Patents

Literature

305results about How to "Adjust the tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

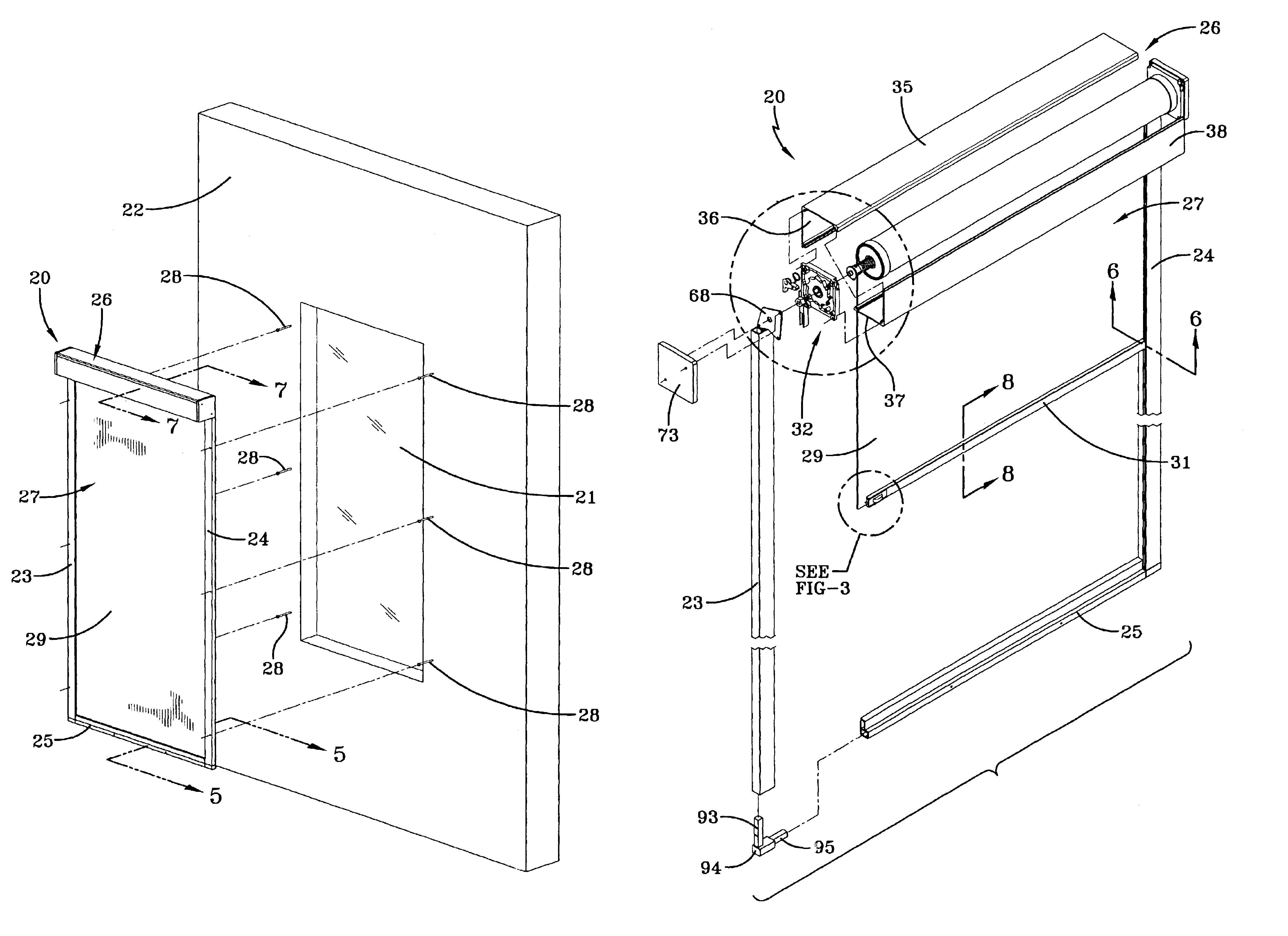

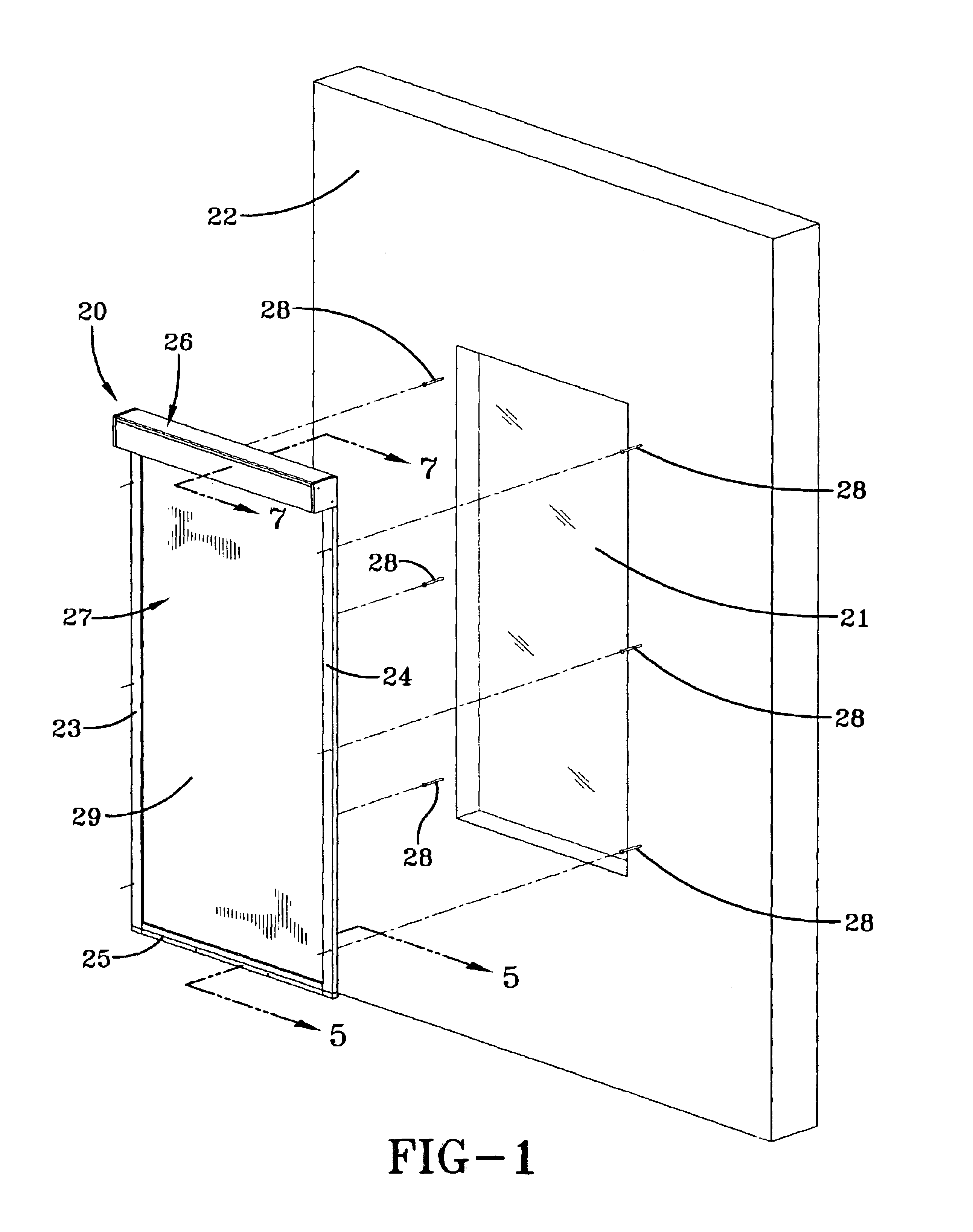

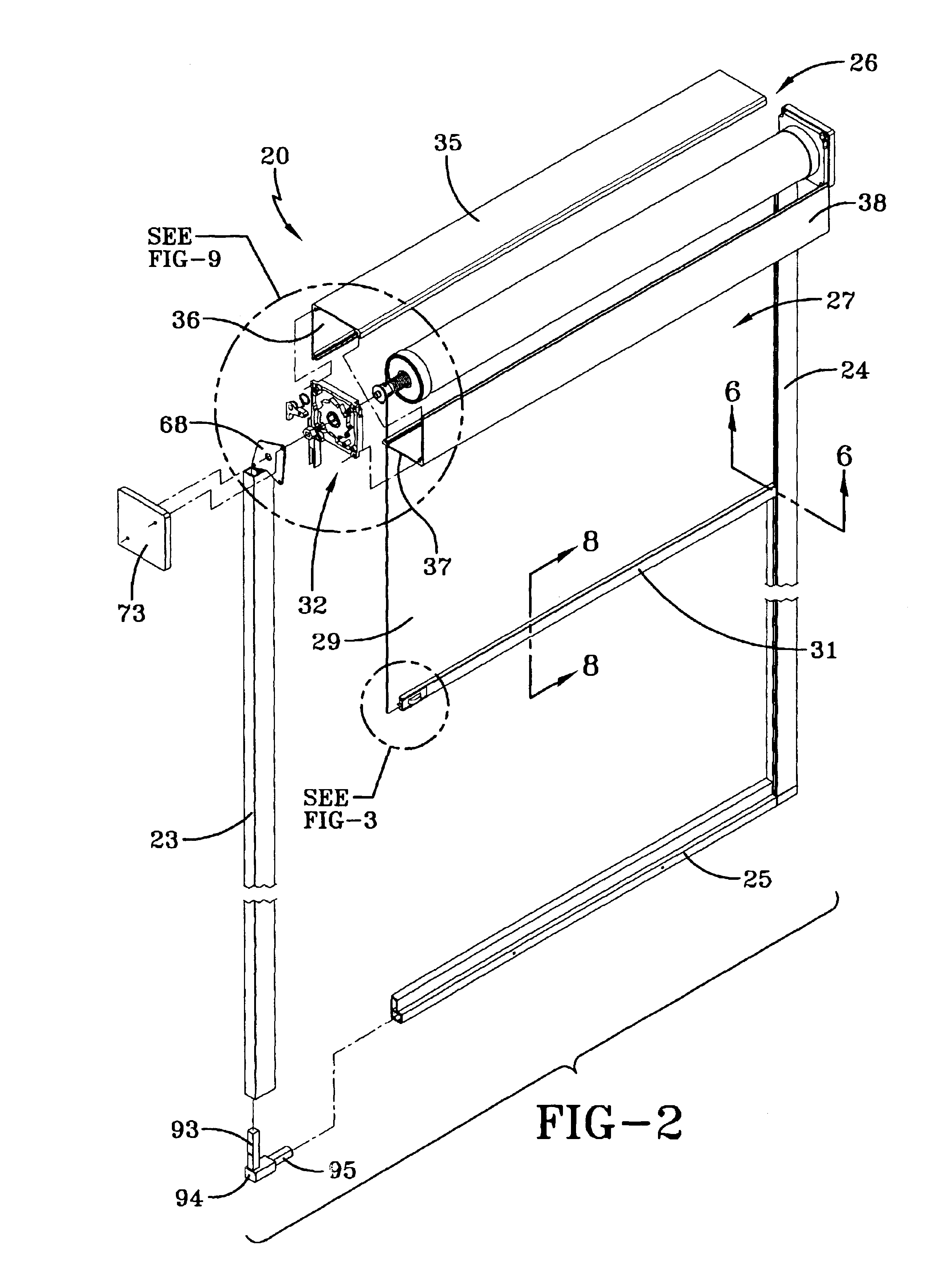

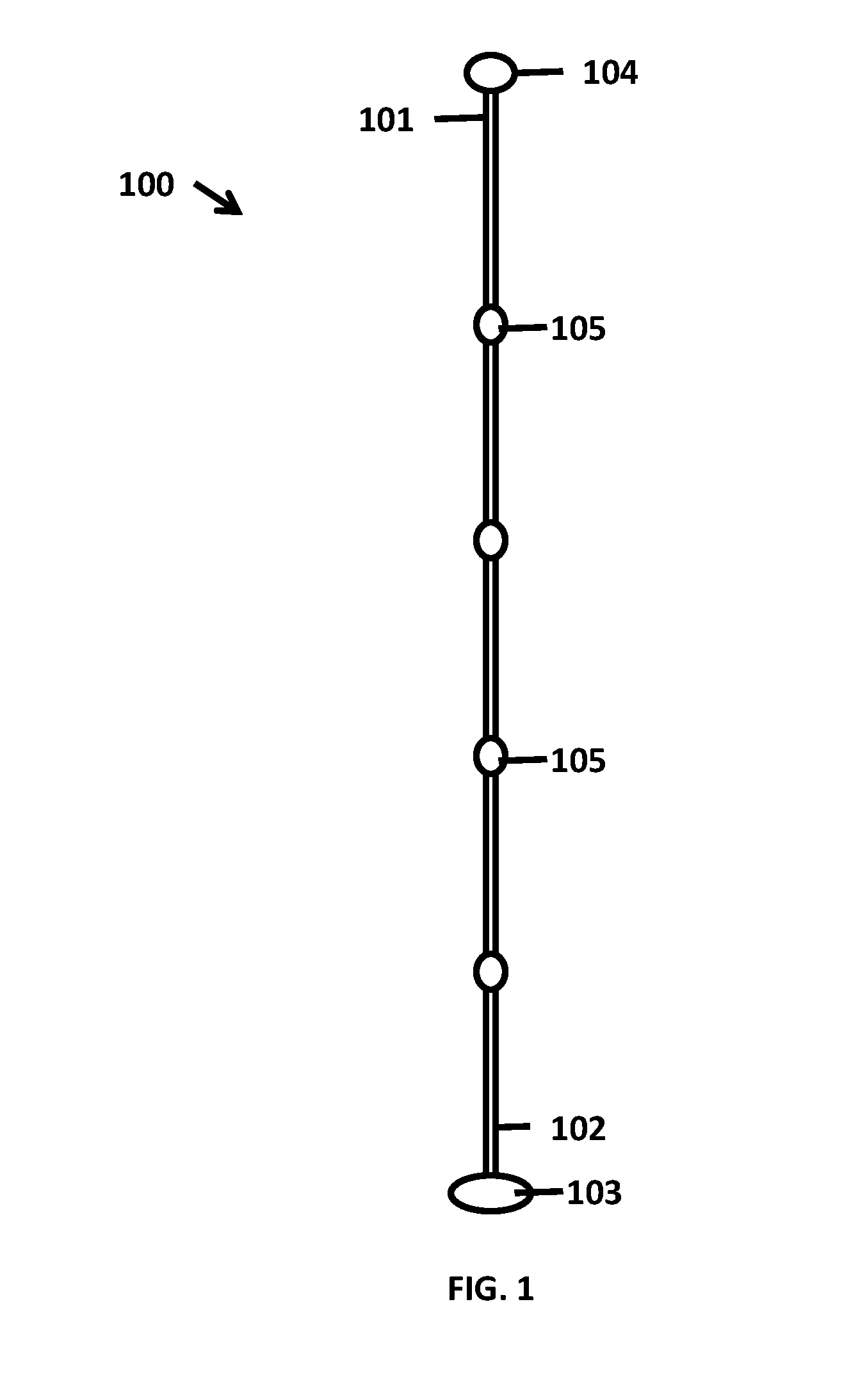

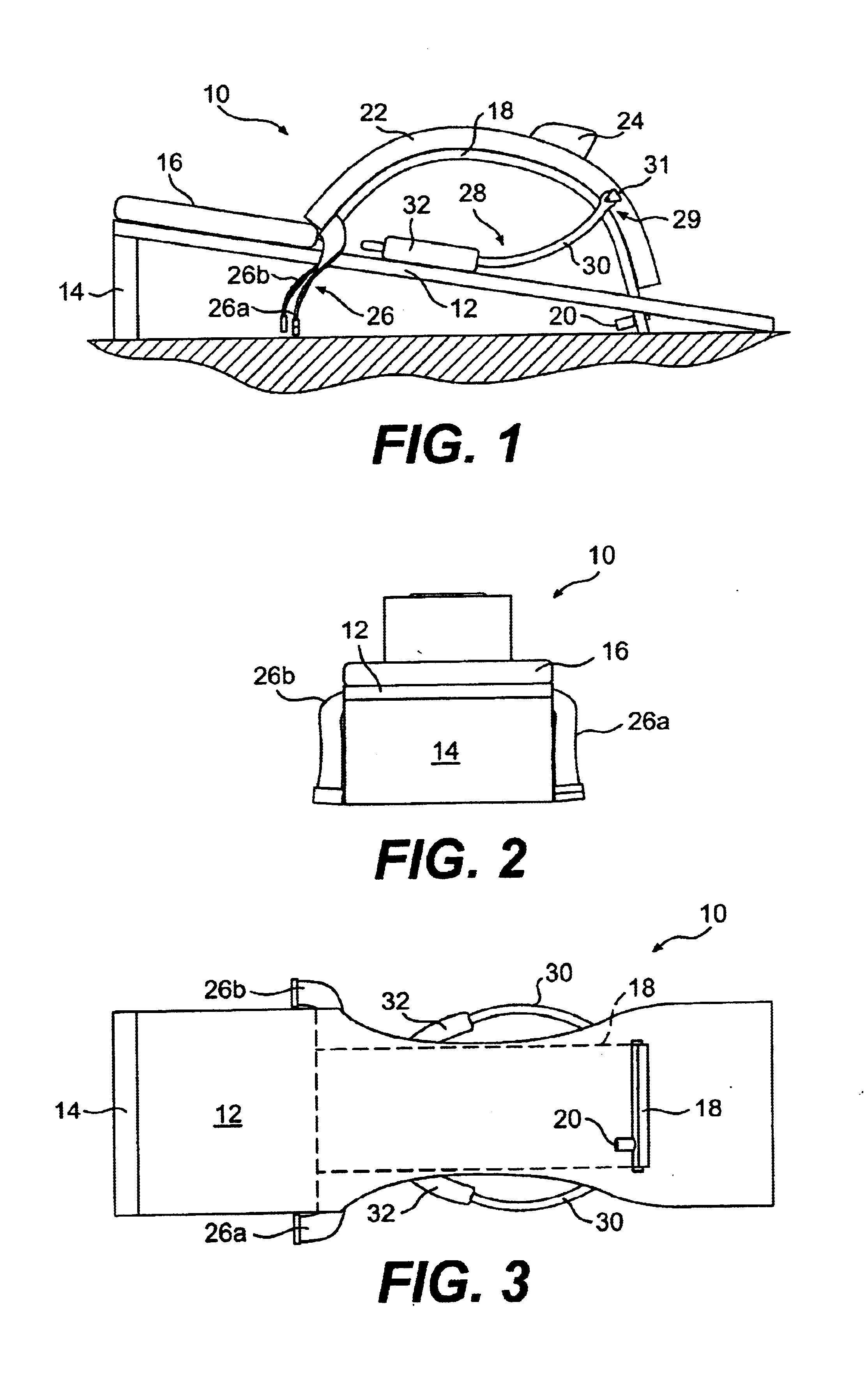

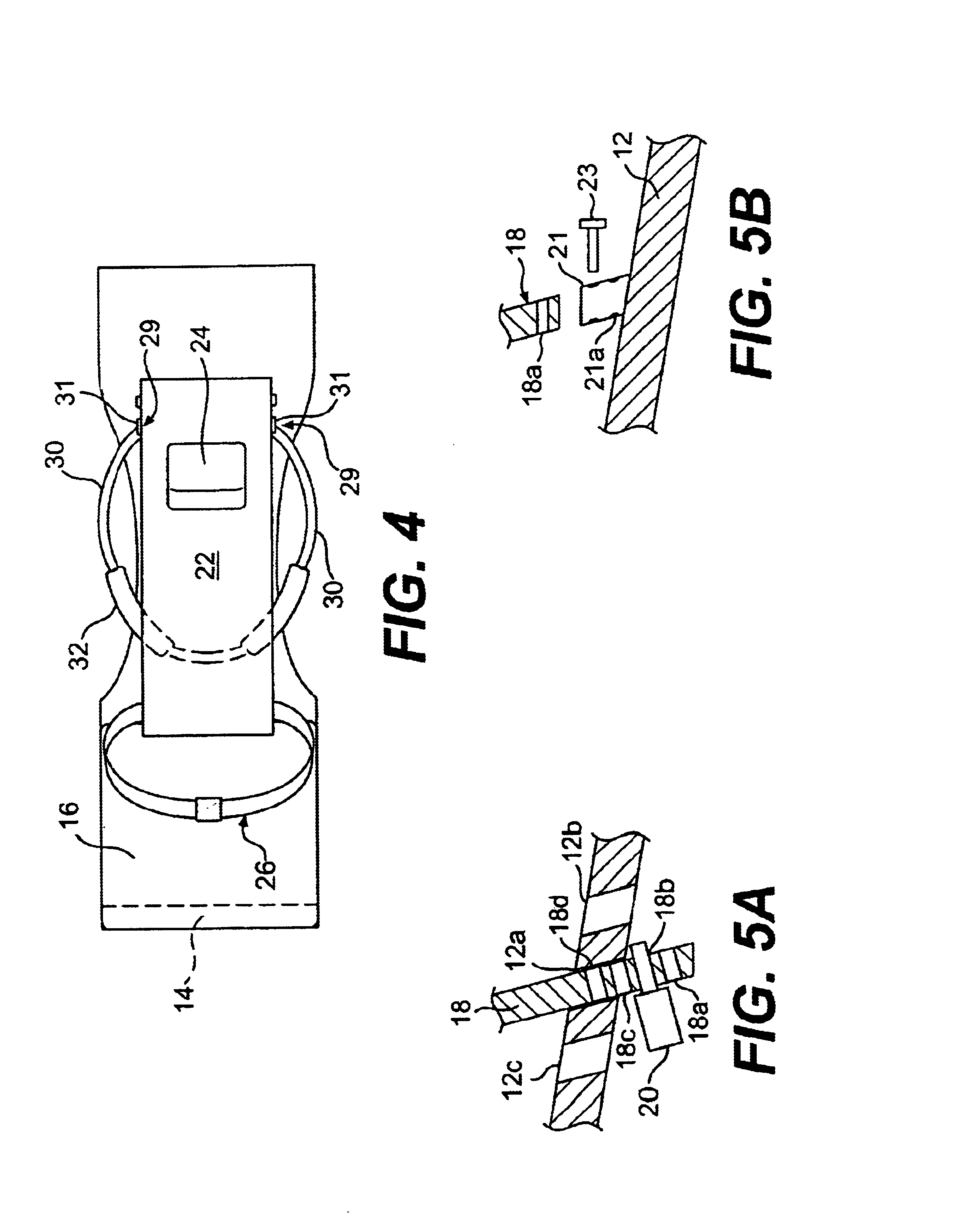

Apparatus for covering an opening in a building

InactiveUS6959748B2Adjust the tensionAdjustable tensionShutters/ movable grillesCurtain suspension devicesWindow openingEngineering

A storm protector (20) to be attachable over a window (21) or other opening of a building (22) includes a header (26), a bottom sill (25) and side frames (23, 24) extending between the ends of the header (26) and the sill (25). The header (26) carries a tube (53) which has one end of a curtain assembly (27) attached thereto. The curtain assembly (27)is biased by a spring (54) to be normally coiled on the tube (53), but the curtain assembly (27) may be manually moved along the frames (23, 24) to the sill (25) to cover the window opening (21). A bar (31) is formed at the other end of the curtain assembly (27), and the bar (31) carries a guide and lock assembly (110) which rides in and can engage at least one of the side frames (23, 24) to guide and selectively hold the curtain assembly (27) at any selected position along the side frames (23, 24). A tensioning assembly (32) is positioned in the header (26) and, without disassembling the protector (20), it may be accessed to adjust the tension of the spring (54). The header (26) includes a sealing surface (50), the sill (25) includes a sealing surface (105) and each side frame (23, 24) includes a sealing surface (89). A force upon the curtain assembly (27) causes it to engage the sealing surfaces (50, 89, 105) to provide a full perimeter seal around the window opening (21).

