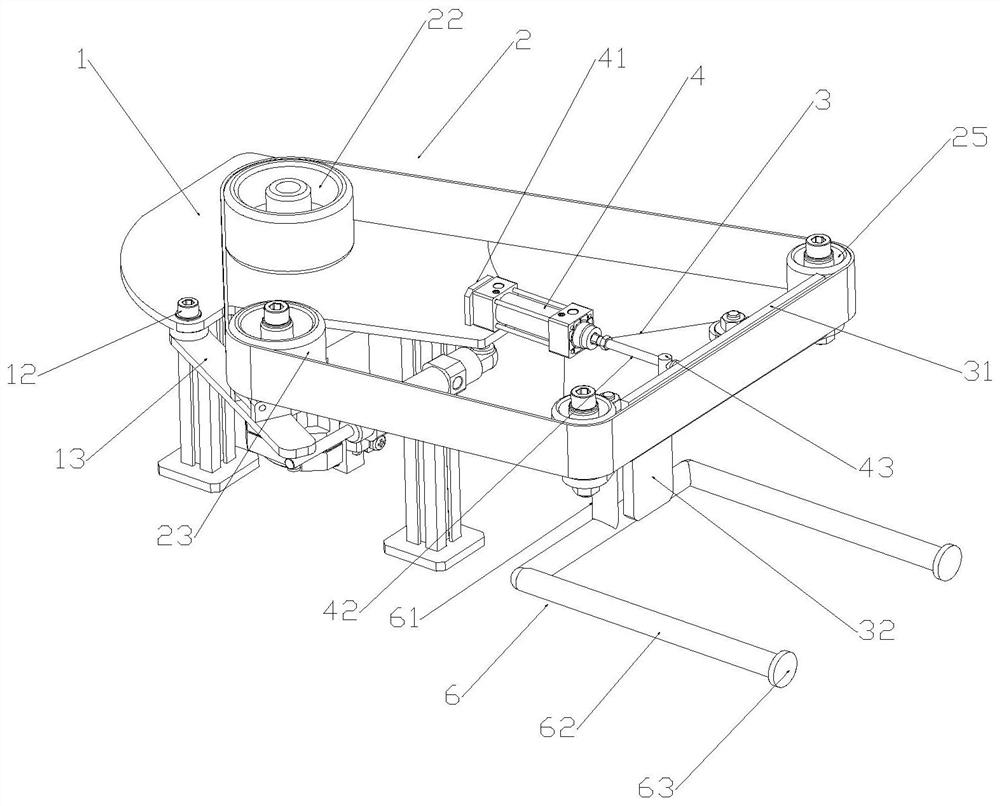

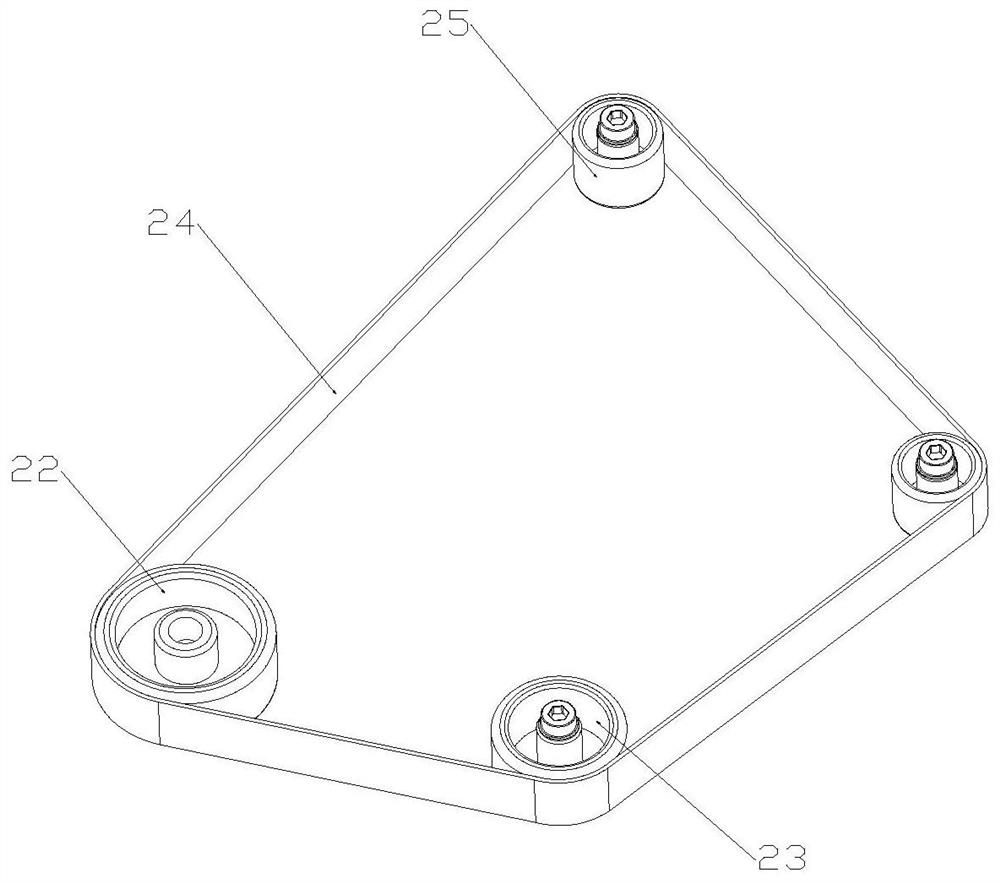

High-precision polishing equipment for die-casting workpiece and polishing method thereof

ActiveCN111730470AHigh precisionAdjust the tensionGrinding drivesBelt grinding machinesPolishingElectric machinery

The invention discloses high-precision polishing equipment for a die-casting workpiece and a polishing method thereof. A polishing mechanism is arranged between a first supporting platform and a second supporting platform, a second pneumatic cylinder is driven, a supporting plate can be driven to rotate, the tensioning degree of a polishing belt is further adjusted, a first pneumatic cylinder is driven, the position of the polishing belt can be adjusted, the polishing position of the polishing belt on a workpiece is further adjusted, the polishing position and the polishing degree can be conveniently adjusted, the adjustment is convenient, and the polishing precision is high when the workpiece is polished. According to the equipment and the method, the upper end of a third supporting platform is provided with a rotating device and a clamping device, when the polishing equipment is used, a third motor is driven to drive the die-casting workpiece to rotate for one circle to polish the workpiece, a second motor is driven, a rotating shaft is rotated to drive a bearing plate to rotate so as to drive the die-casting workpiece for revolution, a next die-casting workpiece can be polishedconveniently, polishing is finished through the rotation when the polishing equipment is used, replacement is finished through the revolution, equipment halt is avoided, and the working efficiency isimproved.

