Dual-roller four-time natural luster finishing machine

A technology of ironing machine and ironing roller, which is applied to conveyors, textiles and papermaking, and fabric surface trimming, etc., which can solve the problems of large occupied space, insufficiently compact structure, and large equipment volume, so as to reduce occupied space and structure Compact, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

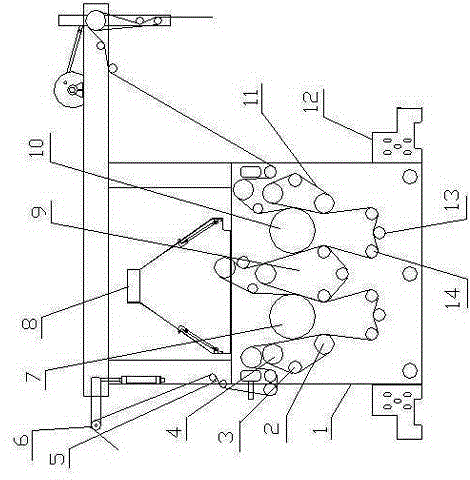

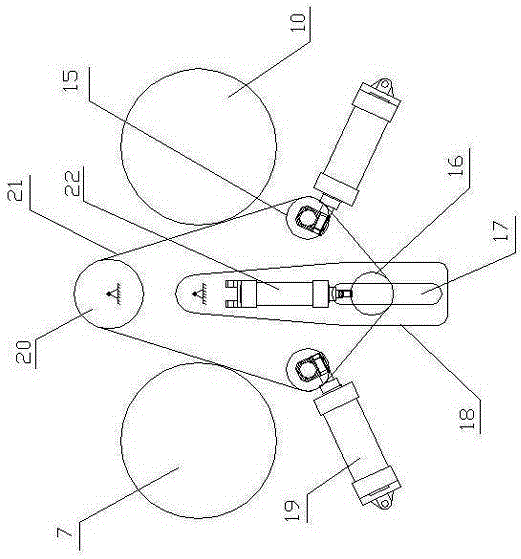

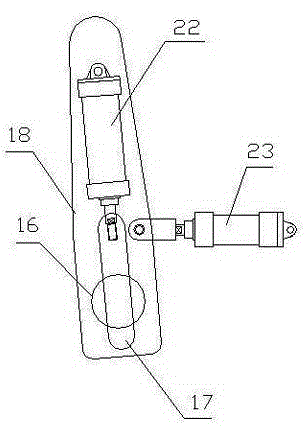

[0019] refer to Figure 1-4 , a two-roller four-time ironing machine, equipped with a frame 1, and on the frame 1, ironing roller I7 and ironing roller II10 are arranged side by side from the cloth inlet side to the cloth outlet side, and the ironing roller I7 and ironing roller The frame 1 between the rollers II10 is equipped with a double-side support mechanism that cooperates with the two ironing rollers at the same time, and a single-side support mechanism is provided on the cloth inlet side of the ironer roller I7 and the cloth outlet side of the ironer roller II10. The belt mechanism is provided with a lower fabric guide mechanism on the frame 1 below the ironing roller I7 and ironing roller II10, and an upper fabric guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com