Owner:OVERHEAD DOOR

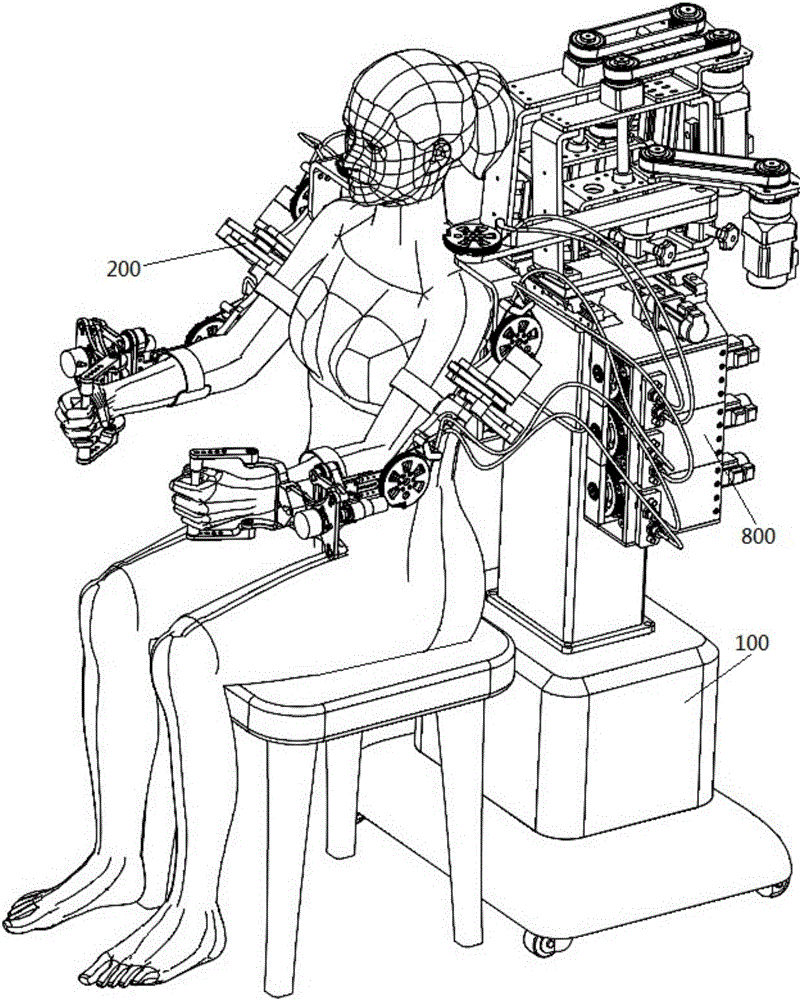

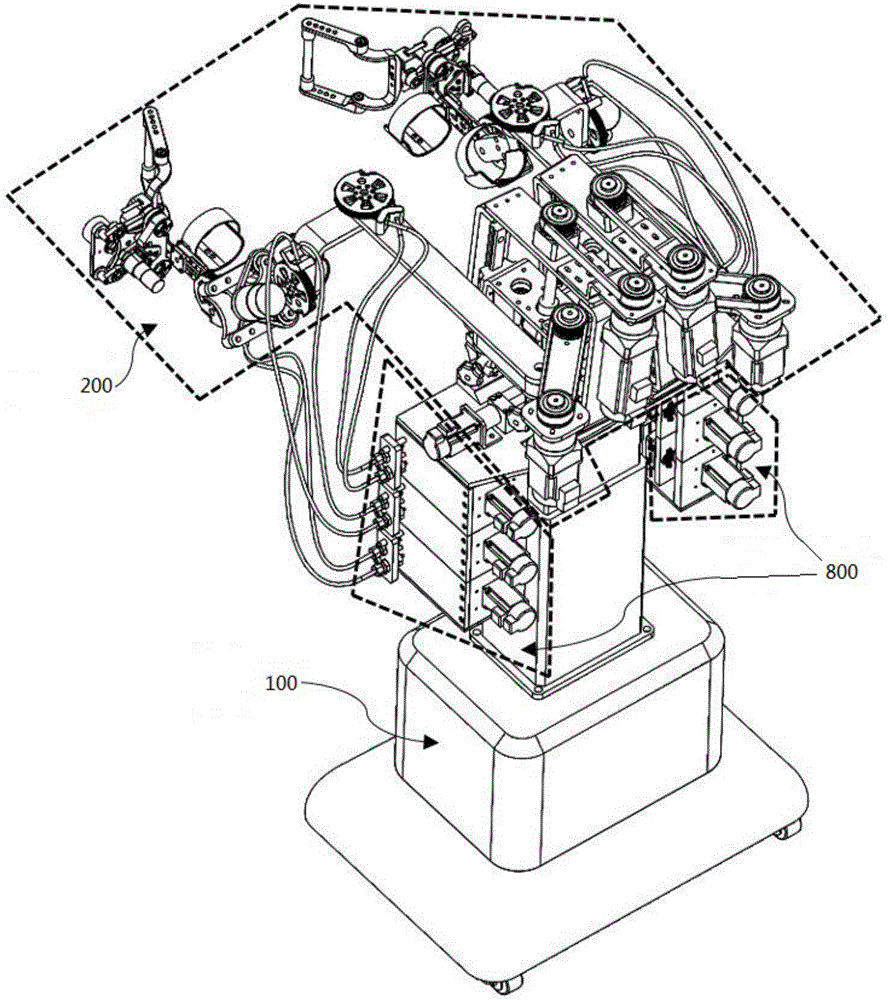

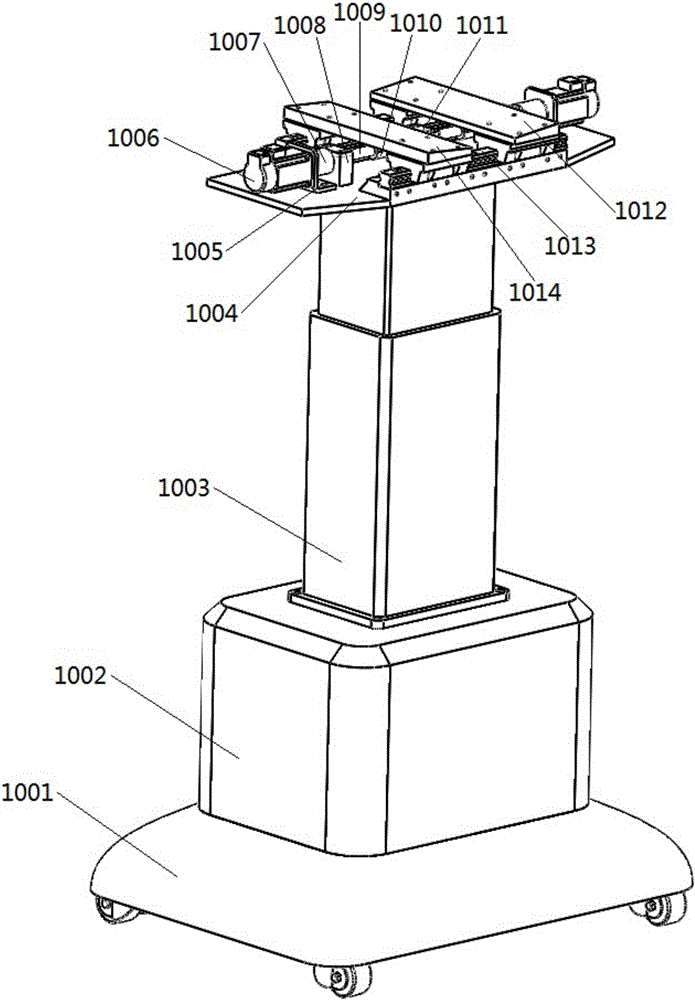

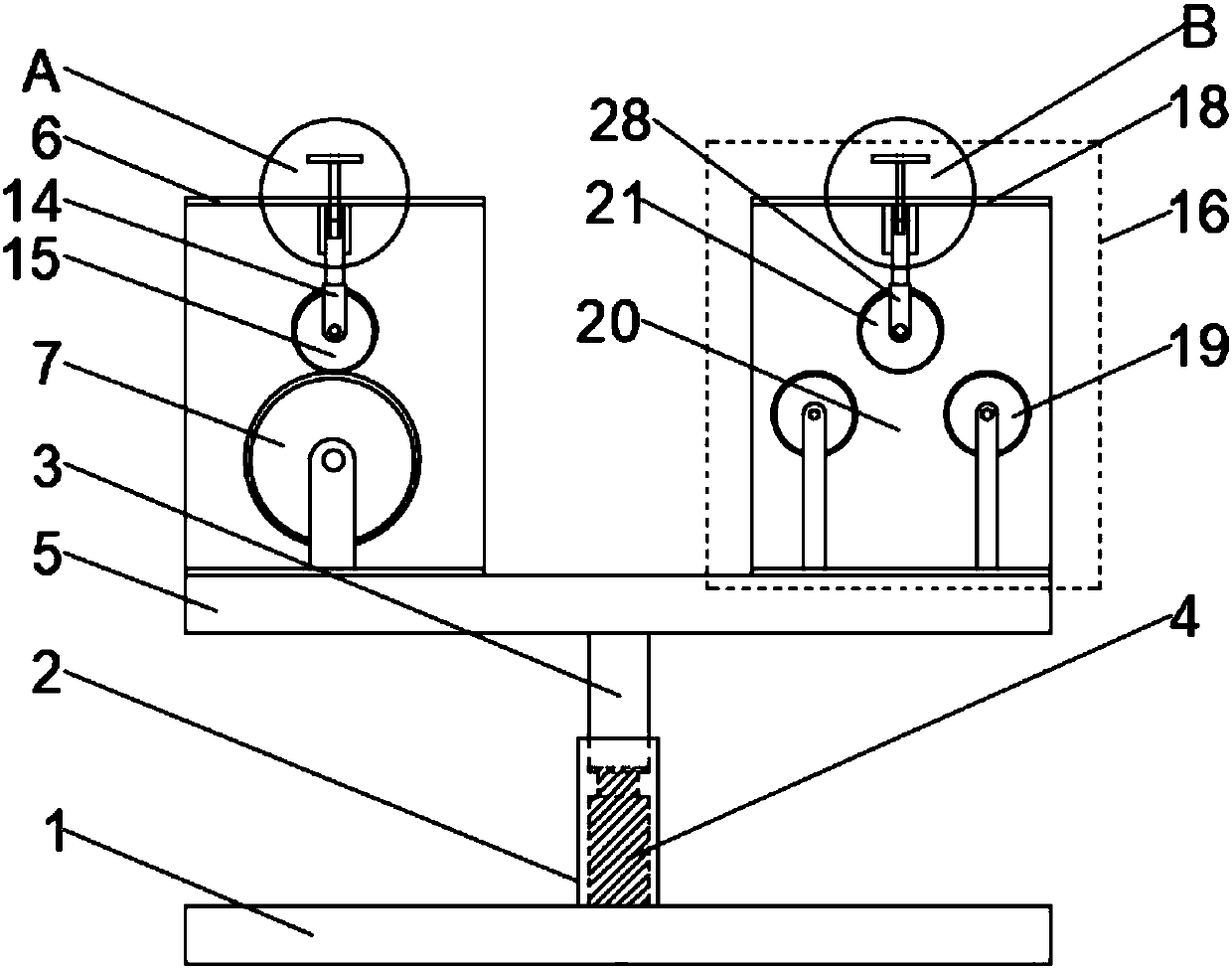

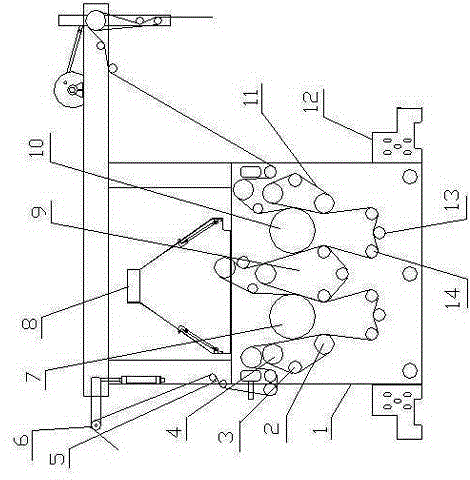

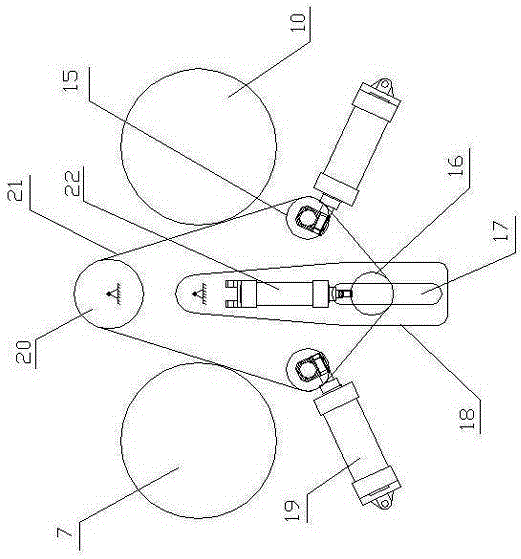

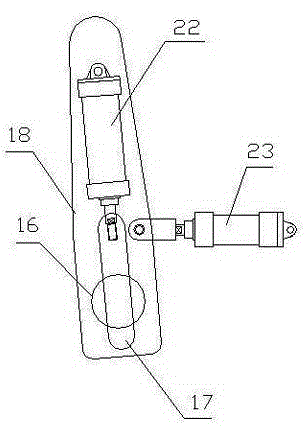

Exoskeletal rehabilitation robot for upper limbs

PendingCN105662782ASolving Mismatch ProblemsWon't hurtProgramme-controlled manipulatorChiropractic devicesEngineeringUpper limb rehabilitation

The invention discloses an exoskeletal rehabilitation robot for upper limbs. The exoskeletal rehabilitation robot comprises a base, two mechanical arm assemblies and six motor driving components, wherein the base comprises a moving base, an electrical cabinet, an electric lifting post, a base platform, a motor mounting corner bracket, a base rotating motor, a coupling, a base main bearing block, a base and ball screw nut assembly, a base nut seat, a base shared secondary bearing block, a right support, a base linear guide rail assembly and a left support; the mechanical arm assembly comprises a mechanical shoulder girdle assembly, a mechanical shoulder joint assembly, a mechanical elbow joint assembly, a mechanical front arm assembly, a mechanical wrist joint assembly and a mechanical hand part assembly; each motor driving assembly comprises a motor and speed reducing component, a torque sensor component and a driving component which are respectively arranged on the same motor driving base frame. The exoskeletal rehabilitation robot can be worn on the upper limbs of the human body and can be used for assisting the upper limbs of the human body in moving in a three-dimensional space and performing rehabilitation training.

Owner:SHANGHAI ZHUODAO MEDICAL TECH CO LTD

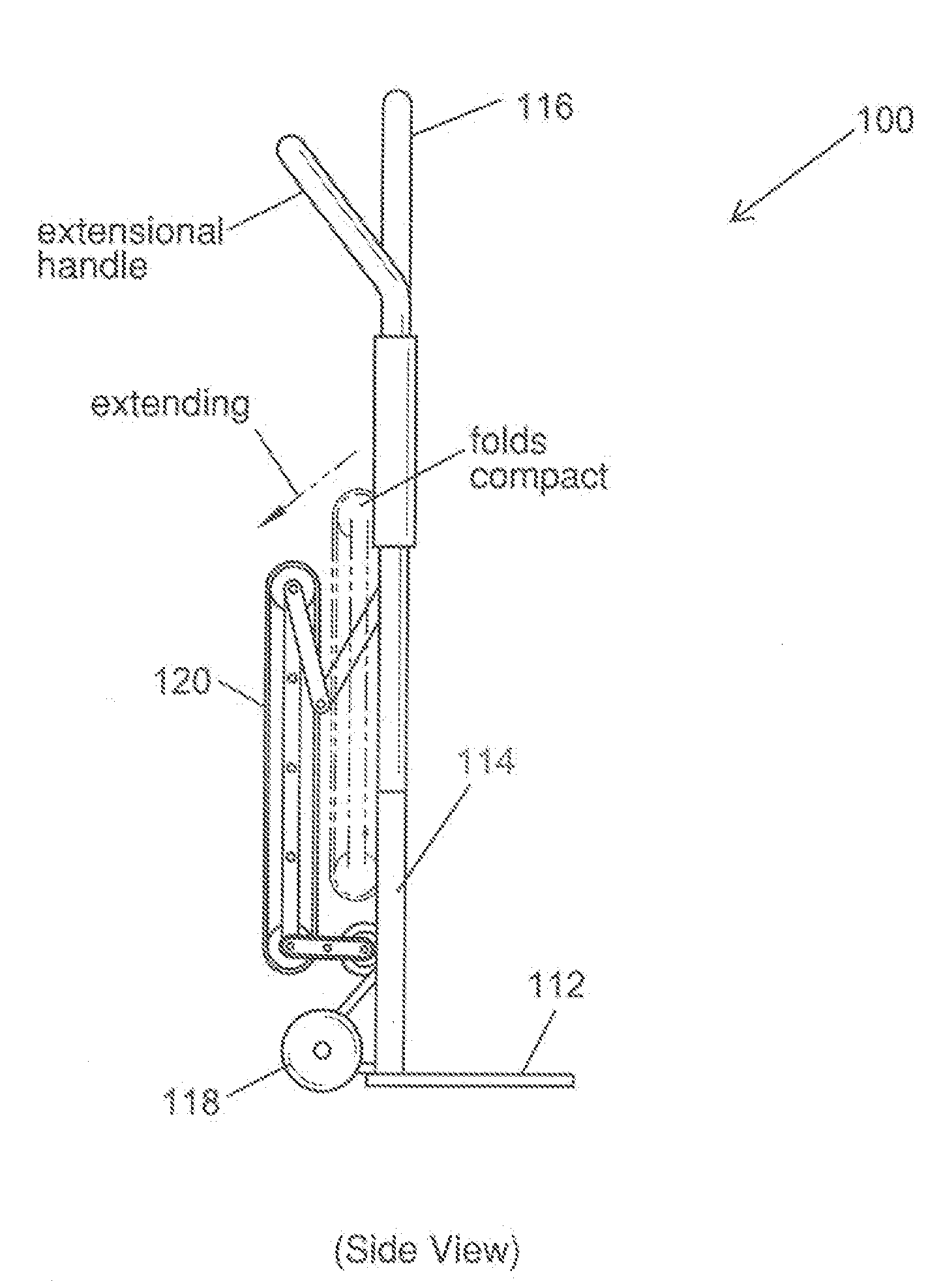

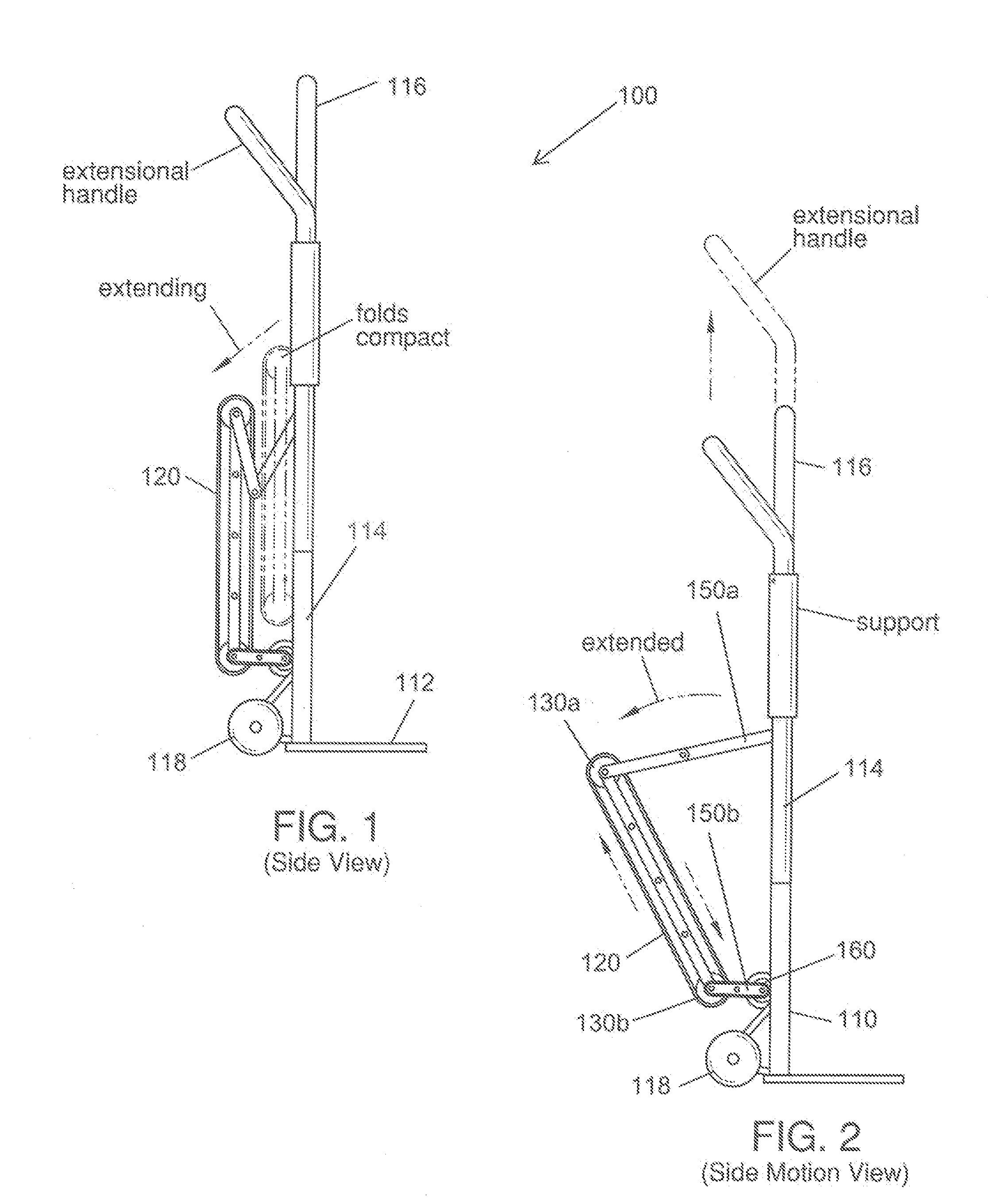

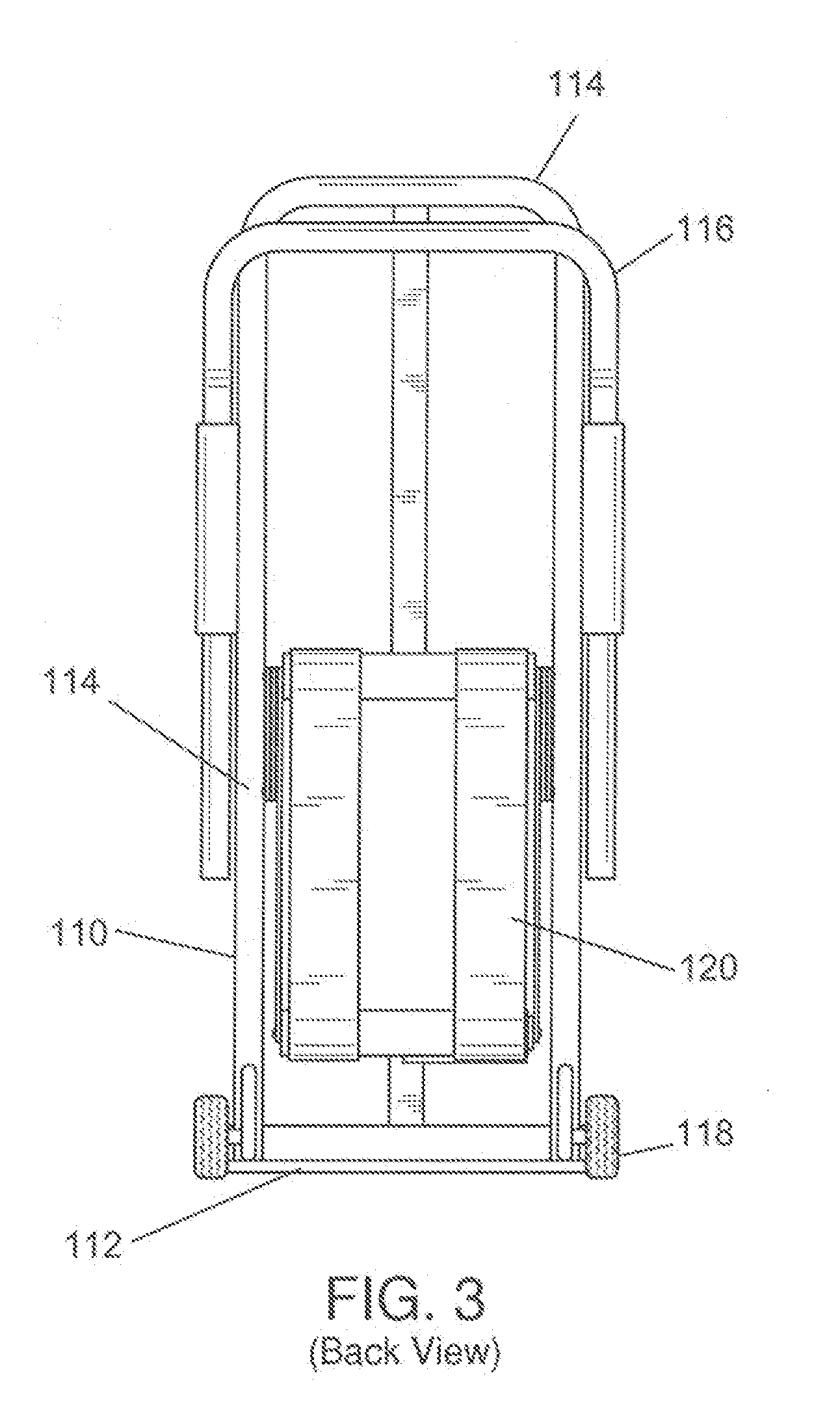

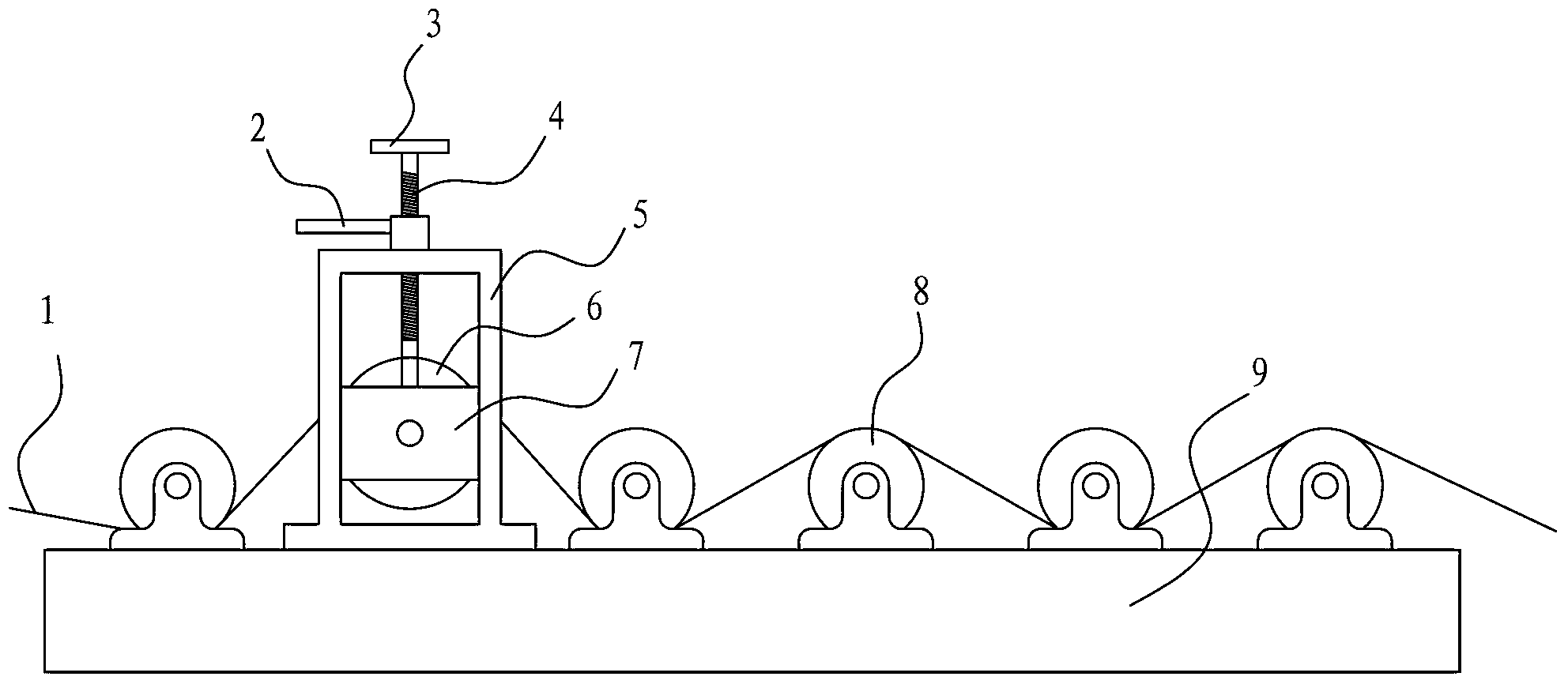

Dolly system for transporting objects up and down stairs

InactiveUS8439371B1Adjust the tensionCarriage/perambulator accessoriesSledge wheelsConveyor beltWrap around

An electric dolly system for transporting an object up and down stairs having a base platform connected to a bottom end of support rails, a handle at a top end and a pair of wheels at the bottom end, a track belt wrapped around a first and second rotator component adapted to rotate around the rotator components like a conveyor belt using a motor, the first rotator component is connected to the support rails via a first extension arm and the second rotator component is connected to the support rails via a second extension arm, the first extension arm is positioned closer to the handle and is longer than the second extension arm such that the track belt is at an angle with respect to the support rails.

