Electromagnetic vibration generating device of permanent magnet and application thereof in vibration detection system

A technology of electromagnetic vibration and power generation device, which is applied in the direction of electromagnetic wave system, circuit device, generator/motor, etc., and can solve problems such as short life, low energy conversion efficiency, and poor performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

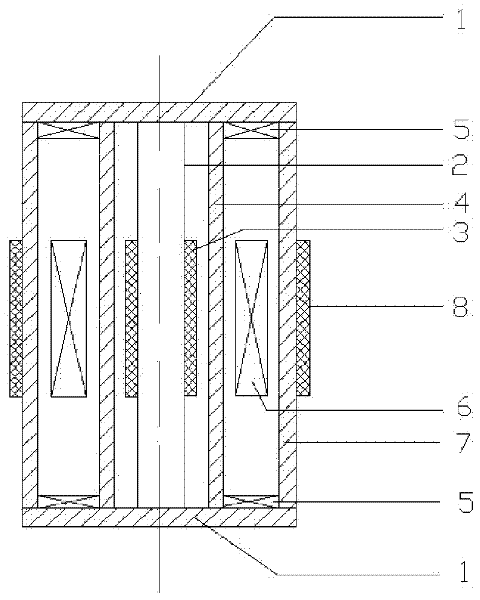

[0046] The configuration of the electromagnetic vibration power generation device of the permanent magnet that supplies the voltage of 5.1V.

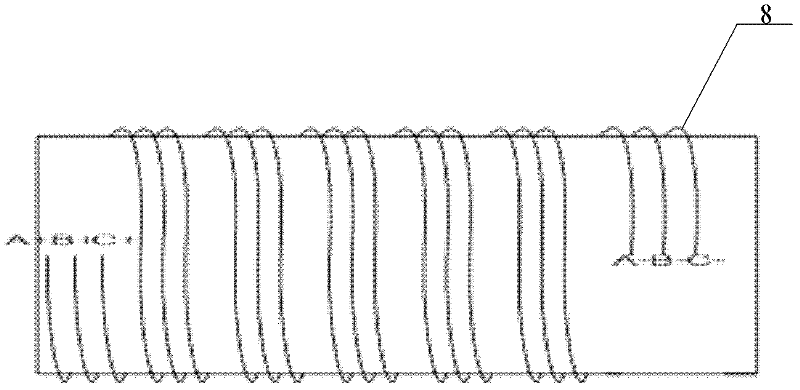

[0047] The selected materials and parts are: two annular permanent magnets with a thickness of 1mm, an inner diameter of 10mm and an outer diameter of 24mm are used as a fixed annular permanent magnet 5, and a ring permanent magnet with a thickness of 10mm, an inner diameter of 10mm and an outer diameter of 24mm A piece of magnet is used as a moving annular permanent magnet 6, and the permanent magnet material used is a NdFeB permanent magnet, and the remanence of the material is 1.276T. according to figure 2In the shown embodiment, the outer coil 8 adopts three independent copper windings A, B and C to be wound at the same time. The number of turns of the three independent copper windings A, B and C is the same, which is 600 turns respectively. The above three independent copper windings The induced voltage generated by the mass wind...

Embodiment 2

[0050] The composition of the electromagnetic vibration power generation device of the permanent magnet that supplies the voltage of 15.3V.

[0051] except by figure 2 In the shown embodiment, the outer coil 8 connects the above-mentioned three independent copper windings A, B and C in series as a voltage source for power supply, that is, connects A+ and B+, B- and C-, then A- and C+ are connected in series The final output voltage is 15.3V, other is the same as embodiment 1, thus makes the electromagnetic vibration power generation device of the permanent magnet that provides 15.3V voltage.

Embodiment 3

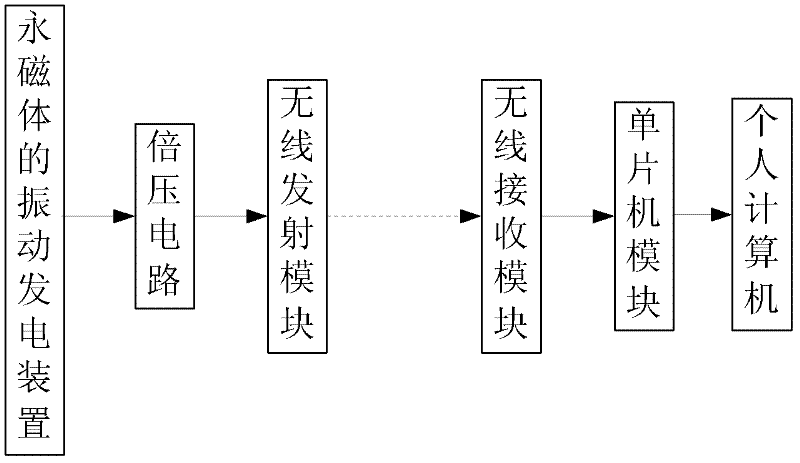

[0053] When the vibration detection system needs to provide a voltage level of 5.1V, the application of the electromagnetic vibration power generation device with a 5.1V voltage permanent magnet prepared in Example 1 in the vibration detection system.

[0054] Such as image 3 In the illustrated embodiment, the six components used in the vibration detection system of this embodiment are as follows:

[0055] The electromagnetic vibration generating device of the permanent magnet is the electromagnetic vibration generating device of the permanent magnet of the 5.1V voltage that embodiment 1 makes, namely Figure 4 The vibration power generation device 11 of the permanent magnet in it. As the only power source in the vibration detection system, the vibration power generation device 11 of the permanent magnet converts the vibration mechanical energy into electrical energy and outputs a voltage of 5.1V while collecting mechanical vibration energy in all directions, making the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com