Owner:宁波敏嵘机械有限公司

Power redundancy control system and method of GPU server and medium

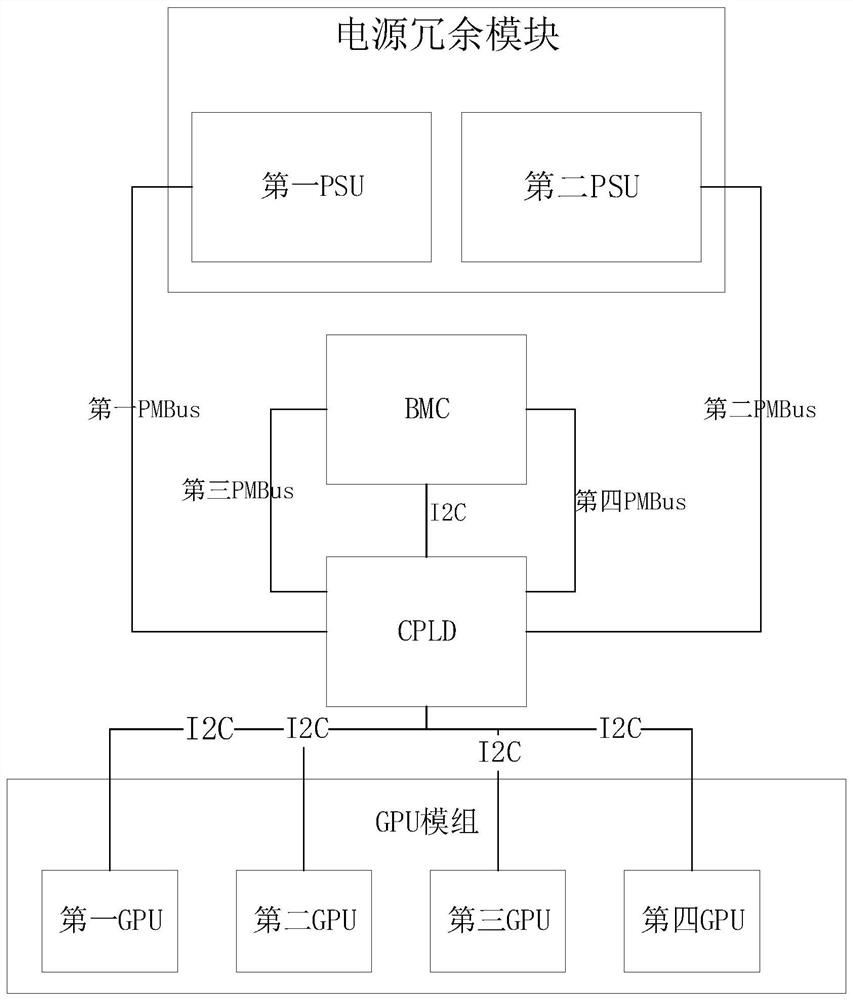

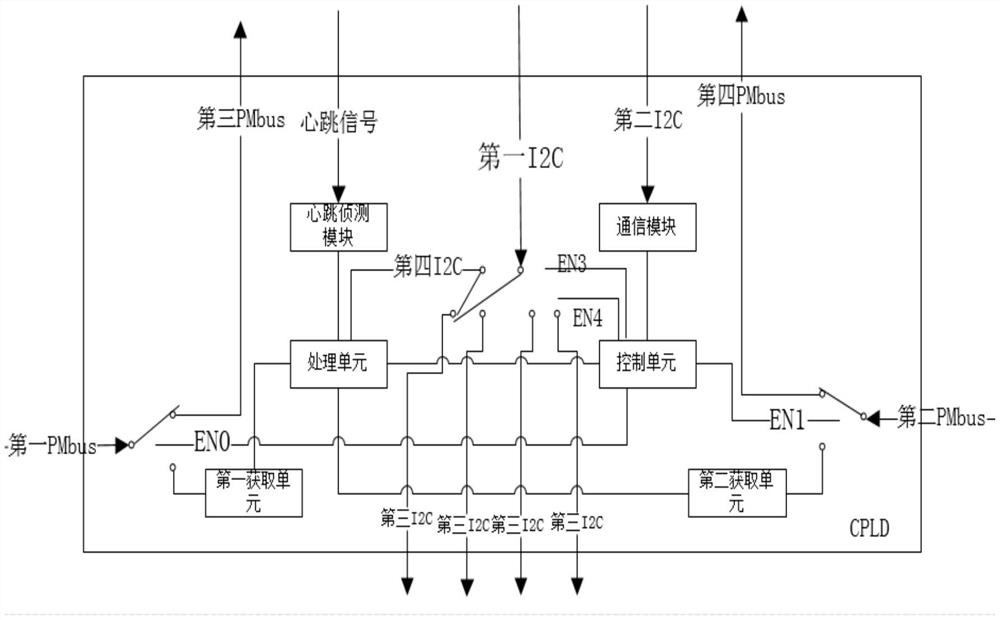

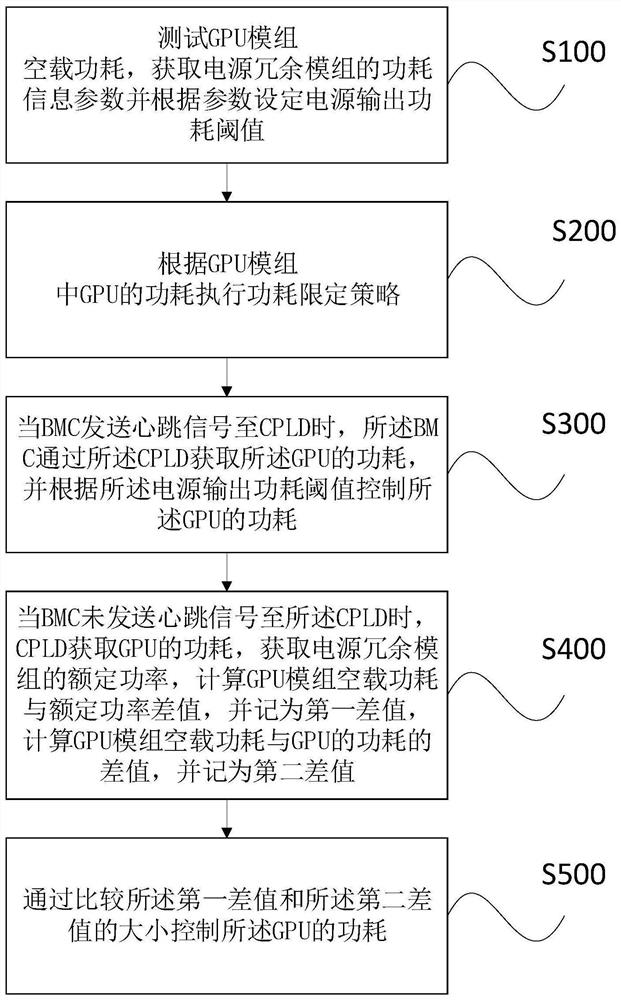

PendingCN113064479AReduce lossesImprove processing powerPower supply for data processingEnergy efficient computingEmbedded systemComputer hardware

The invention discloses a power redundancy control system of a GPU server. The power redundancy control system comprises a power redundancy module, a BMC, a CPLD and a GPU module; the power supply redundancy module comprises a first PSU and a second PSU, and the GPU module comprises a plurality of GPUs; the first PSU is connected with the CPLD through a first bus; the second PSU is connected with the CPLD through a second bus; the BMC is connected with the CPLD through the first I2C bus and the second I2C bus and sends heartbeat information to the CPLD; the CPLD is connected with the BMC through a third bus and a fourth bus; the CPLD is connected with the plurality of GPUs through a third I2C bus. According to the invention, when the BMC is abnormal or restarted, the CPLD can control the overall power consumption of the server, and meanwhile, the server can be ensured not to have a downtime phenomenon, so that the loss caused by the abnormal or restarted BMC to a client is reduced.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