Owner:VAZQUEZ JORGE

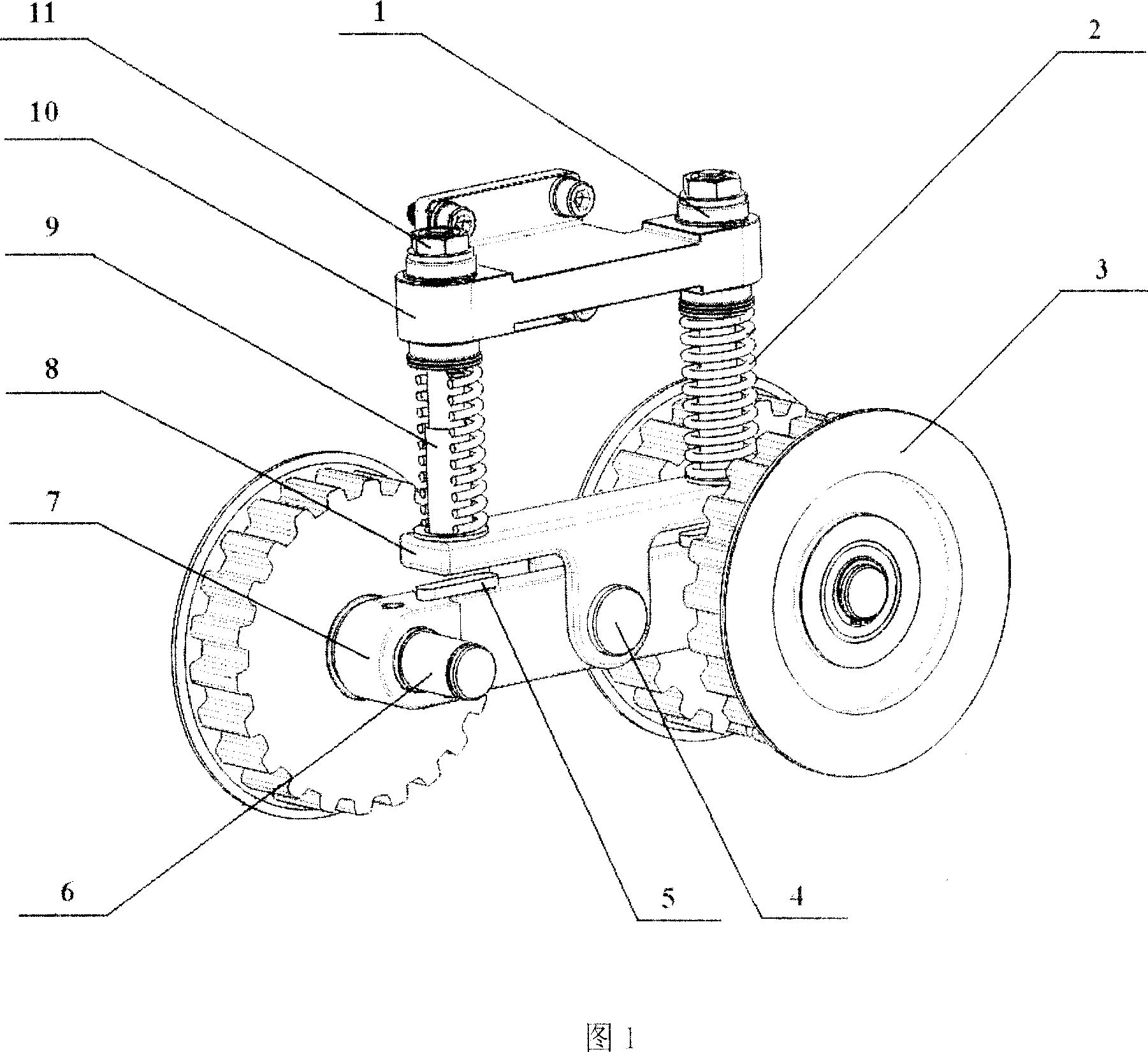

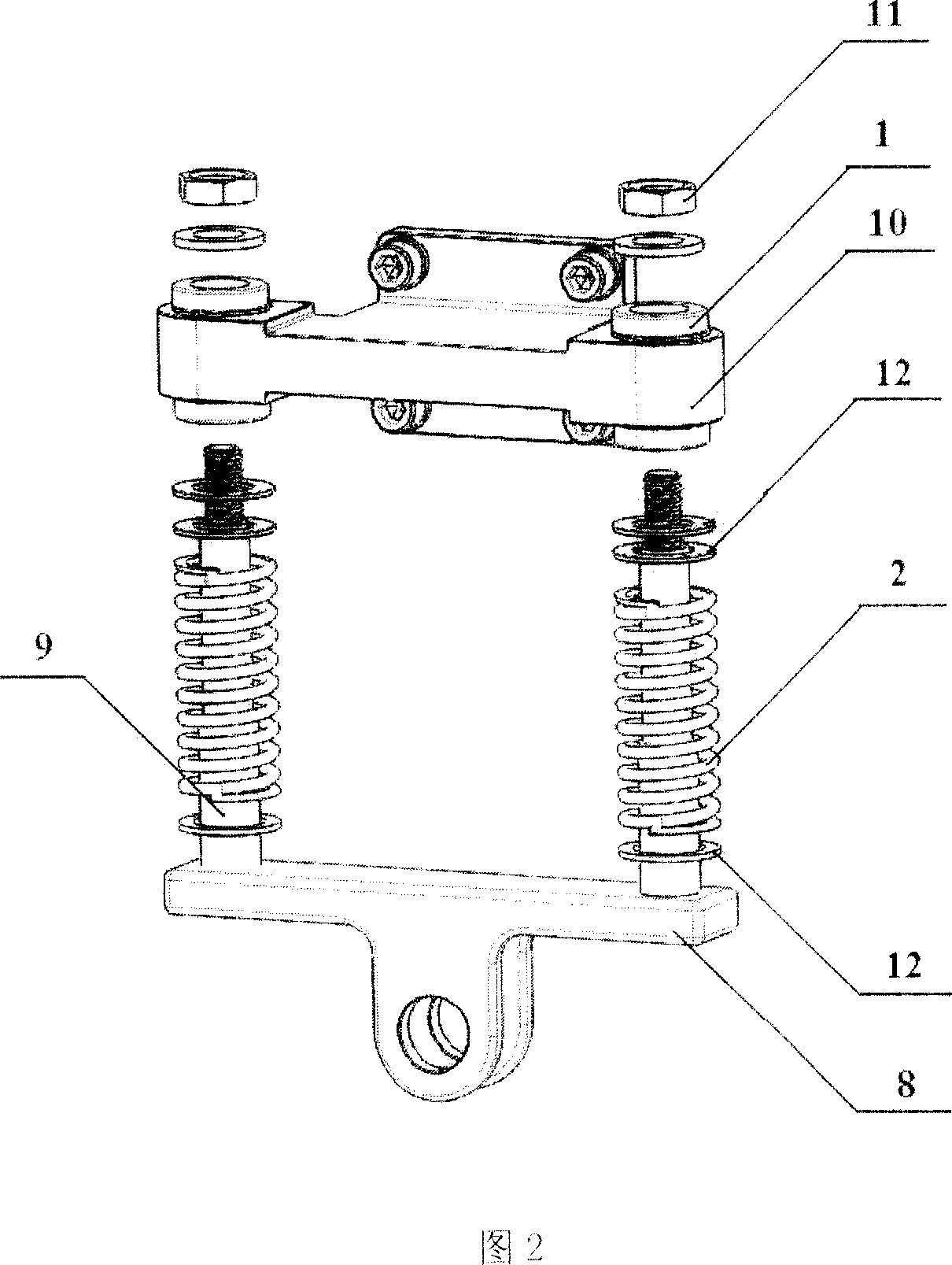

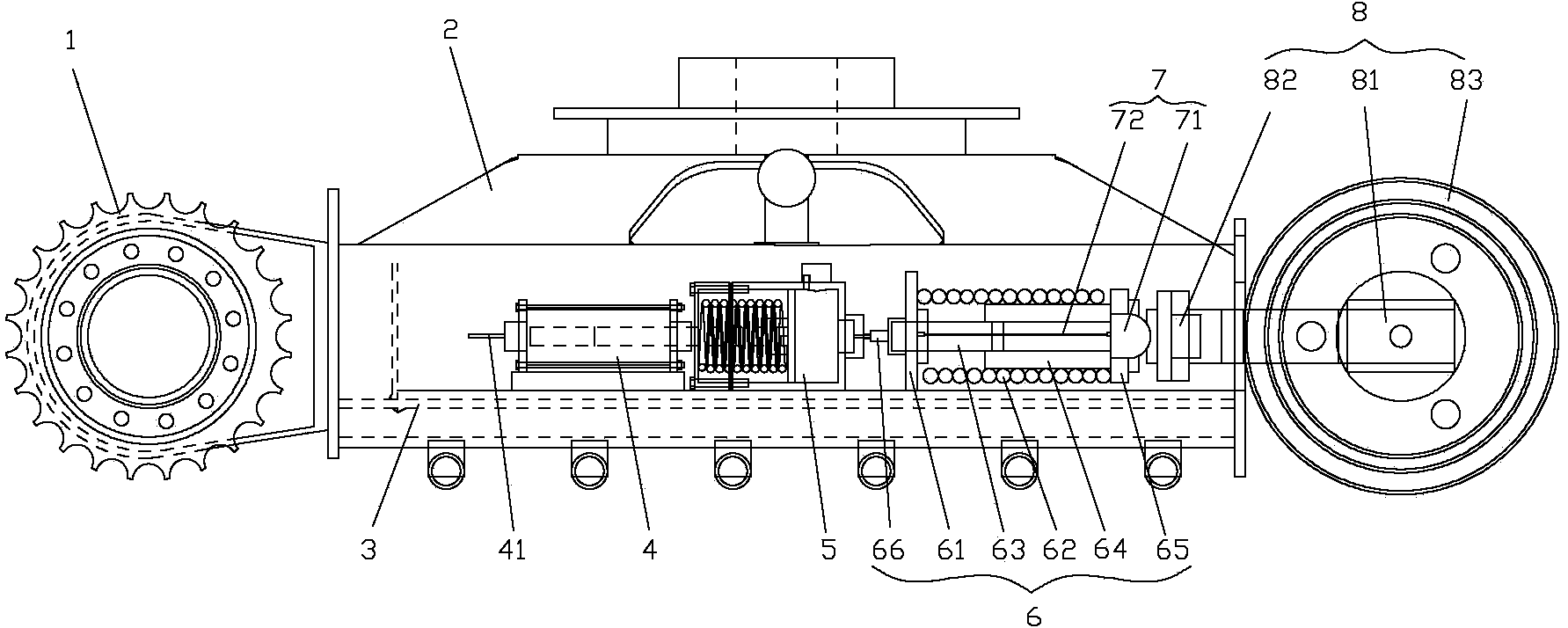

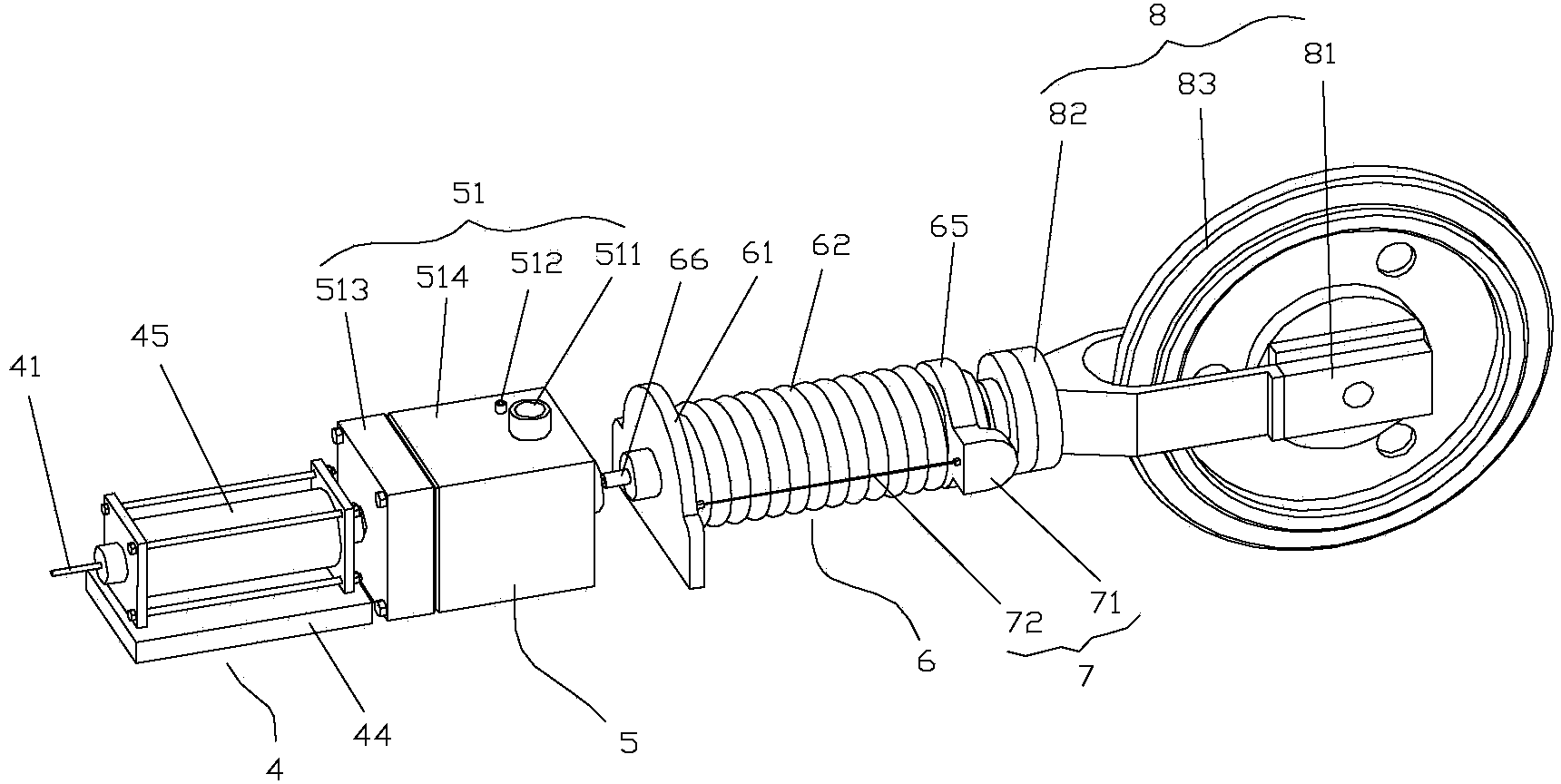

Light crawler motor platform vibration suspension device

InactiveCN100999235AImprove obstacle performanceImprove driving stabilityEndless track vehiclesEngineeringMechanical engineering

The present invention relates to a vibration-damping suspension device for light caterpillar motor-platform. It is composed of spring vibration-damping component and swinging component. Said swinging component is positioned in the lower portion and is used for mounting loading wheel, and is hinged with spring vibration-damping component; the spring vibration-damping component is fixedly connected with motor-platform body by means of fixed seat. Said vibration-damping suspension device ensure reliable engagement of platform loading wheel and caterpillar.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

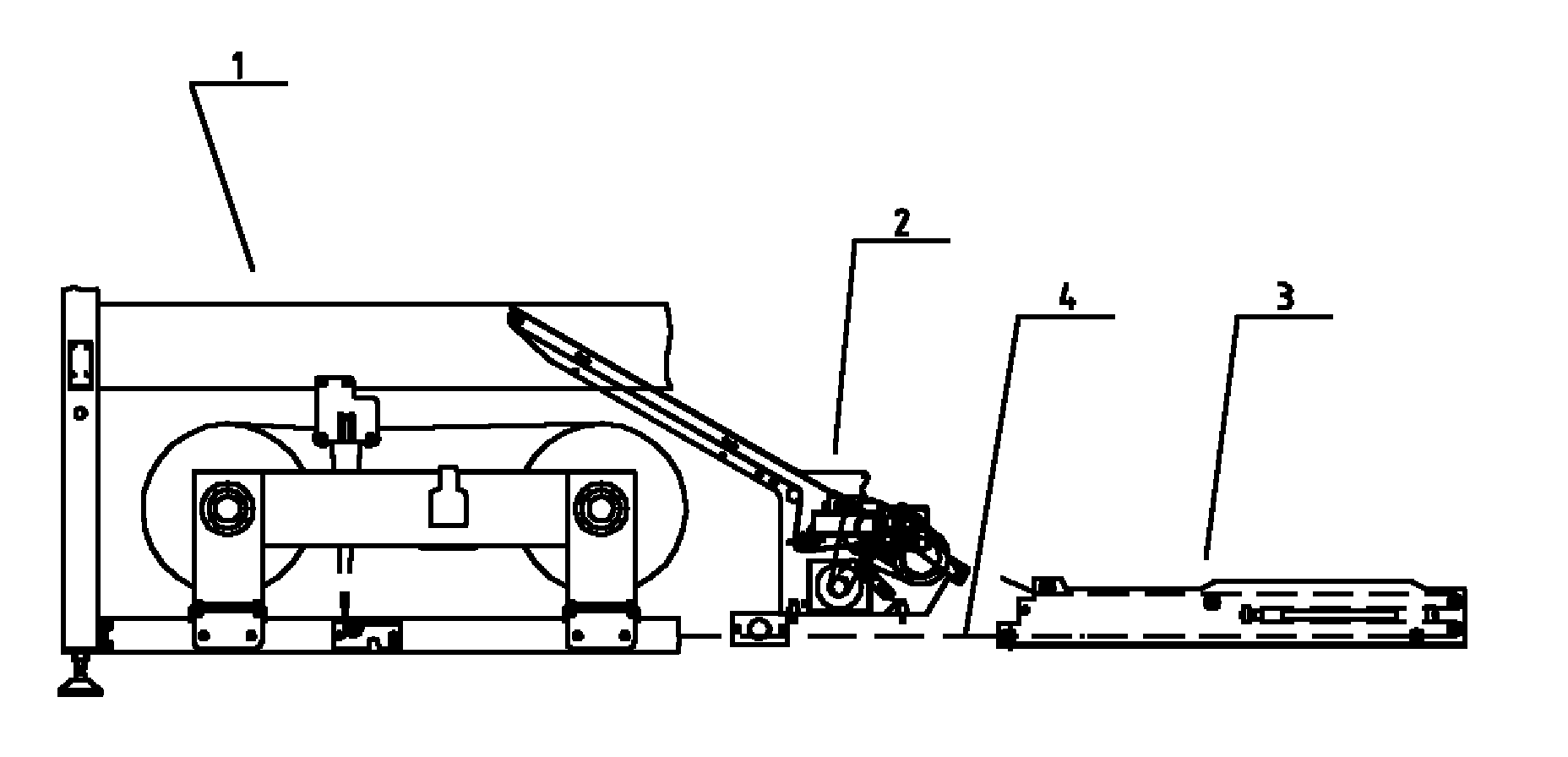

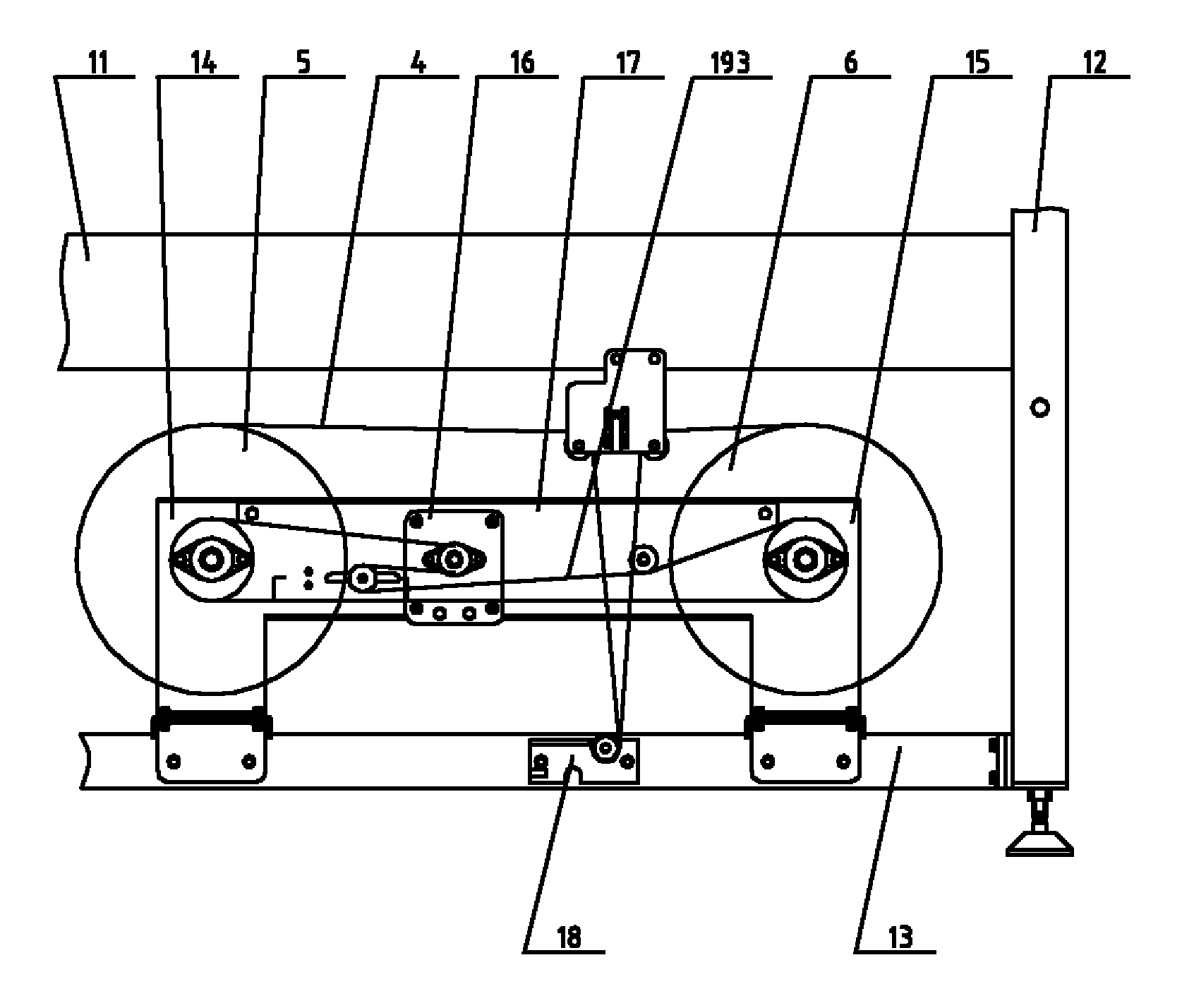

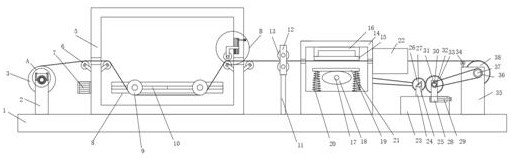

Film-feeding and film-cutting mechanisms of film packager

ActiveCN102070035AShorten the timeIncrease productivityWrapping material feeding apparatusWebs handlingEngineeringConveyor belt

The invention discloses film-feeding and film-cutting mechanisms of a film packager, which comprises a film roll supporting component, a film-tension component and a film-cutting transmission component according to the sequence of material transmission direction, wherein when one film roll in the film roll supporting component is in operation, another film roll is standby, and when the working film roll is used up, the spare film roll is enabled; an action of changing the film roll conveniently and efficiently can be finished by connecting the front end of the spare film roll to the end of the film roll in operation; the film-tension component comprises a frame, a transitional wheel and a tension-adjusting device, wherein the film-tension component is used as the transition between the film roll supporting component and the film-cutting transmission component, thus adjusting the tension strength between the two components; and the film-cutting transmission component comprises a film-cutting part and a film-feeding part, wherein the film-cutting part of the film-cutting transmission component is arranged at one end of the conveyor belt as an input end, which is connected to the film-tension component, thus lowering the height of the film-cutting part in an integral level and being convenient in maintenance.

Owner:广州市万世德智能装备科技有限公司

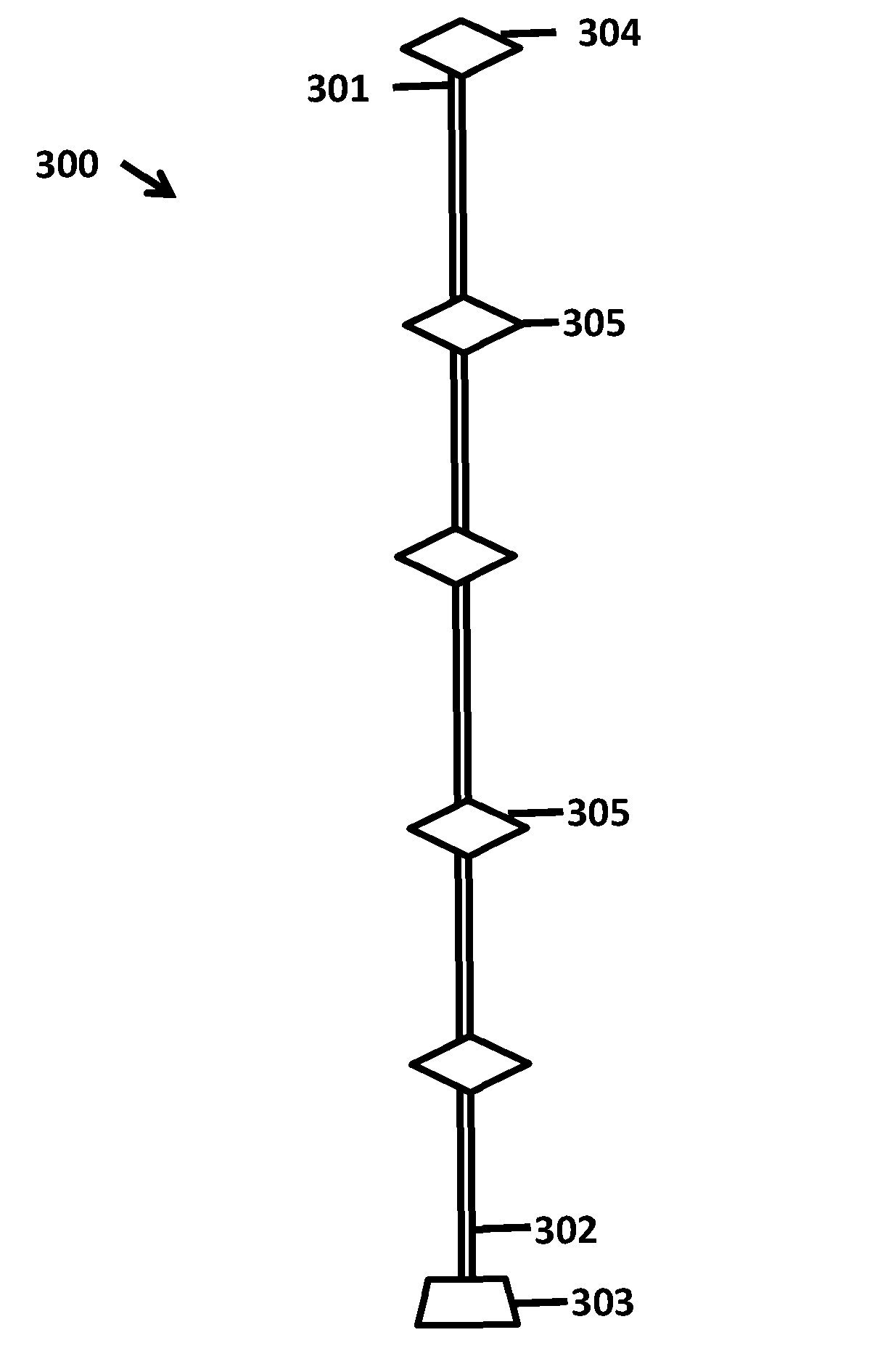

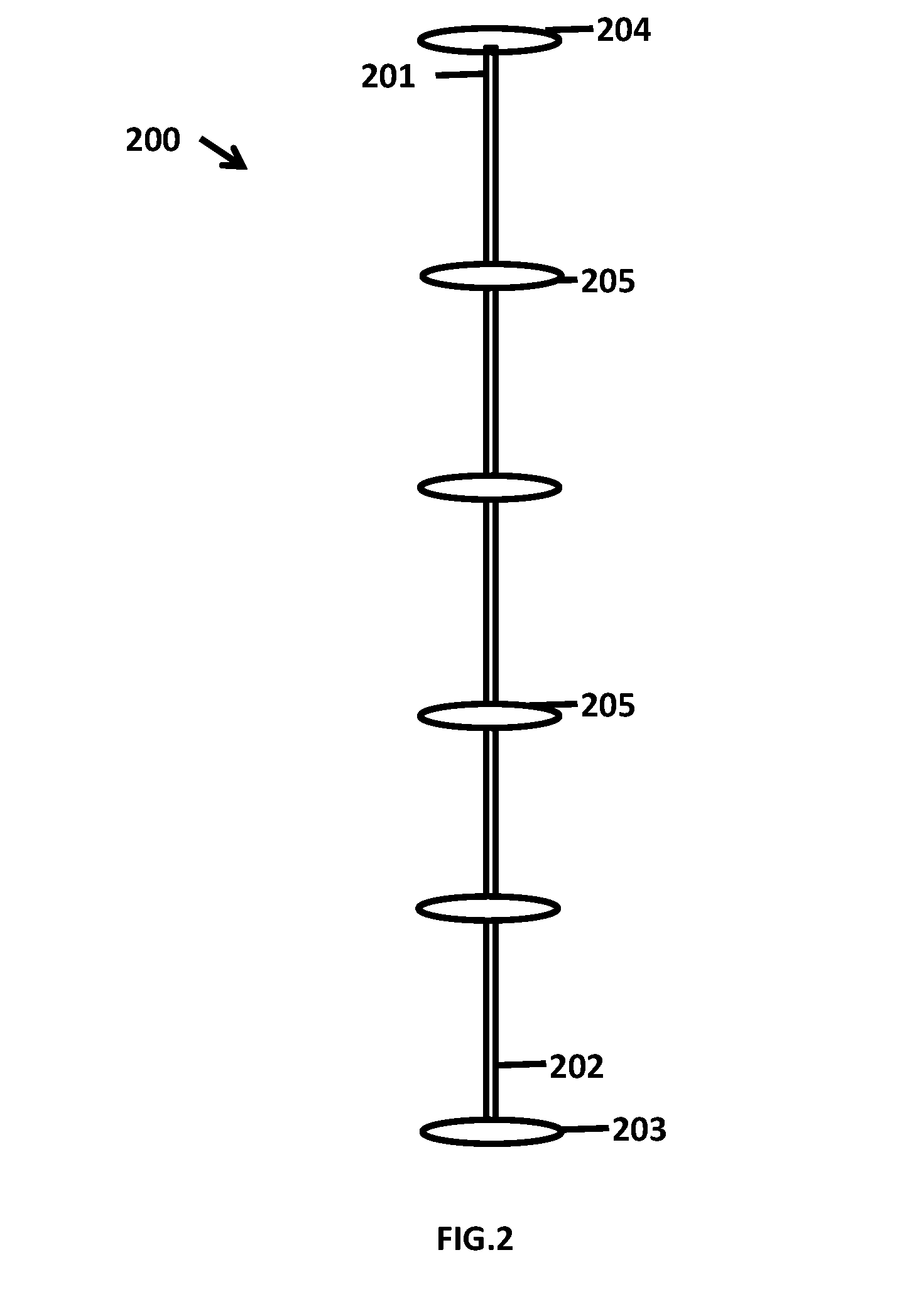

Resistance exercise and physical therapy apparatus

ActiveUS8157712B1High tensionEasily be dislodgedResilient force resistorsPhysical medicine and rehabilitationResistance training

A resistance exercise and physical therapy apparatus is provided. The resistance exercise and physical therapy apparatus includes: an elongate resilient member having a proximal end and a distal end, wherein the elongate resilient member includes an elastic material with a first enlargement at the proximal end, a second enlargement at the distal end, and one or more spaced-apart third enlargements along the length of the elongate resilient member, wherein the first enlargement is grasped by a first foot of a human user or by one or more floor or wall mounted sockets. A method of resistance exercise and a kit including the resistance exercise and physical therapy apparatus are also provided.

Owner:MUSACHIO NICHOLAS R

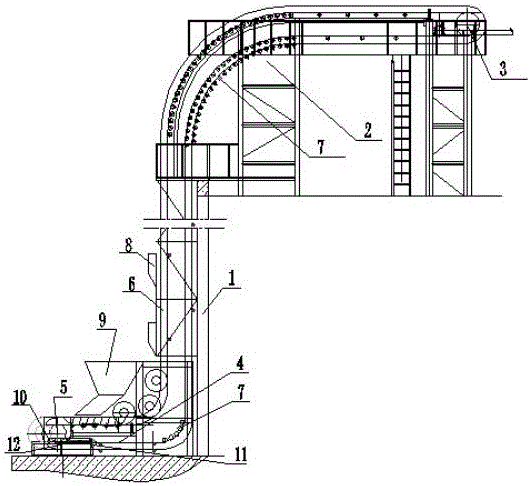

Vertical lifting corrugation flange conveyor

The invention discloses a vertical lifting corrugation flange conveyor. The vertical lifting corrugation flange conveyor comprises a truss, a head support, an upper end redirection drum, a tail support, a lower end redirection drum and a corrugation flange belt which is arranged in the tail support, the truss and the head support and can do vertical rotation running; the tail support and the head support are horizontally arranged and are perpendicular to the truss, a concave-arc turn frame is arranged at the connecting position of the tail support and the truss, a convex-arc turn frame is arranged at the connecting position of the head support and the truss, encryption lifting rollers are arranged on the outer ring of the concave-arc turn frame and the inner ring of the convex-arc turn frame, the included angle between a transverse partition plate and a bottom plate of the corrugation flange belt is 75 degrees, a plurality of anti-scattering plates are arranged at the position, on the ascending side of the corrugation flange belt, of the truss and are bend plates, each anti-scattering plate at leas comprises an outer baffle, two side baffles and an inclined plate connected with the outer baffle and the two side baffles, and the inclined plates face the corrugation flange belt.

Owner:中铁隧道局集团有限公司勘察设计研究院 +1

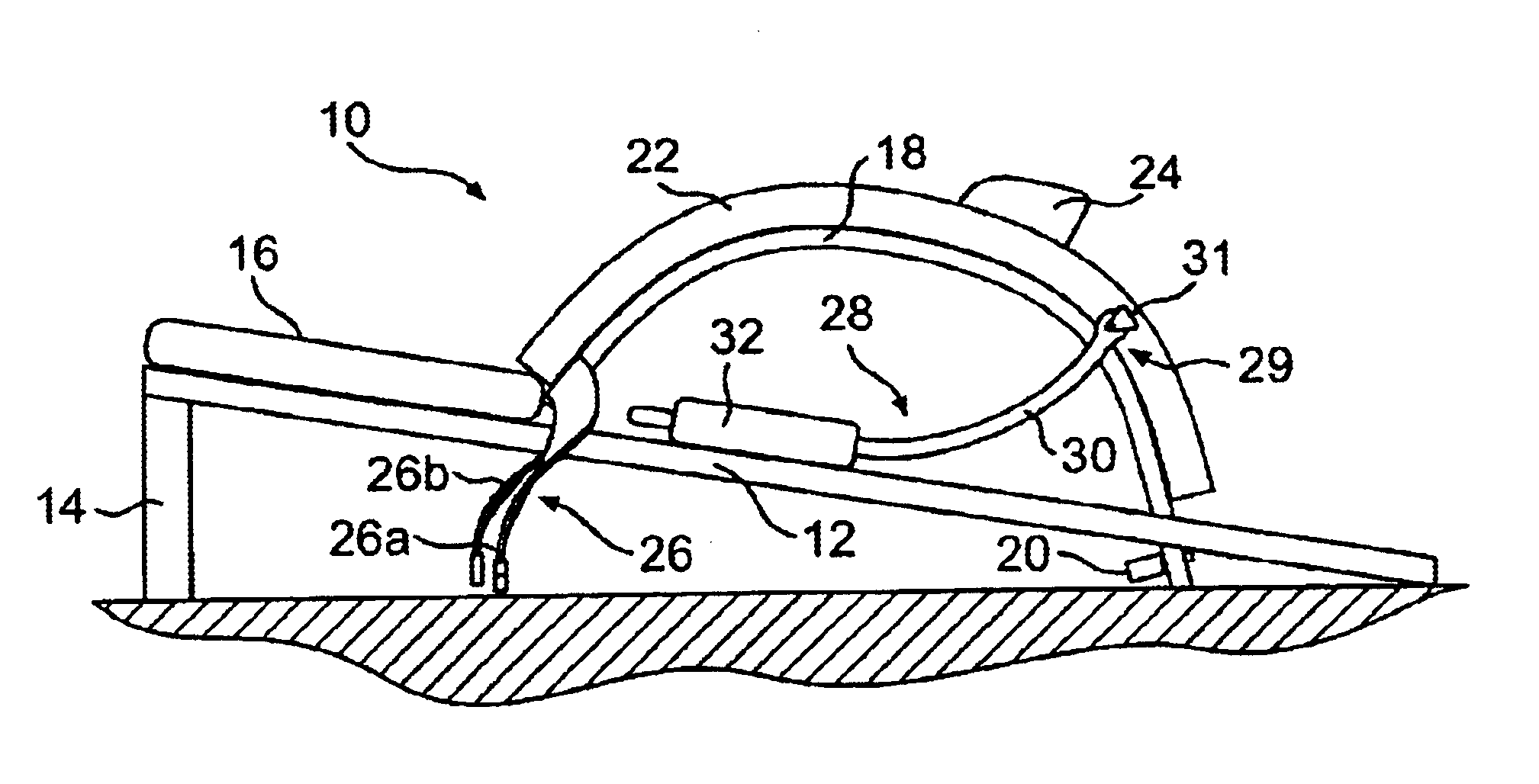

Exercise device for exercising of the abdominal muscles

InactiveUS6843759B2Simple and lightweight in constructionEasy to carryResilient force resistorsChiropractic devicesEngineeringBack support

An exercise device is provided which is used in exercising of the abdominal muscles as well as in exercising the muscles of the upper torso, shoulders and arms while the back of the user is supported, elongated and stretched. The device includes a platform which is elevated at one end from a supporting surface for the device. A seat is located at the one end of the platform and a bowed back support member is disposed on the platform adjacent to the seat. The support member presents a convex curved surface of a longitudinal extent such that the back and head of the user can rest thereon with the user in a backwardly reclining posture. A resilient belt fits around the waist of the user while a restraining arrangement preferably in the form of flexible restraining members is adapted to engage the arms of the user during movement of the user from the backwardly reclining posture wherein the back of the user rests against the convex curved surface to a sitting position. The restraining arrangement thus increases the force that must be exerted by the abdominal muscles of the user in carrying out this movement.

Owner:WALLERSTEIN ROBERT S

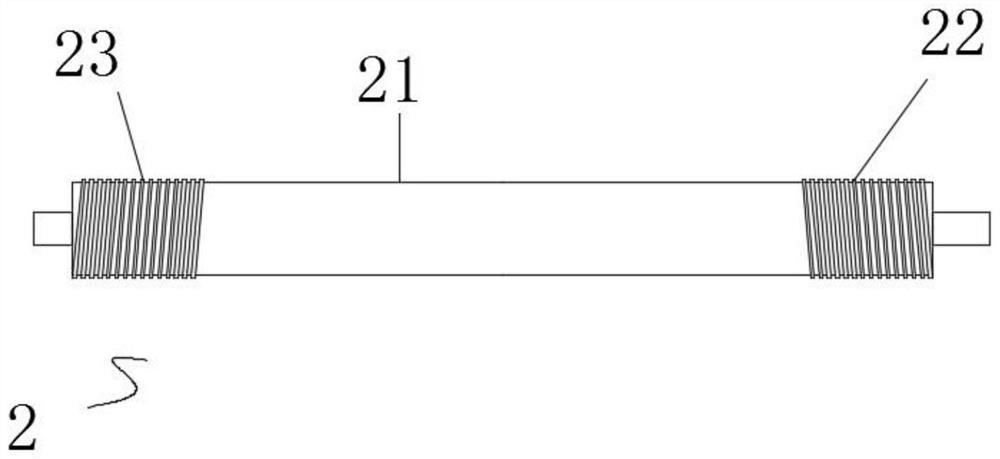

Tension roll of dividing and cutting machine

The invention discloses a tension roll of a dividing and cutting machine, which comprises a base and tension roll bodies arranged on the base in a rolling manner, and is characterized by further comprising a bracket on the base, an adjusting block arranged on the bracket in a sliding manner, an adjusting bolt connected with the adjusting block and the bracket, and an adjusting roll rotatably arranged on the adjusting block, wherein the bracket is arranged among the plurality of parallel tension roll bodies; and the adjusting roll and the tension roll bodies are parallel to each other. According to the invention, the tension degree of the paper tape can be adjusted according to the paper tape condition, as the height-adjustable adjusting roll is adopted.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