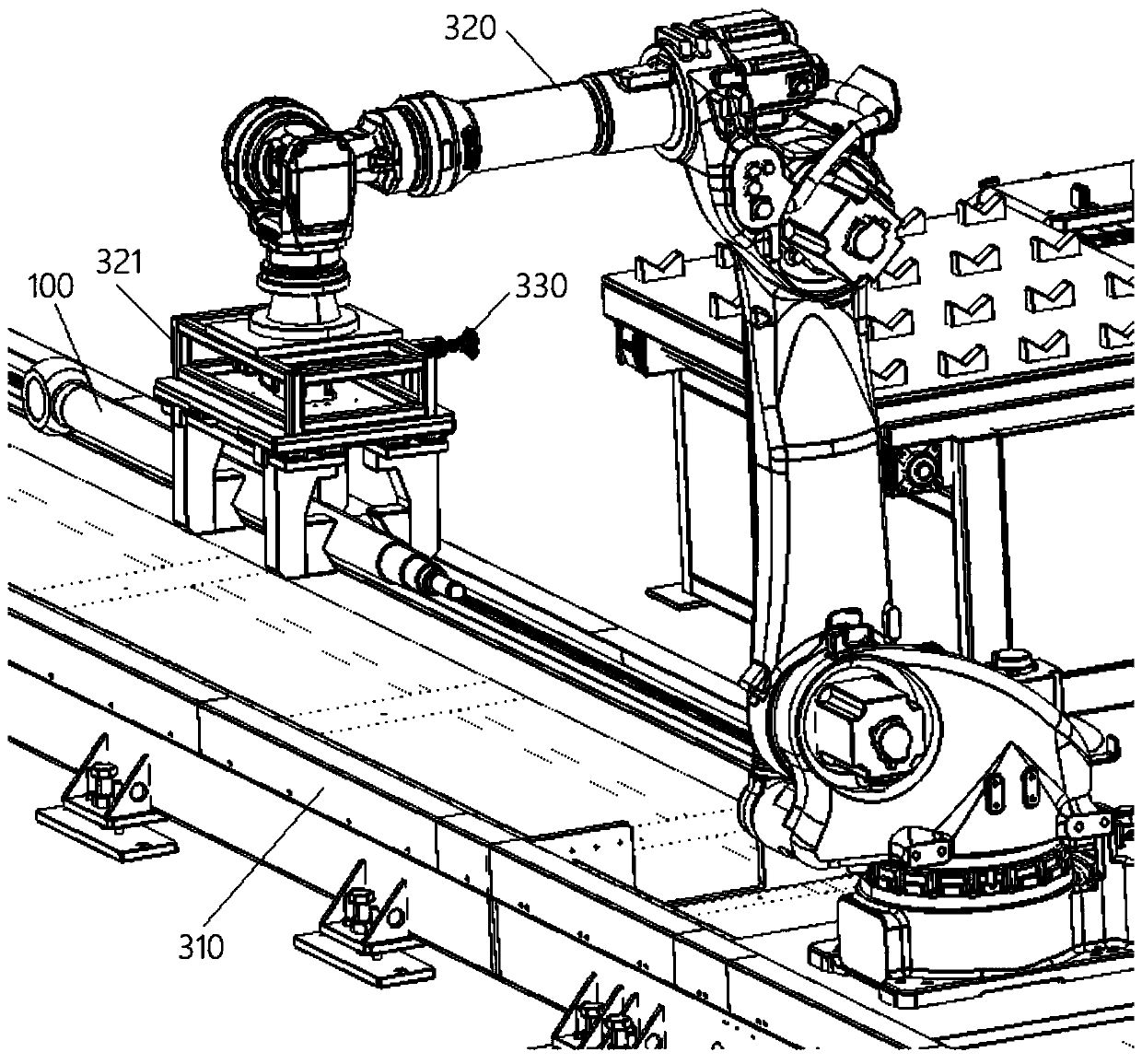

Plated piston rod assembly polishing processing device and processing method thereof

PendingCN110682169AQuick actionSmall range of motionRevolution surface grinding machinesGrinding feed controlRobot handControl engineering

The inventin provides a plated piston rod assembly polishing processing device which comprises loading and unloading caching stations, a ground track robot, cylindrical grinding machines, grinding machine caching stations and a detection platform. The two loading and unloading caching stations are distributed on the front side of the ground track robot; workpiece trays are arranged on the loadingand unloading caching stations; multiple V-shaped support blocks are arranged on the workpiece trays and can position piston rod assemblies; a ground track of the ground track robot is arranged alongthe left-and-right direction; a manipulator can move along the ground track; the two cylindrical grinding machines are located on the back side of the ground track robot; the two grinding machine caching stations are located on the front sides of the two cylindrical grinding machines; a first workpiece support frame and a second workpiece support frame are arranged on the grinding machine cachingstations; the detection platform is located between the two loading and unloading caching stations; a detection scanner is arranged on the detection platform and can be used for detecting faults of the surfaces of the piston rod assemblies; the detection scanner is connected with a controller; and the controller is connected with the ground track robot. The plated piston rod assembly polishing processing device provided by the invention has high processing efficiency.