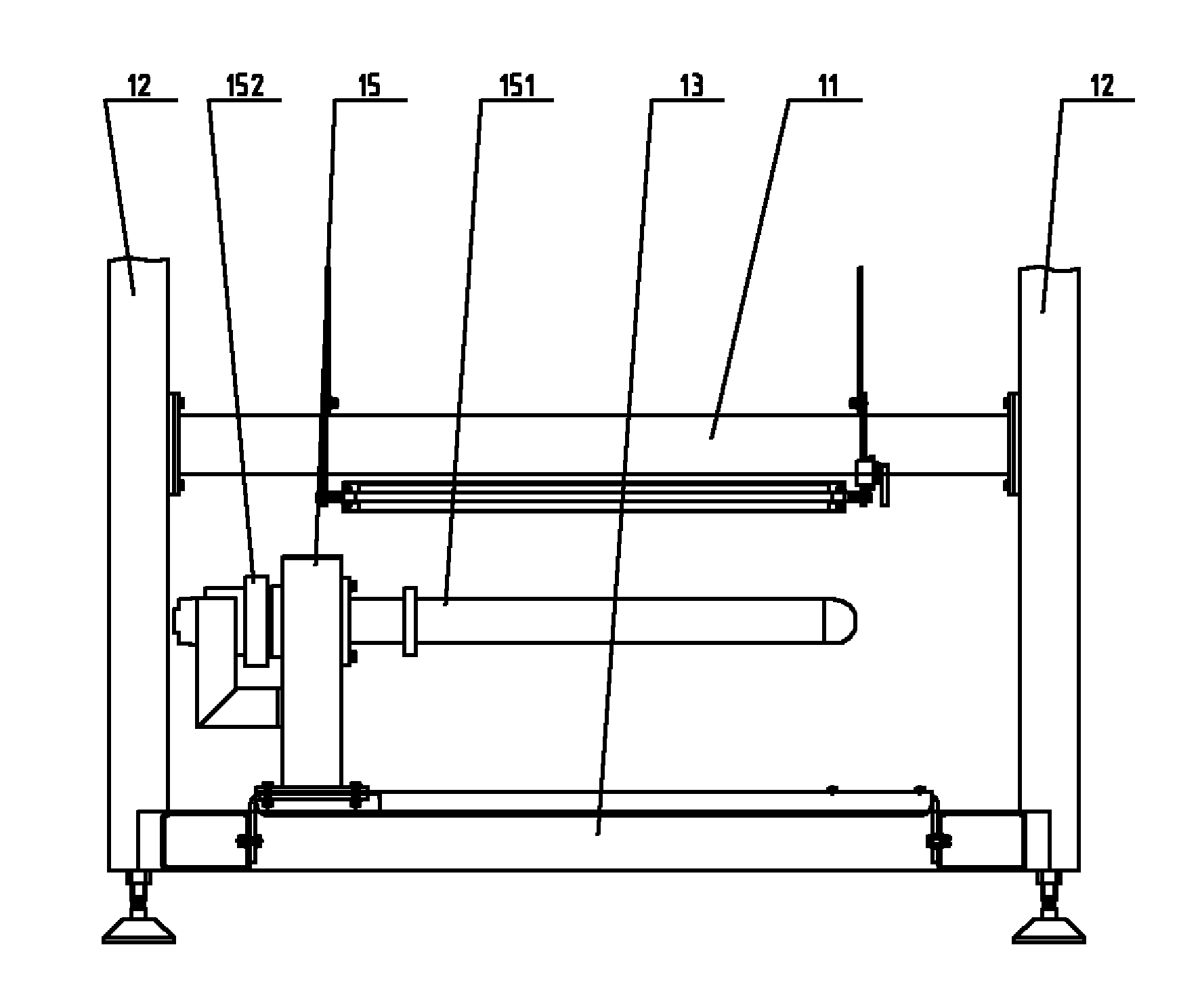

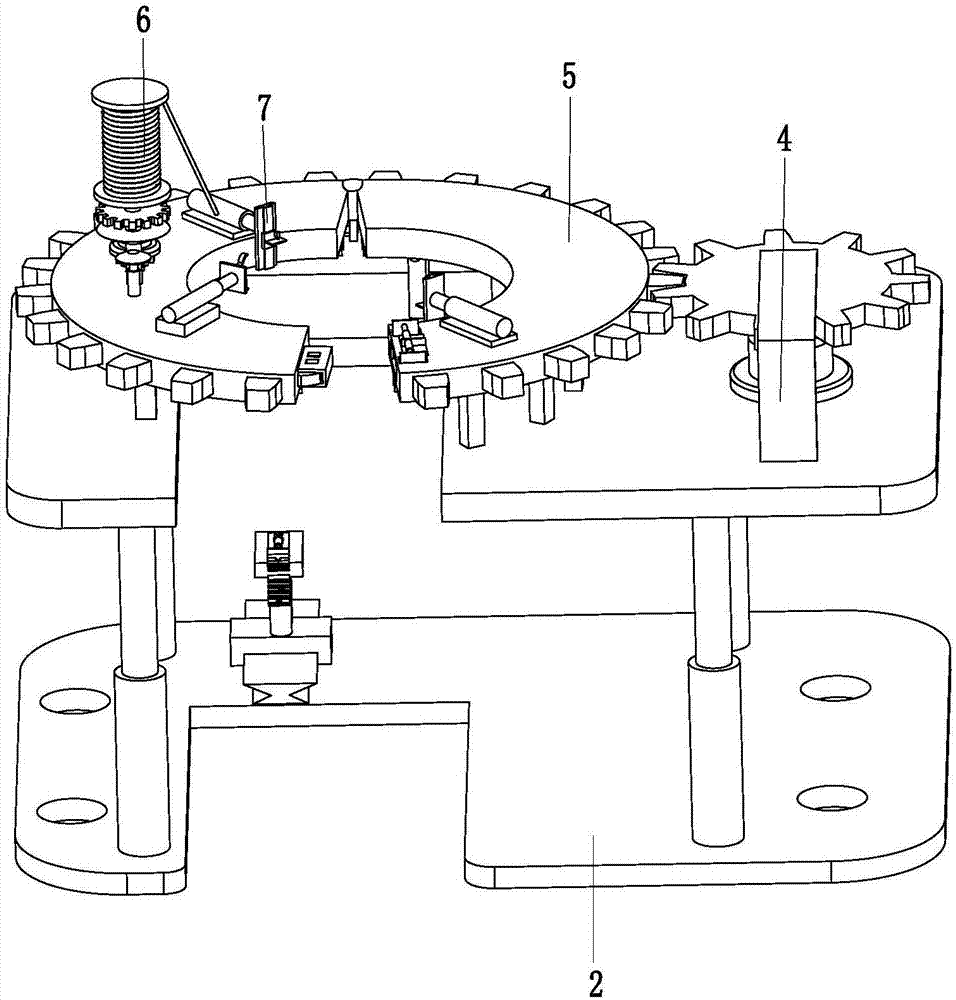

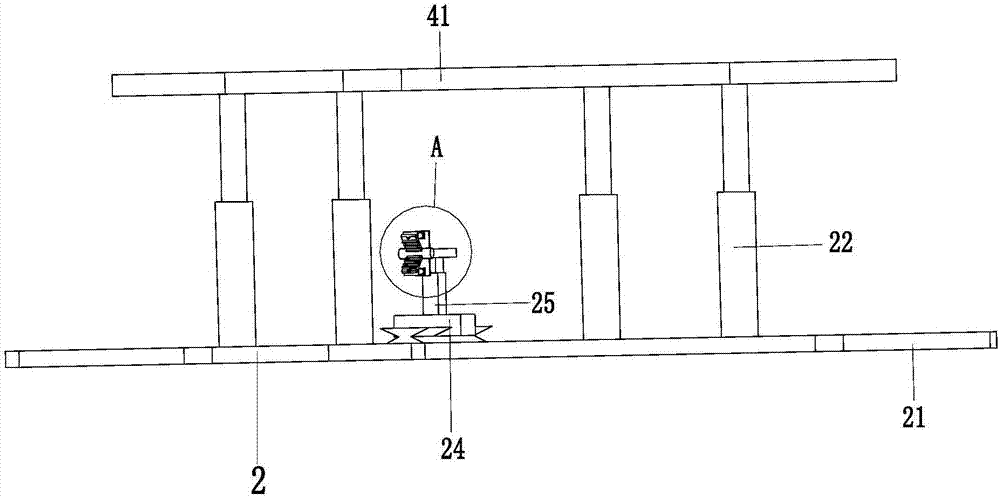

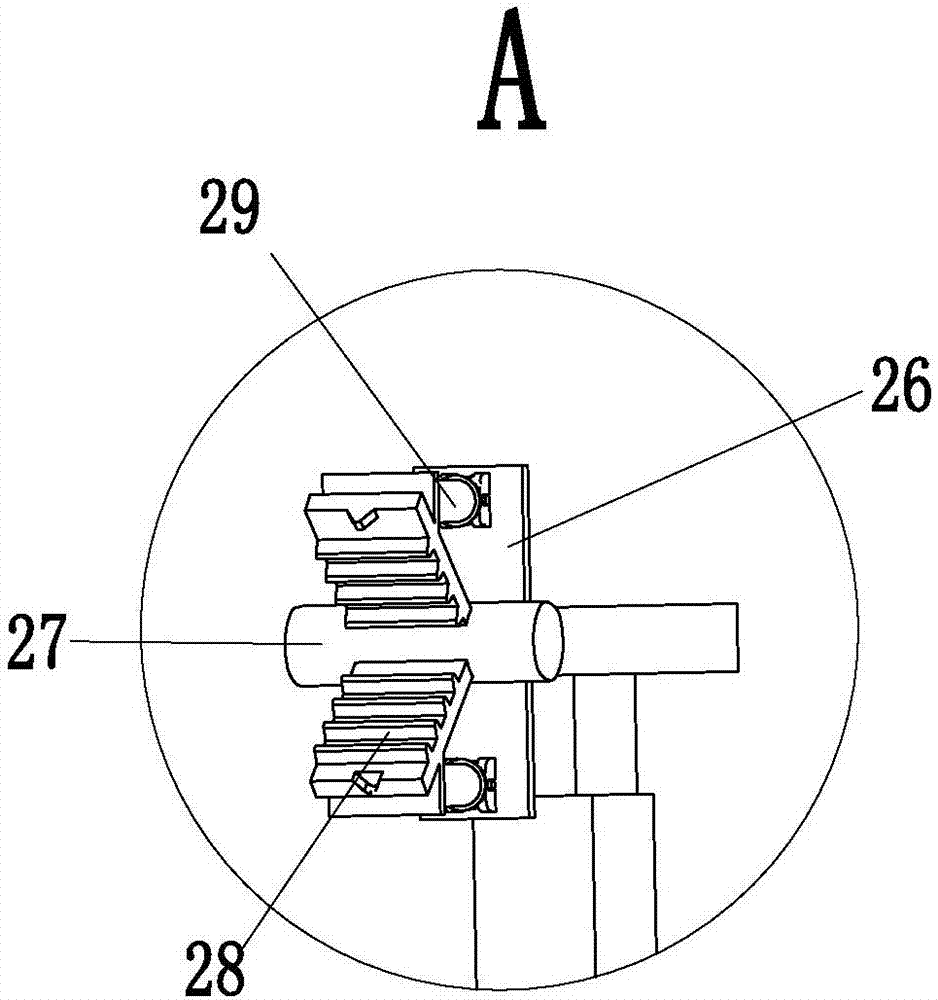

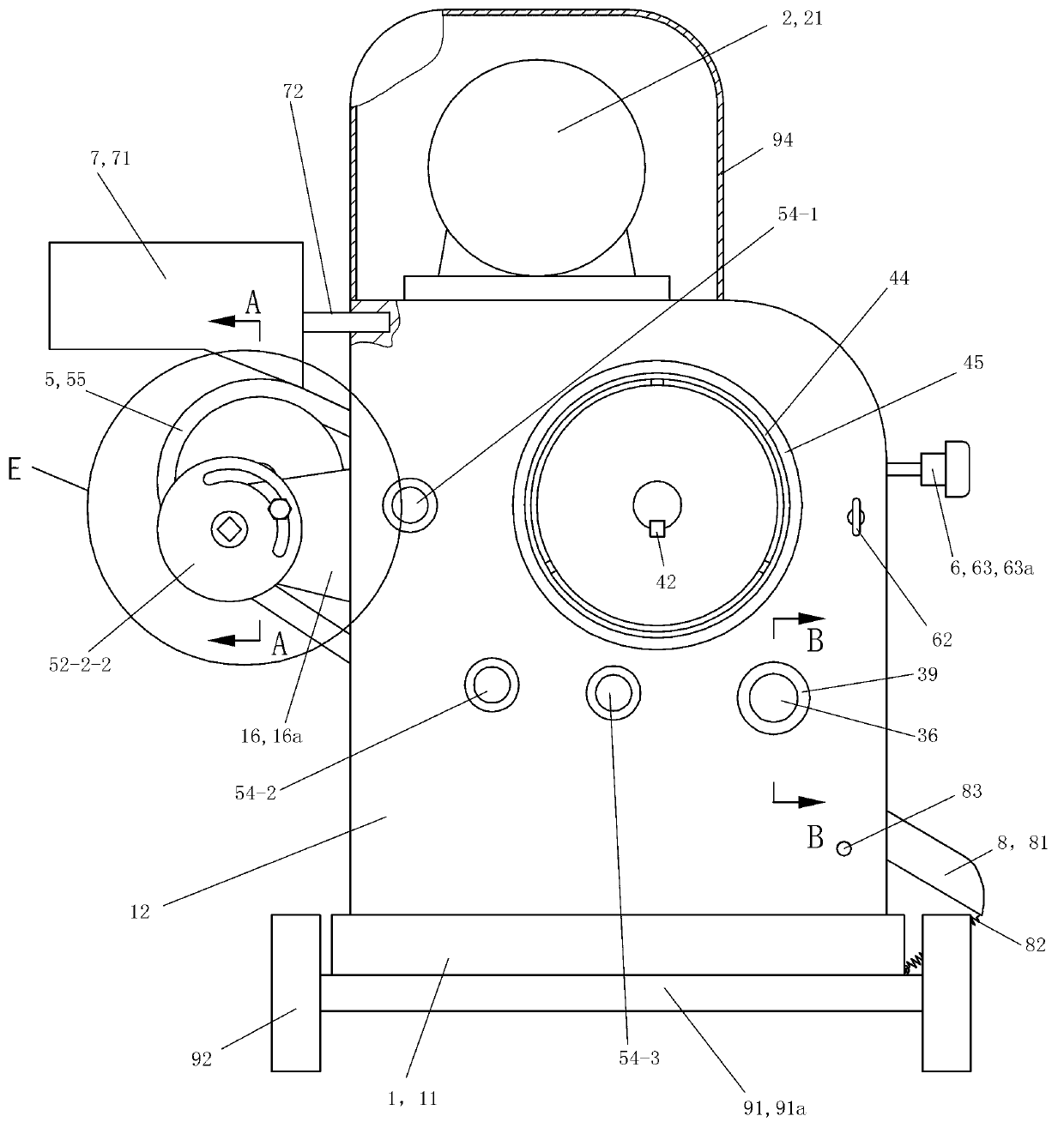

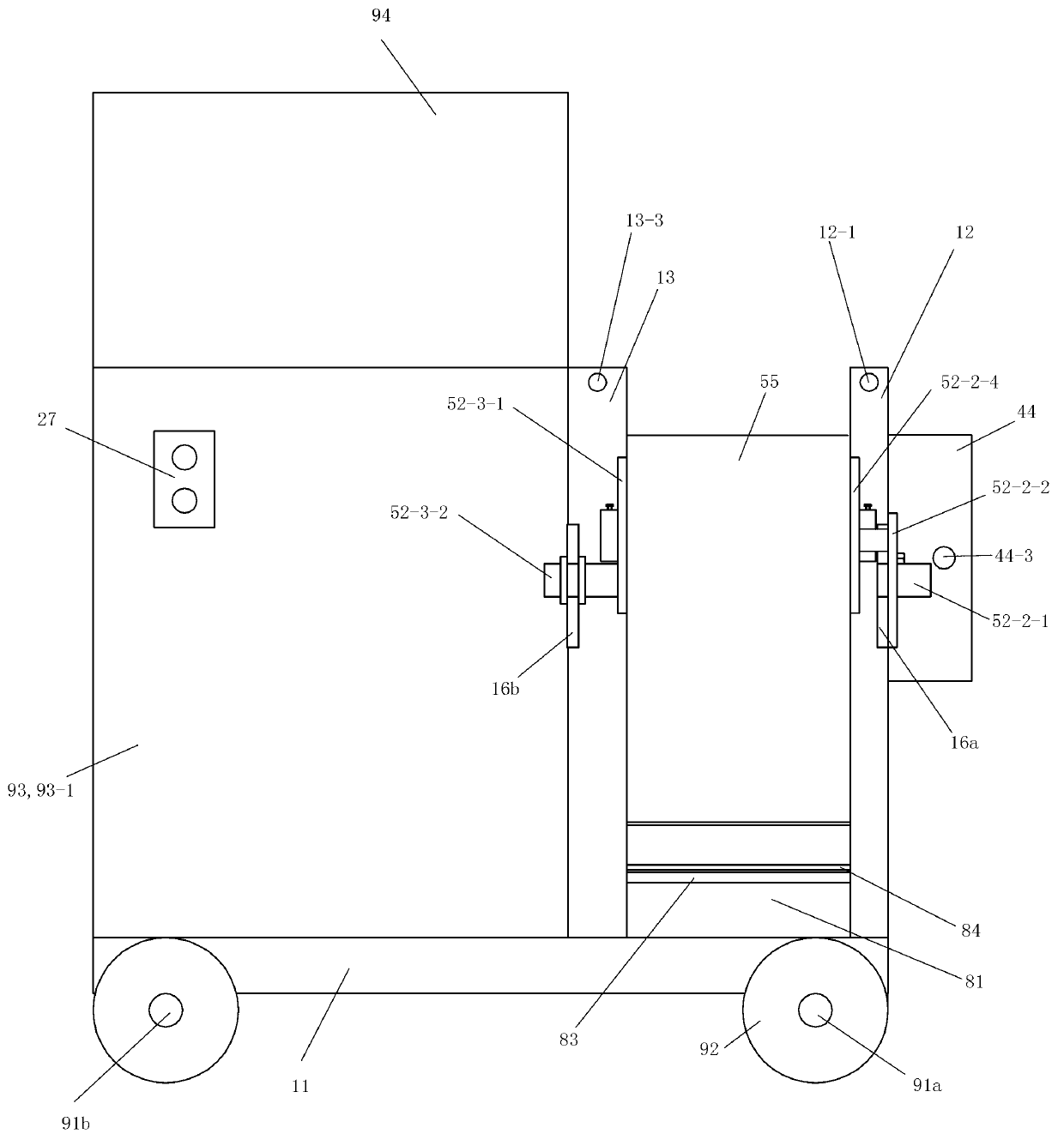

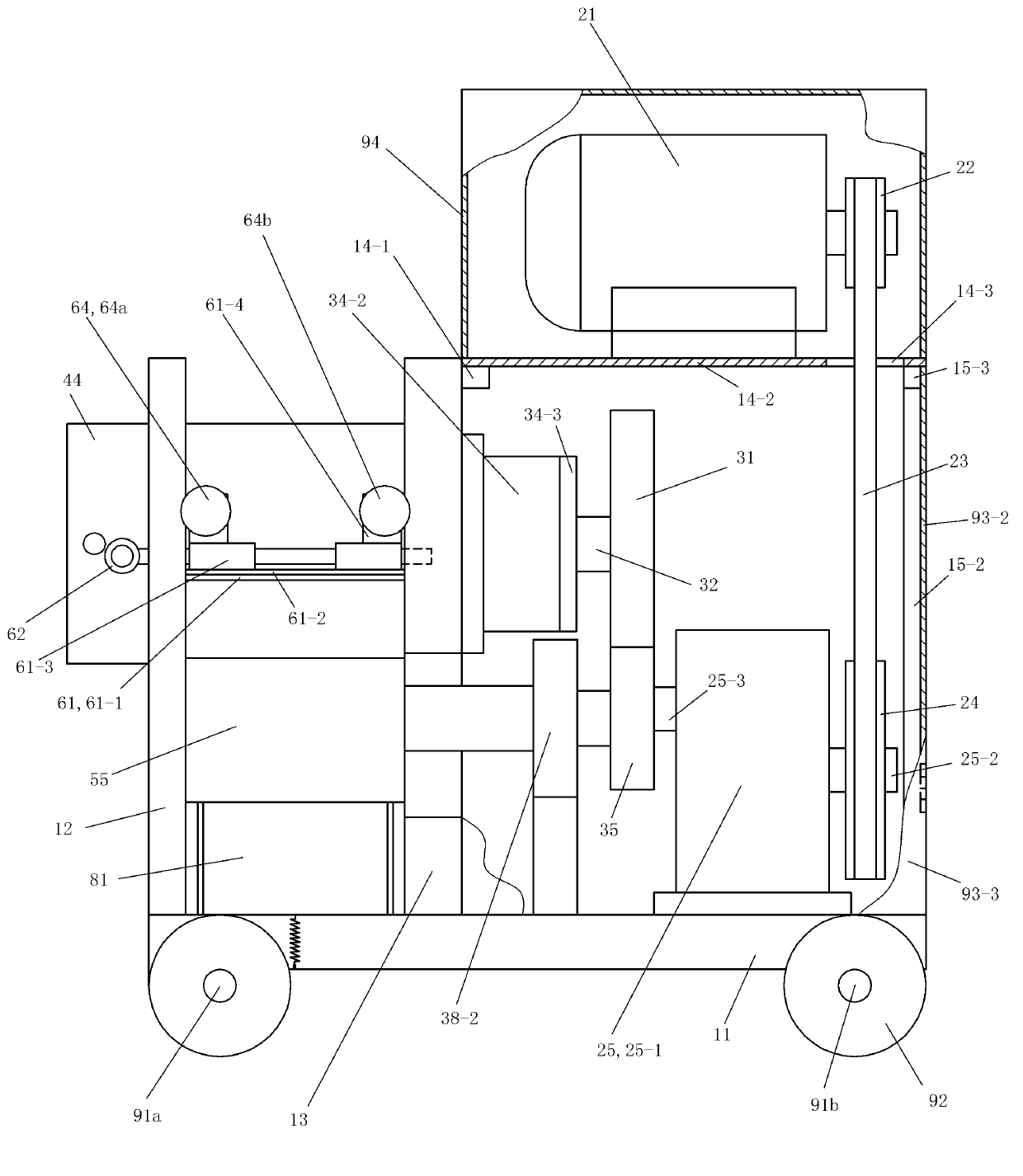

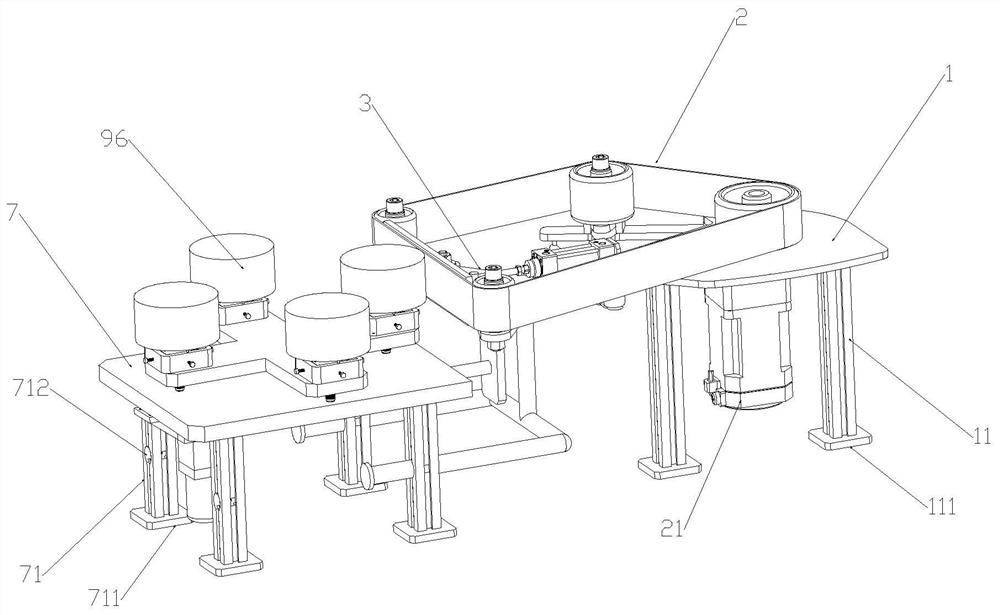

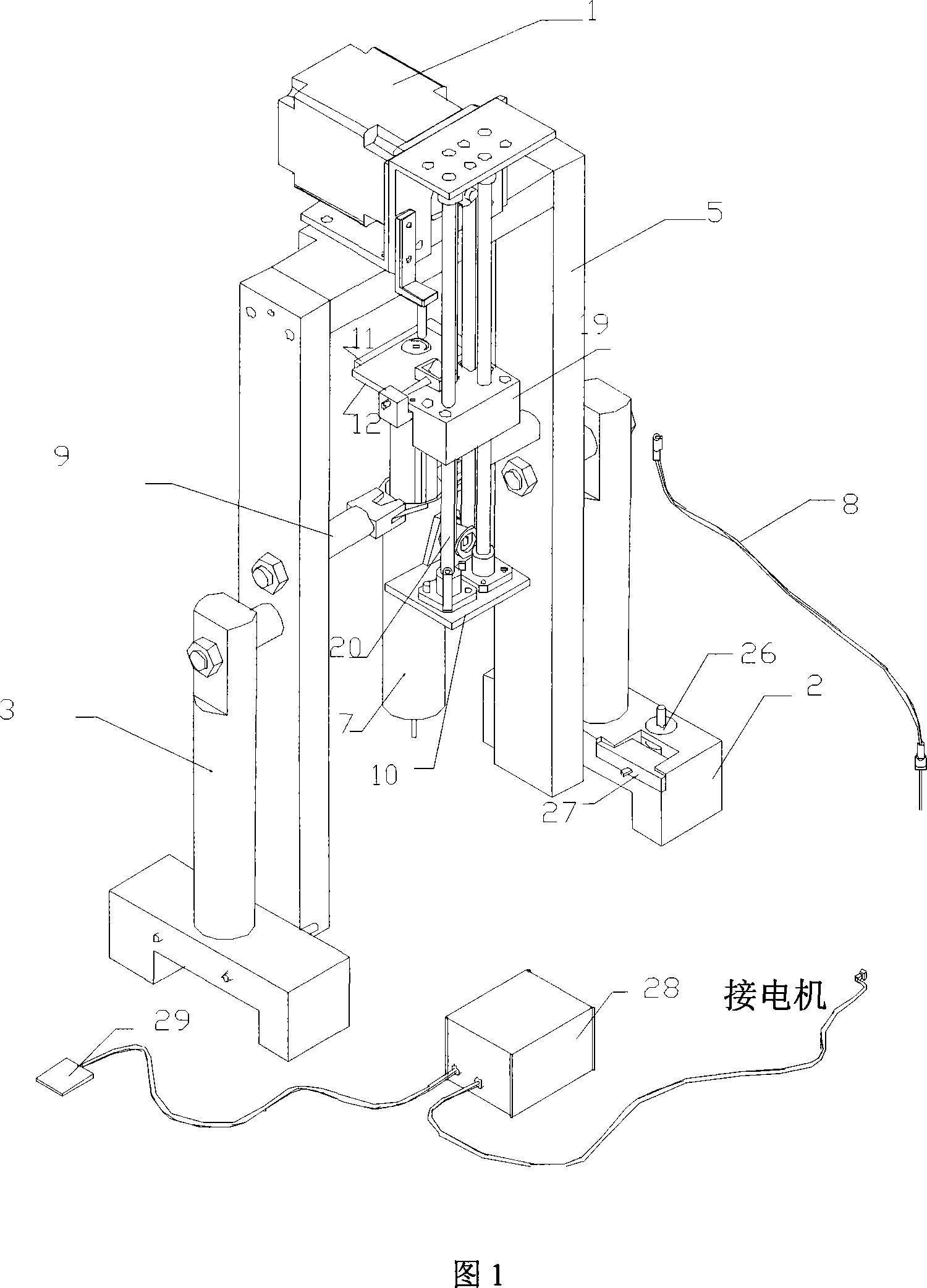

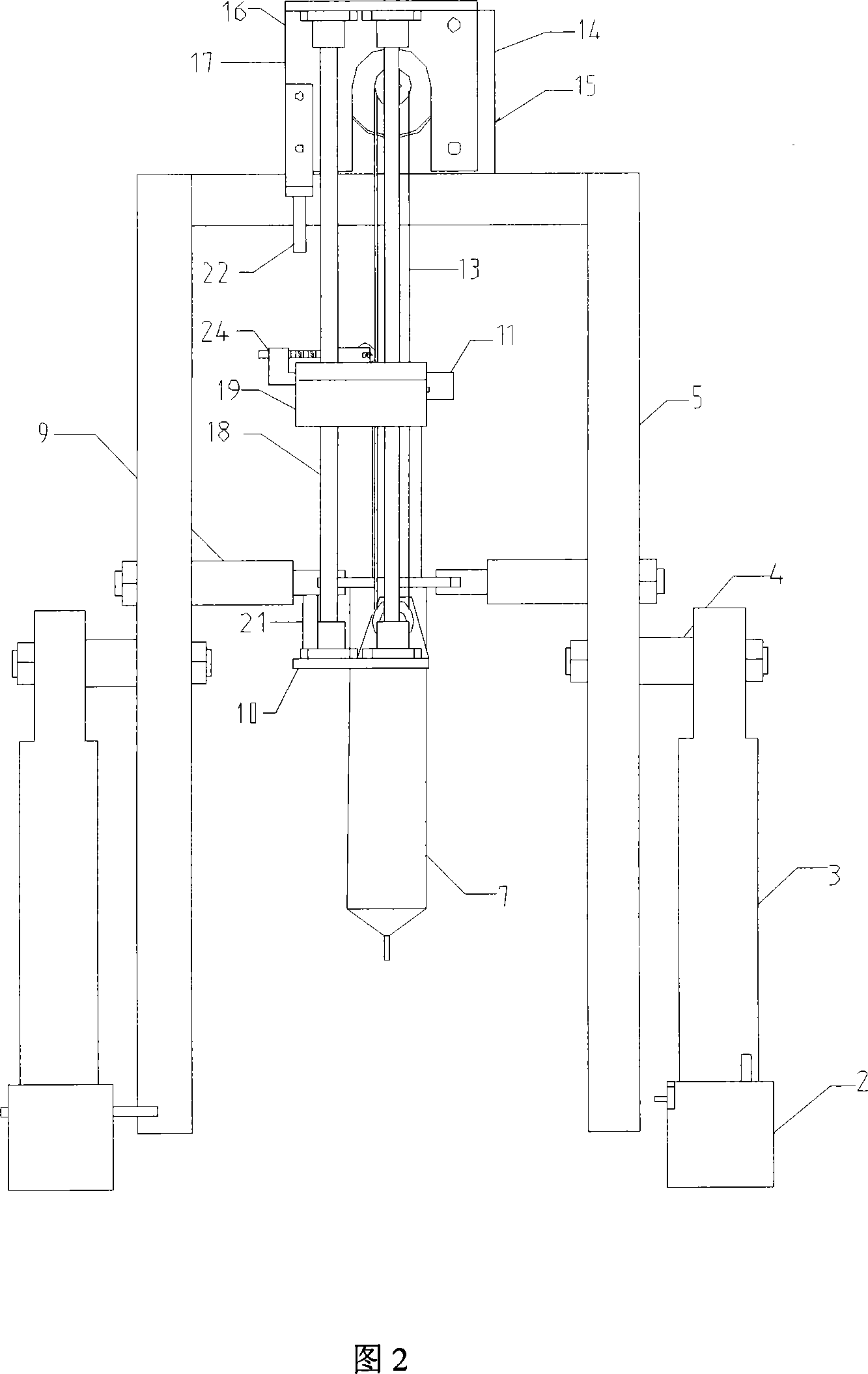

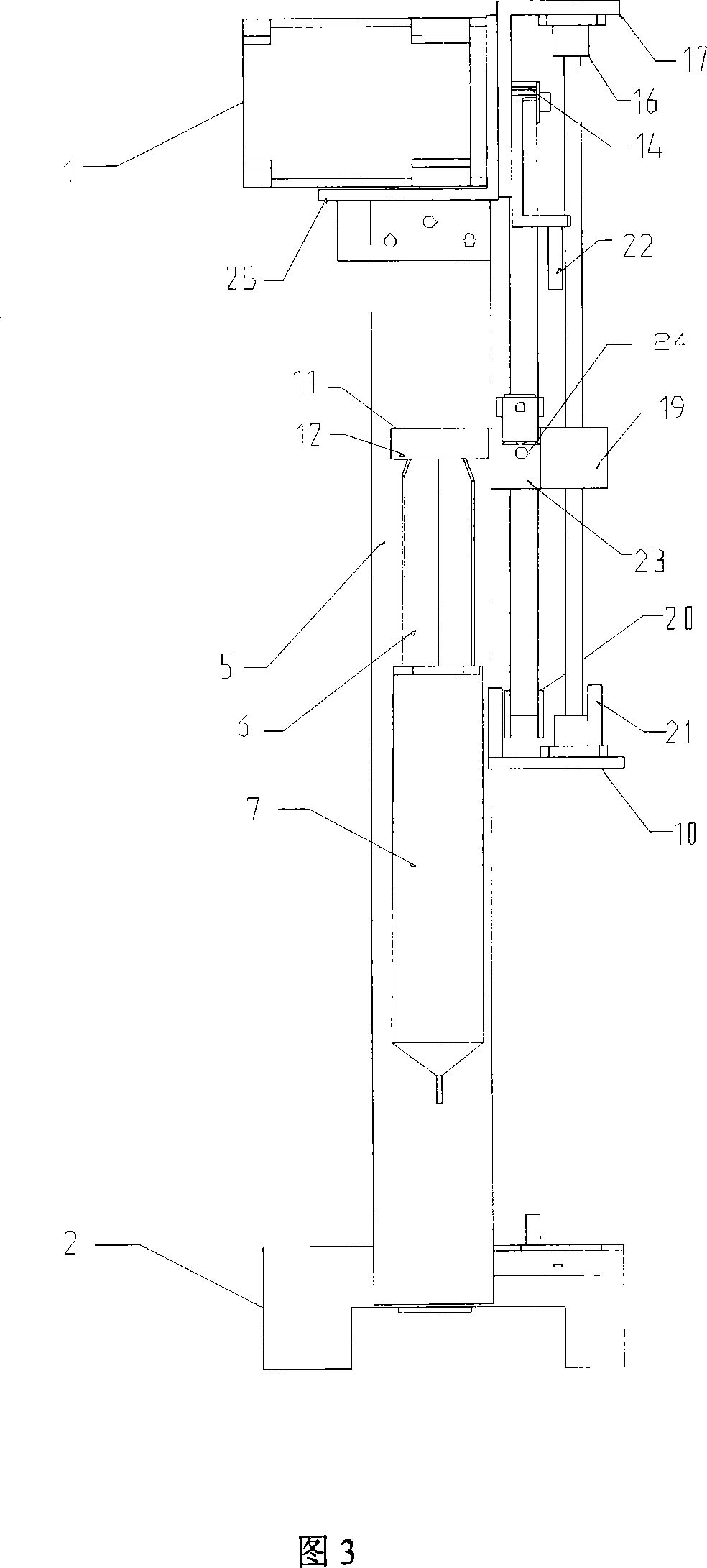

Automatic rope bundling machine for transplanting of trees of various diameters with high survival rate for municipal garden maintenance

The invention relates to an automatic rope-tying machine for transplanting trees of various diameters with a high survival rate for municipal garden maintenance, which includes a lifting device, a supporting rotating device, a rotating device, a retracting device and a correcting device. The supporting rotating device is installed on the lifting device On the top, the rotating device is connected with the supporting rotating device, and the retracting device and the correcting device are installed on the rotating device. The present invention can solve the problems of low work efficiency, high labor intensity, inability to tie ropes at higher positions of trees, inability to tighten ropes when tying trees, and poor effect on tree tying ropes when tying trees manually. Good, it is troublesome to arrange the ropes after tying the trees; it can realize the function of adjusting the winding distance when tying the trees with different diameters, and has high work efficiency and low labor intensity. It has the advantages of adjusting the tension of the rope when tying the rope to the trees, having a good effect on tying the rope to the trees, and automatically rewinding the rope after tying the rope to the trees.

Owner:潘军

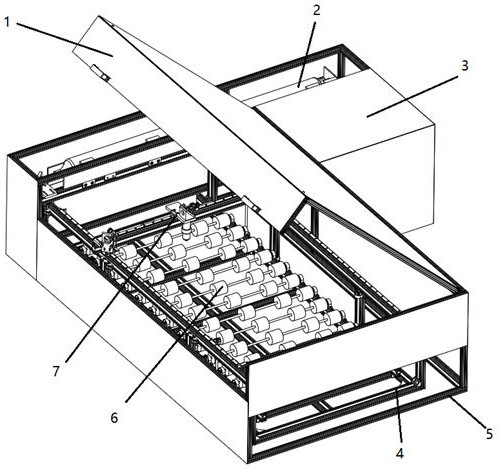

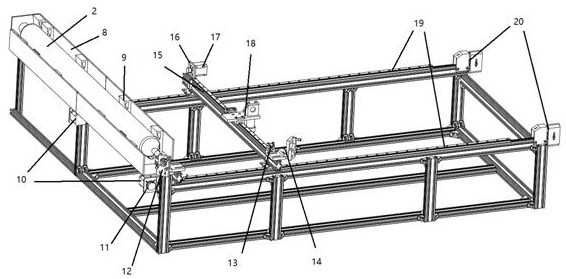

Automatic logistics conveying line

The invention discloses an automatic logistics conveying line in the technical field of logistics conveying. The automatic logistics conveying line comprises a frame, the cross section of the frame isof a U-shaped structure, a plurality of conveying rollers are rotationally arranged in the frame, and the adjacent conveying rollers are arranged at equal intervals. According to the automatic logistics conveying line, by arranging forward and reverse spirals at the two ends of the conveying rollers, when goods are conveyed on the rollers and deflect, the goods are made to move towards the middleof the conveying rollers through transmission force of the spirals, therefore collision and friction between the goods and side plates of a conveying line are avoided, by arranging structures such assorting equipment and a recognition module, the conveyed goods can be classified and conveyed to a set area so as to facilitate subsequent treatment of the goods, a arranged roller synchronous transmission mechanism is in snake-shaped winding connection between a plurality of guide rollers and a roller center shaft through a chain, compared with the prior art, the design mode has the advantages that the failure rate is reduced, the rollers are stressed uniformly as well, and the movement synchronism is high.

Owner:成都毅莘瑞科技有限公司

Fish meat and bone separating device

The invention discloses a fish meat and bone separating device. The device comprises a rack and a driving device, a transmission mechanism, a meat separator, an extrusion device, a feeding device and a discharge device, which are all arranged on the rack. The device is characterized in that the device also comprises a fish skin peeling device; the meat separator comprises a connecting disc and a main barrel; the axis of the connecting disc is arranged in the anterior-posterior direction; the main barrel is fixedly connected on the connecting disc from the front; the main barrel is integrally shaped like a cylinder shell; meat separating holes with diameters being 1-8mm are uniformly distributed in the wall of the main barrel and run through the wall; the distance between the edges of the adjacent meat separating holes is 2-20mm; the transmission mechanism transmits power to the meat separator and the extrusion device respectively via the driving device and acquires the fish meat via mutual extrusion; and the fish skin peeling device is arranged on the right of the main barrel of the meat separator and peels the remaining fish skin and fish bones from the main barrel.

Owner:常州市天水食品有限公司

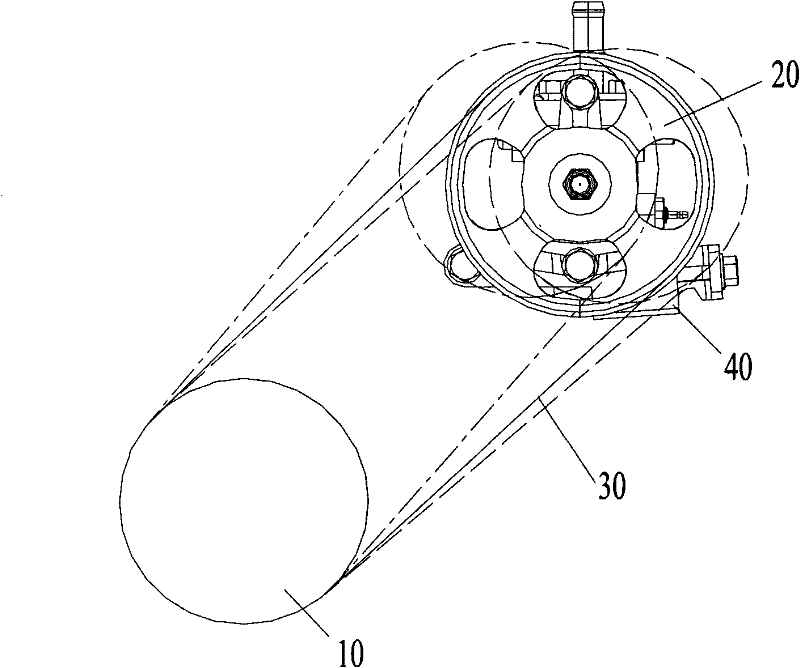

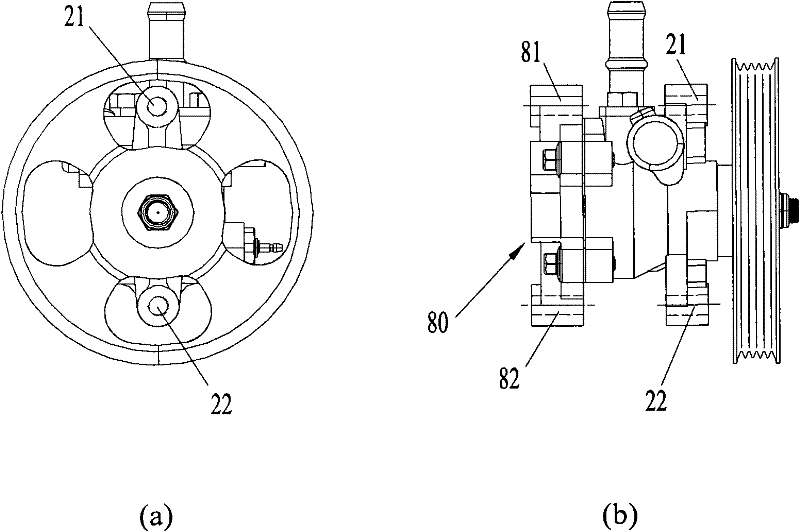

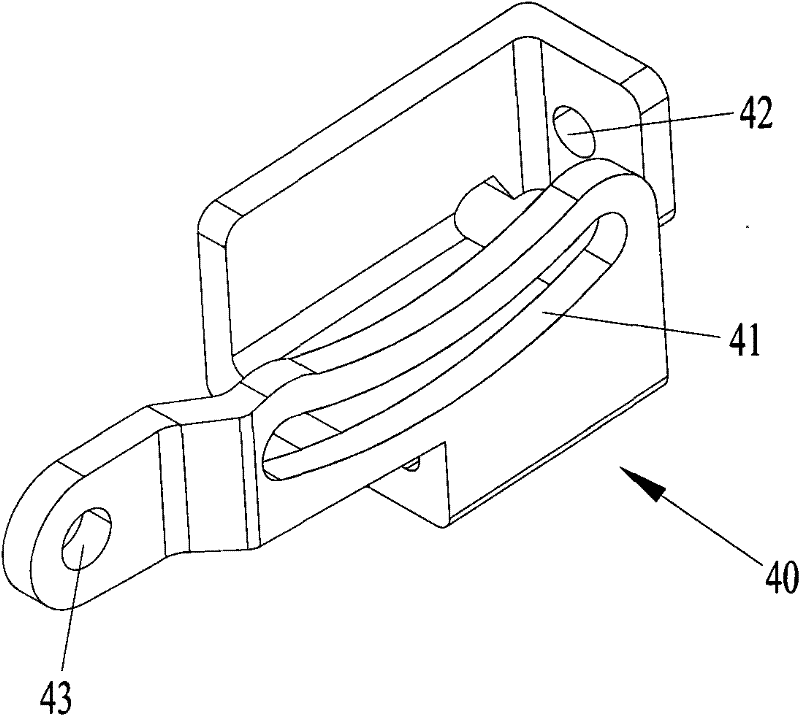

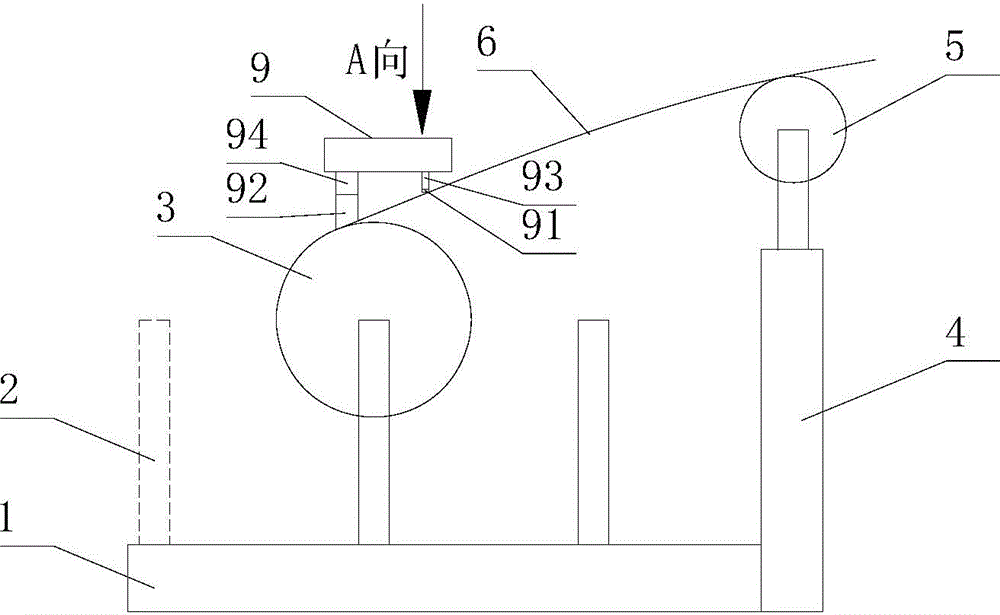

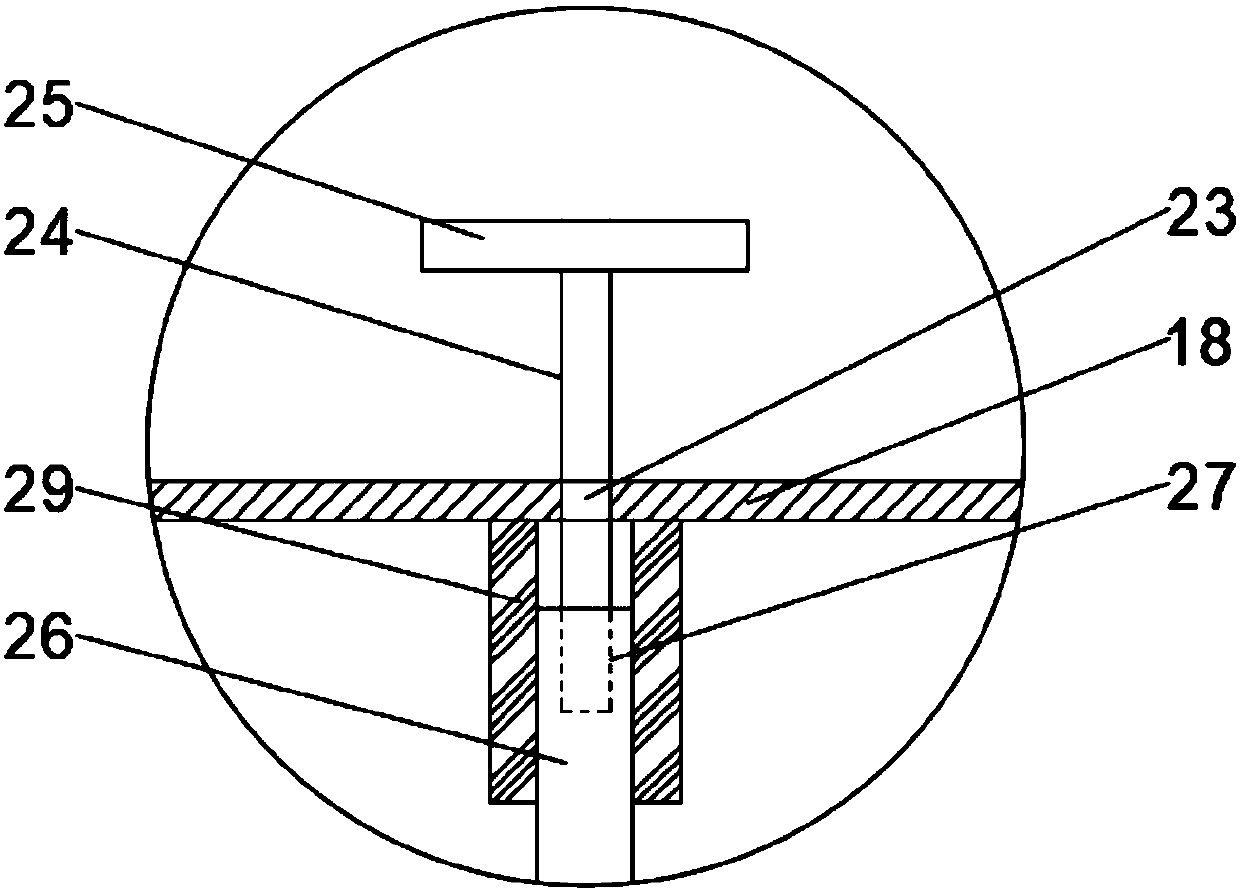

Pulley mechanism and power steering pump assembly

ActiveCN102278434AAdjust the tensionImprove space utilizationGearingFluid steeringPower steeringPulley

The invention provides a belt pulley mechanism which is convenient to regulate the tension degree of a belt. The belt pulley mechanism comprises a first belt pulley, a second belt pulley and a belt, and the first belt pulley and the second belt pulley are connected through the belt in a transmission manner, wherein the belt pulley mechanism further comprises a tension bracket fixed on a mounting base. The tension bracket comprises a first sidewall, and an arc guide channel is arranged on the first sidewall; the second belt pulley comprises a mounting rack, the mounting rack is provided with a first fastening hole and a second fastening hole which are parallel to the axial direction of the second belt pulley; the first fastening bolt is used for connecting the second belt pulley to the mounting base through a first fastening hole; and the second fastening bolt can adjustably fix the second belt pulley on the tension bracket through the arc guide channel and a second fastening hole. The invention further provides a power-assisted steering pump assembly. In the belt pulley mechanism disclosed by the invention, the second belt pulley or the second belt pulley has functions of a transmission belt pulley and a tension pulley at the same time, thus the utilization rate of space is improved, and the tension degree can be regulated as required randomly.

Owner:BEIQI FOTON MOTOR CO LTD

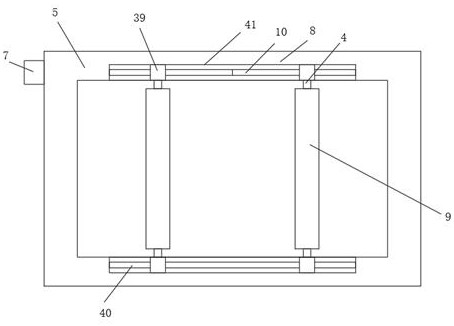

Cloth winding device for textile

InactiveCN105197649AAdjust the tensionConsistent tightness of windingWebs handlingEngineeringPressure sensor

The invention discloses a cloth winding device for textile. The cloth winding device comprises a base. A cloth winding mechanism and a tensioning device are arranged on the base. The cloth winding mechanism comprises two sets of reel supports and a reel. Annular sliding grooves are further formed in the base. The sliding grooves comprise the first sliding groove and the second sliding groove. The first reel support of each set of reel supports is arranged in the first sliding groove in a sliding mode. The second reel support in each set of reel supports is arranged in the second sliding groove in a sliding mode. The tensioning device comprises a tensioning wheel support and a tensioning wheel arranged on the tensioning wheel support. A pressure sensor is arranged on the tensioning wheel. A telescopic device is arranged between the tensioning wheel and the tensioning wheel support and connected with a driver. The pressure sensor is connected with the driver. The cloth winding device further comprises a cloth cutting device. The cloth cutting device comprises a cutter. A pressing plate is arranged on the side portion of the cutter. According to the cloth winding device, winding efficiency can be effectively improved, and winding quality is high.

Owner:WUXI JIAMEIDA RUBBER & PLASTIC EQUIP

Suture anchor assembly

PendingCN109730734AAvoid cutting damageAdjust the tensionSuture equipmentsProsthesisInterference fitSuture anchors

The invention provides a suture anchor assembly. The suture anchor assembly comprises an anchor sleeve and a clamping part, wherein the anchor sleeve is provided with an axial hole and an external thread and implanted into a human body; the clamping part is at least partially arranged in the axial hole and provided with multiple chucks, and gaps are formed among two or more chucks and used for placing sutures, wherein at least part of the wall of the axial hole is in interference fit with the clamping part when the clamping part extends into the anchor sleeve, and the gaps among the multiple chucks shrink to clamp the sutures in the gaps. In the technical scheme, the two ends of the sutures are clamped into a pressurizing device at the same time, it is avoided that since pulling is too tight, the sutures are cut and damaged by the external thread of the anchor sleeve, and knotting is not needed; in addition, by adjusting the implanting depth of the anchor sleeve, the tensile force of the sutures can be adjusted, the sutures are prevented from being too loose or too tight, operation difficulty is lowered, and the efficiency and safety of an operation are promoted.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

Low odor environmentally-friendly nano-pigment inkjet ink composition

ActiveUS20130190421A1Improve solubilityImprove the inkjet fluencyInksGaseous substancesWeather resistanceHuman health

A low odor environmentally-friendly nano-pigment inkjet ink composition has good storage stability, inkjet stability, and good print quality. The printhead nozzles are not easily clogged by such an inkjet ink composition. The printed image has high gloss, scratch resistance, and weather resistance. The inkjet ink composition using low toxic and low odor raw material has a high flash point, and has high security to human health and environment. The inkjet ink composition can meet both the environmental requirement and the print quality requirement. The inkjet ink composition includes 1-10% of N-ethyl pyrrolidone, 1-20% propylene carbonate, 50-80% glycol ether solvent, pigment, dispersant, resin, plasticizer, surfactant, and cyclic tertiary amine compound as an acidity regulator.

Owner:JETBEST CORP

High-precision polishing equipment for die-casting workpiece and polishing method thereof

ActiveCN111730470AHigh precisionAdjust the tensionGrinding drivesBelt grinding machinesPolishingElectric machinery

The invention discloses high-precision polishing equipment for a die-casting workpiece and a polishing method thereof. A polishing mechanism is arranged between a first supporting platform and a second supporting platform, a second pneumatic cylinder is driven, a supporting plate can be driven to rotate, the tensioning degree of a polishing belt is further adjusted, a first pneumatic cylinder is driven, the position of the polishing belt can be adjusted, the polishing position of the polishing belt on a workpiece is further adjusted, the polishing position and the polishing degree can be conveniently adjusted, the adjustment is convenient, and the polishing precision is high when the workpiece is polished. According to the equipment and the method, the upper end of a third supporting platform is provided with a rotating device and a clamping device, when the polishing equipment is used, a third motor is driven to drive the die-casting workpiece to rotate for one circle to polish the workpiece, a second motor is driven, a rotating shaft is rotated to drive a bearing plate to rotate so as to drive the die-casting workpiece for revolution, a next die-casting workpiece can be polishedconveniently, polishing is finished through the rotation when the polishing equipment is used, replacement is finished through the revolution, equipment halt is avoided, and the working efficiency isimproved.

Owner:宁波敏嵘机械有限公司

Hydraulic control system of crawler tensioning device

ActiveCN103625570AAdjust the tensionGet tension at any timeEndless track vehiclesControl signalEngineering

The invention provides a hydraulic control system of a crawler tensioning device. The system comprises a tensioning cylinder, a detecting device, a hydraulically driven oil filling mechanism and a control device, wherein the tensioning cylinder is provided with a moving end; the detecting device is arranged on the tensioning cylinder and is used for detecting the displacement of the moving end of the tensioning cylinder and generating a detecting result; the control device is electrically connected with the detecting device and the hydraulically driven oil filling mechanism and is used for sending a control signal to the hydraulically driven oil filling mechanism according to the detecting result; the hydraulically driven oil filling mechanism is connected with the tensioning cylinder and is used for filling oil into the tensioning cylinder according to the control signal to adjust the displacement of the moving end of the tensioning cylinder. By the technical scheme of the invention, the tensioning status of a crawler can be automatically fed back and timely adjusted, so that the crawler is in an ideal tensioning state.

Owner:ZOOMLION HEAVY IND CO LTD

Height-adjustable cloth inspection device

InactiveCN102296453ASimple structureHeight adjustableInspecting textilesOptically investigating flaws/contaminationActive supportEngineering

The invention discloses a height-adjustable cloth inspection device. The cloth inspection device includes a support frame, a fastening rod, a cloth inspection support, a cloth inspection rod, and a detector. Both ends of the fastening rod are connected with the support frame. , the cloth inspection support is arranged on the top of the support frame and connected with the support frame, the two ends of the cloth inspection rod are connected with the cloth inspection support, the support frame includes two support legs, both supports are movably connected with the rotating shaft, and the support legs There are fastening installation holes on the top, cloth inspection installation holes on the cloth inspection support, a camera is arranged on the cloth inspection rod, and the camera and the detector are connected by wires. The cloth inspecting machine of the present invention has the advantages of simple structure, adjustable height, and can adjust the tension degree of the gauze when it passes through the cloth inspecting device, and has low cost.

Owner:张洪

Yarn clamping mechanism for spinning machine

The invention discloses a yarn clamping mechanism for a spinning machine. The mechanism comprises a base, a lifting cylinder is arranged on the base, a lifting column is arranged in the lifting cylinder, a hydraulic cylinder is arranged at the lower end of the lifting column, a foundation bed is arranged at the upper end of the lifting column, a clamping frame with the hollow inner portion is arranged on the foundation bed, a yarn passing wheel is arranged in the clamping frame, a yarn passing groove is formed in the wheel surface of the yarn passing wheel, a yarn clamping lifting hole with threads is formed in the upper end surface of the clamping frame, a yarn clamping lifting rod is internally connected with the yarn clamping lifting hole through the threads, a yarn clamping sliding rodis arranged at the lower end of the yarn clamping lifting rod, a yarn clamping installation hole is formed in the upper end of the yarn clamping sliding rod, the lower end of the yarn clamping lifting rod is fixed into the yarn clamping installation hole through a bearing, yarn clamping lifting grooves fixed to the clamping frame are formed in the two sides of the yarn clamping sliding rod, a yarn clamping support is arranged at the lower end of the yarn clamping sliding rod, a yarn clamping wheel is arranged at the lower end of the yarn clamping support, and a tensioning device is arranged on the foundation bed. By means of the yarn clamping mechanism, yarn can be effectively clamped all the time, the use ratio of the machine is improved, machine halts are reduced, and clamping force onthe yarn and the tensioning degree of the yarn can be adjusted.

Owner:阜阳恒泰纺织有限公司

Dual-roller four-time natural luster finishing machine

InactiveCN104358062ASmall footprintAdjust the corner sizeConveyorsTextile shapingPulp and paper industrySupport belt

The invention relates to a dual-roller four-time natural luster finishing machine. The dual-roller four-time natural luster finishing machine is provided with a rack, wherein a natural luster finishing roller I and a natural luster finishing roller II are arranged on the rack from a cloth feeding side to a cloth discharging side in a side-by-side manner, a double-side supporting belt mechanism matched with two natural luster finishing rollers is arranged on the rack between the natural luster finishing roller I and the natural luster finishing roller II, single-side supporting belt mechanisms are arranged at the cloth feeding side of the natural luster finishing roller I and the cloth discharging side of the natural luster finishing roller II, a lower cloth guiding mechanism is arranged on the rack under the natural luster finishing roller I and the natural luster finishing roller II, and an upper cloth guiding mechanism is arranged on the rack above the natural luster finishing roller I and the natural luster finishing roller II. According to the dual-roller four-time natural luster finishing machine, two natural luster finishing rollers are combined with one supporting belt to realize the dual-roller four-time natural luster finishing treatment by the double-side supporting belt mechanism, the occupied space of the supporting belt mechanism is reduced, and a main machine is compact; and a tension correcting roller is arranged to collect the deflected supporting belt on the double-side supporting belt mechanism under the action of a swing arm, the tensioning intensity adjusting effect can be achieved under the action of an adjusting slot hole, and the use is convenient.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

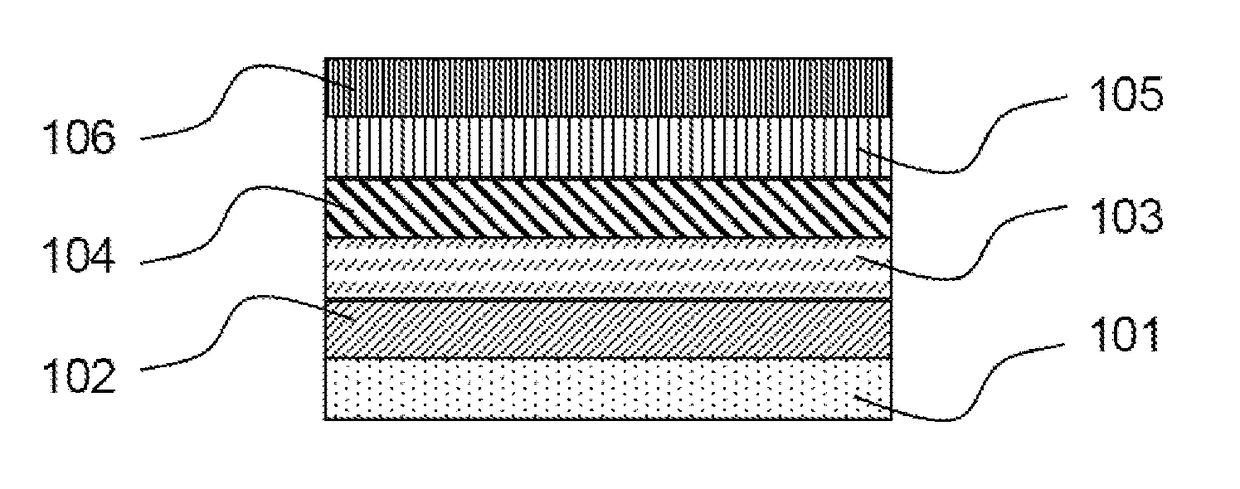

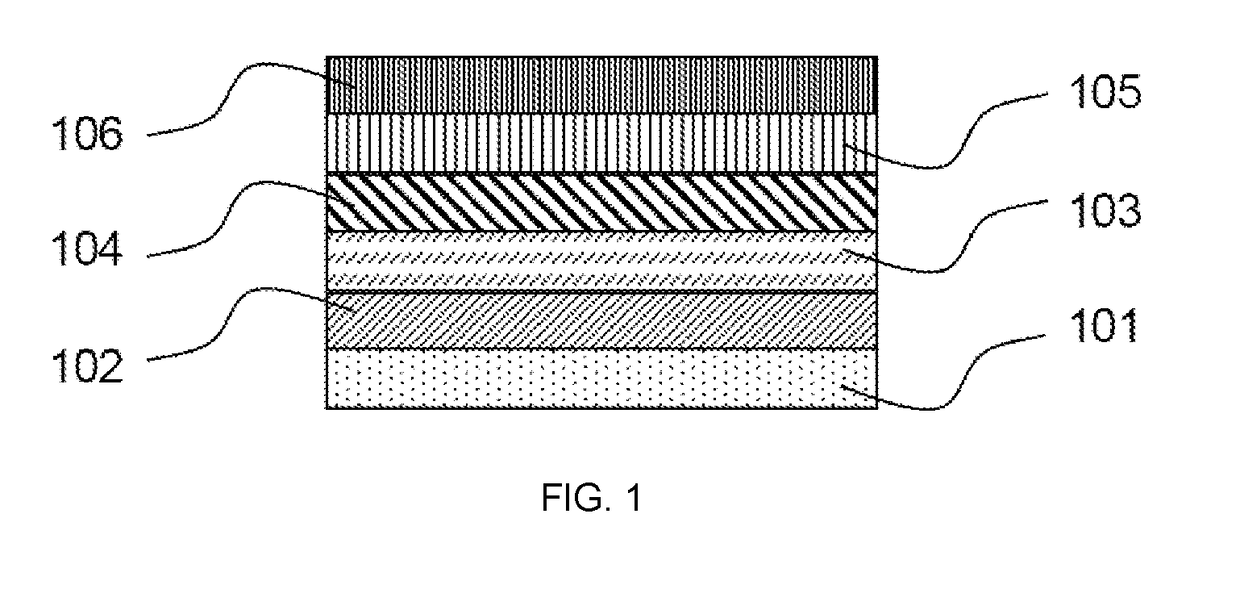

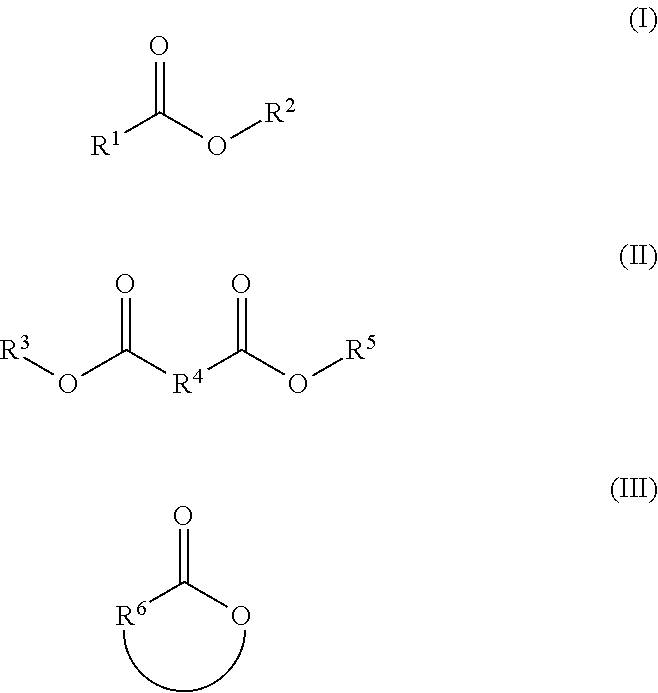

Printing ink and electronic device

ActiveUS20180237649A1Guaranteed performanceAdjustment of surface tensionLaser active region structureSolid-state devicesOrganic solventQuantum dot

Provided are a printing ink comprising inorganic nano-materials and an electronic device manufactured by printing with the printing ink, in particular, an electroluminescent device. The composition of the provided ink comprises at least one inorganic nano-material, in particular, quantum dots, and at least one ester-based organic solvent.

Owner:GUANGZHOU CHINARAY OPTOELECTRONICS MATERIALS

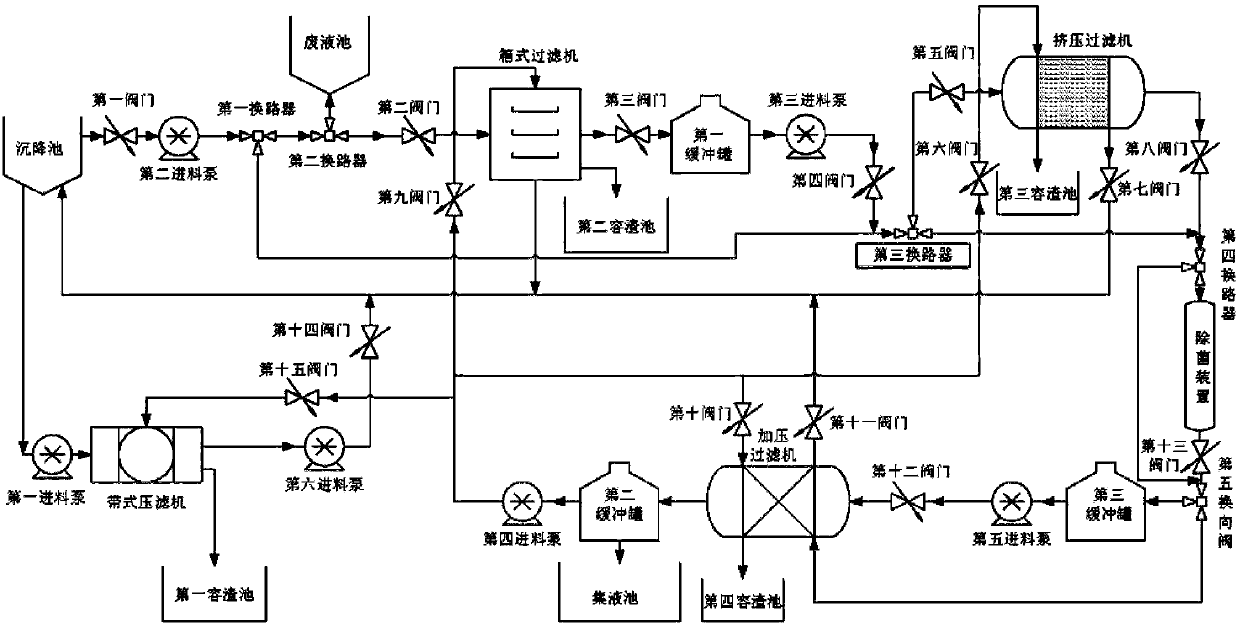

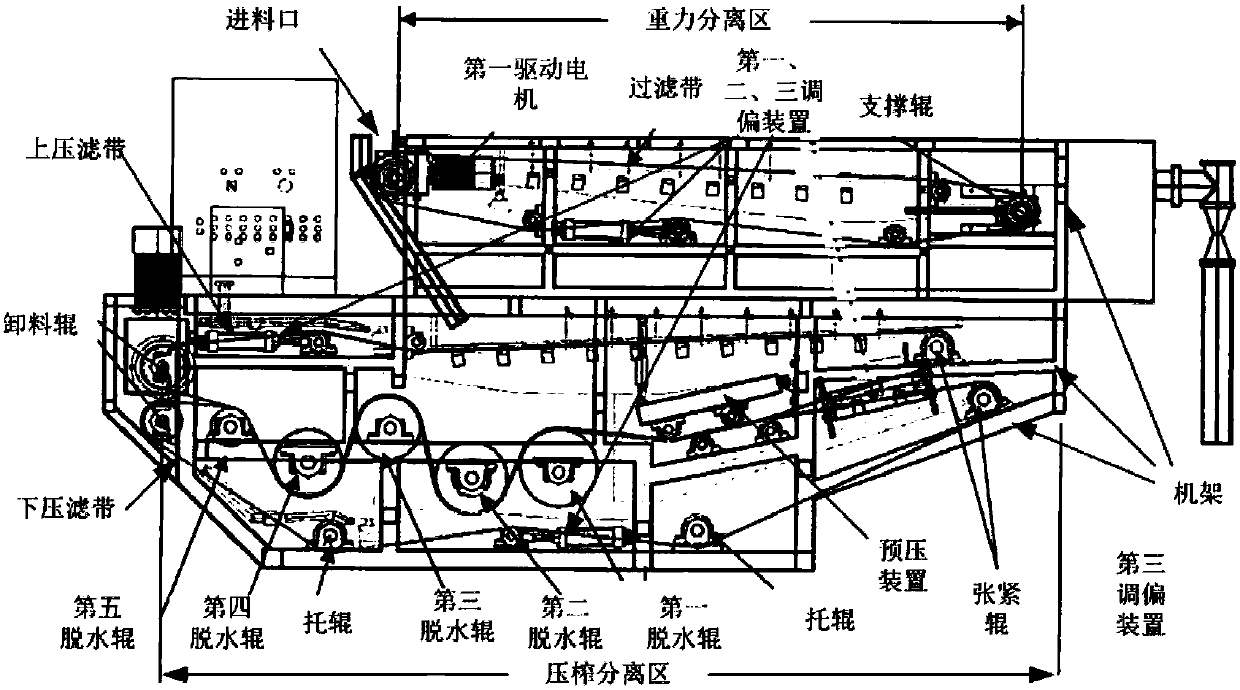

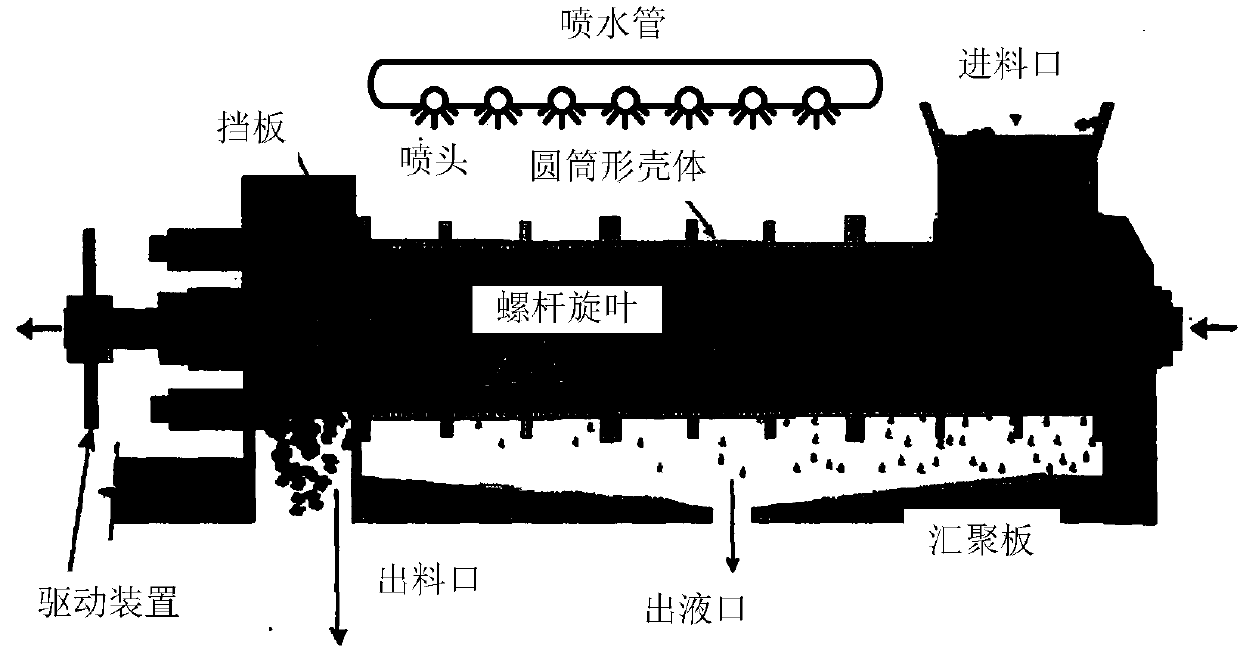

Chemical slurry squeezing filtration system

ActiveCN107670385ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagFiltration

The invention discloses a chemical slurry squeezing filtration system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device,one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The squeezing filter comprises a waster spray pipe, a cylindrical housing, screw vanes, a driving motor and a gathering plate. The screw vanes are arranged at intervals.

Owner:山东辰安化学有限公司

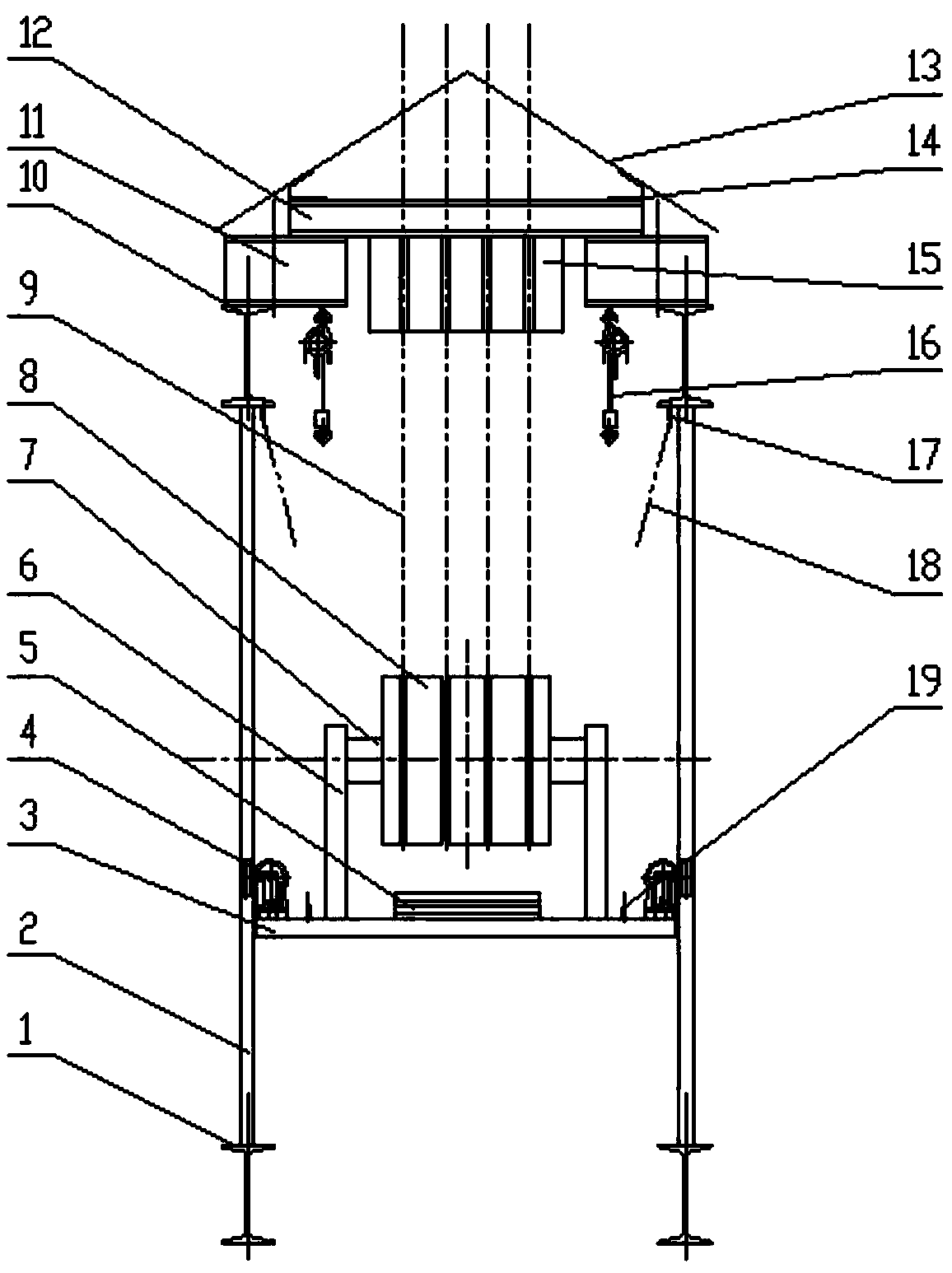

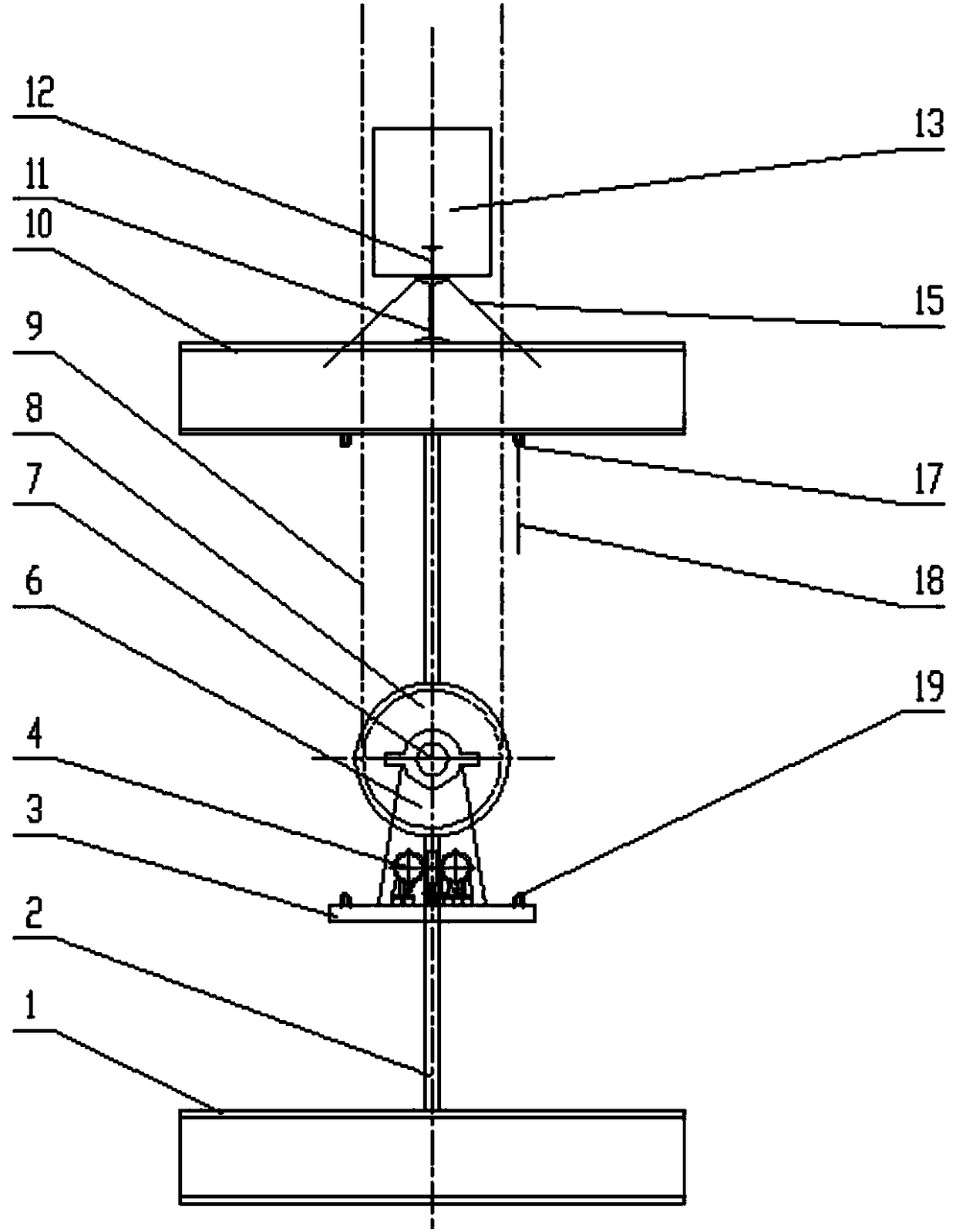

Tail rope tensioning device and installation method thereof

The invention provides a tail rope tensioning device and an installation method for the tail rope tensioning device and relates to the technical field of mining machinery. The tail rope tensioning device comprises upper supporting beams, lower supporting beams, square tube guide rails and a steel platform, the square tube guide rails are a pair, connected with the upper supporting beams and the lower supporting beams and arranged between the upper supporting beams and the lower supporting beams, the steel platform is arranged between the pair of square tube guide rails and moves up and down, arm hanging beams are arranged between the upper supporting beams, the two arm hanging beams are connected by a baffle beam, the lower end of the baffle beam is provided with lengthways baffles, a ropeguide wheel is arranged above the steel platform, the rope guide wheel is fixed by a shaft, two ends of the shaft are supported above the steel platform through open bearings and supports, two edgesof the steel platform are arranged on the square tube guide rails through roller cage shoe components, and a steel wire rope runs through the rope guide wheel. By means of the tail rope tensioning device and the installation method for the tail rope tensioning device, defects in the prior art are overcome, a tail rope is tensioned, and free swing of the tail rope is limited.