Owner:苏州迅益科系统科技有限公司

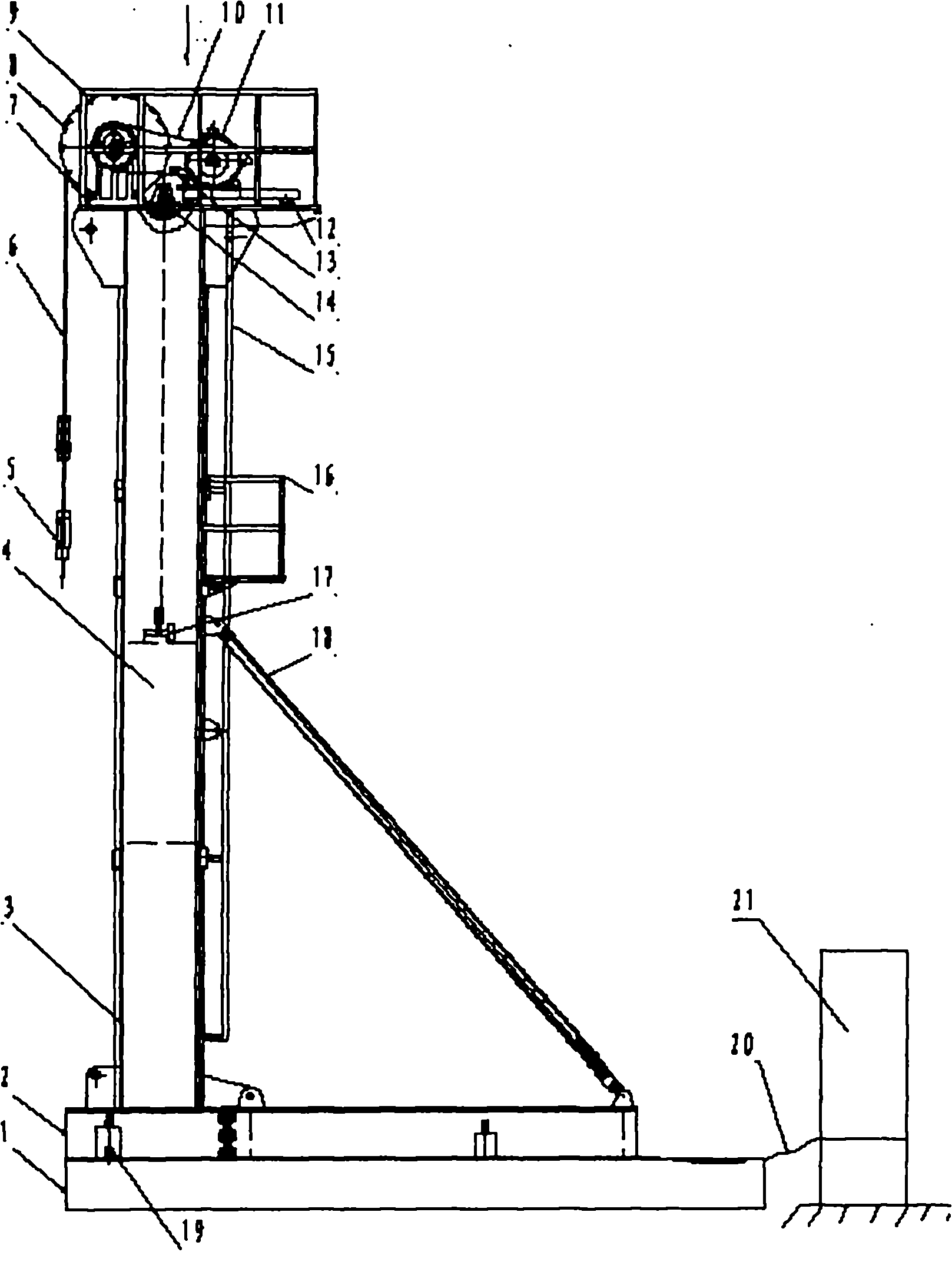

Numerically-controlled distance-measuring brake drum oil pumping unit

ActiveCN102182427AWith detection functioWith protective functionFluid removalProgrammable logic controllerControl signal

The invention discloses a numerically-controlled distance-measuring brake drum oil pumping unit, which comprises a base, a rack, a balanced box, a beam hanger, a load belt, an upper platform, a reduction brake drum mechanism, a driving mechanism, a tight-up belt, a broken rod protection mechanism, a lifting / descending travelling mechanism, an electric control mechanism, a load discharging mechanism of a fixed rope hanging pile and zeroing soft iron, wherein the reduction brake drum mechanism is arranged in front of the upper platform and connected with the driving mechanism by the tight-up belt; the broken rod protection mechanism is arranged between the reduction brake drum mechanism and the driving mechanism; a programmable logic controller (PLC) of the electric control mechanism carries out logic operation according to an input state and outputs a control signal; the control signal directs the controller to control the on and off, a rotary speed and forward and reverse rotation of a motor and directs broken rod protection; and the electric control mechanism is used for safely operating the oil pumping unit, adjusting the stroke frequency and stroke of the oil pumping unit without downtime, judging a fault and executing protection.