Owner:HEFEI UNIV +2

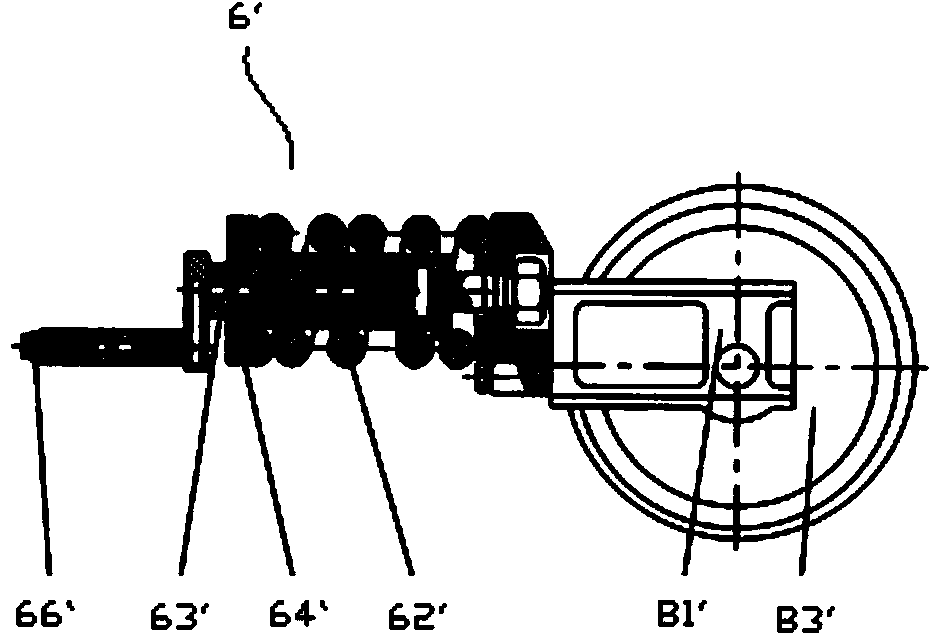

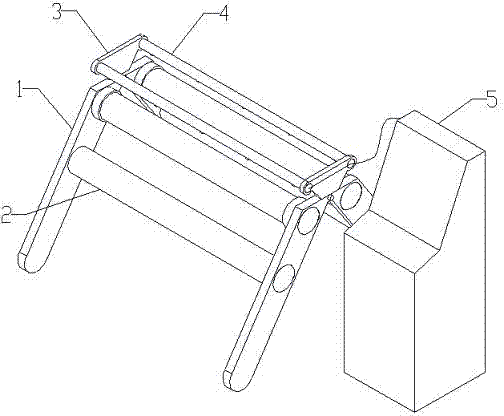

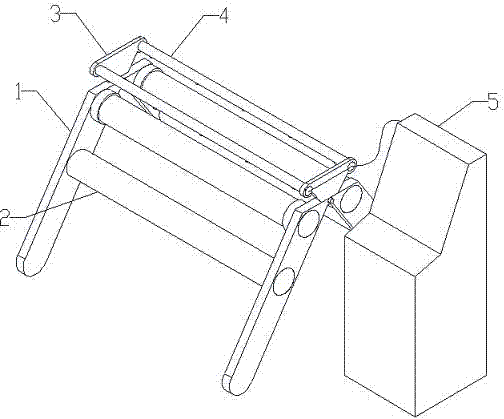

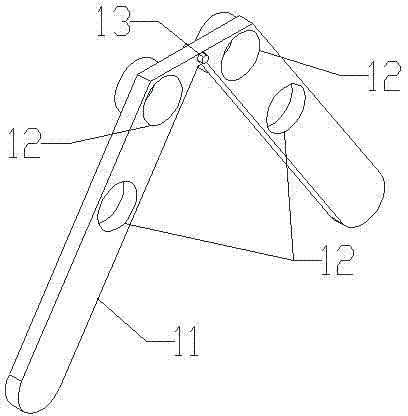

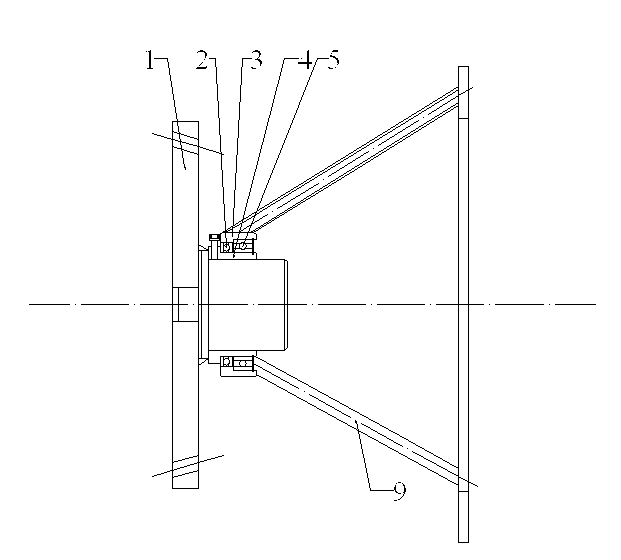

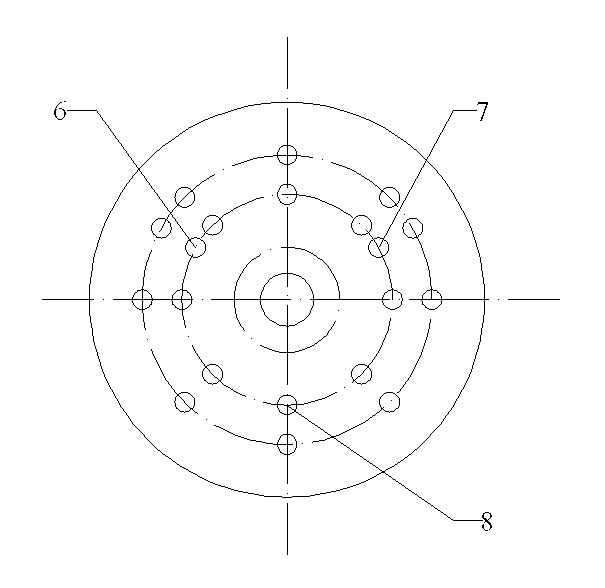

Twisting adjusting device and method of rope twisting method

The invention provides a twisting adjusting device and method of a rope twisting method and relates to the field of rope twisting methods. The twisting adjusting device comprises a porous disk (1), a fixing support (9) and a sleeve assembly (3), one end of the fixing support (9) is fixed and the other end of the fixing support (9) is connected with the sleeve assembly (3). The sleeve assembly (3) is connected with the porous disk (1) through an inner bearing bush (4) arranged therein, the porous disk (1) rotates around the central axis of the inner bearing bush (4) along the inner bearing bush (4), the porous disk (1) is provided with a plurality of small holes, and rope strands can pass from the small holes. Included angles among the rope strands are uniformized through the porous disk during twisting, tension on the rope strands can be uniformized by the rotatable porous disk, and twisting is uniform during twisting the rope strands into ropes, so that strength of the ropes is greatly improved. Accordingly, the twisting adjusting device is simple in design, easy to mount, convenient to use and low in device cost.

Owner:SHANDONG ROPE TECH CO LTD

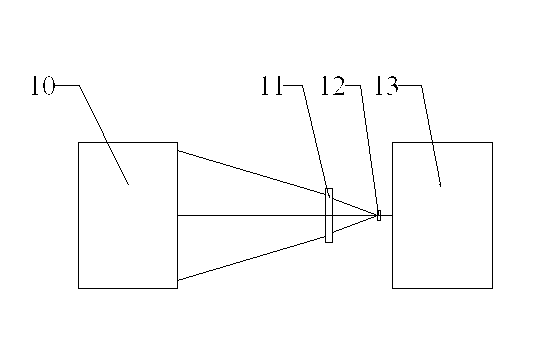

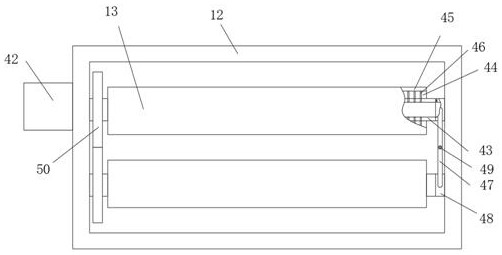

Medicine formulation automatic drawing out and infusion device for clinical pharmaceutics

InactiveCN101077329AImprove work efficiencyReduce pollutionPharmaceutical product form changeIntravenous devicesPharmaceuticsPiston

The present invention discloses one kind of automatic pumping and injecting device for clinical medicine compounding. The automatic pumping and injecting device includes one frame, a pumping and injecting needle cylinder-piston mechanism, a transmission mechanism, a power set and a controlling mechanism connected together. The present invention is used in clinical medicine compounding, and has high efficiency and less medicine contaminating possibility.

Owner:SICHUAN UNIV

Intelligent textile printing and dyeing system

InactiveCN113897749AAdjust the tensionIncrease temperatureLiquid/gas/vapor removal by squeezing rollersDrying gas arrangementsTextile printerAir pump

The invention discloses an intelligent textile printing and dyeing system which comprises a base. The top of the base is fixedly connected with a first fixing frame, the top of the first fixing frame is provided with a cloth roller, one side of the first fixing frame is provided with a dyeing box fixedly connected with the top of the base, and the two sides of the dyeing box are each provided with a first guide roller. An air pump is started, the air pump conveys hot air in a heating box to a three-way pipe and distributes the hot air to a U-shaped connecting pipe and a fixing pipe, the hot air enters a connecting block through the U-shaped connecting pipe and circulates into a hollow shaft, then heating sleeves are heated through a vent groove, the two sets of heating sleeves heat, dry and flatten cloth, the flattened cloth is printed in a printing box and then enters a drying box, the hot air enters the drying box through the fixing pipe and heats the interior of the drying box, the temperature in the drying box is increased, and the printed cloth is dried.