Owner:山东创新石油技术有限公司

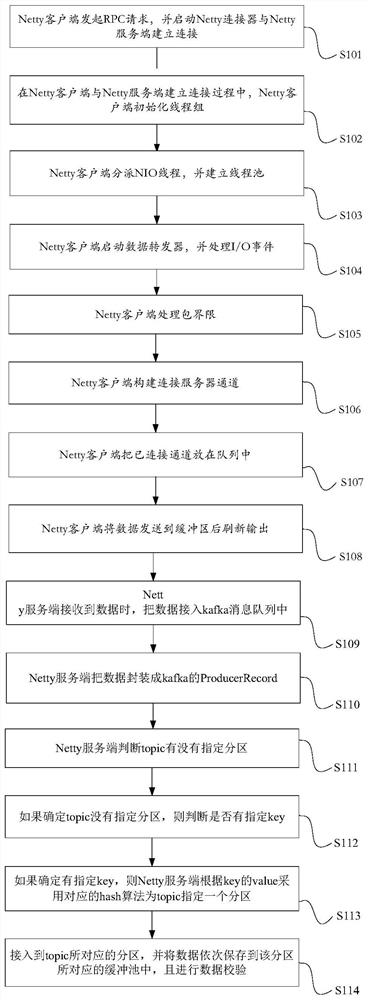

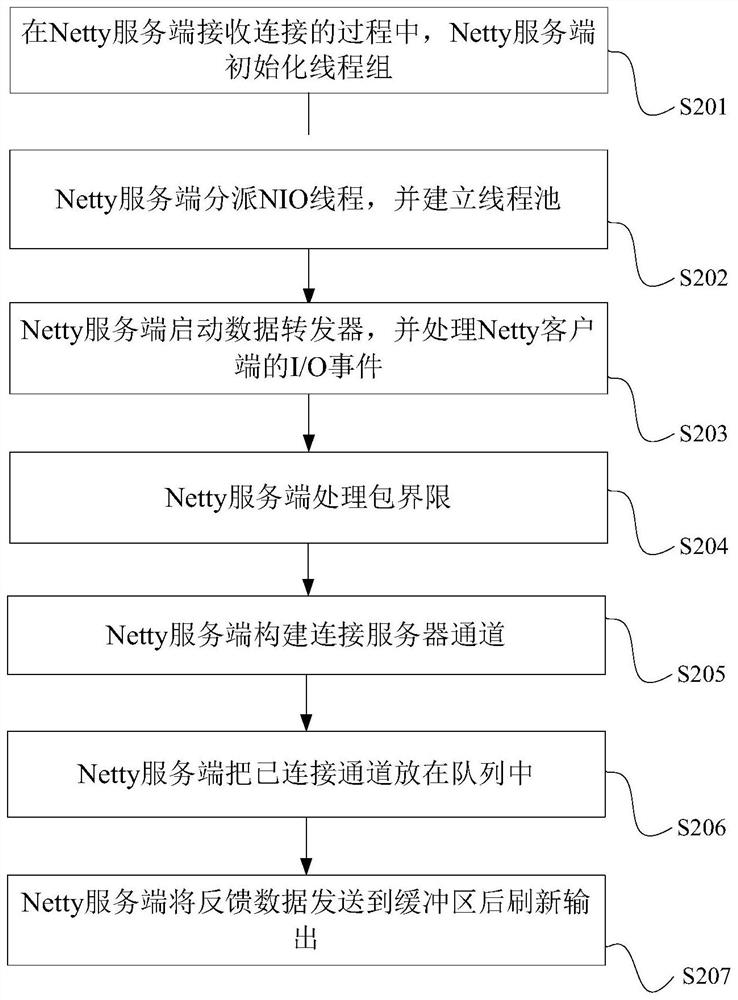

Remote data transmission method based on Netty

InactiveCN112148500AImprove throughputImprove processing efficiencyResource allocationInterprogram communicationEngineeringRemote data transmission

The invention discloses a remote data transmission method based on Netty. The method comprises the following steps: initiating an RPC request; in the process of establishing the connection, initializing a thread group; assigning an NIO thread, and establishing a thread pool; starting a data transponder, and processing an I / O event; processing packet boundaries; constructing a connection server channel; putting the connected channels into a queue; sending the data to a buffer area and then refreshing and outputting; when receiving the data, accessing the data into a kafka message queue; packaging the data into Producer Record of kafka; judging whether a specified partition exists in the topic or not; if it is determined that the specific partition does not exist in the top, judging whethera specific key exists or not; if it is determined that the specified key exists, specifying a partition for the top by adopting a corresponding hash algorithm according to the value of the key; and accessing to the partitions corresponding to the topics, and sequentially storing the data into the buffer pools corresponding to the partitions. By means of the mode, high-throughput data transmissioncan be achieved, the I / O event processing efficiency is effectively improved, and the phenomenon of server downtime caused by thread stack overflow is avoided.

Owner:CHINA SOUTHERN POWER GRID DIGITAL GRID RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com