Owner:徐杰

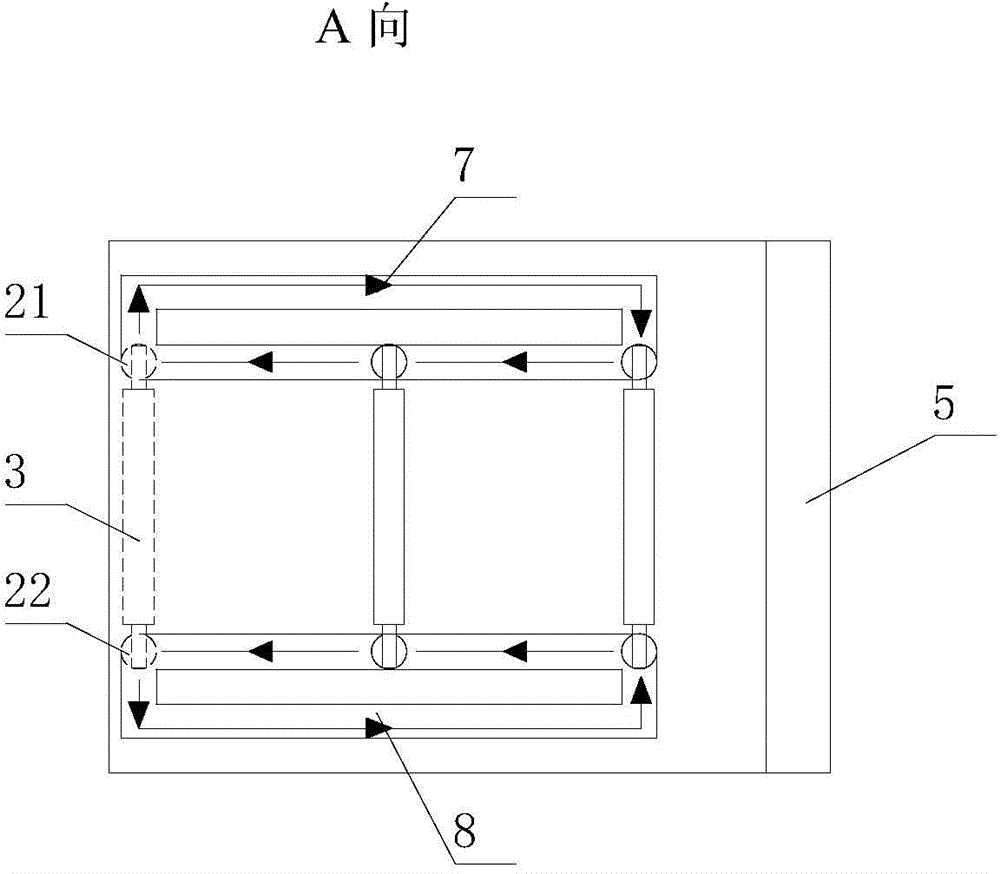

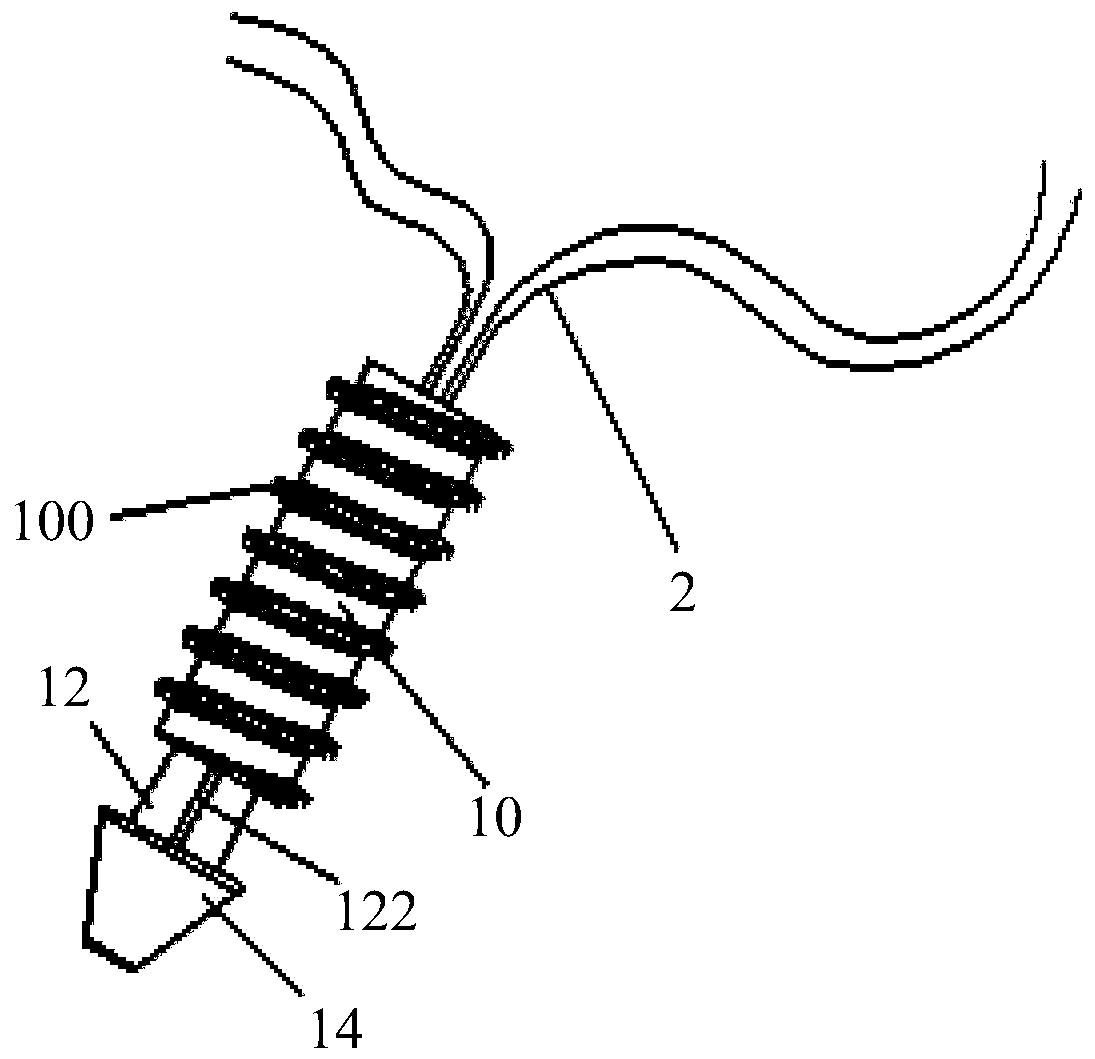

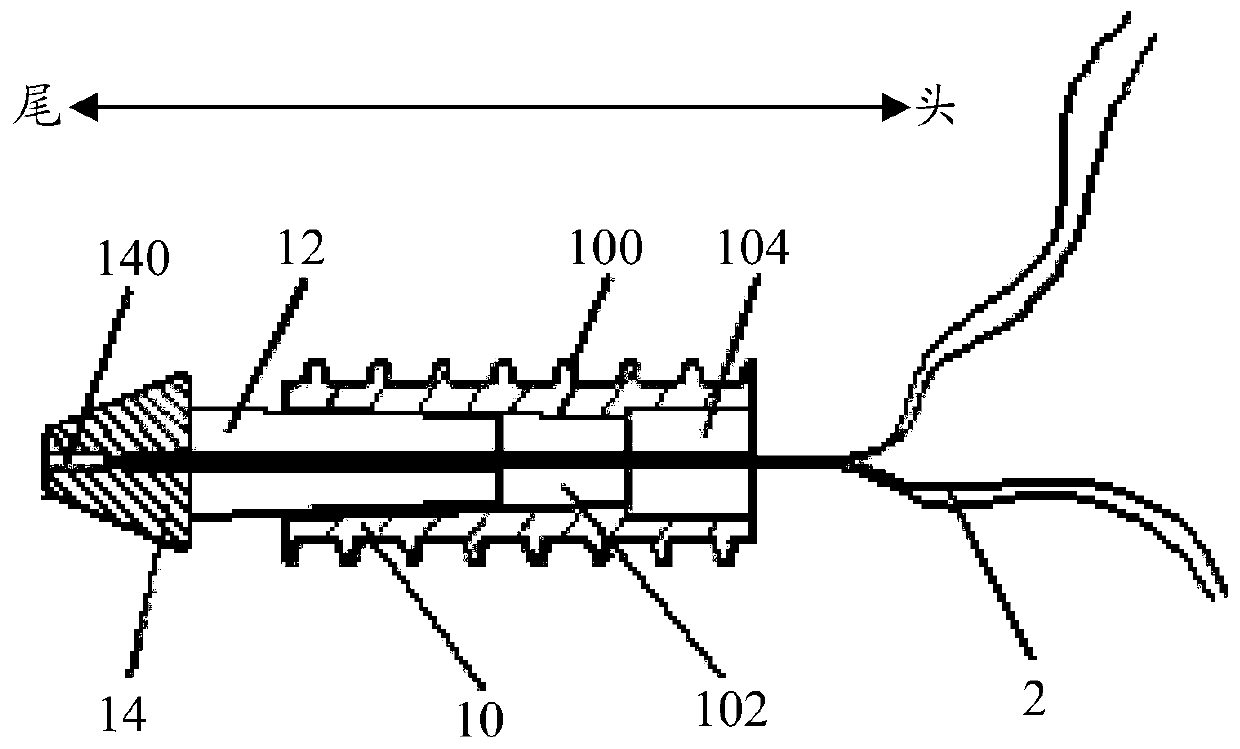

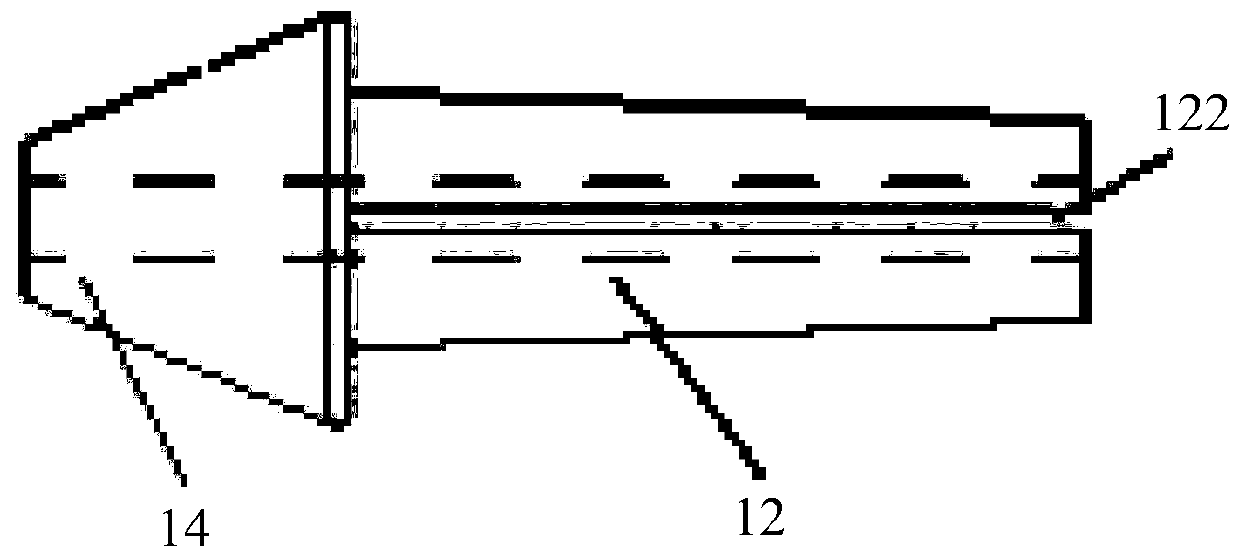

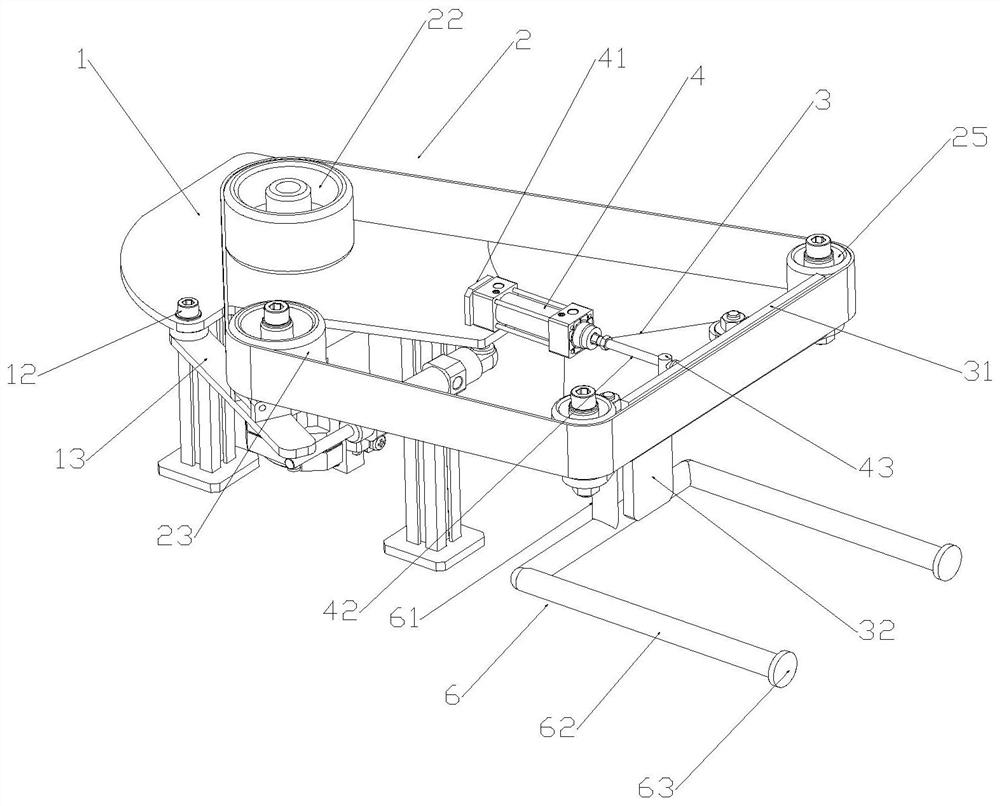

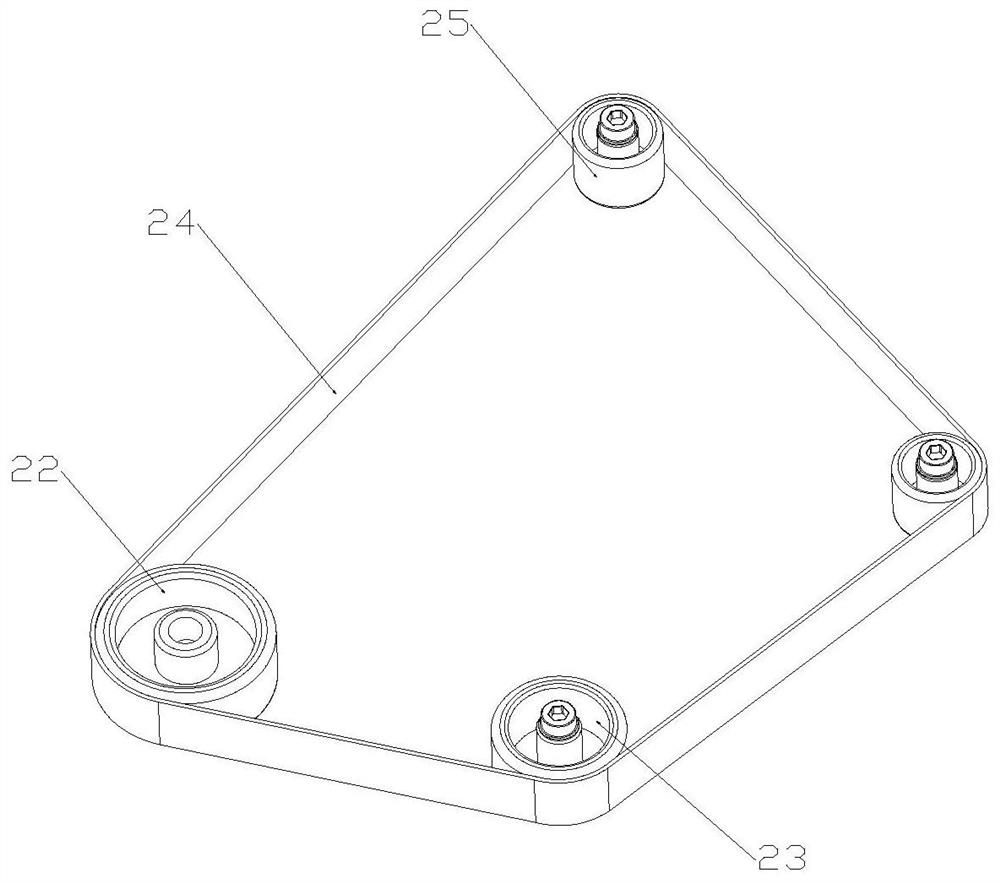

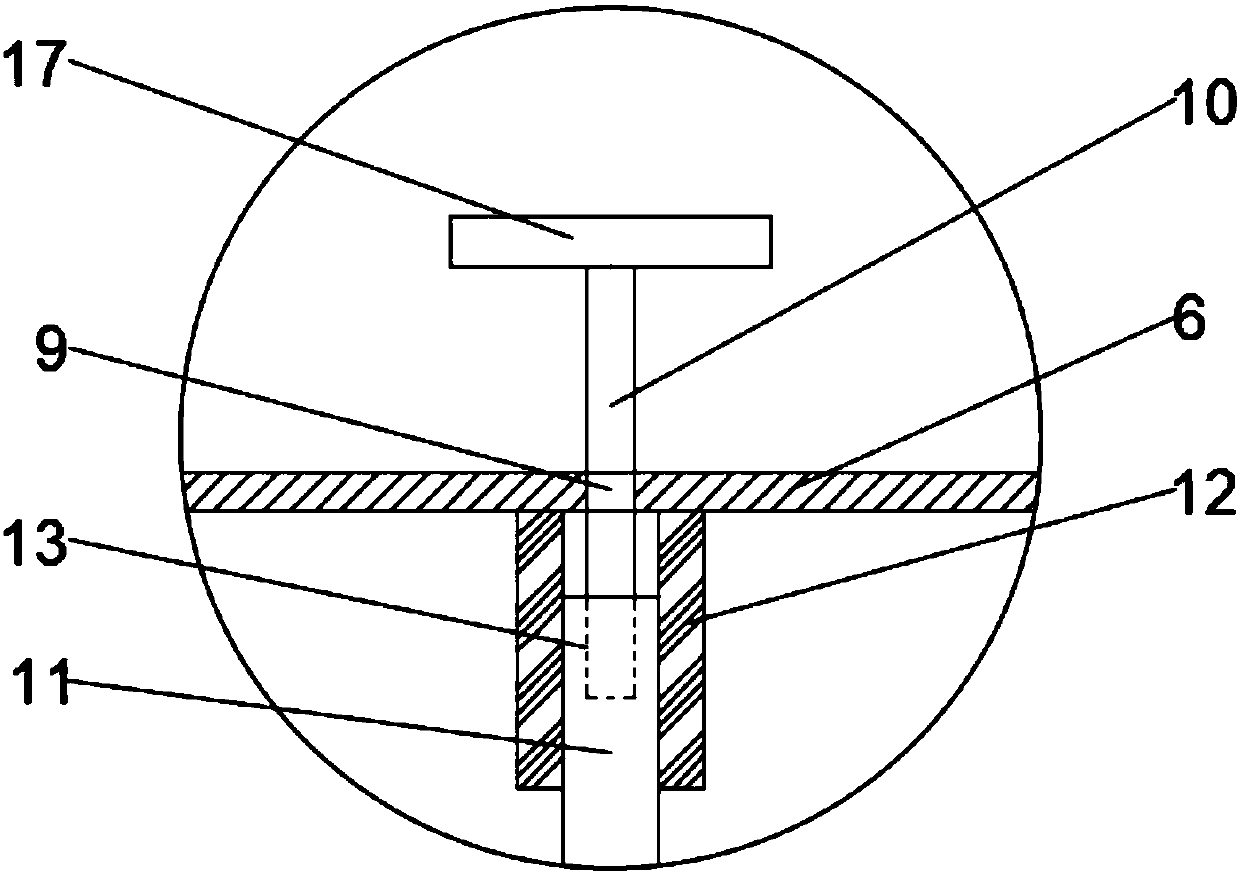

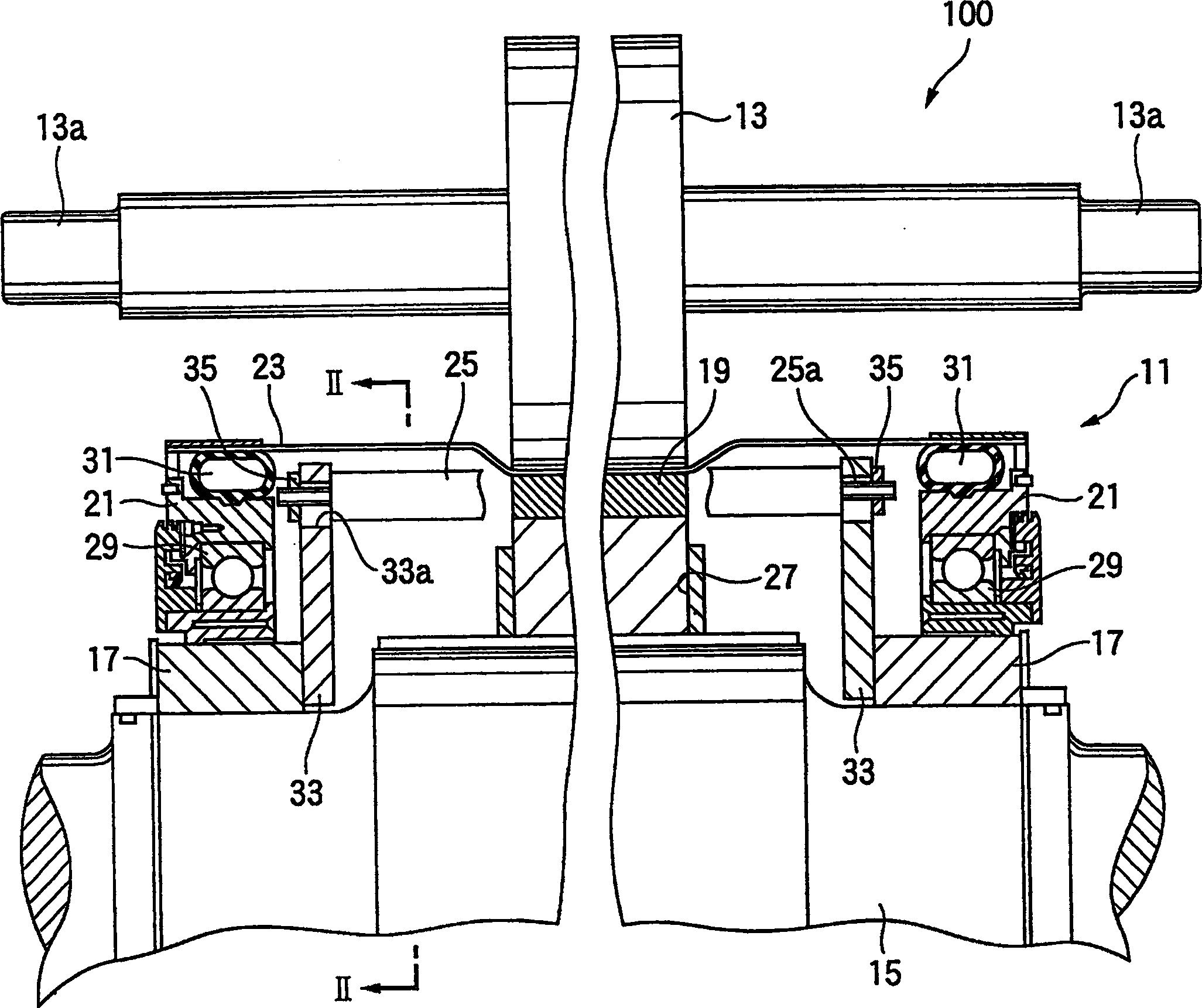

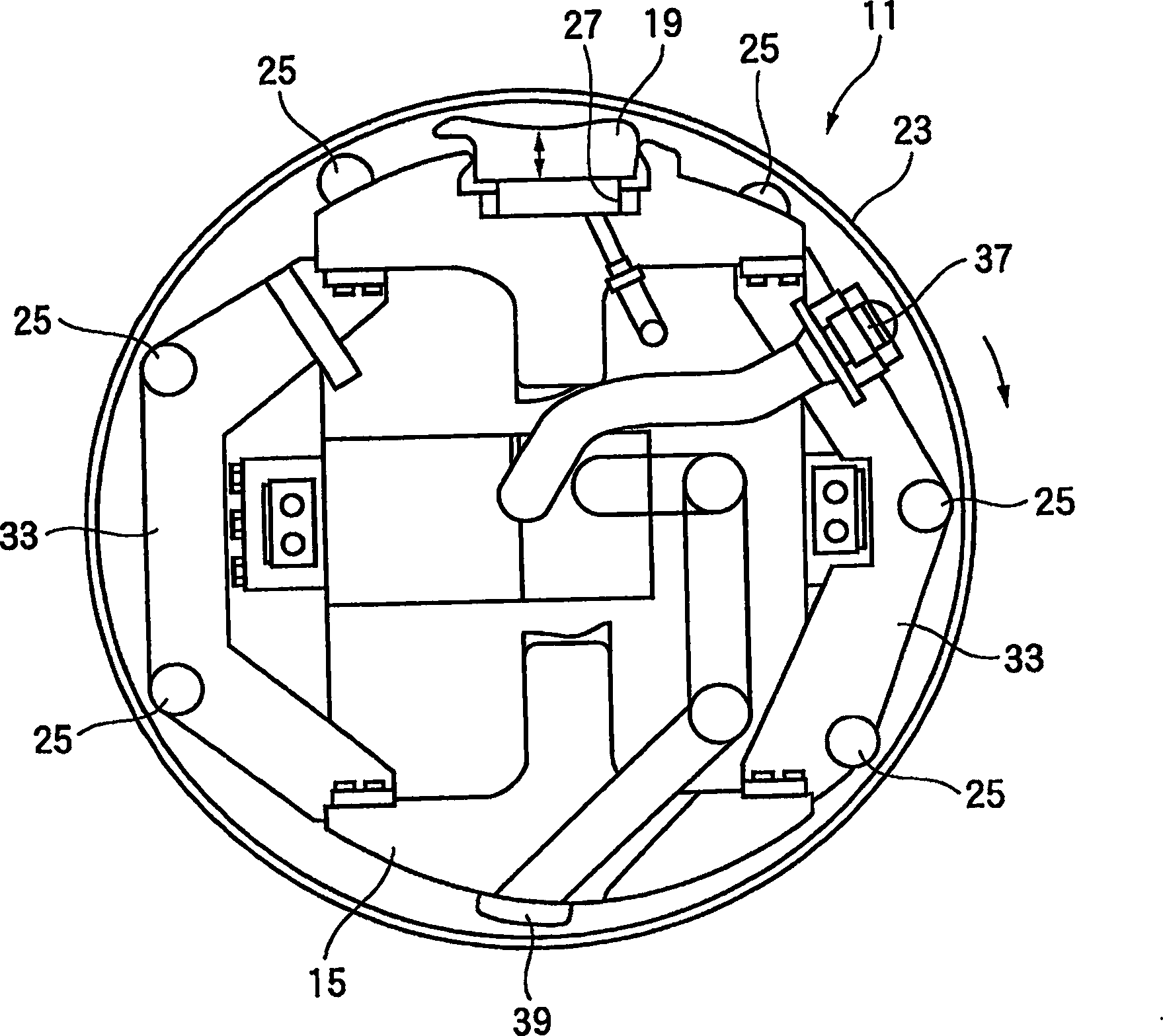

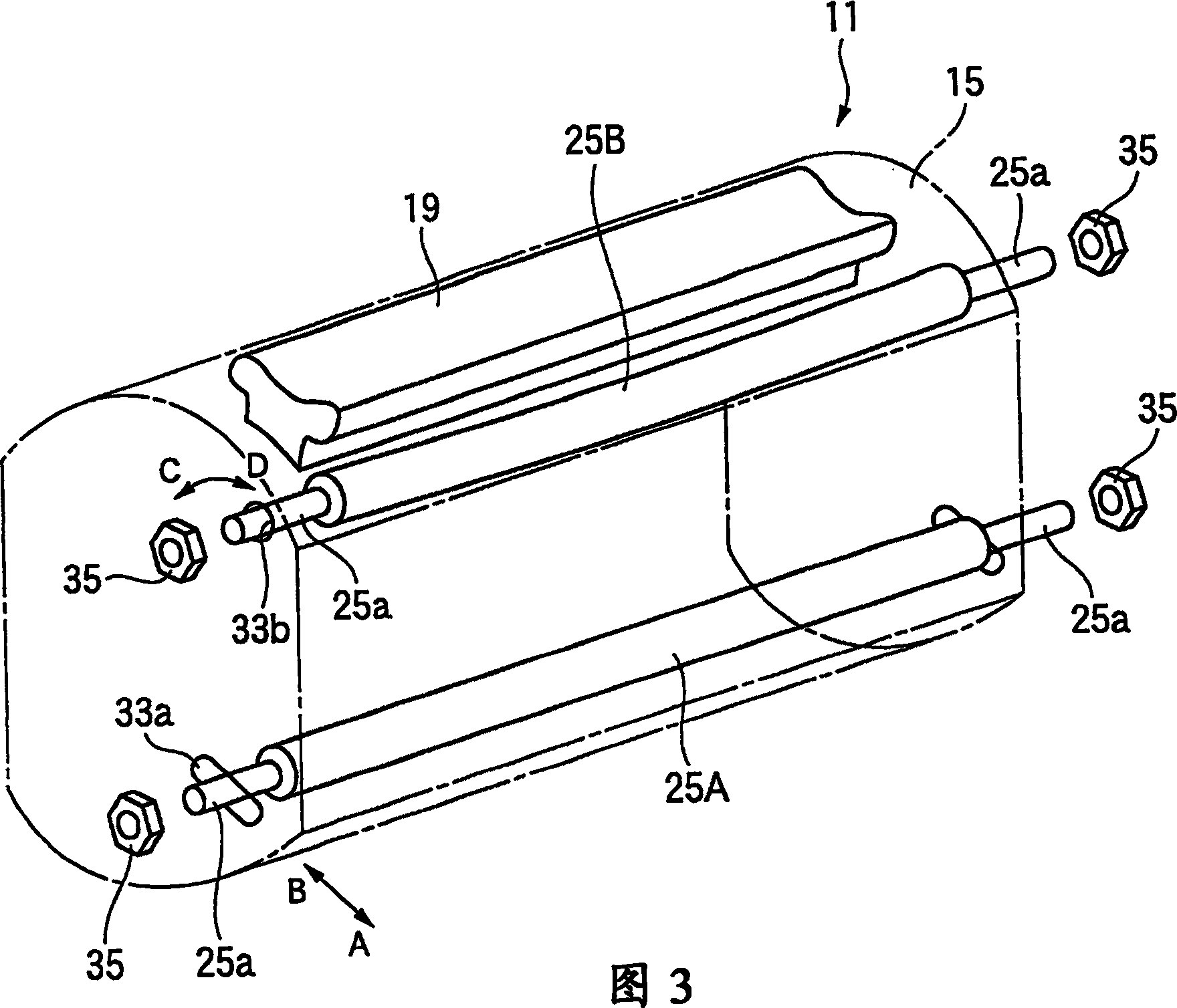

Shoe press mechanism of paper machine

InactiveCN1873092AEasy to adjust the tension stateAdjust the tensionPress sectionEngineeringPaper machine

A shoe press mechanism 100 of a paper machine includes a shoe press 11 , and a press roll 13 disposed so as to face the shoe press 11. A wet paper web to be fed is nipped by the press roll 13 and the press shoe 19 together with an annular belt. The shoe press 11 includes a supporter 15 , a press shoe 19 that is provided to the supporter 15 so as to move in the direction of approaching or being separated from the press roll 13, a pair of supporting disks 21 that is rotatably supported by the supporter 15, an annular belt 23 that is fixed to the supporting disks 21 and is disposed so as to include the press shoe 19 therein, and adjusting stay bars 25 that are disposed parallel to an axis of the annular belt 23. A mounting position of the adjusting stay bar 25 with respect to the supporter 15 can be adjusted, and the tension of the annular belt 23 is adjusted by adjusting the mounting position.

Owner:ICHIKAWA ELECTRIC CO LTD

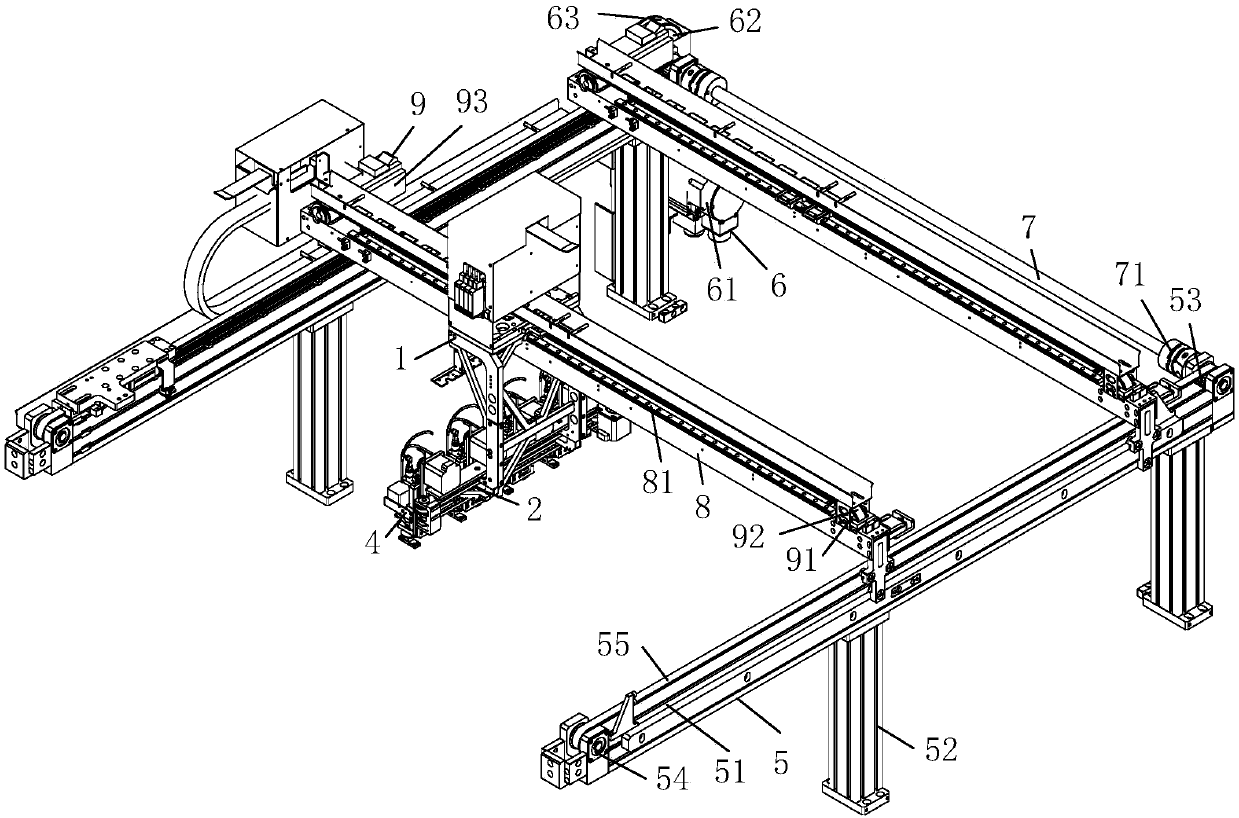

Laser cutting equipment

PendingCN113369711AImprove utilizationExpand the scope of workLaser beam welding apparatusLaser cuttingMachining

The invention relates to laser cutting equipment. The laser cutting equipment comprises an XY supporting frame, a cutting bed, a vertical floating mechanism, a laser generation assembly, an X-axis movement mechanism, a Y-axis movement mechanism and a laser cutting assembly, the cutting bed can slide up and down on the vertical floating mechanism, the laser generation assembly is fixedly installed at the top of the XY supporting frame, the laser cutting assembly can freely move on an XY plane which is located above the cutting bed and composed of the X-axis movement mechanism and the Y-axis movement mechanism, laser generated by the laser generation assembly enters a laser cutting head of the laser cutting assembly, the laser cutting head emits laser to a to-be-cut object located on a machining station on the cutting bed to achieve cutting operation, and a feeding port and a discharging port are formed in the front end and the rear end of the cutting bed correspondingly. The equipment is compact in structure, small in size, easy to install and use, low in operation cost and labor cost, low in environment requirement and suitable for being popularized and used in vast small and medium-sized enterprises.

Owner:JINLING INST OF TECH

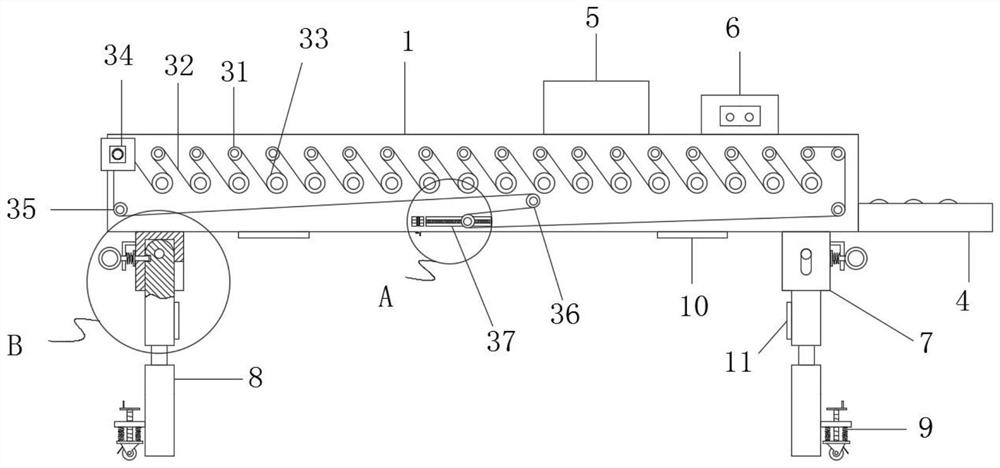

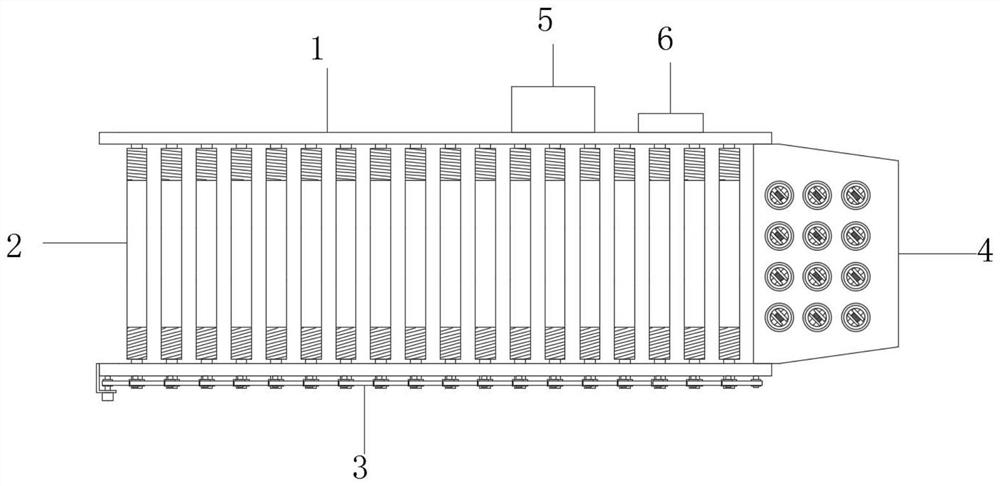

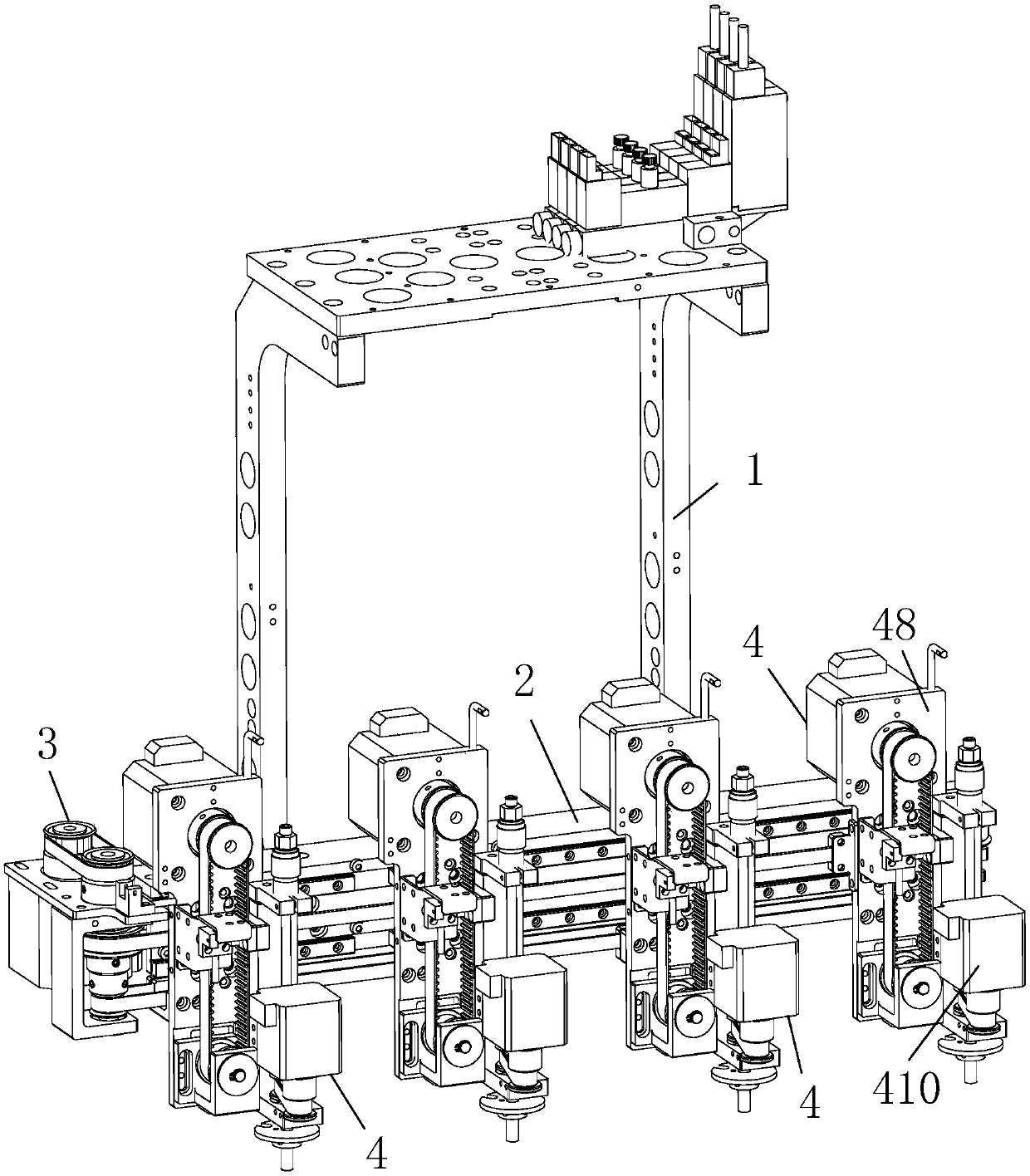

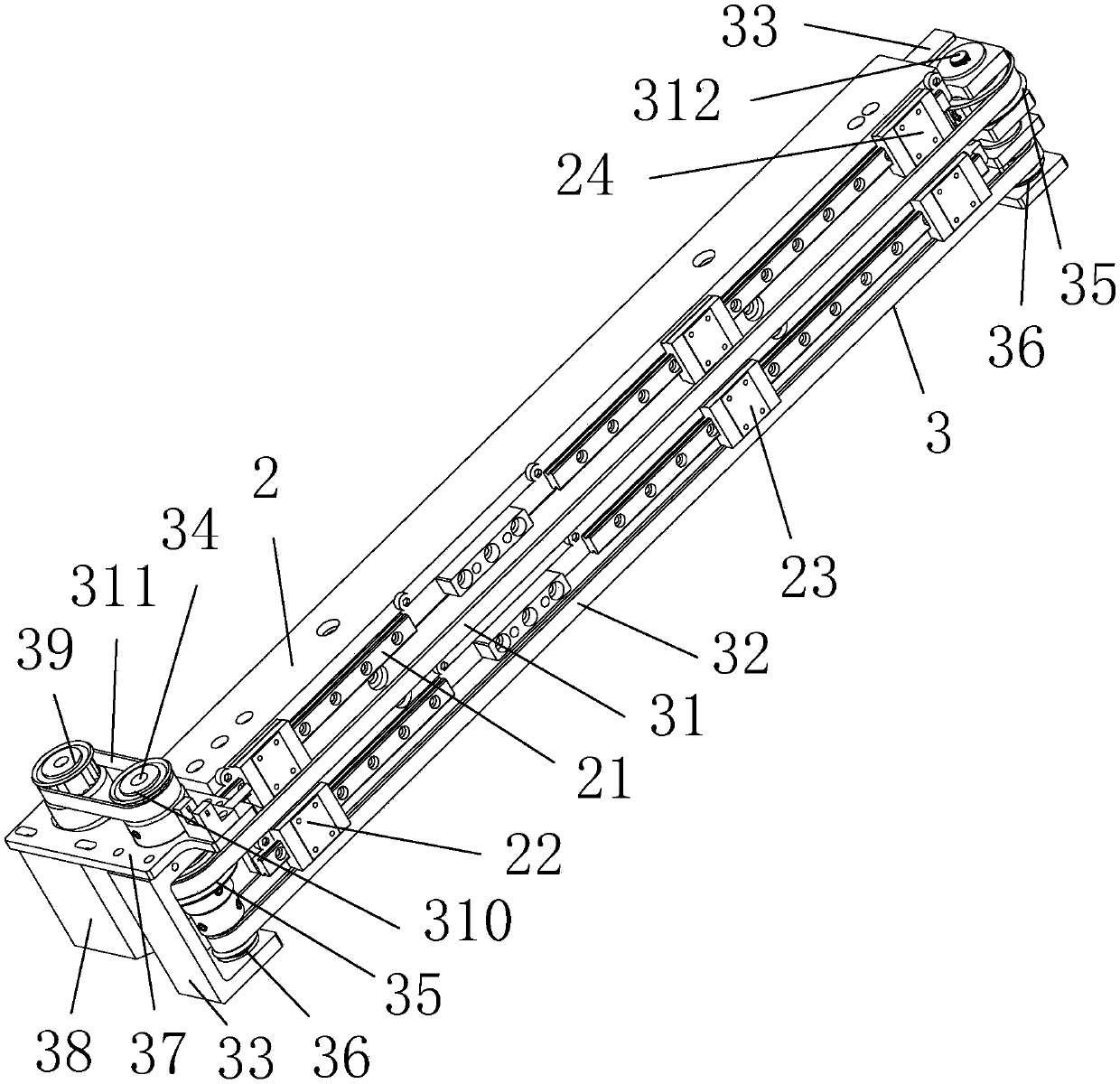

Fingerprint module test conveyor

ActiveCN107697637AHigh positioning accuracySmooth Adsorption PitchConveyorsConveyor partsEngineeringMechanical engineering

The invention aims to provide a fingerprint module test conveyor, which comprises an adsorption device of a connecting support, two longitudinal beams provided with longitudinal guide rails, longitudinal transmission assemblies and a plurality of supporting feet, a longitudinal drive device, a synchronous shaft, a cross beam provided with a cross slide way and two ends connected with slide blocksof the two longitudinal guide rails in a one-to-one correspondence way, and a horizontal drive device. Each longitudinal transmission assembly comprises a longitudinal transmission drive synchronizingwheel pin-jointed with one end of each longitudinal beam, a longitudinal transmission driven synchronizing wheel pin-jointed with the other end of each longitudinal beam, and a longitudinal transmission synchronous belt; one side of each longitudinal transmission synchronous belt is connected with the slide block of each longitudinal guide rail; two ends of the synchronous shaft are in transmission connection with the longitudinal transmission drive synchronizing wheels of the two longitudinal transmission assemblies in a one-to-one correspondence way; and the connecting support is connectedwith a slide block of the cross slide way. The fingerprint module test conveyor is smooth to move and higher in in-place accuracy.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com